Mechanical part grinding fixing device

A technology for fixing devices and mechanical parts, which is applied in the direction of grinding drive devices, grinding machine parts, grinding machines, etc. It can solve the problems of difficult polishing, inaccurate fixing and positioning of round tube parts, and parts that do not meet production requirements. Achieve convenient and effective polishing and polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

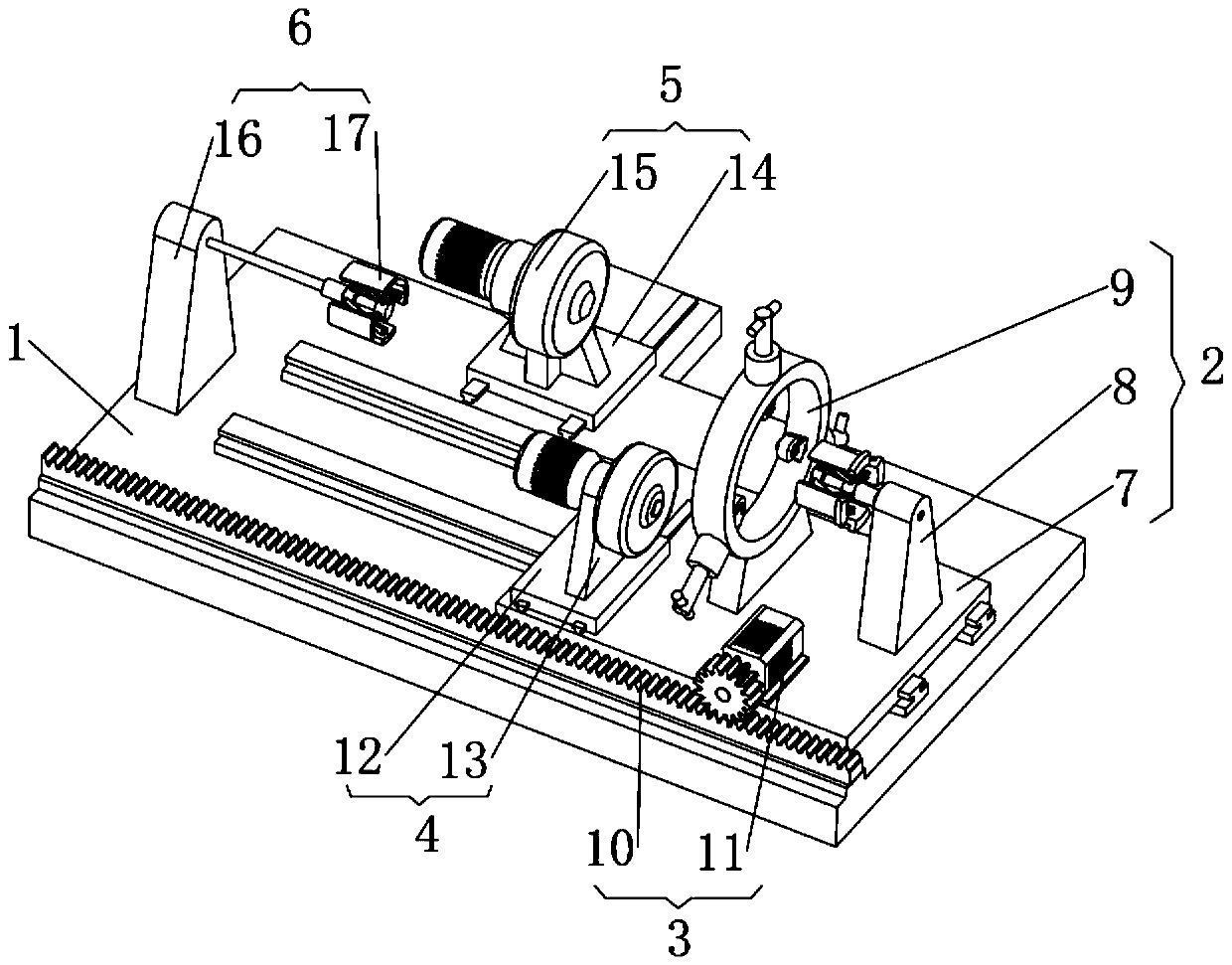

[0038] The present invention provides such Figure 1-7 A grinding and fixing device for mechanical parts shown includes a base 1, a fixing device 2, an axial driving unit 3, a rotating driving unit 4, an outer wall polishing unit 5 and an inner wall polishing unit 6, and the fixing device 2 includes a fixing device base 7, Inner wall fixing device 8 and outer wall limiting device 9.

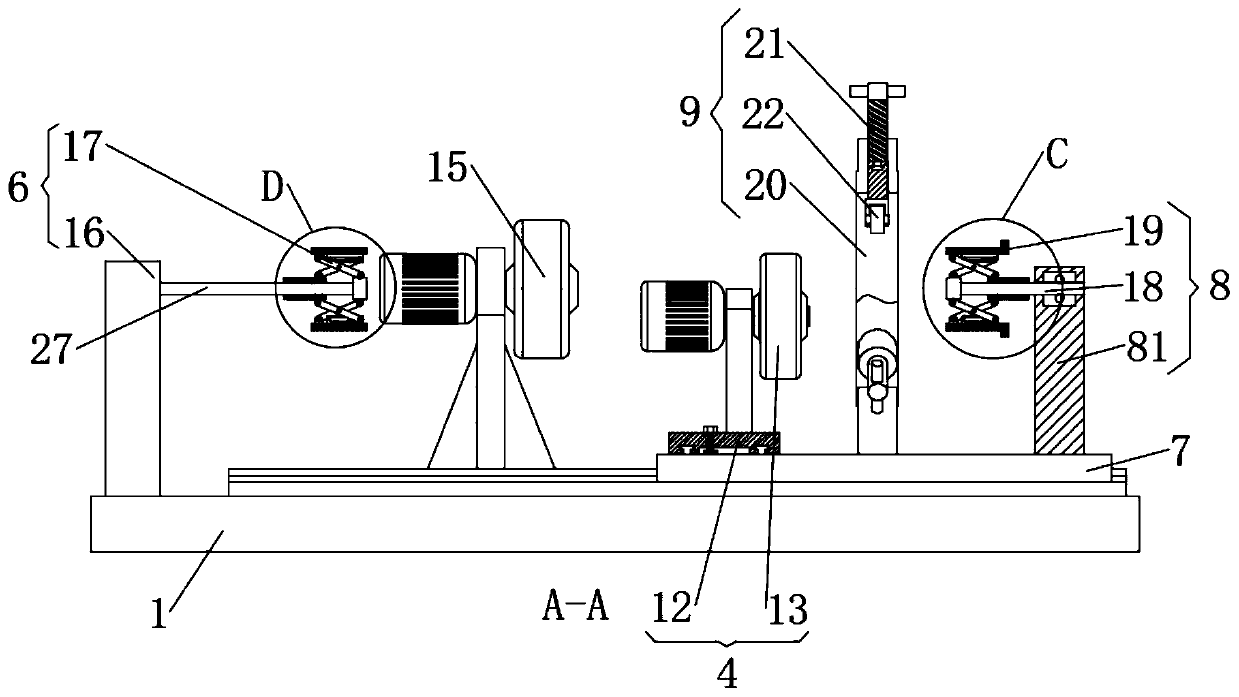

[0039] combine figure 1 and figure 2 As shown, the upper surface of the abutment 1 is provided with two slide rails 1 extending left and right in the length direction, and the bottom of the fixing device base 7 is slidably connected with the two slide rails 1. figure 2 and image 3 As shown, the right side of the upper surface of the fixing device base 7 is provided with an inner wall fixing device 8, the inner wall fixing device 8 is composed of a fixing device supporting column 81, an inner wall fixing screw 18 and an inner wall fixing head 19, and the bottom of the fixing device supportin...

Embodiment 2

[0043] The difference with embodiment 1 is:

[0044] combine image 3 and Figure 6 As shown, the middle part of the upper surface of the fixing device base 7 is provided with an outer wall limiting device 9, and the outer wall limiting device 9 includes an outer wall limiting ring seat 20, an outer wall limiting rod 21 and a runner 22, and the outer wall limiting ring seat 20 is circular. ring body, and the outer wall limit ring seat 20 is welded to the upper surface of the fixture base 7 by the bracket, and the outer wall limit ring seat 20 is connected with three outer wall limit rods 21, such as Figure 7 , the outer wall limit rod 21 is composed of a screw part and a limit rod part, the lower end of the screw part of the outer wall limit rod 21 is a "convex" type connection end, and the "convex" type connection end of the lower end of the outer wall limit rod 21 screw part is connected to the limit The upper end of the position rod part is rotationally connected, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com