Method for preparing aluminum-copper alloy microarc oxidation film

An aluminum-copper alloy, micro-arc oxidation technology, applied in the direction of anodic oxidation, etc., can solve the problems of burning parts, restricting the application of aluminum-copper alloy, and many defects in the oxide film layer, and achieves easy proportioning, easy operation and control, and rich sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

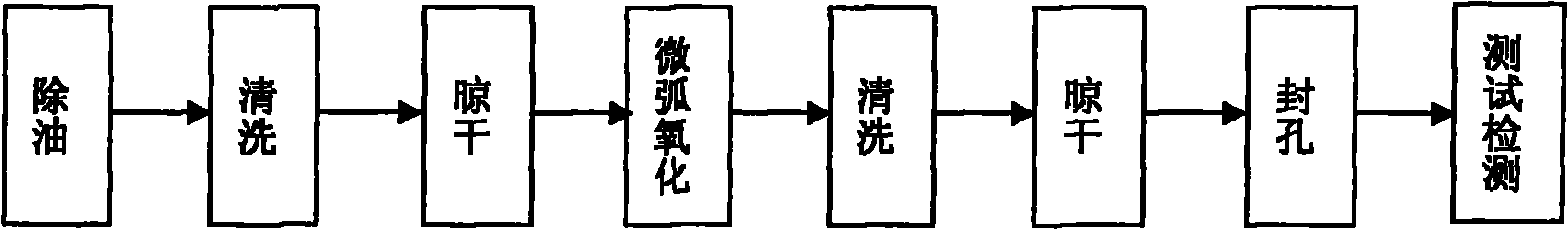

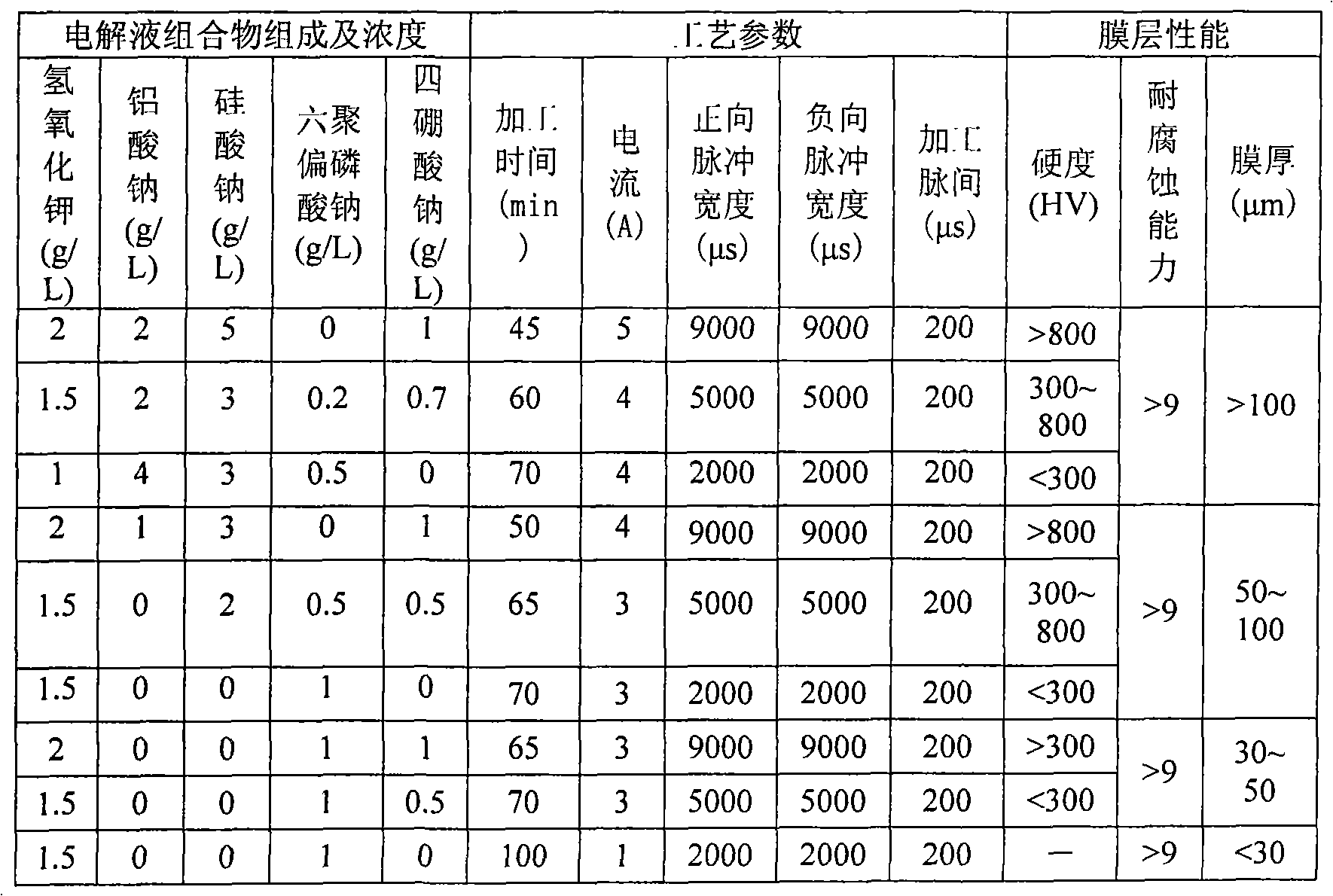

[0017] In this example, the test material is cast aluminum-copper alloy ZL201, according to the process flow figure 1 Prepare the micro-arc oxidation film layer, the composition of the electrolyte composition, process parameters and film layer properties are shown in Table 1:

[0018] Table 1. The composition of the electrolyte composition, process parameters and film layer performance comprehensive table

[0019]

[0020] Note: 1. The power supply voltage used in Table 1 is 550V~700V.

[0021] 2. The test temperature is not higher than 35 ℃.

[0022] 3. The corrosion resistance of the film layer is tested according to the experimental standards required by the national standard GB / T 10125-1997 (eqv ISO 9227: 1990) of the People's Republic of China. Continuous spray is used, and the salt spray test period is 96 hours. The grade after assessment implemented by the national standard GB6461-86 of the People's Republic of China.

[0023] 4. The hardness is measured by a Vick...

Embodiment 2

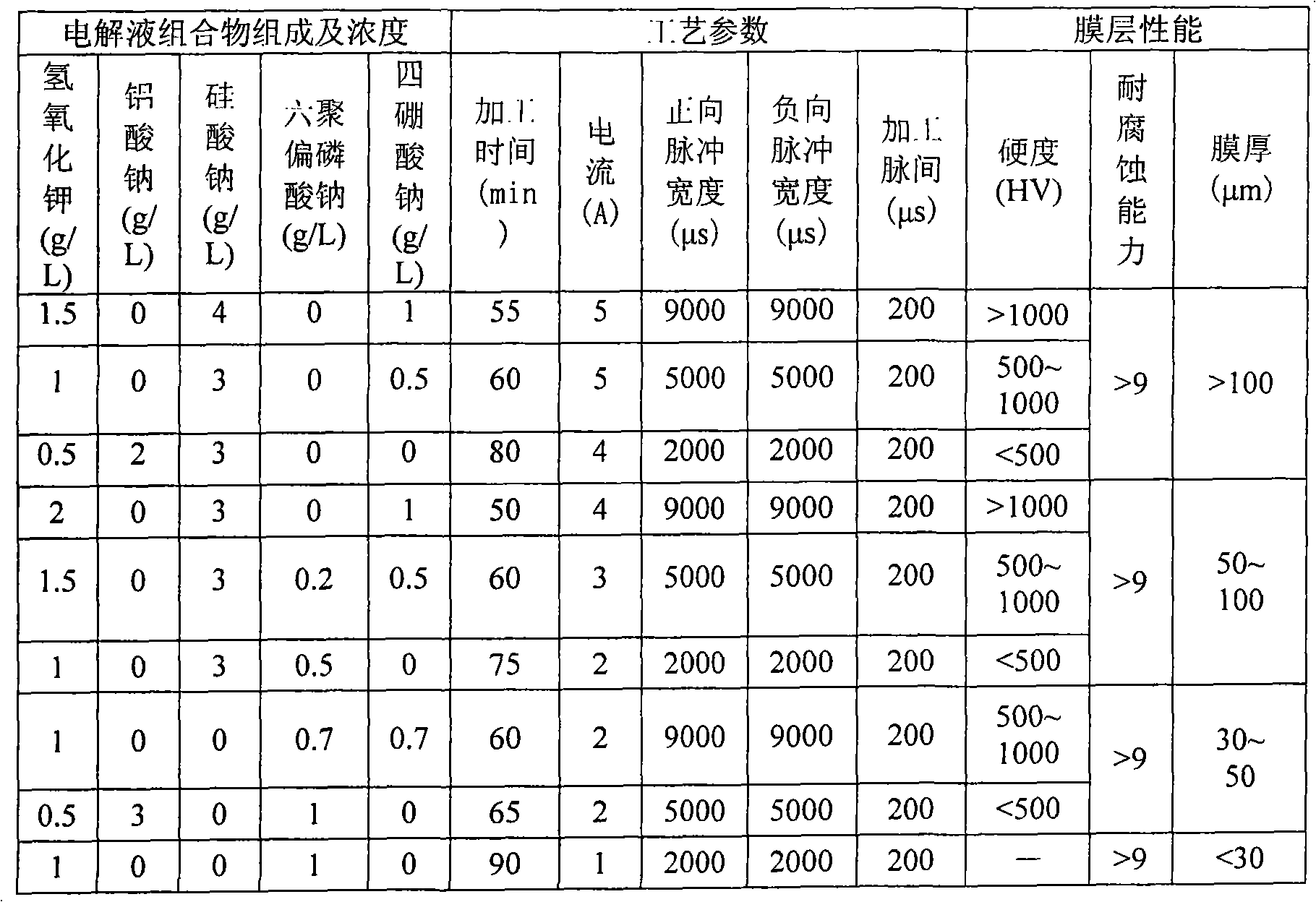

[0025] In this embodiment, the test material is the deformed aluminum-copper alloy 2A14, according to the process flow figure 1 Prepare the micro-arc oxidation film layer, the composition, process parameters and film layer performance of the electrolyte composition are shown in Table 2:

[0026] Table 2. The composition of the electrolyte composition, process parameters and film layer performance comprehensive table

[0027]

[0028] Note: 1. The power supply voltage used in Table 2 is 550V~700V.

[0029] 2. The test temperature is not higher than 35 ℃.

[0030] 3. The corrosion resistance of the film layer is tested according to the experimental standards required by the national standard GB / T 10125-1997 (eqv ISO 9227: 1990) of the People's Republic of China. Continuous spray is used, and the salt spray test period is 96 hours. The grade after assessment implemented by the national standard GB6461-86 of the People's Republic of China.

[0031] 4. The hardness is measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com