Leak repair method

a leakage repair and leak technology, applied in the field of leakage repair methods, can solve the problems of casting aluminum wheels manufactured, market-wide porosity in materials, and detrimental to the performance of wheels,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

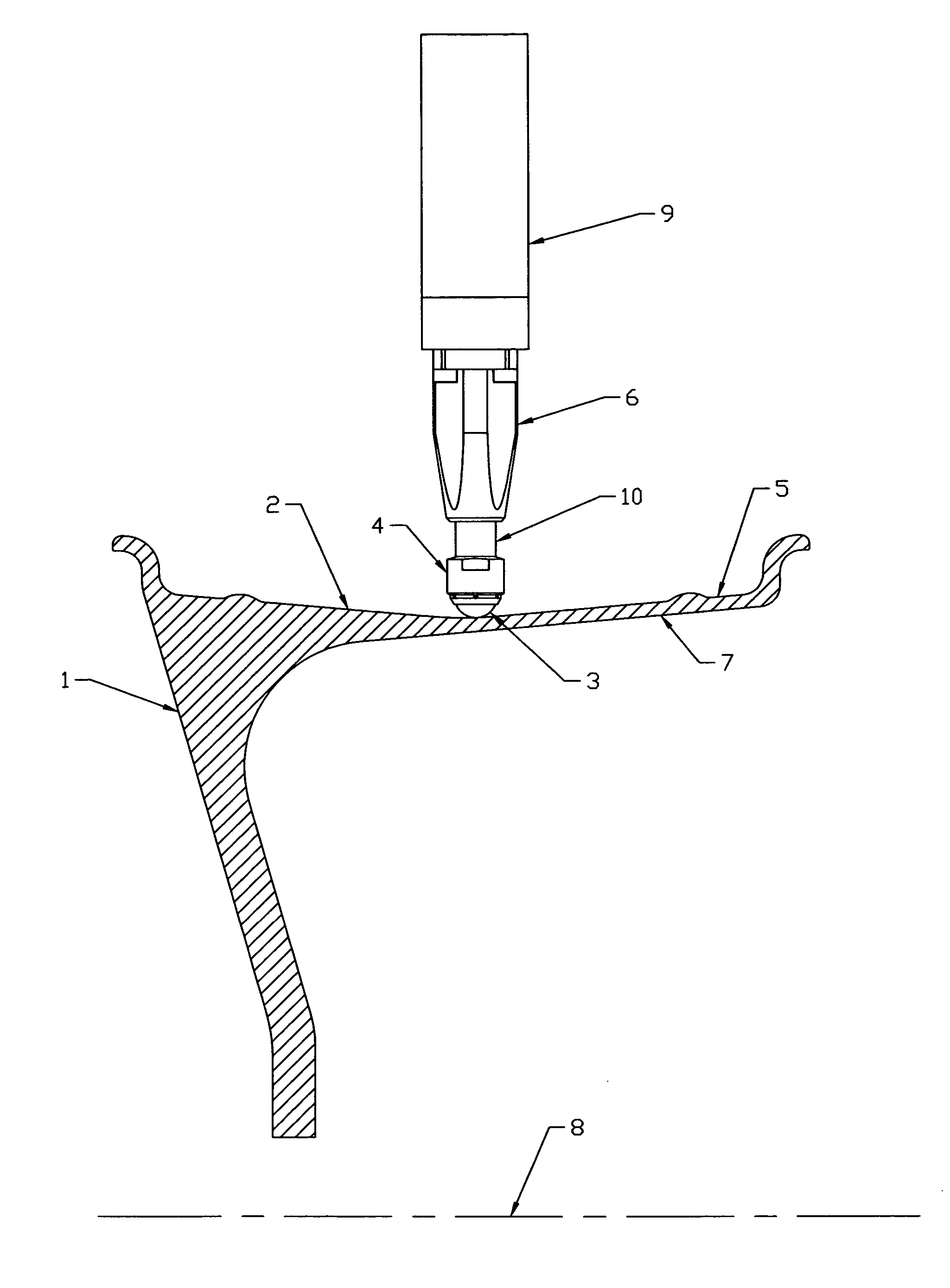

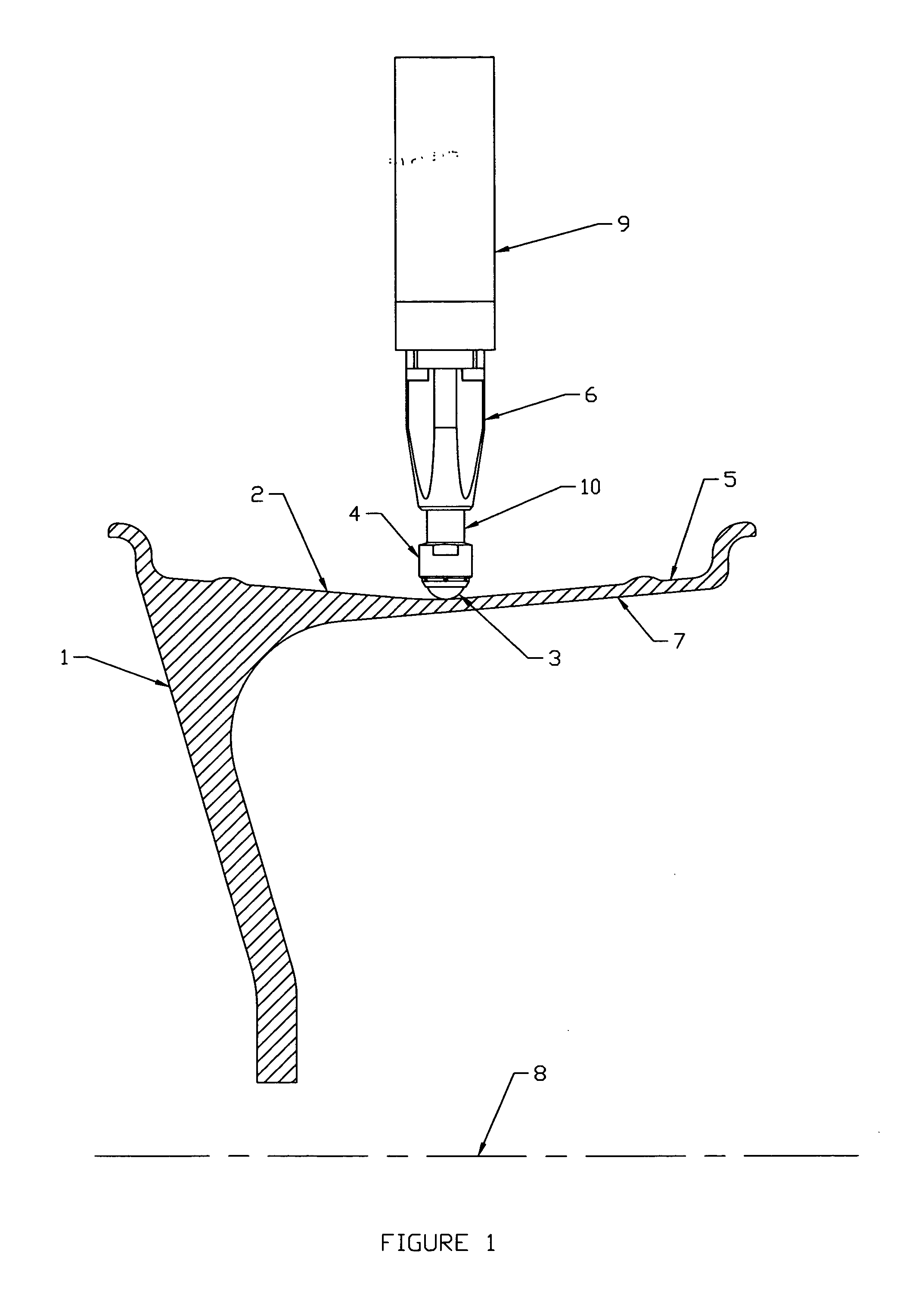

[0009] The invention involves using a roller burnishing tool to deep roll the surface of a cast aluminum wheel such that the porosity becomes sealed and the wheel no longer leaks air. Deep rolling is a method of roller burnishing where the parameters of the burnishing process are tightly controlled. Particularly, the parameters of applied force, feed rate, roller material properties, and roller geometry are required to be specified and validated. Unfortunately, past commercially available burnishing tools were not capable of maintaining tight control of the operational parameters to the degree necessary. Deep rolling produces cold work and plastic deformation in the surface of the wheel due to the Hertzian contact stress induced by the action of the roller under an applied load. This plastic deformation effectively closes the porosity in the near surface layers in the wheel material. The residual compressive stresses and cold work induced by the deep rolling process also acts to kee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

| seal porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com