A detection method for micro-defects in quasi-single crystal silicon wafers

A detection method and micro-defect technology, applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., to achieve the effects of improving conversion efficiency, convenient operation, and fast and accurate testing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

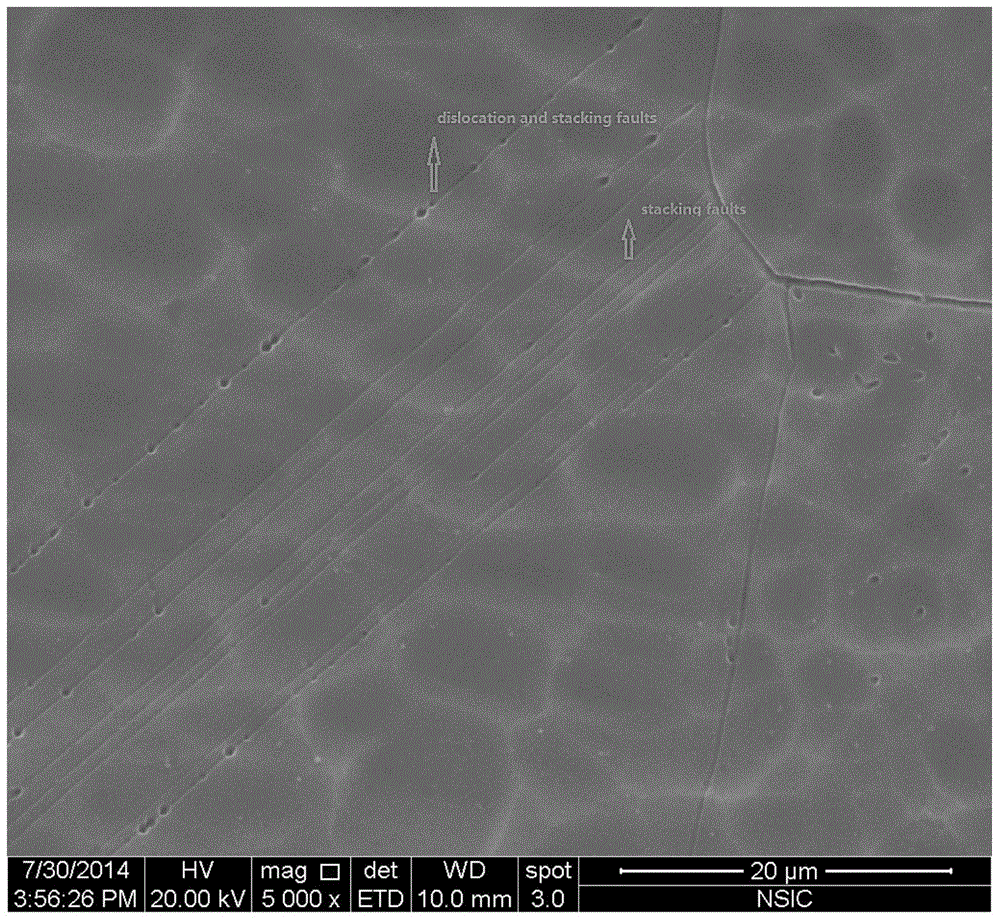

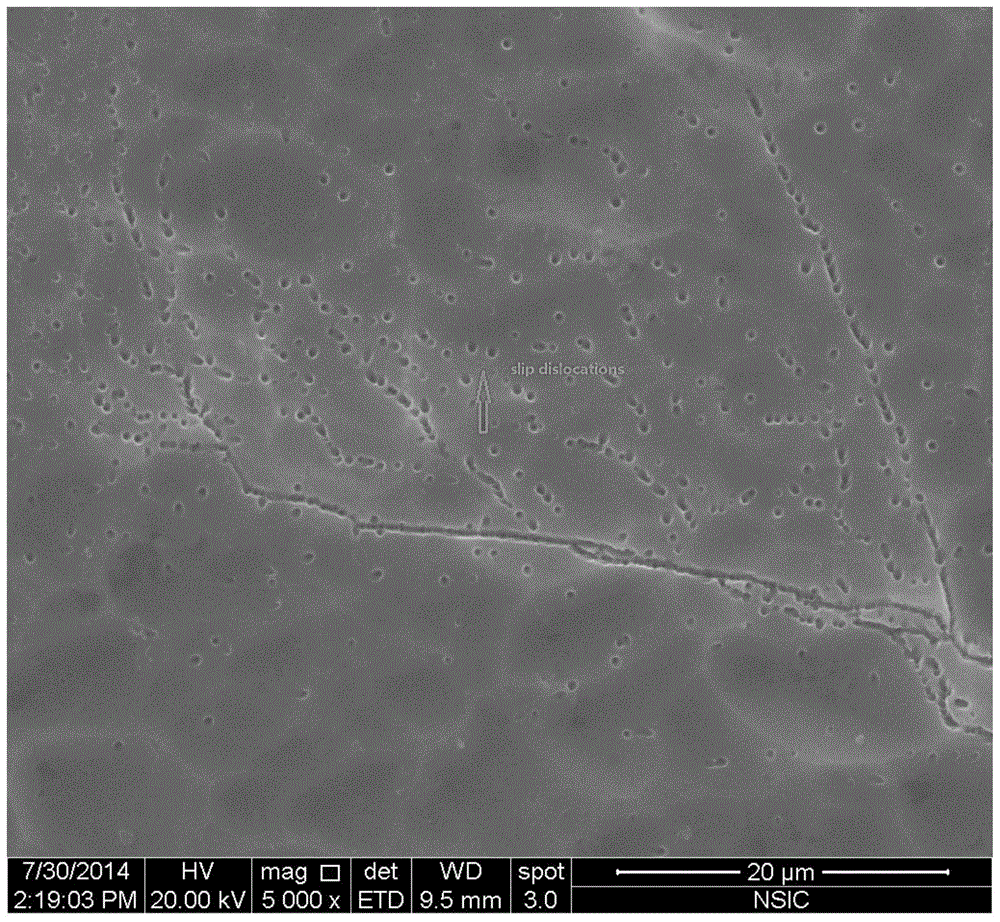

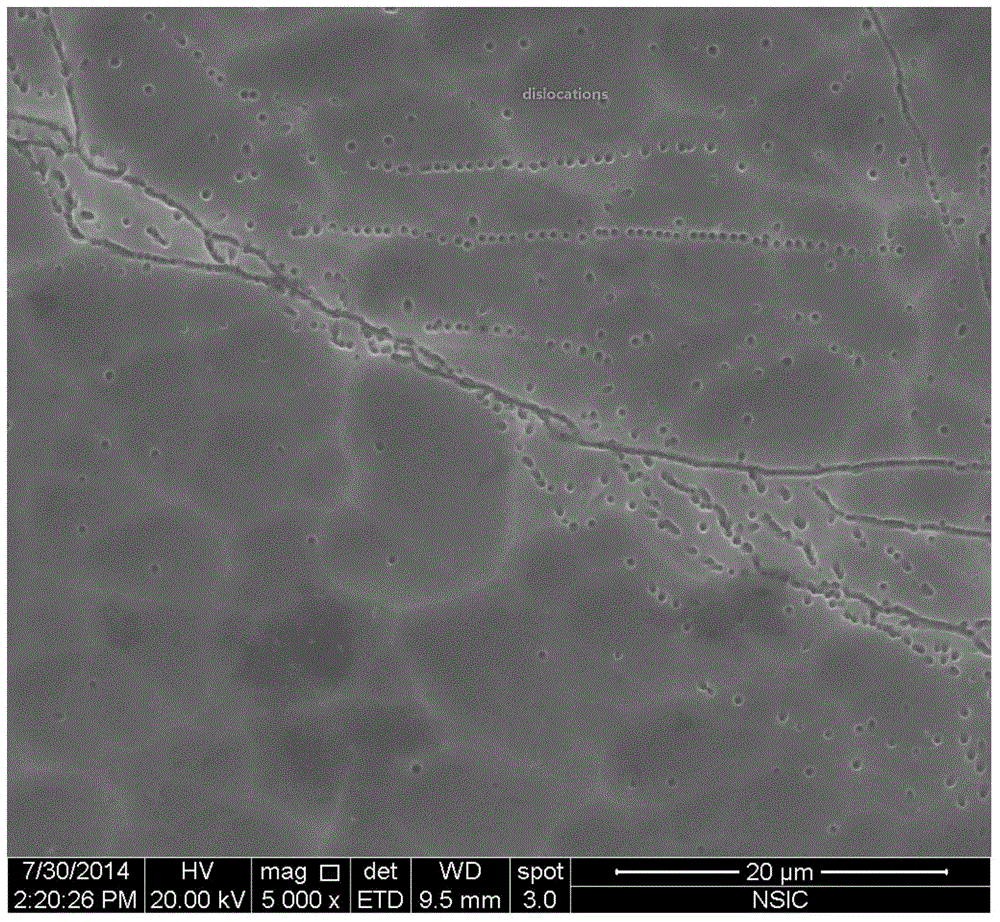

Image

Examples

Embodiment 1

[0037] Taking a cast quasi-single crystal silicon wafer produced by a large-scale photovoltaic crystalline silicon material enterprise as a sample, the invention provides a method for detecting micro-defects in a quasi-single crystal silicon wafer, which includes the following steps:

[0038] (1) Manual mechanical polishing: the quasi-monocrystalline silicon wafer to be etched is manually mechanically polished, and rinsed with deionized water; The thickness of the polishing pad is 2 mm, the polishing solution is a solution of ultrafine silicon carbide water suspension or nano silicon dioxide slurry added with 1% hydrogen peroxide by volume, and the rotating speed of the polishing disc is 30 r / min.

[0039] (2) chemical corrosion polishing: the silicon chip after mechanical polishing is cleaned is carried out chemical corrosion polishing, and rinses with deionized water; A mixed solution of nitric acid and hydrofluoric acid; the content of hydrofluoric acid in said hydrofluoric...

Embodiment 2

[0061] The difference between embodiment 2 and embodiment 1 is that the present invention provides a method for detecting micro-defects in quasi-single crystal silicon wafers, comprising the following steps:

[0062] In step (1), manual mechanical polishing: perform manual mechanical polishing on the quasi-single crystal silicon wafer to be corroded, and rinse with deionized water; The thickness of the single crystal silicon wafer is 3 mm, the polishing solution is a solution of superfine silicon carbide aqueous suspension or nano silicon dioxide slurry added with 1% hydrogen peroxide by volume, and the rotational speed of the polishing disc is 36 r / min.

[0063] In step (2), chemical etching and polishing: the mechanically polished silicon wafer is chemically etched and polished, and rinsed with deionized water; after the mechanical polishing, the silicon wafer is cleaned and the silicon wafer is chemically etched with an etching solution. Said corrosion solution is nitric ac...

Embodiment 3

[0066] The difference between embodiment 3 and embodiment 2 is that the present invention provides a method for detecting micro-defects in quasi-single crystal silicon wafers, comprising the following steps:

[0067] In step (1), manual mechanical polishing: perform manual mechanical polishing on the quasi-single crystal silicon wafer to be corroded, and rinse with deionized water; The thickness of the monocrystalline silicon wafer is 3 mm, the polishing solution is a solution of ultrafine silicon carbide water suspension or nano silicon dioxide slurry added with 1% hydrogen peroxide by volume, and the rotational speed of the polishing disc is 40 r / min.

[0068] In step (2), chemical etching and polishing: the mechanically polished silicon wafer is chemically etched and polished, and rinsed with deionized water; after the mechanical polishing, the silicon wafer is cleaned and the silicon wafer is chemically etched with an etching solution. Said corrosion solution is nitric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com