Wire rod having good superior surface properties, high strength, and high toughness, and a method for manufacturing same

a technology of surface properties and wire rods, applied in the field of wire rods, can solve the problems of affecting the application of wire rods, deteriorating quality, and needing to remove the iron oxide layer on the surface of the wire rod, and achieve the effects of suppressing surface defects, high strength, and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0047]Steels satisfying compositions of Table 1 were prepared and subjected to a solution heat treatment at 1100° C. Next, after strain was applied to the steels at a strain rate of 0.6 and 10 / s at 950° C., cooling was performed thereon at a cooling rate of 2° C. / s. Then, wire drawing was performed thereon at 10 to 80%, such that wire rods were manufactured.

TABLE 1TheClassificationCSiMnPSSbremainderInventive0.250.150.60.20.0150.005Festeel 1Inventive0.250.150.60.20.0150.015Festeel 2Inventive0.250.150.60.20.0150.02Festeel 3The related0.250.250.60.20.015—Feart steelComparative0.250.150.60.20.0150.002FeSteel 1Comparative0.250.150.60.20.0150.05FeSteel 2

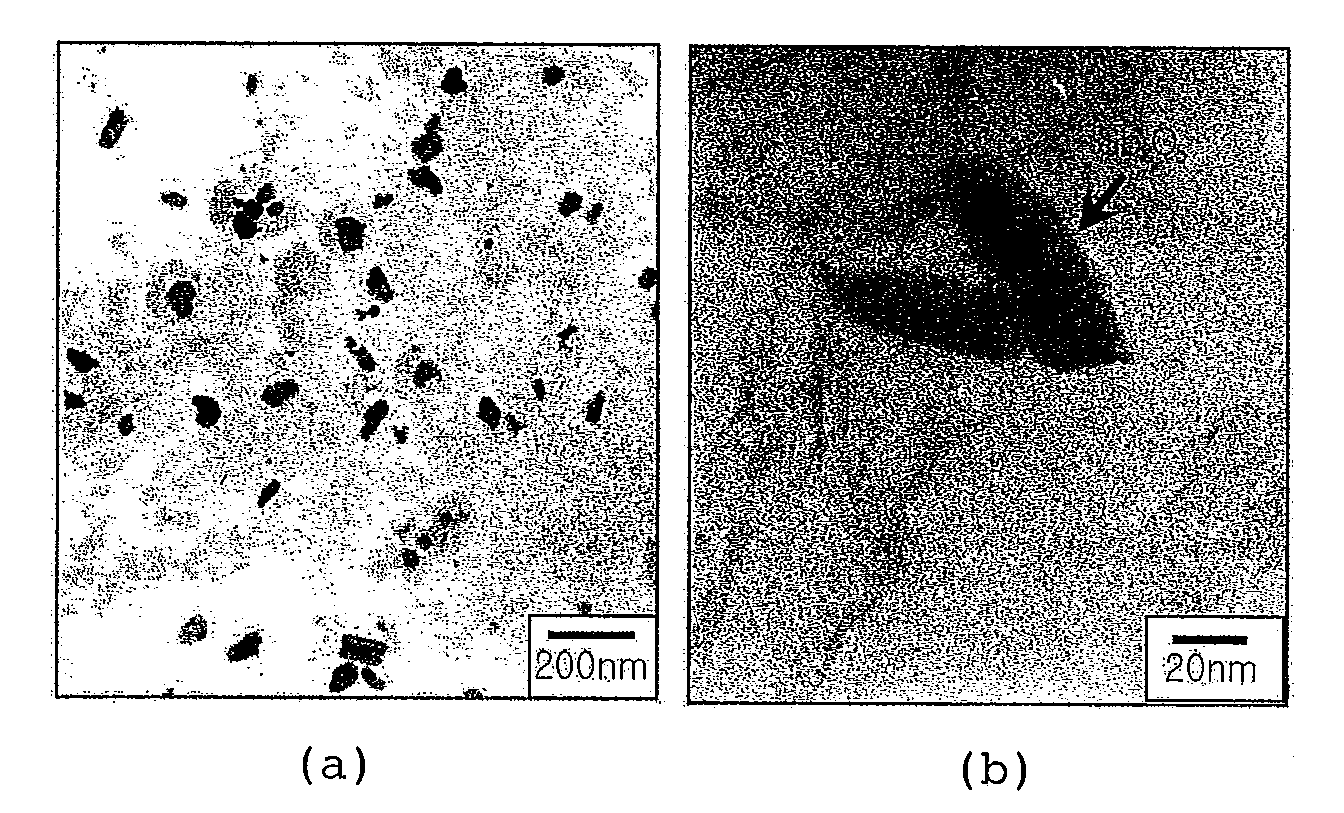

[0048]FIG. 1A and FIG. 1B respectively show microstructures of the related art steel and inventive steel 1, observed using an optical microscope. As shown in FIG. 1, the related art steel had a ferrite-pearlite structure, but a ferrite fraction thereof was less than 40% and a structure size thereof was about 35 to 50 μm. On the other hand,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain diameter | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com