Chemical polishing solution and alloy surface polishing treatment method

A technology of chemical polishing and polishing liquid, applied in the field of chemical polishing solution, to achieve the effect of easy control, pollution reduction, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Prepare chemical polishing fluid according to the following components:

[0024] Each liter of polishing liquid contains: sodium persulfate 90g, 98% concentrated sulfuric acid 350ml, polyethylene glycol 600015g, CTAB0.5g, arginine 5g, methionine 5g, sulfosalicylic acid 2g, and the balance is water.

[0025] 2, a kind of chemical polishing method, concrete steps are as follows:

[0026] The copper alloy samples were subjected to degreasing (40g / L sodium carbonate, 35g / L sodium phosphate and 2ml / L OP-10 emulsifier, treatment for 1min), running water washing, pickling activation (10% sulfuric acid, treatment for 10s), running water Then put the sample in the chemical polishing solution prepared above and immerse it at 40°C for 8 minutes. During the chemical polishing process, the solution was properly stirred, and the sample was taken out for cleaning (washing with running water + ultrasonic cleaning with distilled water), and then blunt in turn. Chemical (6g / L benzotr...

Embodiment 2

[0028] 1. Prepare chemical polishing fluid according to the following components:

[0029] Each liter of polishing liquid contains: 40g of sodium persulfate, 450ml of 98% concentrated sulfuric acid, 600025g of polyethylene glycol, 3g of thiourea, 0.5g of cetyltrimethylammonium bromide, and the balance is water.

[0030] 2, a kind of chemical polishing method, concrete steps are as follows:

[0031] The copper alloy samples were subjected to degreasing (40g / L sodium carbonate, 35g / L sodium phosphate and 2ml / L OP-10 emulsifier, treatment for 1min), running water washing, pickling activation (10% sulfuric acid, treatment for 10s), running water Then put the sample in the chemical polishing solution prepared above and immerse it at 40°C for 6 minutes. During the chemical polishing process, the solution was properly stirred, and the sample was taken out for cleaning (washing with running water + ultrasonic cleaning with distilled water), and then blunt in turn. Chemical (6g / L benz...

Embodiment 3

[0033] 1. Prepare chemical polishing fluid according to the following components:

[0034] Each liter of polishing liquid contains: 60g of sodium persulfate, 400ml of 98% concentrated sulfuric acid, 15g / L of polyvinylpyrrolidone, CuSO 4 5g / L, sulfosalicylic acid 2g / L, arginine 5g / L, CTAB 0.5g / L, and the balance is water.

[0035] 2, a kind of chemical polishing method, concrete steps are as follows:

[0036] The copper alloy samples were subjected to degreasing (40g / L sodium carbonate, 35g / L sodium phosphate and 2ml / L OP-10 emulsifier, treatment for 1min), running water washing, pickling activation (10% sulfuric acid, treatment for 10s), running water Then put the sample in the chemical polishing solution prepared above and immerse it at 40°C for 9 minutes. During the chemical polishing process, the solution was properly stirred, and the sample was taken out for cleaning (washing with running water + ultrasonic cleaning with distilled water), and then blunt in turn. Chemical...

PUM

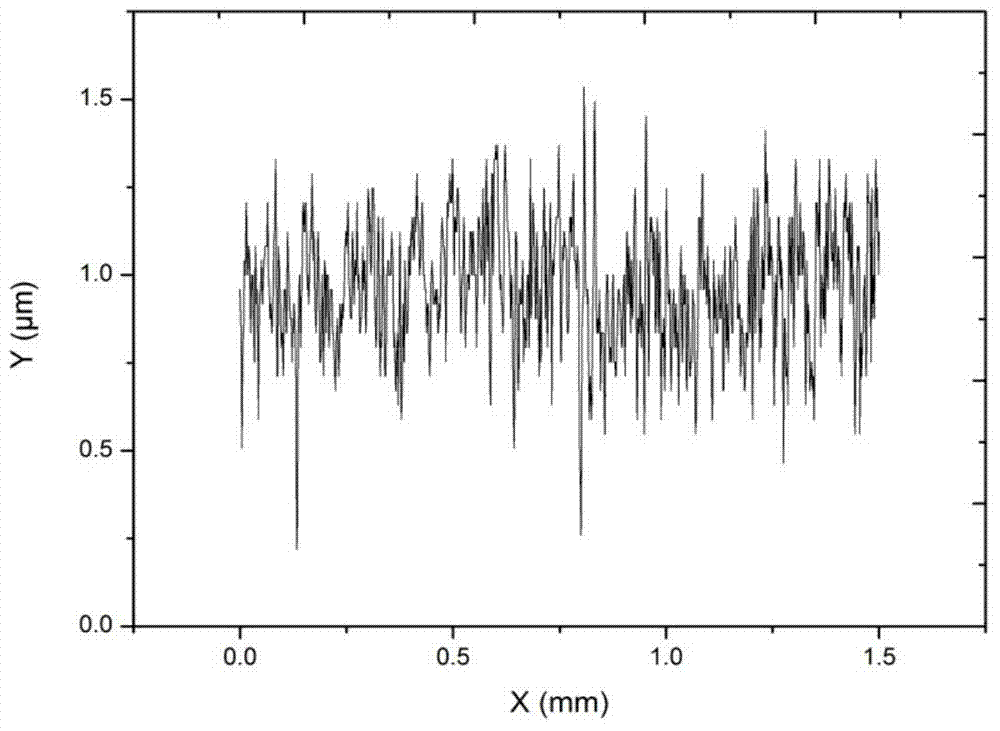

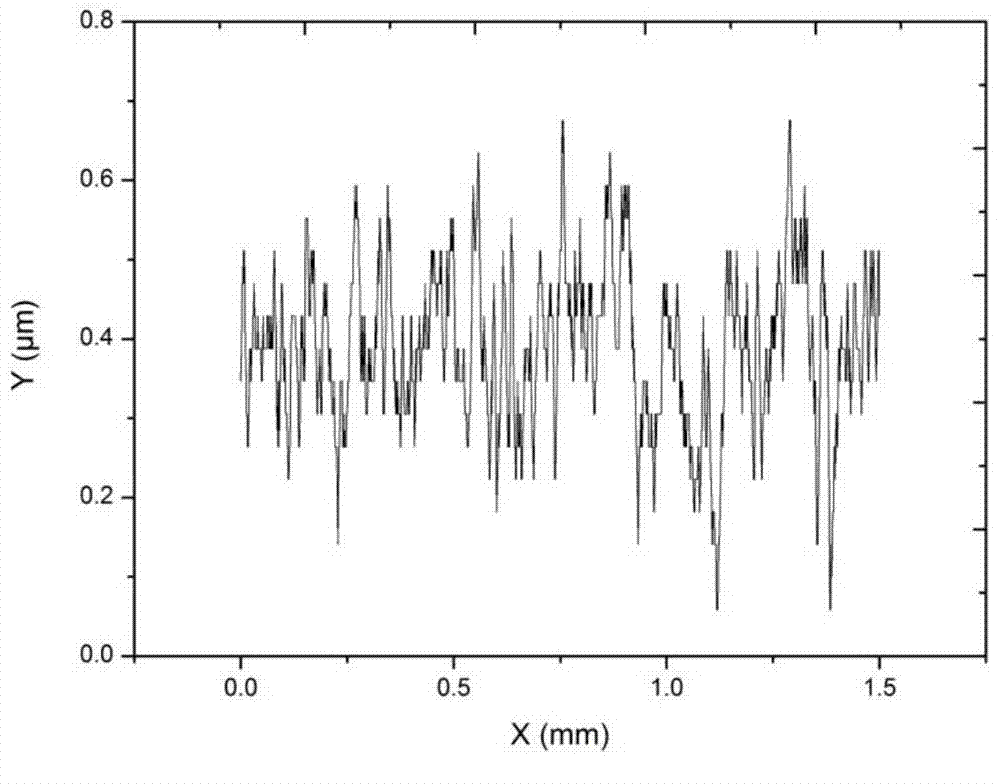

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com