Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Suppression of surface defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polishing composite for silicon wafer polishing

InactiveCN101451046AFast polishing rateReduce surface defectsSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesIonEther

The invention discloses a silicon wafer polishing composition in the field of chemical mechanical polishing (CMP). The polishing composition comprises silica, a polishing interface control agent, a surfactant, a chelating agent, an alkaline compound and water, wherein the particle diameter of the silica in the polishing composition is between 1 and 200 nm; the content of the silica is between 0.05 and 50 weight percent; the polishing interface control agent is polyhydroxy cellulose ether; the content of the polishing interface control agent is between 0.001 and 10 weight percent; the content of the surfactant is between 0.001 and 1 weight percent; the content of the chelating agent is between 0.001 and 1 weight percent; the content of the alkaline compound is between 0.001 and 10 weight percent; the balance being water; and the PH value is between 8.5 and 12. The polishing interface control agent can control a polishing interface between abrasive particles and a polishing object in the chemical mechanical polishing process in order that the surface of the polished silicon wafer is more perfect. The polishing composition is in particular suitable for polishing the silicon wafer and has the advantages of rapid polishing speed, little surface defect and high planeness; and the polished silicon wafer has few metal ion contaminants and is easy to clean.

Owner:TSINGHUA UNIV +1

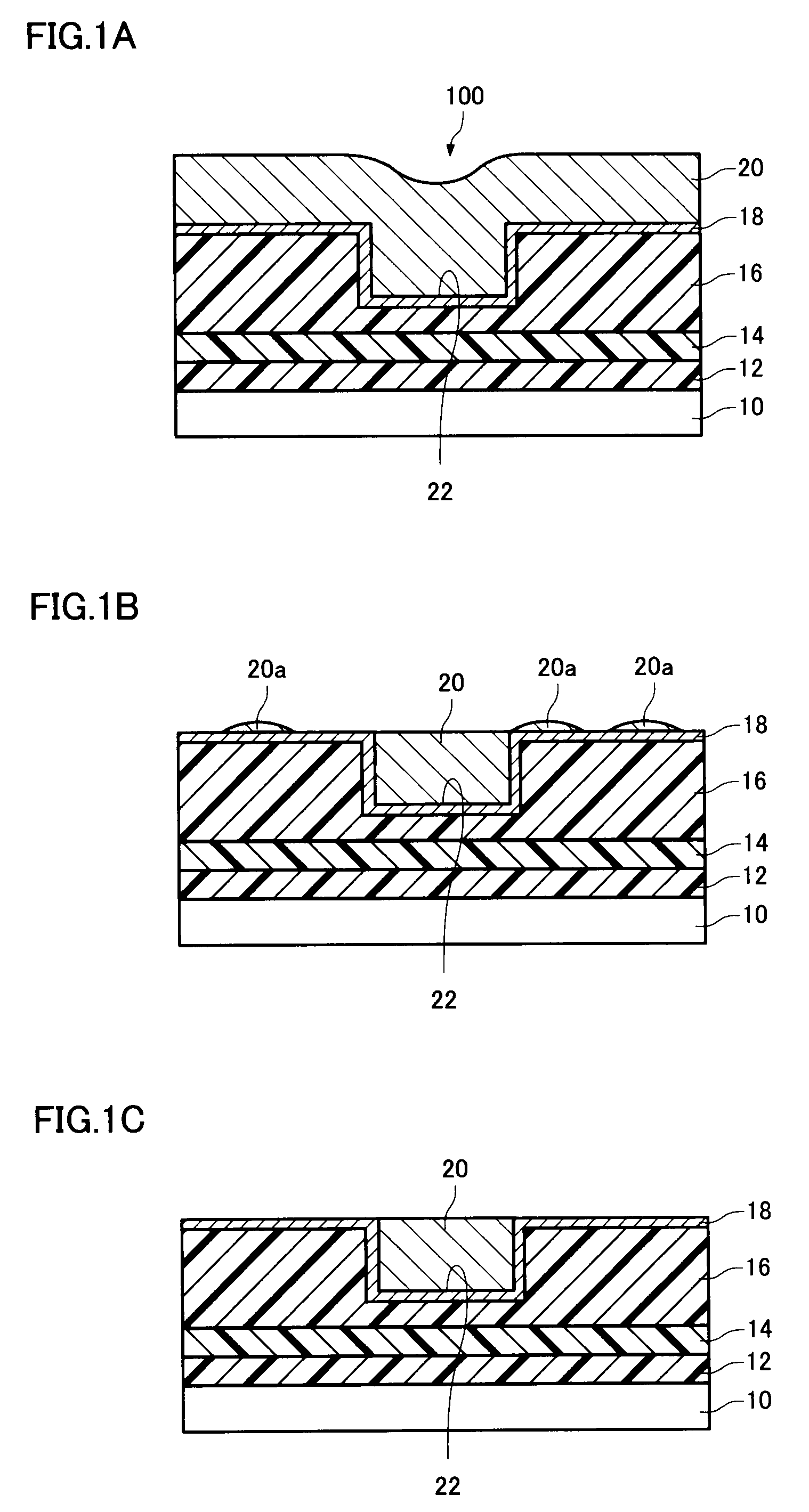

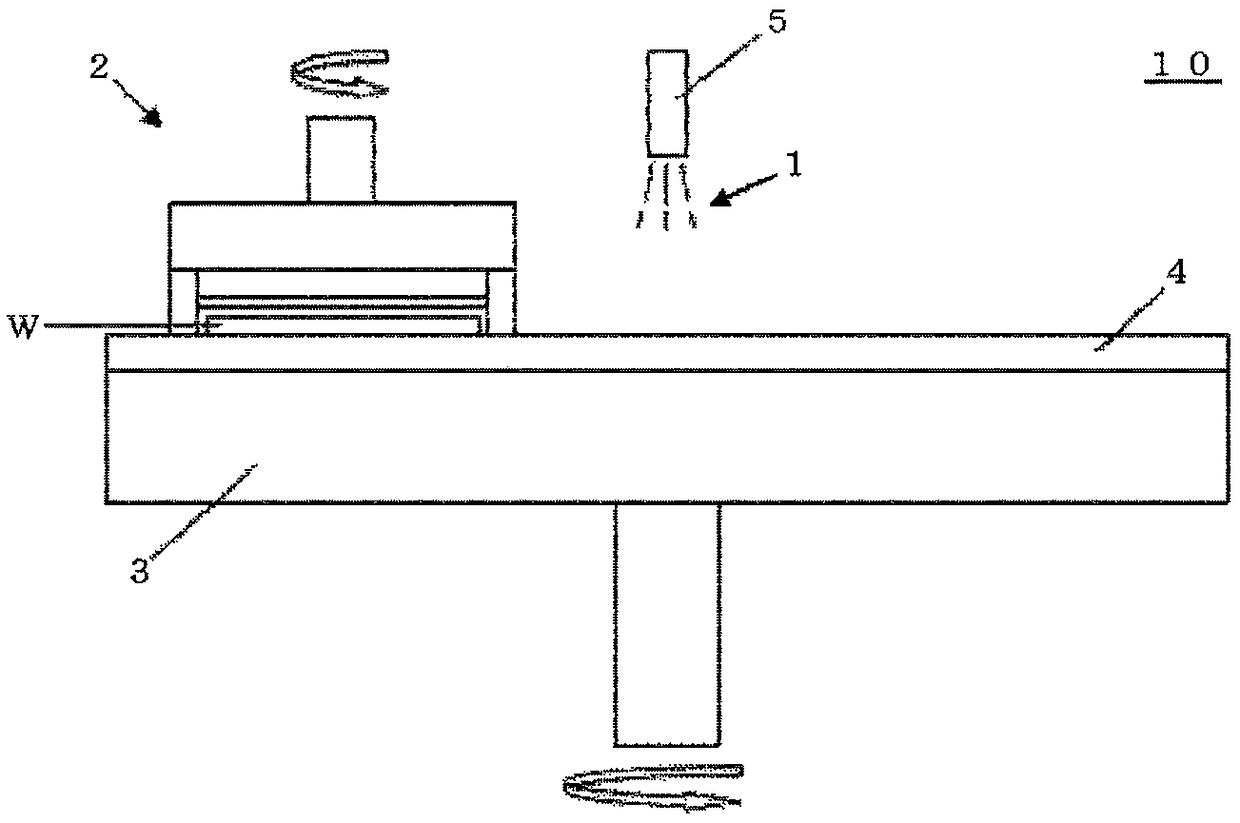

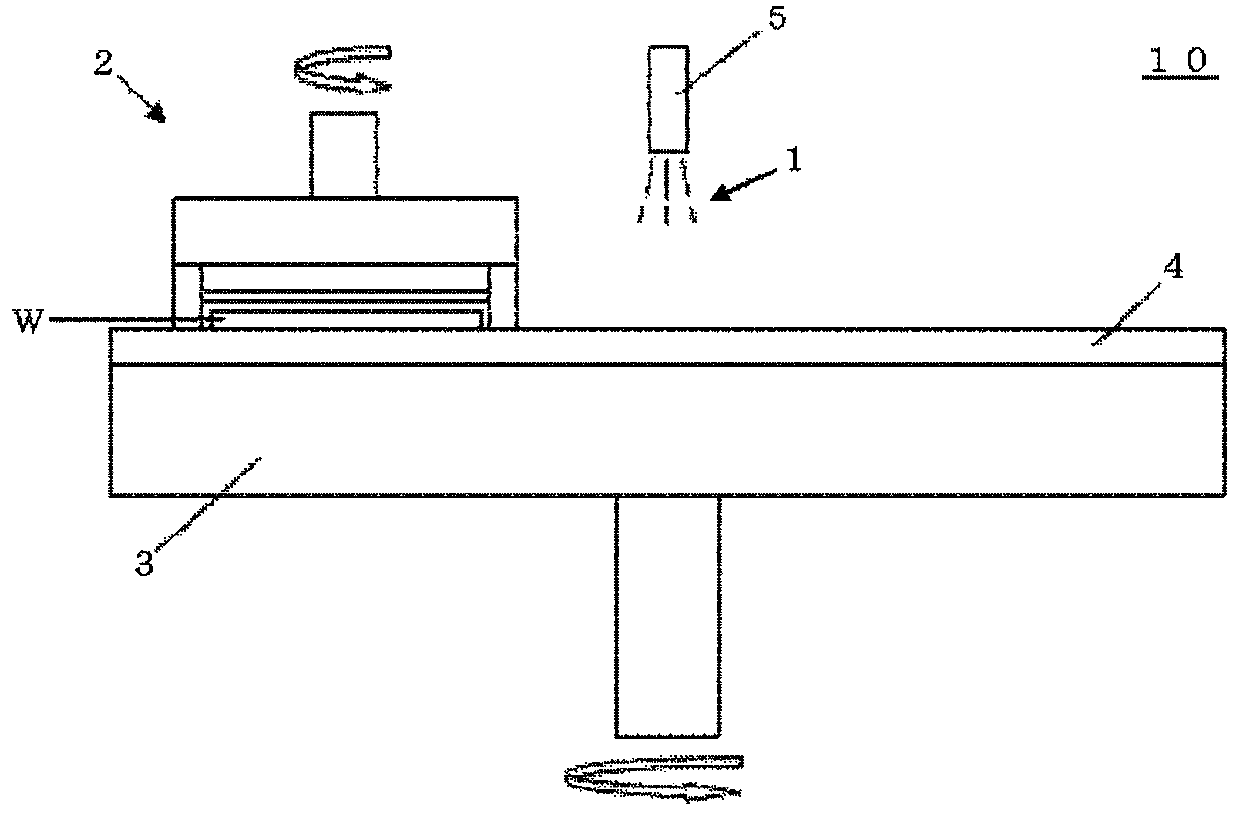

Aqueous dispersion for chemical mechanical polishing and chemical mechanical polishing method

InactiveUS20110081780A1Reduce polishing rateHigh polishing rateOther chemical processesSemiconductor/solid-state device manufacturingOrganic acidSilica particle

A chemical mechanical polishing aqueous dispersion includes (A) silica particles, and (B1) an organic acid, the number of silanol groups included in the silica particles (A) calculated from a signal area of a 29Si-NMR spectrum being 2.0 to 3.0×1021 / g.

Owner:JSR CORPORATIOON

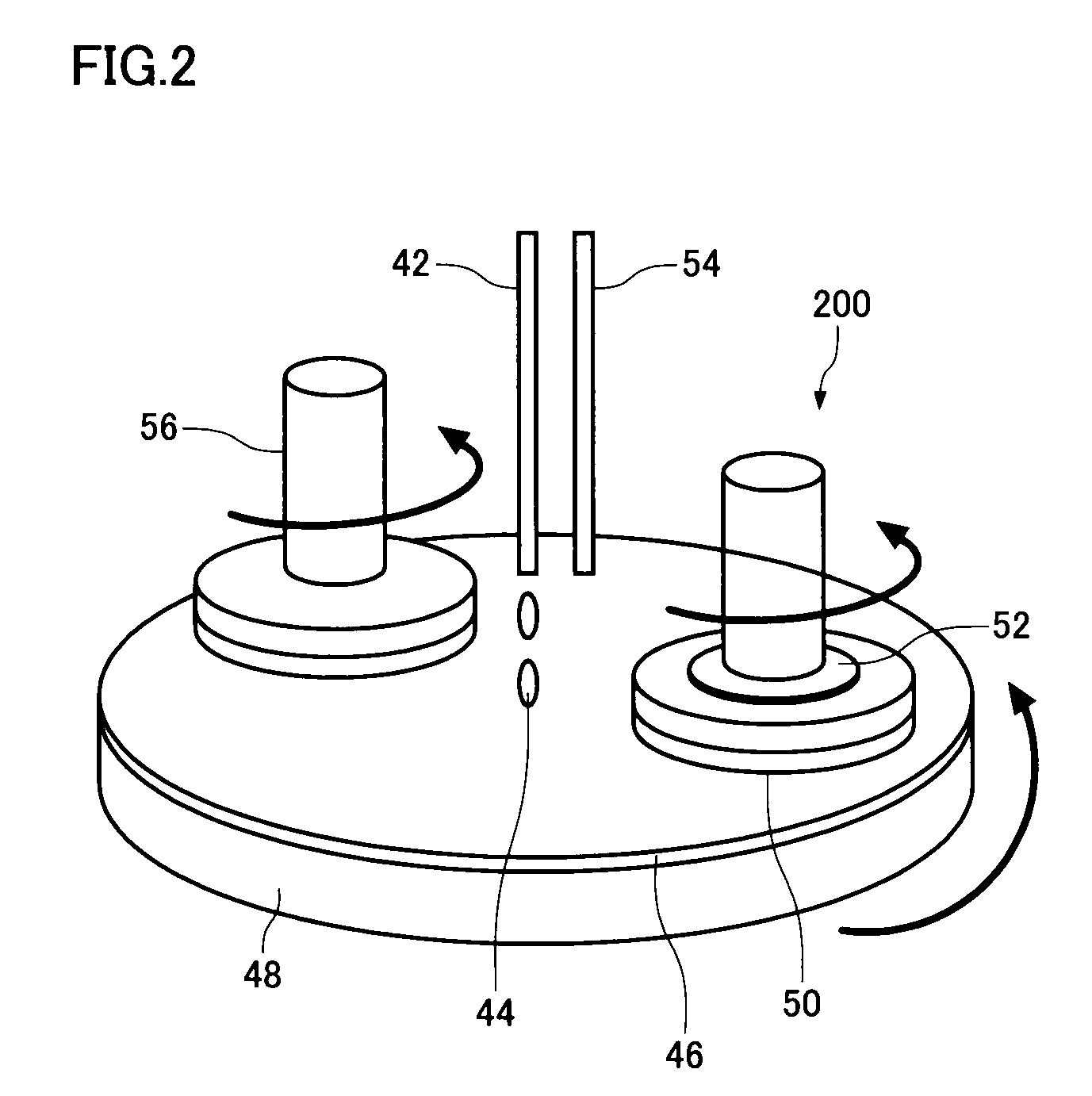

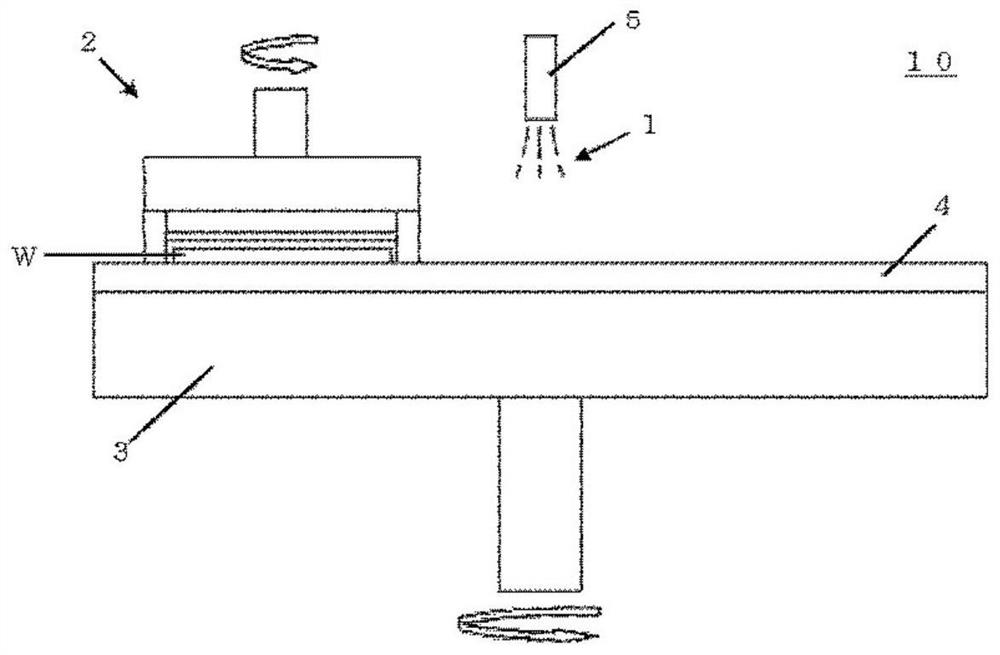

Process for chemical mechanical polishing of semiconductor substrate and aqueous dispersion for chemical mechanical polishing

InactiveUS7183211B2Reduce generationHigh removal rateOther chemical processesSemiconductor/solid-state device manufacturingDevice materialCarboxylic acid

The object of the present invention is to provide a process for chemical mechanical polishing of semiconductor substrate that is particularly useful for chemical mechanical polishing a wafer having a wiring pattern and an insulating layer having a low dielectric constant is formed between wiring patterns, interlayers in the case of a multi-layer wiring and the like in the process of producing a semiconductor device, and an aqueous dispersion for chemical mechanical polishing which is used in this process. The process for chemical mechanical polishing of a semiconductor substrate of the present invention is that a surface to be polished of the semiconductor substrate is polished under conditions of a rotation speed of a polishing table fixing a polishing pad at the range from 50 to 200 rpm and a pressing pressure of the semiconductor substrate fixed to a polishing head against a polishing pad at the range from 700 to 18,000 Pa, by using an aqueous dispersion for chemical mechanical polishing comprising an abrasive and at least one compound selected from the group consisting of polycarboxylic acid having a heterocycle and anhydride thereof, and the polishing pad.

Owner:JSR CORPORATIOON

Chemical mechanical polishing composite of stainless steel surface polishing

InactiveCN101654599ASuppression of surface defectsFacilitates mechanical polishing capabilitiesPolishing compositions with abrasivesPseudoboehmiteHydrated alumina

The invention relates to a chemical mechanical polishing composite of stainless steel surface polishing; the polishing composite is composed of grinding material, oxidizer, polishing accelerant, metalchelator, penetrant, and surfactant; the invention is characterized in that: aluminum oxide sol, namely hydrated alumina dispersed in acidic aqueous solution in sol state, is added, the hydrated alumina can be boehmite, fake boehmite, diaspore or gibbsite.

Owner:JIANGSU HAIXUN IND GROUP SHARE

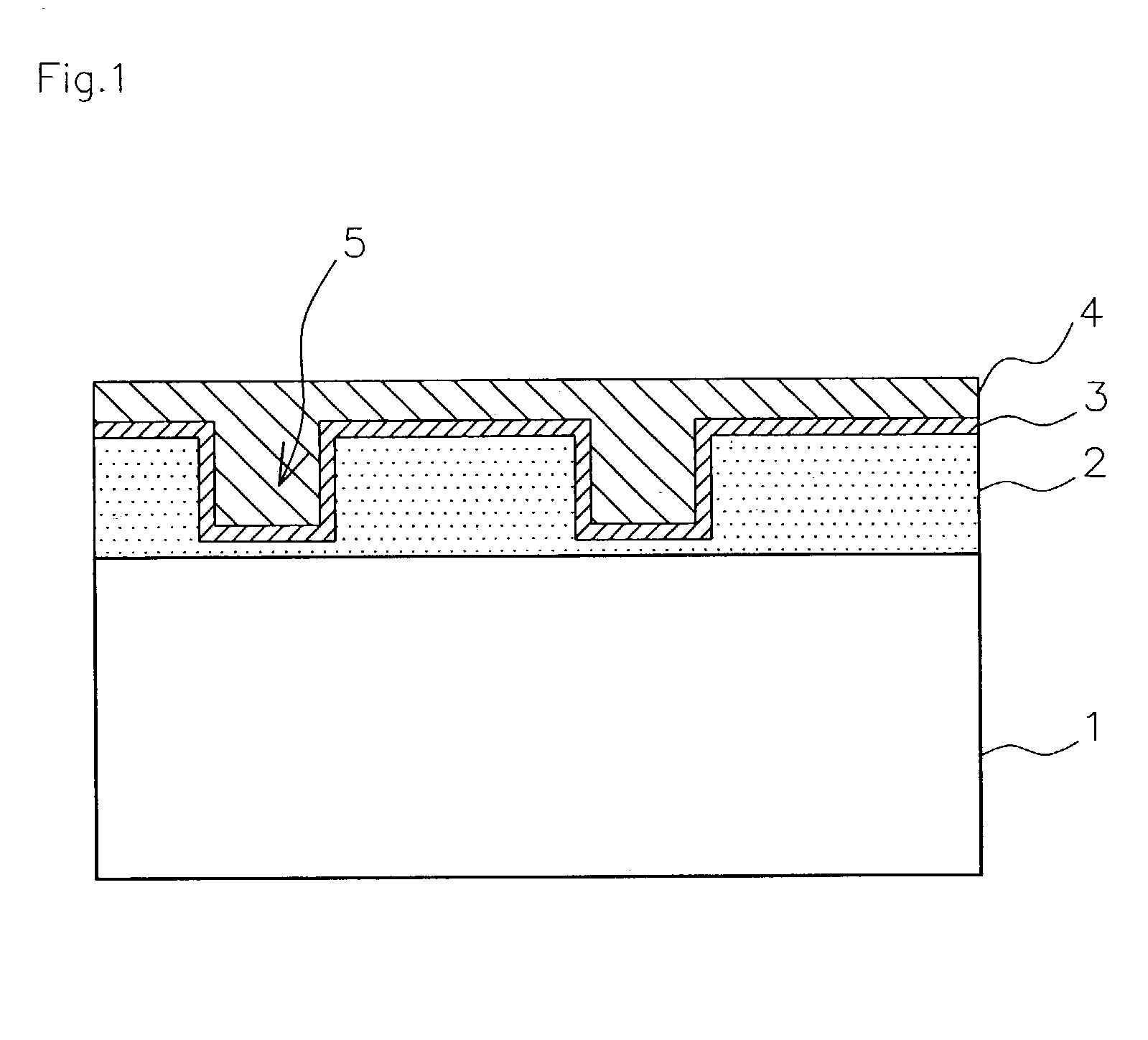

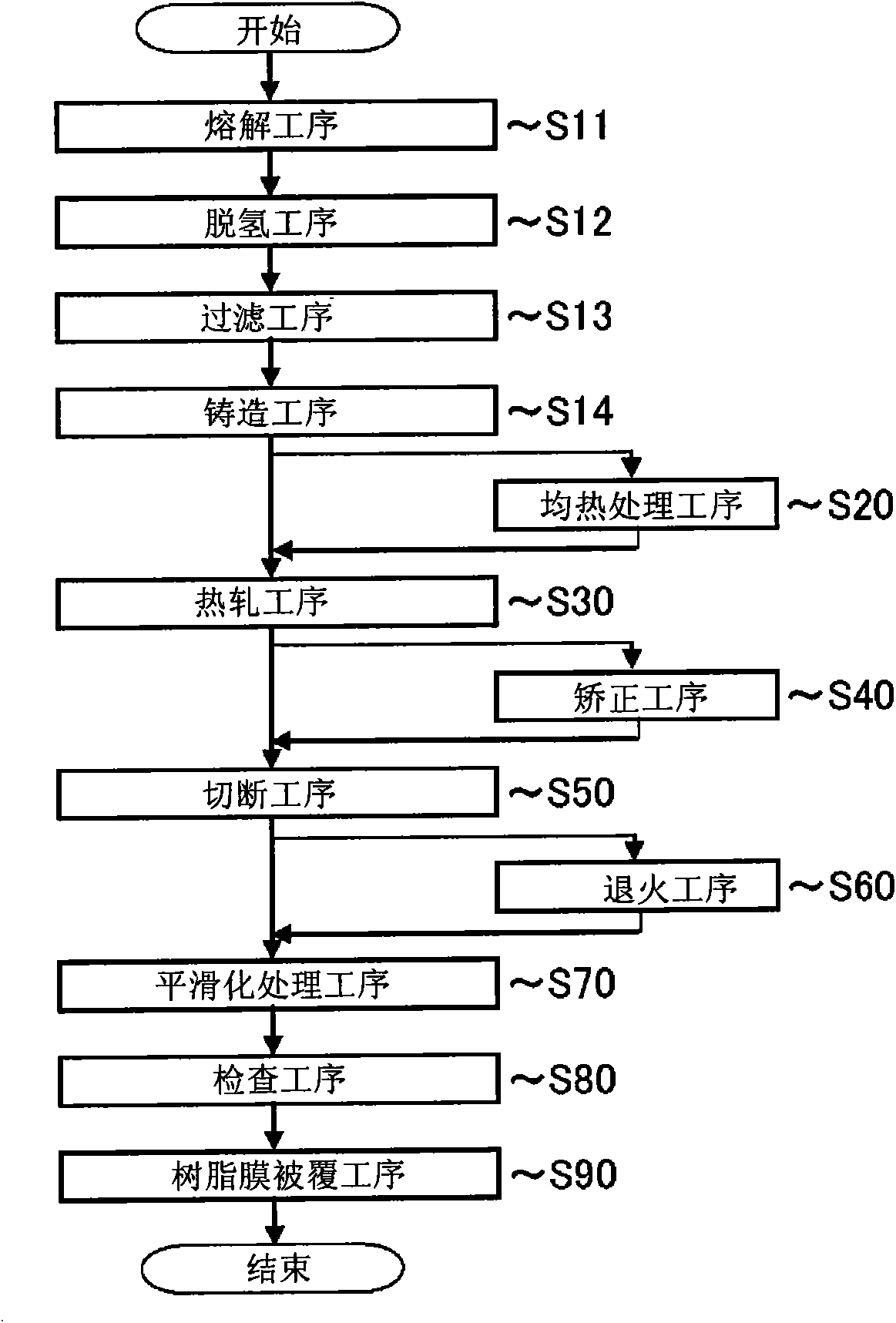

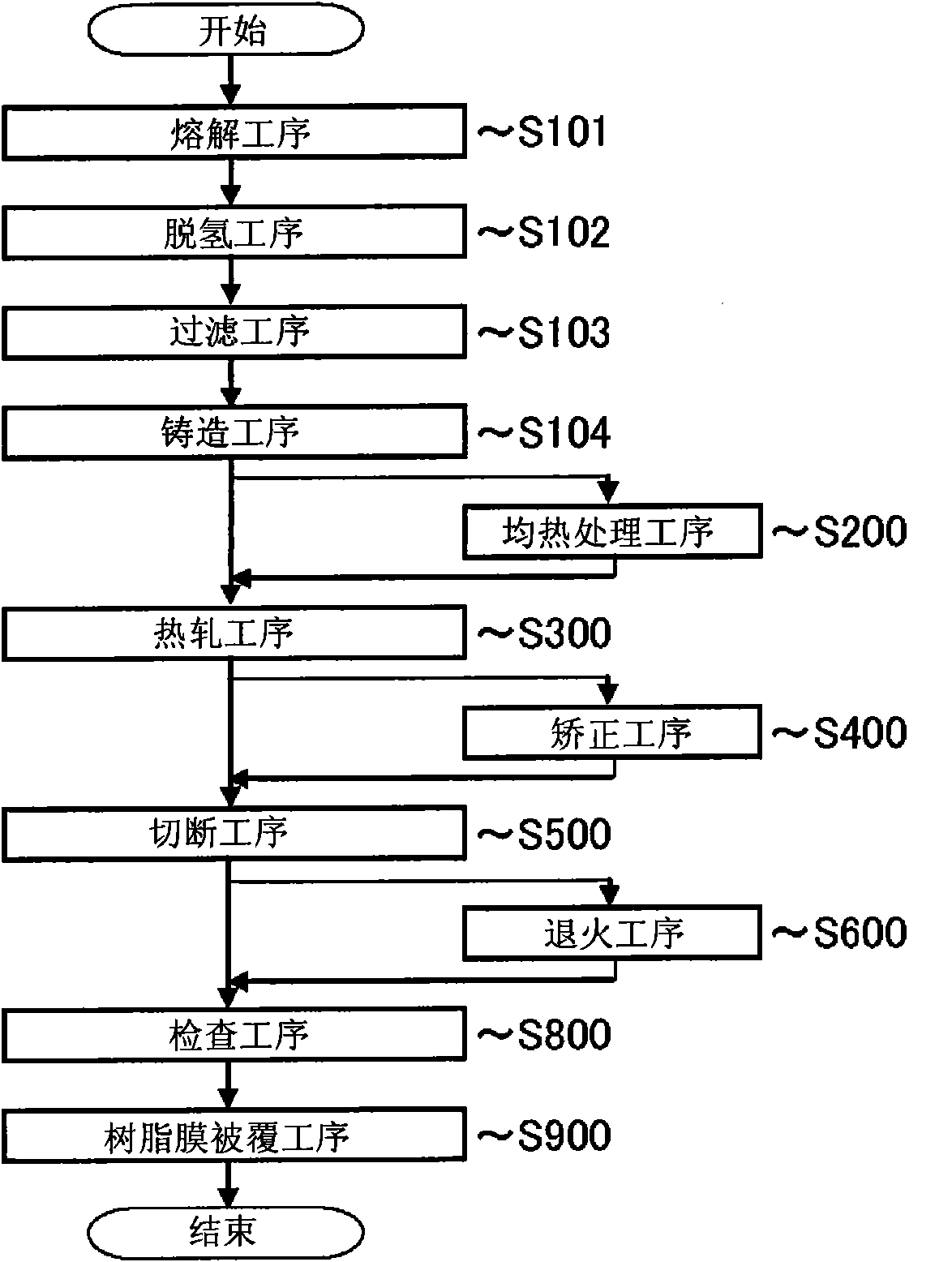

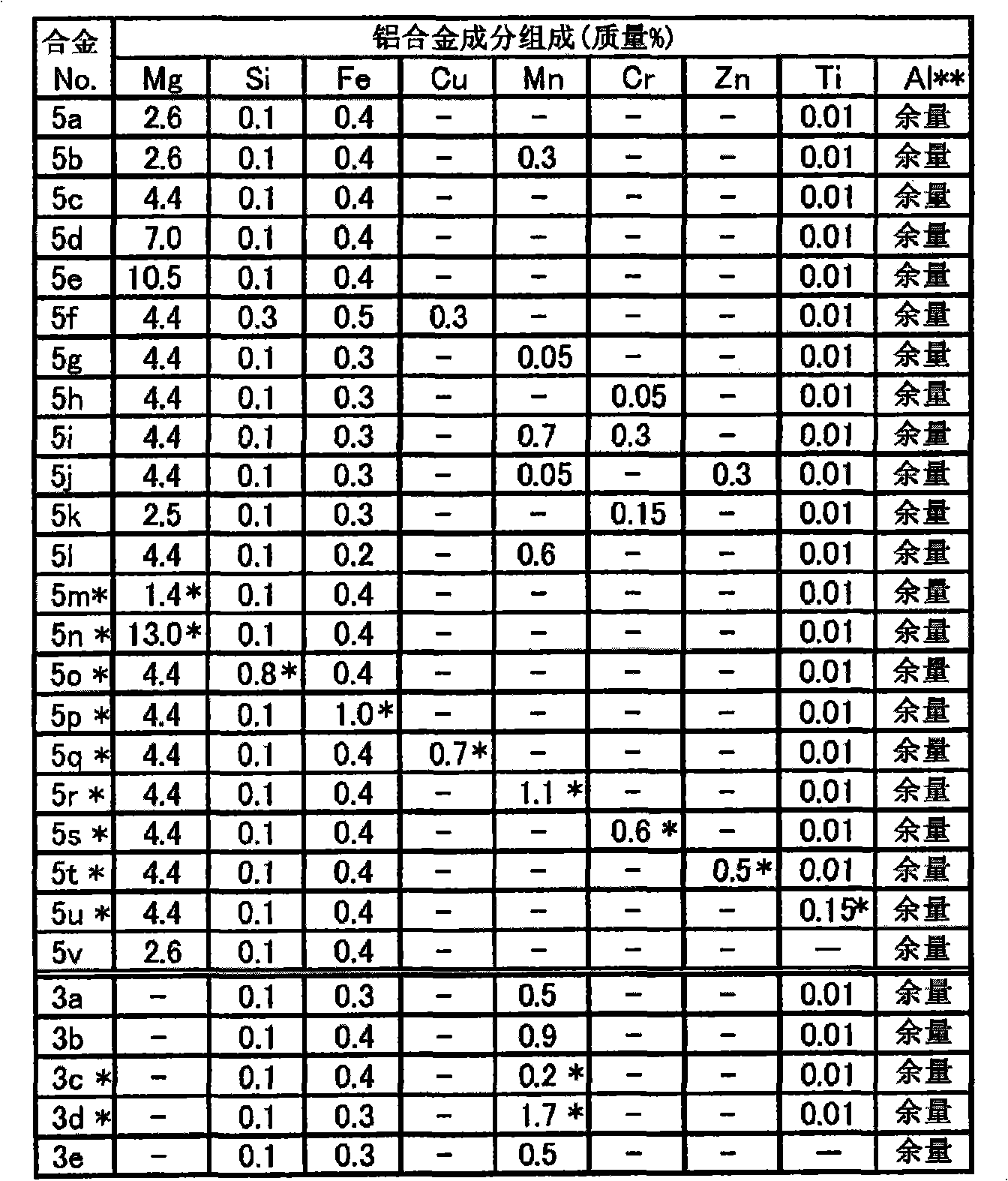

Aluminum alloy plate and process for producing the same

InactiveCN101959625AHigh strengthImprove surface propertiesWork treatment devicesMetal rolling arrangementsHydrogenFiltration

An aluminum alloy plate is provided which is suitable for use as members for apparatuses relating to semiconductors. The alloy plate is satisfactory in plate thickness precision and flatness and can be inhibited from having surface defects. Also provided is a process for producing the plate. An aluminum alloy comprising given components is melted (melting step), and hydrogen gas and inclusions are removed therefrom (dehydrogenation step and filtration step). This melt is cast into an ingot (casting step). According to need, the ingot is homogenized by a heat treatment (soaking step). This ingot is hot-rolled to a given thickness (hot-rolling step), cut (cutting step), and finished by smoothening the surfaces (smoothening step). According to need, the plate may be subjected to straightening (straightening step) and a heat treatment, e.g., annealing (annealing step). The aluminum alloy plate obtained has a surface flatness of 0.2 mm or less per m of rolling-direction length and has fluctuations in plate thickness within +-0.5% of a desired plate thickness.

Owner:KOBE STEEL LTD

Chemical mechanical polishing aqueous dispersion, chemical mechanical polishing method, and chemical mechanical polishing aqueous dispersion preparation kit

ActiveUS20090291620A1Suppression of surface defectsIncrease speedOther chemical processesSemiconductor/solid-state device manufacturingActive agentPhysical chemistry

A chemical mechanical polishing aqueous dispersion includes: (A) an amino acid, (B) abrasive grains, (C) a surfactant, (D) an oxidizing agent, and (E) ammonia, the ratio (WA / WD) of the content (WA) of the amino acid to the content (WD) of the oxidizing agent being 1.5 to 6.0, and the ratio (WE / WD) of the content (WE) of the ammonia to the content (WD) of the oxidizing agent being 0.05 to 0.6.

Owner:JSR CORPORATIOON

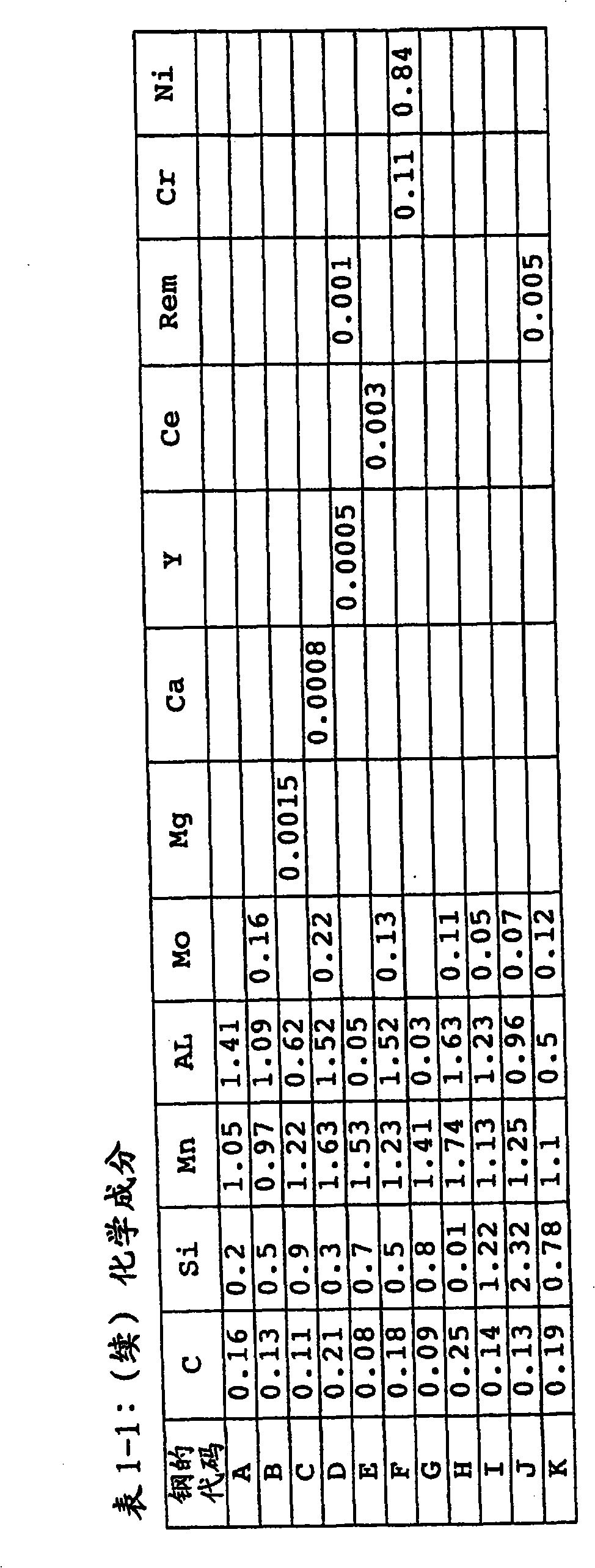

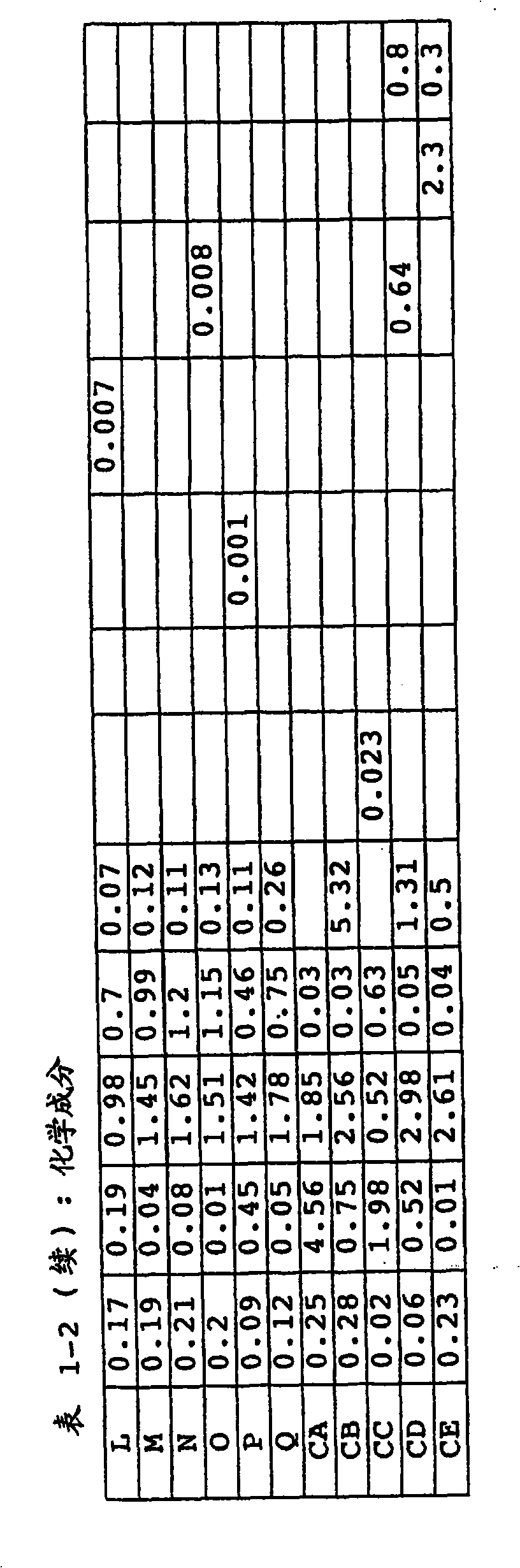

Hot-dip galvannealed steel sheet, steel sheet treated by hot-dip galvannealed layer diffusion and a method of producing the same

InactiveCN101264681AImprove fatigue resistanceImprove corrosion resistanceHot-dipping/immersion processesSolid state diffusion coatingSheet steelHigh intensity

The present invention provides: a high-strength high-ductility hot-dip galvanized steel sheet and hot-dip galvannealed steel sheet having high fatigue resistance and corrosion resistance; a high-strength hot-dip galvanized steel sheet excellent in ductility, which improves non-plating defects and plating adhesion after severe deformation, and a method of producing the same; a high-strength and high-ductility hot-dip galvanized steel sheet having high fatigue resistance and corrosion resistance; a high-strength hot-dip galvanized steel sheet and hot-dip galvannealed steel sheet having superior appearance and workability, which suppresses the generation of non-plating defects, and a method of producing the same; and a high-strength hot-dip galvannealed steel sheet and a high-strength hot-dip galvanized steel sheet, which suppress non-plating defects and surface defects and have both corrosion resistance, in particular corrosion resistance in an environment containing chlorine ion, and high ductility, and a method of producing the same.

Owner:NIPPON STEEL CORP

Material for Forming Resist Protection Films and Method for Resist Pattern Formation with the Same

ActiveUS20080299503A1Easy to handleExcellent propertyPhotosensitive materialsPhotomechanical exposure apparatusAcrylic polymerPolymer chemistry

The formation of high-resolution resist patterns by liquid immersion lithography with various fluids is enabled by protecting a resist film from deterioration (such as bridging) during the immersion exposure in a fluid (such as water) and the fluid from deterioration and improving the stability of a resist film in the storage after exposure without increase in the number of treatment steps. A material for forming resist protection films which comprises an alkali-soluble polymer for forming a protective overcoat for a resist film, characterized in that the contact angle of the polymer to water is 90° or above. The polymer is preferably an acrylic polymer which comprises as the essential components constituent units derived from (meth) acrylic acid and constituent units derived from a specific acrylic ester.

Owner:TOKYO OHKA KOGYO CO LTD

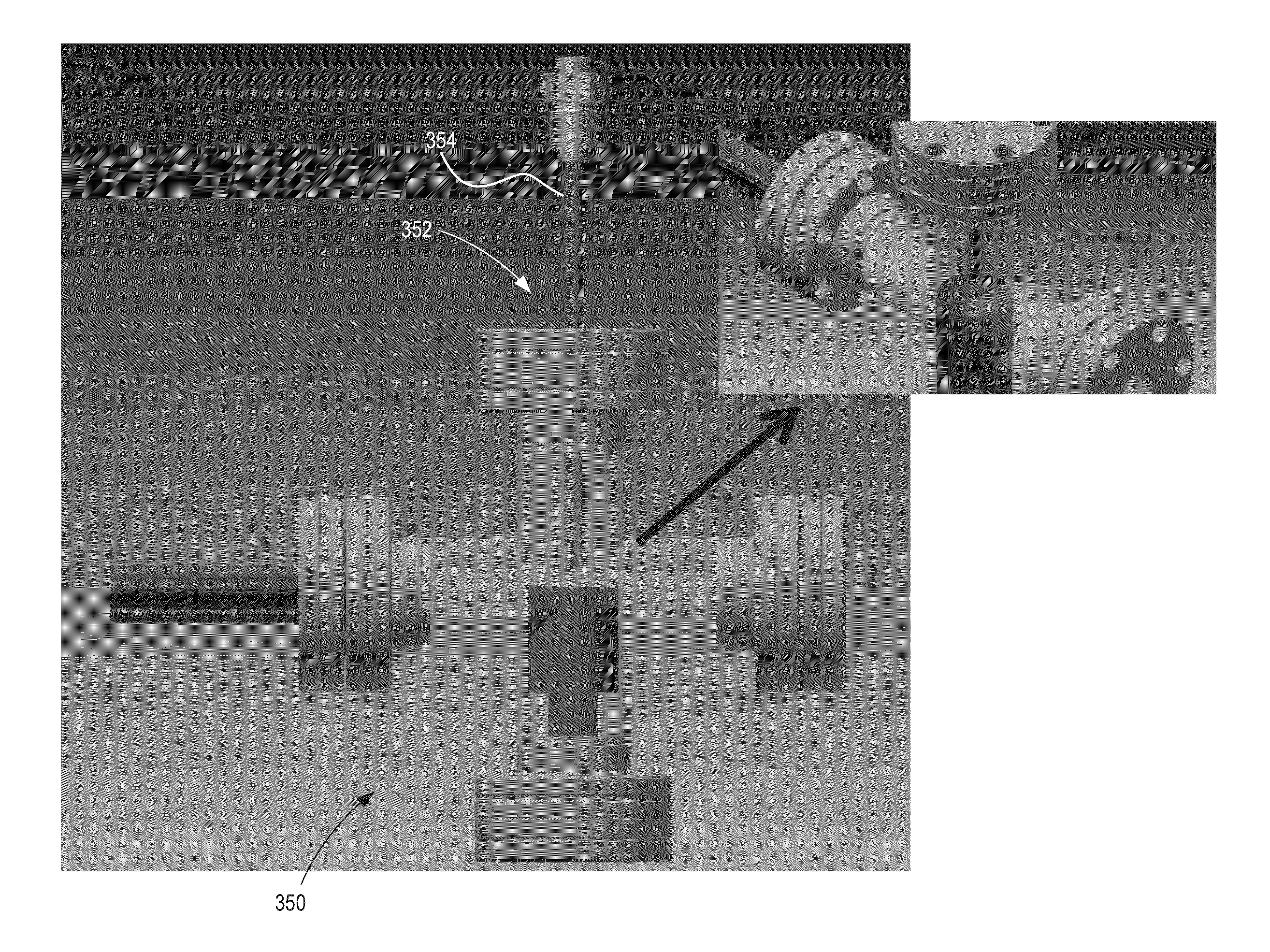

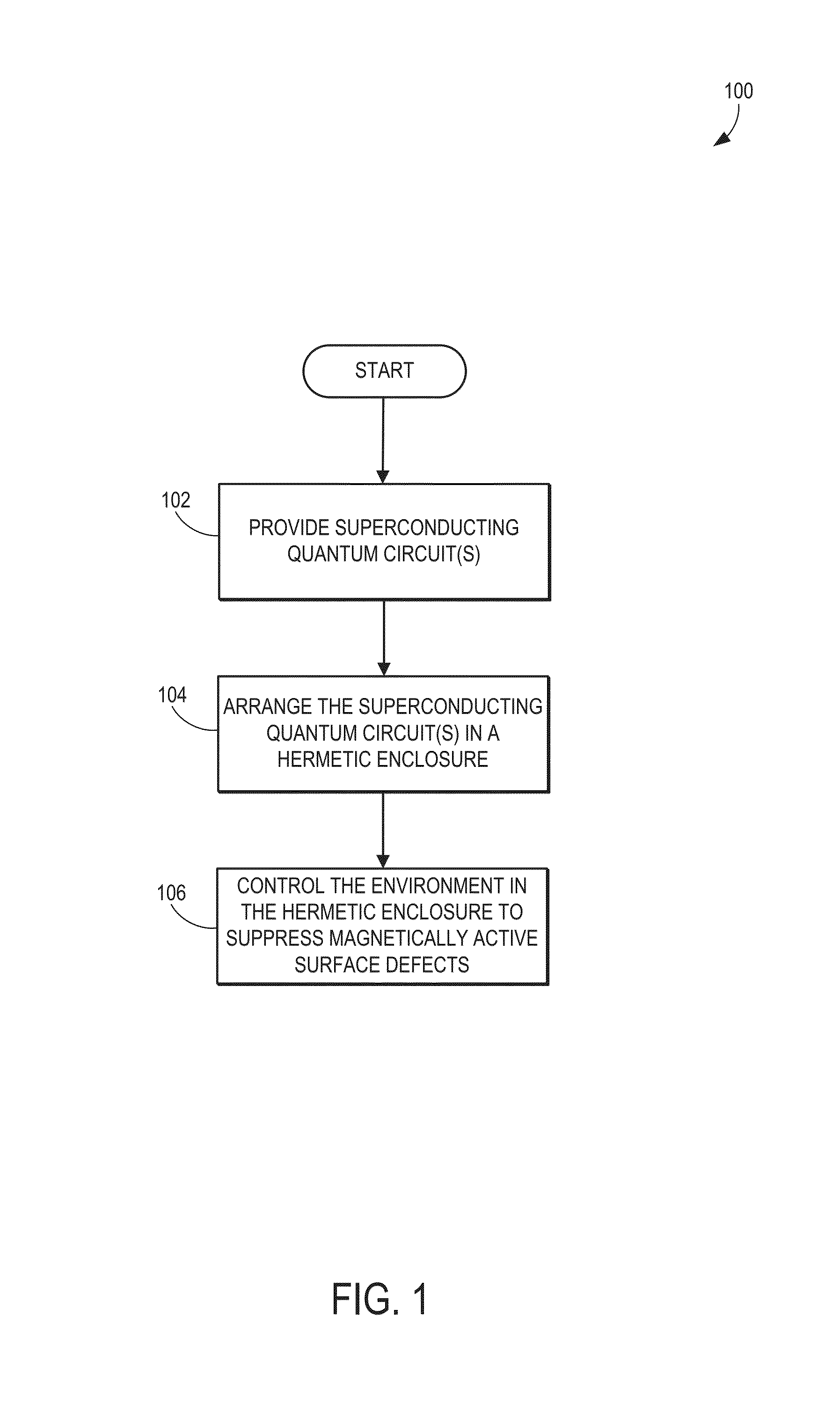

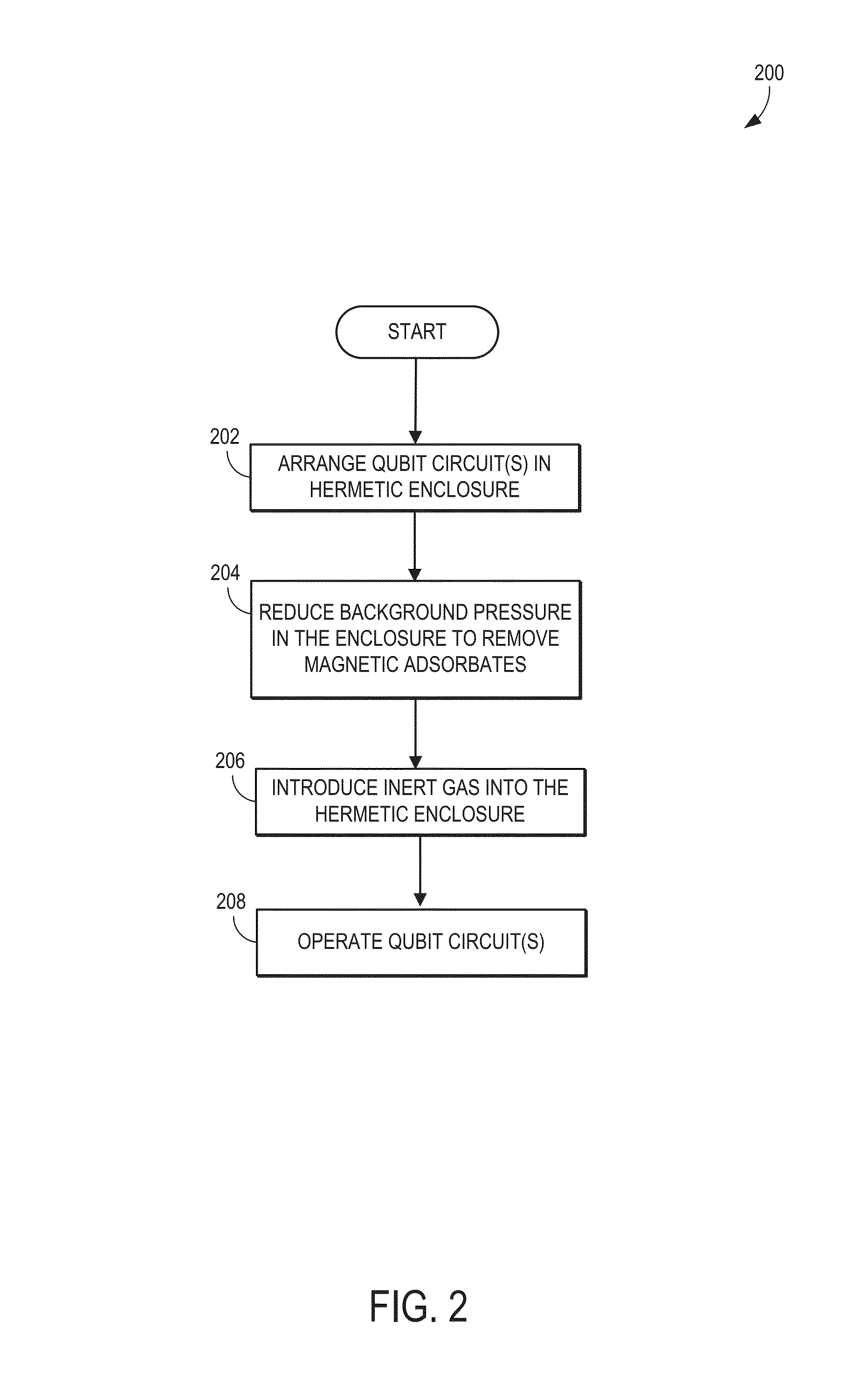

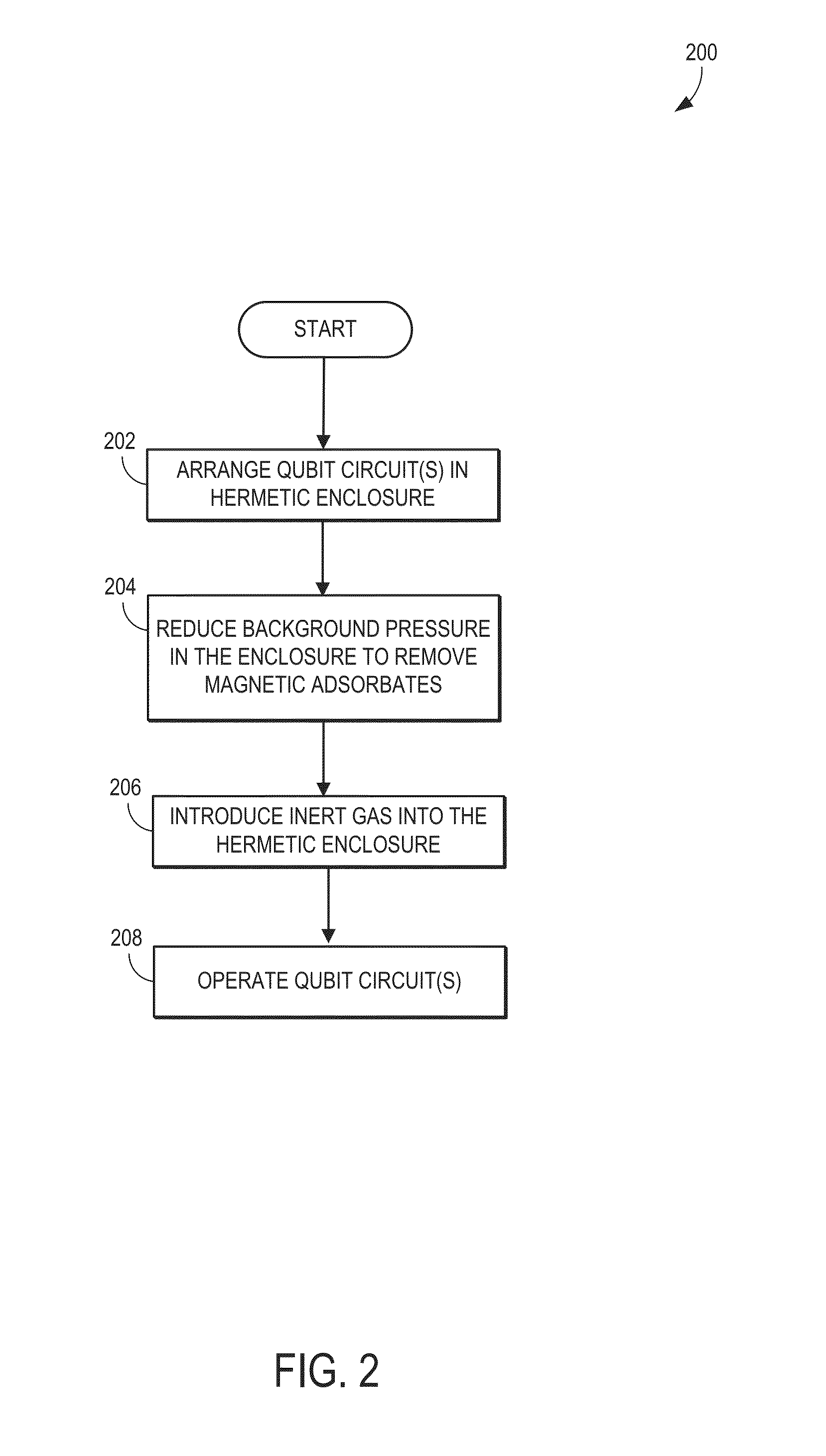

Systems and Methods for Suppressing Magnetically Active Surface Defects in Superconducting Circuits

ActiveUS20160254434A1Source of noise can be reduced and eliminatedOvercomes drawbackQuantum computersSolid-state devicesQuantum circuitUltraviolet lights

Systems and methods for suppressing magnetically active surface defects in superconducting quantum circuits are provided. A method includes providing one or more superconducting quantum circuits, and arranging the one or more superconducting quantum circuits in a hermetic enclosure capable of isolating the one or more superconducting circuits from ambient surroundings. The method also includes controlling an environment in the hermetic enclosure to suppress magnetically active surface defects associated with the one or more superconducting quantum circuits. In some aspects, the method further includes introducing an inert gas into the hermetic enclosure to passivate a surface of the one or more superconducting quantum circuits. In other aspects, the method further includes coating a surface of the one or more superconducting circuits with a non-magnetic encapsulation layer. In yet other aspects, the method further includes irradiating the one or more superconducting circuits using ultraviolet light.

Owner:WISCONSIN ALUMNI RES FOUND

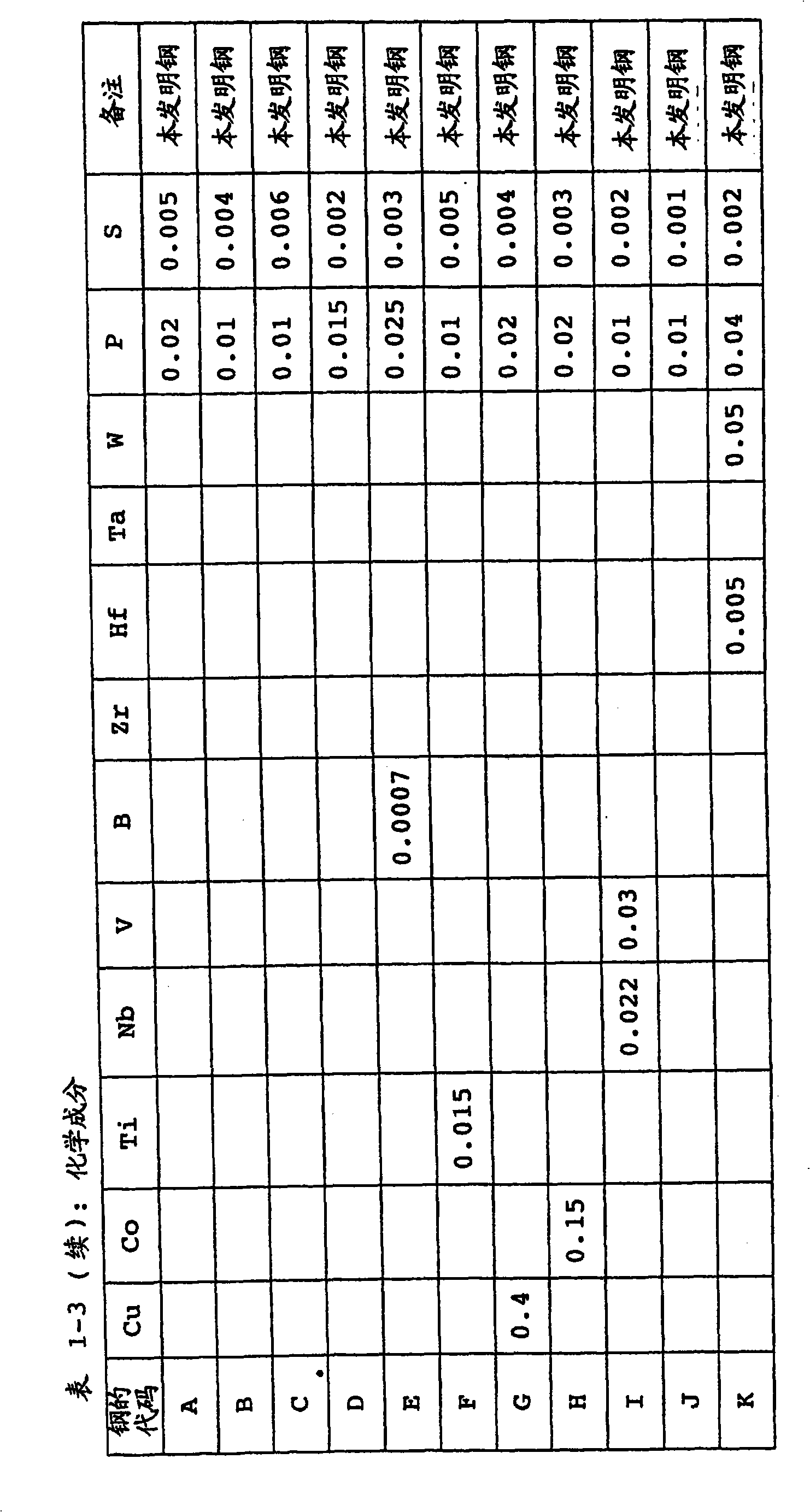

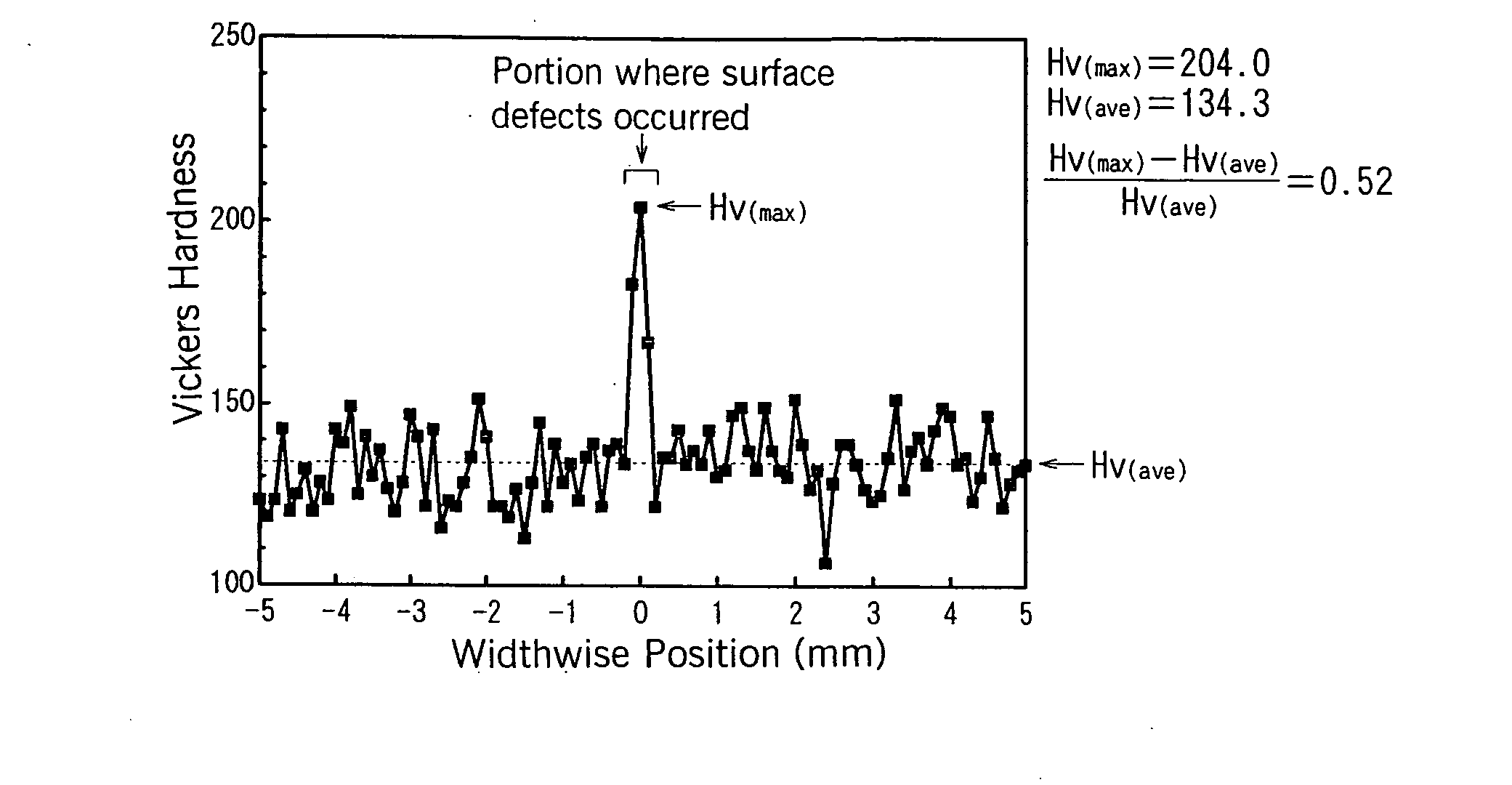

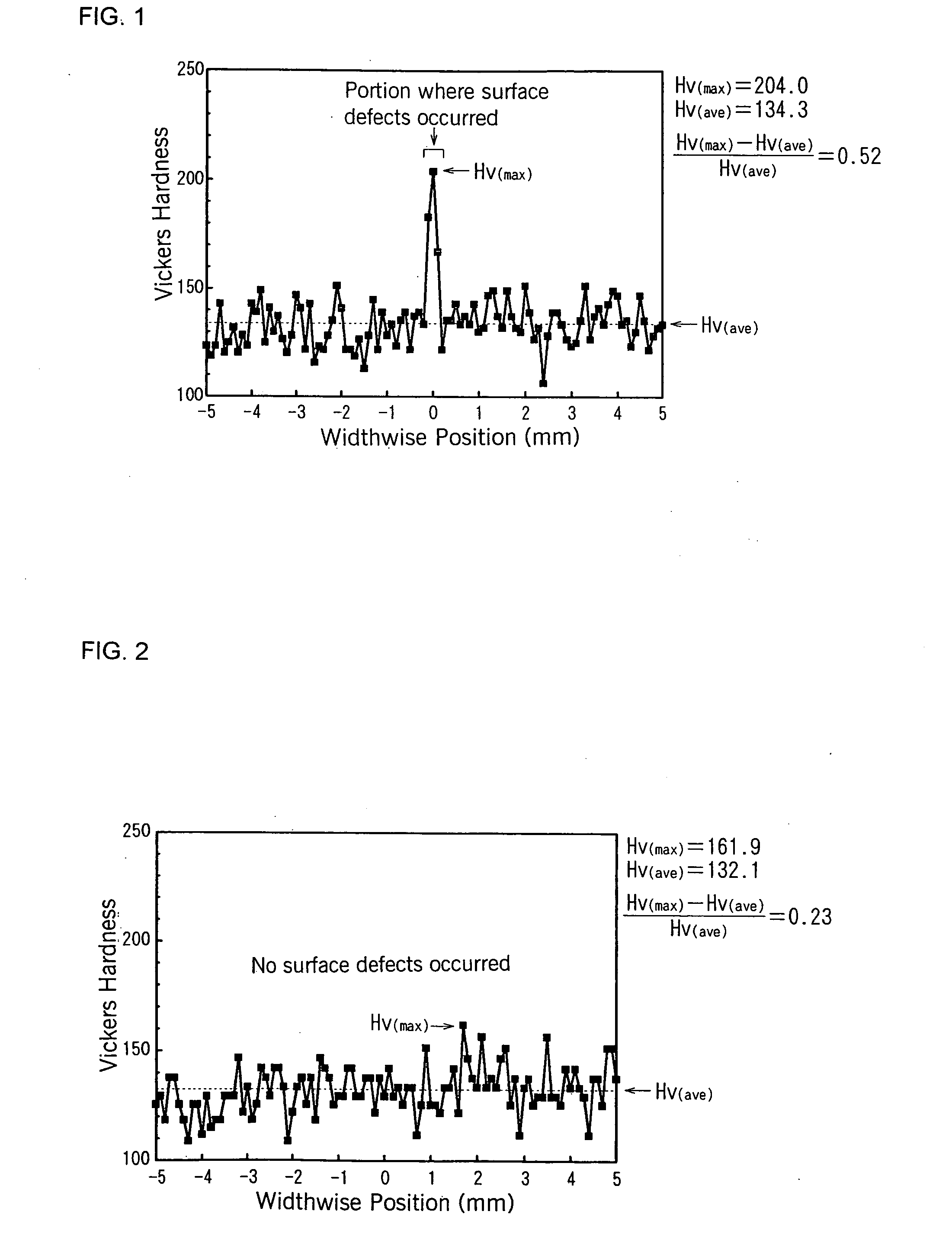

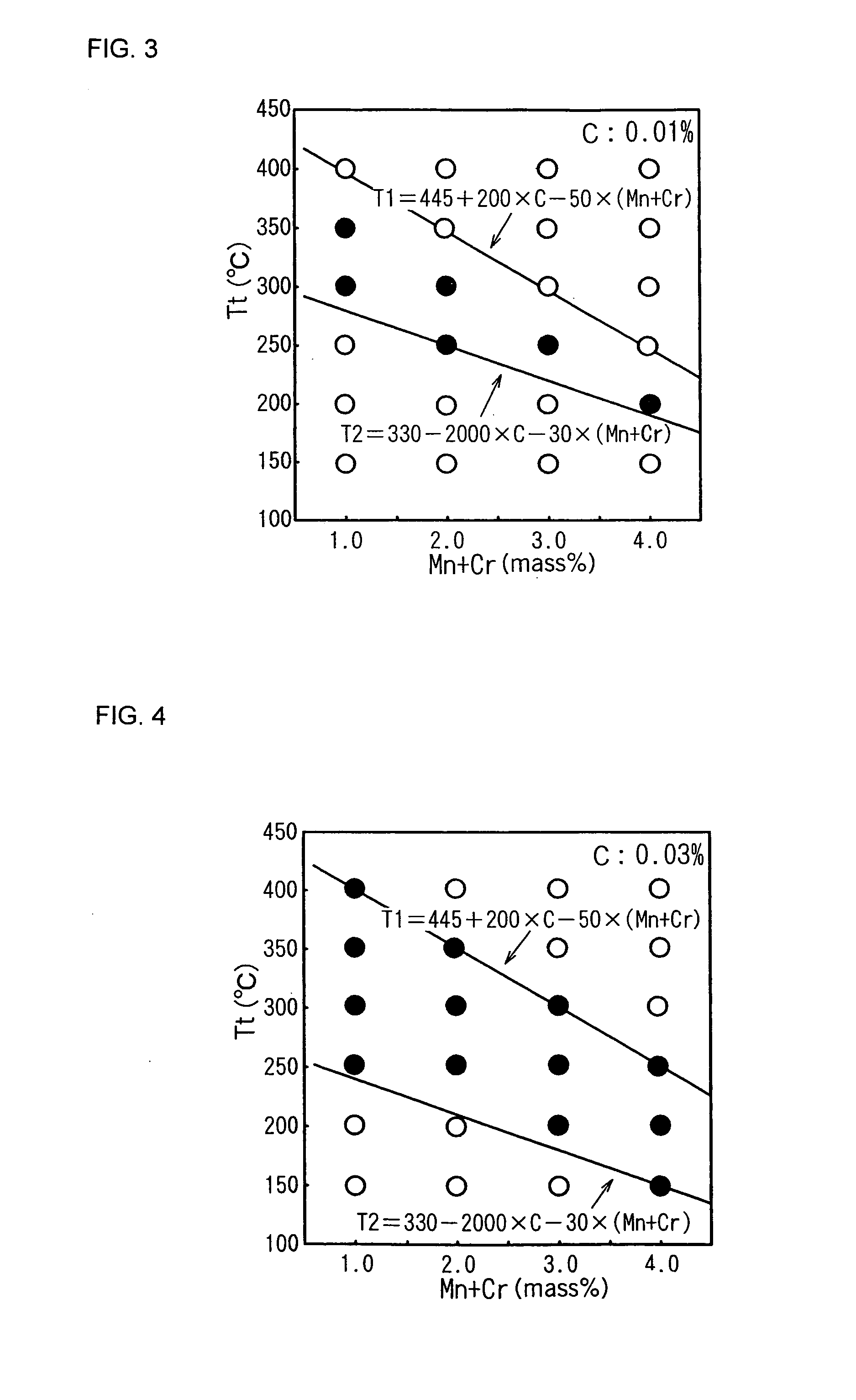

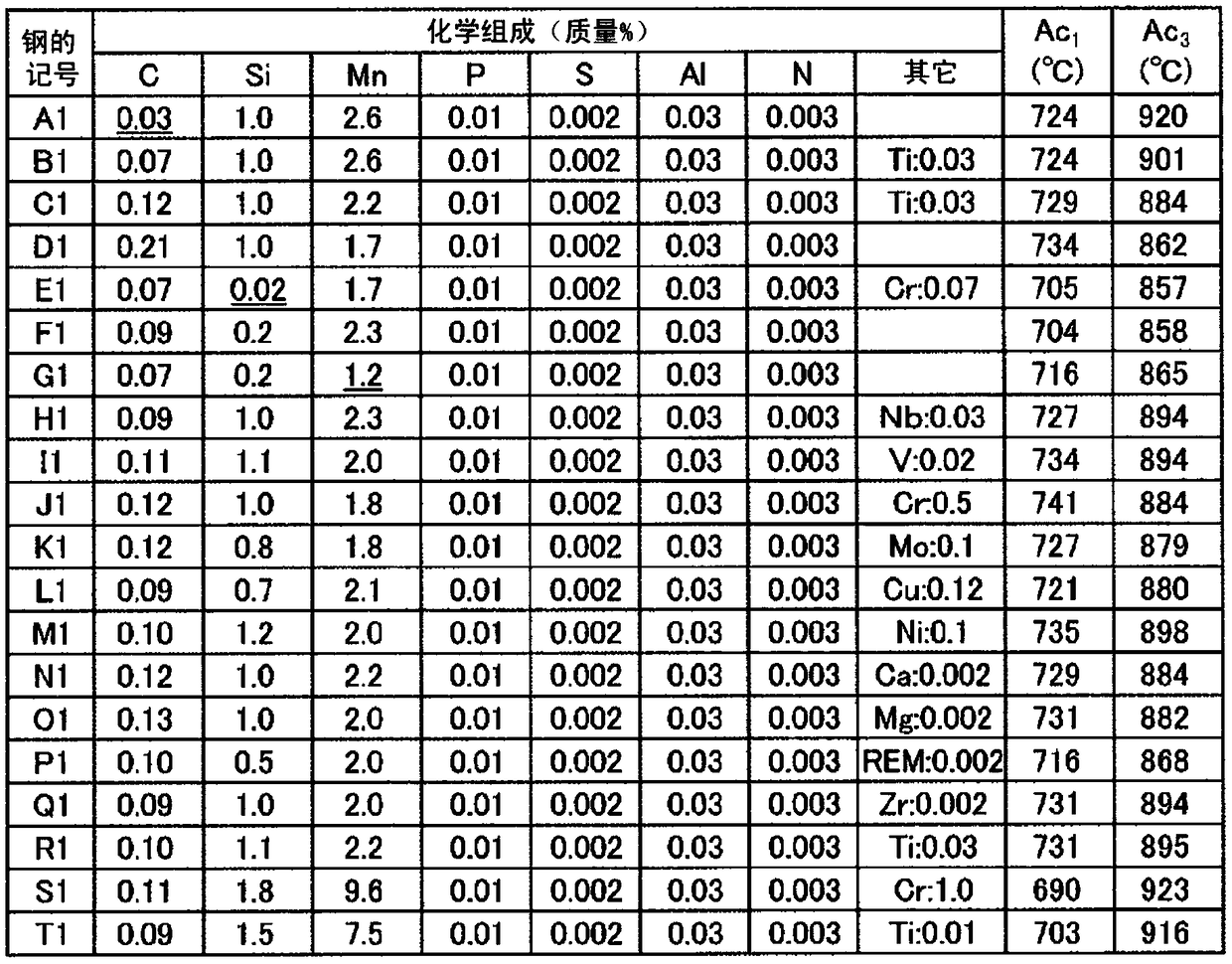

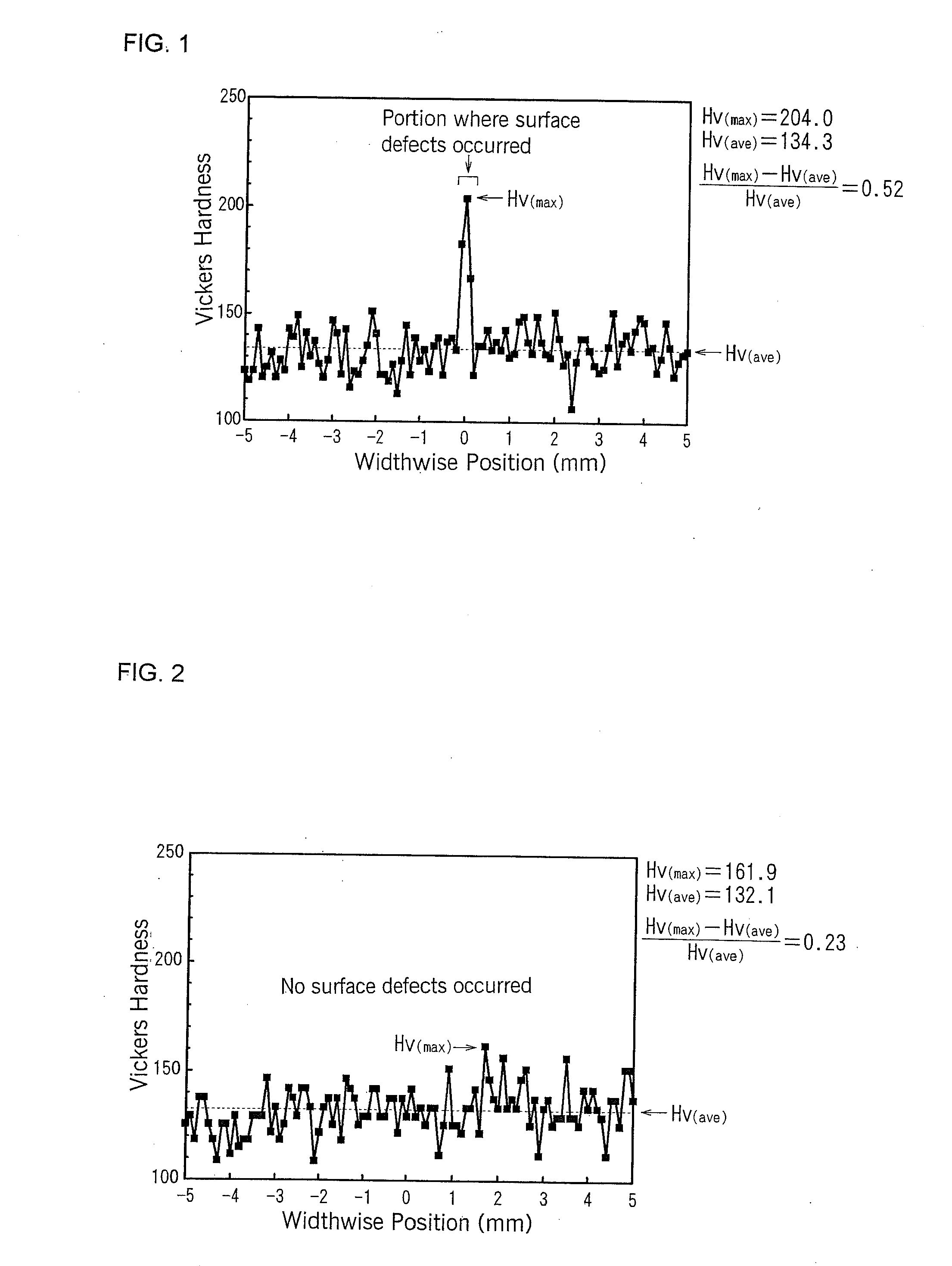

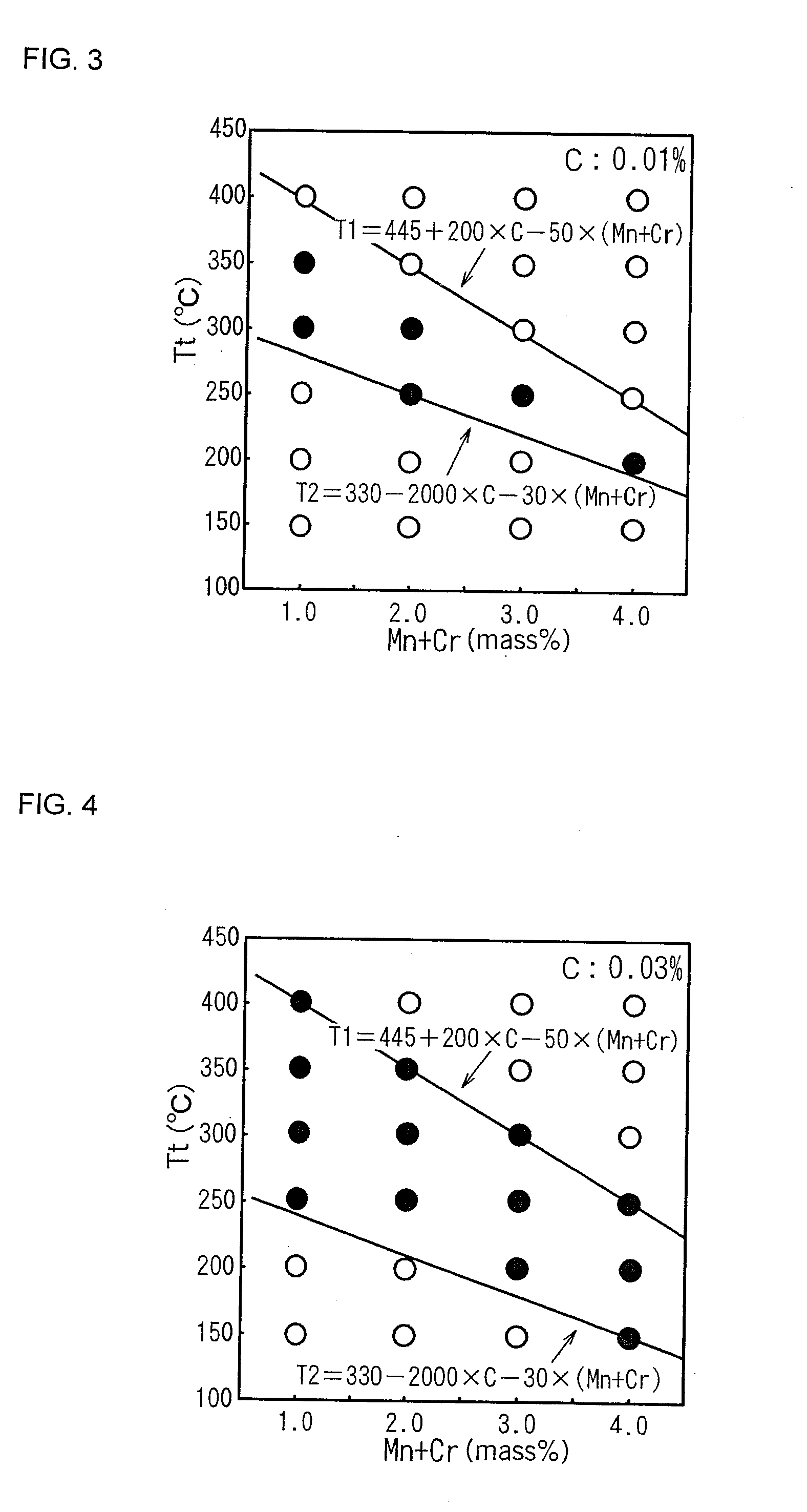

High-strength cold-rolled steel sheet, high-strength plated steel sheet, and methods for their manufacture

InactiveUS20080202638A1Sufficient formabilityNot develop surface defectHot-dipping/immersion processesFurnace typesRoom temperatureHigh intensity

A high-strength cold-rolled steel sheet providing a product with a good surface condition after press forming, having excellent bake hardenability and anti room temperature aging property, and having a dual phase structure with a tensile strength of at least 340 MPa is provided.A high-strength cold-rolled steel sheet has a structure comprising a main phase which is a ferrite and a secondary phase which is a low temperature transformation product including a martensite and has a hardness distribution of the ferrite phase in an arbitrary cross section having a length of 10 mm in the widthwise direction of the sheet which satisfies the relationship prescribed by (Hv(max)−Hv(ave))<0.5×(Hv(ave). Hv(max) is the maximum Vickers hardness of ferrite grains in a region at a distance of from (⅛)t to (¼)t in the thickness direction from the surface when the thickness of the high-strength cold-rolled steel sheet is t, and Hv(ave) is the average Vickers hardness of ferrite grains in this region.

Owner:SUMITOMO METAL IND LTD

Hot-dip galvanized thin steel sheet, thin steel sheet processed by hot-dip galvanized layer, and a method of producing the same

InactiveCN101125472AImprove fatigue resistanceImprove corrosion resistanceHot-dipping/immersion processesSolid state diffusion coatingHot-dip galvanizationDuctility

The present invention provides: a high-strength high-ductility hot-dip galvanized steel sheet and hot-dip galvannealed steel sheet having high fatigue resistance and corrosion resistance; a high-strength hot-dip galvanized steel sheet excellent in ductility, which improves non-plating defects and plating adhesion after severe deformation, and a method of producing the same; a high-strength and high-ductility hot-dip galvanized steel sheet having high fatigue resistance and corrosion resistance; a high-strength hot-dip galvanized steel sheet and hot-dip galvannealed steel sheet having superiorappearance and workability, which suppresses the generation of non-plating defects, and a method of producing the same; and a high-strength hot-dip galvannealed steel sheet and a high-strength hot-dip galvanized steel sheet, which suppress non-plating defects and surface defects and have both corrosion resistance, in particular corrosion resistance in an environment containing chlorine ion, and high ductility, and a method of producing the same.

Owner:NIPPON STEEL CORP

Polishing composition and fabrication method of substrate using same

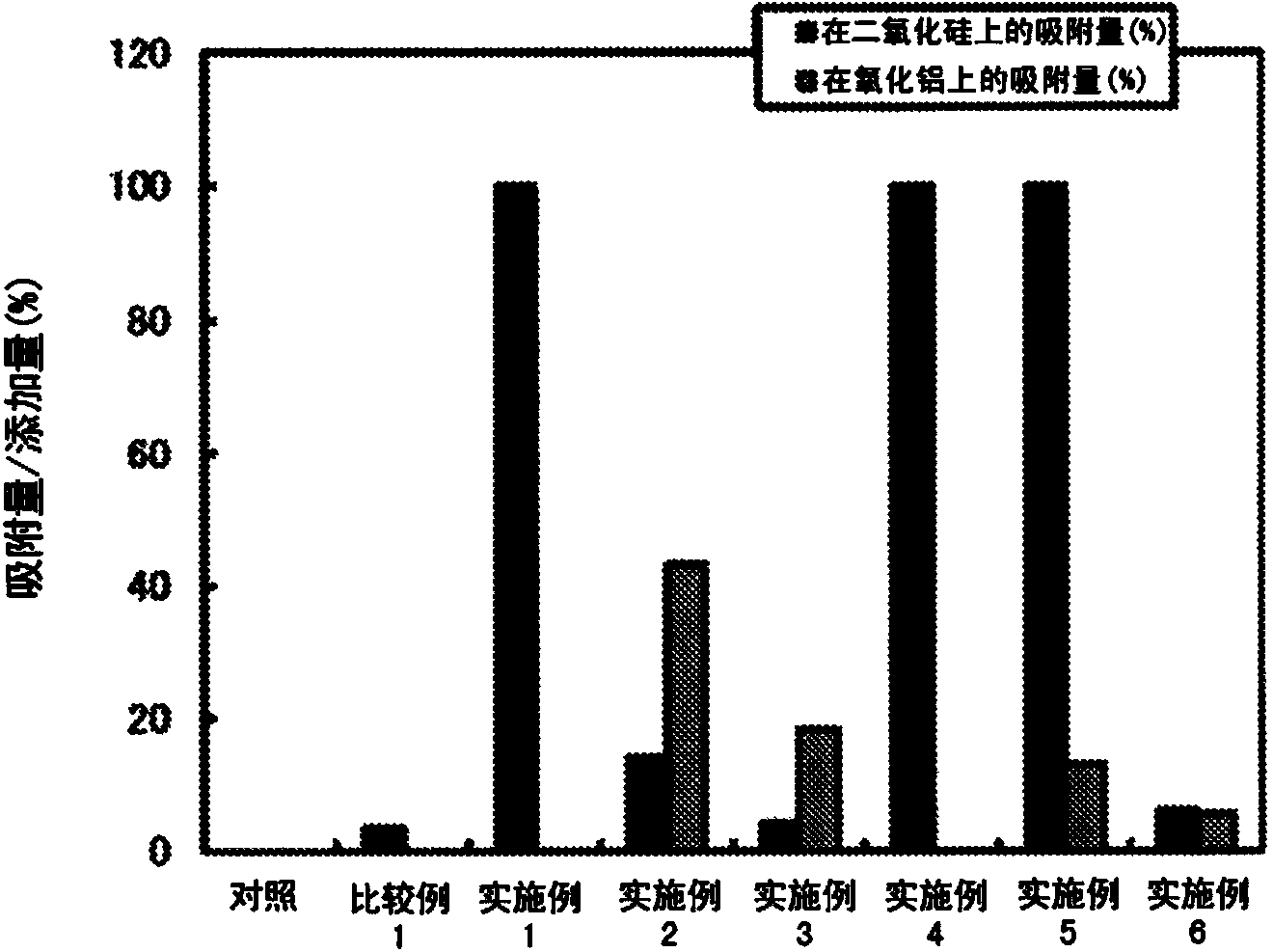

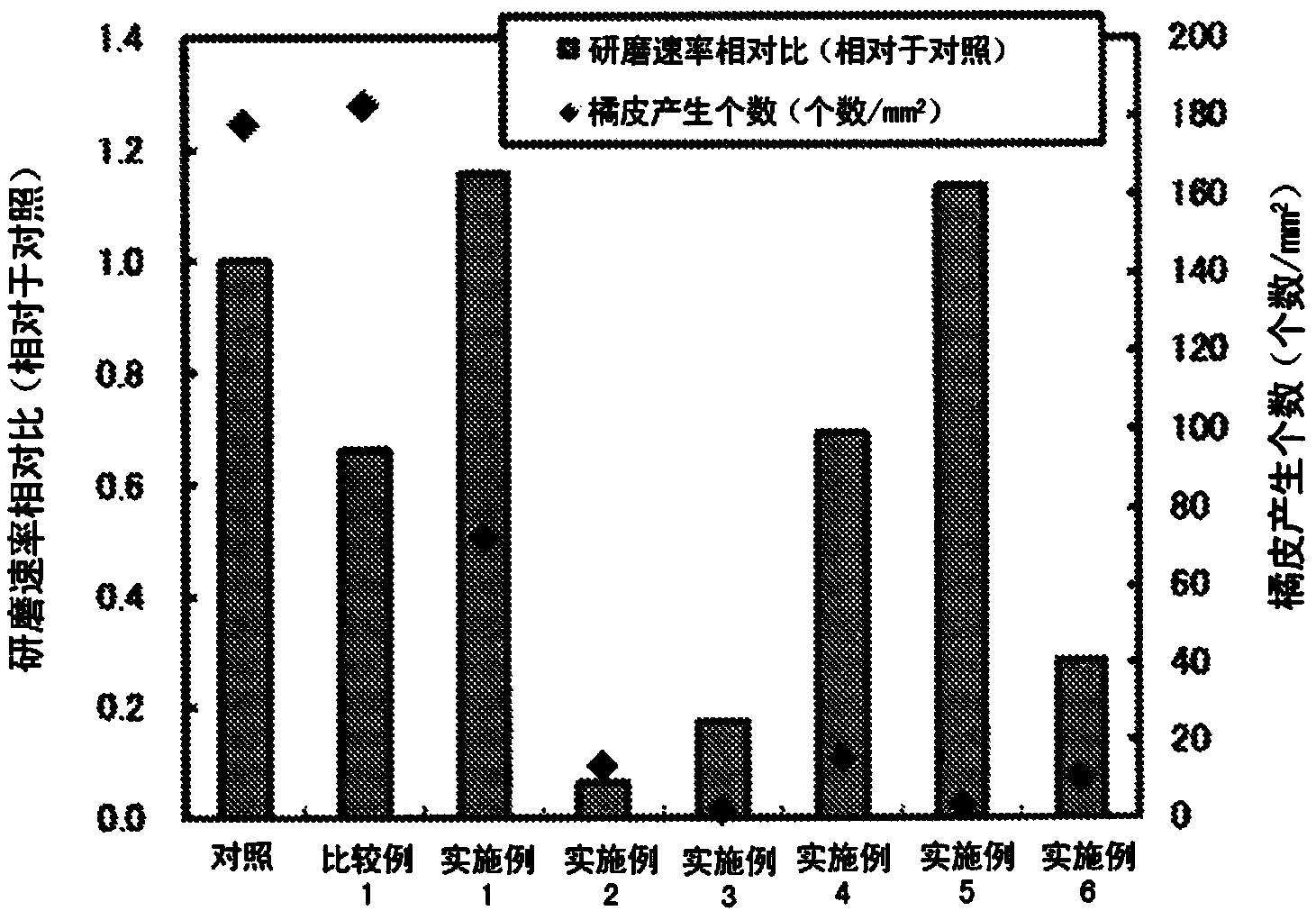

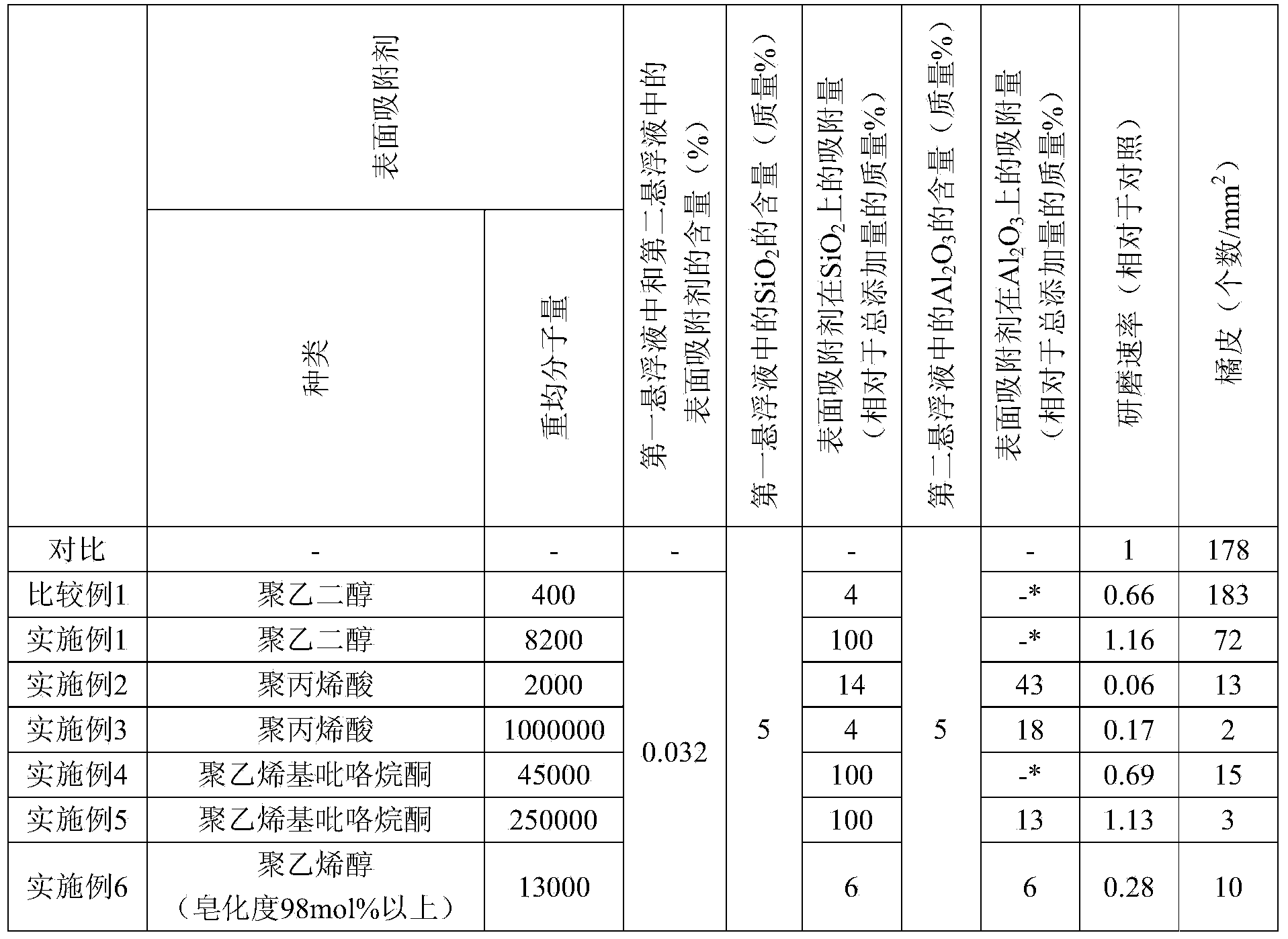

ActiveCN104395039ASuppression of surface defectsOther chemical processesSemiconductor/solid-state device manufacturingMaterials science

In the present invention, a polishing composition contains abrasive particles, a surface adsorption agent, and water and is used to polish a polishing target comprising crystalline metallic compounds. Compared to the case where the surface adsorption agent is removed from the polishing composition, the polishing composition reduces the surface defects of the polishing target after polishing.

Owner:FUJIMI INCORPORATED

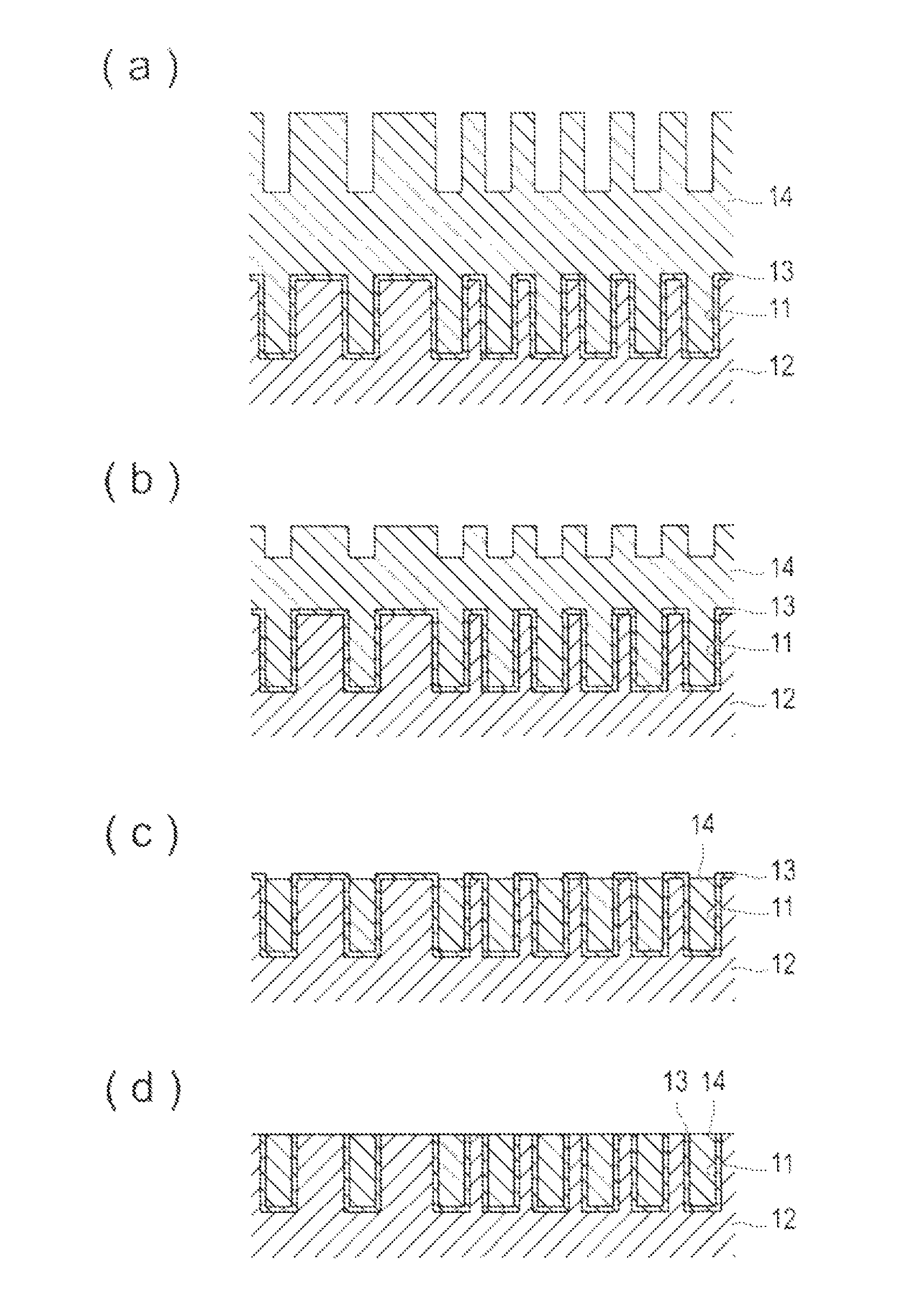

Production method for thin-film crystal wafer, semiconductor device using it and production method therefor

InactiveUS20060060132A1Suppress formationGood chemical stabilityPolycrystalline material growthSemiconductor/solid-state device manufacturingWork functionSingle crystal

The n+-GaAs layer 8 of the GaAs single crystal 10 is formed by epitaxial growth, followed by epitaxially growing the Si-layer 11 in the same epitaxial growth furnace, and then the aluminum electrode 12 is formed on the Si-layer 11 as an ohmic electrode. The Si-layer 11 can suppress the formation of a surface defect level on the surface of the n+-GaAs layer 8 and can effectively prevent the formation of an unnecessary potential barrier. Since the Si-layer 11 has a smooth surface and is excellent in chemical stability, a good ohmic electrode can be obtained by forming the electrode 12 using aluminum or the like has a suitable work function to the Si-layer 11.

Owner:SUMITOMO CHEM CO LTD

Polishing composition

ActiveUS9505951B2High rateSuppression of surface defectsOther chemical processesSemiconductor/solid-state device manufacturingMaterials scienceMetal

[Problem] Provided is a polishing composition that can sufficiently maintain a high polishing rate for a barrier layer and an insulating film and suppress the occurrence of a surface defect such as erosion or fang.[Solution] Provided is a polishing composition which is used in the application to polish a polishing object having a barrier layer, a metal wiring layer and an insulating film, the polishing composition including abrasive grains, an oxidant, a metal corrosion inhibitor, a pH adjusting agent and water, in which an aspect ratio of abrasive grains is 1.22 or less and a ratio D90 / D10 of a diameter D90 of particles when a cumulative particle weight from the fine particle side reaches 90% of the total particle weight to a diameter D10 of particles when the cumulative particle weight from the fine particle side reaches 10% of the total particle weight of the entire particles is 1.5 or more in a particle size distribution of the abrasive grains determined by a laser diffraction scattering method.

Owner:FUJIMI INCORPORATED

High-strength hot-dip galvanized steel sheet and hot-dip galvannealed steel sheet having fatigue resistance, corrosion resistance, ductility and plating adhesion, after severe deformation, and a method of producing the same

InactiveUS20080035247A1Nice appearanceImprove workabilityHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

Owner:NIPPON STEEL CORP

High-strength hot-dip galvanized steel sheet and hot-dip galvannealed steel sheet having fatigue resistance corrosion resistance ductility and plating adhesion after servere deformation and a method of producing the same

InactiveUS7267890B2Improve coating adhesionNice appearanceHot-dipping/immersion processesDomestic articlesHot-dip galvanizationDuctility

The present invention provides: a high-strength high-ductility hot-dip galvanized steel sheet and hot-dip galvannealed steel sheet having high fatigue resistance and corrosion resistance; a high-strength hot-dip galvanized steel sheet excellent in ductility, which improves non-plating defects and plating adhesion after severe deformation, and a method of producing the same; a high-strength and high-ductility hot-dip galvanized steel sheet having high fatigue resistance and corrosion resistance; a high-strength hot-dip galvanized steel sheet and hot-dip galvannealed steel sheet having superior appearance and workability, which suppresses the generation of non-plating defects, and a method of producing the same; and a high-strength hot-dip galvannealed steel sheet and a high-strength hot-dip galvanized steel sheet, which suppress non-plating defects and surface defects and have both corrosion resistance, in particular corrosion resistance in an environment containing chlorine ion, and high ductility, and a method of producing the same.

Owner:NIPPON STEEL CORP

Hot-dip galvanized thin steel sheet, thin steel sheet processed by hot-dip galvanized layer, and a method of producing the same

InactiveCN101125473AHigh strengthImprove ductilityHot-dipping/immersion processesSolid state diffusion coatingSheet steelHigh intensity

The present invention provides: a high-strength high-ductility hot-dip galvanized steel sheet and hot-dip galvannealed steel sheet having high fatigue resistance and corrosion resistance; a high-strength hot-dip galvanized steel sheet excellent in ductility, which improves non-plating defects and plating adhesion after severe deformation, and a method of producing the same; a high-strength and high-ductility hot-dip galvanized steel sheet having high fatigue resistance and corrosion resistance; a high-strength hot-dip galvanized steel sheet and hot-dip galvannealed steel sheet having superior appearance and workability, which suppresses the generation of non-plating defects, and a method of producing the same; and a high-strength hot-dip galvannealed steel sheet and a high-strength hot-dip galvanized steel sheet, which suppress non-plating defects and surface defects and have both corrosion resistance, in particular corrosion resistance in an environment containing chlorine ion, and high ductility, and a method of producing the same.

Owner:NIPPON STEEL CORP

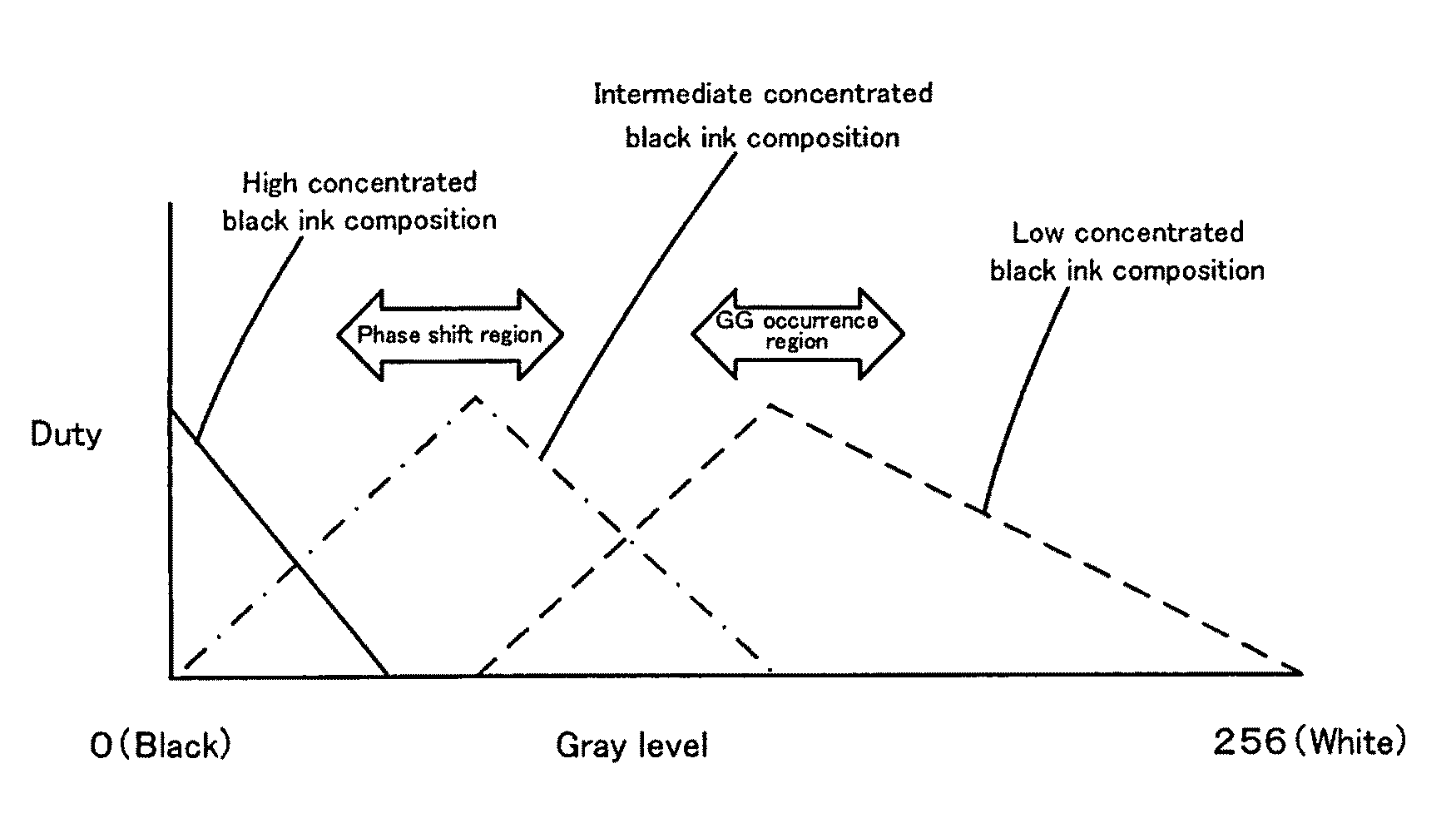

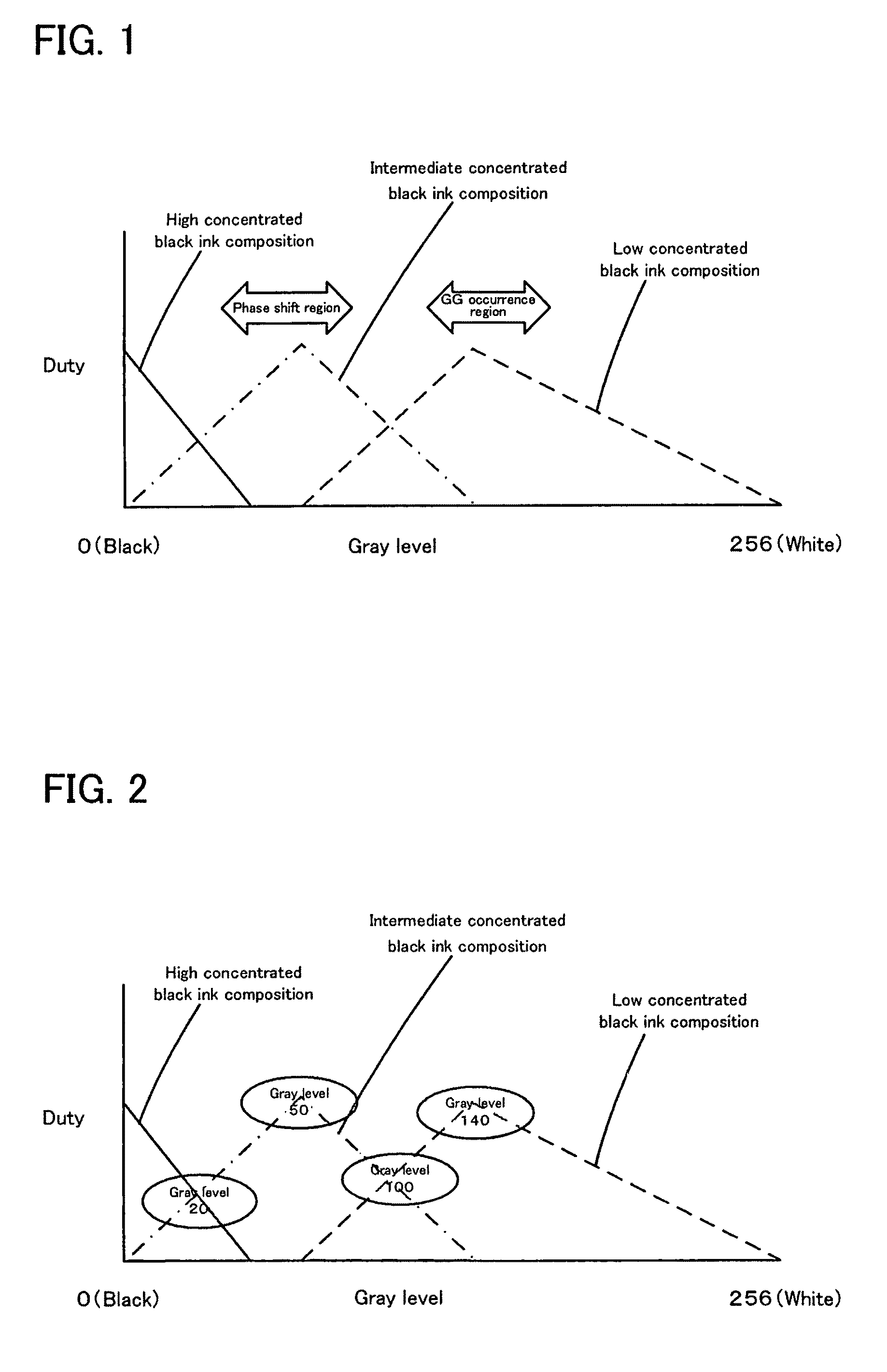

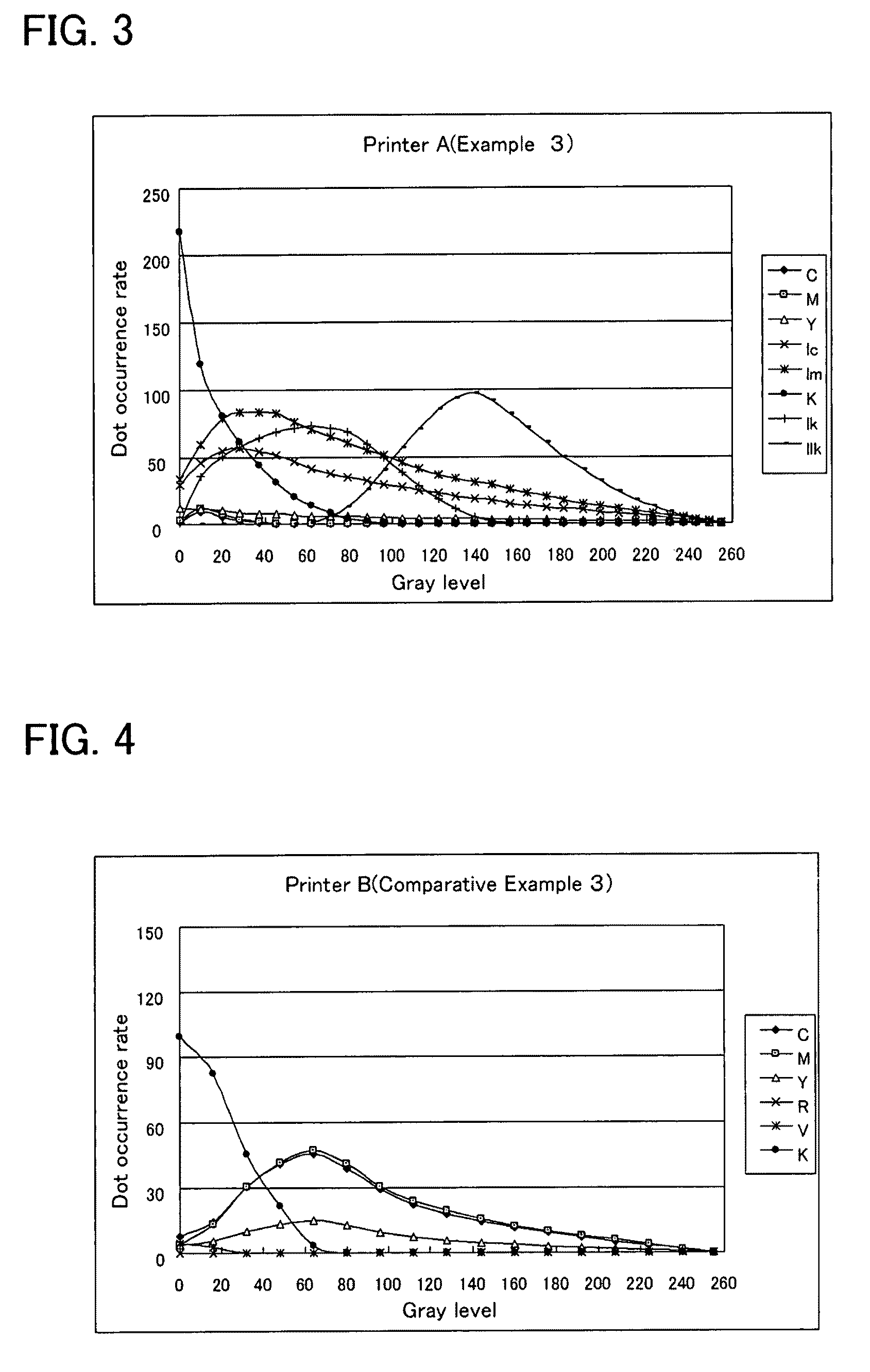

Aqueous ink composition and urethane resin composition for aqueous ink composition

An object of the present invention is to provide a black ink composition by which a recorded matter in which a fine surface defect on a recorded matter is effectively suppressed, can be obtained. For this object, the present invention is a black ink composition containing water, carbon black, and a water-soluble polyurethane resin, wherein when a content of carbon black is not less than 0.4% by weight and less than 1.5% by weight, a content of a solid matter of the water-soluble polyurethane resin is not less than 0.67-fold and not more than 2.5-fold a content of the carbon black and, when a content of the carbon black is less than 0.4% by weight, a content of a solid matter of the water-soluble polyurethane resin is not less than 7.5-fold a content of the carbon black.

Owner:SEIKO EPSON CORP

Polishing composition

ActiveUS20150315418A1High rateSuppression of surface defectsOther chemical processesSemiconductor/solid-state device manufacturingMetalMaterials science

[Problem] Provided is a polishing composition that can sufficiently maintain a high polishing rate for a barrier layer and an insulating film and suppress the occurrence of a surface defect such as erosion or fang.[Solution] Provided is a polishing composition which is used in the application to polish a polishing object having a barrier layer, a metal wiring layer and an insulating film, the polishing composition including abrasive grains, an oxidant, a metal corrosion inhibitor, a pH adjusting agent and water, in which an aspect ratio of abrasive grains is 1.22 or less and a ratio D90 / D10 of a diameter D90 of particles when a cumulative particle weight from the fine particle side reaches 90% of the total particle weight to a diameter D10 of particles when the cumulative particle weight from the fine particle side reaches 10% of the total particle weight of the entire particles is 1.5 or more in a particle size distribution of the abrasive grains determined by a laser diffraction scattering method.

Owner:FUJIMI INCORPORATED

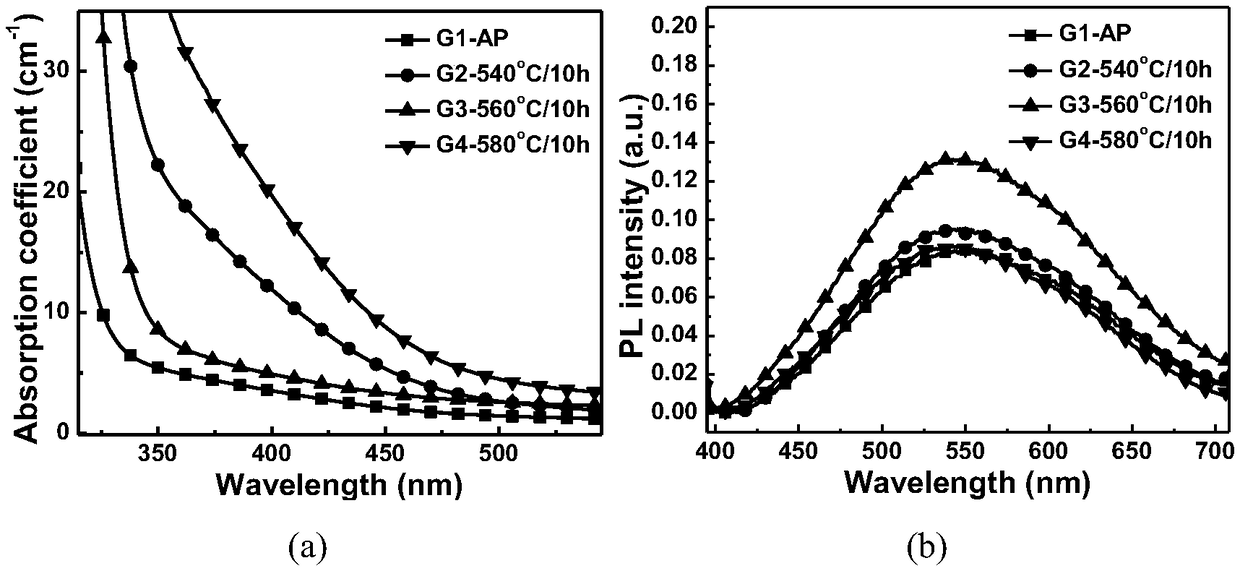

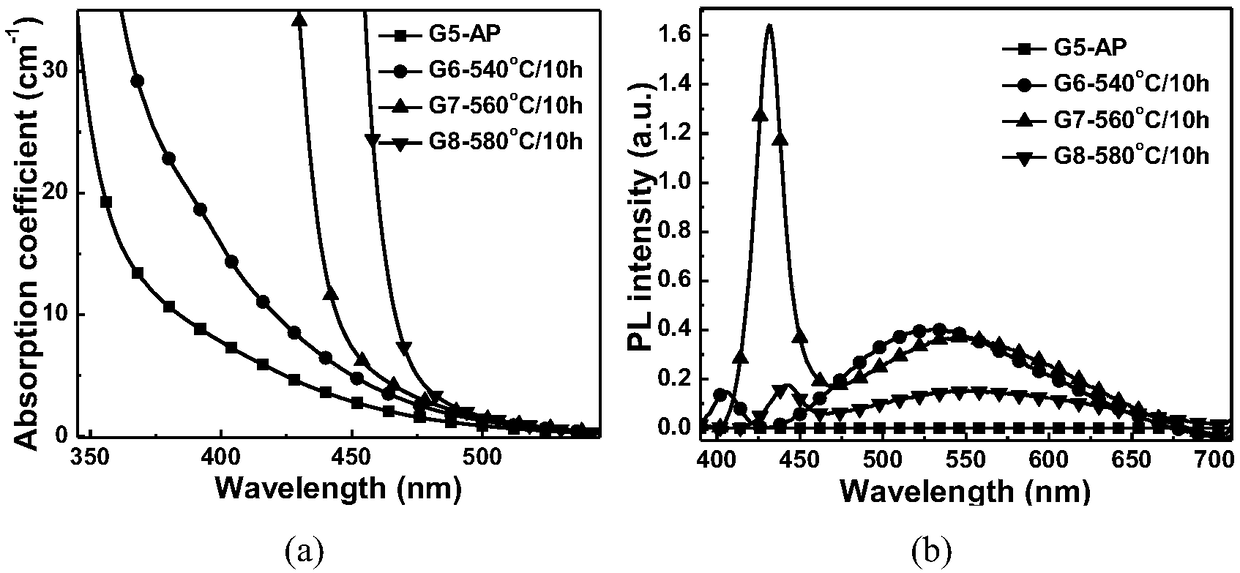

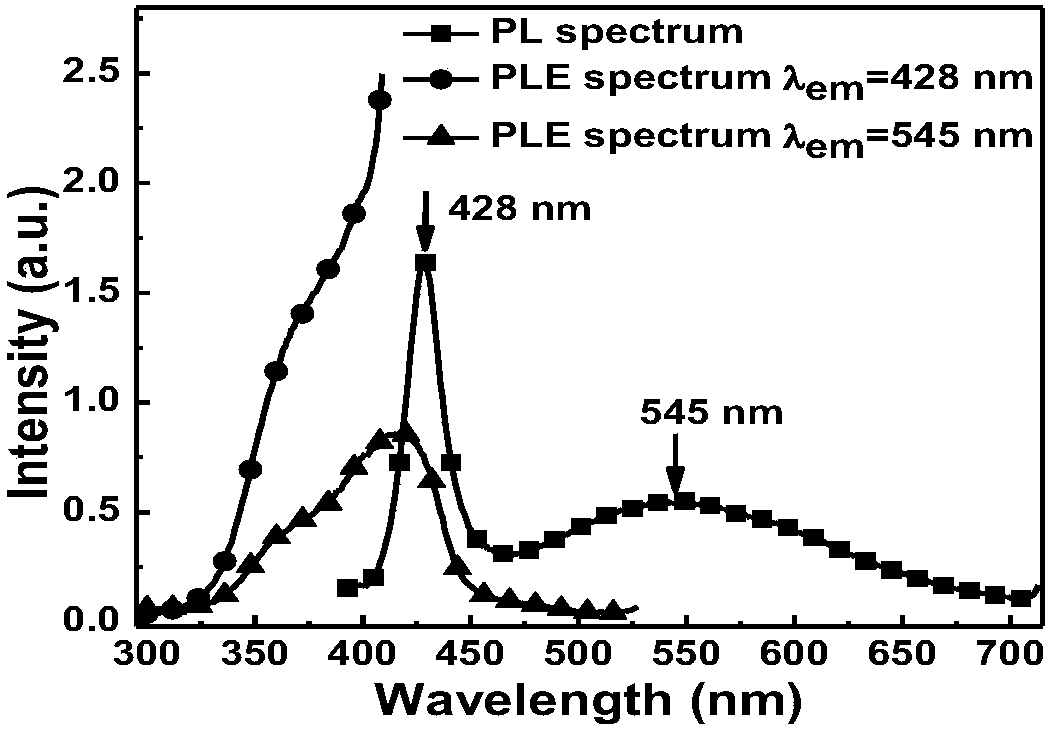

ZnSe quantum dot-doped glass and preparation method thereof

The invention provides ZnSe quantum dot-doped glass and a preparation method thereof. The ZnSe quantum dot-doped glass comprises the following components according to the molar percentage: 35-50 percent of SiO2, 0-15 percent of B2O3, 5-20 percent of Na2O, 0-10 percent of Li2O, 6-25 percent of ZnO and 4-9 percent of ZnSe. The preparation method of the ZnSe quantum dot-doped glass comprises the following steps: weighing a certain amount of raw materials according to the above molar percentage, fully and uniformly mixing, melting for 30-60 minutes at a temperature of 1300-1450 DEG C and then forming. The ZnSe quantum dot-doped glass and the preparation method thereof provided by the invention have the beneficial effects that a ZnSe quantum dot is successfully prepared in borosilicate for thefirst time, and the intrinsic luminescence wavelength of the ZnSe quantum dot is continuously adjustable within the range of 400-450 nm; the ZnSe quantum dot-doped glass prepared by the invention hasgood chemical stability and higher intrinsic luminescence and is a very promising luminescent material.

Owner:WUHAN UNIV OF TECH

Systems and methods for suppressing magnetically active surface defects in superconducting circuits

ActiveUS9437800B1Suppress noiseAppreciable magnetic noiseQuantum computersSolid-state devicesQuantum circuitUltraviolet lights

Systems and methods for suppressing magnetically active surface defects in superconducting quantum circuits are provided. A method includes providing one or more superconducting quantum circuits, and arranging the one or more superconducting quantum circuits in a hermetic enclosure capable of isolating the one or more superconducting circuits from ambient surroundings. The method also includes controlling an environment in the hermetic enclosure to suppress magnetically active surface defects associated with the one or more superconducting quantum circuits. In some aspects, the method further includes introducing an inert gas into the hermetic enclosure to passivate a surface of the one or more superconducting quantum circuits. In other aspects, the method further includes coating a surface of the one or more superconducting circuits with a non-magnetic encapsulation layer. In yet other aspects, the method further includes irradiating the one or more superconducting circuits using ultraviolet light.

Owner:WISCONSIN ALUMNI RES FOUND

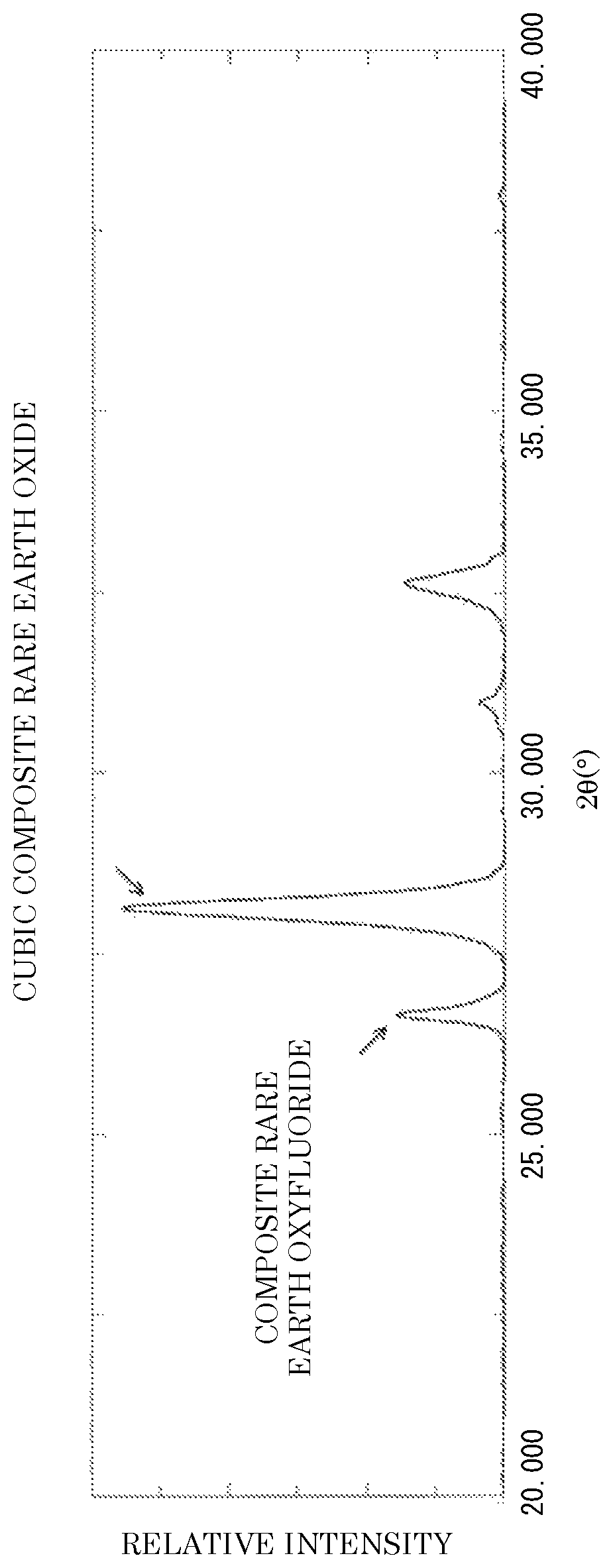

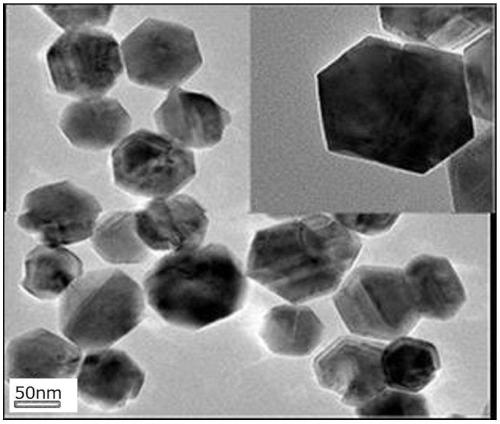

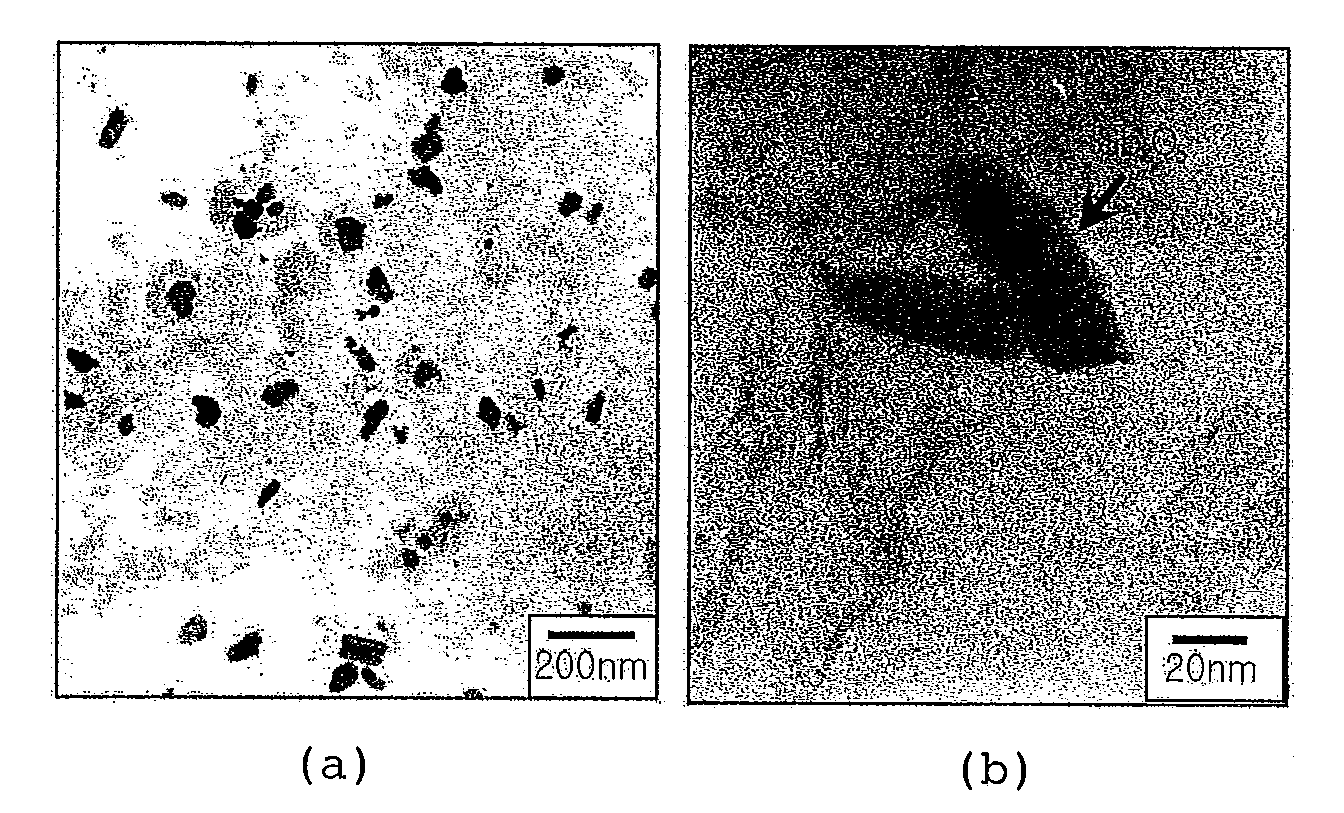

Cerium-based abrasive material and process for producing same

ActiveUS10717909B2High quality polishingHigh rateOther chemical processesCerium oxides/hydroxidesCeriumPhysical chemistry

A cerium-based abrasive that achieves a high polishing rate and suppresses the occurrence of surface defects such as scratches and pits and the deposition of the abrasive particles on the polished surface in surface polishing of glass substrates or the like, at low cost with a high production efficiency. The cerium-based abrasive includes a cubic composite rare earth oxide and a composite rare earth oxyfluoride, containing 95.0 to 99.5 mass % of total rare earth elements in terms of oxides, containing 54.5 to 95.0 mass % of cerium in terms of oxide, 4.5 to 45.0 mass % of lanthanum in terms of oxide, and 0.5 to 2.0 mass % of neodymium in terms of oxide relative to the total rare earth elements in terms of oxides, containing 0.5 to 4.0 mass % of fluorine atoms, and containing 0.001 to 0.50 mass % of sodium atoms relative to the total rare earth elements in terms of oxides.

Owner:RESONAC CORPORATION

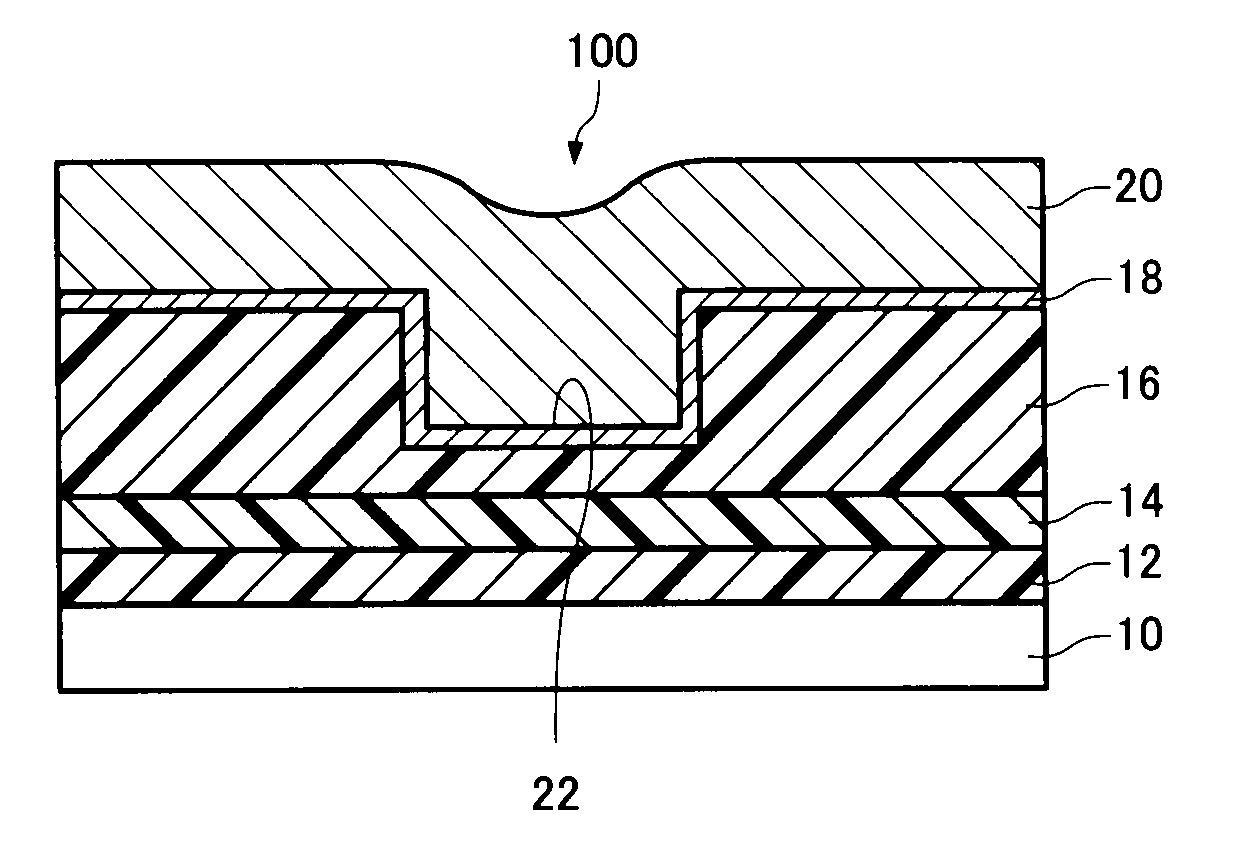

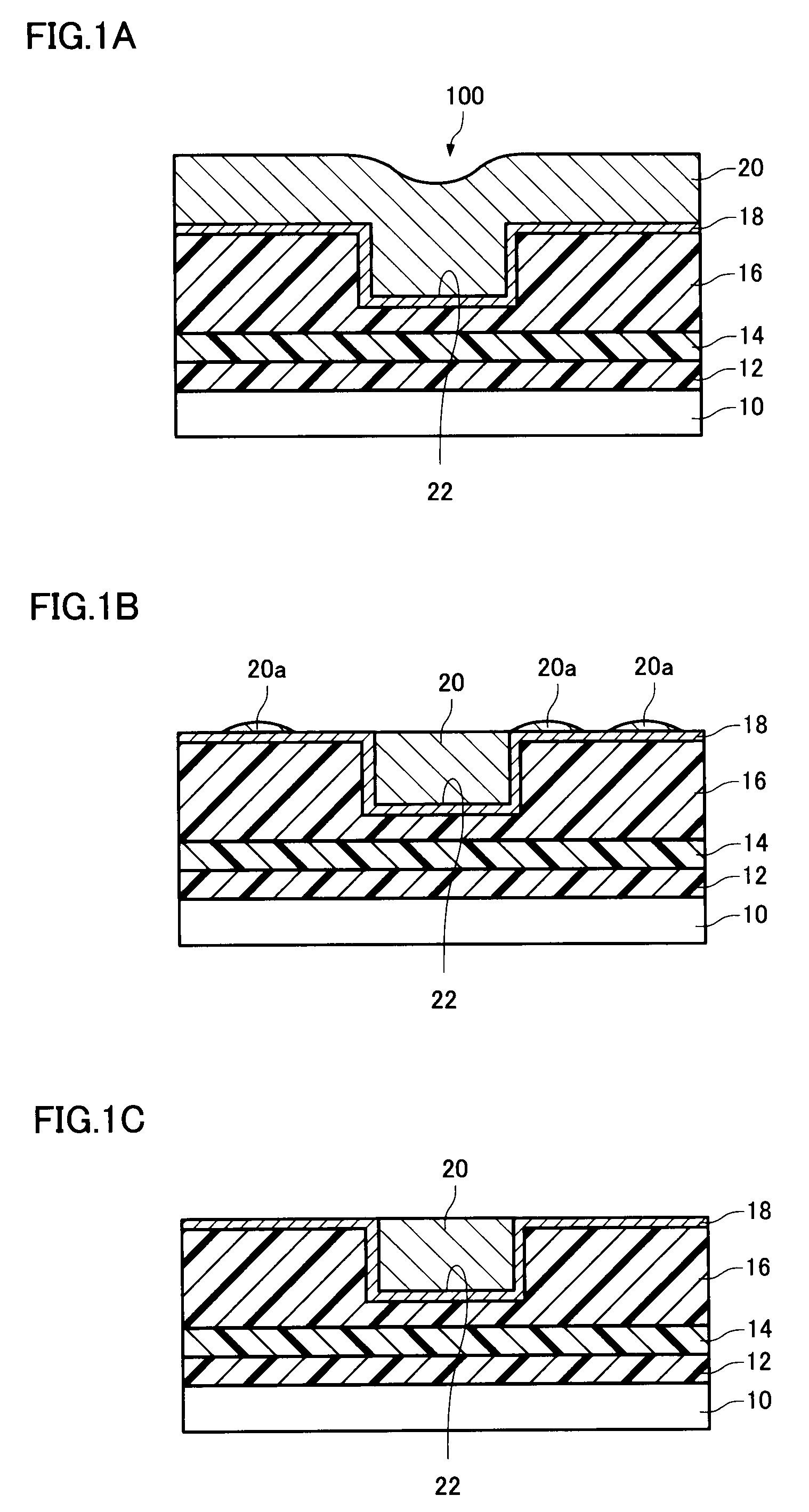

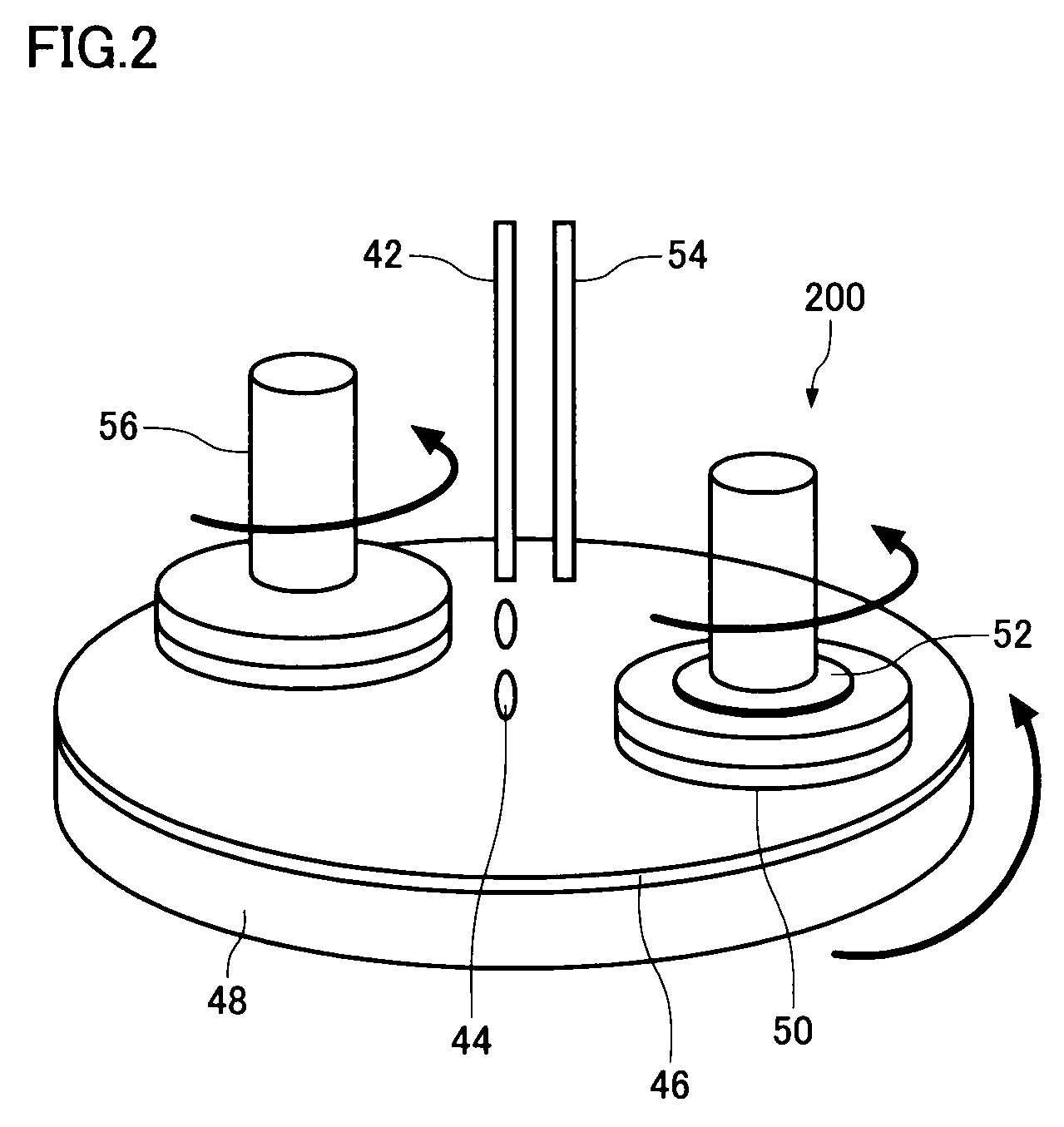

Chemical mechanical polishing aqueous dispersion, chemical mechanical polishing method, and chemical mechanical polishing aqueous dispersion preparation kit

ActiveUS8262435B2Suppression of surface defectsIncrease speedOther chemical processesSemiconductor/solid-state device manufacturingActive agentPhysical chemistry

A chemical mechanical polishing aqueous dispersion includes: (A) an amino acid, (B) abrasive grains, (C) a surfactant, (D) an oxidizing agent, and (E) ammonia, the ratio (WA / WD) of the content (WA) of the amino acid to the content (WD) of the oxidizing agent being 1.5 to 6.0, and the ratio (WE / WD) of the content (WE) of the ammonia to the content (WD) of the oxidizing agent being 0.05 to 0.6.

Owner:JSR CORPORATIOON

Steel sheet

ActiveCN109415785AHigh strengthGood molding effectFurnace typesHeat treatment furnacesChemical compositionMaterials science

Owner:NIPPON STEEL CORP

High-strength cold-rolled steel sheet, high-strength plated steel sheet, and methods for their manufacture

InactiveUS20110073218A1Decrease variations in hardness inside a steel sheetDeterioration in fixabilityHot-dipping/immersion processesFurnace typesHardnessMartensite

Owner:NIPPON STEEL CORP

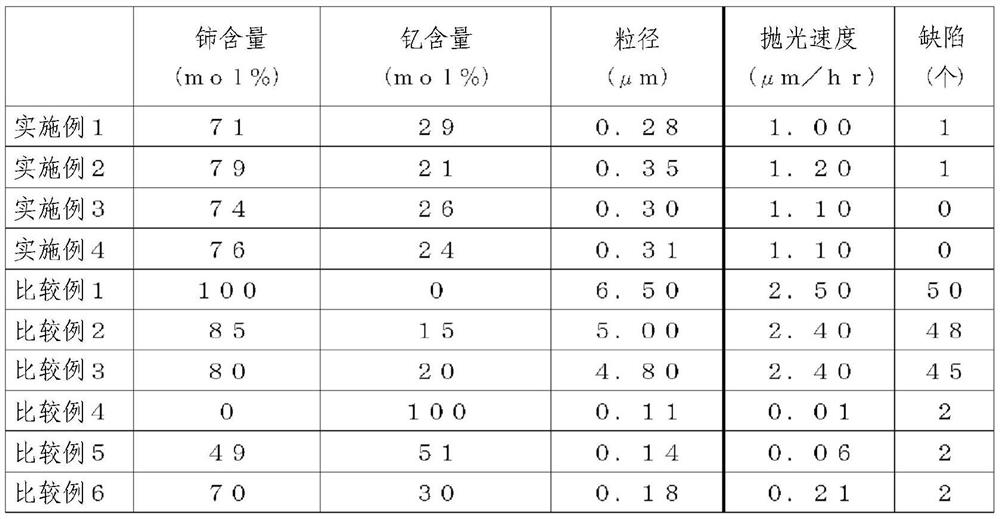

Polishing agent for synthetic quartz glass substrates, method for producing same, and method for polishing synthetic quartz glass substrate

ActiveCN112004906ASuppression of surface defectsDoes not slow down polishing speedOther chemical processesLapping machinesPhysical chemistryCerium

The present invention is a polishing agent for synthetic quartz glass substrates, which contains polishing particles and water, and which is characterized in that: the polishing particles are composite oxide particles of cerium and yttrium; and the cerium content in the polishing particles is from 71 mol% to 79 mol% (inclusive). Consequently, the present invention is able to provide a polishing agent for synthetic quartz glass substrates, which is capable of sufficiently reducing the occurrence of defects in the surface of a synthetic quartz glass substrate due to polishing without lowering the polishing rate.

Owner:SHIN ETSU CHEM IND CO LTD

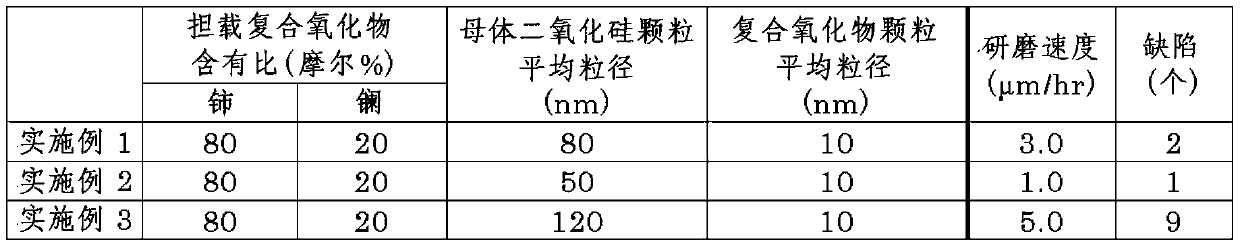

Polishing material for synthetic quarts glass substrate and method for polishing synthetic quarts glass substrate

ActiveCN109104866ASuppression of surface defectsImprove productivityOther chemical processesSemiconductor/solid-state device manufacturingRare-earth elementCerium(IV) oxide

The present invention is a polishing material for synthetic quarts glass substrates which comprises abrasive grains and water, characterized in that the abrasive grains comprise ceria particles as base particles and, fixed to the surfaces of the base particles, particles of a composite oxide including cerium and at least one rare-earth element selected from among trivalent rare-earth elements excluding cerium. Due to this, a polishing material for synthetic quarts glass substrates which has a high polishing rate and can be sufficiently inhibited from causing polishing defects is provided.

Owner:SHIN ETSU CHEM CO LTD

Synthetic quartz glass substrate polishing agent, production method therefor, and synthetic quartz glass substrate polishing method

ActiveCN110546233ASuppression of surface defectsImprove productivityOther chemical processesLapping machinesRare-earth elementSilica particle

The present invention provides a synthetic quartz glass substrate polishing agent comprising polishing particles and water, and is characterized in that the polishing particles comprise silica particles as base particles, on the surface of which are supported particles of a composite oxide of cerium and at least one rare-earth element selected from among trivalent rare-earth elements excluding cerium. The synthetic quartz glass substrate polishing agent has a high polishing rate and is capable of reducing the occurrence of polishing defects to a sufficient degree.

Owner:SHIN ETSU CHEM IND CO LTD

Wire rod having good superior surface properties, high strength, and high toughness, and a method for manufacturing same

InactiveUS20140027025A1Improve functionalityHigh strengthFurnace typesHeat treatment furnacesWire rodHigh intensity

Provided is a wire rod having high strength and high toughness, which suppresses the generation of surface oxide and has superior surface properties through uniform oxide formation, and to a method for manufacturing same. For this purpose, a wire rod comprising 0.005˜ to 0.02 wt. % of Sb, having superior surface properties, high strength and high toughness, and a method for manufacturing same are provided.

Owner:POHANG IRON & STEEL CO LTD

Steel sheet

ActiveUS11365465B2Good formabilityHigh strengthFurnace typesHeat treatment furnacesChemical compositionMaterials science

A steel sheet includes a predetermined chemical composition, and includes a steel microstructure represented by, in an area ratio, ferrite: 5% to 80%, a hard microstructure constituted of bainite, martensite or retained austenite or an arbitrary combination of the above: 20% to 95%, and a standard deviation of a line fraction of the hard microstructure on a line in a plane perpendicular to a thickness direction: 0.050 or less in a depth range where a depth from a surface when a thickness of a steel sheet is set as t is from 3t / 8 to t / 2.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com