ZnSe quantum dot-doped glass and preparation method thereof

A technology of doping glass and quantum dots, which is applied in the field of ZnSe quantum dot-doped glass and its preparation, can solve the problems of low fluorescence intensity and inability to meet the requirements of practical applications, and achieve improved solubility, enhanced chemical stability, and composition The effect of regulation optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The molar ratio of the glass chemical composition of the present embodiment is SiO 2 : 35l%; B 2 o 3 : 15%; Na 2 O: 14%; Li 2 O: 10%; ZnO: 20%; ZnSe: 6%. The chemical raw materials weighed according to the above molar percentages are mixed uniformly, melted at a high temperature of 1350°C for 50 minutes, shaped, and annealed to obtain the original glass, which is recorded as G1, which is cut into a specific size for heat treatment.

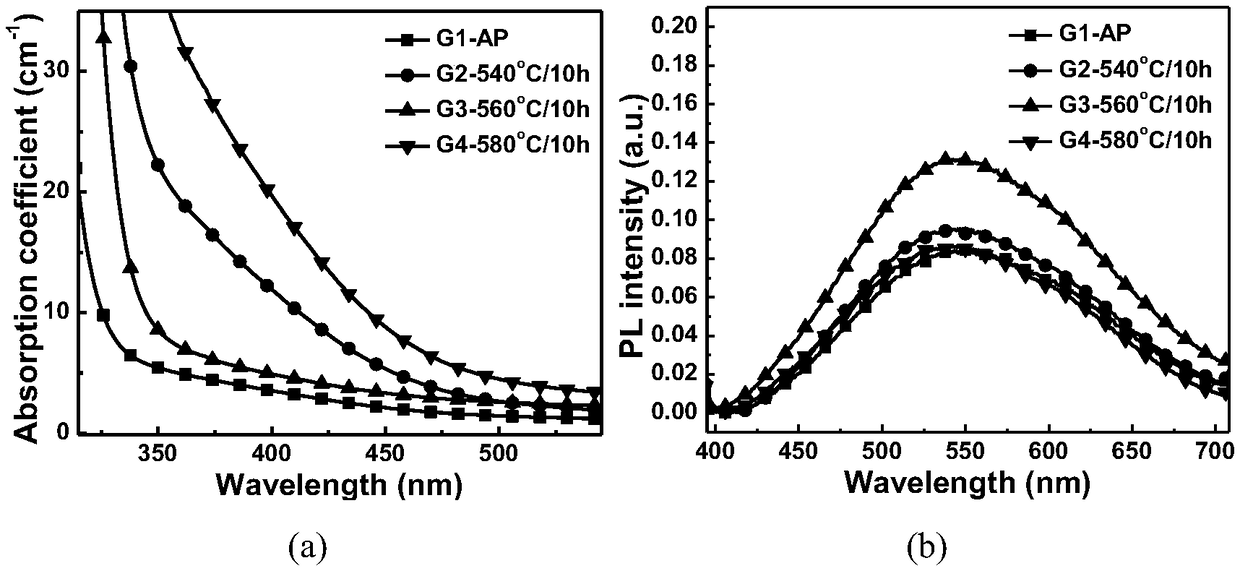

[0038] Next, the original glass was heat-treated at 540°C, 560°C, and 580°C for 10 h, and cooled to room temperature with the furnace to obtain ZnSe quantum dot silicate glass samples, which were denoted as G2, G3, and G4, respectively. The absorption and fluorescence spectra were as follows: figure 1 As shown in (a) and (b), AP represents the original glass sample without heat treatment, and 540°C / 10h, 560°C / 10h, and 580°C / 10h represent the heat treatment conditions. From the absorption spectrum, it can be seen that the absorption edg...

Embodiment 2

[0040] The mole percent of the glass chemical composition of the present embodiment is SiO 2 : 45%; B 2 o 3 : 5%; Na 2 O: 14%; Li 2 O: 10%; ZnO: 20%; ZnSe: 6%. The chemical raw materials weighed according to the above molar percentages are mixed uniformly, melted at a high temperature of 1350°C for 50 minutes, shaped, and annealed to obtain the original glass, which is recorded as G5, which is cut into a specific size for heat treatment.

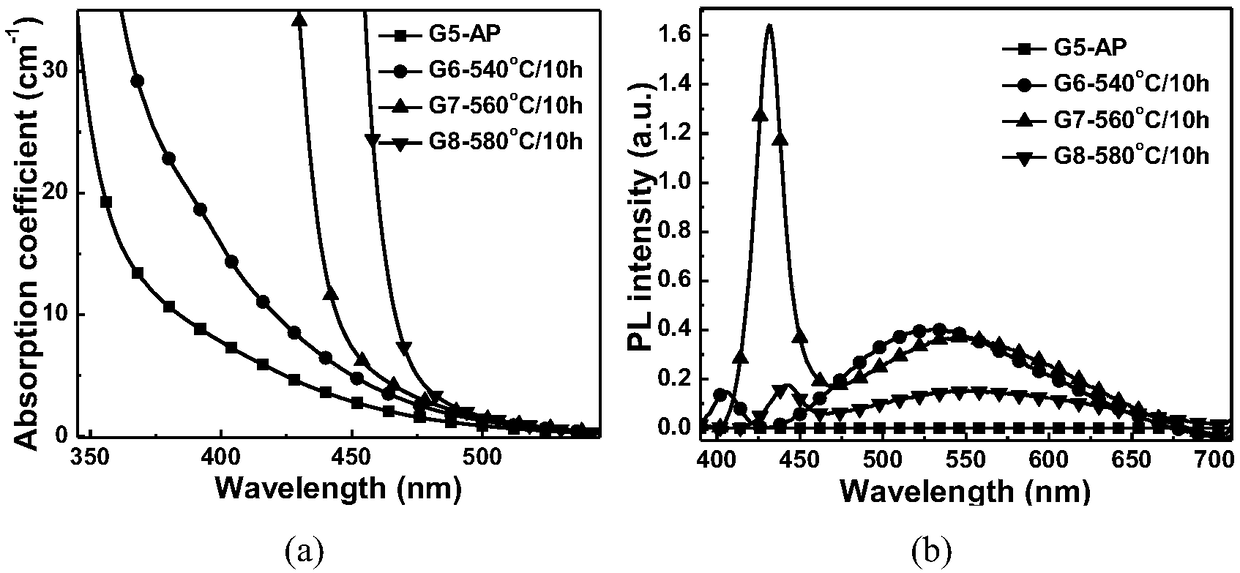

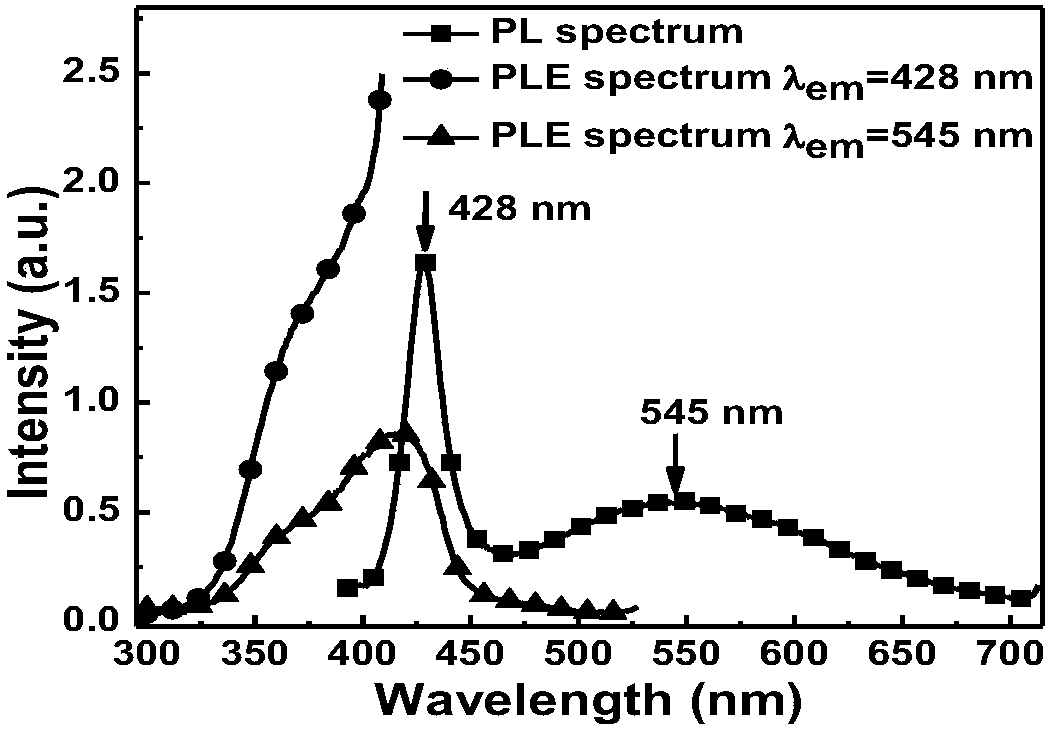

[0041] Then the original glass was heat-treated at 540°C, 560°C, and 580°C for 10 h, and cooled to room temperature with the furnace to obtain ZnSe quantum dot silicate glass samples, which were denoted as G6, G7, and ZnSe quantum dot silicate glass samples respectively. G8, the absorption spectrum and fluorescence spectrum are as follows figure 2 As shown in (a) and (b), AP represents the original glass sample without heat treatment, and 540°C / 10h, 560°C / 10h, and 580°C / 10h represent the heat treatment conditions. From the absorption ...

Embodiment 3

[0044] The molar ratio of the glass chemical composition of the present embodiment is SiO 2 : 45%; B 2 o 3 : 5%; Na 2 O: 20%; ZnO: 21%; ZnSe: 9%. The chemical raw materials weighed according to the above molar percentages are mixed uniformly, melted at a high temperature of 1350°C for 50 minutes, shaped, and annealed to obtain the original glass, which is recorded as G9, which is cut into a specific size for heat treatment.

[0045] Then heat-treat the original glass at 540°C, 560°C, and 580°C for 10 h, and cool to room temperature with the furnace to obtain ZnSe quantum dot silicate glass samples, which are denoted as G10, G11, and ZnSe quantum dot silicate glass samples respectively. G12, absorption spectrum and fluorescence spectrum are as follows Figure 6 As shown in (a) and (b), AP represents the original glass sample without heat treatment, and 540°C / 10h, 560°C / 10h, and 580°C / 10h represent the heat treatment conditions. Such as Figure 6 (a) As shown in the absorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com