Lanthana cerium oxyfluoride rare earth polishing liquid and preparation method thereof

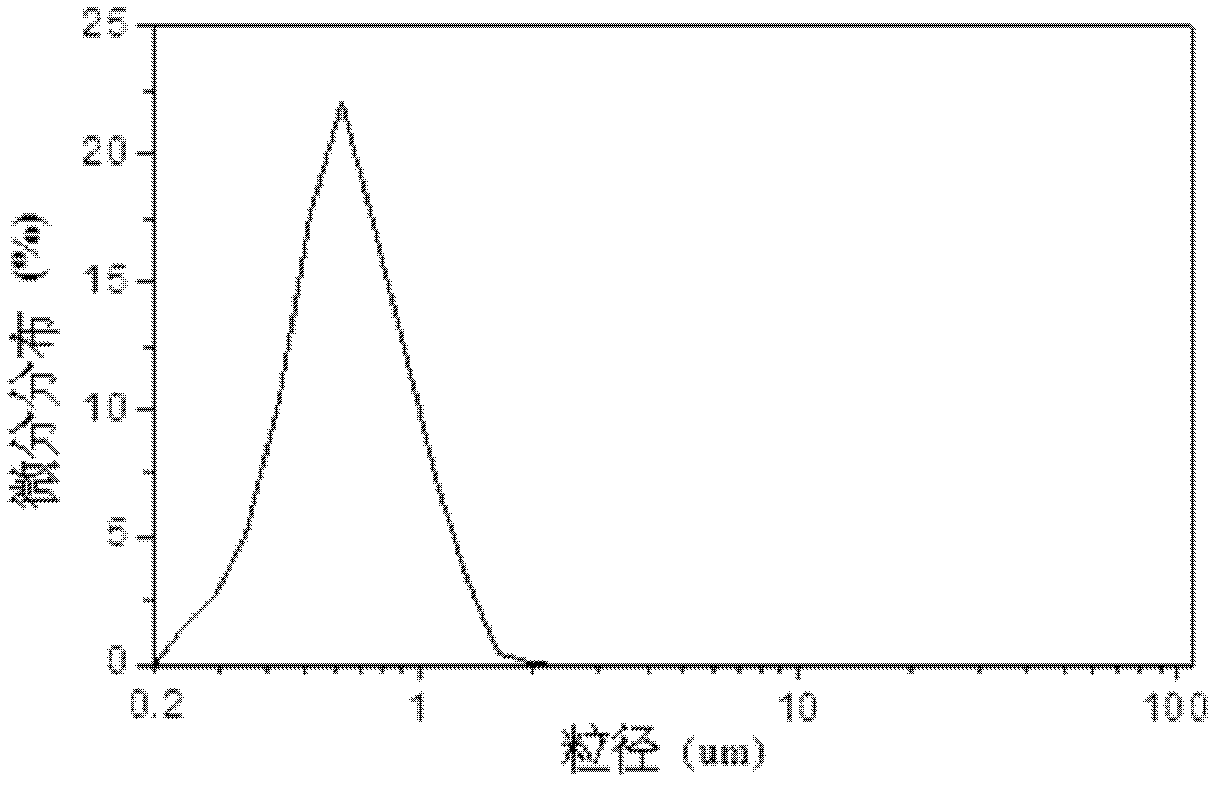

A lanthanum cerium oxyfluoride and rare earth polishing technology, applied in chemical instruments and methods, other chemical processes, aqueous dispersants, etc., can solve the problems of low polishing precision and large particle size of polishing powder, and achieve fast polishing rate and rare earth particles. Small particle size, the effect of delaying sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Precipitation: 1 L of lanthanum cerium nitrate aqueous solution with a concentration of 100 g / l is heated to 80° C., wherein the fraction of cerium in the solution to the total mass of lanthanum cerium is 60 wt%, and a concentration of 60 g / l is added under stirring conditions. Ammonium bicarbonate was precipitated until the pH value of the mixed solution was 6.5, filtered and washed 3 times with deionized water to obtain a mixture of lanthanum and cerium carbonate;

[0043] (2) Fluorination: add hydrofluoric acid to the obtained lanthanum cerium carbonate mixture to carry out fluorination reaction, wherein the addition of hydrofluoric acid is 5wt% of the total weight of lanthanum cerium carbonate;

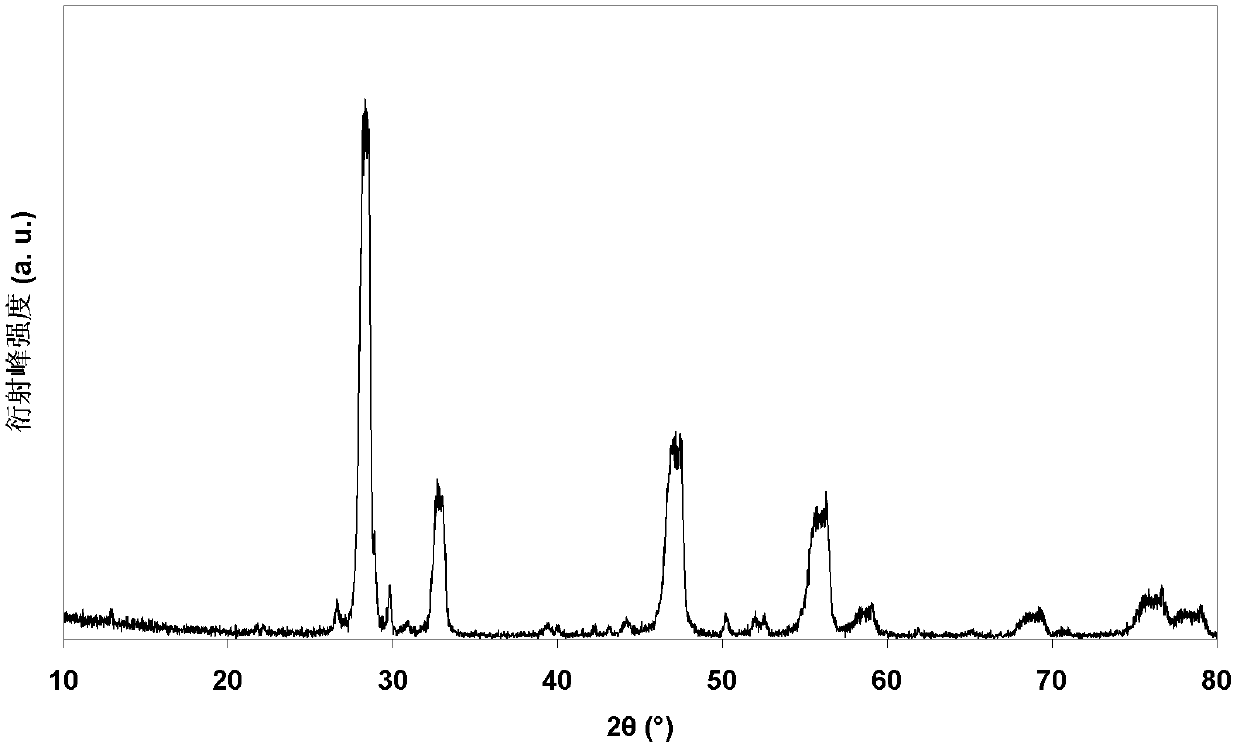

[0044] (3) Roasting: the lanthanum cerium carbonate after fluorination is centrifugally separated and dehydrated, and the filter cake obtained is dried at 100° C. for 15 hours. After drying, the powder is roasted at 950° C. for 5 hours to obtain lanthanum cerium oxyfluor...

Embodiment 2

[0048](1) Precipitation: 1 L of lanthanum cerium nitrate aqueous solution with a concentration of 150 g / l is heated to 80° C., wherein the cerium in the solution accounts for 70 wt % of the total mass of lanthanum cerium, and a concentration of 60 g / l is added under stirring conditions. Ammonium bicarbonate and sodium carbonate mixed solution are precipitated (ammonium bicarbonate and sodium carbonate mass ratio are 1: 1), until the pH value of the mixed solution is 8.5, after filtering, wash with deionized water 3 times to obtain a mixture of lanthanum and cerium carbonate;

[0049] (2) Fluorination: adding hydrofluoric acid to the obtained lanthanum cerium carbonate mixture to carry out fluorination reaction, wherein the addition of hydrofluoric acid is 7wt% of the total weight of lanthanum cerium carbonate;

[0050] (3) Roasting: the fluorided lanthanum cerium carbonate is centrifugally separated and dehydrated to obtain a filter cake that is dried at 120° C. for 12 hours, a...

Embodiment 3

[0054] (1) Precipitation: Heat 1 L of lanthanum cerium chloride aqueous solution with a concentration of 200 g / L to 90° C., wherein the cerium in the solution accounts for 80 wt % of the total mass of lanthanum cerium, and add a concentration of 60 g / L under stirring conditions. The sodium carbonate is precipitated until the pH value of the mixed solution is 10, filtered and washed 3 times with deionized water to obtain a mixture of lanthanum and cerium carbonate;

[0055] (2) Fluorination: adding hydrofluoric acid to the lanthanum cerium carbonate precipitate to carry out fluorination reaction, wherein the addition of hydrofluoric acid is 7wt% of the total weight of lanthanum cerium carbonate;

[0056] (3) Roasting: the lanthanum cerium carbonate after fluorination is centrifugally separated and dehydrated, and the filter cake obtained is dried at 120° C. for 12 hours. After drying, the powder is roasted at 900° C. for 8 hours to obtain lanthanum cerium oxyfluoride polishing p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com