Surface treatment liquid for 3D printed stainless steel parts and surface treatment device

A surface treatment liquid, 3D printing technology, applied in machine tools suitable for grinding workpiece edges, surface polishing machine tools, polishing compositions containing abrasives, etc. problems, to achieve the effect of improved product corrosion resistance, high surface treatment efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

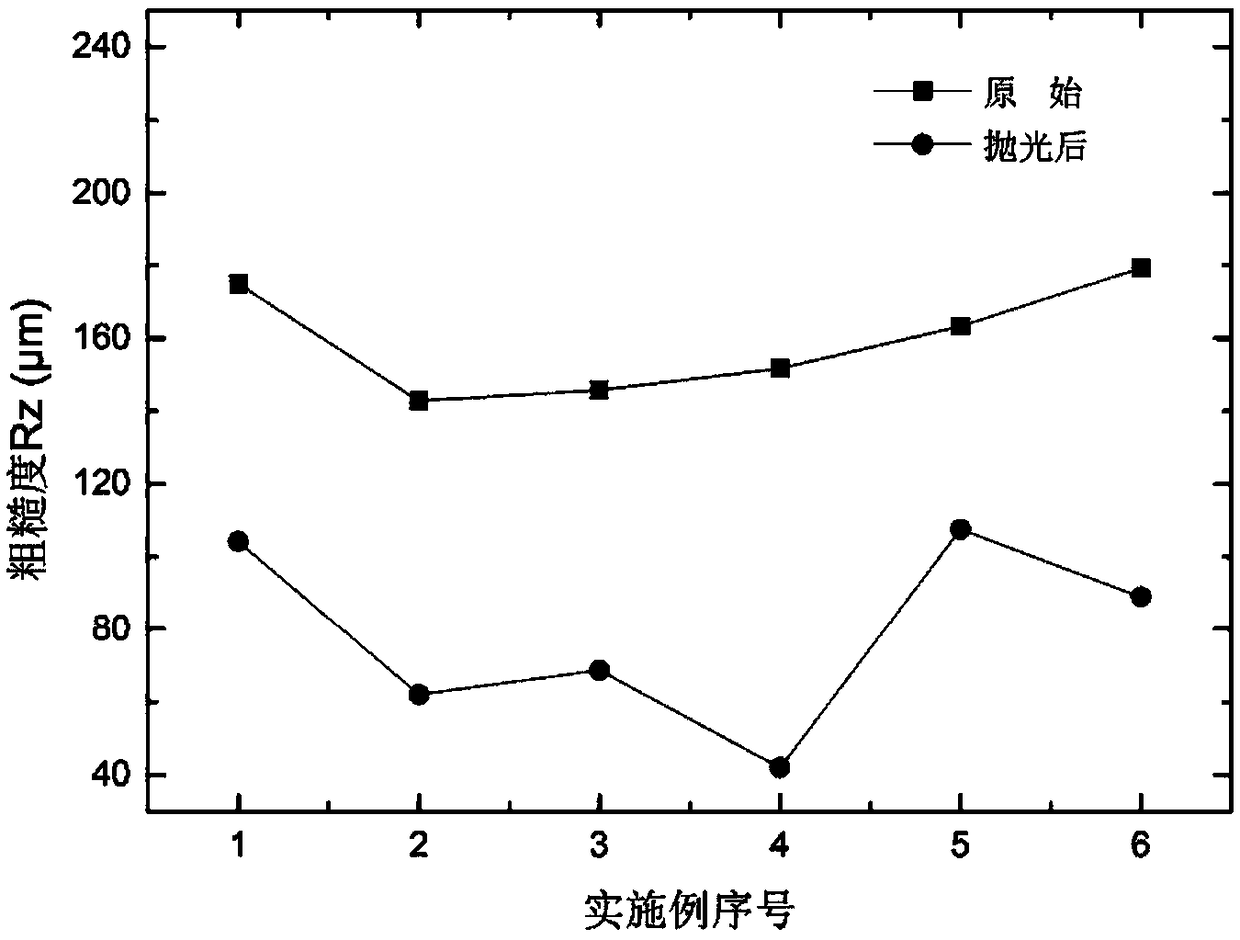

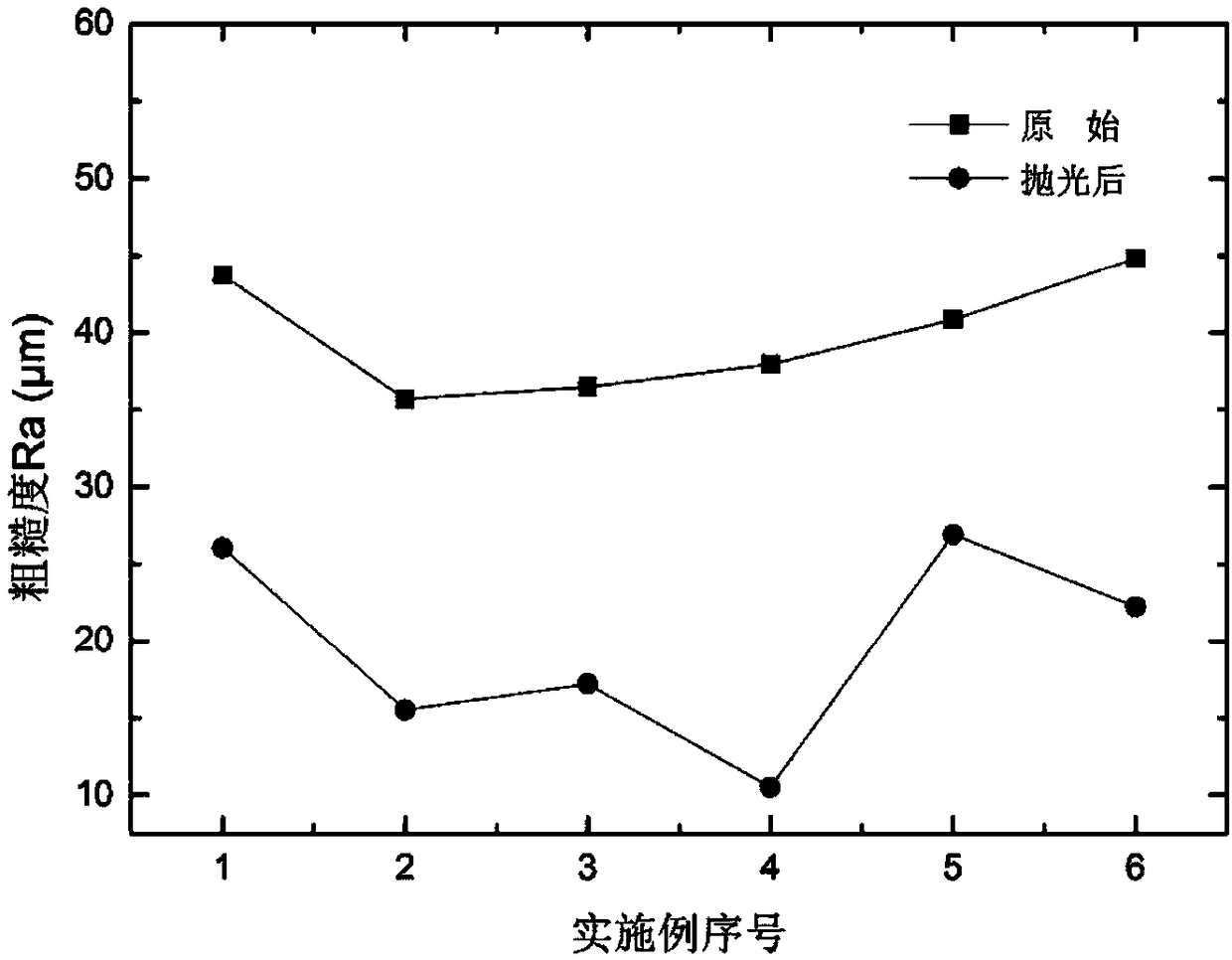

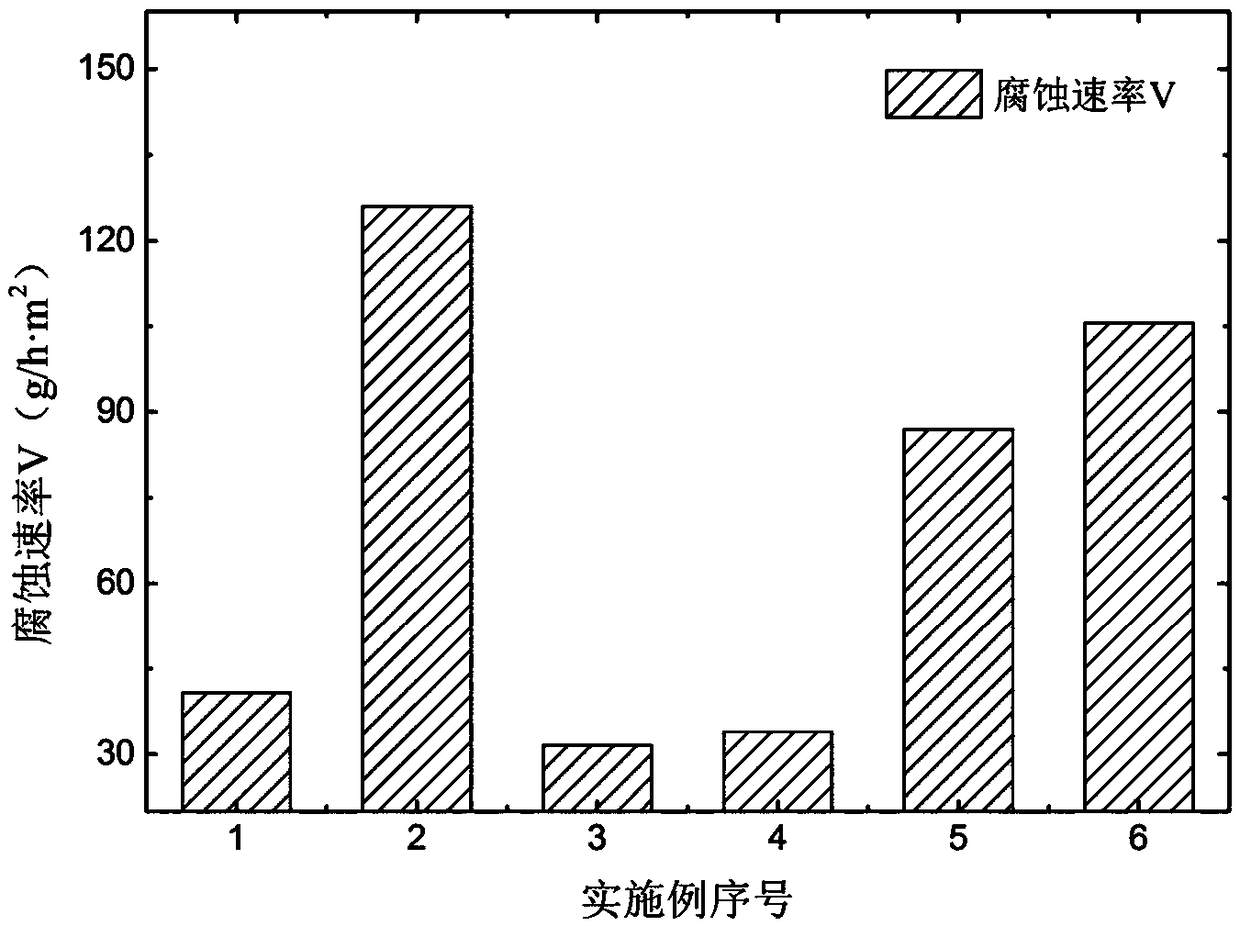

Examples

Embodiment 1

[0054] A surface treatment liquid for 3D printing stainless steel parts, including alkaline boiling liquid, pickling liquid and chemical polishing liquid:

[0055] The mass fraction ratio of sodium hydroxide, nitrate, and chloride ion-containing salt in the alkaline cooking liquid is as follows: 10:5:0.15.

[0056] Nitrate is composed of sodium nitrate and sodium nitrite, and the mass ratio of sodium nitrate and sodium nitrite is 3:1.

[0057] The chloride ion-containing salt is composed of sodium chloride and ferric chloride, and the mass ratio of sodium chloride and ferric chloride is 2.5:1.

[0058] The mass ratio of hydrochloric acid, sodium chloride, ferric chloride and corrosion inhibitor in the pickling solution is 15:3.2:0.6:0.2.

[0059] The corrosion inhibitor is composed of potassium iodide and rhodin, and the mass ratio of potassium iodide and rhodin is 2:1.

[0060] The chemical polishing liquid is composed of nano-scale silica abrasive, 36wt% hydrochloric acid,...

Embodiment 2

[0083] Embodiment 2 includes the solution preparation step and surface treatment device of Embodiment 1, and the surface treatment solution of Embodiment 2 includes alkali cooking liquid, acid washing liquid and chemical polishing liquid:

[0084] The mass fraction ratio of sodium hydroxide, nitrate and chloride ion-containing salt in the alkaline cooking liquid is as follows: 18:3:0.05.

[0085] Nitrate is composed of sodium nitrate and sodium nitrite, and the mass ratio of sodium nitrate and sodium nitrite is 5:1.

[0086] The chloride ion-containing salt is composed of sodium chloride and ferric chloride, and the mass ratio of sodium chloride and ferric chloride is 1:1.

[0087] The mass ratio of hydrochloric acid, sodium chloride, ferric chloride and corrosion inhibitor in the pickling solution is: 15:4:0.8:0.2.

[0088] The corrosion inhibitor is composed of potassium iodide and rhodin, and the mass ratio of potassium iodide and rhodin is 3:1.

[0089] Nanoscale silica ...

Embodiment 3

[0101] Embodiment 3 includes the solution preparation step and surface treatment device of Embodiment 1, and the surface treatment solution of Embodiment 3 includes alkaline boiling liquid, acid washing liquid and chemical polishing liquid:

[0102] The mass fraction ratio of sodium hydroxide, nitrate, and chloride ion-containing salt in the alkaline cooking liquid is as follows: 15:5:0.1.

[0103] Nitrate is composed of sodium nitrate and sodium nitrite, and the mass ratio of sodium nitrate and sodium nitrite is 5:1.

[0104]The chloride ion-containing salt is composed of sodium chloride and ferric chloride, and the mass ratio of sodium chloride and ferric chloride is 2.5:1.

[0105] The mass fraction ratio of hydrochloric acid, sodium chloride, ferric chloride and corrosion inhibitor in the pickling solution is: 20:3.2:0.8:0.1;

[0106] The corrosion inhibitor is composed of potassium iodide and rhodin, and the mass ratio of potassium iodide and rhodin is 2:1.

[0107] Nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com