Antibiotic polymer material

A technology of polymer materials and oligomers, applied in the polymer field, can solve the problem of high price of antibacterial monomers and achieve long-term antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

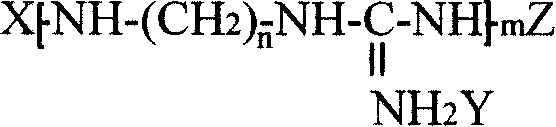

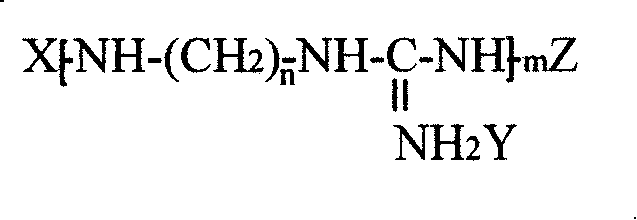

Method used

Image

Examples

Embodiment 1

[0035] Get 95 grams of methyl methacrylate, 5 grams of maleyl of polyethylenediamine guanidinium carbonate, and 1 gram of benzoyl peroxide, and mix them uniformly. After polymerization, an antibacterial polymer material can be obtained, which is designated as 1#.

Embodiment 2

[0037] Take 60 grams of bisphenol A glycidyl methacrylate ("bis-GMA"), 10 grams of polyhexamethylenediamine guanidine nitrate methacryl, SiO within 40nm 2 18 grams, SiO above 400nm 212 grams, 0.8 grams of benzoyl peroxide-dimethylaniline, mixed homogeneously, can obtain antibacterial polymer material after polymerization, and is recorded as 2#.

Embodiment 3

[0039] Get 70 grams of tetra-(meth)acrylic acid-pentaerythritol ester, 10 grams of acryloyl of polyethylenediamine guanidine hydrochloride, 10 grams of calcium carbonate within 40nm, 10 grams of calcium carbonate above 400nm, 1.0 grams of camphorquinone, mix uniformly, After polymerization, an antibacterial polymer material can be obtained, which is denoted as 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com