Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Fast polishing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polishing composite for silicon wafer polishing

InactiveCN101451046AFast polishing rateReduce surface defectsSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesIonEther

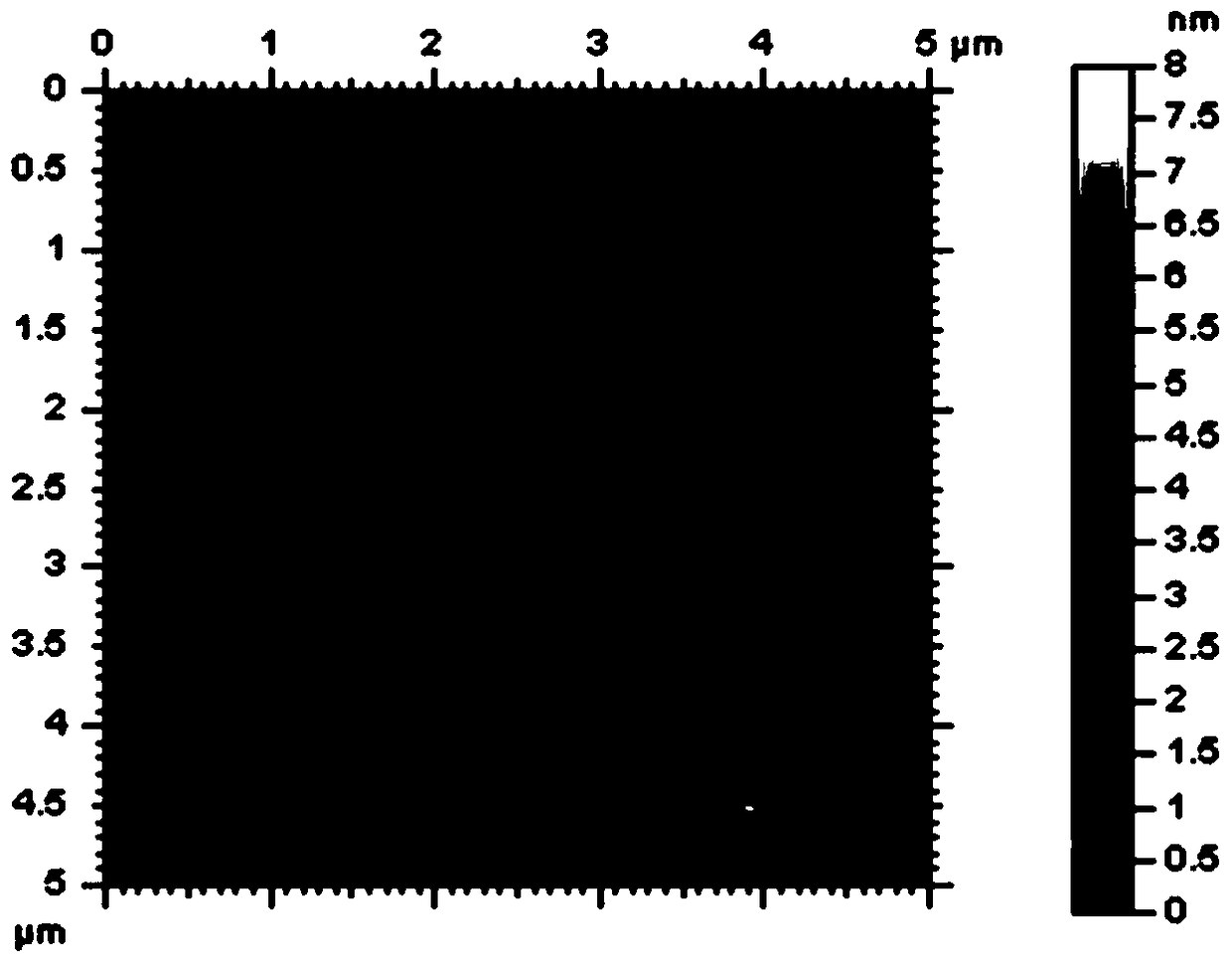

The invention discloses a silicon wafer polishing composition in the field of chemical mechanical polishing (CMP). The polishing composition comprises silica, a polishing interface control agent, a surfactant, a chelating agent, an alkaline compound and water, wherein the particle diameter of the silica in the polishing composition is between 1 and 200 nm; the content of the silica is between 0.05 and 50 weight percent; the polishing interface control agent is polyhydroxy cellulose ether; the content of the polishing interface control agent is between 0.001 and 10 weight percent; the content of the surfactant is between 0.001 and 1 weight percent; the content of the chelating agent is between 0.001 and 1 weight percent; the content of the alkaline compound is between 0.001 and 10 weight percent; the balance being water; and the PH value is between 8.5 and 12. The polishing interface control agent can control a polishing interface between abrasive particles and a polishing object in the chemical mechanical polishing process in order that the surface of the polished silicon wafer is more perfect. The polishing composition is in particular suitable for polishing the silicon wafer and has the advantages of rapid polishing speed, little surface defect and high planeness; and the polished silicon wafer has few metal ion contaminants and is easy to clean.

Owner:TSINGHUA UNIV +1

Polishing composition capable of improving silicon wafer polishing accuracy and preparation method thereof

InactiveCN102408837AOvercome precisionOvercome CorrosivityPolishing compositions with abrasivesPhysical chemistrySilicon dioxide

The invention discloses a polishing composition capable of improving silicon wafer polishing accuracy and a preparation method thereof, and belongs to the technical field of chemical and mechanical polishing. The polishing composition consists of the following components in percentage by weight: 0.05-50 percent of functionalized silicon dioxide sol, 0.001-1 percent of oxidant, 0.001-5 percent of chelating agent, 0.001-10 percent of alkaline compound, 0.001-1 percent of surfactant and the balance of de-ionized water, wherein the functionalized silicon dioxide sol is aminated silicon dioxide sol. After a silicon wafer is polished by the polishing component, the surface accuracy of the wafer is higher, the surface corrosion is less, the polishing speed is high, and the flatness is high.

Owner:TSINGHUA UNIV +2

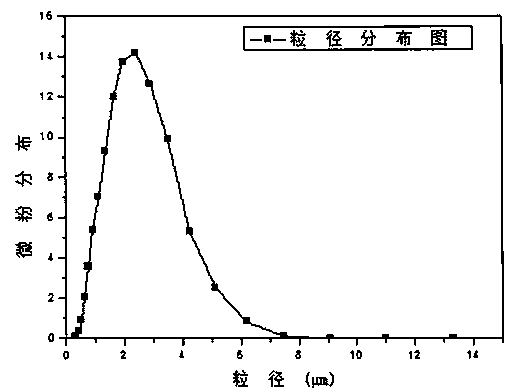

Lanthana cerium oxyfluoride rare earth polishing liquid and preparation method thereof

ActiveCN102337086AHigh suspension stabilityFast polishing rateAqueous dispersionsChemistrySilicon oxide

The invention provides a lanthana cerium oxyfluoride rare earth polishing liquid and a preparation method thereof. The lanthana cerium oxyfluoride rare earth polishing liquid contains lanthana cerium oxyfluoride polishing powder, a dispersing agent and a pH value regulating agent, based on water as a carrier; the content of the dispersing agent is 0.5-1wt% of the total mass of the polishing liquid, the amount of the pH value regulating agent is based on the fact that the pH value of the polishing liquid reaches 8.5-10.0 as a reference, the mass solid content of the polishing liquid is 25-45wt%, the mass of cerium accounts for 60-80wt% of total mass of lanthana and cerium, and the mass fraction of fluoride is 3-5wt% of total mass of lanthana cerium oxyfluoride. The lanthana cerium oxyfluoride rare earth polishing liquid has the performance characteristics of high suspending stability, rapid polishing rate, less scratch and high abrasion resistance on silicon oxide glass, and the particle size of corresponding rare earth particle is small; and the pH value regulating agent and the organic dispersing agent are added, thereby delaying the deposition of an abrasive material in the material liquid, improving the polishing rate of the polishing liquid on a glass substrate and reducing the scratch.

Owner:上海华明高纳稀土新材料有限公司

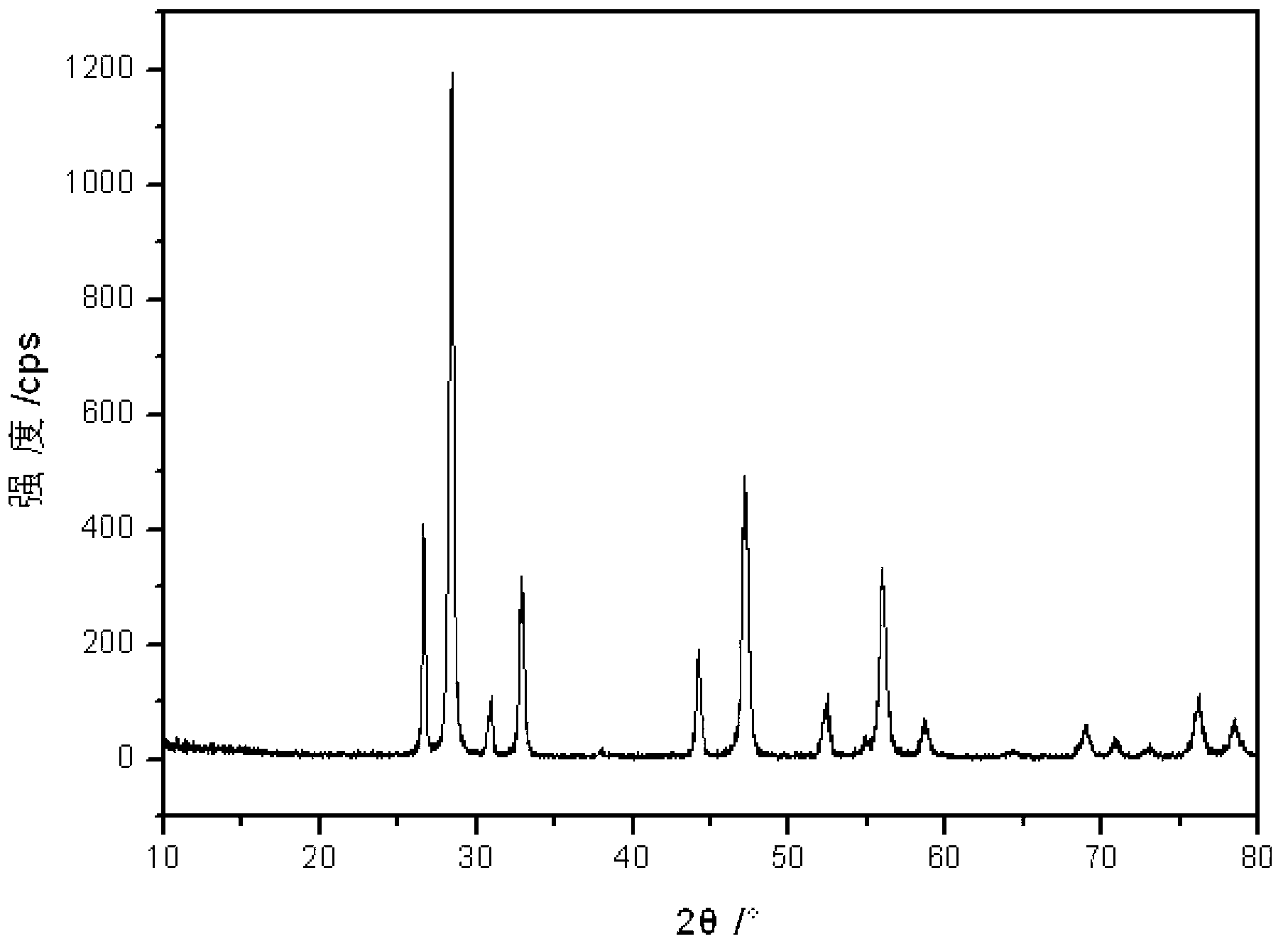

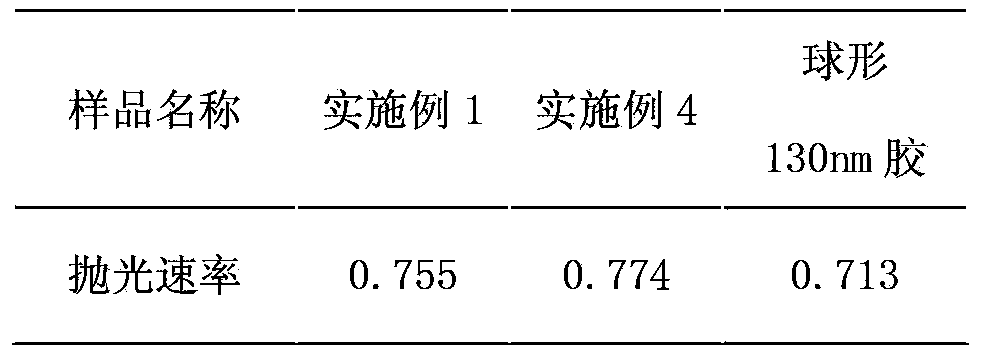

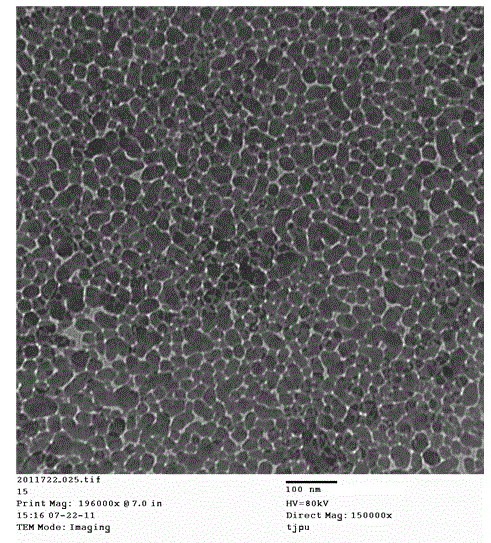

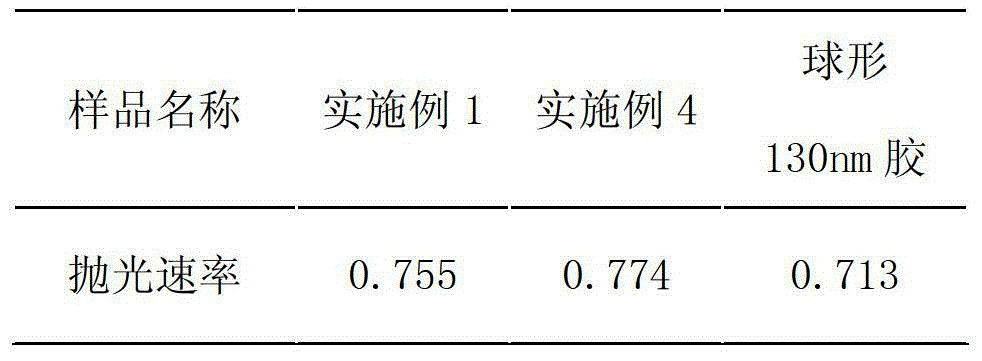

Preparation method of nonspherical nanometer-scale silica sol

InactiveCN102390837AImprove stabilityImprove polishing rateSilicaNanotechnologyCrystallographySilicic acid

The invention provides a preparation method of nonspherical nanometer-scale silica sol. The preparation method comprises the following steps of: with 2-5 percent of small-size nonspherical silica sol as seed crystals, dropwise adding a 5-40% mixed base solution, adjusting the pH value to 10, stirring and heating to 90-100 DEG C; and then dropwise adding active silicic acid to the system, maintaining a constant liquid level by adopting a heating concentration method, reacting for 10-40h and dropwise adding the mixed base solution to keep the pH value of the reaction system to 9-11 in the reaction peroid. The preparation method of the nonspherical nanometer-scale silica sol has the beneficial effects that: the nonspherical silica sol with grain size of 30-50nm is prepared by using the small-size nonspherical silica sol as the seed crystals, therefore the stability is good; the preparation method is suitable for chemically mechanical polishing and high polishing speed, and the polishing speed is accelerated by more than 10 percent compared with the polishing speed of the spherical silica sol with large size (130nm).

Owner:JIANGSU TIANHENG NANO SCI & TECH

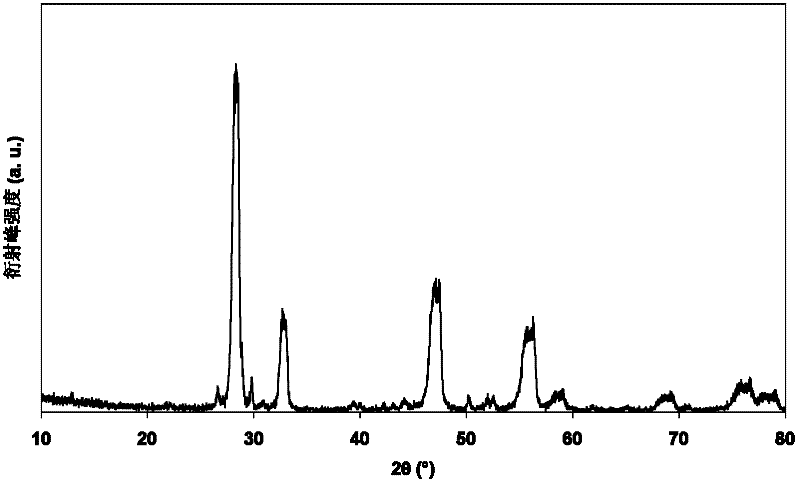

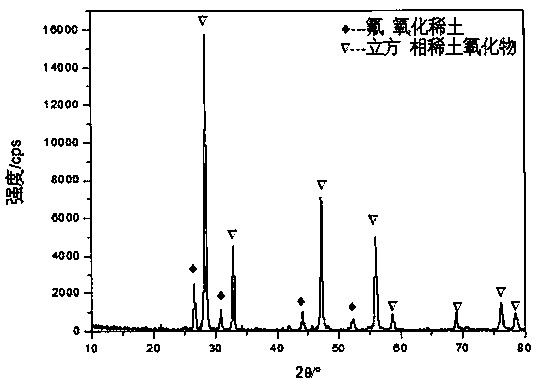

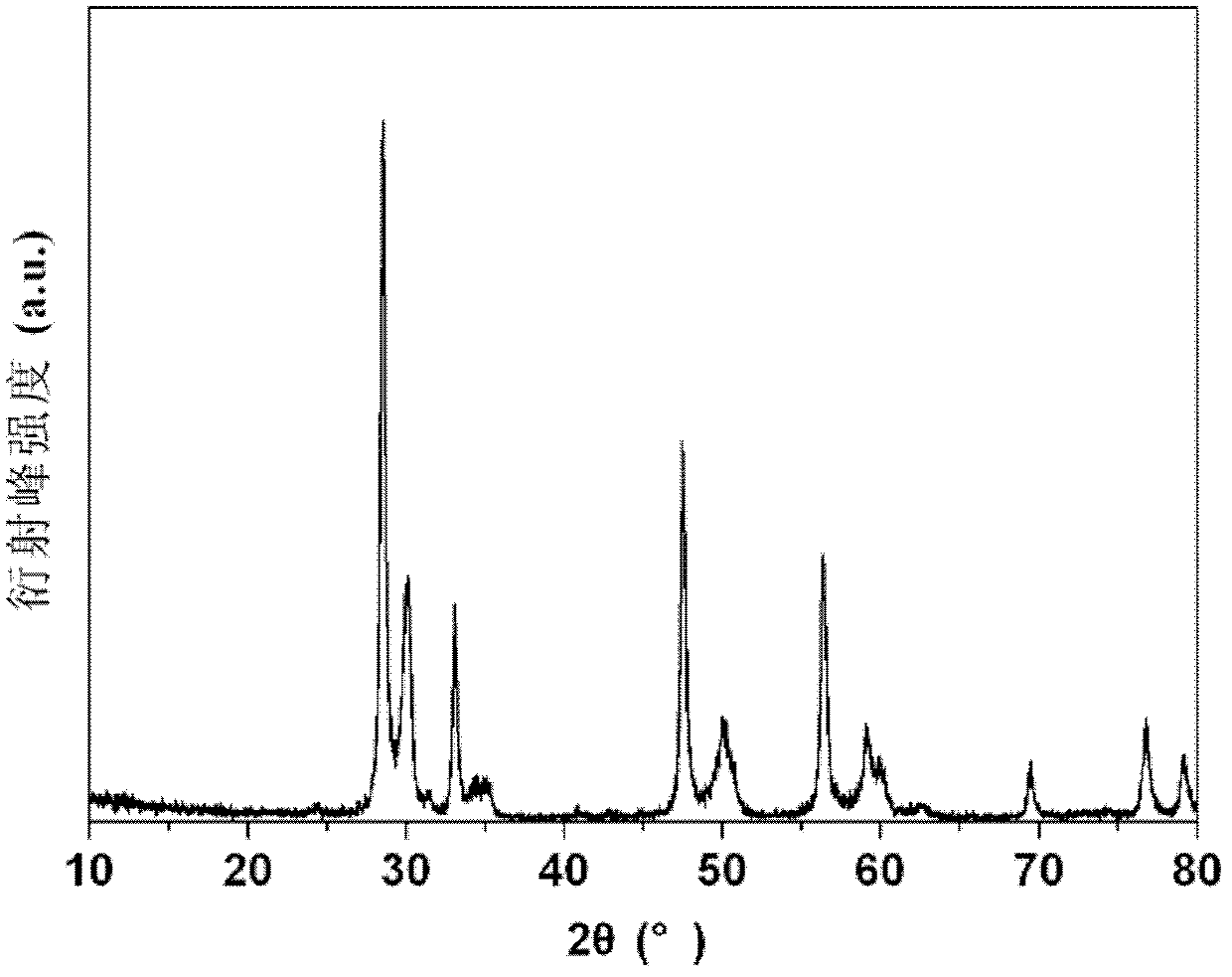

Rare earth polishing material and preparation method thereof

InactiveCN102585708AGood suspensionImprove wear resistancePolishing compositions with abrasivesRare earthSolid solution

The invention aims to disclose a rare earth polishing material and a preparation method thereof. The rare earth polishing material comprises the following components by weight part: 65 to 98 parts of rare earth polishing powder, 1 to 5 parts of dispersant, 5 to 30 parts of suspension, and 0.05 to 0.3 part of pH regulator. Compared with the conventional product, the invention has the advantages as follows: the polishing powder is a crystalline homogeneous solid solution composed of oxyfluoride rare earth and cubic phase rare earth oxide; the suspension property of the prepared rare earth polishing material is good, and the polishing powder product is good in wear resistance, high in polishing speed and easy to control in polishing accuracy; and the product is good in homogeneity, high in production efficiency and low in cost, is free from contamination, and is applicable to surface polishing of precise devices in the electronic information industry, such as integrated circuits, two-dimensional displays and optical glass, so as to achieve the purposes of the invention.

Owner:上海华明高纳稀土新材料有限公司

Metal polish liquid, and prepartion method

InactiveCN101092540AImprove concentrationFast polishing ratePolishing compositions with abrasivesGranularityMetal

This invention relates to a metal polishing solution, which is composed of: abrasive material 10-50 wt. %, surfactant 0.1-1 wt. %, pH regulator 1-5 wt. %, chelating agent 0.1-1 wt. %, and deionized water as balance. The granularity of the abrasive material is 15-100 nm. The pH value of the metal polishing solution is 8-12. The metal polishing solution is prepared by: filtering and purifying the above components of the metal polishing solution, introducing the components into a container through a mass flowmeter under negative pressure in a class 1000 clean room, and stirring uniformly. The metal polishing solution has such advantages as high polishing speed, high smoothness, small diameters, and little damage to wafer surface, wasy cleaning, no toxicity, no odor, no corrosion, simple process and easy operation.

Owner:天津晶岭电子材料科技有限公司

Finishing polish liquid in use for silicon wafer

InactiveCN101092541ASmall particle sizeNo damageSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesWater solubleHYDROSOL

This invention discloses a fine polishing solution for silicon wafer. The fine polishing solution is composed of: composite abrasive material 5-30 wt. %, surfactant 0.1-1 wt. %, chelating agent 0.1-1 wt. %, pH regulator 1-6 wt. %, and deionized water as balance. The composite abrasive material is composed of water-soluble silica sol and Al2O3 hydrosol or CeO2 hydrosol at a weight ratio of 4:1. The composite abrasive material has particle sizes of 10-60 nm. The fine polishing solution has such advantages as small particle sizes of the composite abrasive material, no damage to wafer surface after polishing, high polishing speed, high fluidity, and no sodium ion contamination (by using organic alkali as the pH regulator). By utilizing nonionic surfactant, the composite abrasive material and the reaction product can be easily removed from wafer surface.

Owner:天津晶岭电子材料科技有限公司

Sapphire polishing solution and preparation method thereof

InactiveCN108359384AHigh hardnessFast polishing ratePolishing compositions with abrasivesBall millSapphire

The invention discloses a sapphire polishing solution. The sapphire polishing solution is prepared from the following raw materials: a composite abrasive, a pH (Potential of Hydrogen) regulator, a dispersant and a surfactant, wherein the composite abrasive is prepared by adopting the following technology: adding an abrasive, silica sol and the dispersant in a wet ball mill, regulating pH value tobe 2.5 to 8.5, and carrying out ball milling, thus obtaining a prefabricated material A; adding water for diluting the prefabricated material A into a dispersing solution of which the mass percent concentration is 2 to 7 percent, adding metal salt under room temperature, rising the temperature to 80 to 100 DEG C, stirring for 0.5 to 1 hour, then dropwise adding silicic acid for promoting growth ofparticle size, regulating the pH value to be 8 to 12, and aging, thus obtaining a prefabricated material B; concentrating the prefabricated material B, thus obtaining the composite abrasive. The sapphire polishing solution disclosed by the invention has high polishing efficiency on sapphire, cannot scratch the sapphire, and is simple and convenient in preparation technology and lower in cost.

Owner:HEFEI NORMAL UNIV

Polishing liquid for silica dioxide medium and preparation method thereof

InactiveCN101096573AFast polishing rateImprove flatnessAqueous dispersionsPolishing compositions with abrasivesSilicon dioxideIon

The invention discloses a polishing liquid for silica dioxide medium, which comprises the following parts: 10-50% abradant, 0.01-0.6% soxidant, 1-6% pH adjusting agent, 0.01%-15% chelant and 28.4-88.98% deionized water, wherein pH value range of polishing liquid is 11-12, and the grain diameter is 15nm-100nm. The preparing method comprises the following steps: taking the material; filtering; purifying; mixing homogeneously. The invention doesn't corrode and pollute the device, which has the simple technology and the low cost.

Owner:天津晶岭电子材料科技有限公司

Polishing liquid for germanium wafer and preparation method thereof

InactiveCN101081965AImprove concentrationFast polishing ratePolishing compositions with abrasivesSURFACTANT BLENDIon

The germanium wafer polishing fluid consists of abradant 10.0-50.0 wt%, surfactant 0.1-1.0 wt%, pH value regulator 1.0-5.0 wt%, chelating agent 0.1-1.0 wt% and deionized water for the rest; and has pH 8-12, and grain size of 15-100 nm. It is prepared through filtering all the ingredients, and mixing via stirring under the action of negative pressure in a clean condition. The germanium wafer polishing fluid has the advantages of high polishing speed, high polished flatness, small grain size causing less surface damage of wafer, simple preparation process and easy use.

Owner:天津晶岭电子材料科技有限公司

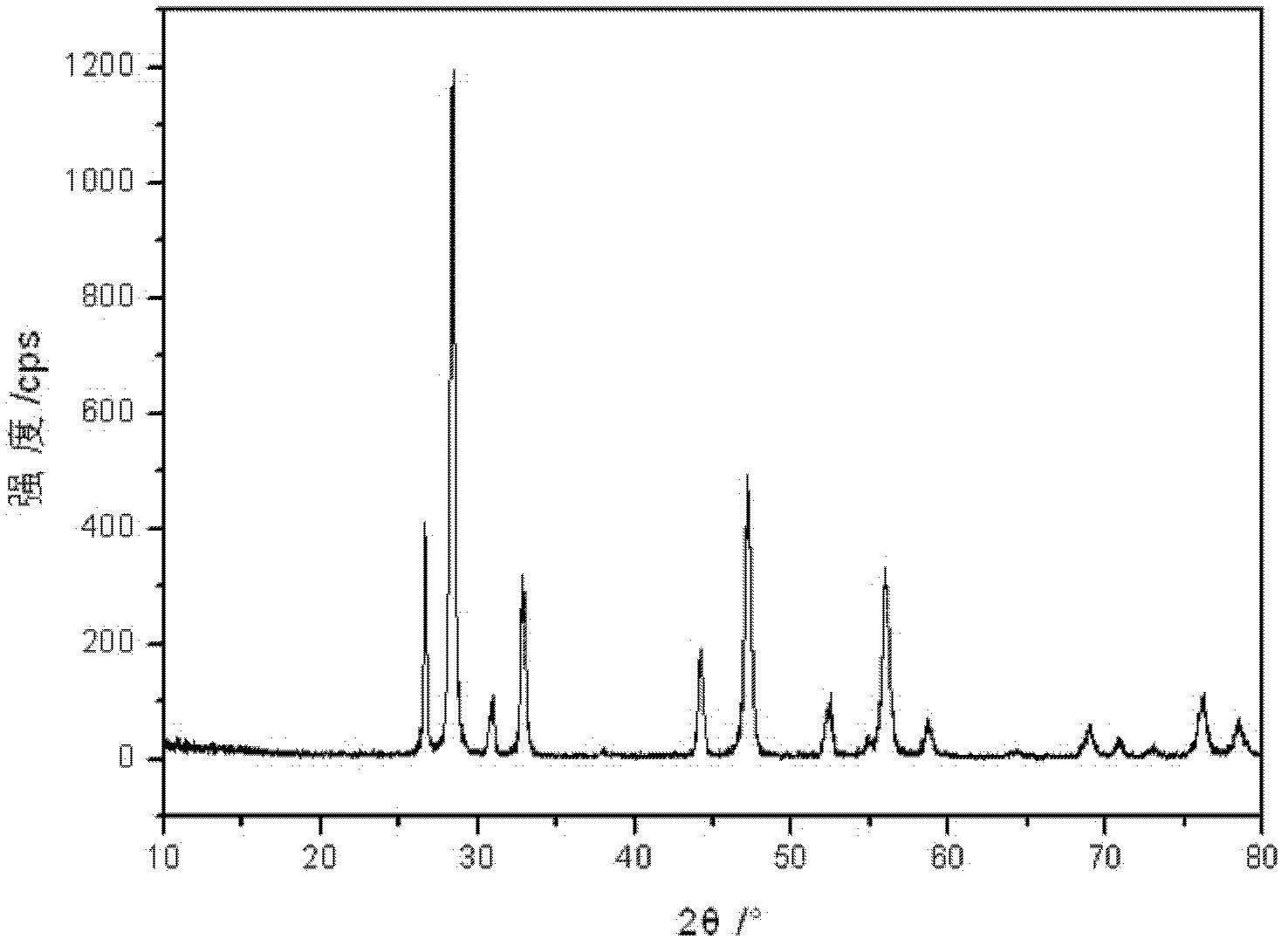

Preparation method of rear-earth polishing powder

InactiveCN103288119AImprove wear resistanceGuaranteed sizeRare earth metal compoundsPolishing compositions with abrasivesRare earthSlurry

The invention discloses a preparation method of rear-earth polishing powder. The preparation method comprises the following steps of: (1), mixing rare earth carbonate with water, and adding a mineralizer for ageing to obtain alkaline type rare earth carbonate slurry; (2), adding a hydrofluoric acid solution to the alkaline type rare earth carbonate slurry for stirring for 1 hour to 3 hours and dehydrating to obtain rear-earth carbonate; (3), roasting the rear-earth carbonate to obtain rear-earth oxyfluoride; and (4), crushing and classifying the rear-earth oxyfluoride to obtain rear-earth polishing powder. The preparation method of the rear-earth polishing powder disclosed by the invention can be used for obtaining polishing powder of a special crystal form, so that the dimension size and morphology uniformity of the polishing powder particles are ensured without generating free fluorine ions and fluoride that affect the polishing precision and the polishing speed, and therefore, the crystallization degree is high; moreover, the product polishing powder is good in wear resistance, quick in polishing speed and easily controllable in polishing precision. Besides, the product is good in uniformity, high in production efficiency, low in cost, free of pollution and suitable for surface polishing machining of electronic information industrial precise apparatuses including an integrated circuit, a panel display, optical glass and the like.

Owner:上海华明高纳稀土新材料有限公司

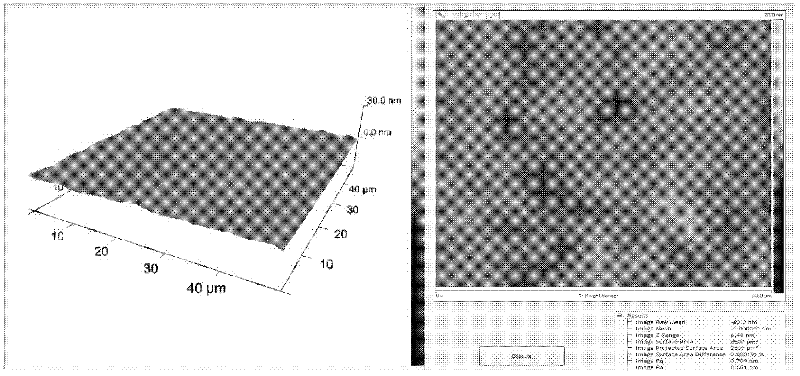

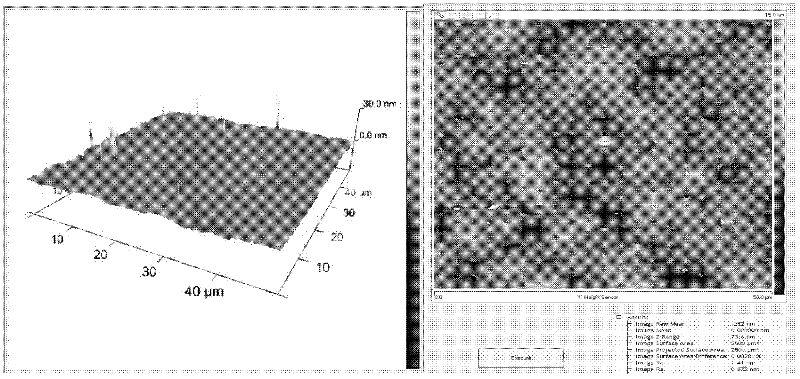

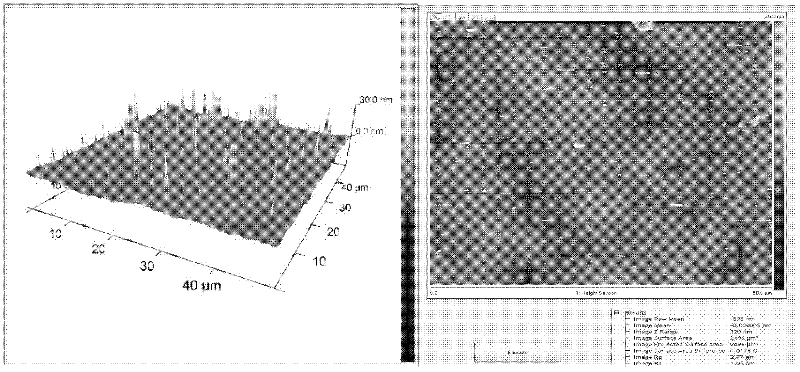

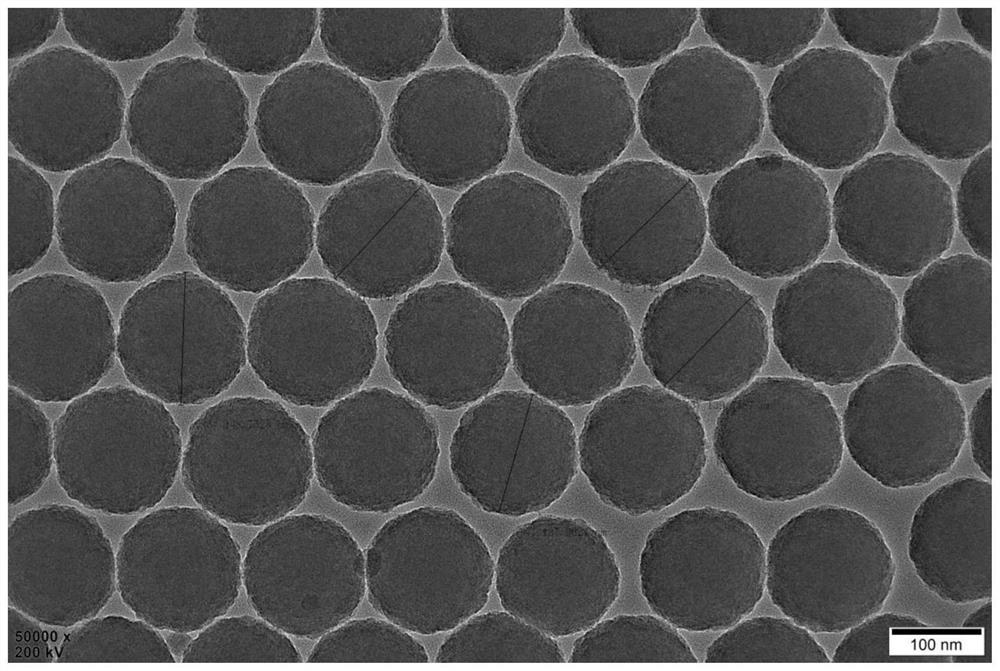

Preparation method and application of silica sol with irregular shape

The invention provides a preparation method of silica sol with an irregular shape. The silica sol with the irregular shape is silicon dioxide sol particles with irregular shapes, in a state of the aggregation growth of 2-3 particles, and when the silicon dioxide sol particles are in linear shapes or bent shapes, the long axes of each of the particle diameters of the particles subjected to aggregation growth can achieve 30-60 nm. The preparation method comprises the following steps: with spherical silica sol with a concentration of 2-3.5% and a small particle diameter of 10 nm or 15 nm as mother liquor, adding the mother liquor in a reactor; adding a soluble divalent anion salt solution or trivalent cation salt solution in the mother liquor, and uniformly stirring; then adjusting the pH value to 9-10 by inorganic base with a concentration of 5% or 10%; stirring and heating to boil; then dripping active silicic acid in the reaction system, meanwhile, dripping an inorganic base solution to keep the pH value of the reaction system to be in a range from 9 to 10; and after the dripping is concluded, cooling the reaction product to a room temperature. The preparation method provided by the invention has the technical benefits of being simple in process and good in colloidal stability.

Owner:阳江市惠尔特新材料科技有限公司

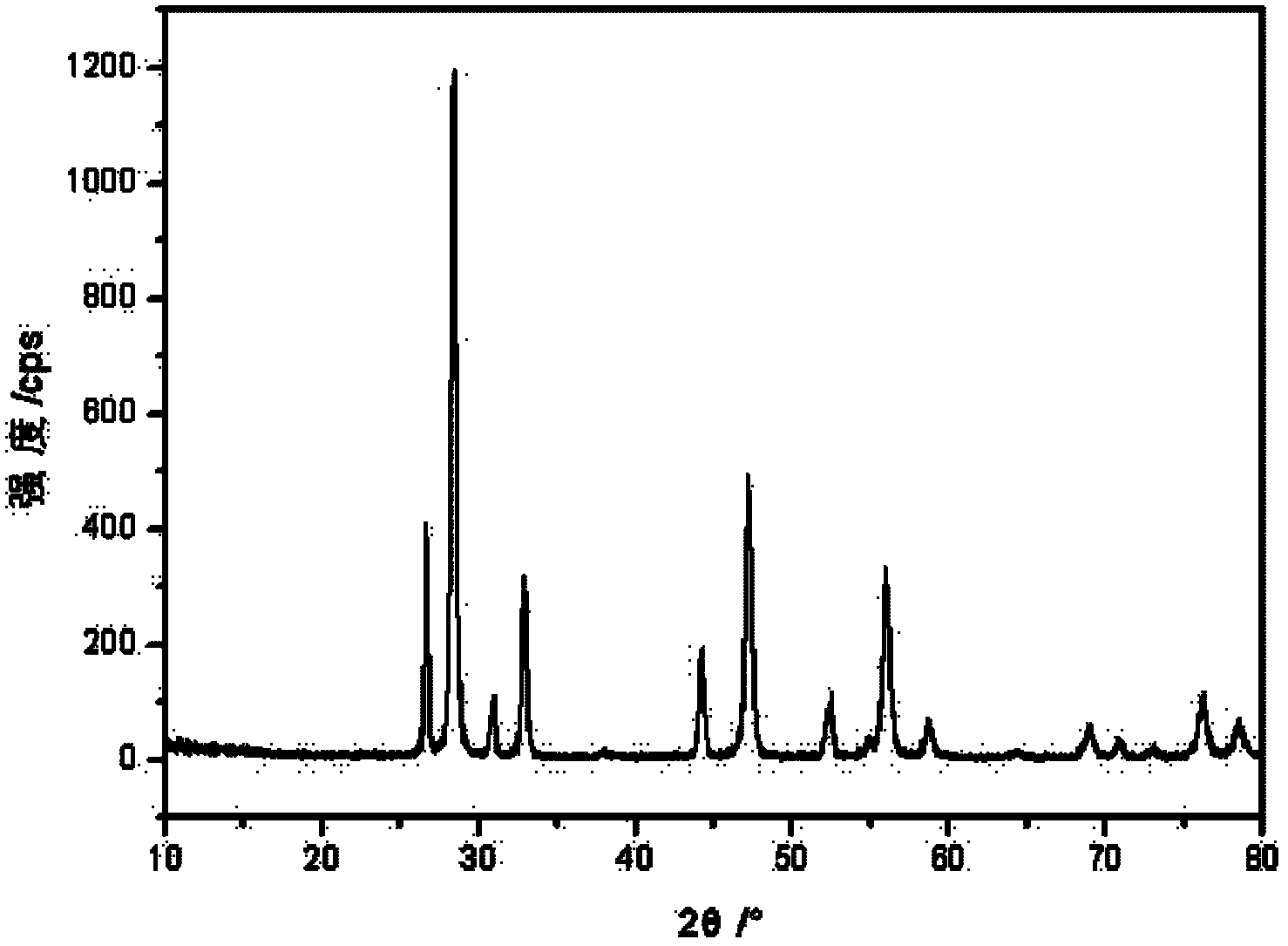

Precision-type mischmetal polishing powder and preparation method thereof

ActiveCN103013444AImprove wear resistanceUniform grain sizeOther chemical processesPolishing compositions with abrasivesFlat panel displayIntegrated circuit

The invention provides precision-type mischmetal polishing powder and a preparation method thereof. The precision-type mischmetal polishing powder is a uniform solid solution composed of an oxyfluoride-crystal form rare earth and a cubic-phase rare-earth oxide. Compared with the existing products, the precision-type mischmetal polishing powder has the advantages that 1, through ball-milling crushing and utilization of a homogenization assistant, a rare-earth carbonate precursor comprises uniform crystal grains; a fluorination reaction is uniform and complete; dissociative fluorinions and fluorides influencing a polishing precision and a polishing rate are not produced; and a high crystallization degree is obtained; 2, wear resistance is good; a polishing rate is fast; and a polishing precision can be controlled easily; 3, product uniformity is good; production efficiency is high; pollution is not produced; and a cost is low; and 4, the precision-type mischmetal polishing powder is suitable for surface polishing processing of precision components such as integrated circuits, flat panel displays and optical glass in the electronic information industry and realizes the purpose of the invention.

Owner:包头华明高纳稀土新材料有限公司

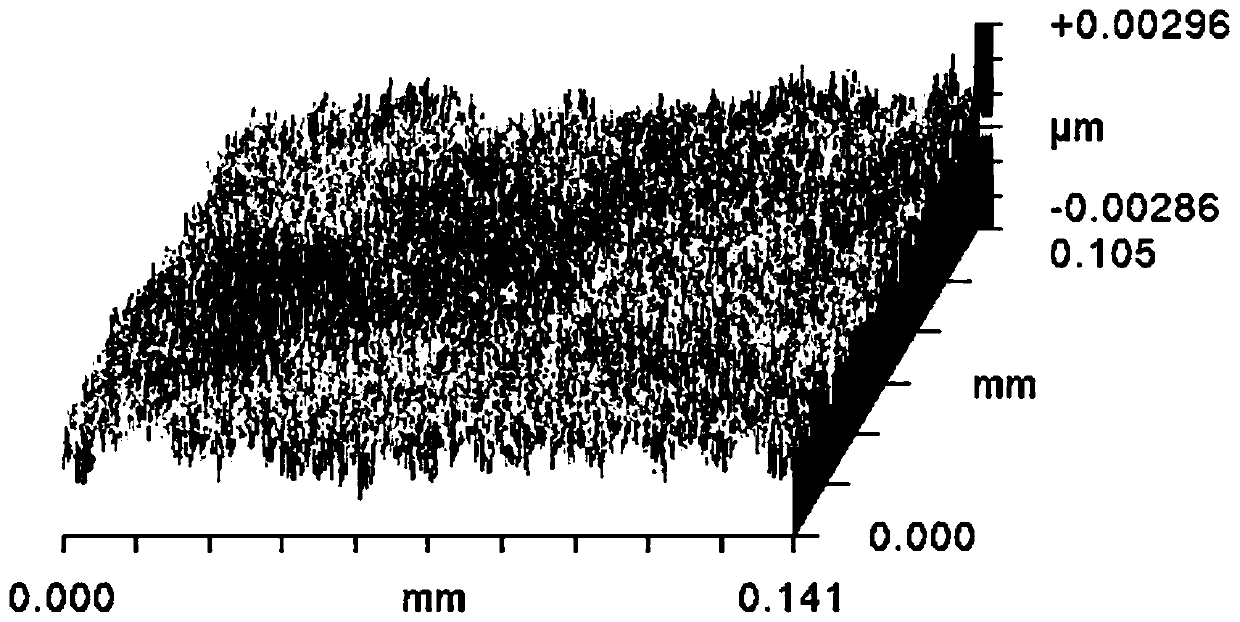

High-efficiency mixed abrasive chemical mechanical polishing solution for sapphire substrate

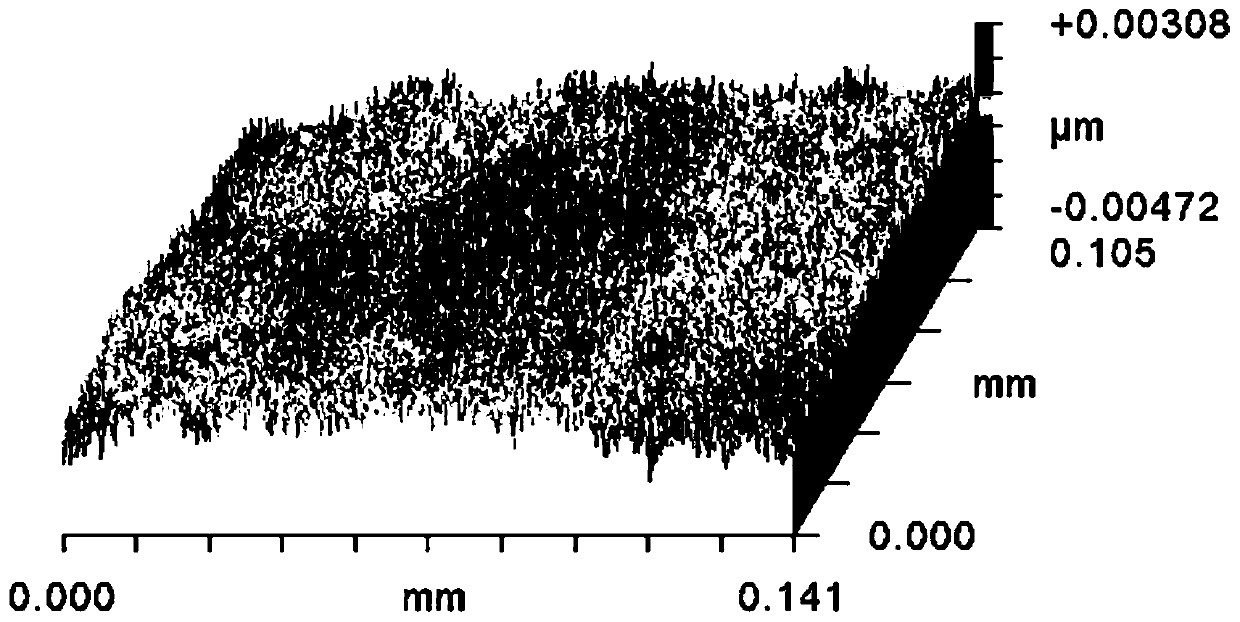

InactiveCN110511679AEvenly dispersedStable pHPolishing compositions with abrasivesMaterial removalSurface roughness

The invention belongs to the technical field of ultra-precision machining of hard and brittle materials, and provides a high-efficiency mixed abrasive chemical mechanical polishing solution for a sapphire substrate. The high-efficiency mixed abrasive chemical mechanical polishing solution comprises a mixed abrasive, a surfactant, a chelating agent, a pH regulator and deionized water. After chemical mechanical polishing, the surface roughness Ra of the sapphire substrate is 0.530 nm and the material removal rate is 6.78 mu m / h in a large detection range of 105*141 mu m<2>. The ultra-high material removal rate of the sapphire substrate and the chemical mechanical polishing of the undamaged sub-nanometer surface roughness are realized.

Owner:DALIAN UNIV OF TECH

Rare earth polishing powder and preparation method thereof

InactiveCN109054655AImprove polishing effectChange shapePolishing compositions with abrasivesRare earthFlat panel display

The invention discloses rare earth polishing powder and a preparation method thereof. The rare earth polishing powder is prepared from the following components by mass percent: 60-80 percent of CeO2,30-40 percent of La2O3, 0.1-5 percent of Pr6O11, 4-6 percent of F of, and 1-3 percent of P2O5; the preparation method of the rare earth polishing powder comprises the steps of synthesizing a modifiedrare earth carbonate precursor, washing the modified rare earth carbonate precursor, dehydration of the modified rare earth carbonate precursor, calcinating, smashing, and the like. The rare earth polishing powder prepared by the method has good abrasion resistance and fast polishing speed, and the polishing precision is easily controlled; the rare earth polishing powder has the advantages of goodproduct homogeneity, high production efficiency, low cost and no pollution, and is applicable to surface polishing processing of electronic information industry precision devices such as an integrated circuit, a flat panel display and optical glass.

Owner:上海祥介德新材料科技有限公司

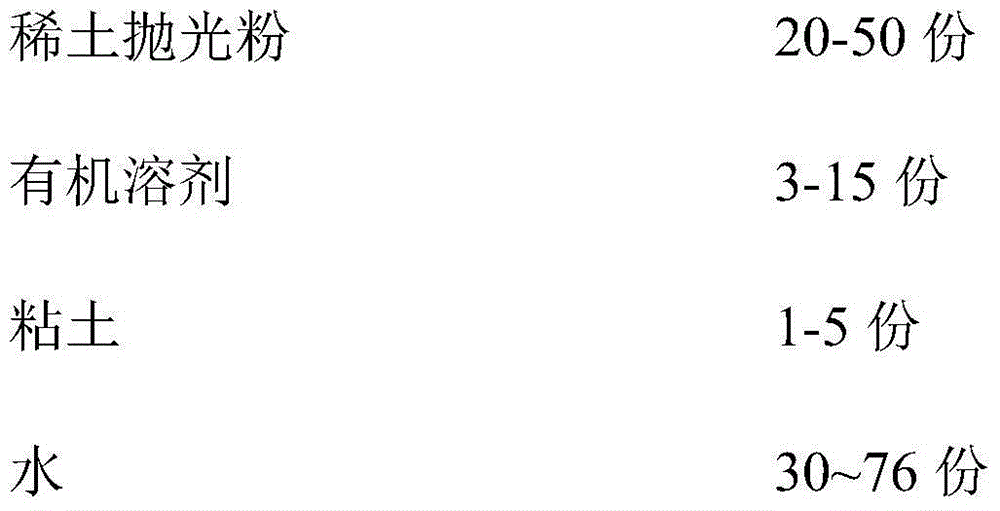

Rare earth polishing liquid and preparation method thereof

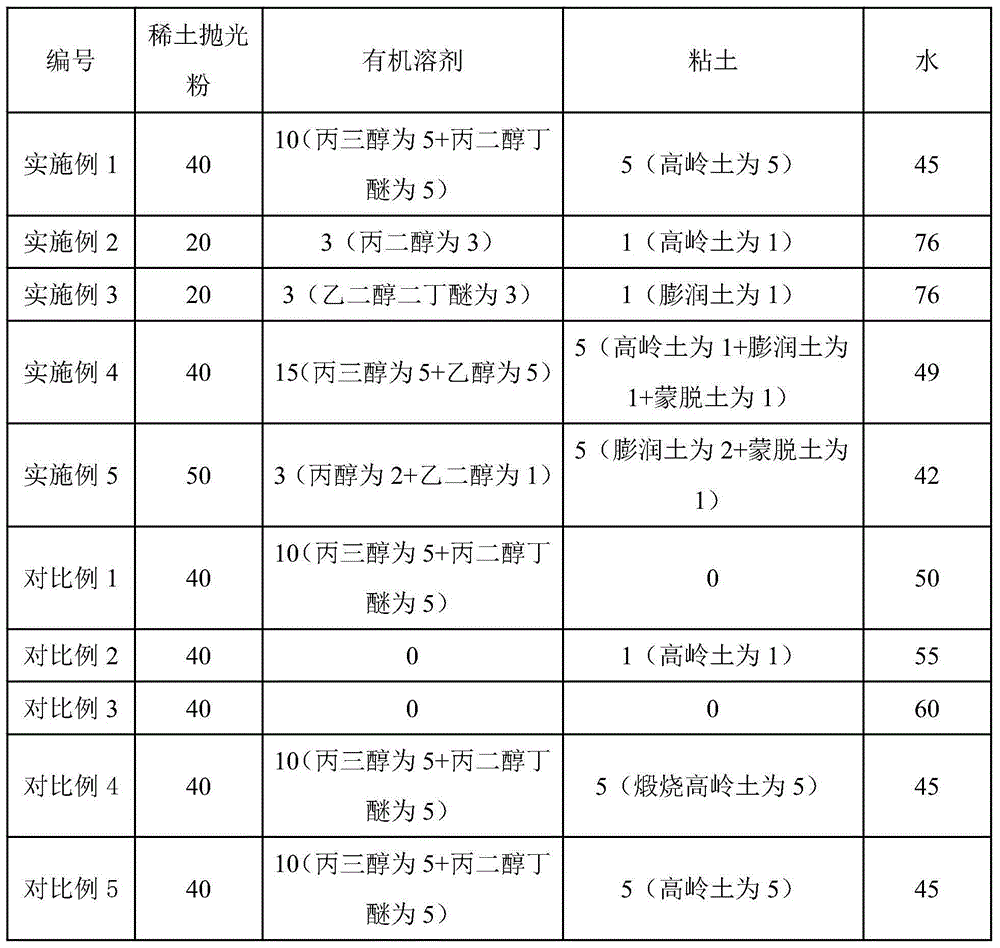

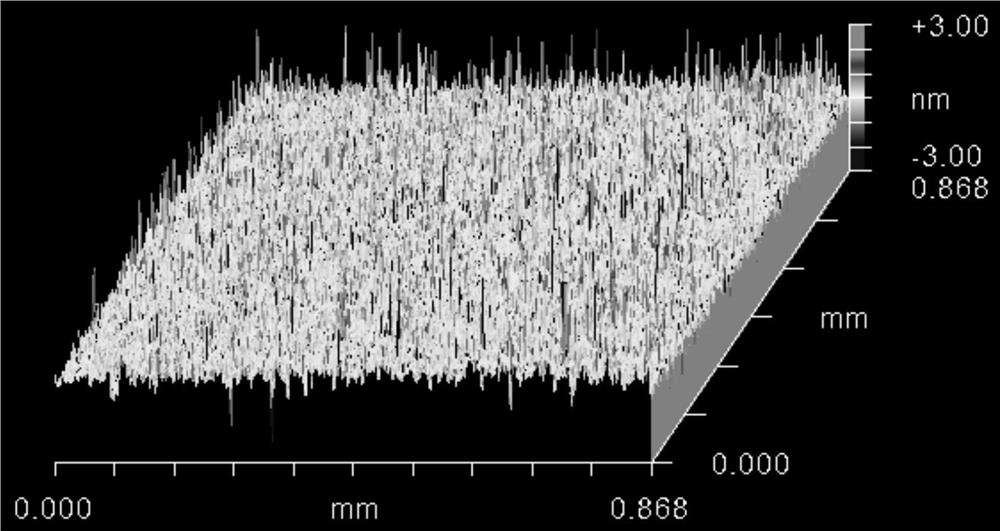

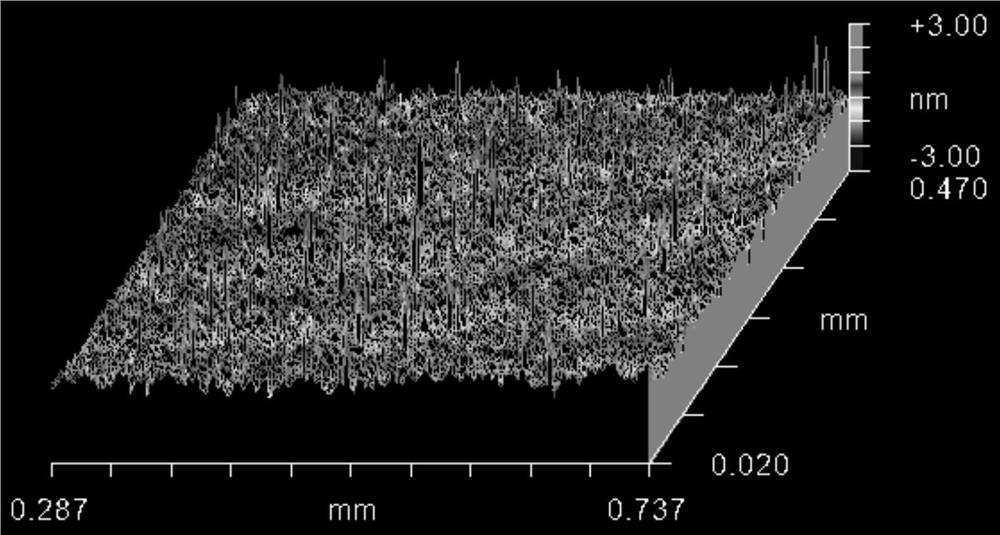

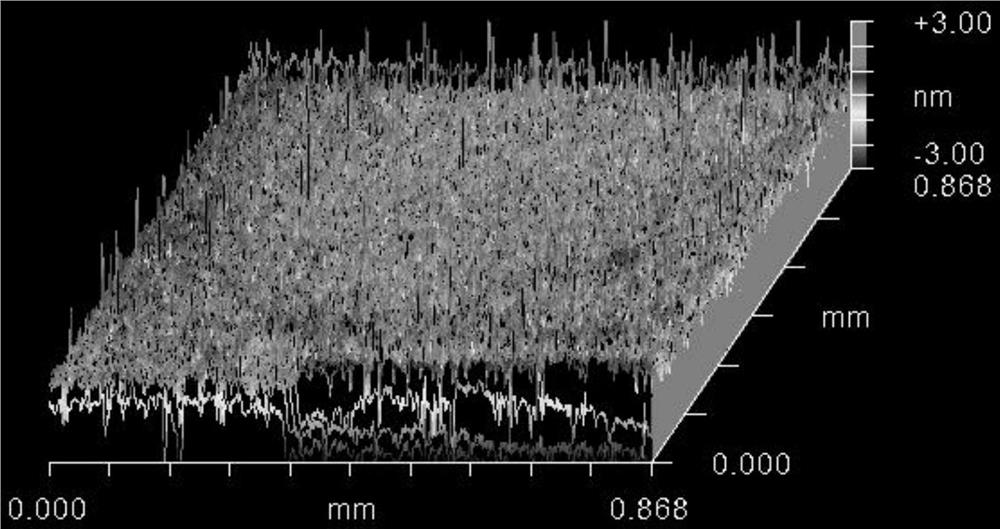

ActiveCN104479555AEasy to prepareSolve the ease of cleaningPolishing compositions with abrasivesOrganic solventRare earth

The invention provides a rare earth polishing liquid and a preparation method thereof; the rare earth polishing liquid comprises the following components in parts by weight: 20-50 parts of a rare earth polishing powder, 3-15 parts of an organic solvent, 1-5 parts of clay, and 30-76 parts of water. The rare earth polishing liquid solves the problem of suspension dispersion of a polishing powder in water, overcomes the bonding problem of the polishing liquid in preparation and storage processes and good cleaning problem of the polishing liquid in a use process at present, and has the characteristics of good suspension dispersibility, fast polishing speed, high polishing precision, excellent cleaning performance of polished products and the like. The rare earth polishing liquid is suitable for surface polishing processing of integrated circuits, flat panel display, optical glass and other electronic information industry precision devices, and meets polishing yield rate requirements of increasingly-strict business on polishing materials in accuracy, polishing corrosion amount, easy cleaning and the like.

Owner:NUOXUAN CHEM TECH SHANGHAI

Visible light assisted diamond chemical mechanical polishing solution and polishing method

ActiveCN113831845AReduce surface roughnessFast polishing rateLapping toolsPolishing compositions with abrasivesUltraviolet lightsSurface roughness

The invention provides a visible light assisted diamond chemical mechanical polishing method, and belongs to the field of ultra-precision machining of ultra-hard materials. The polishing solution is composed of a grinding material, an oxidizing agent, a visible light photocatalyst and deionized water. According to the invention, under irradiation of a visible light source, a polishing solution is used for conducting chemical mechanical polishing on diamond, wherein the visible light source is arranged at the position 10-20 cm right above a polishing disc, the polishing disc (pad) is a glass disc or a polyurethane polishing pad, the rotating speed of the polishing disc (pad) is 50-70 r / min, the polishing pressure is 1-2 MPa, the flow of the polishing solution is 10-20 ml / min, and the surface roughness of the polished diamond can reach 0.250 to 0.354 nm; high-efficiency ultra-smooth chemical mechanical polishing of the diamond is realized; compared with a traditional polishing method, the crystal surface roughness is reduced, and the polishing efficiency is improved; and compared with an ultraviolet light-assisted chemical mechanical method, used equipment is simple in structure and high in practicability.

Owner:DALIAN UNIV OF TECH

Surface treatment liquid for 3D printed stainless steel parts and surface treatment device

ActiveCN109097778AIncrease brightnessReduce roughnessEdge grinding machinesPolishing machinesPhosphoric acidSilicon dioxide

The invention discloses surface treatment liquid for 3D printed stainless steel parts and a surface treatment device. The surface treatment liquid comprises soda boiling liquid, a pickling solution and a chemical polishing solution. The soda boiling liquid is composed of sodium hydroxide, nitrates and salt containing chloride ions. The pickling solution is composed of hydrochloric acid, sodium chloride, ferric chloride and a corrosion inhibitor. The chemical polishing solution is composed of nano-scale silica abrasives, 36wt% of hydrochloric acid, 85wt% of phosphoric acid, 68wt% of nitric acid, a corrosion inhibitor, a viscosity modifier, a brightener, an OP-10 emulsifier, a complexing agent and deionized water. The surface treatment liquid for the 3D printed stainless steel parts and thesurface treatment device have the characteristics of effectively reducing the surface roughness of the 3D printed stainless steel parts, improving the surface flatness and being good in surface treatment quality and high in surface treatment efficiency.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of sapphire substrate polishing solution

ActiveCN104109481AAvoid enteringEnsure the safety of the production environmentPolishing compositions with abrasivesFiltrationPhysical chemistry

The invention provides a preparation method of a sapphire substrate polishing solution, which comprises the following steps: employing a membrane filtration device to remove metal ions and other impurities in a silica sol raw material; passing the filtered silica sol with concentration of 48-50% under a vacuum negative pressure state through a 100 nano-level folding filter core and then adding in an enclosed reaction pot; adding a stabilizing agent under the vacuum negative pressure state in the enclosed reaction pot; adding a synergist with pH value of 8.0-8.5 under the vacuum negative pressure state in the enclosed reaction pot; fully stirring the liquid in the enclosed reaction pot under a negative pressure tumbling state for 60 minutes, and uniformly mixing and then loading. The preparation method has the following beneficial effects that the alkalescence sapphire substrate polishing solution has no corrosion effect to the polishing device, after the usage of the polishing solution is finished, and then the polishing solution is processed, the processed polishing solution can be used as a building paint additive, so that the problems of easy coagulation and difficult recovery of a traditional acidic polishing solution can be solved.

Owner:HEBEI YUTIAN HAOYUAN NANO MATERIAL

Lanthana cerium oxyfluoride rare earth polishing liquid and preparation method thereof

ActiveCN102337086BHigh suspension stabilityImprove wear resistanceOther chemical processesAqueous dispersionsPhysical chemistryCerium

The invention provides a lanthana cerium oxyfluoride rare earth polishing liquid and a preparation method thereof. The lanthana cerium oxyfluoride rare earth polishing liquid contains lanthana cerium oxyfluoride polishing powder, a dispersing agent and a pH value regulating agent, based on water as a carrier; the content of the dispersing agent is 0.5-1wt% of the total mass of the polishing liquid, the amount of the pH value regulating agent is based on the fact that the pH value of the polishing liquid reaches 8.5-10.0 as a reference, the mass solid content of the polishing liquid is 25-45wt%, the mass of cerium accounts for 60-80wt% of total mass of lanthana and cerium, and the mass fraction of fluoride is 3-5wt% of total mass of lanthana cerium oxyfluoride. The lanthana cerium oxyfluoride rare earth polishing liquid has the performance characteristics of high suspending stability, rapid polishing rate, less scratch and high abrasion resistance on silicon oxide glass, and the particle size of corresponding rare earth particle is small; and the pH value regulating agent and the organic dispersing agent are added, thereby delaying the deposition of an abrasive material in the material liquid, improving the polishing rate of the polishing liquid on a glass substrate and reducing the scratch.

Owner:上海华明高纳稀土新材料有限公司

Precision-type mischmetal polishing powder and preparation method thereof

ActiveCN103013444BImprove wear resistanceUniform grain sizeOther chemical processesPolishing compositions with abrasivesRare earthElectronic information

The invention provides precision-type mischmetal polishing powder and a preparation method thereof. The precision-type mischmetal polishing powder is a uniform solid solution composed of an oxyfluoride-crystal form rare earth and a cubic-phase rare-earth oxide. Compared with the existing products, the precision-type mischmetal polishing powder has the advantages that 1, through ball-milling crushing and utilization of a homogenization assistant, a rare-earth carbonate precursor comprises uniform crystal grains; a fluorination reaction is uniform and complete; dissociative fluorinions and fluorides influencing a polishing precision and a polishing rate are not produced; and a high crystallization degree is obtained; 2, wear resistance is good; a polishing rate is fast; and a polishing precision can be controlled easily; 3, product uniformity is good; production efficiency is high; pollution is not produced; and a cost is low; and 4, the precision-type mischmetal polishing powder is suitable for surface polishing processing of precision components such as integrated circuits, flat panel displays and optical glass in the electronic information industry and realizes the purpose of the invention.

Owner:包头华明高纳稀土新材料有限公司

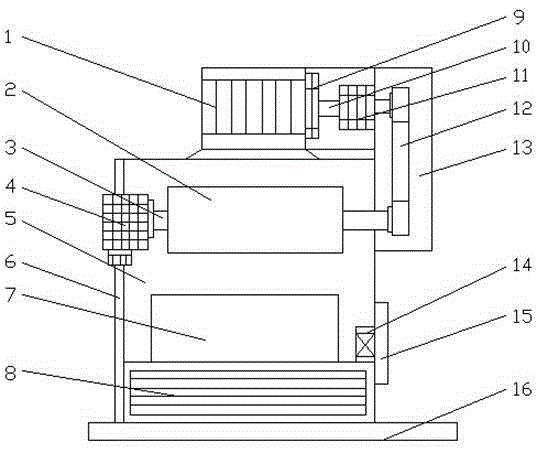

Convenient polishing machine for machining bearings

InactiveCN105345642ASimple materialImprove wear resistanceGrinding carriagesPolishing machinesDrive shaftDrive motor

The invention discloses a convenient polishing machine for machining bearings. The convenient polishing machine comprises a driving motor, a polishing wheel, a rotating shaft, a machine head device, a machine body, a lifting frame, a workbench, a circuit box, a driving rotating wheel, a driving shaft, an adjuster, a transmission belt, a protective cover, a controller, a control panel and a fixed base. The driving motor is connected with the driving rotating wheel. The driving shaft is fixed to the right side of the driving rotating wheel. The transmission belt is located on the inner side of the protective cover. The rotating shaft is fixed to the left side of the transmission belt. The control panel is located on the outer side of the machine body. The fixed base is connected with the machine body. The polishing wheel of the convenient polishing machine for machining the bearings is made of good materials and has high abrasion resistance. The lifting equipment is arranged, so that the situation that the polishing direction is single during working is well avoided. The size of the convenient polishing machine is small, and the high-quality polishing equipment is arranged, so that the polishing efficiency is greatly improved, the polishing speed is increased, and the production development speed is increased.

Owner:LEIYANG XINDAWEI TECH

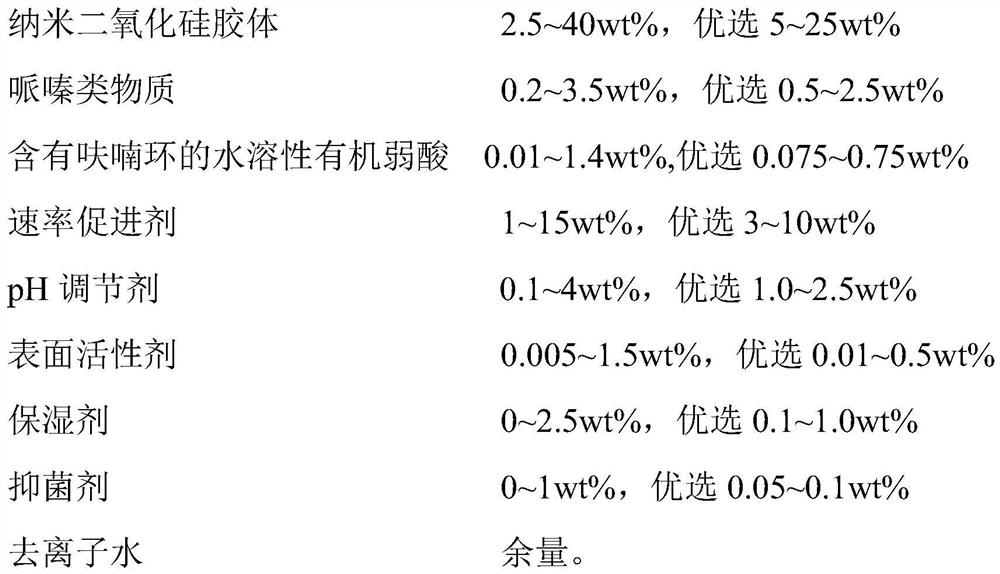

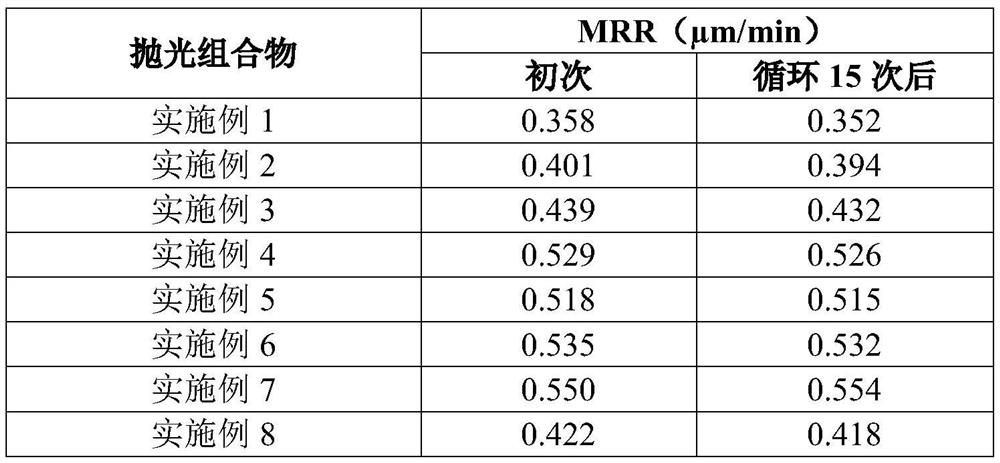

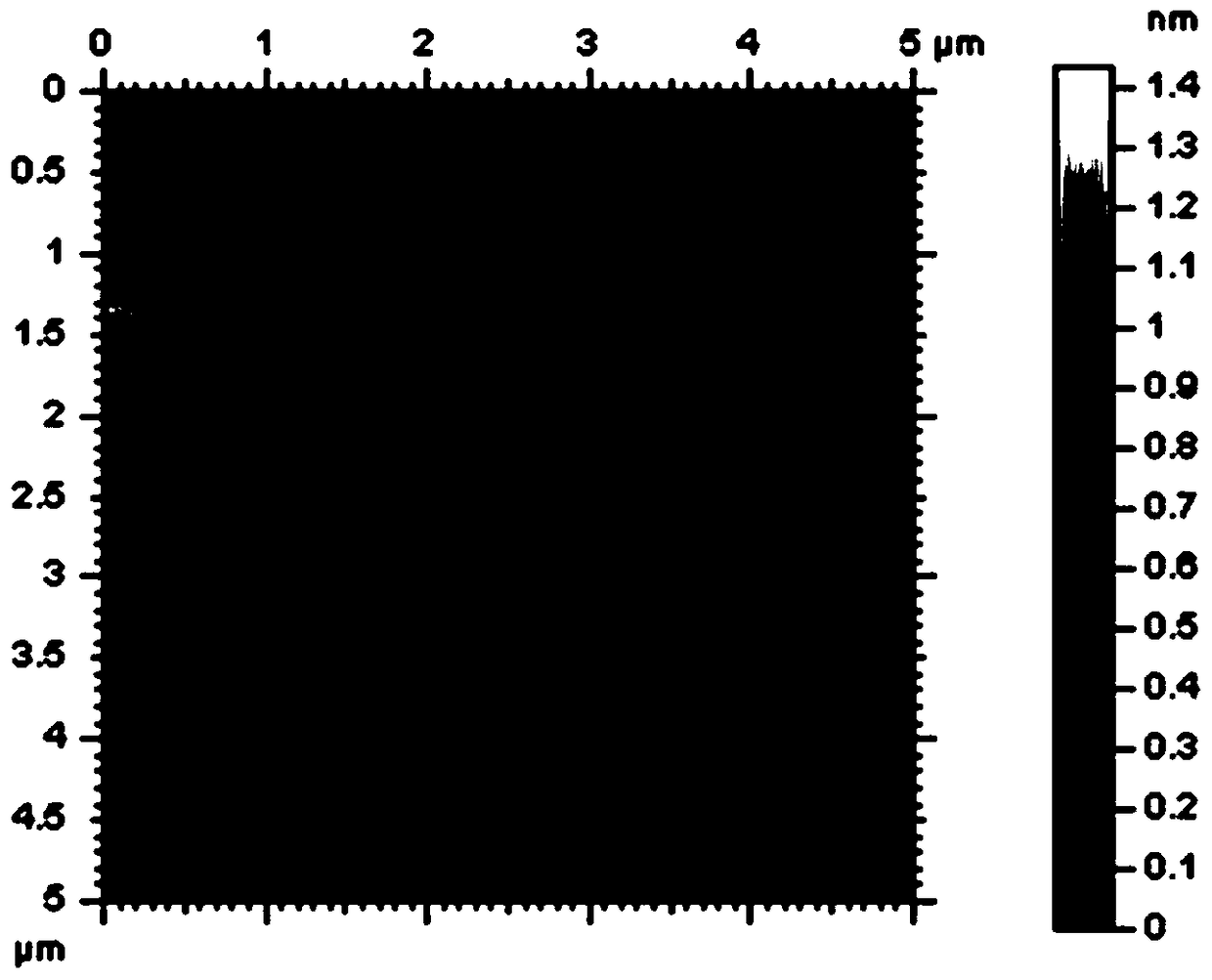

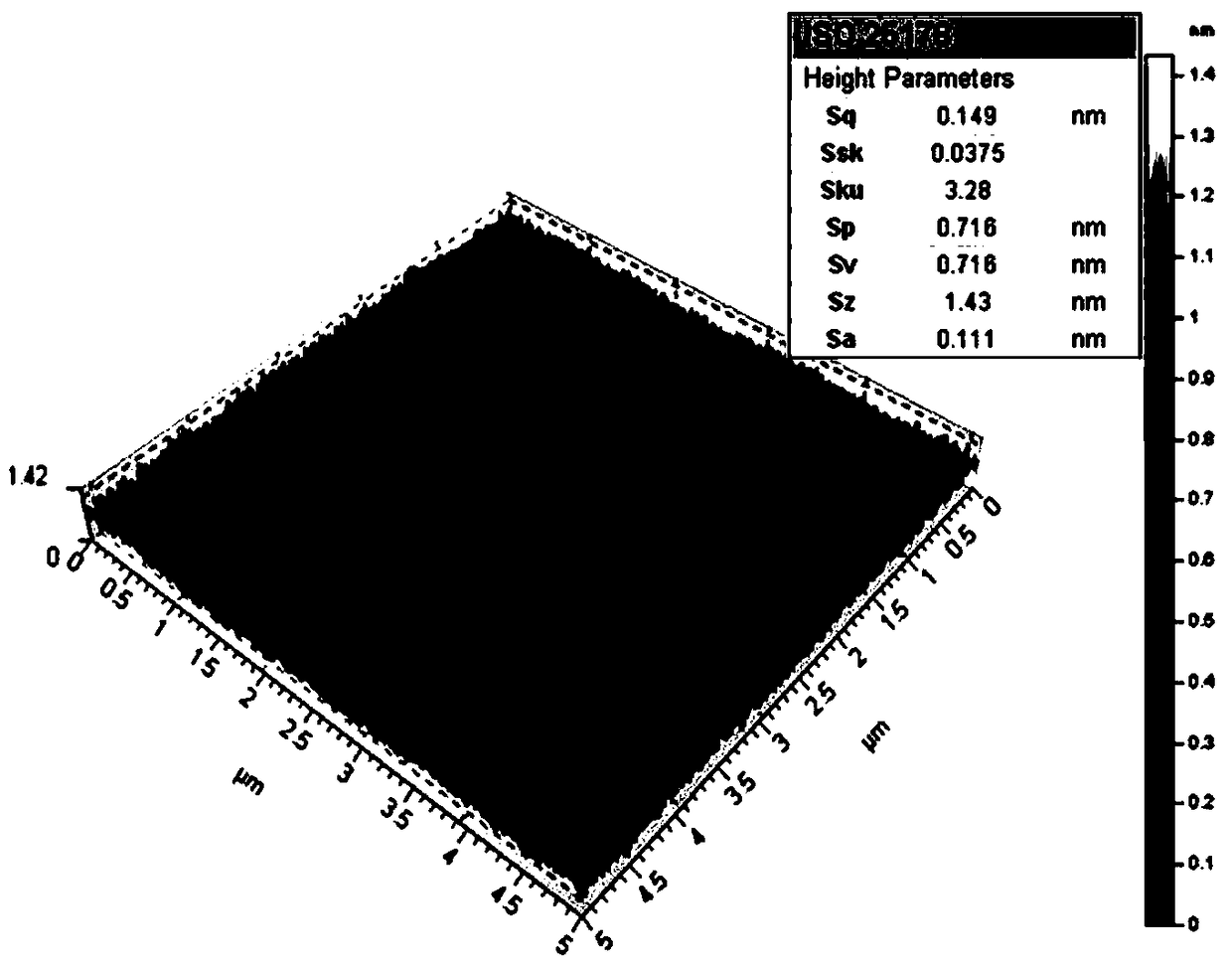

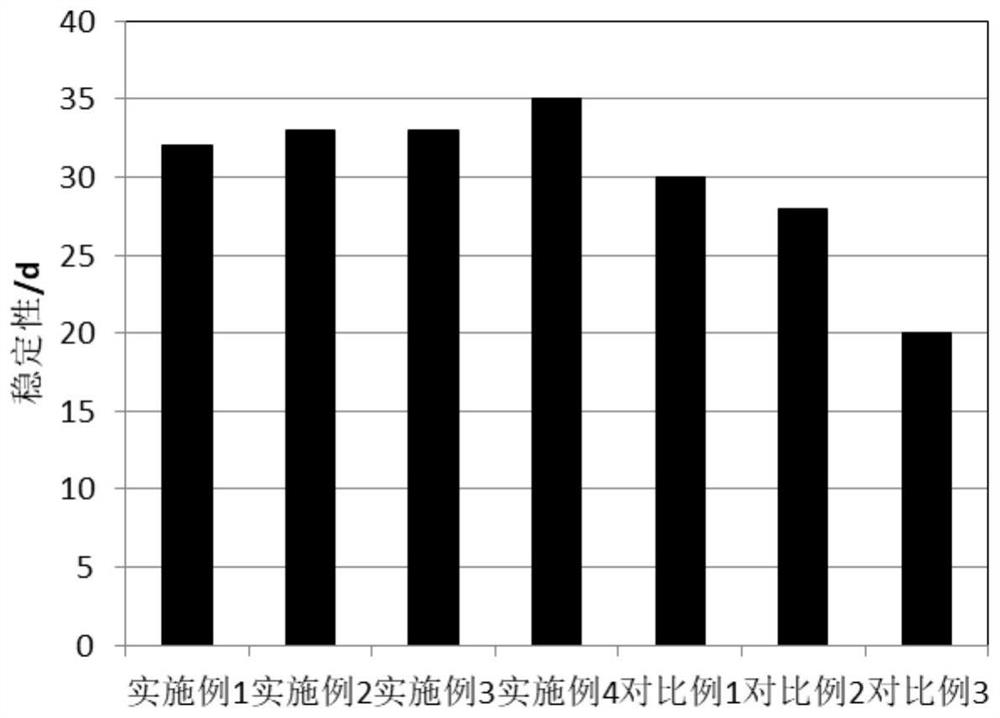

Silicon polishing composition, preparation method and application thereof

PendingCN114806414AFast polishing ratePolished surface cleaningPolishing machinesPolishing compositions with abrasivesFuranAqueous solubility

The invention provides a silicon polishing composition as well as a preparation method and application thereof, the silicon polishing composition takes nano silicon dioxide colloid as a main polishing component, and piperazine substances and water-soluble organic weak acid containing furan rings are added as auxiliaries. The piperazine substance and the water-soluble organic weak acid containing the furan ring are simultaneously added into the silicon polishing composition to serve as the stability auxiliaries, the grinding material agglomeration can be effectively inhibited, the storage time and the service life of the polishing solution are prolonged, and compared with the prior art, the silicon polishing composition has obvious advantages.

Owner:万华化学集团电子材料有限公司

A kind of asphalt polishing disk and preparation method thereof

ActiveCN105602454BImprove surface stabilityImprove flatnessOptical surface grinding machinesGrinding devicesWaxNanoparticle

Owner:BEIJING GRISH HITECH

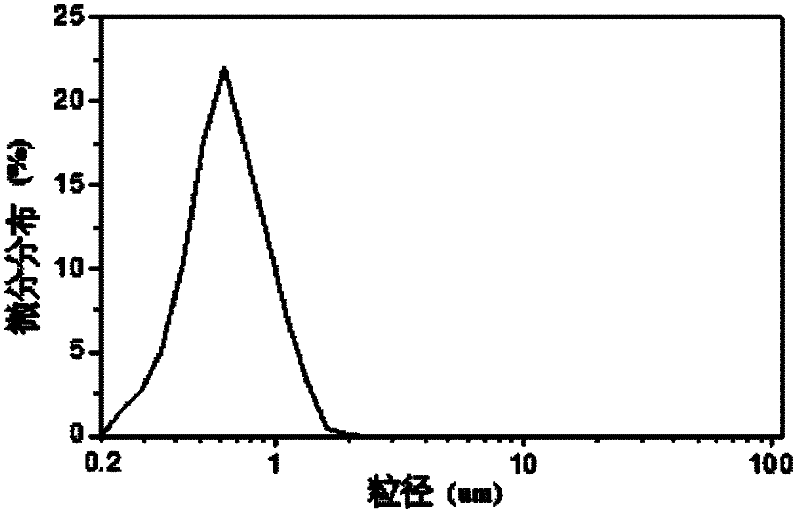

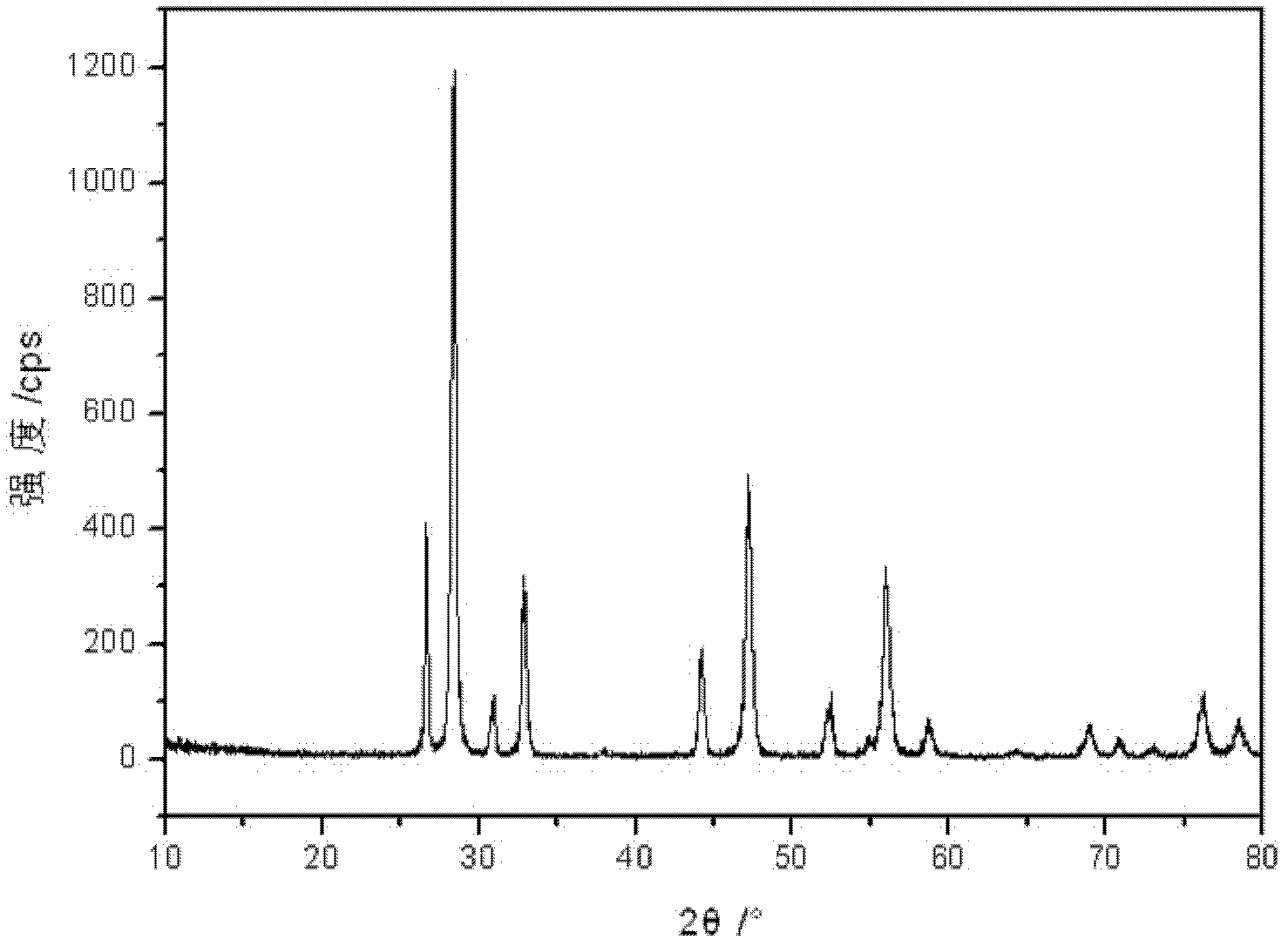

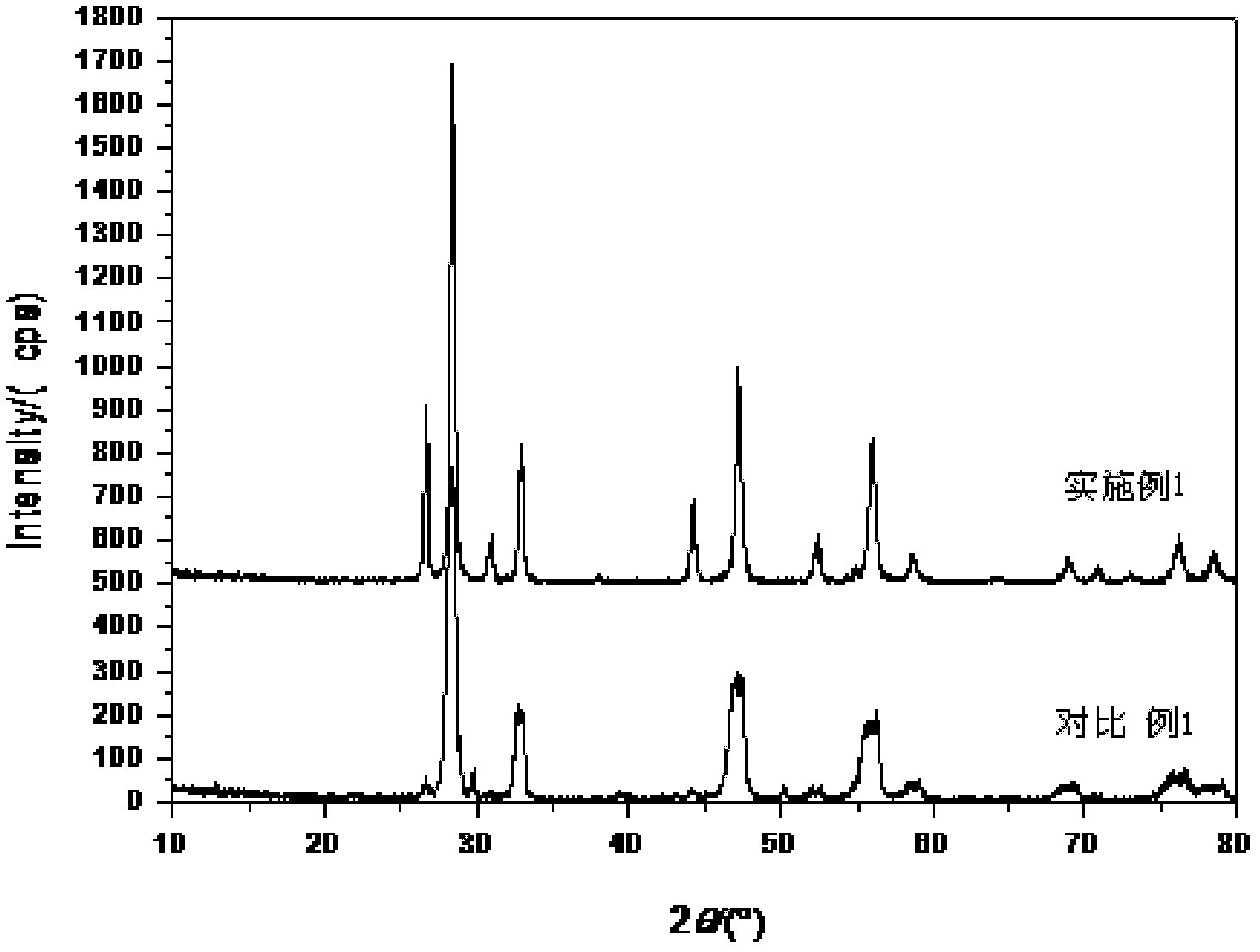

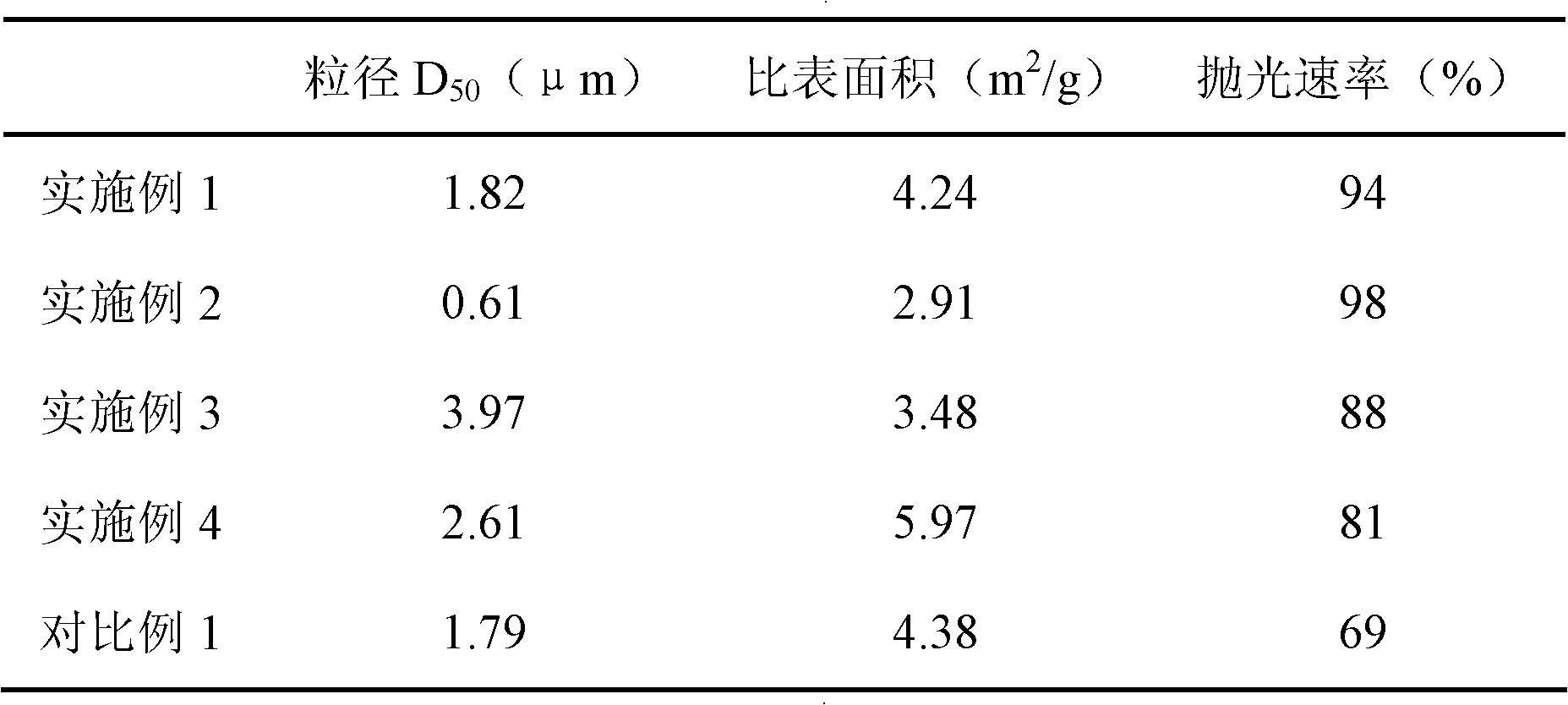

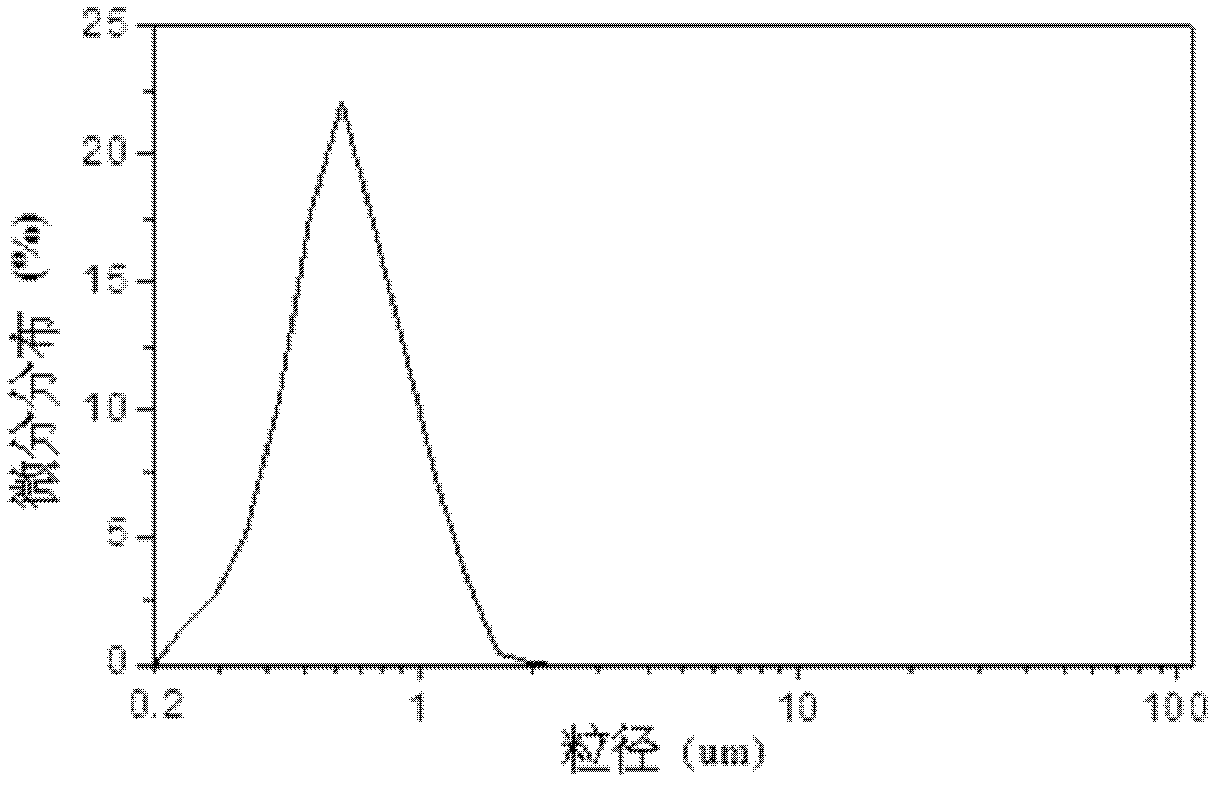

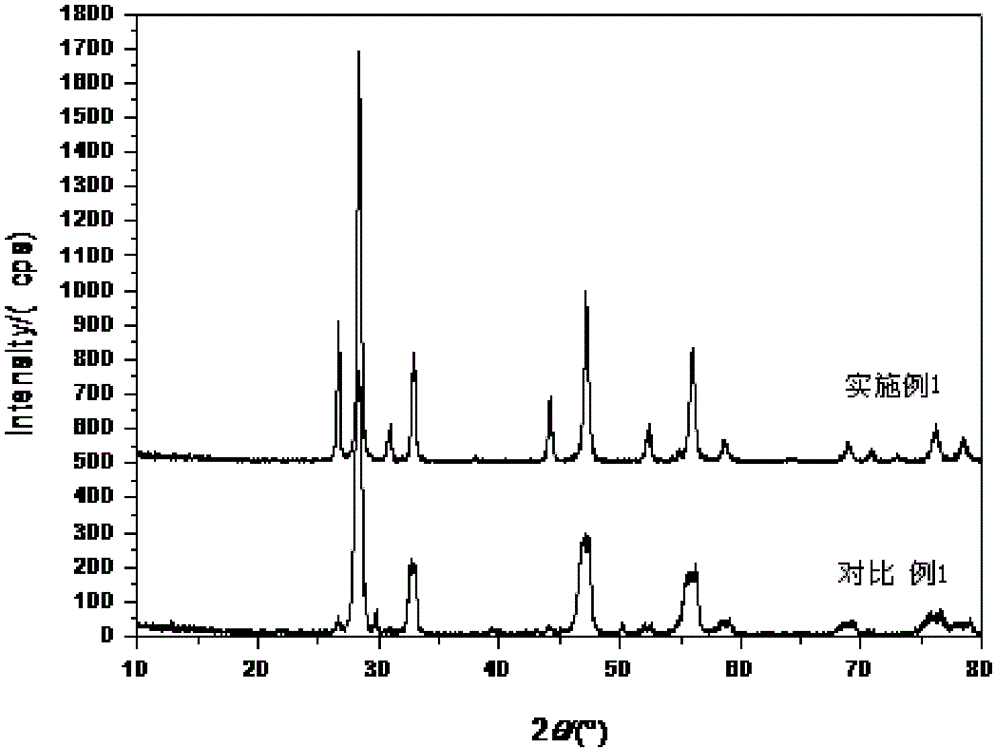

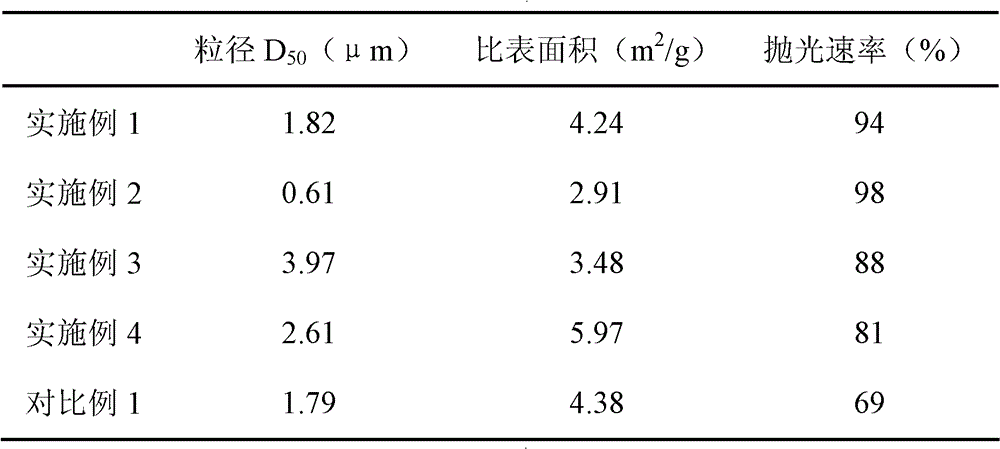

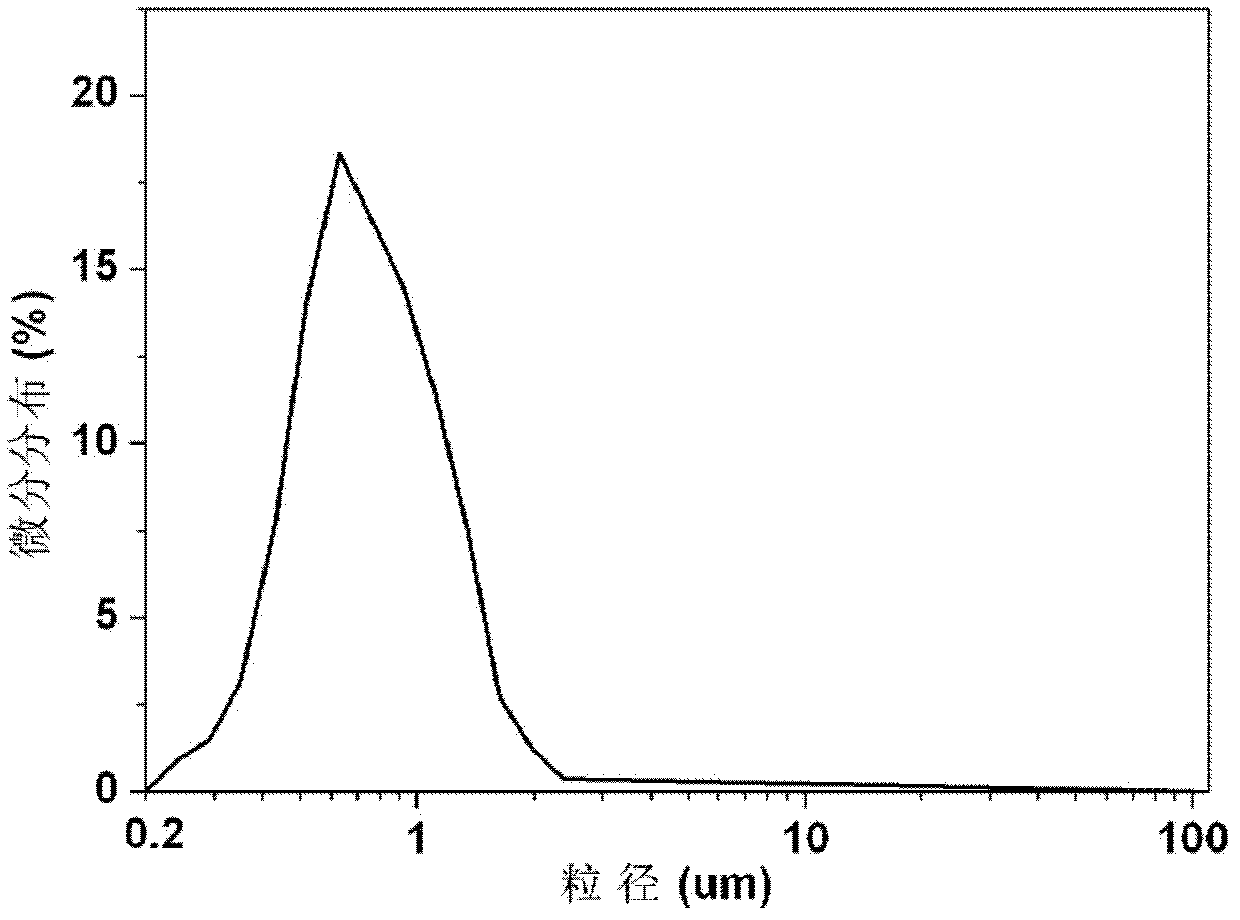

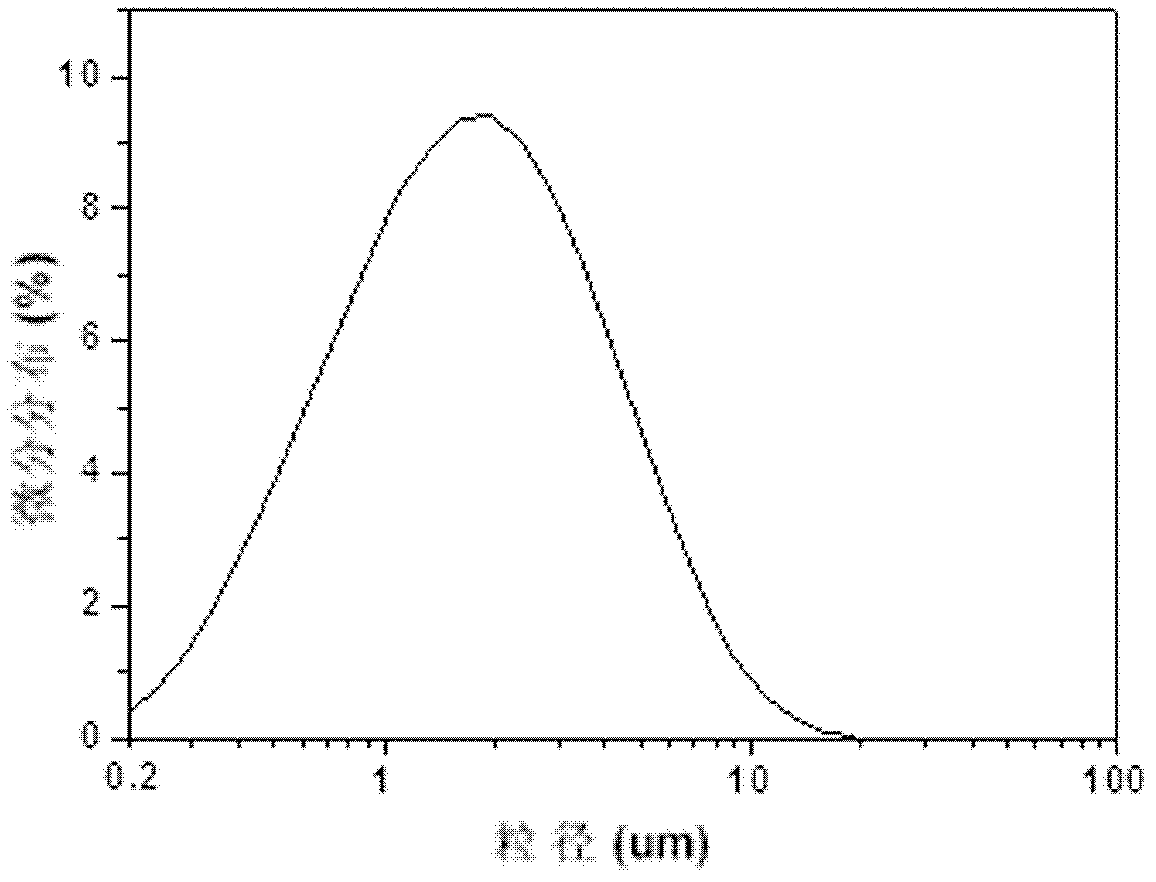

Preparation method of composite cerium-zirconium oxide polishing powder

The invention provides a preparation method of a composite cerium-zirconium oxide polishing powder. The preparation method comprises the following steps: (1) preparing insoluble cerium salts into slurry, carrying out ball milling and smashing until the average particle size D50 of particles in the slurry is distributed within a range from 0.55mu m to 0.75mu m, and the average particle size D90 ofparticles in the slurry is distributed within a range from 1.1mu m to 1.4mu m; (2) adding soluble zirconium salts into a product obtained in the step (1), adding a precipitator, standing and ageing, dehydrating and drying, wherein the precipitator is ammonia water, ammonium bicarbonate or oxalic acid; and (3) roasting for 3-8 hours at the temperature of 850-1000 DEG C, and carrying out jet milling so as to obtain the composite cerium-zirconium oxide polishing powder. According to the invention, the obtained polishing powder has small particle size and narrow size distribution range, has the performance characteristics of rapid polishing rate, less scratches and high abrasive resistance on a glass substrate, and has obvious synergetic polishing effect.

Owner:上海华明高纳稀土新材料有限公司

Preparation method and application of silica sol with irregular shape

Owner:阳江市惠尔特新材料科技有限公司

A kind of preparation method of sapphire substrate polishing liquid

ActiveCN104109481BAvoid mixingAvoid enteringPolishing compositions with abrasivesFiltrationPhysical chemistry

The present invention proposes a kind of preparation method of sapphire substrate polishing liquid, and its method step is as follows: adopt membrane filter equipment to remove metal ion and other impurity in silica sol raw material; % to 50% of the silica sol is added to the closed reaction tank through a 100-nanometer pleated filter element; the stabilizer is added to the closed reaction tank under vacuum negative pressure; The effect agent is added into the closed reaction tank; the liquid in the closed reaction tank is fully stirred for 60 minutes under the negative pressure tumbling state, and the filling is carried out after mixing evenly. The beneficial effects of the present invention are as follows: the alkaline sapphire substrate polishing liquid prepared by the method of the present invention has no corrosive effect on polishing equipment, and after the polishing liquid is used and treated, it can also be used as an additive for architectural coatings, which solves the problem of traditional acidic The polishing liquid is easy to gel, difficult to recycle and many other problems.

Owner:HEBEI YUTIAN HAOYUAN NANO MATERIAL

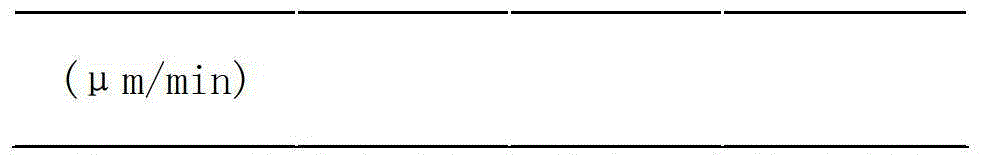

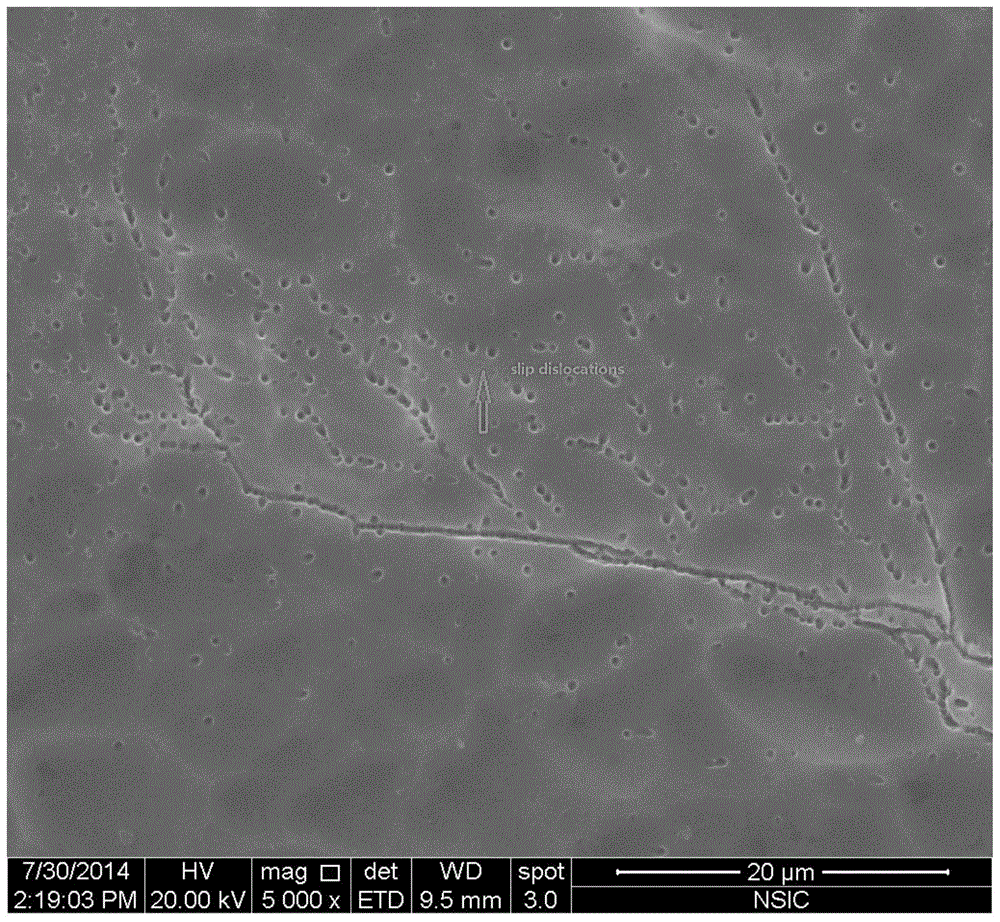

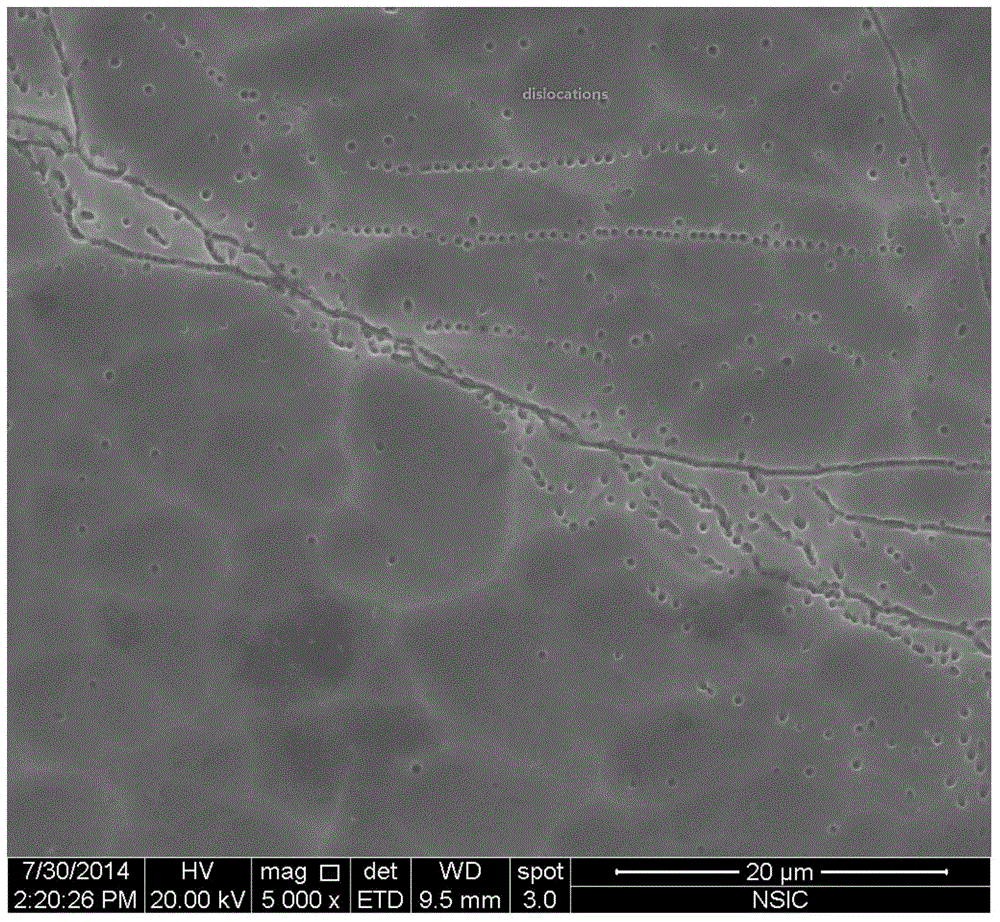

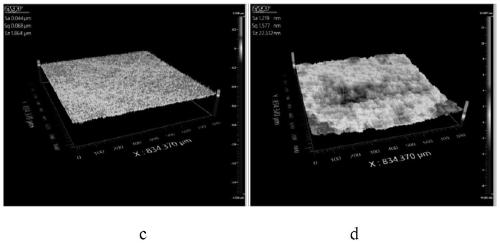

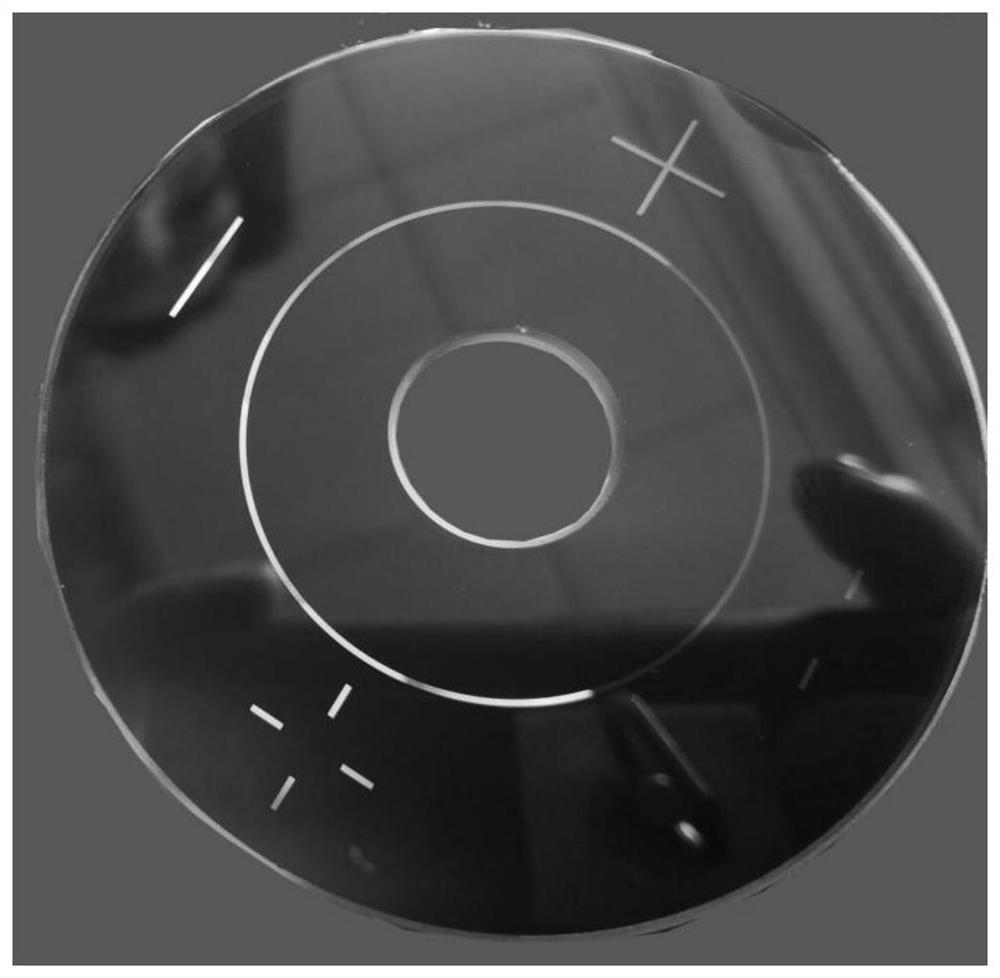

A detection method for micro-defects in quasi-single crystal silicon wafers

InactiveCN104900758BImprove photoelectric conversion efficiencyFast polishing rateFinal product manufactureSemiconductor devicesCooking & bakingMicroscopic observation

The invention discloses a method for detecting microdefects of quasi monocrystalline silicon sheets. The method includes a manually and mechanically polishing step of manually and mechanically polishing aquasi monocrystalline silicon sheet to be etched and flushing the quasi monocrystalline silicon sheet with deionized water; a chemical etch polishing step of chemically etching and polishing the silicon sheet subjected to the mechanical polishing and rinsing the silicon sheet with deionized water; a preferential microdefect etching step of carrying out preferential microdefect etching on the silicon sheet subjected to the chemically etching and polishing, rinsing the silicon sheet with deionized water and drying the silicon sheet in a baking oven; and a microdefect observation process of carrying out minority carrier lifetime and iron-boron opposite scanning for the etched silicon chip, observing the minority carrier lifetime scanning color distribution by a metallographic microscope, accurately positioning the microdefect positions, classifying the defect types, positioning and cutting the silicon chip into pieces, and marking the pieces. The method is rapid, accurate, energy-saving, environmental-friendly, pollution-free and highly practical.

Owner:连云港市产品质量监督检验中心

Multipurpose polishing solution main solution

PendingCN111647357AEfficient removalPrevent storage and retentionPolishing compositions with abrasivesSODIUM METAPHOSPHATETetramethylammonium hydroxide

The embodiment of the invention discloses a multipurpose polishing solution main solution, and belongs to the technical field of surface treatment, the multipurpose polishing solution main solution comprises a component A selected from one or more of ethanolamine, hexamethylenetetramine, pyridine, triethanolamine, N-methylmorpholine, tetramethylethylenediamine and tetramethylammonium hydroxide; the component B is selected from one or more of sodium tripolyphosphate, sodium polyphosphate, sodium hexametaphosphate, sodium pyrophosphate, diethylenetriamine pentaacetic acid amino trimethylene phosphonic acid, ethylenediamine tetramethylene phosphonic acid, diethylenetriamine pentamethylene phosphonic acid, amino trimethylene phosphonic acid, polyacrylic acid, polyepoxysuccinic acid and maleicacid; and the component C is selected from one or more of triethylene diamine, ethylenediamine, isopropylamine and p-toluidine. The multipurpose polishing solution main solution not only can be used for polishing sapphire materials, but also can be used for polishing glass materials, ceramic materials and the like, realizes multiple purposes, and is low in cost, simple in component, easy to degrade and environment-friendly.

Owner:JIANGSU KERUN PHOTOELECTRIC TECH CO LTD

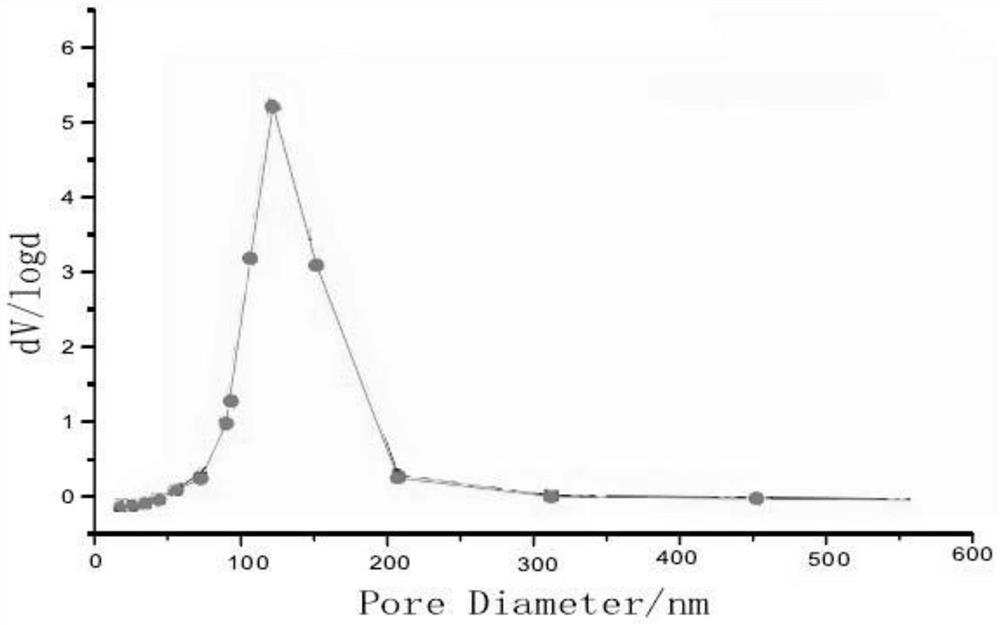

Preparation method and application of silica sol for chemical polishing

PendingCN114477190AReduce the content of metal ionsUniform and stable growthSilicon compoundsPolishing compositions with abrasivesSilicic acidPhysical chemistry

The invention discloses a preparation method and application of silica sol for chemical polishing, and belongs to the technical field of semiconductor chemical polishing materials. According to the invention, silica sol granulation is carried out by adopting a method of combining a traditional silicic acid hydrolysis method and a silica powder hydrolysis method, raw materials are easy to obtain, the preparation process flow can realize mass production, equipment transformation is not needed, and the cost and manual training cost are greatly saved. In the granulation process, silicon powder is introduced as a silicon source, so that the average density of seed particles for granulation is higher, the surface activation energy is favorably increased, and the particles are favorably increased again. The prepared large-particle-size silica sol particles are higher in hardness, show higher surface energy in the terminal application process, and are higher in polishing rate and higher in particle tolerance. The average particle size of the obtained silica sol particles is about 100 nanometers, and the silica sol particles are good in stability, free of agglomeration, high in polishing speed and removal rate and capable of greatly improving the polishing efficiency when applied to chemical polishing.

Owner:山东金亿达新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com