Rare earth polishing powder and preparation method thereof

A technology of rare earth polishing powder and rare earth chloride, applied in polishing compositions containing abrasives, etc., can solve the problems of complex compounding process of fluoride and oxide, complex post-treatment process, secondary sintering of particles, etc., and achieve polishing The effect of easy control of precision, low cost and fast polishing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

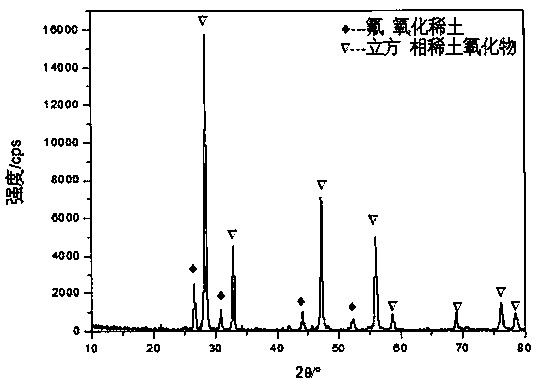

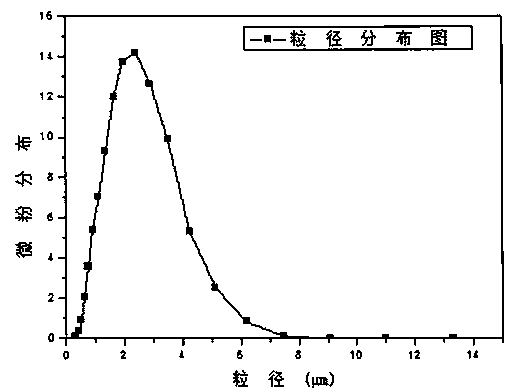

Image

Examples

Embodiment 1

[0046] In the mixed rare earth chloride, the mass ratio of each component is: total rare earth REO is 45%; cerium oxide is 70%, lanthanum oxide is 19.9%, and praseodymium oxide is 0.1%;

[0047] Mix the above 1000kg rare earth chloride with 2500kg water, dissolve it and heat to 60℃, slowly add the mixed solution of NaF and Na2CO3 (the mass fraction of NaF is 2.25%, the mass fraction of Na2C03 is 10%), to the final pH The value is 6.5. After stirring for 0.5h, add 20kg phosphoric acid (content 85%), then add 10% Na2CO3 aqueous solution, precipitate to pH 7, and continue stirring for 2h to obtain modified rare earth carbonate precursor slurry.

[0048] After the slurry was allowed to stand for 2 hours, the upper clear aqueous solution was removed, and the same amount of hot water at 85°C was added. After stirring for 1.5 hours and then standing for 3 hours, the upper clear aqueous solution was removed again, and the upper clear water was washed 3 times with supplementary heating water...

Embodiment 2

[0052] In the mixed rare earth chloride, the mass ratio of each component is: total rare earth REO is 45%; cerium oxide is 80%, lanthanum oxide is 19.9%, and praseodymium oxide is 0.1%;

[0053] Mix the above 1000kg rare earth chloride with 2500kg water, dissolve it and heat it to 80°C, slowly add a mixed solution of NaF and Na2CO3 (the mass fraction of NaF is 3%, and the mass fraction of Na2CO3 is 15%) to the end pH The value is 6.5. After stirring for 0.5h, add 7kg phosphoric acid (content 85%), then add 10% Na2CO3 aqueous solution, precipitate to pH 7, and continue stirring for 2h to obtain modified rare earth carbonate precursor slurry.

[0054] After the slurry was allowed to stand for 2 hours, the upper clear aqueous solution was removed, and the same amount of hot water at 50°C was added. After stirring for 0.5 hours and then standing for 2 hours, the upper clear aqueous solution was removed again, and the upper clear aqueous solution was washed with supplementary heating wat...

Embodiment 3

[0058] In the mixed rare earth chloride, the mass ratio of each component is: total rare earth REO is 45%; cerium oxide is 60%, lanthanum oxide is 35%, and praseodymium oxide is 3%;

[0059] Mix the above 1000kg rare earth chloride with 2500kg water, dissolve it and heat it to 80°C, slowly add a mixed solution of NaF and Na2CO3 (the mass fraction of NaF is 3%, and the mass fraction of Na2CO3 is 15%) to the end pH The value is 6.5. After stirring for 0.5h, 14kg phosphoric acid (content 85%) is added, followed by 10% Na2CO3 aqueous solution, precipitation to pH 7, and stirring is continued for 1h to obtain modified rare earth carbonate precursor slurry.

[0060] After the slurry was allowed to stand for 2 hours, the upper clear aqueous solution was pumped out, and the same amount of hot water at 70°C was added. After stirring for 1 hour and then standing for 2 hours, the upper clear aqueous solution was extracted again, and the upper clear aqueous solution was washed with supplementar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com