Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

645results about "Cams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Elongated member/radially expandable member assembly and methods of assembling the same

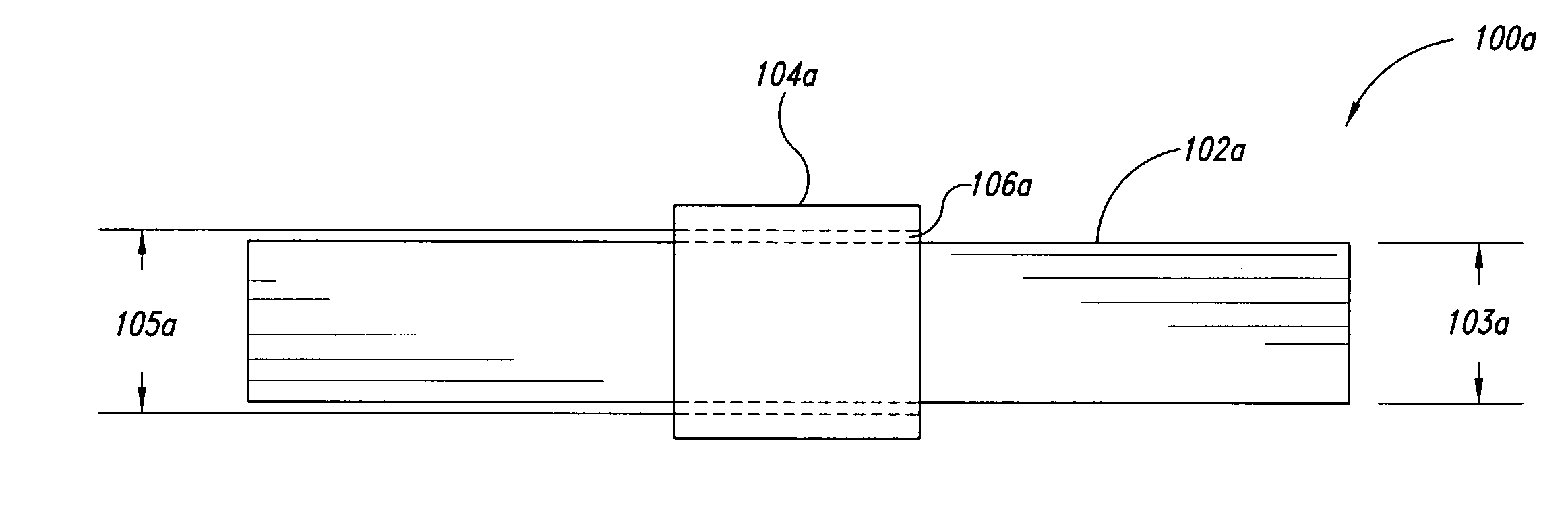

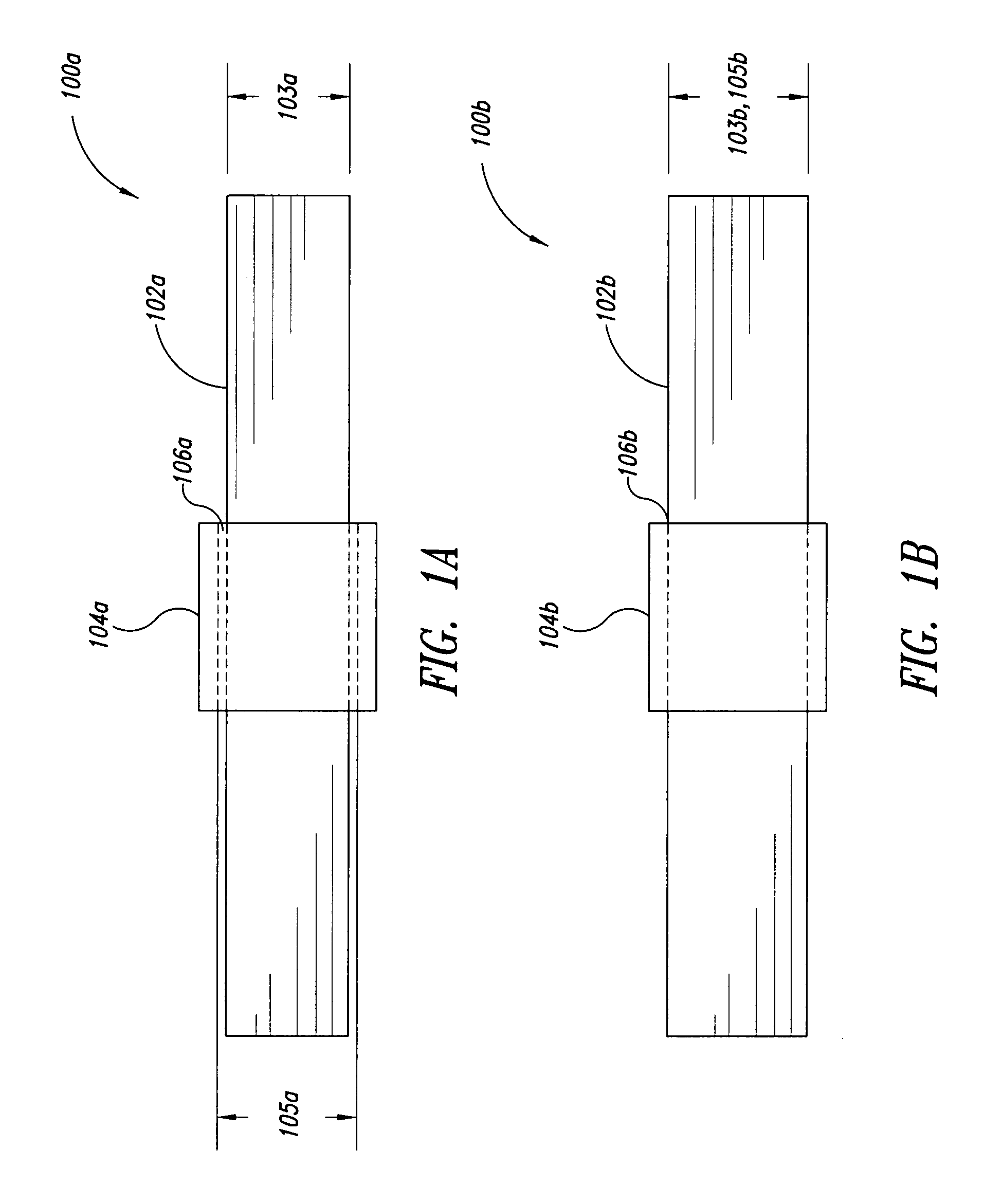

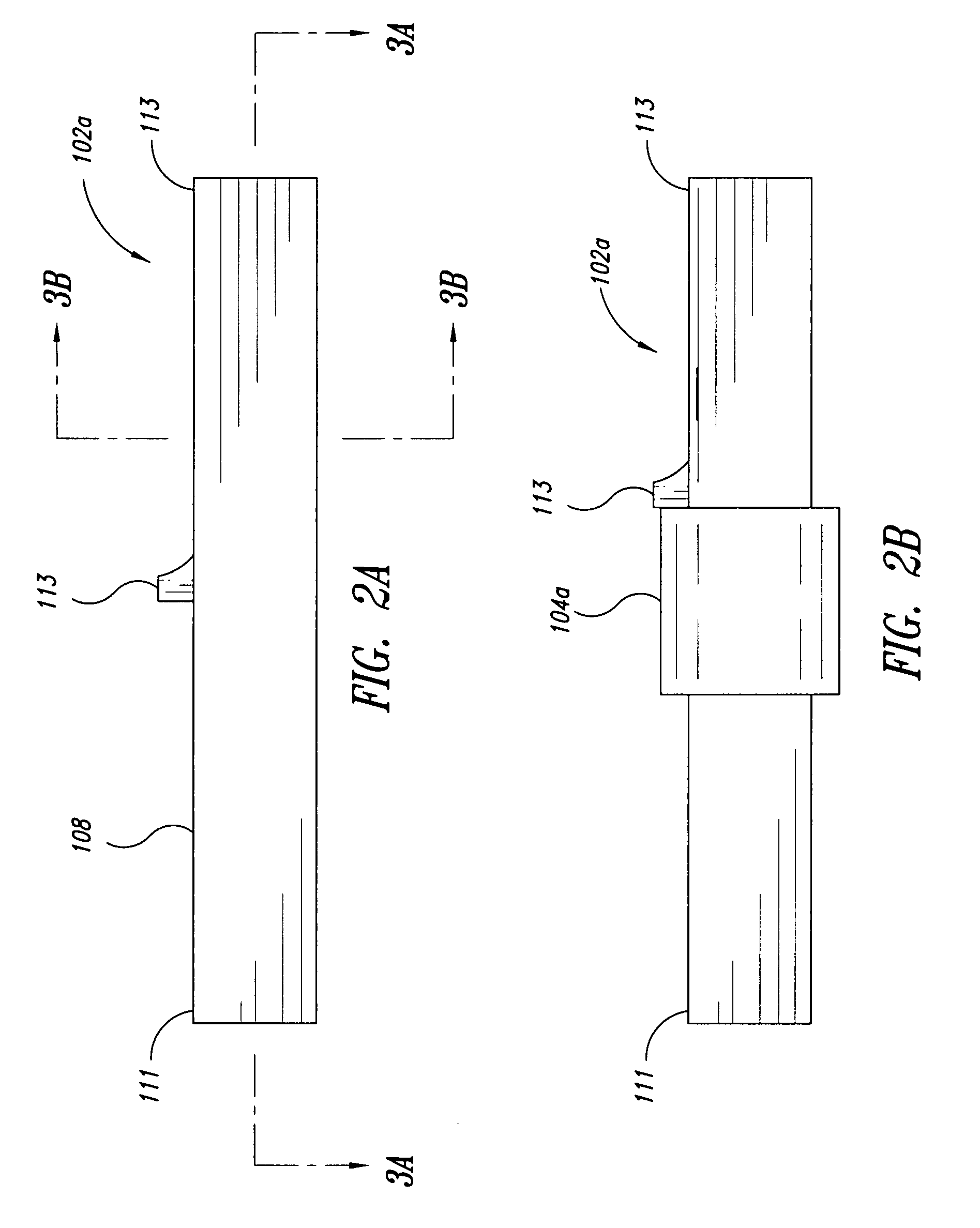

At least one embodiment generally relates to using an installation tool to pass an expansion mandrel through an elongated member to at least locally, radially expand at least a portion of the elongated member and achieve an interference fit with a radially expandable member located about an outer surface of the elongated member. In one embodiment, the elongated member is radially expanded over its entire length and may include a stepped feature so that only a portion of the elongated member achieves the interference fit with the radially expandable member. During the radial-expansion process, both the radially expandable member and the elongated member may be at the same or approximately the same temperature. Before the radial-expansion process, the radially expandable member may be assembled using press-fit techniques, shrink fit techniques, clearance fitting techniques, or combinations thereof.

Owner:FATIGUE TECH

Cutting insert for turning and milling

A cutting insert comprises first and second polygonally-shaped main faces arranged substantially parallel to one another, and a side face structure interconnecting the first and second main faces to define a peripheral edge. At least the first main face includes at least one projection extending to the peripheral edge, the projection formed by: a portion of the first main surface (defining a relief surface), a portion of the side face structure (defining a rake surface), and a portion of the peripheral edge (defining a cutting edge). The insert includes support surfaces defined by a portion of the second main face, and by portions of the side surface structure other than the rake surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

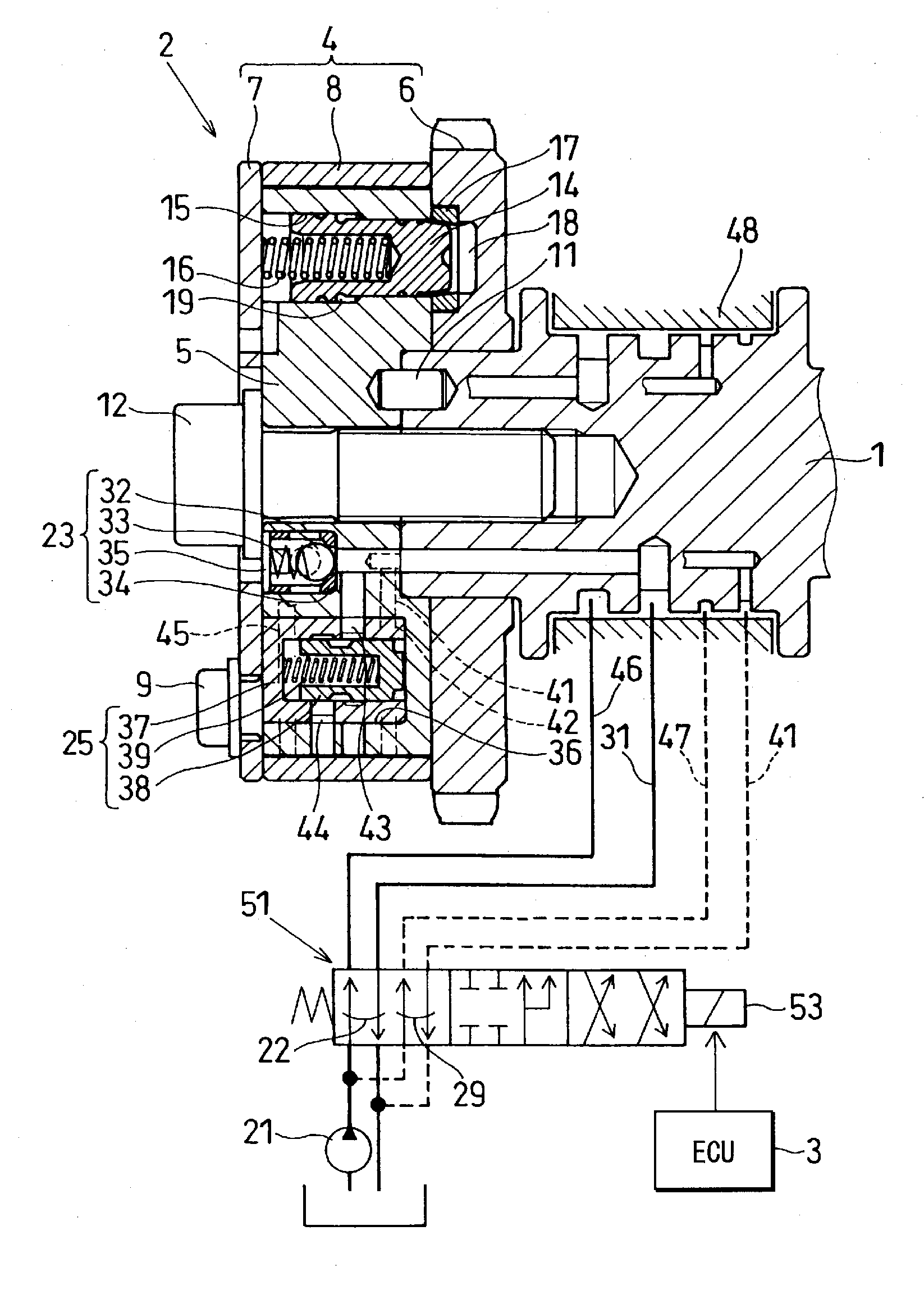

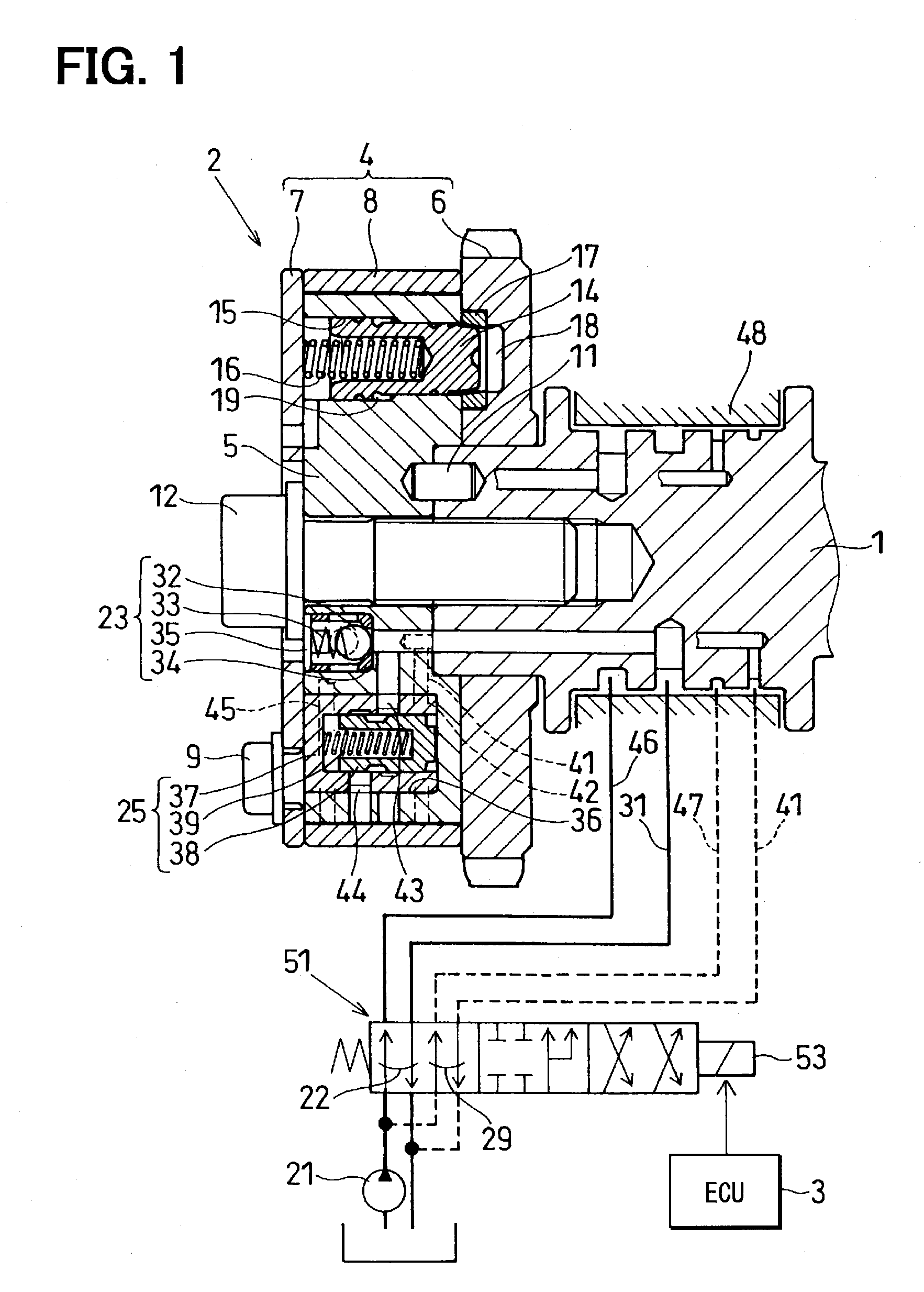

Hydraulic camshaft adjuster for an internal combustion engine

InactiveUS7025023B2Easy to manufactureIncrease expensesCamsYielding couplingExternal combustion engineEngineering

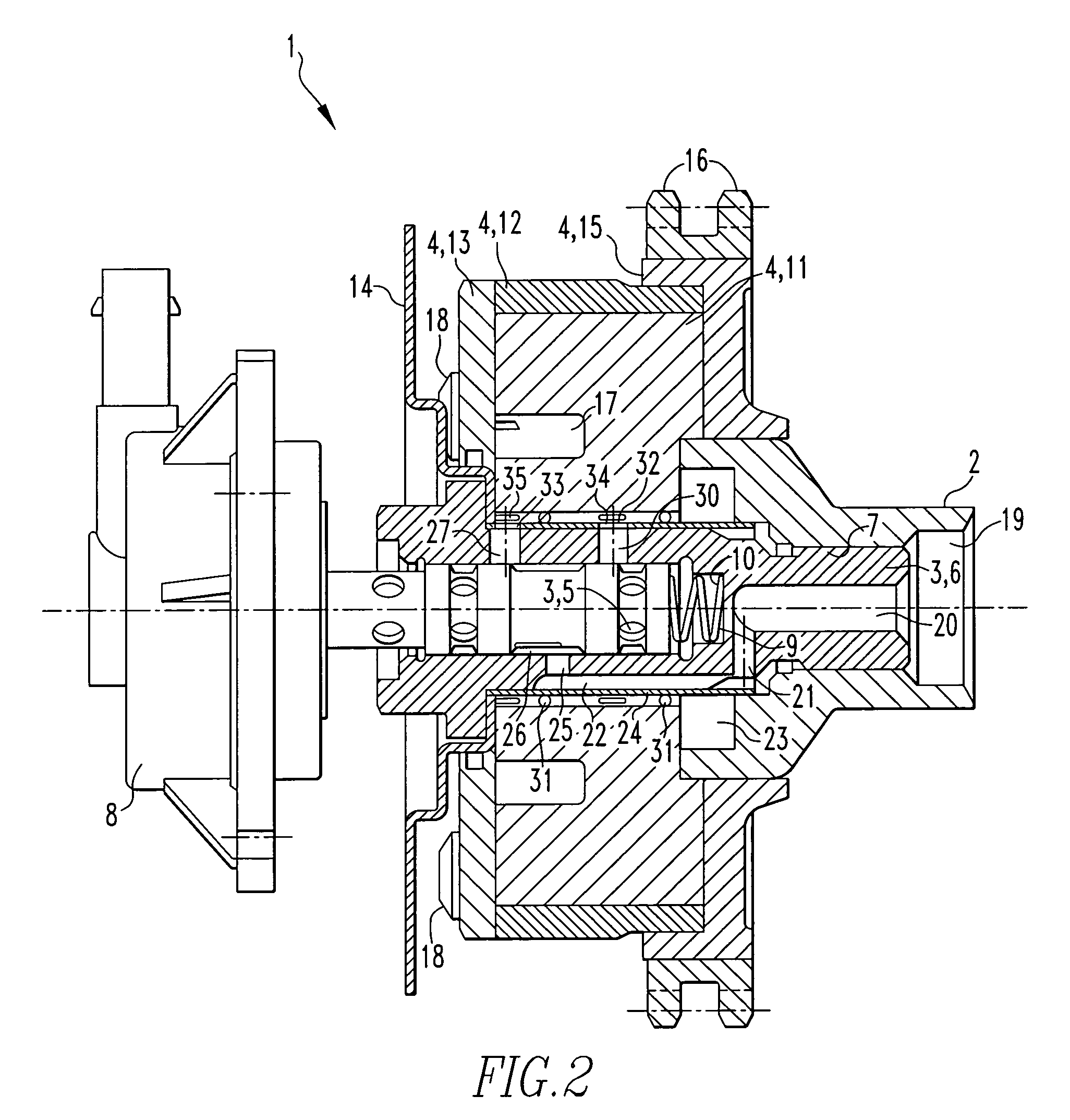

In a hydraulic camshaft adjuster for an internal combustion engine including a hydraulic operating unit for adjusting the angular position of the camshaft relative to a camshaft drive by way of a hydraulic control valve with a valve housing in which a control piston is disposed for controlling the supply of hydraulic fluid to, and its removal from, the hydraulic operating unit and to which hydraulic fluid is supplied from the camshaft by way of a pressure channel which is formed into the valve housing so as to extend along the outer surface thereof and a sleeve tightly surrounds at least the part of the valve housing which includes the channel for tightly covering the channel.

Owner:DAIMLER AG

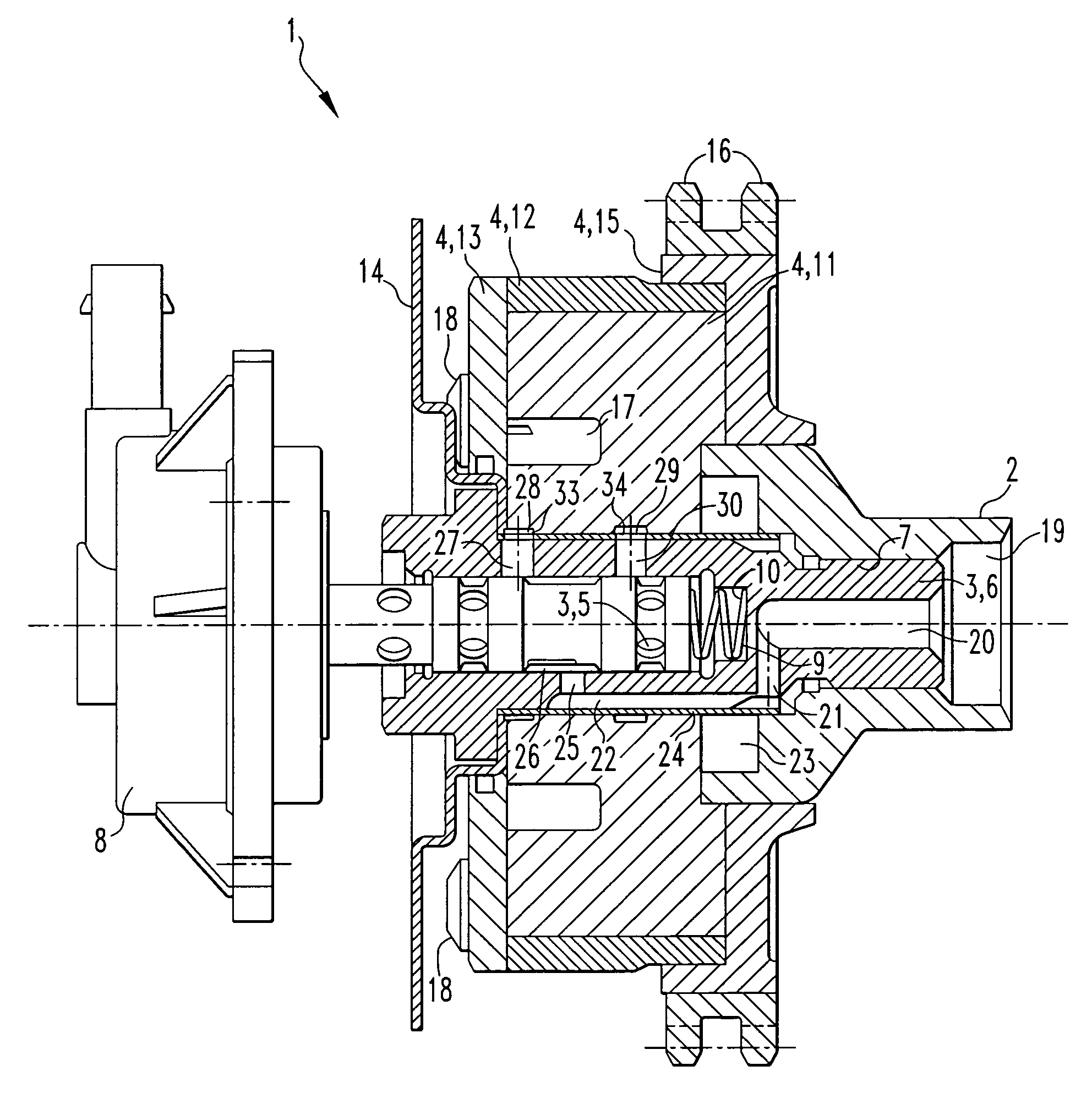

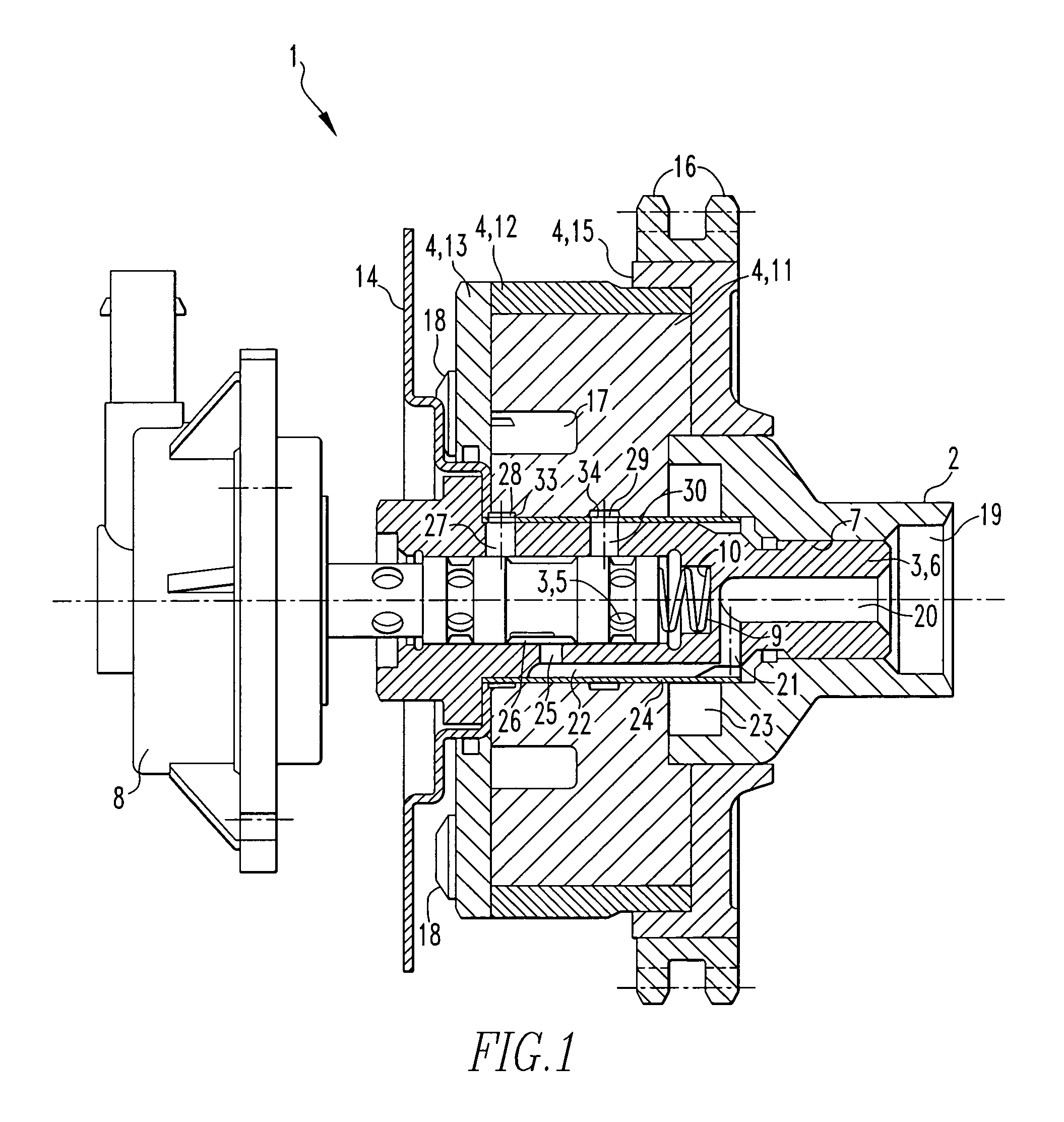

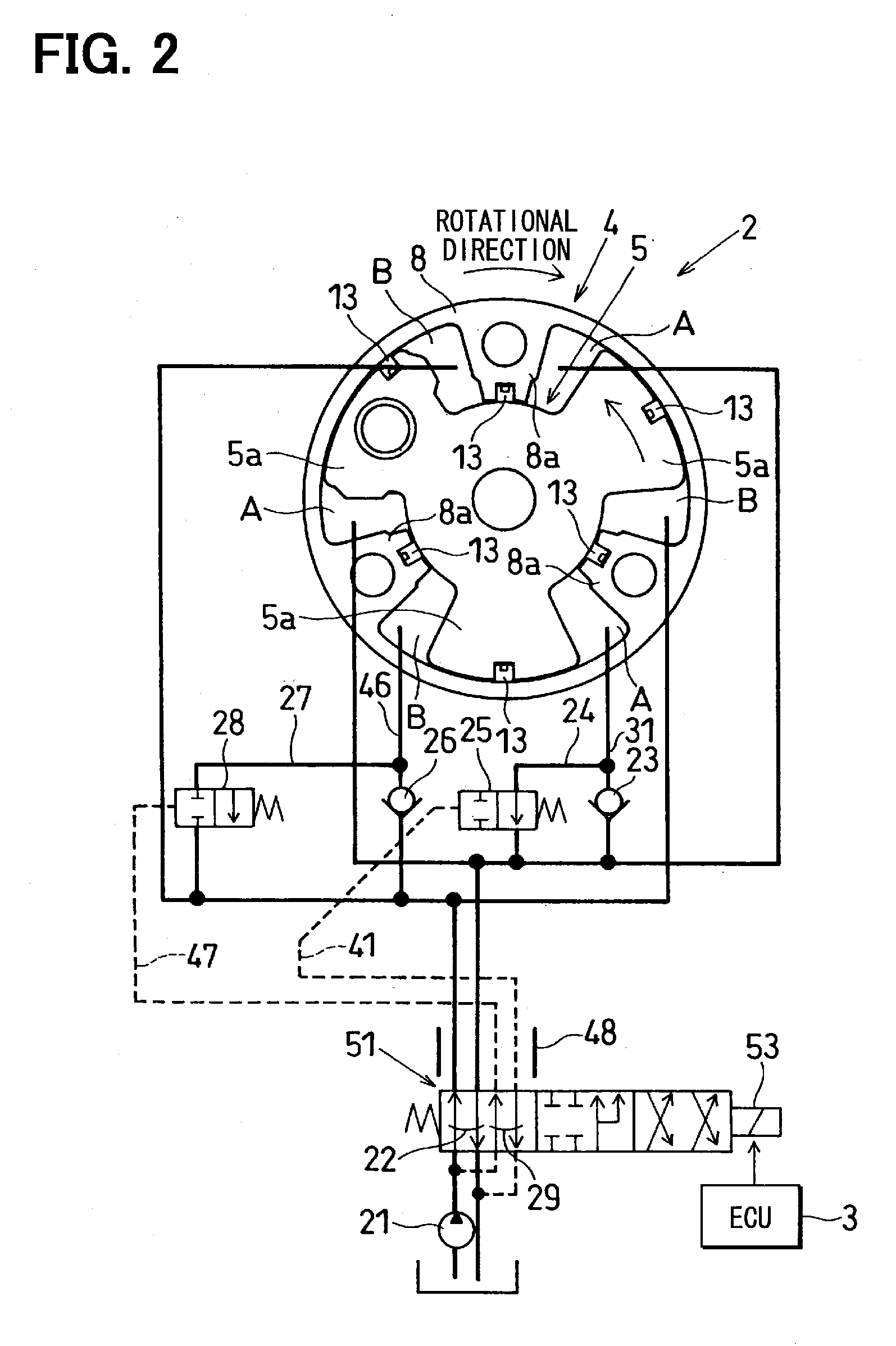

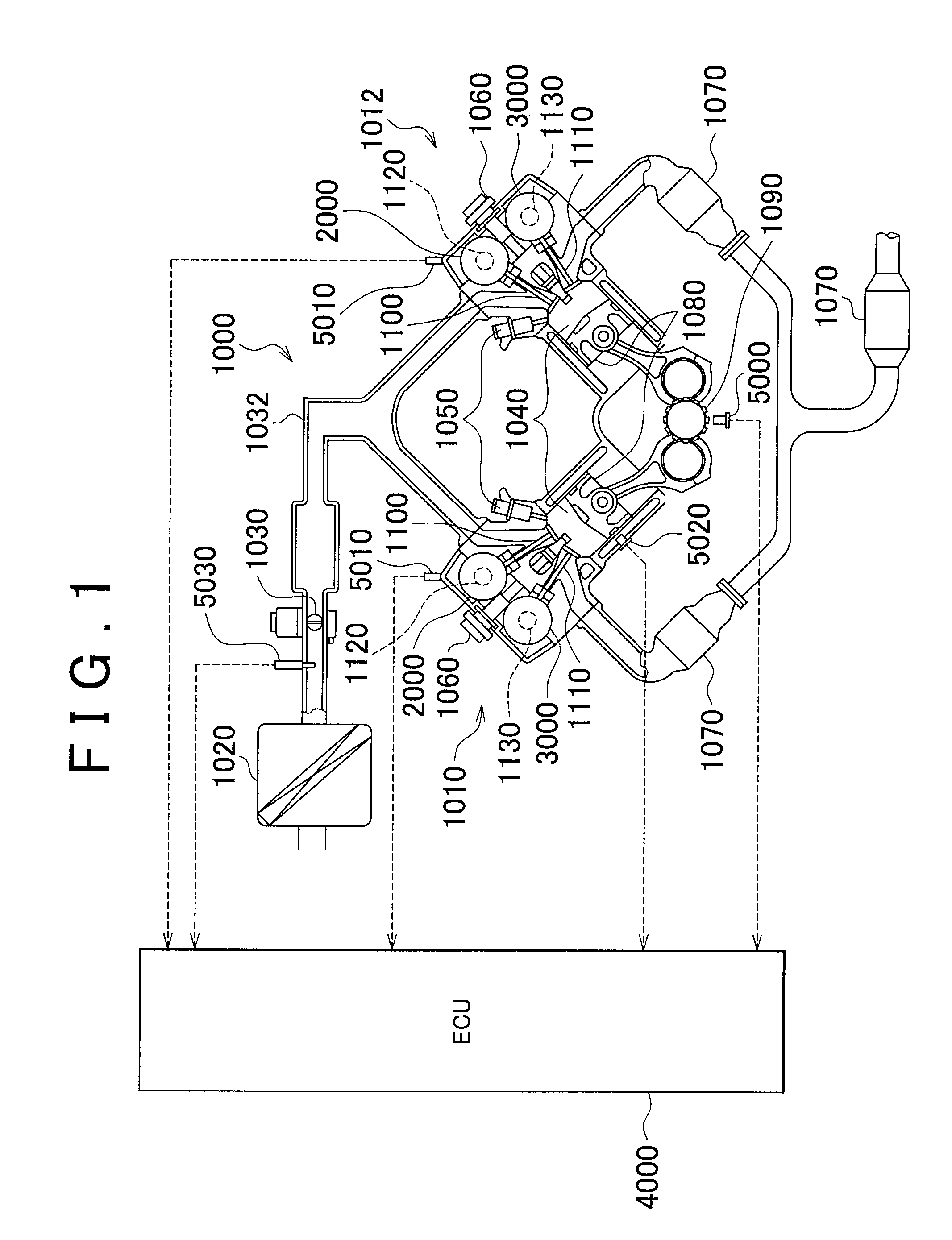

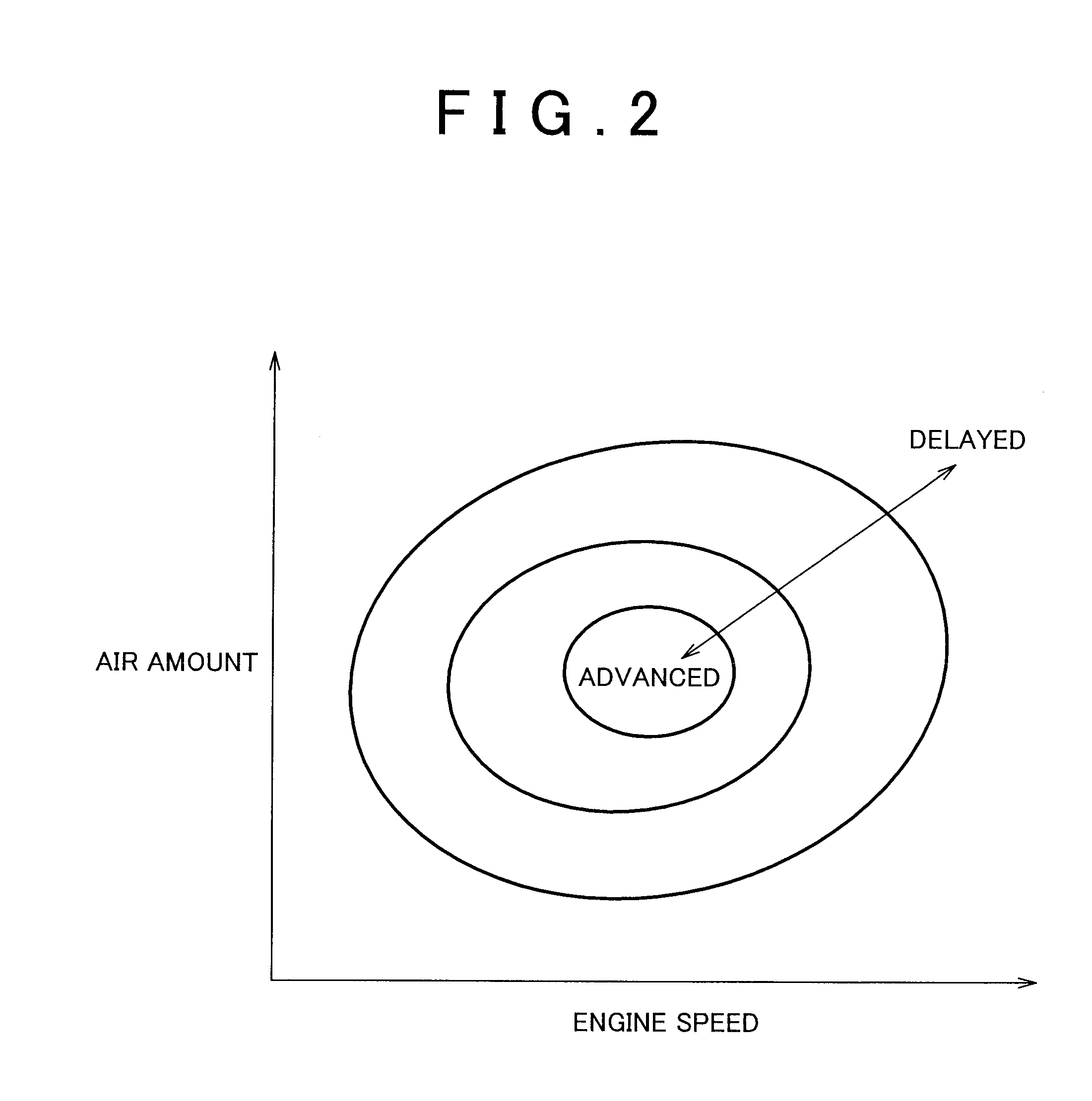

Valve timing control system for internal combustion engine

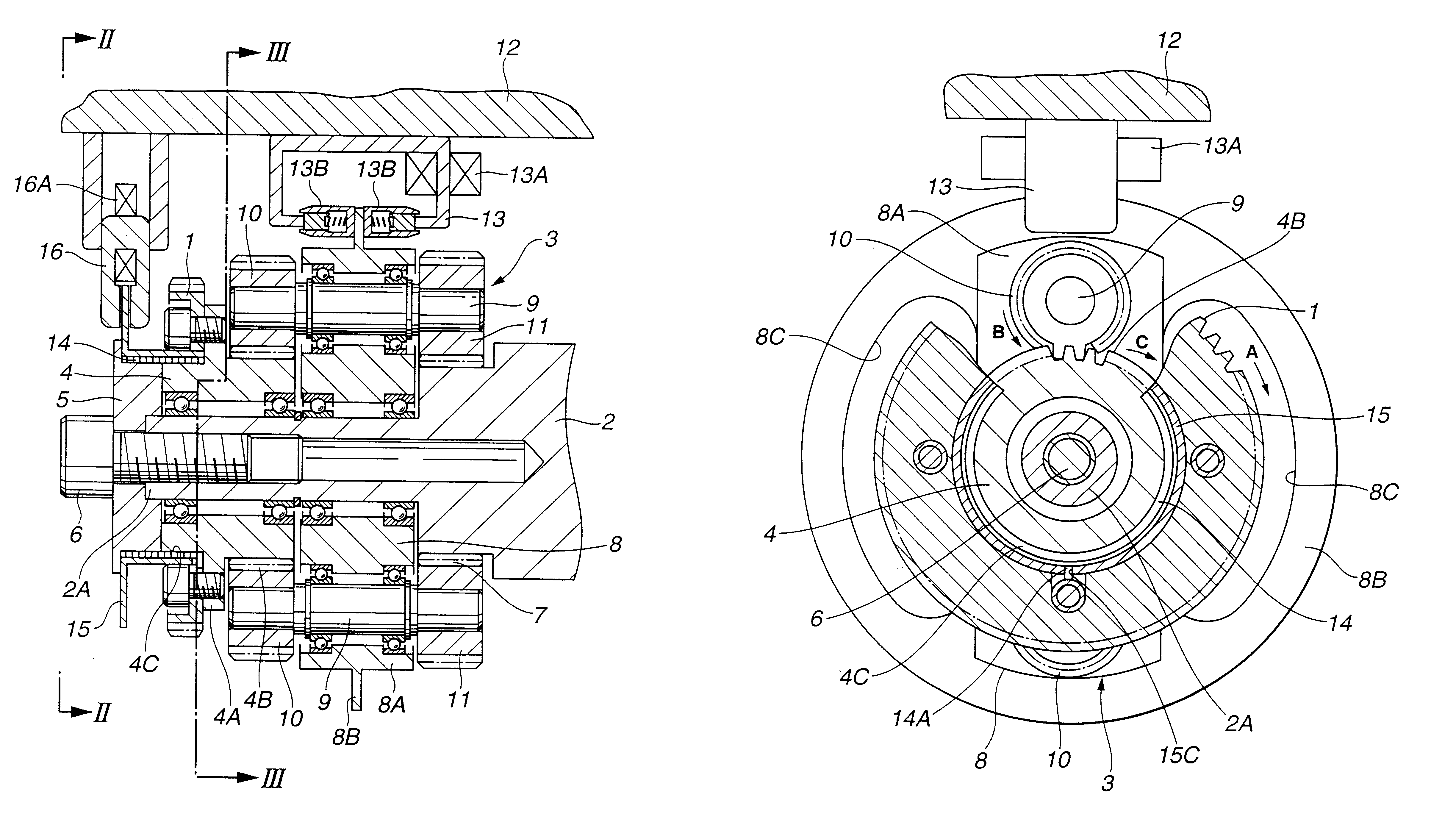

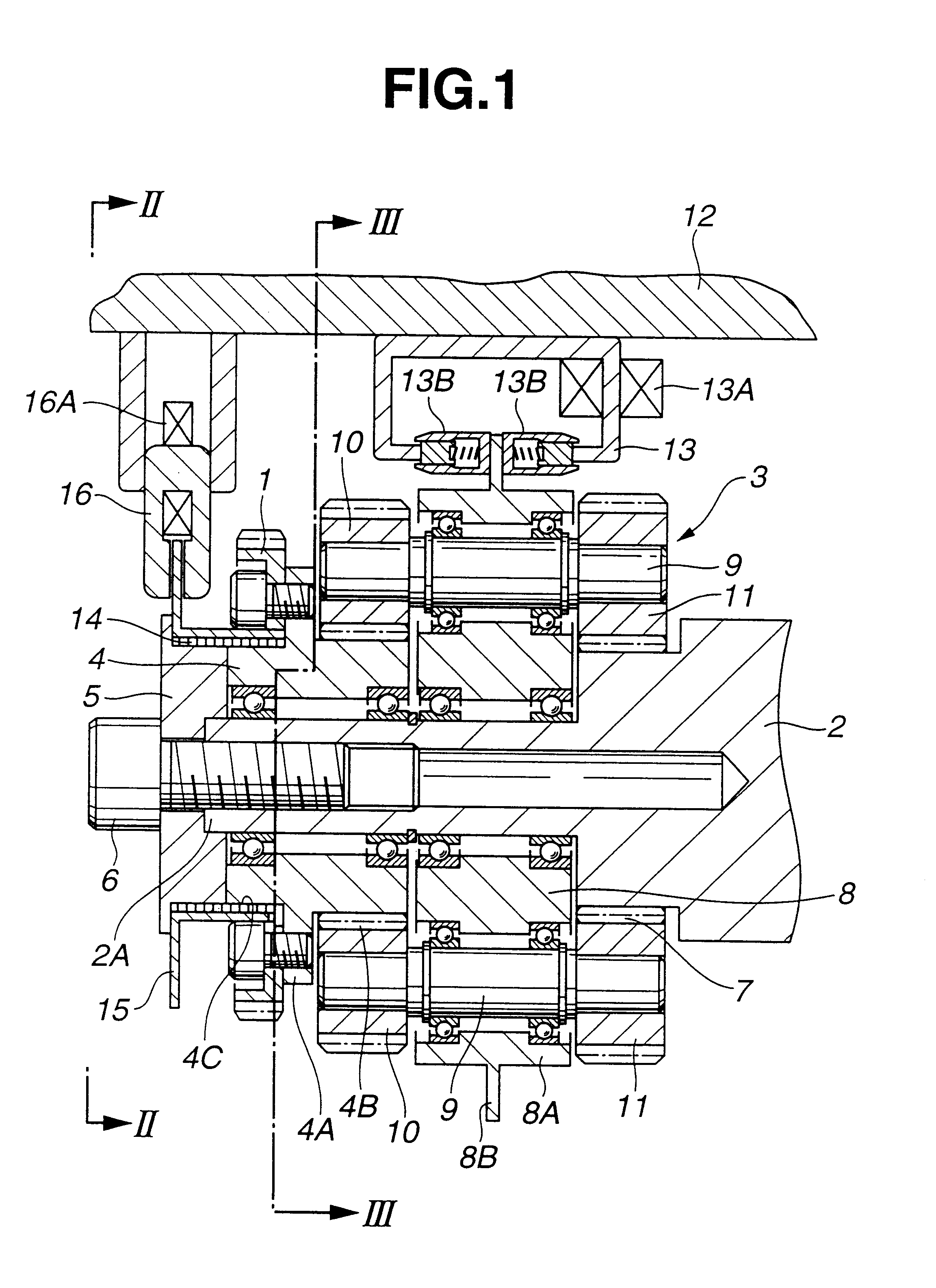

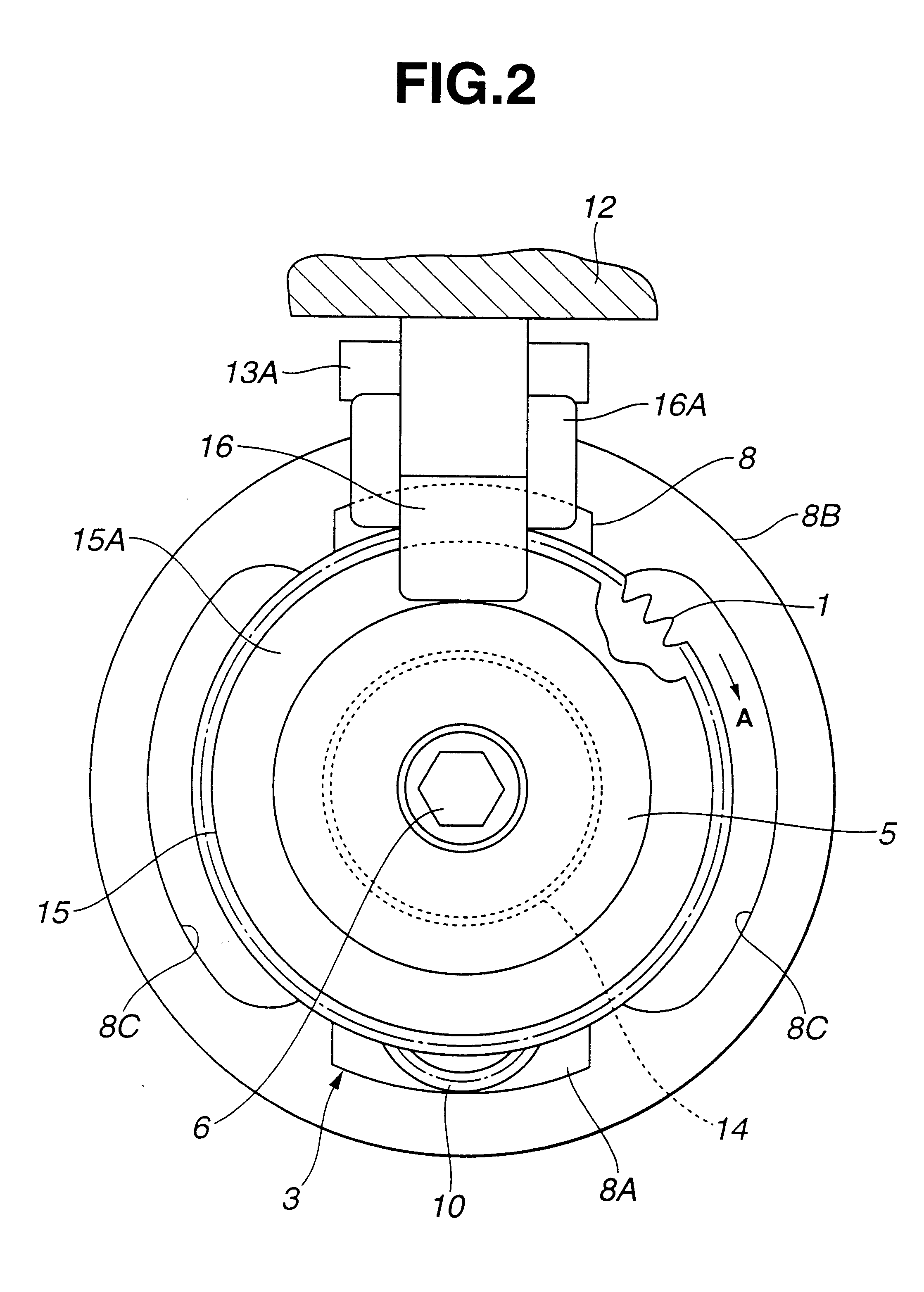

A valve timing control system includes; a rotor rotated by a crankshaft of the internal combustion engine; a camshaft rotated according to the rotation of the rotor to open and close an intake valve and an exhaust valve of the internal combustion engine; and a rotational phase controller for variably controlling a rotational phase of the camshaft relative to the rotor. The rotational phase controller is disposed between the rotor and the camshaft. The rotational phase controller includes; a clutch selectably put in one of a holding state for forbidding a relative rotation between the rotor and the camshaft in at least one of rotational directions and a releasing state for allowing the relative rotation; and a generator for generating a holding toque directing to the rotational direction forbidden by the clutch and applying the holding torque to the clutch when the clutch is put in the holding state.

Owner:UNISIA JECS CORP

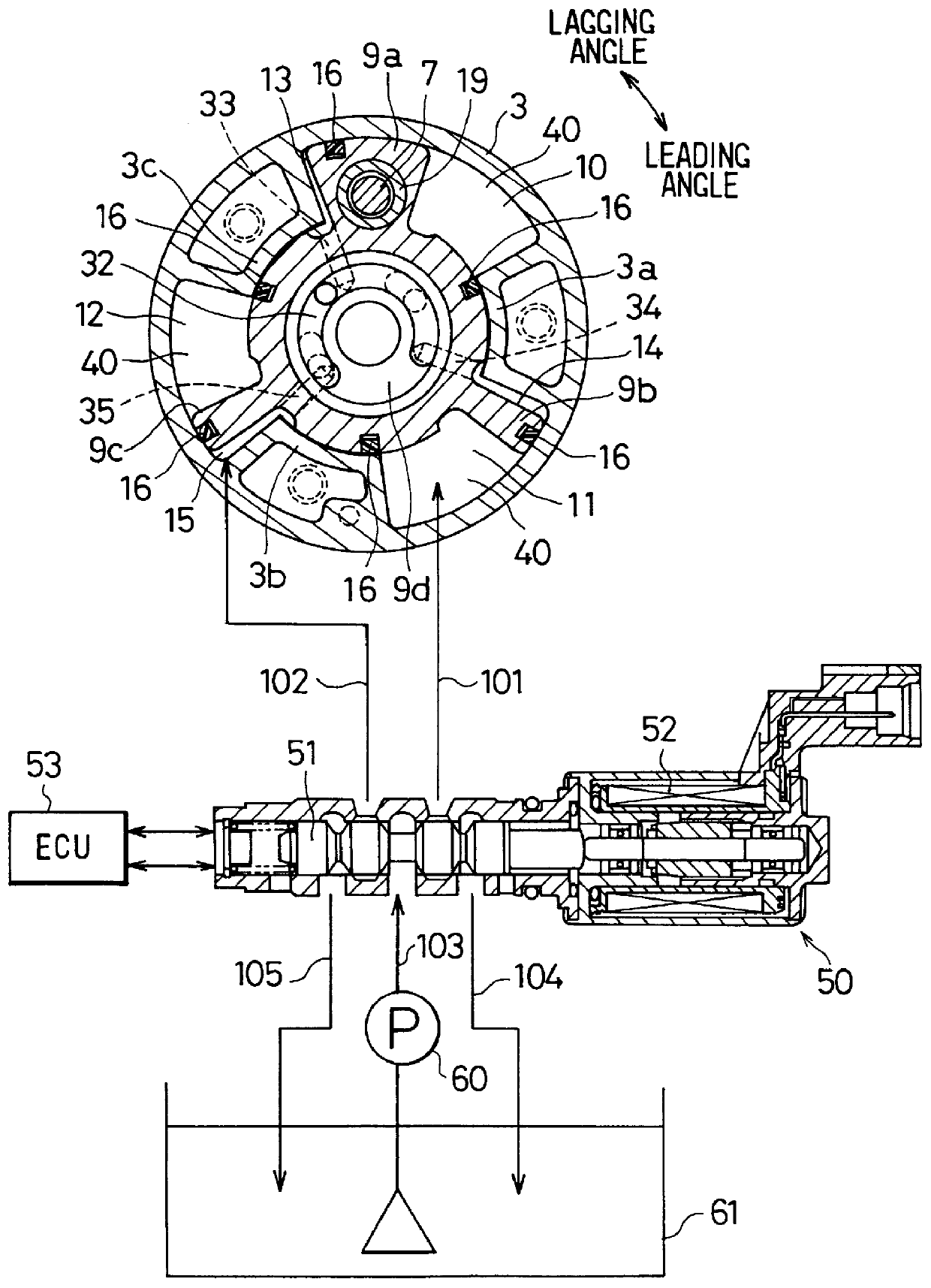

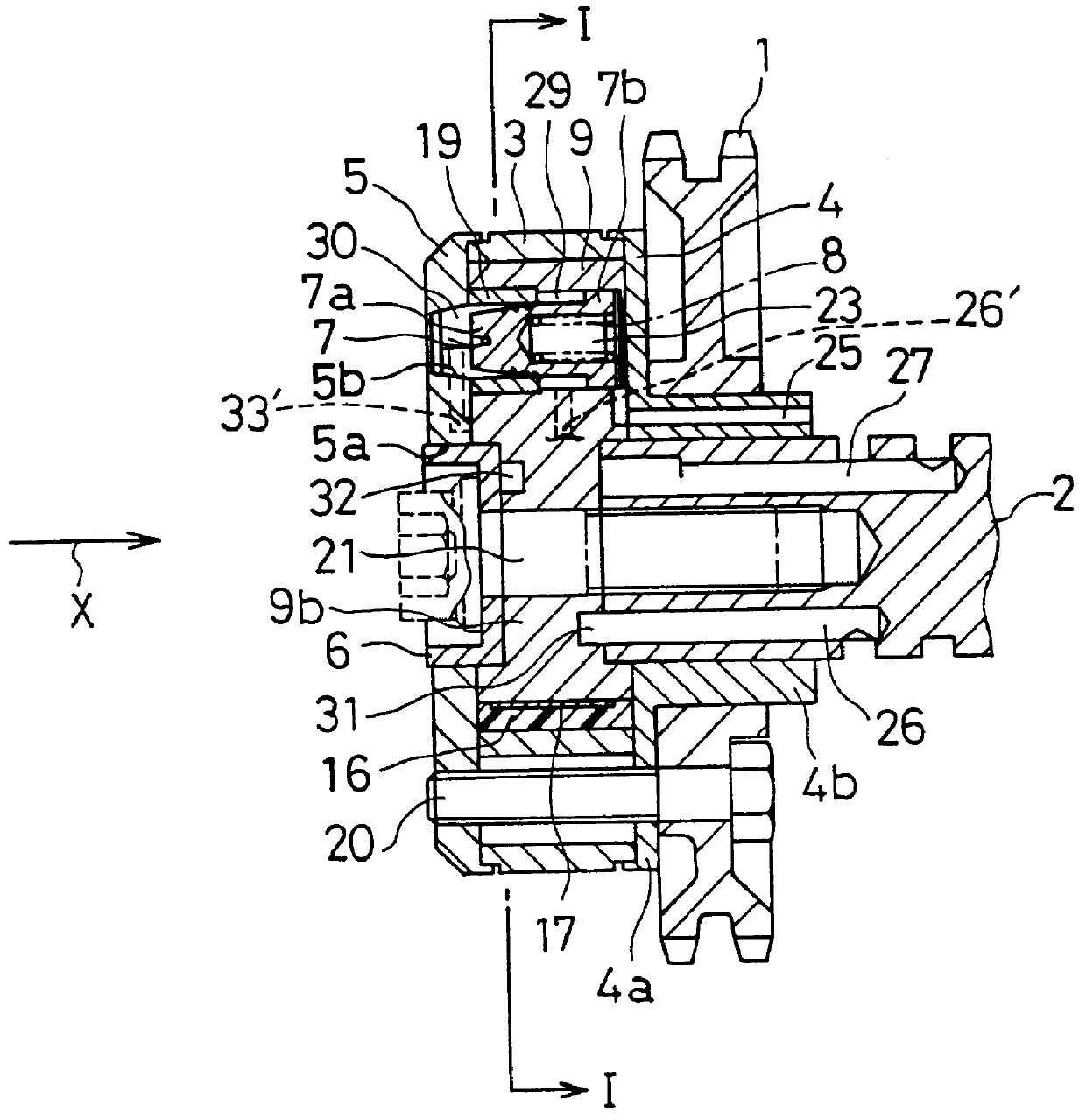

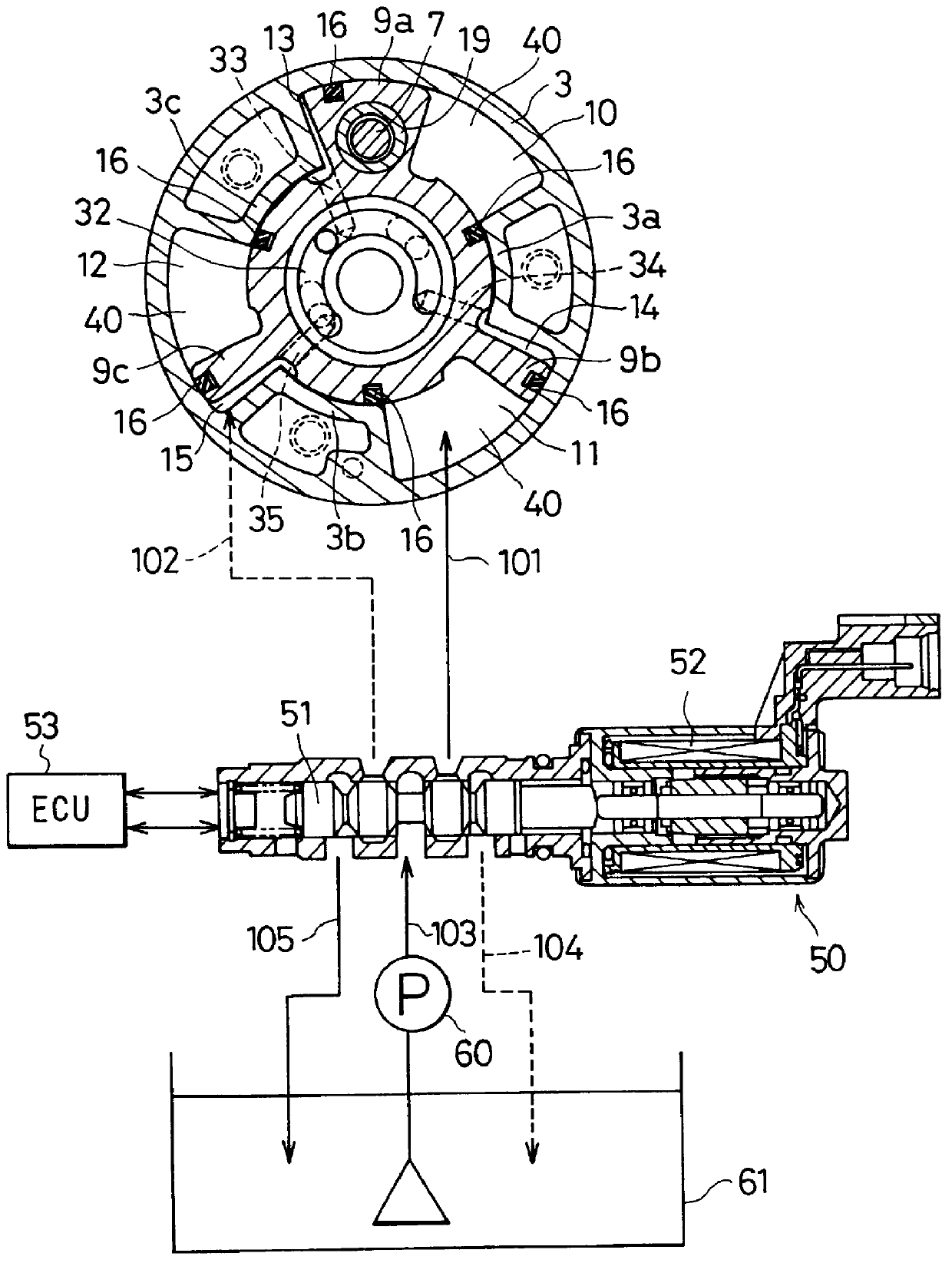

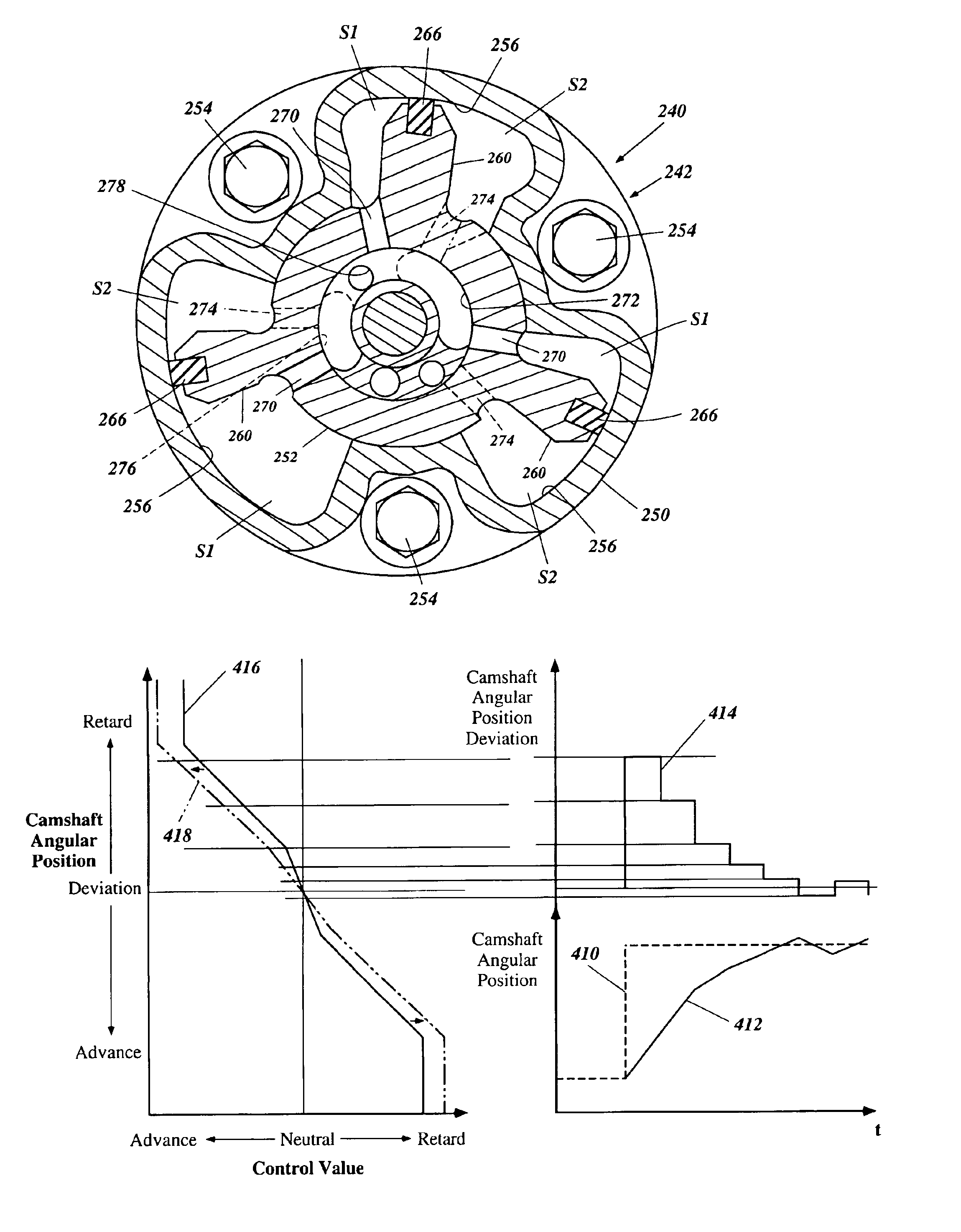

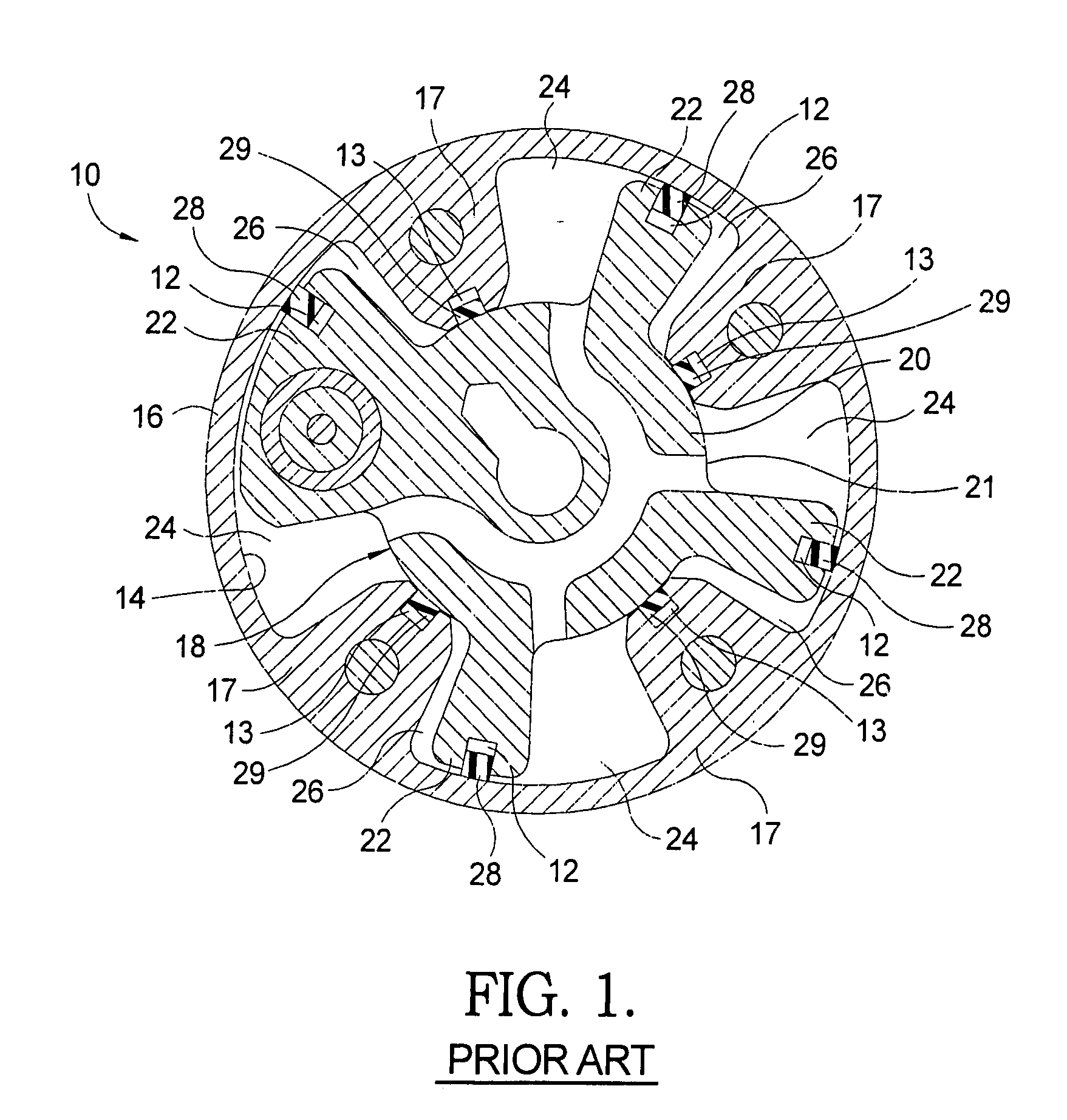

Valve timing adjusting apparatus for internal combustion engines

InactiveUS6024061AEasy to manufactureHigh precisionCamsYielding couplingCombustionExternal combustion engine

A valve timing adjusting apparatus that selectively controls a restraint mechanism for restraining relative rotation between a housing member and a vane member to increase the operational life thereof. When a vane rotor is held at a most lagging angular position, an end holding mode is executed to pull out a stopper piston from a stopper hole by fluid pressures of both a leading angle side and a lagging angle side. As a result, when the vane rotor rotates from the most lagging angular position to the leading angle side, torsional forces on the stopper piston and the stopper hole can be minimized as the vane member direction of rotation changes. Since a fluid pressure has already been applied to each of leading angle fluid pressure chambers in the end holding mode, the vane rotor can be rotated from the most lagging angular position to the leading angle side quickly by increasing fluid pressure applied to each of the leading angle fluid pressure chambers without the need to switch a fluid path. In addition, since the fluid pressure applied to each of the leading angle fluid pressure chambers in the end holding mode is smaller than fluid pressure for rotating the vane rotor to the leading angle side, generation of impact sound due to collisions of vanes can be avoided.

Owner:DENSO CORP

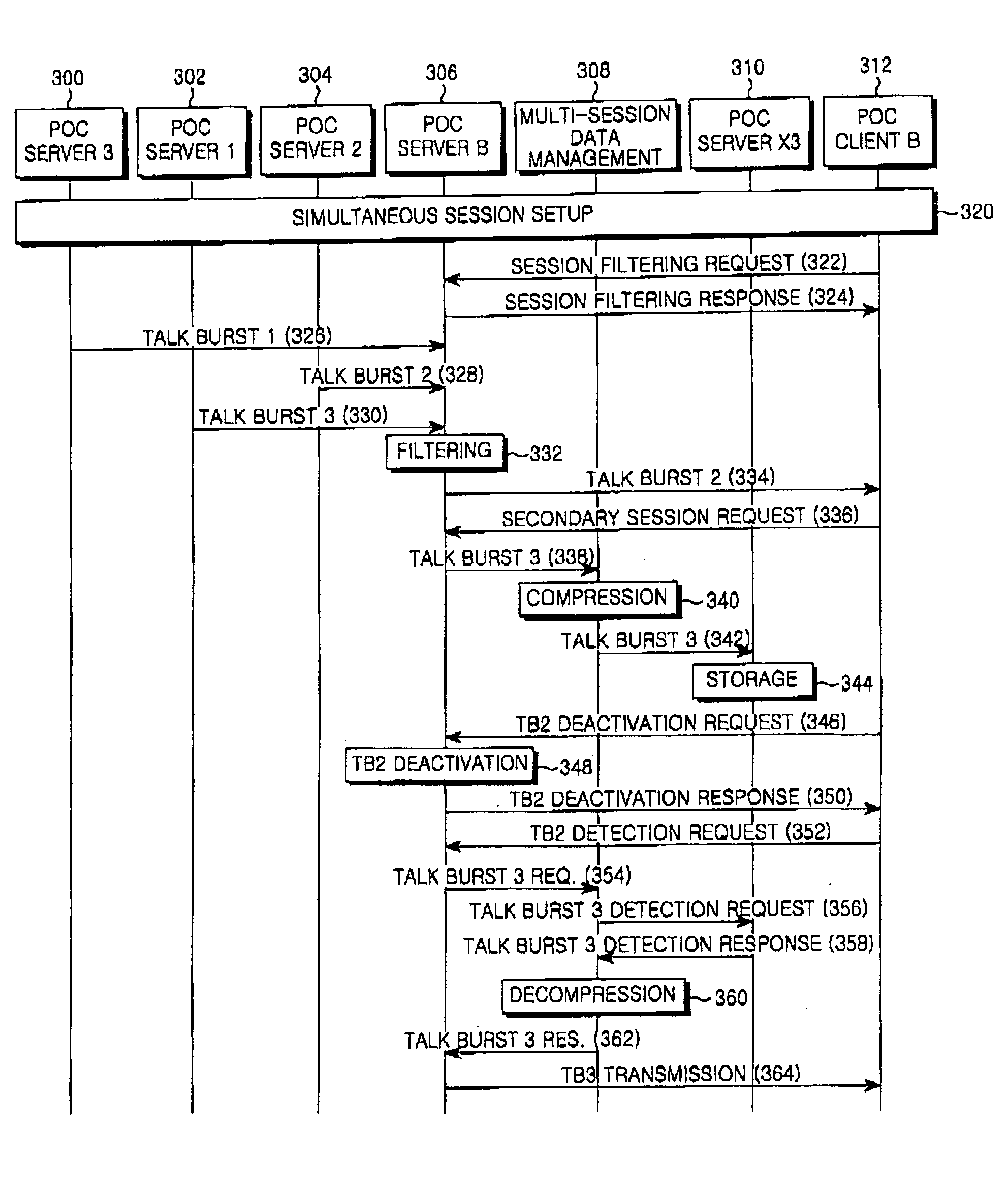

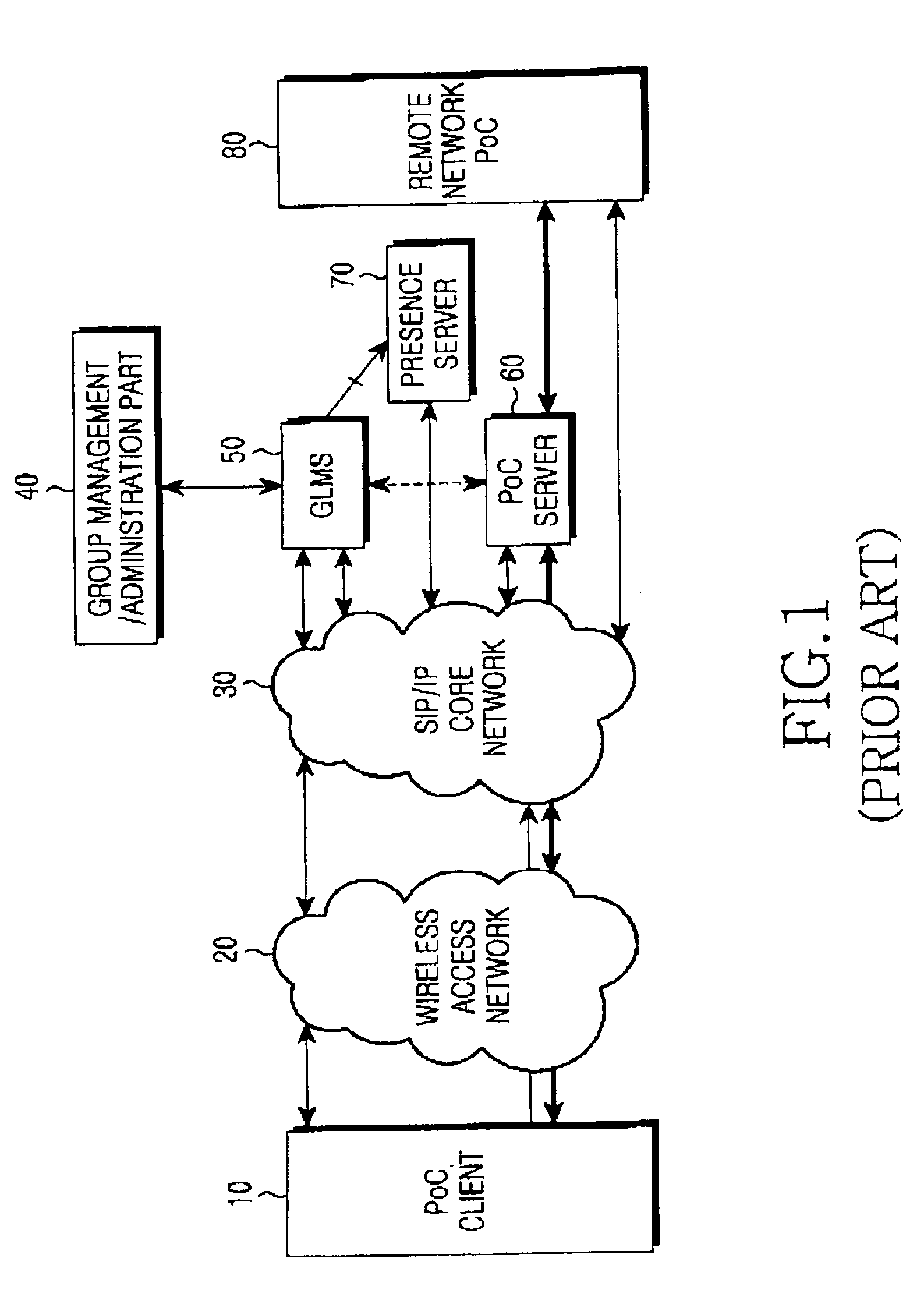

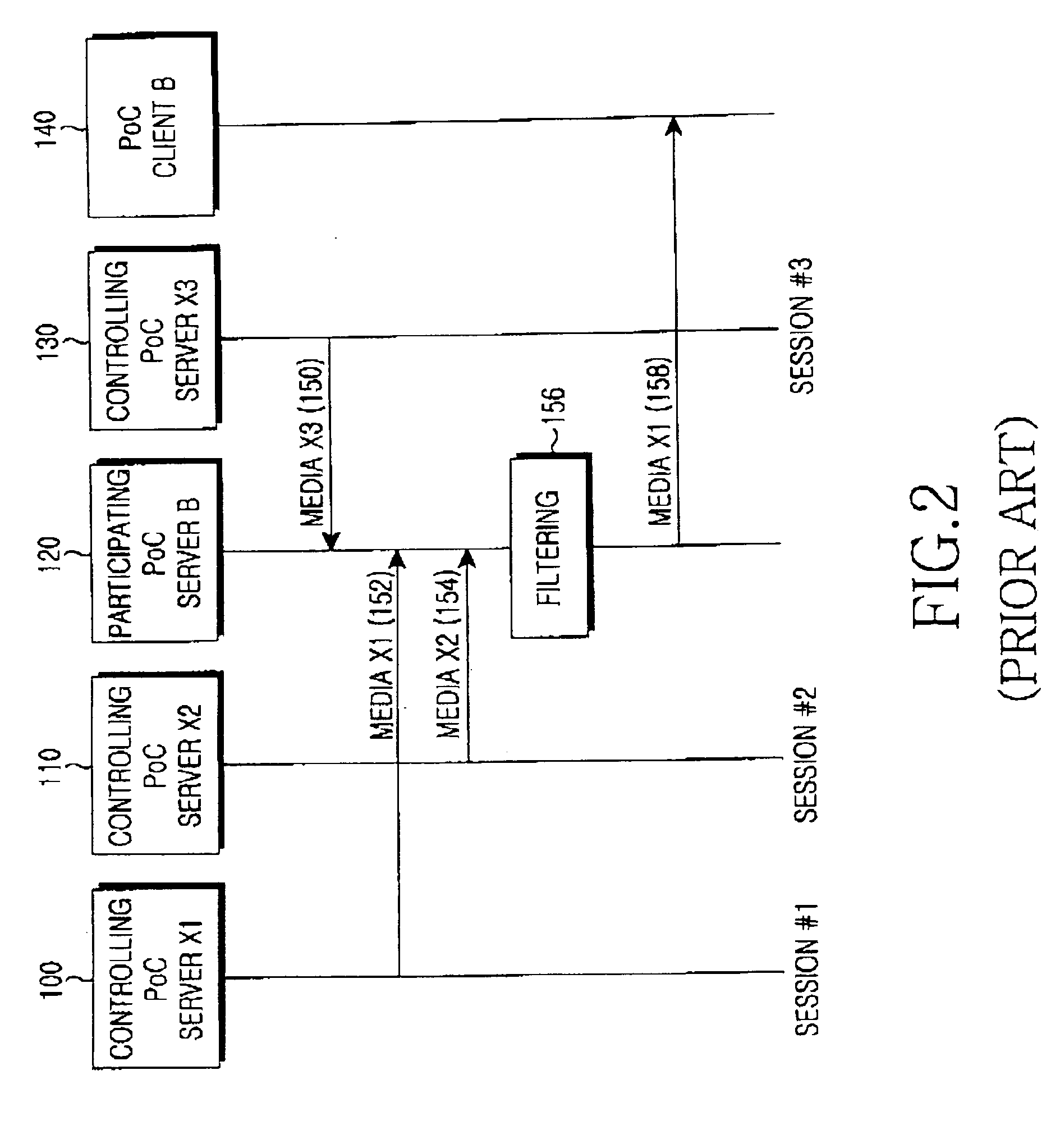

System and method for monitoring simultaneous PoC sessions

The system includes a push to talk over cellular (PoC) client for requesting storage of media data of a sub-participation session among the simultaneous sessions, a storage part for storing the media data of the sub-participation session, and a push to talk over cellular (PoC) server for transmitting the media data of the sub-participation session stored in the storage part to the push to talk over cellular client according to a read out request of the push to talk over cellular client.

Owner:SAMSUNG ELECTRONICS CO LTD

Cutting insert for turning and milling

A cutting insert comprises first and second polygonally-shaped main faces arranged substantially parallel to one another, and a side face structure interconnecting the first and second main faces to define a peripheral edge. At least the first main face includes at least one projection extending to the peripheral edge, the projection formed by: a portion of the first main surface (defining a relief surface), a portion of the side face structure (defining a rake surface), and a portion of the peripheral edge (defining a cutting edge). The insert includes support surfaces defined by a portion of the second main face, and by portions of the side surface structure other than the rake surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

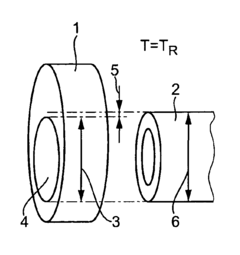

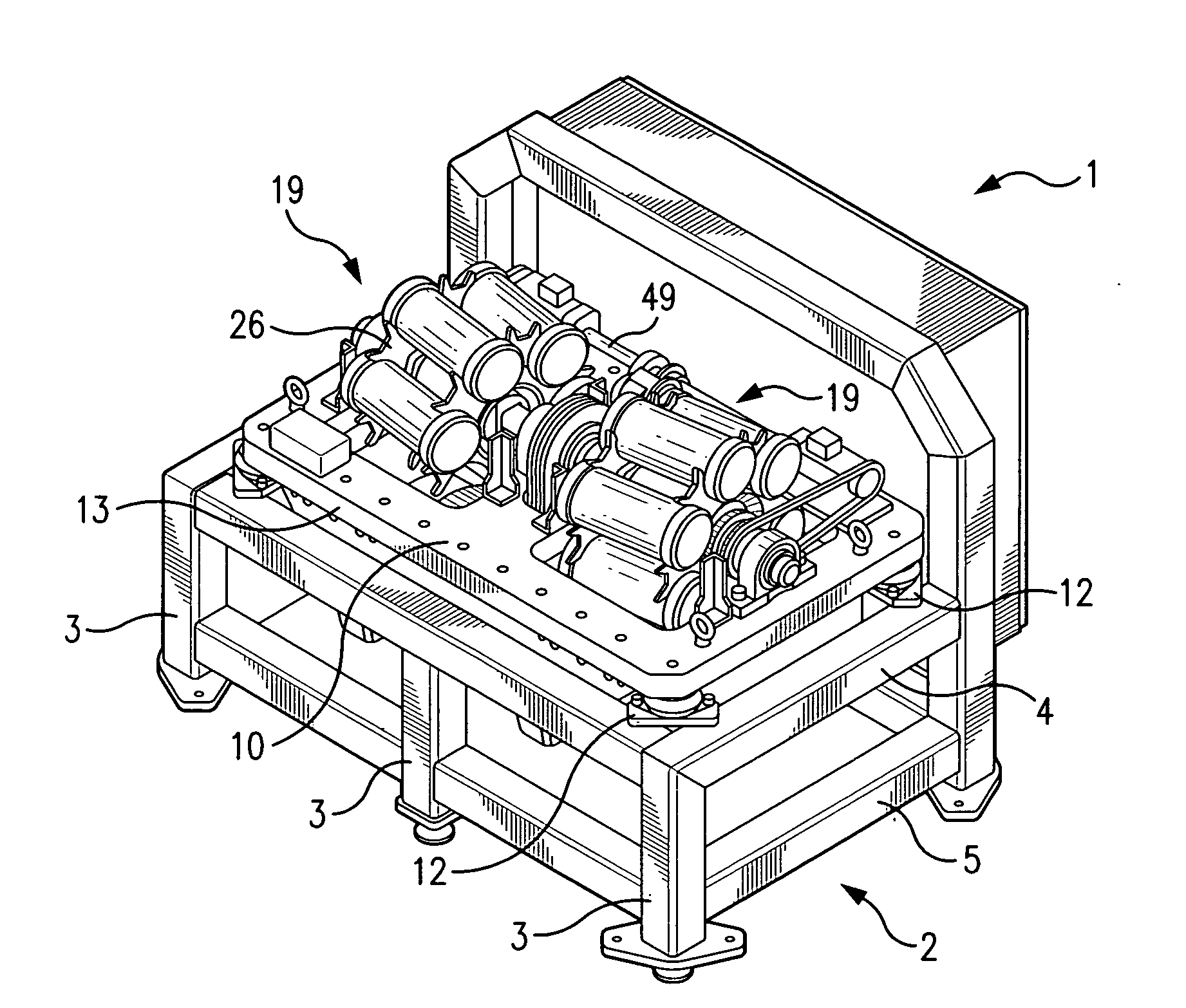

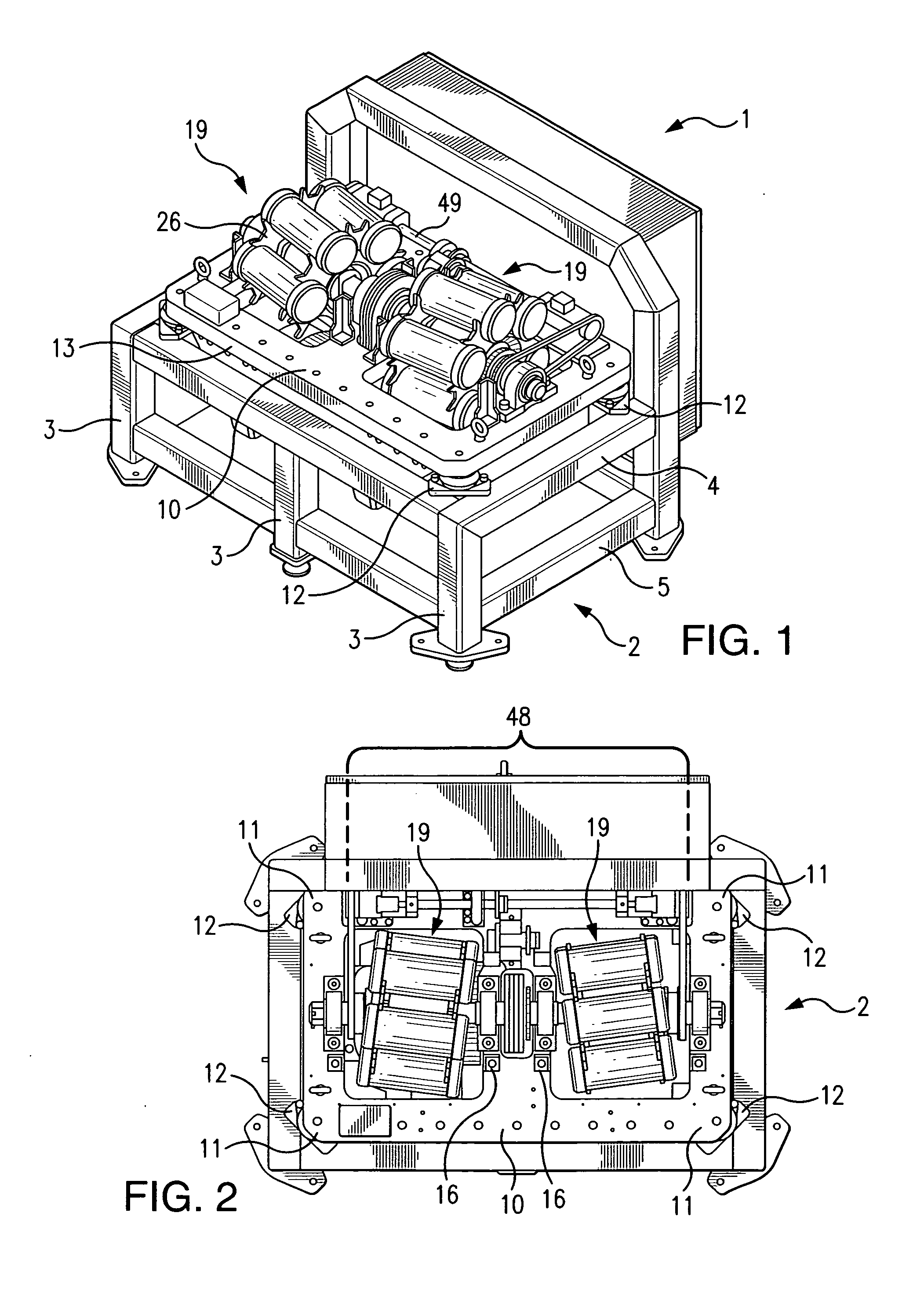

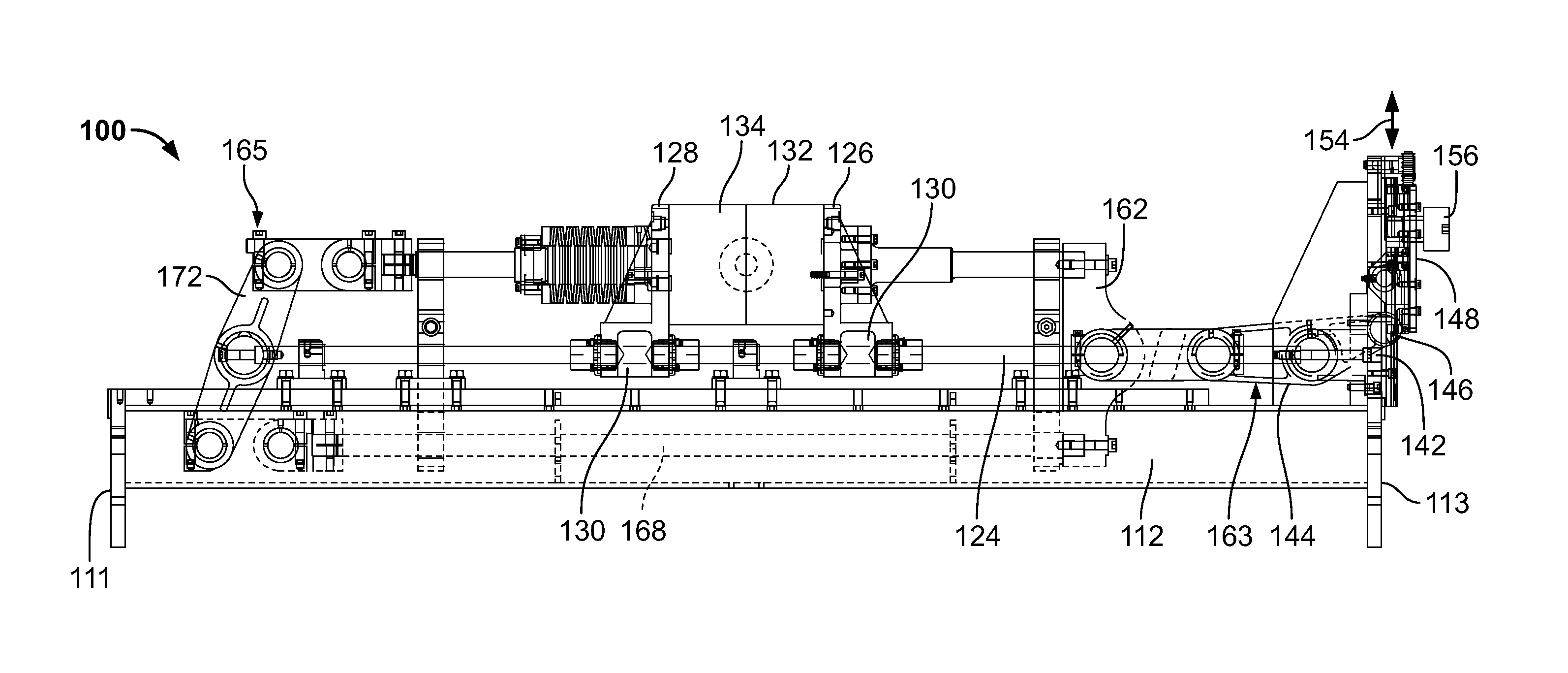

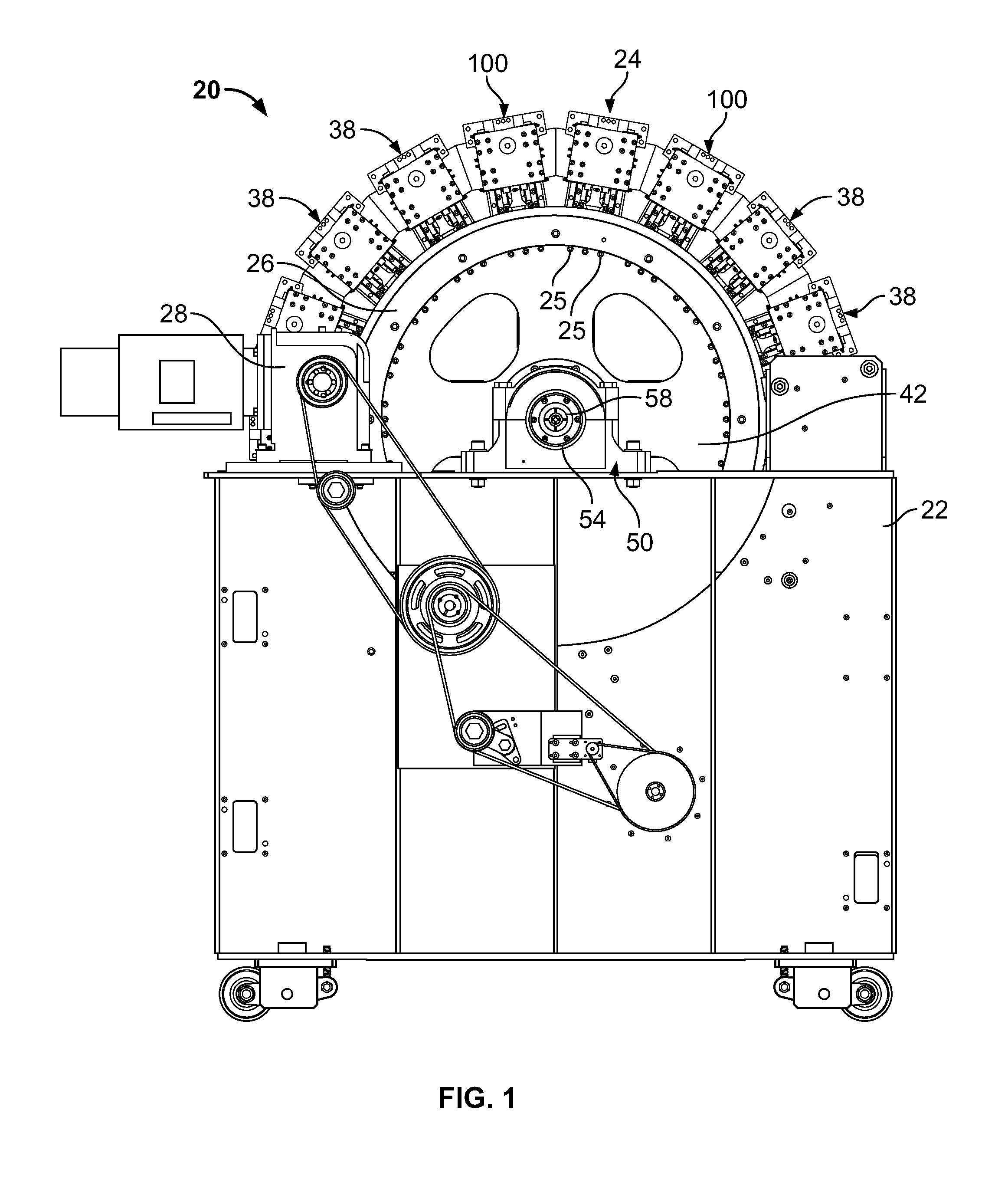

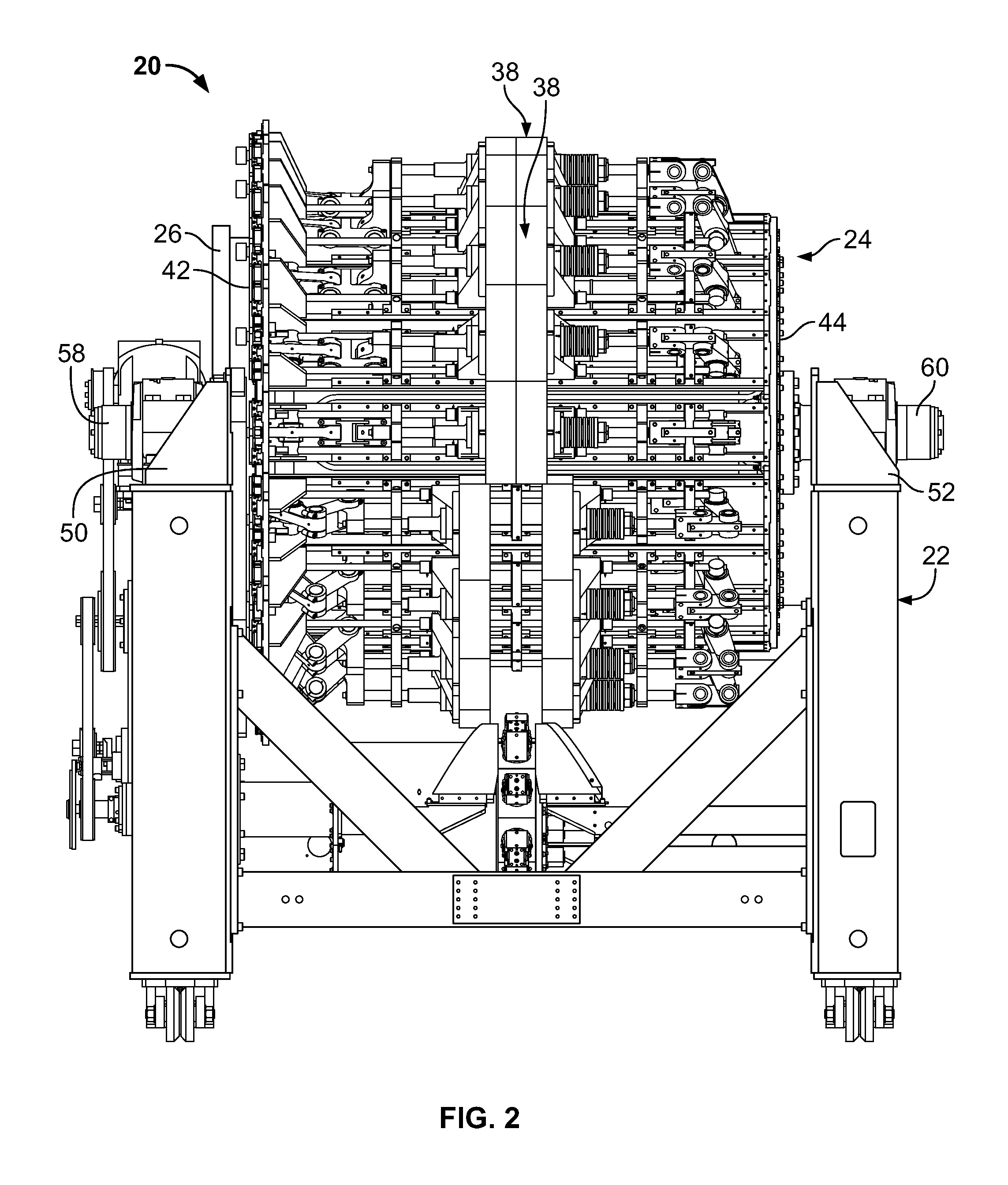

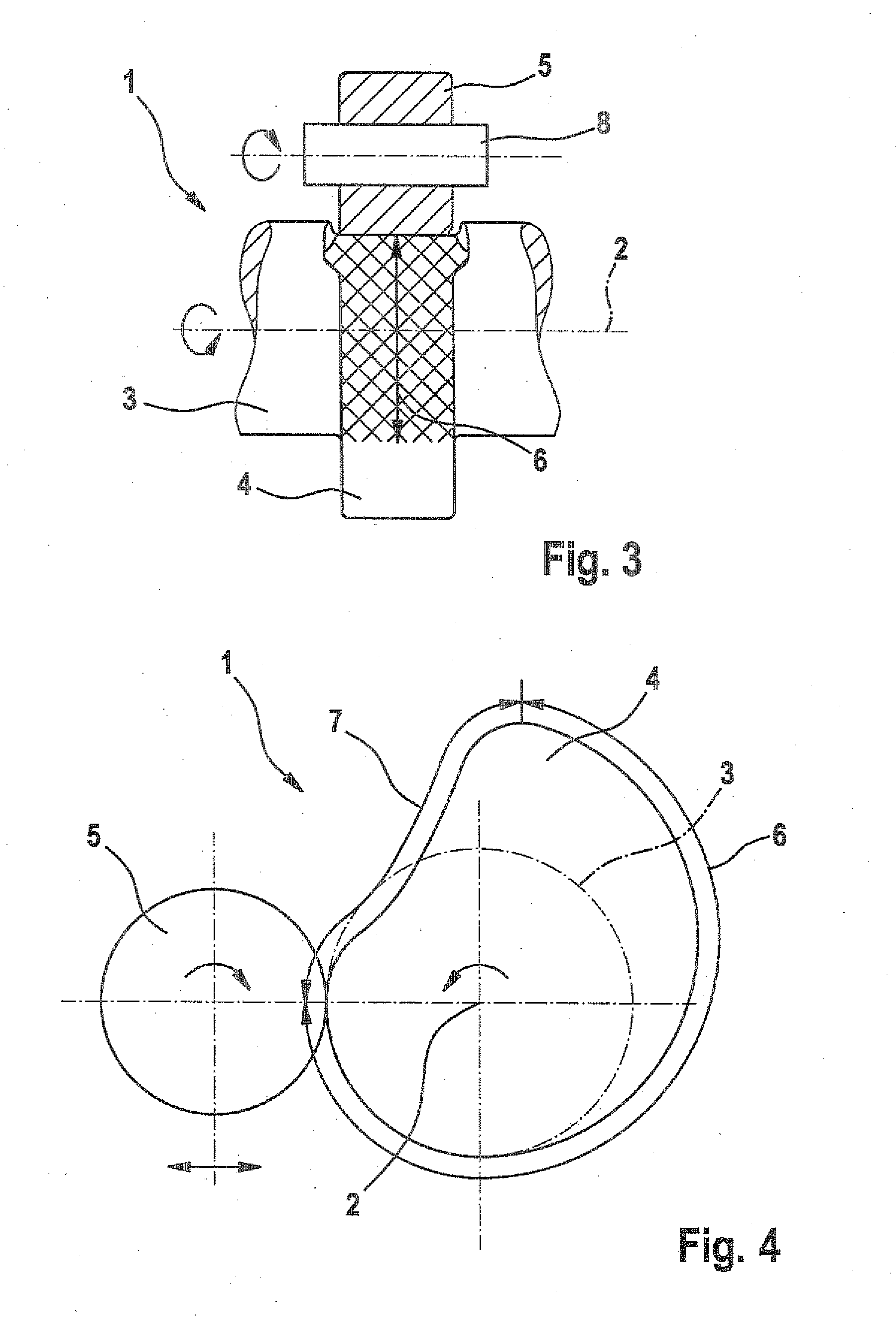

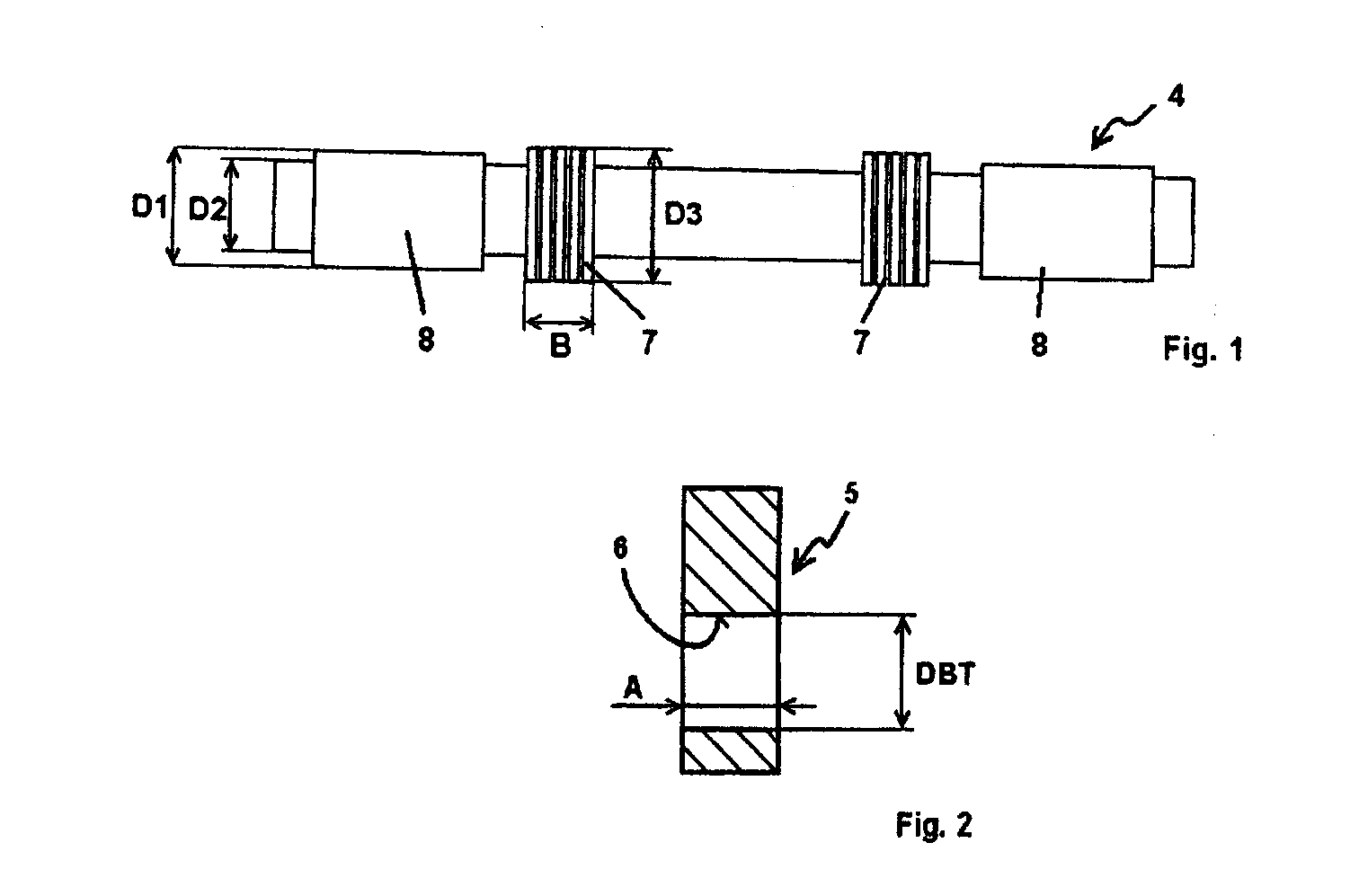

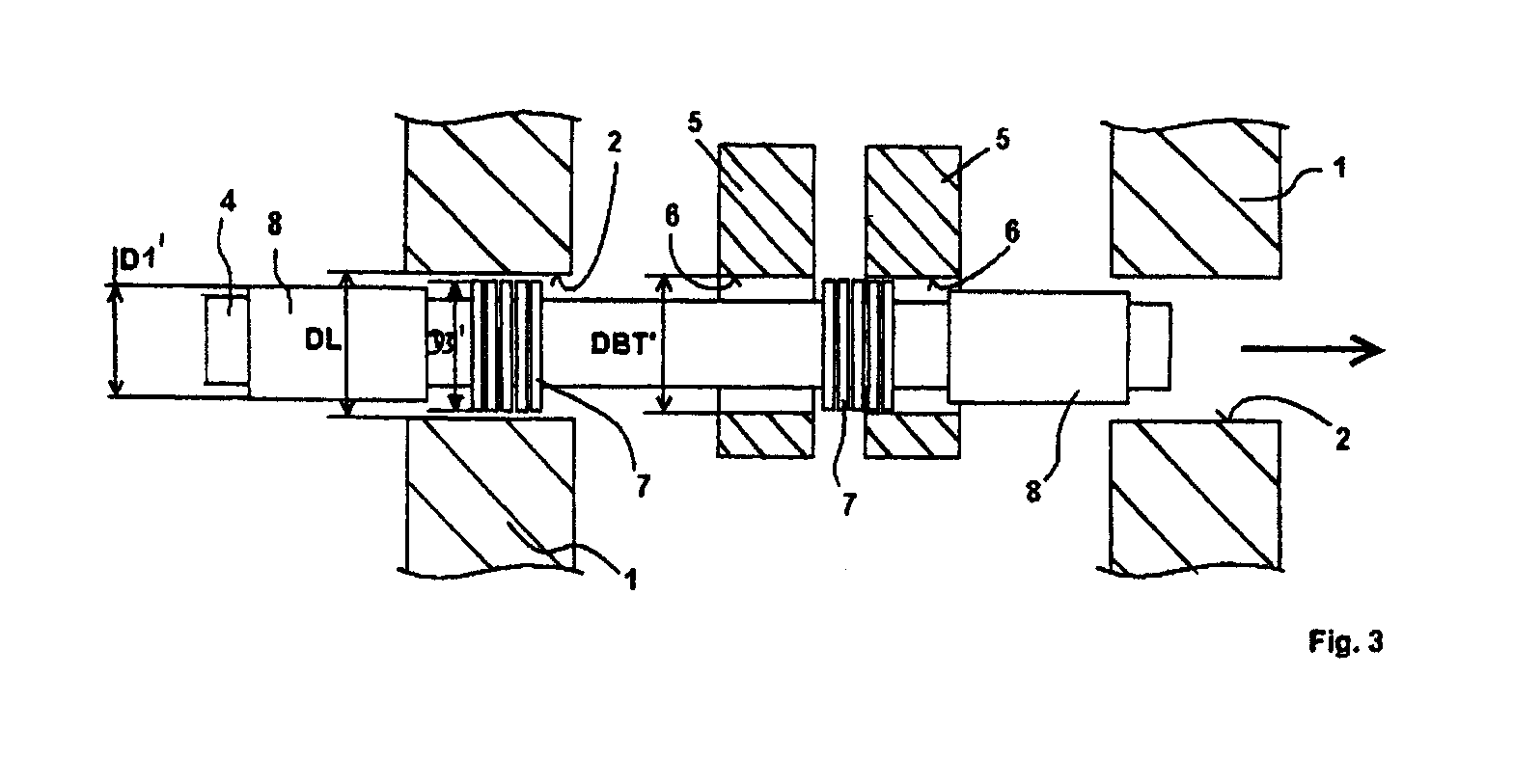

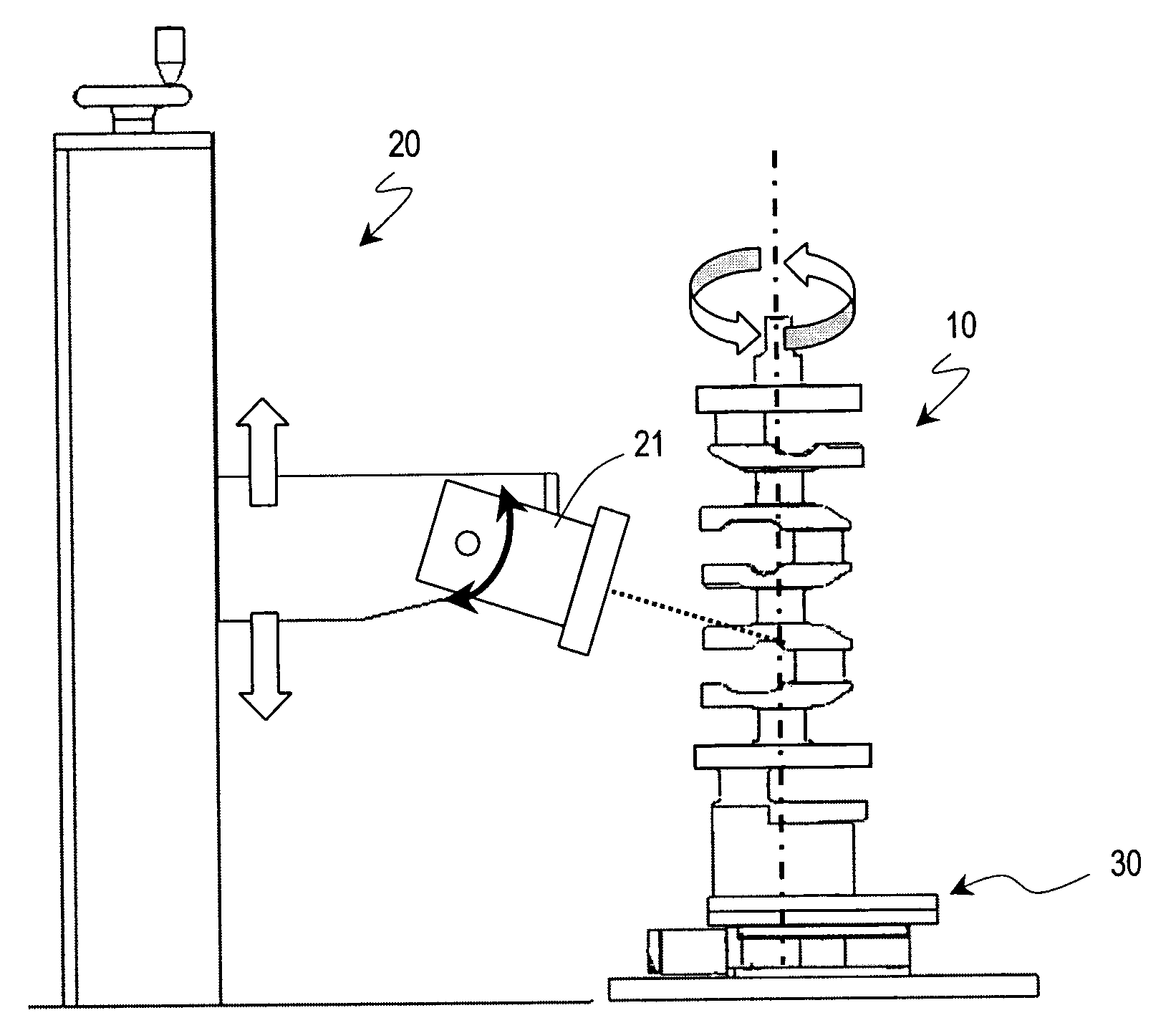

Method and assembly system for manufacturing an assembled camshaft

A method and an assembly system for manufacturing an assembled camshaft having a metallic shaft and at least one shrunk-on cam, includes initially heating the at least one cam, threading the at least one cam onto the shaft in a predetermined position in the heated state, and subsequently shrinking the at least one cam onto the shaft due to a cooling down. The shaft is cooled down prior to thread-on of the cams so that the cams are shrunk onto the shaft due to a temperature equalization which includes heating of the shaft and cooling down of the cams. The assembly system includes multiple drums in which the shafts and the cams to be fitted are accommodated and cooled and / or heated. The shafts are cooled preferably with the aid of a cooling lance inserted into a hollow space of the shaft.

Owner:DAIMLER AG

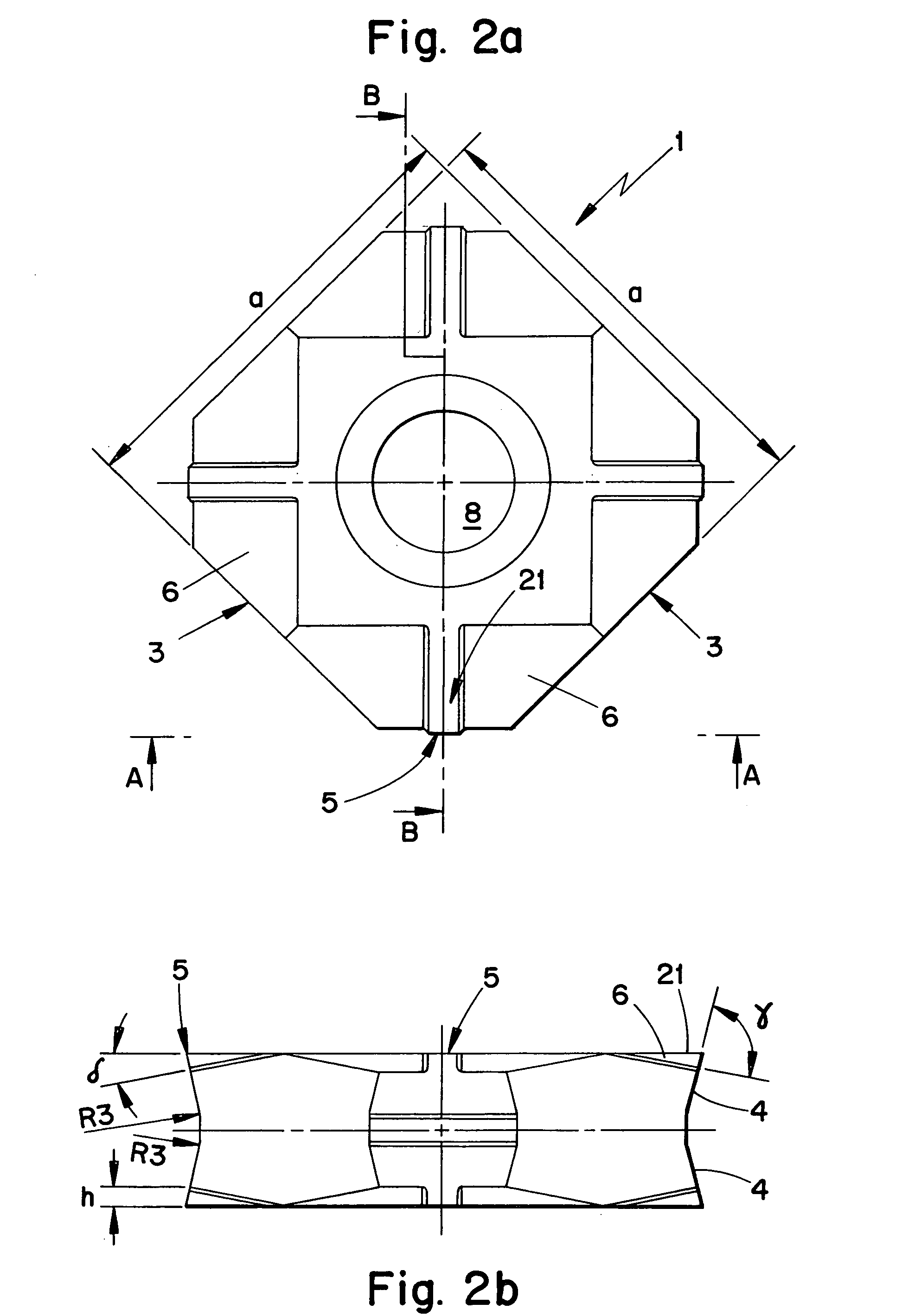

Cam Unit for a Constructed Camshaft

A cam unit for arranging on a camshaft main part of a camshaft in a rotationally fixed and axially movable manner. The cam unit includes a tubular sleeve main part and at least one cam element that lies on the sleeve main part in a rotationally fixed and non-movable manner. The sleeve main part and the at least one cam element are designed as individual parts that can be separately produced and subsequently assembled.

Owner:THYSSENKRUPP PRESTA TECCENTER AG

Mechanical exfoliation apparatus

Apparatus to deliver predetermined forces, containers to hold particulate material and media, media, and the associated parameters for operating such equipment along with methods and compositions provided by the apparatus and methods.

Owner:XG SCI

Barrel cam shift mechanism

A shift mechanism for a dual clutch transmission employs a rotating barrel cam having at least three tracks which are engaged by and translate at least three associated cam followers. The cam followers extend from shift fork bodies which slide on rails and include shift forks which bi-directionally translate at least three synchronizer clutches which engage at least five forward gears or speeds and reverse. A single electric motor and gear train drive the barrel cam.

Owner:GM GLOBAL TECH OPERATIONS LLC

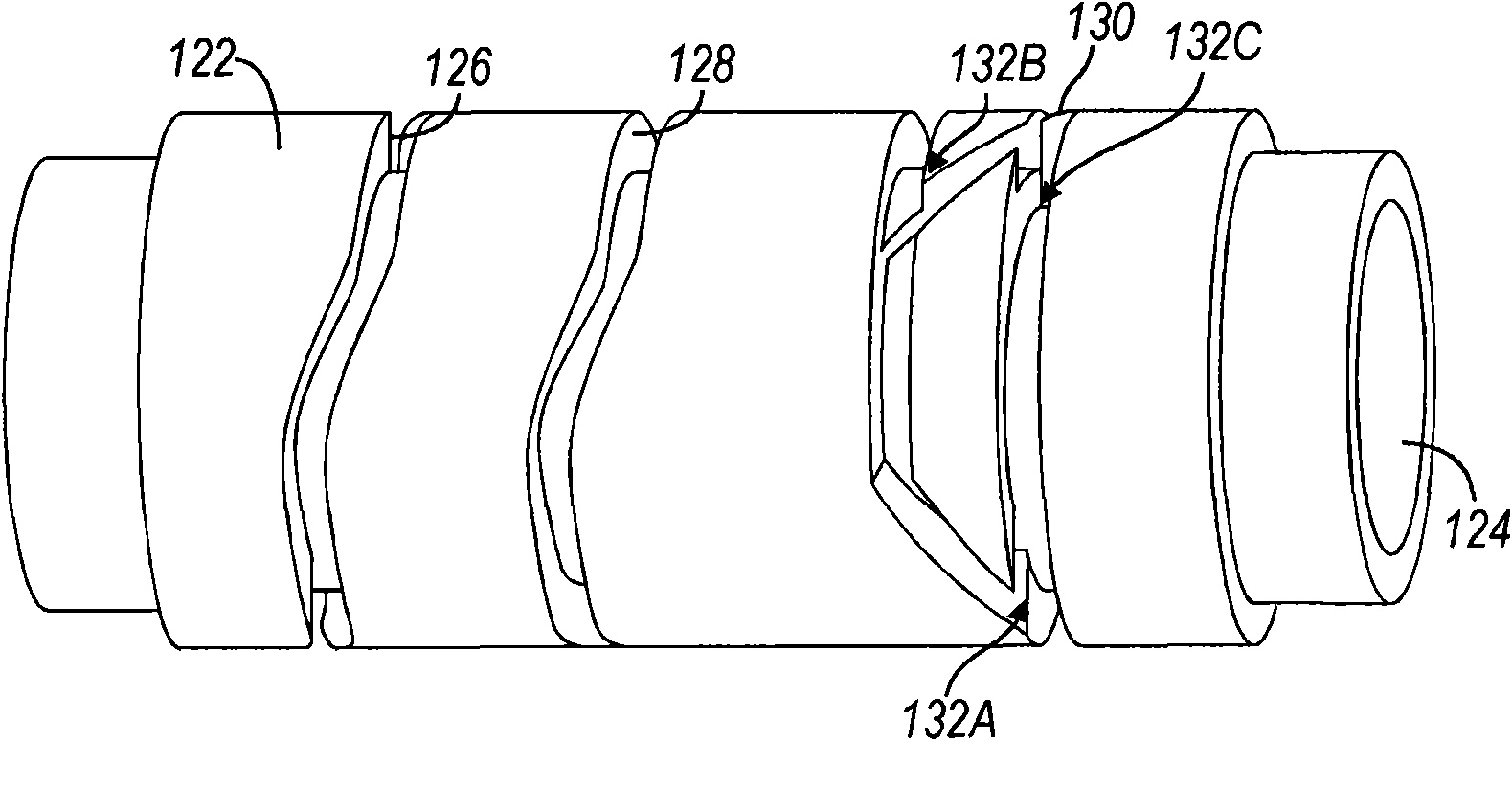

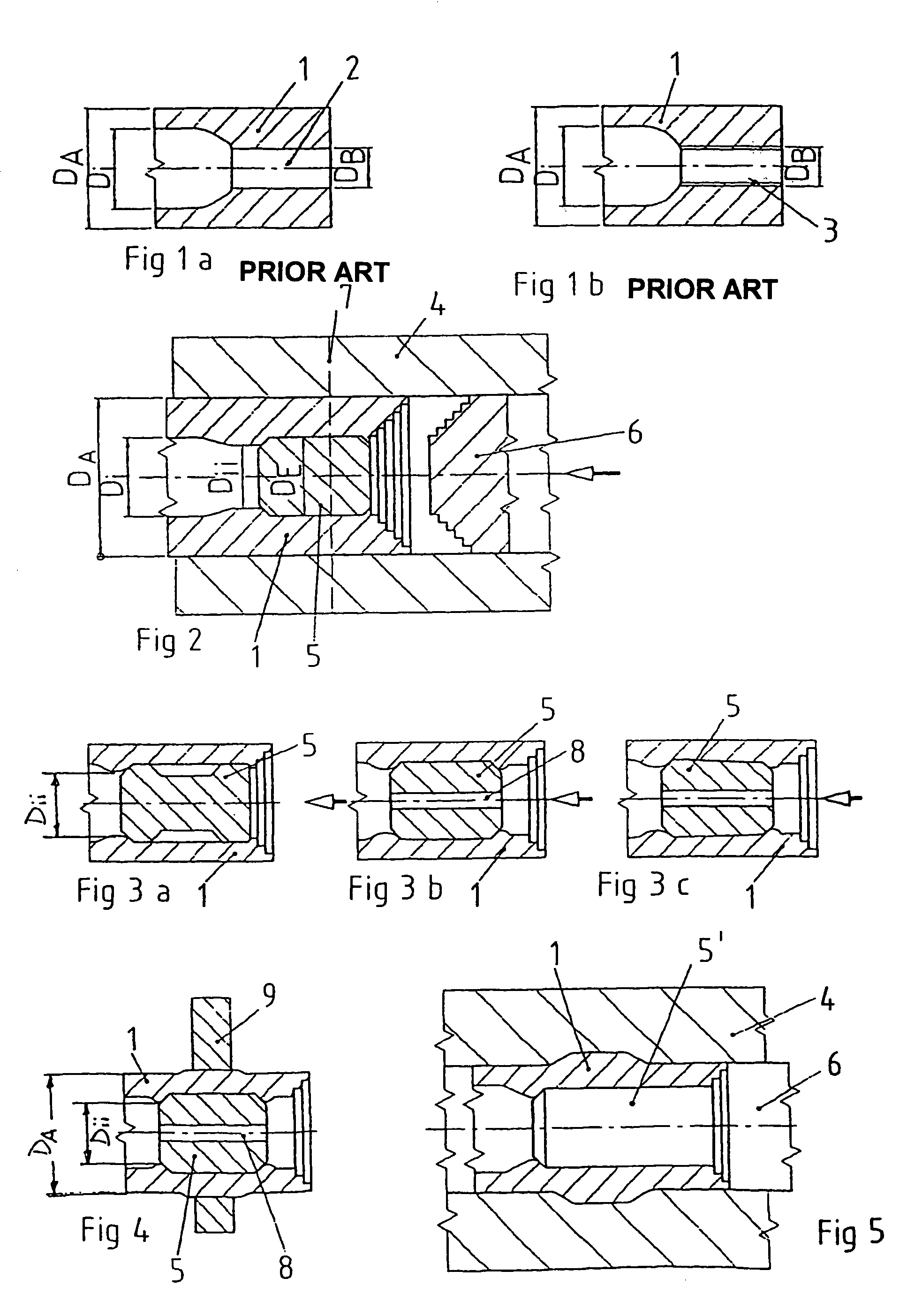

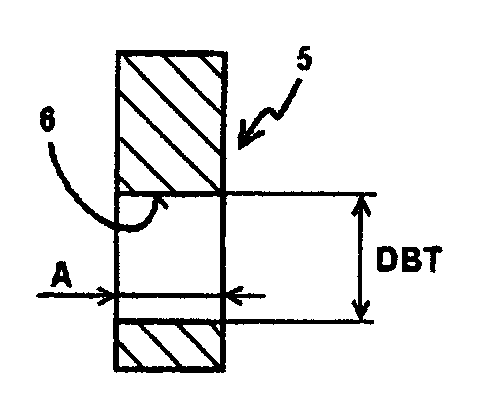

Method for producing a hollow shaft, in particular a camshaft and a camshaft produced according to said method

InactiveUS6961998B2Reduce element in diameterSmooth connectionCamsRopes and cables for vehicles/pulleyEngineeringMechanical pressure

Hollow shafts, and particularly camshafts, are produced using an internal high-pressure forming (IHF) process. Cams and / or machine elements are mounted at intervals onto the outer surface of the hollow shaft, depending on the use of the latter, by a non-positive and / or positive fit, in a position appropriate to their function when the hollow shaft is placed in the forming tool. An element with approximately the same external diameter as the internal diameter of the hollow shaft is placed in at least one of the hollow shaft, and the hollow shaft together with the cams and / or machine elements that have been pushed onto the same and the inserted element are placed in an IHF tool. Once the IHF tool is closed, the medium is caused to act under the required high-pressure in the hollow shaft. At the same time as the medium is acting internally, at least one ram is pressed axially against at least one front face of the hollow shaft. Thus, filling the IHF mould with a material flow induced by the pressure effect of the medium and the mechanical pressure of the ram. The element is thus enclosed by the material of the hollow shaft and the cams and / or elements are connected to the hollow shaft by the non-positive and / or positive fit by means of the expansion of the hollow shaft. The end of the hollow shaft sealed by the element is mechanically machined to suit functional requirements.

Owner:LINAMAR ANTRIEBSTECHN

Adjustable multiple-piece cam track

A multiple-piece cam unit for use in a molding machine. The cam unit has a cam track which engages cam followers of mold assemblies of the molding machine to move the cam followers between a first position and a second position. The cam unit includes a first cam section and a second cam section. The first cam section has an entrance portion which is dimensioned to receive the cam followers therein. The second cam section has an exit portion positioned to release the cam followers therefrom. The second cam section is moveably mounted to the molding machine to allow the exit portion of the second cam section to be moved relative to the entrance portion of the first cam section, to insure that the cam followers exiting the exit portion of the second cam section are properly aligned to enter the entrance portion of the first cam section.

Owner:GRAHAM ENG CO LLC

Camshaft Assembly

The invention relates to a camshaft assembly comprising an inner shaft, an outer tube rotatable relative to the inner shaft, and two groups of cams mounted on the outer tube, the first group of cams being fast in rotation with the outer tube, and the second group being rotatably mounted on the outer surface of the tube and being connected for rotation with the inner shaft by means of connecting members that pass through circumferentially elongated slots in the outer tube. In the invention, the outer tube surrounds the inner shaft with clearance and the members connecting different ones of the cams of the second group to the inner shaft are inclined relative to one another and act to locate the axis of the inner shaft relative to the outer tube.

Owner:MECHADYNE INT

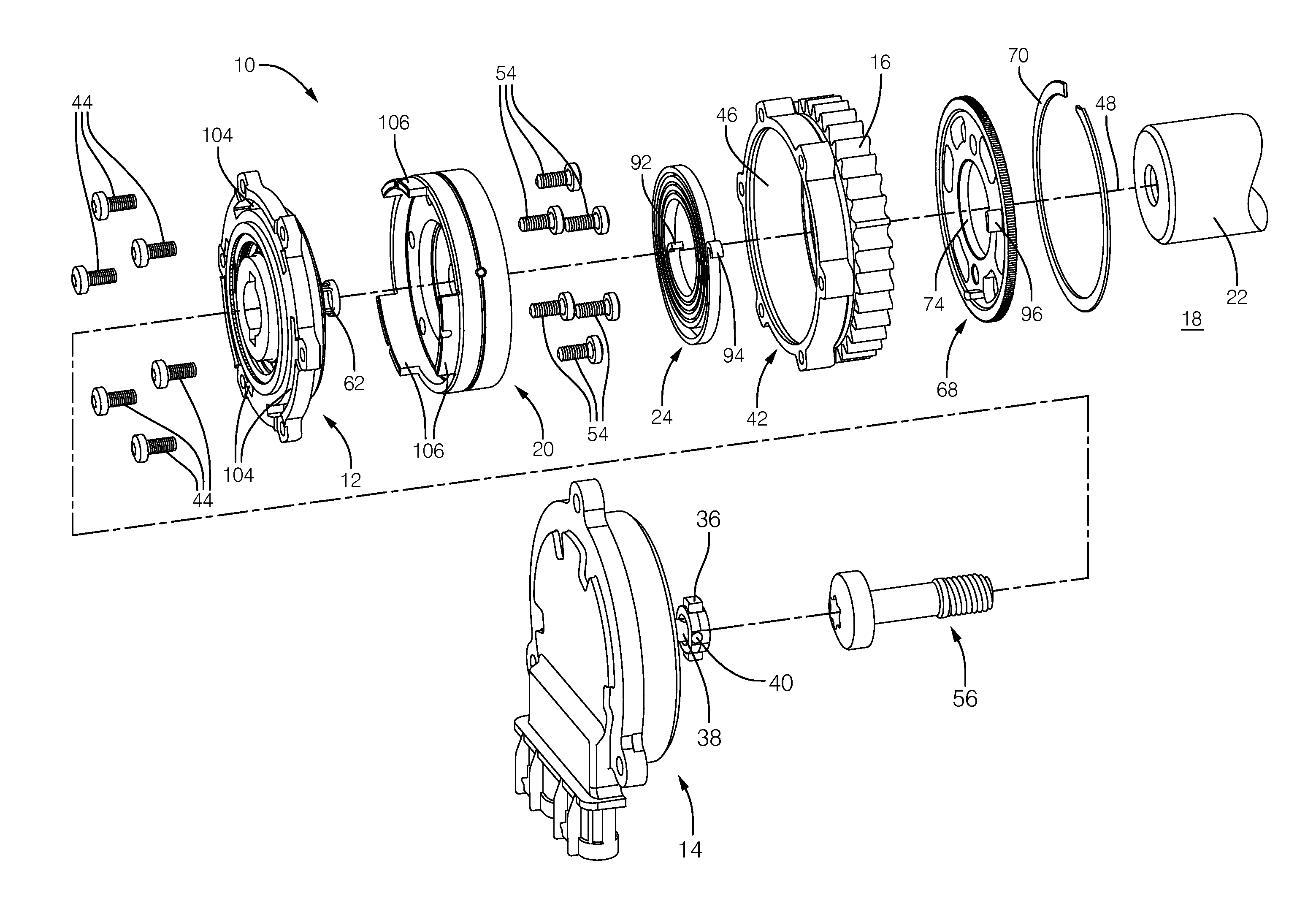

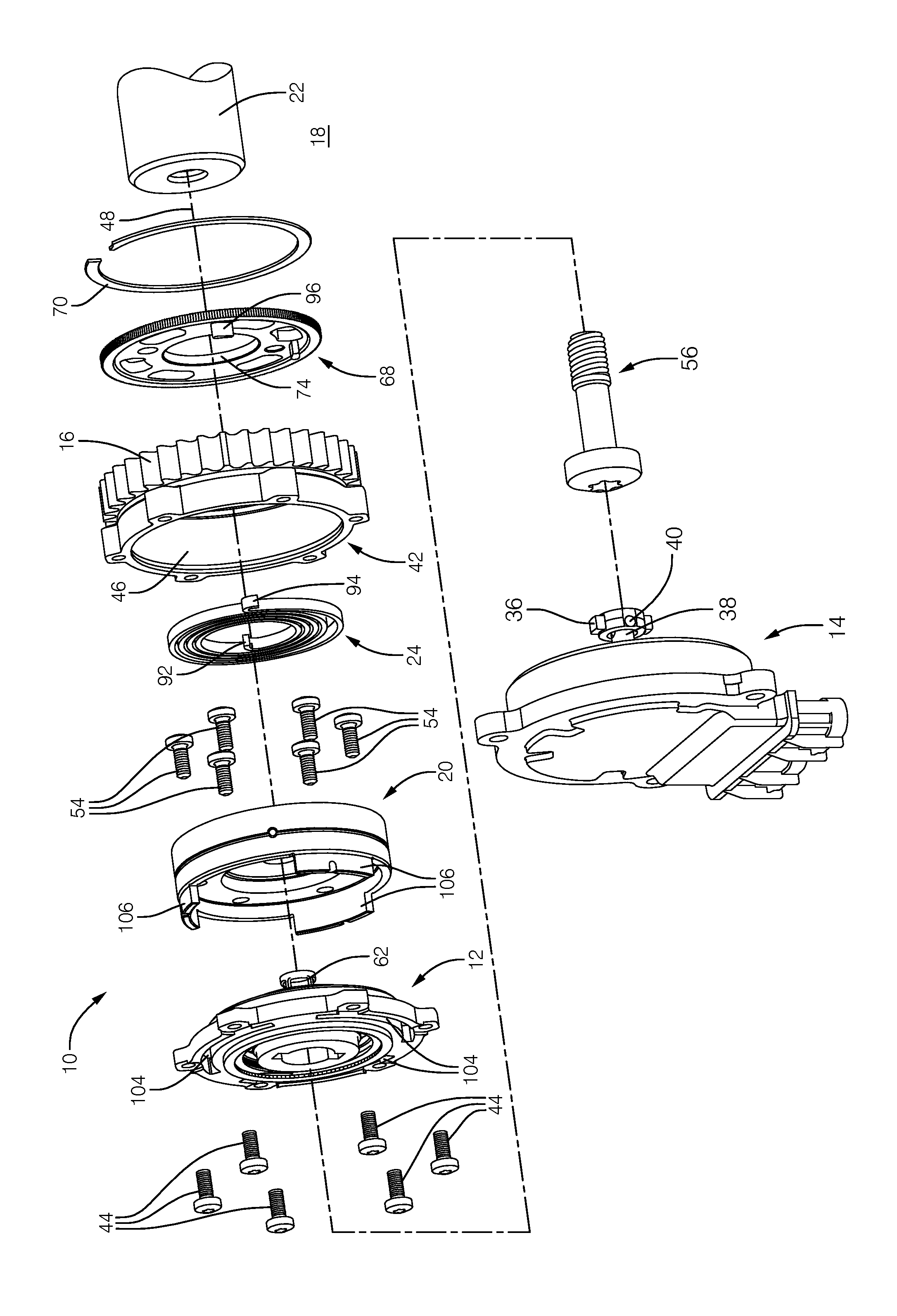

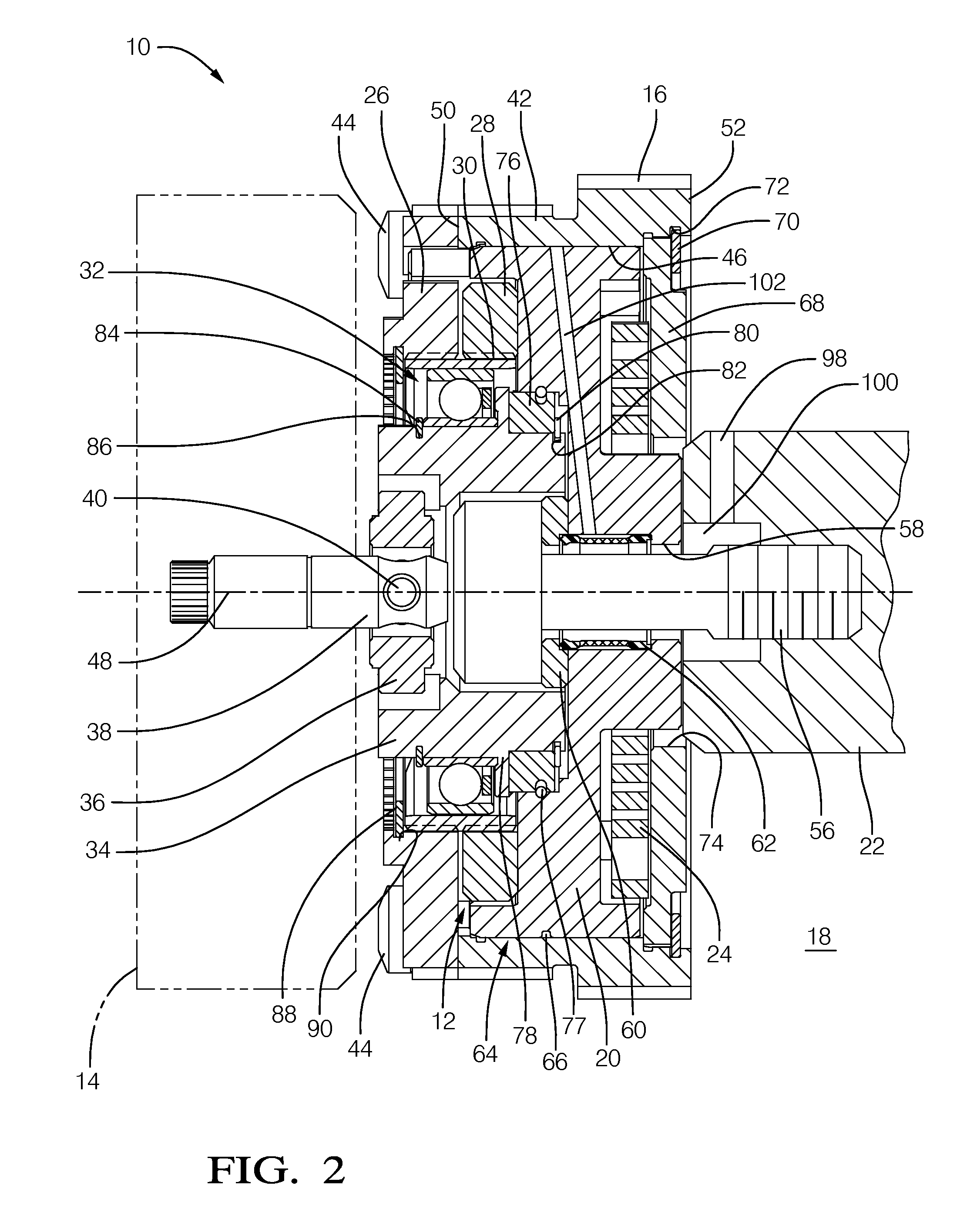

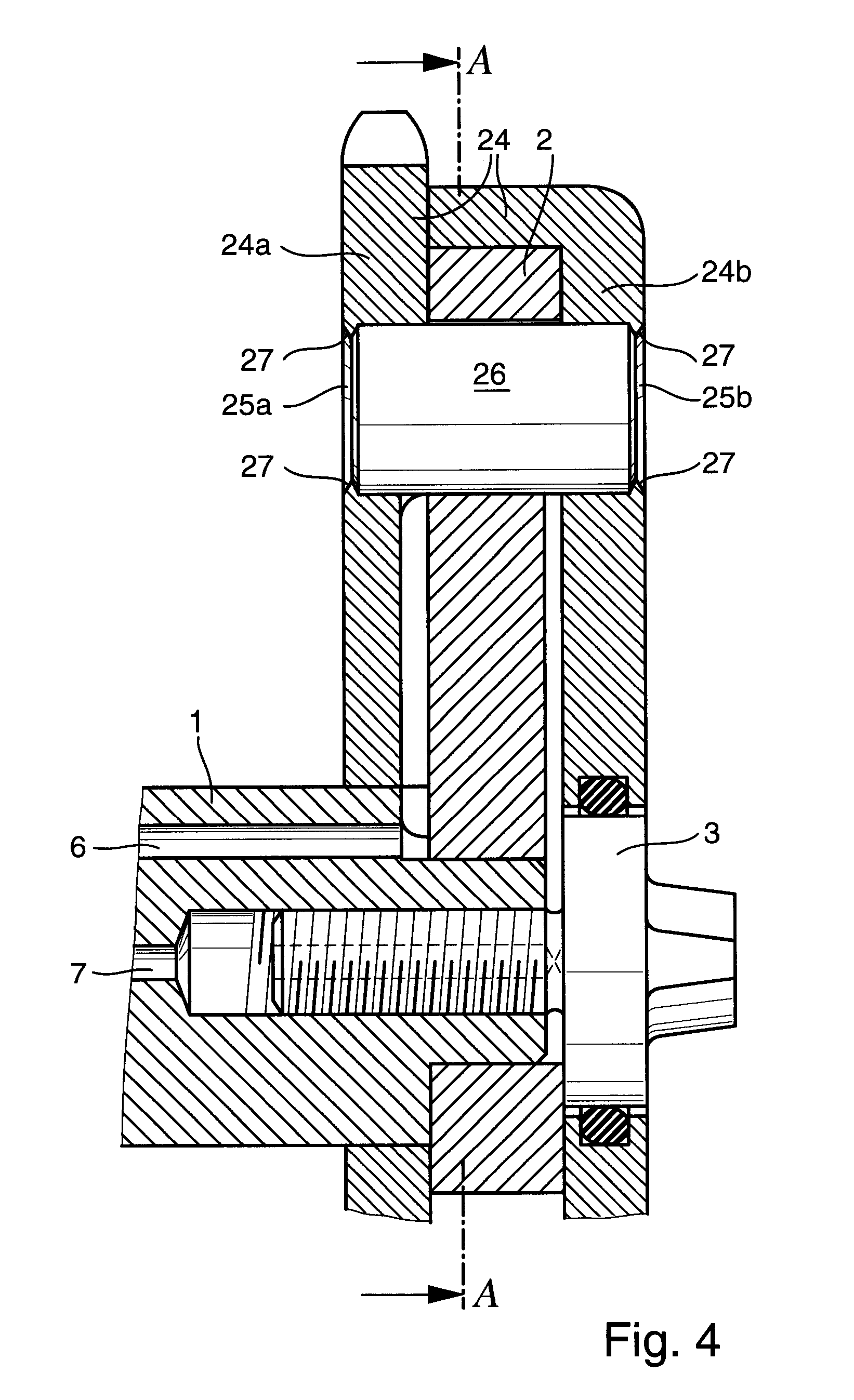

Axially compact electrically driven camshaft phaser

A camshaft phaser for controllably varying the phase relationship between a crankshaft and a camshaft of an internal combustion engine includes a housing having a bore with an open and extending along a longitudinal axis. The camshaft phaser also includes a harmonic gear drive unit having an outer first spline, an outer second spline which is axially adjacent to the outer first spline and disposed within the housing, a flexspline disposed radially within the outer first spline and the outer second spline, a wave generator disposed radially within the flexspline, and a rotational actuator connectable to the wave generator such that rotation of the rotational actuator causes relative rotation between the outer first spline and the outer second spline. The outer first spline is fixed to the housing in order to prevent relative rotation therebetween and serves to close the open end of the housing.

Owner:DELPHI TECH INC

Operation of camshafts, particularly for an injection pump for diesel, having a running pulley driven in a lifting manner

The invention provides for operation of camshafts, particularly for an injection pump for diesel. A camshaft rotates around a longitudinal axis of a camshaft. The camshaft has at least one cam being in cooperation with a pressure roller driven in a lifting manner. The pressure roller rotates on the peripheral surface of the cam. The upward stroke of the pressure roller is a working stroke during which the pressure roller moves away from the longitudinal axis of the camshaft. During a return stroke the pressure roller moves toward the longitudinal axis of the camshaft. The peripheral surface of the cam has a return stroke section and a working stroke section. The peripheral surface of the return stoke section has a greater friction value than the working stroke section. Thus an operation of camshafts for an injection pump for diesel is provided, securing a rotation of the pressure roller around the circumference of the cam within the whole speed range of the camshaft.

Owner:ROBERT BOSCH GMBH

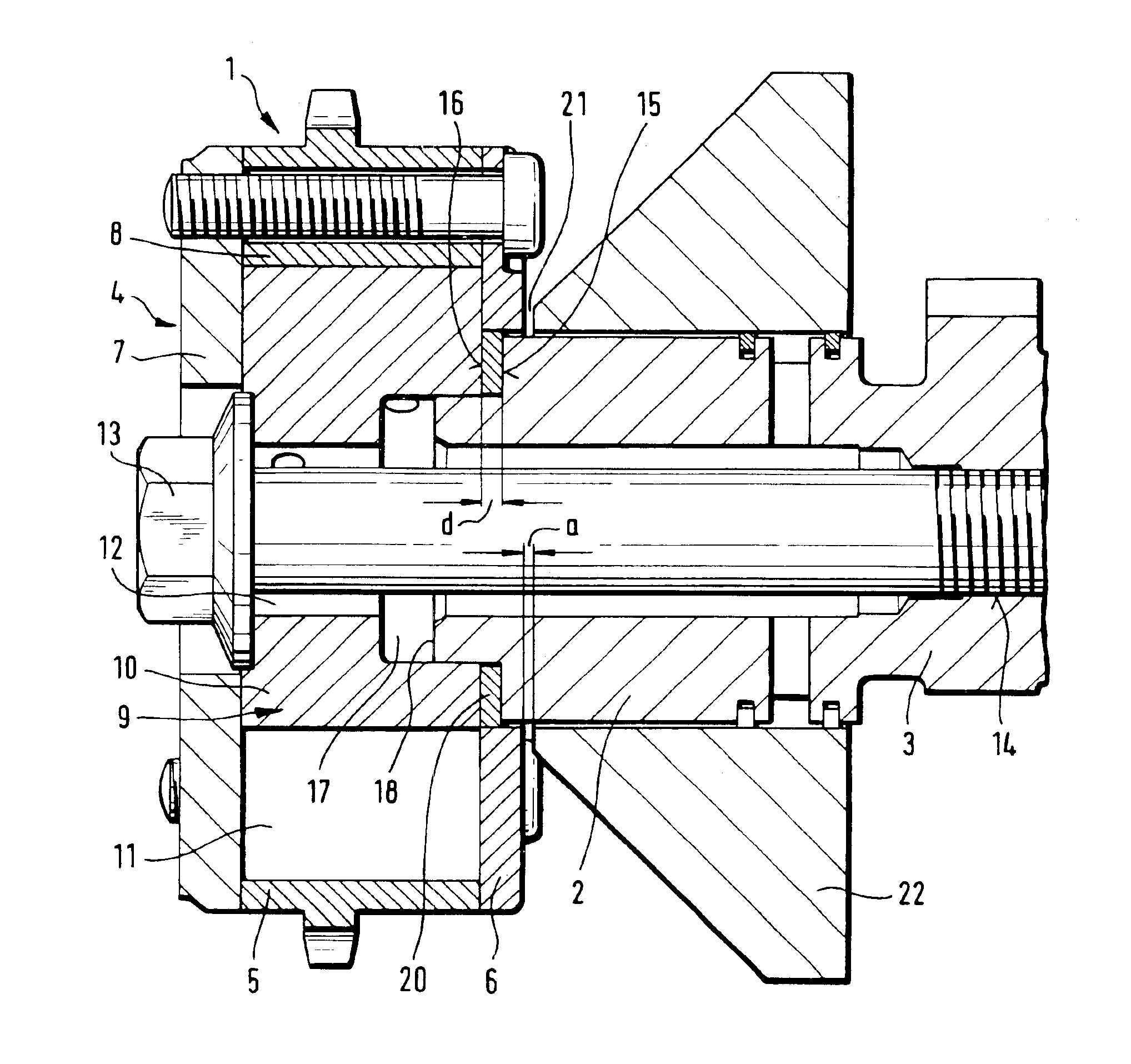

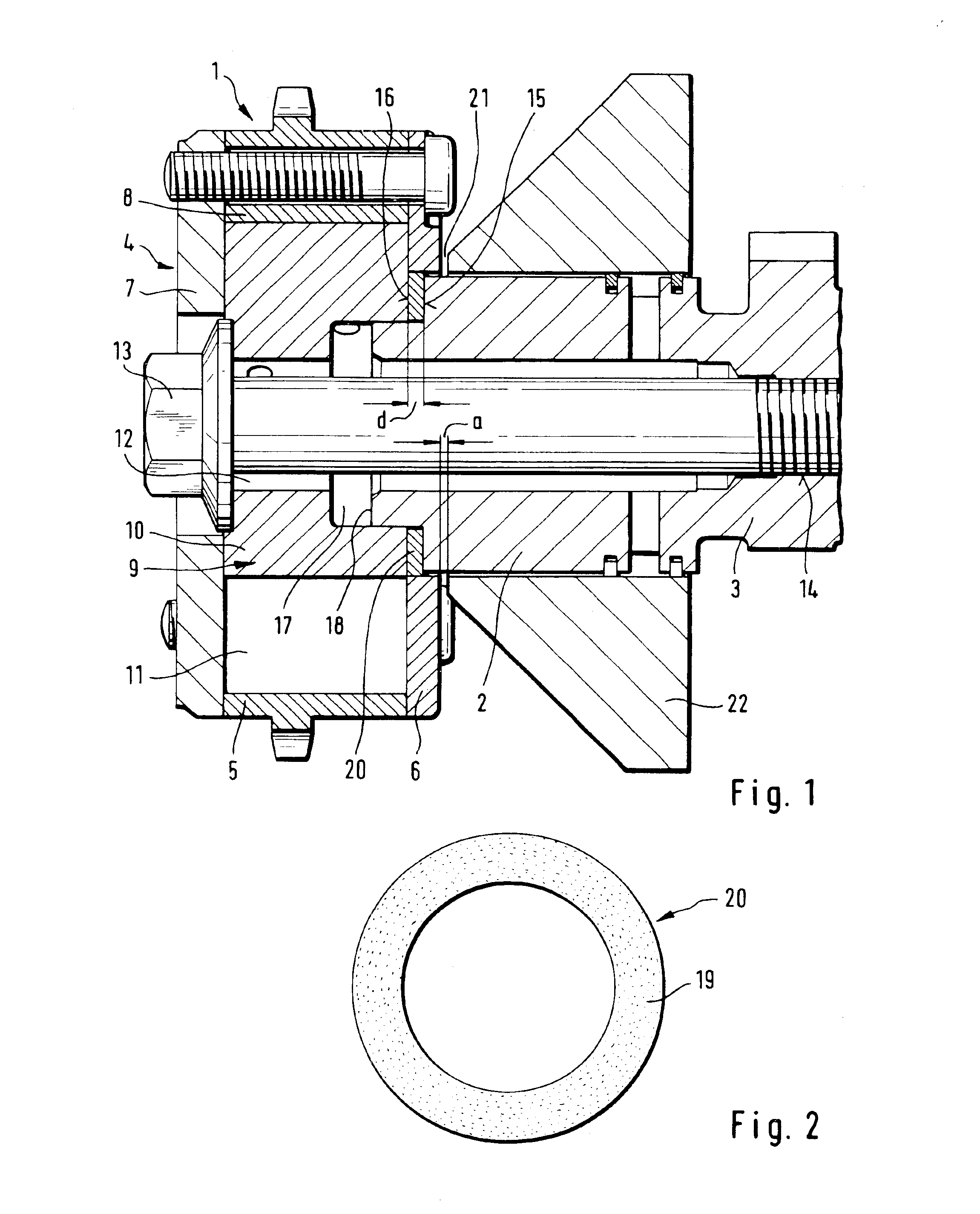

Internal combustion engine adjusting the rotation angle of a camshaft with respect to a crankshaft

A device for hydraulically adjusting the rotation angle of a camshaft with respect to a crankshaft of an internal combustion engine: A drive unit connected to a crankshaft and an output unit connected to a camshaft, having radially extending, axially facing sides secured by the pre-stressing force of a central securing bolt. The drive unit is rotably mounted to the output unit and they are so connected that at least two hydraulic pressure chambers transmit relative rotation forces. An annular disk with coating on opposite sides increases the frictional force between the end face of the output unit which faces the camshaft and the end of the camshaft and enables reduction of the pre-stressing force on the bolt. The character of visually detectable elements on the disk enable detection of the presence or absence of the disk.

Owner:SCHAEFFLER TECH AG & CO KG

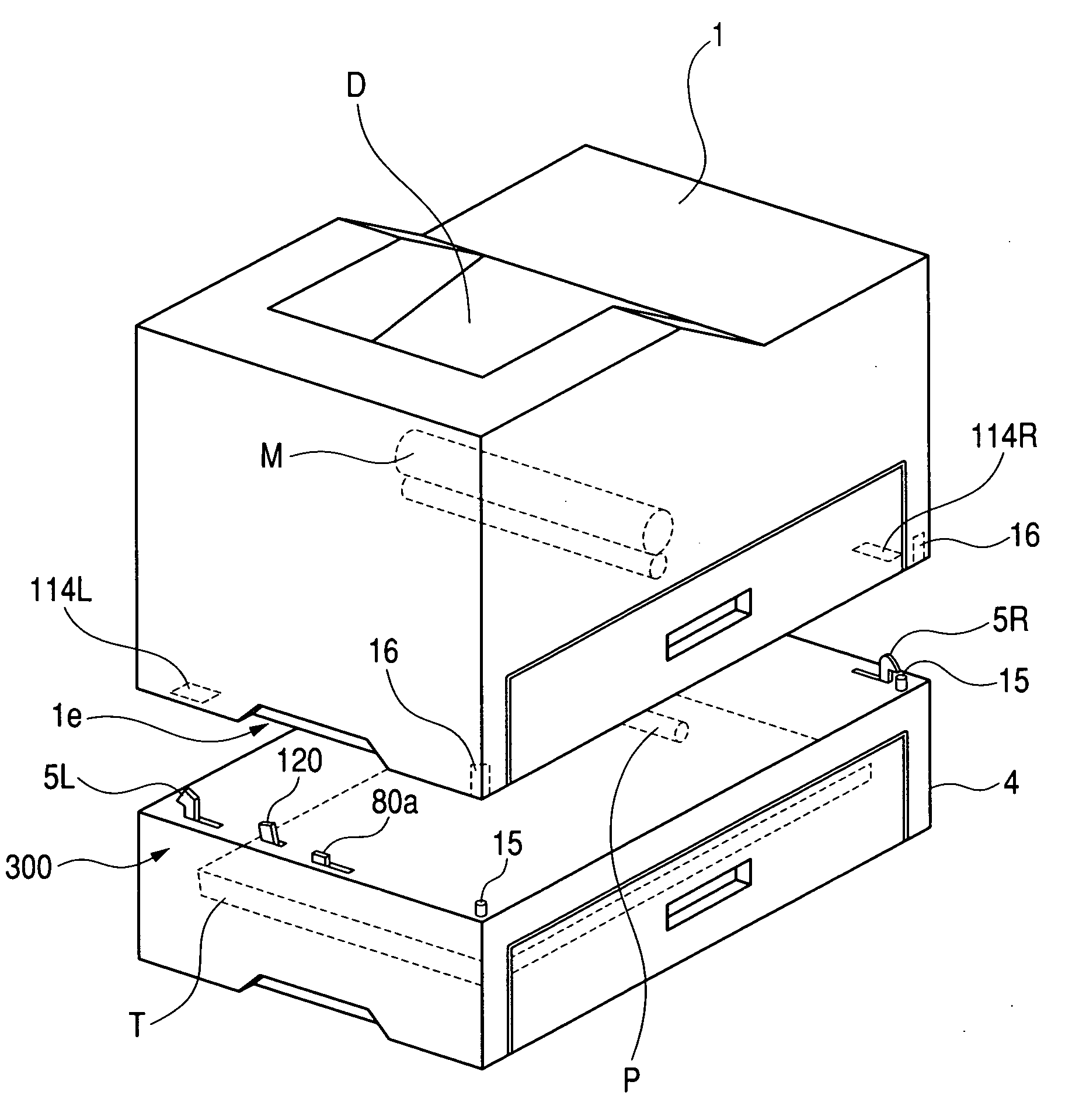

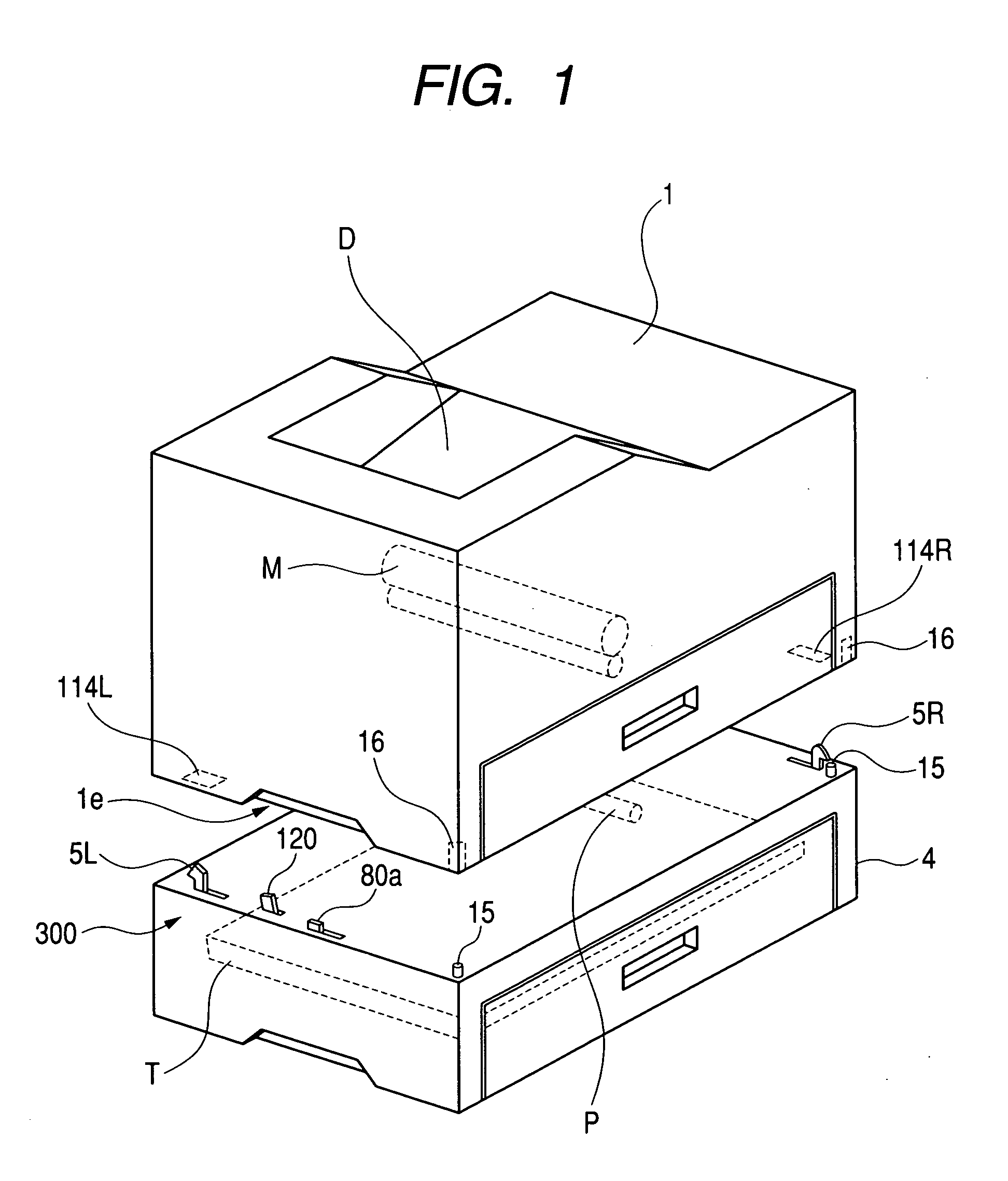

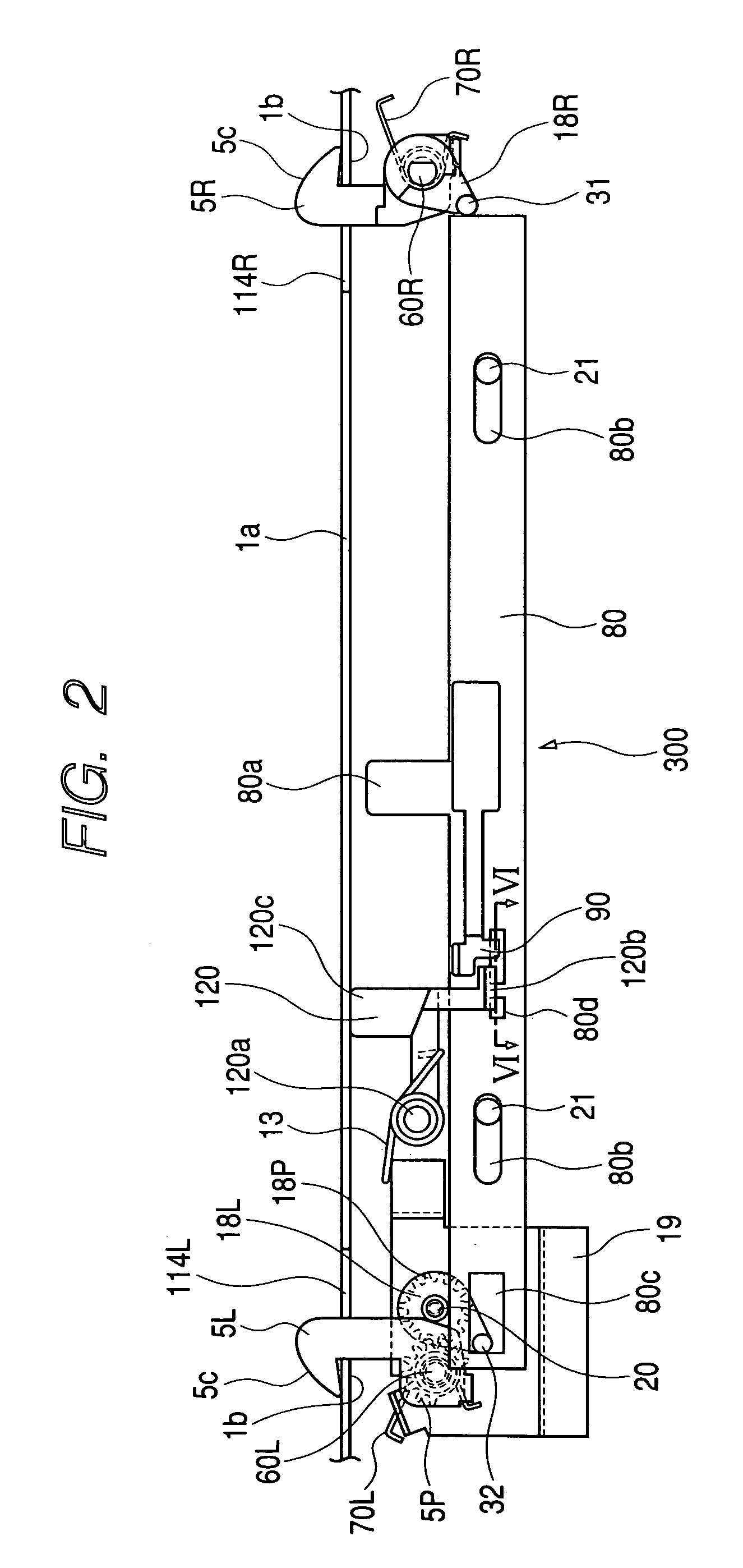

Lock mechanism, and external apparatus and image forming apparatus provided with the same

Owner:CANON KK

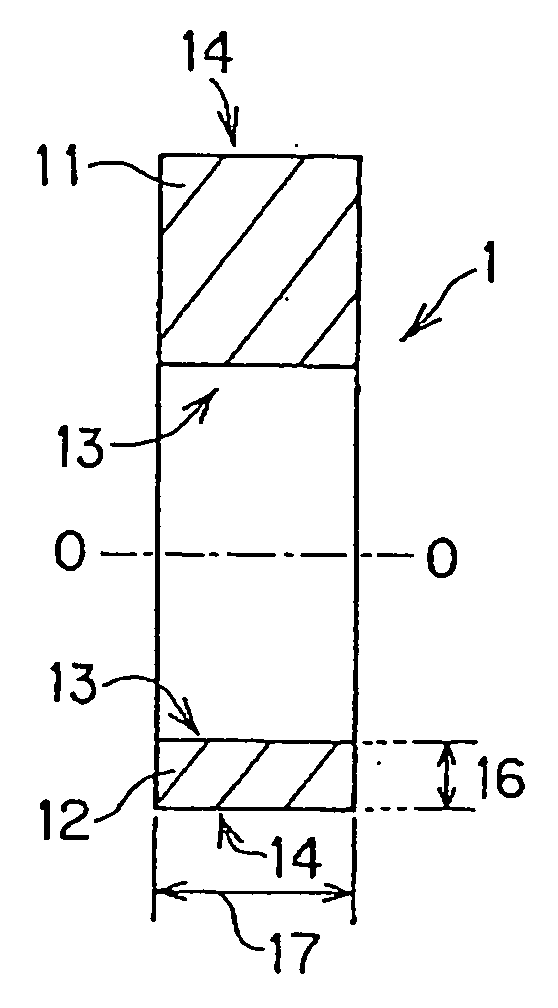

Method of Manufacturing Cam Shaft, Cam Shaft, and Cam Lobe Material Used in the Same

InactiveUS20080276753A1Expand allowanceReduce wall thicknessCamsValve drivesMetallurgyDegrees of freedom

A method of manufacturing a cam shaft that prevents cracks during the joining of a cam lobe to a shaft, and improves the degree of freedom of design of the cam lobe is provided.By a method of manufacturing a cam shaft that after an inner circumferential surface 13 of a cam lobe 1 is subjected to treatment for residual compressive stress addition treatment, the cam lob 1 is joined to a shaft, above problem is solved. It is preferred that the residual compressive stress on the inner circumferential surface 13 of the cam lobe 1 is not less than 100 MPa. In addition, an outer peripheral surface 14 of the cam lobe 1 can be also subjected to treatment for residual compressive stress addition treatment. As the treatment for residual compressive stress addition treatment, shot-peening treatment, induction hardening treatment, barrel polishing treatment, carburizing and quenching treatment or carbonitriding treatment is performed.

Owner:NIPPON PISTONRING CO LTD

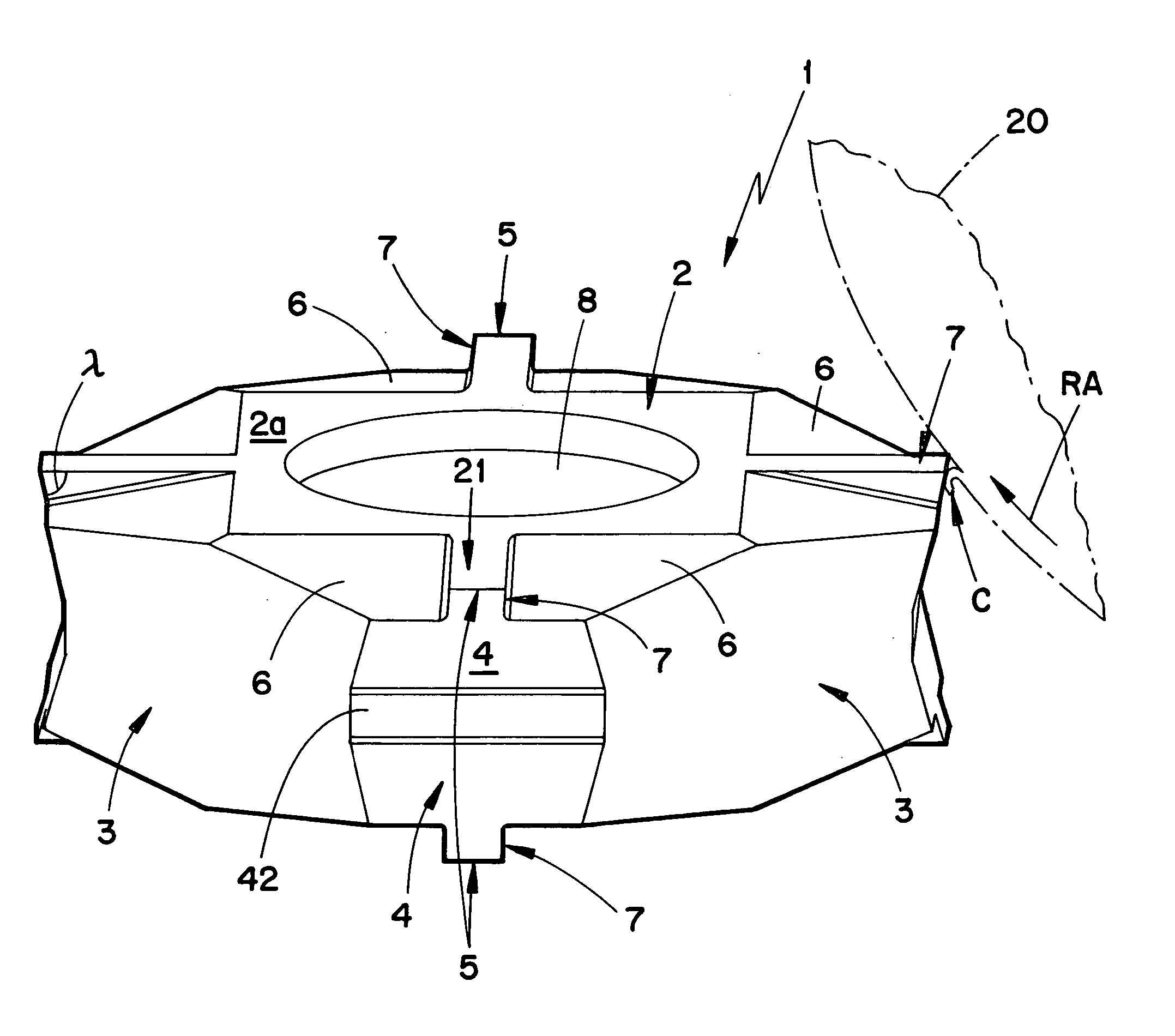

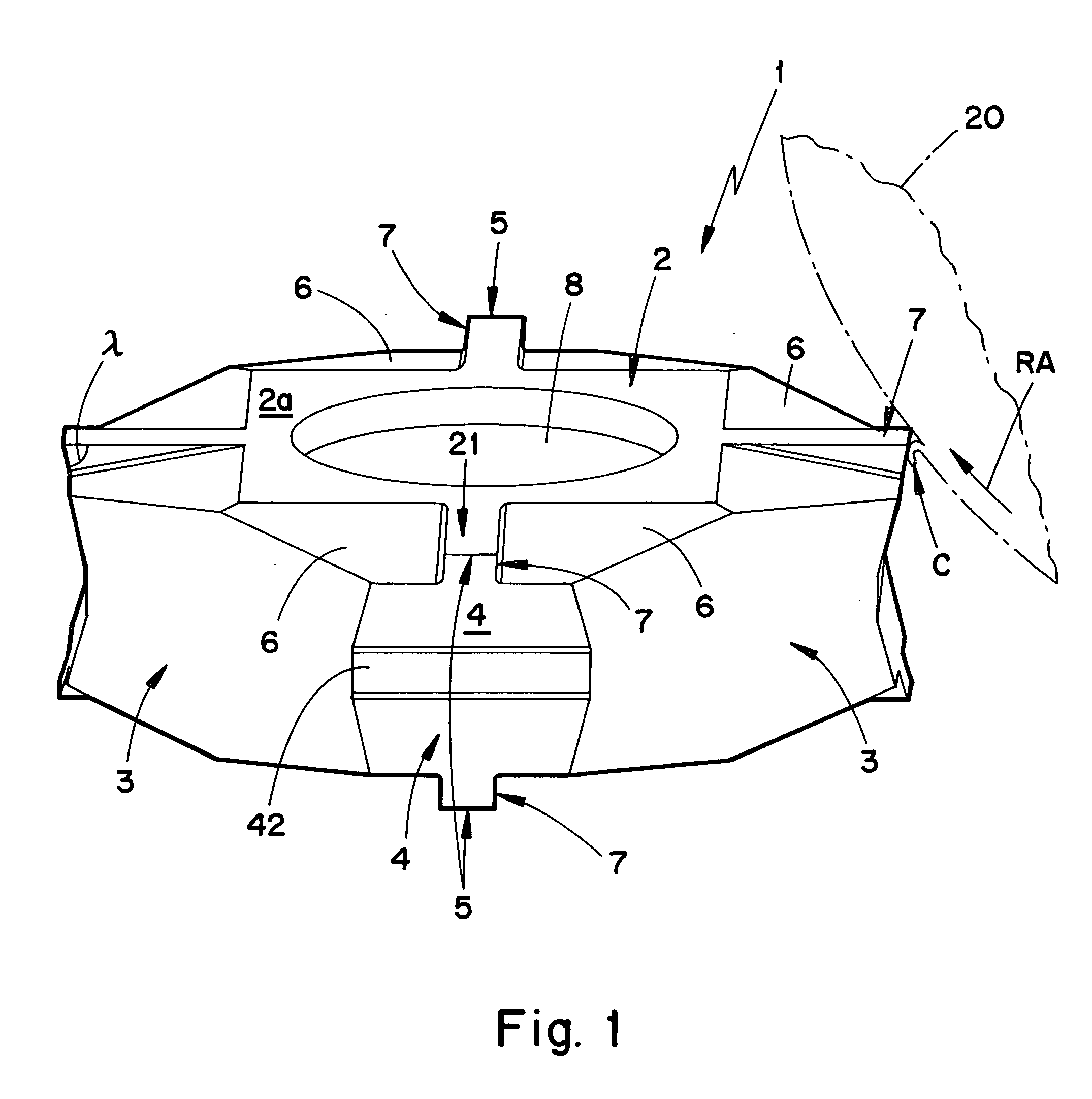

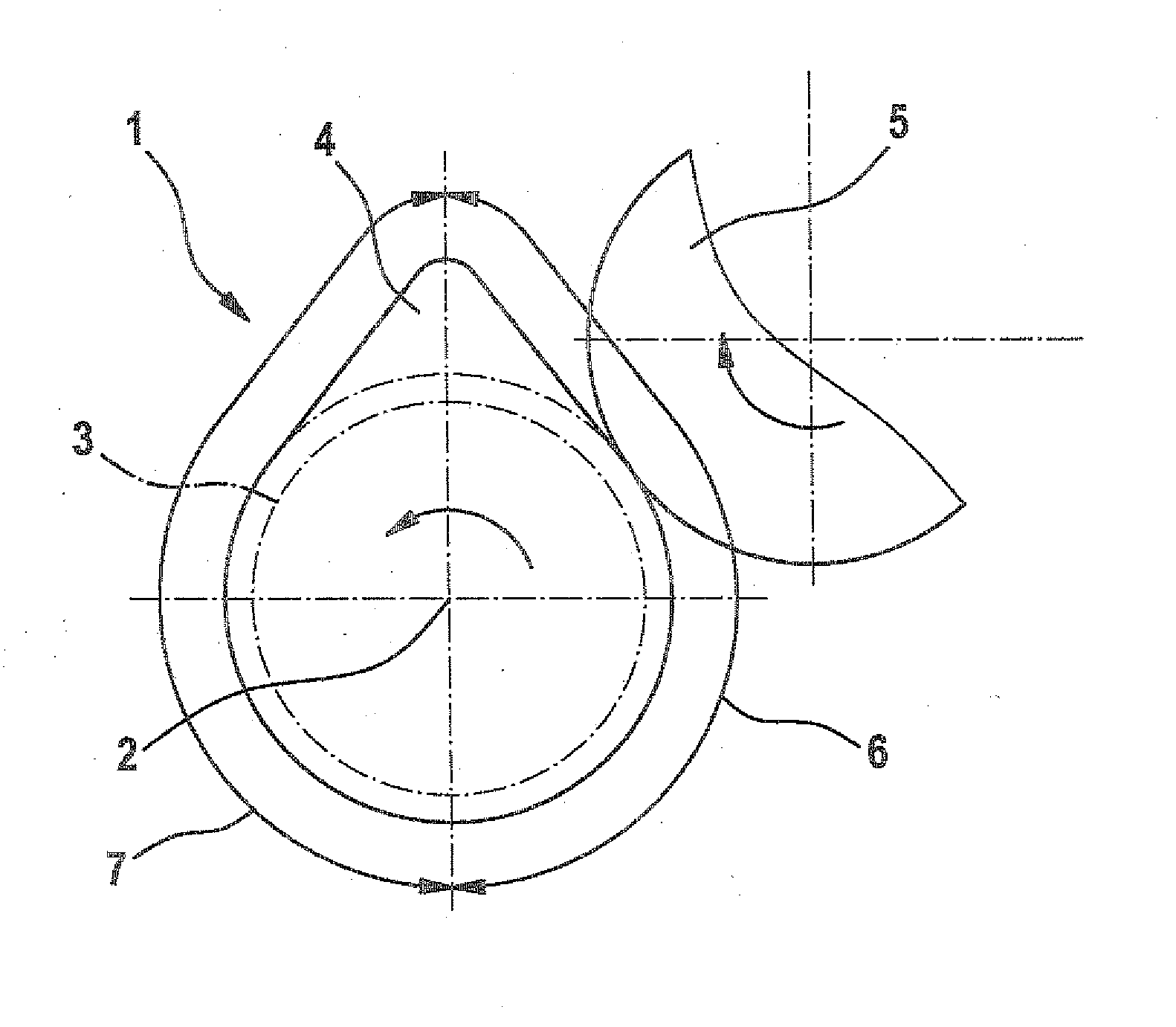

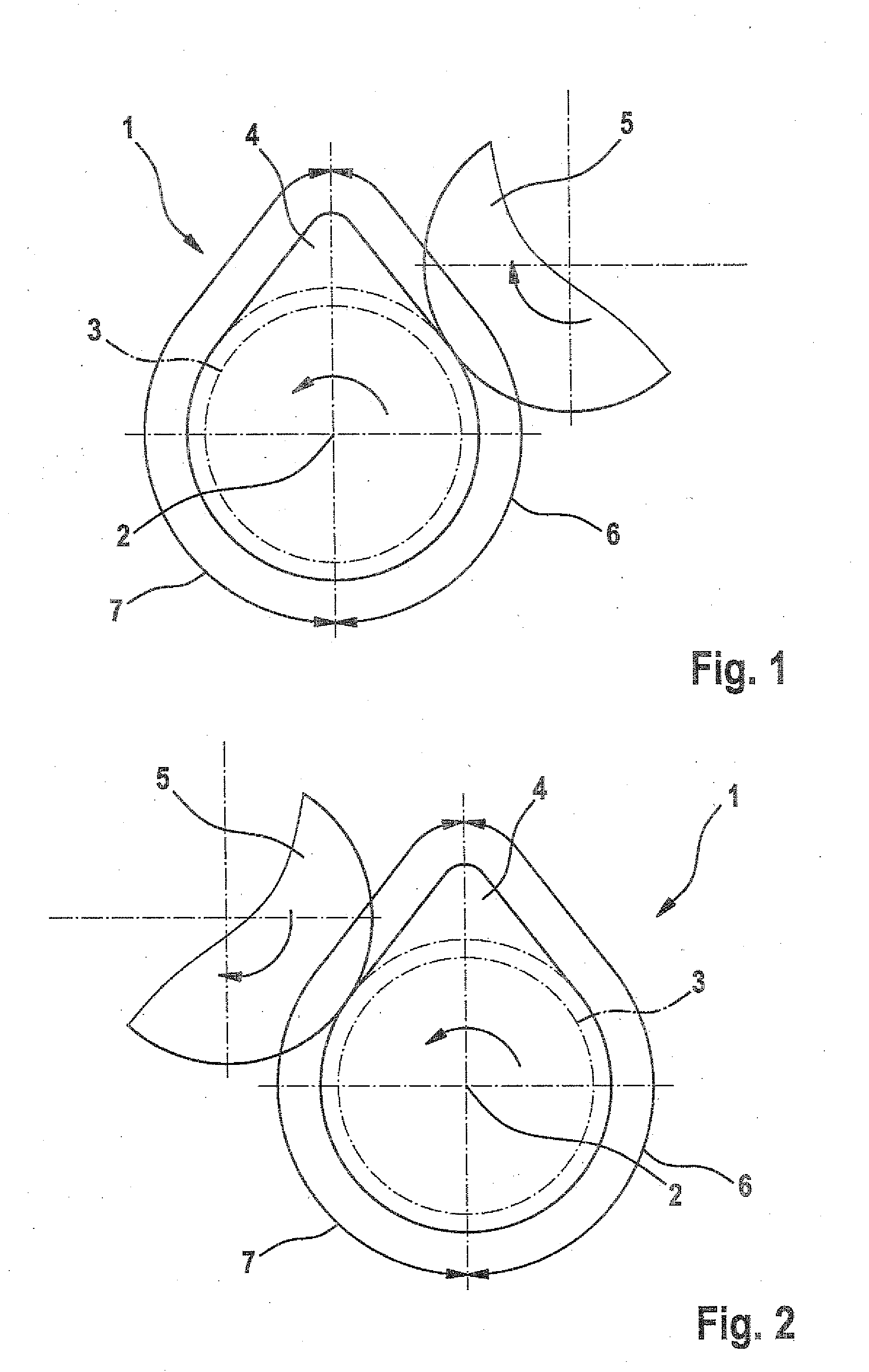

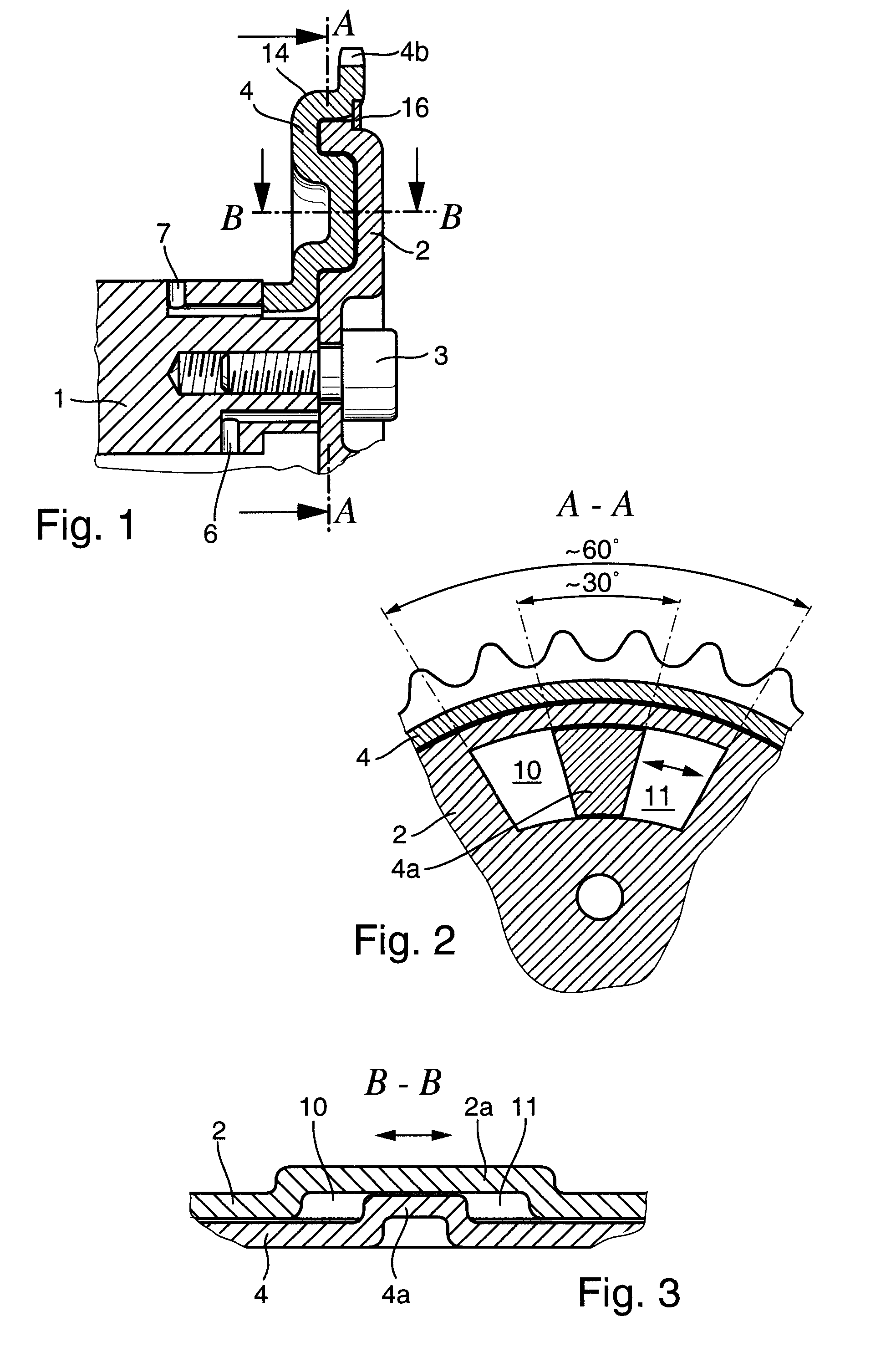

Device for hydraulically adjusting the angle of rotation of a shaft relative to a driving wheel

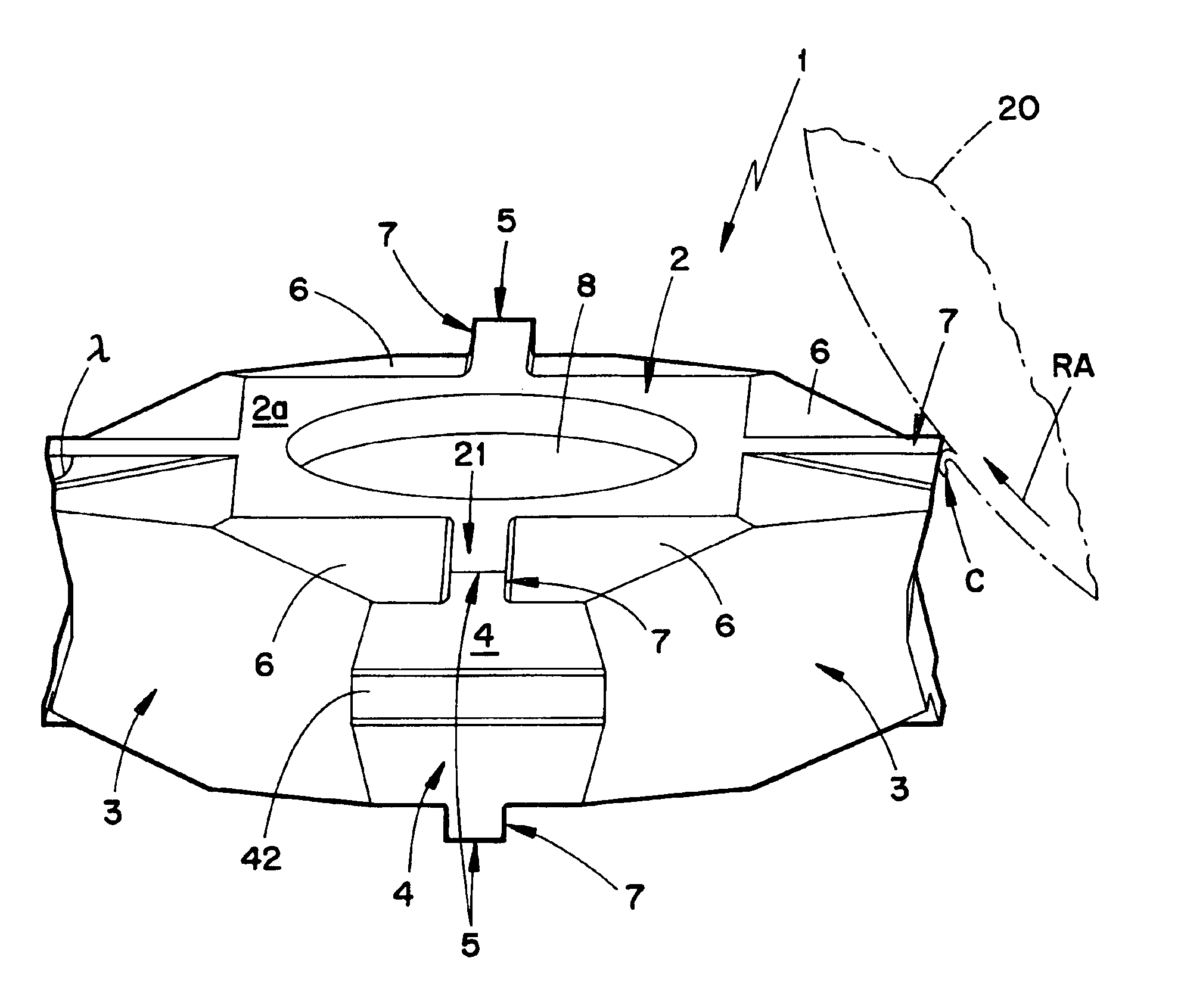

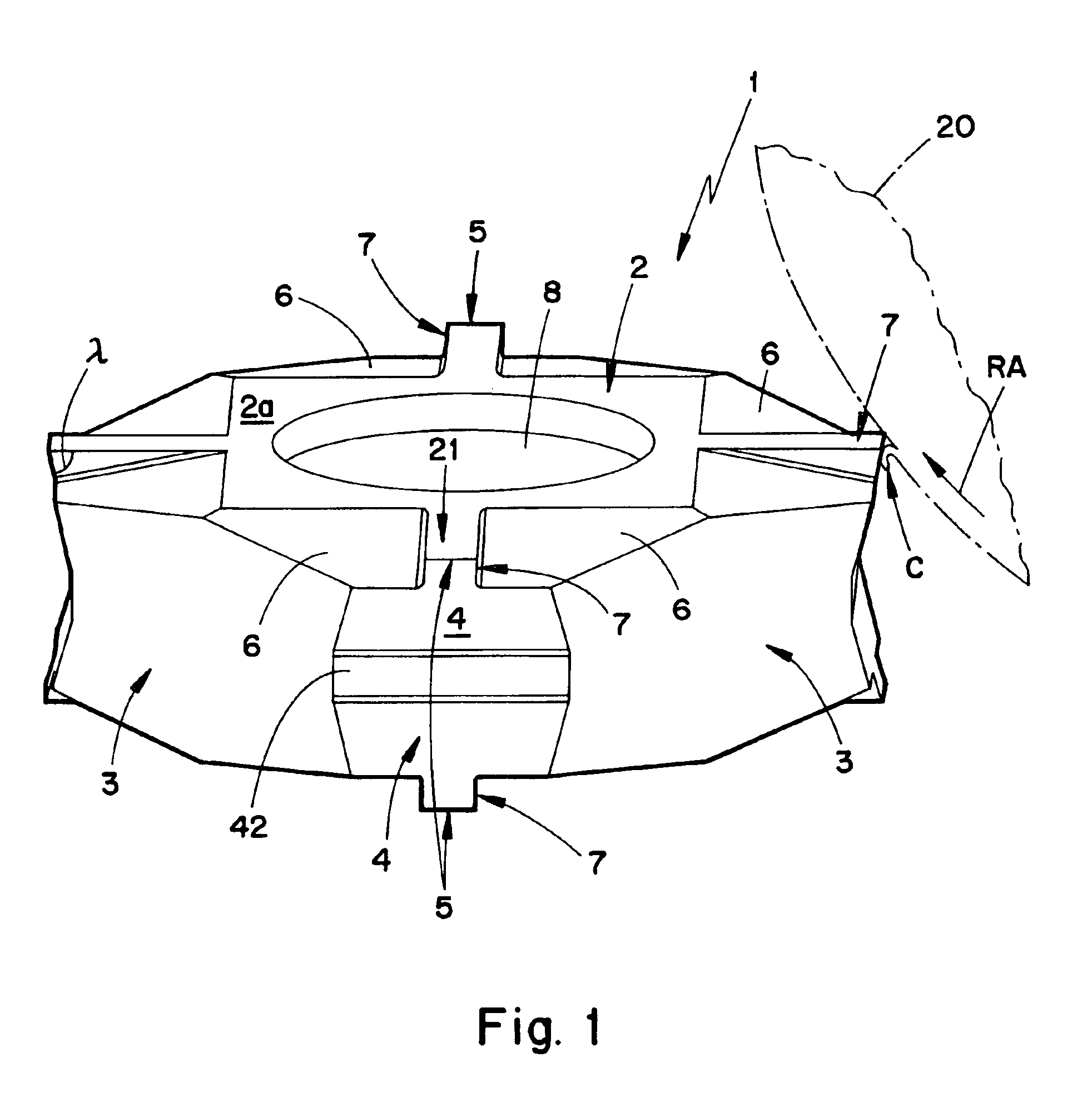

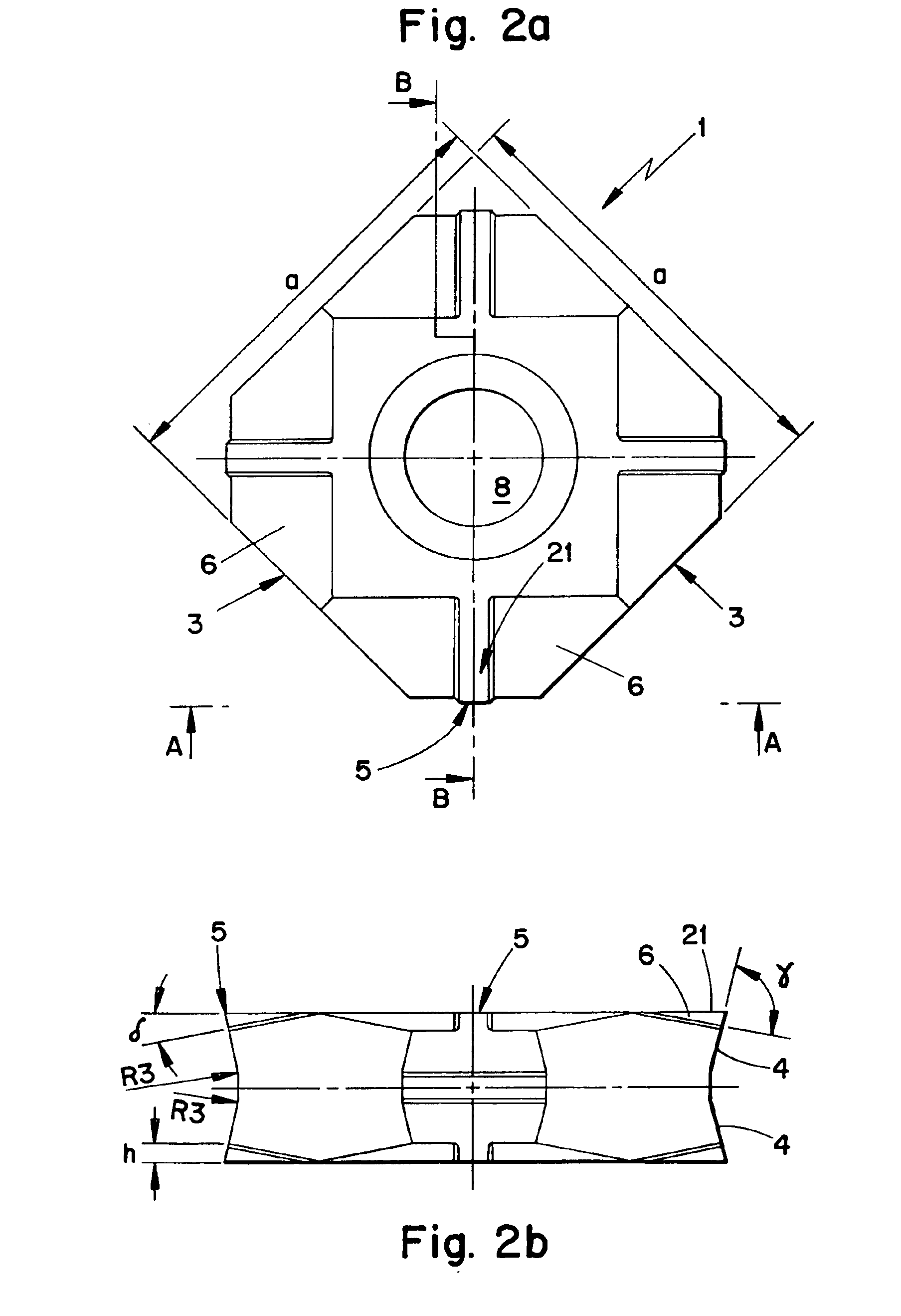

The invention concerns a device for the hydraulic adjustment of the angular position of a shaft (1) relative to a drive pinion (14), said device comprising a plate (2) fixed to the shaft to cooperate with the drive pinion (14) or with a component fixed to the drive pinion. The device comprises at least one ring-segment shaped section (2a) in the plate (2) and a means (4a) arranged on the drive pinion (14) or on said component to cooperate with the shaped section (2a) so as to divide the shaped section into two separate chambers (10, 11). The device further comprises a means for a selective hydraulic pressurization of the chambers (10, 11) for adjusting the relative angular position of the drive pinion (14) and the shaft (1).

Owner:SCHAEFFLER TECH AG & CO KG

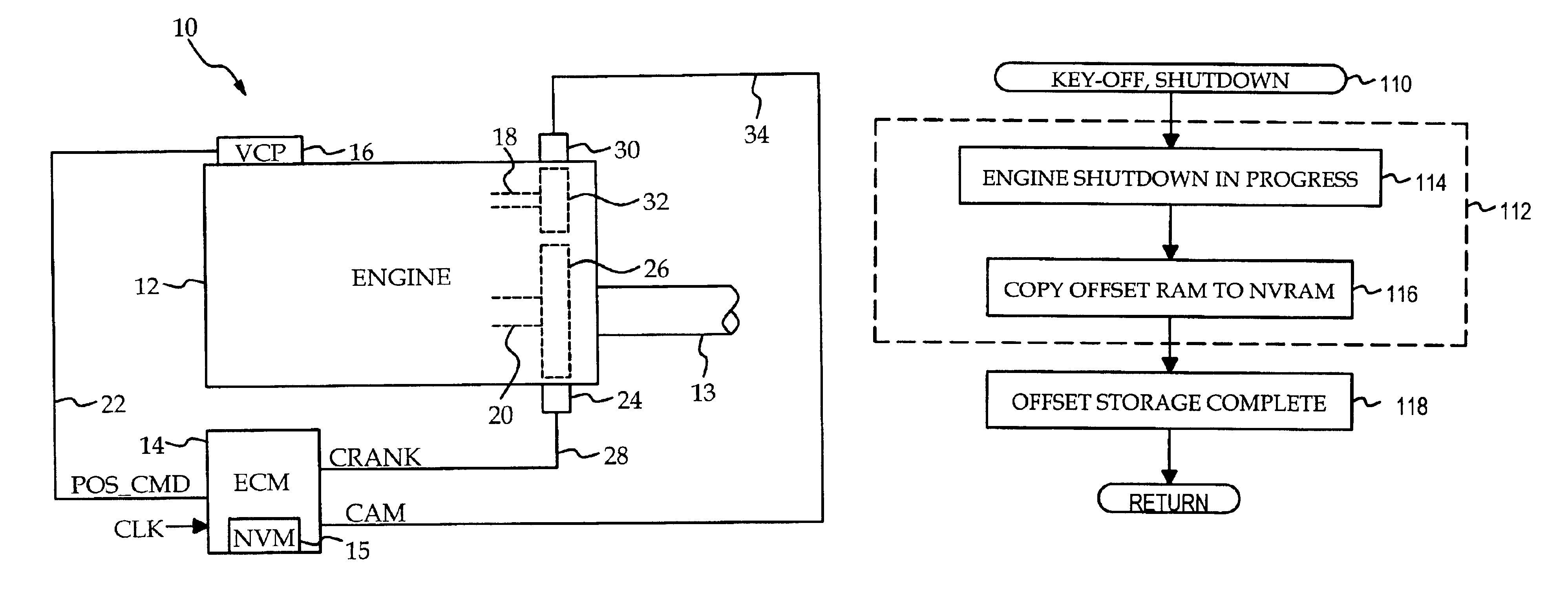

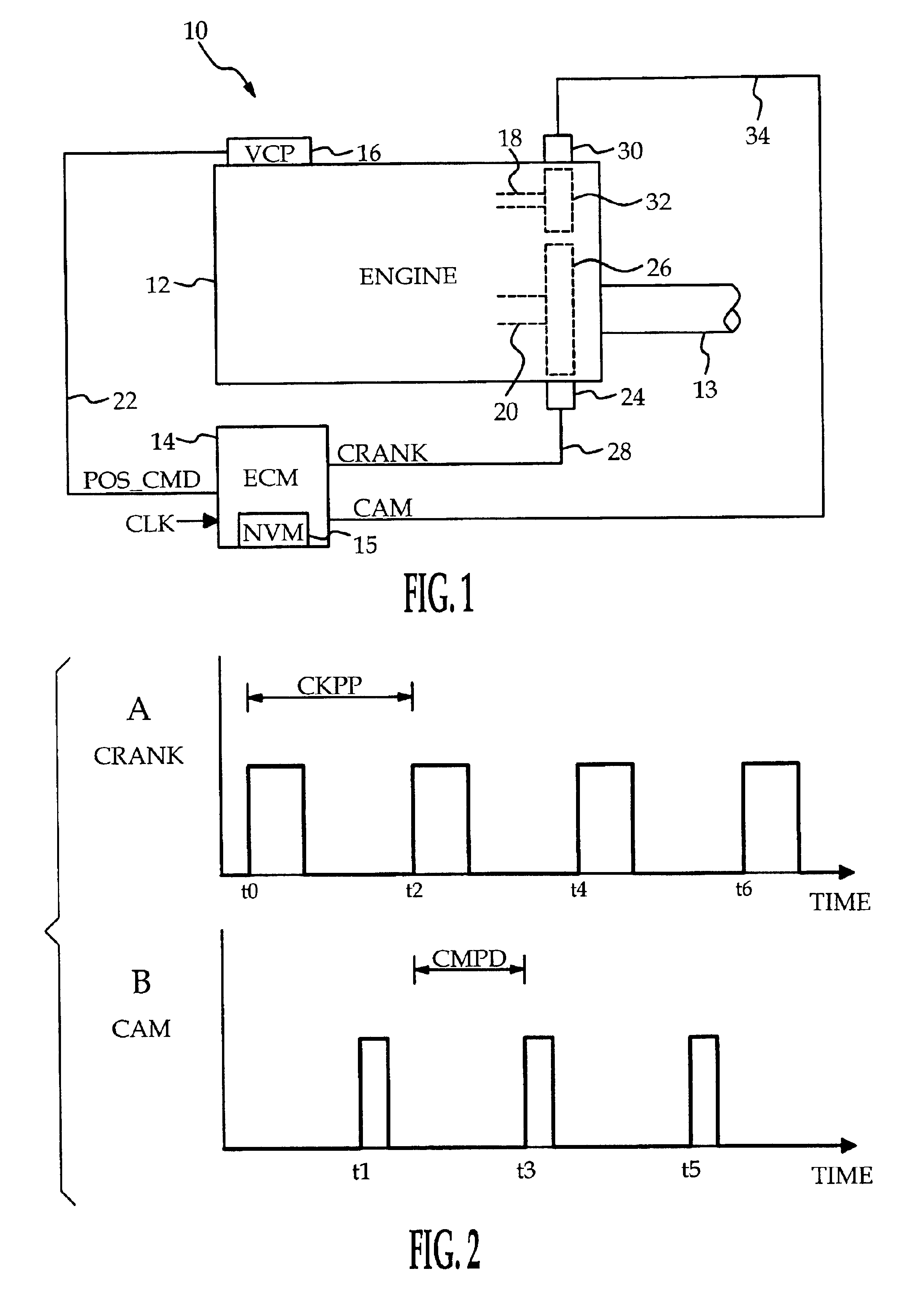

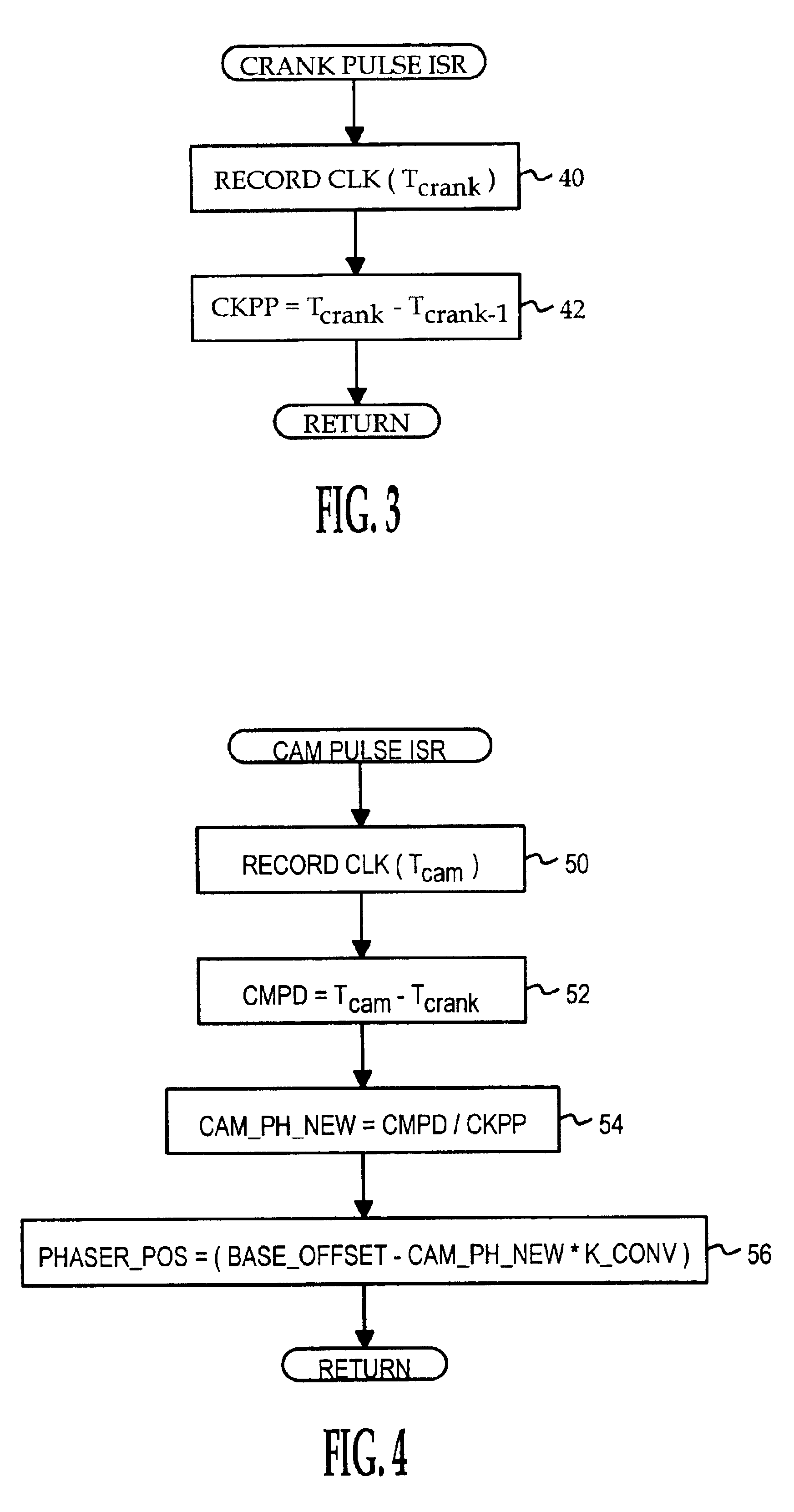

Method of determining the position of a cam phaser

Owner:DELPHI TECH IP LTD

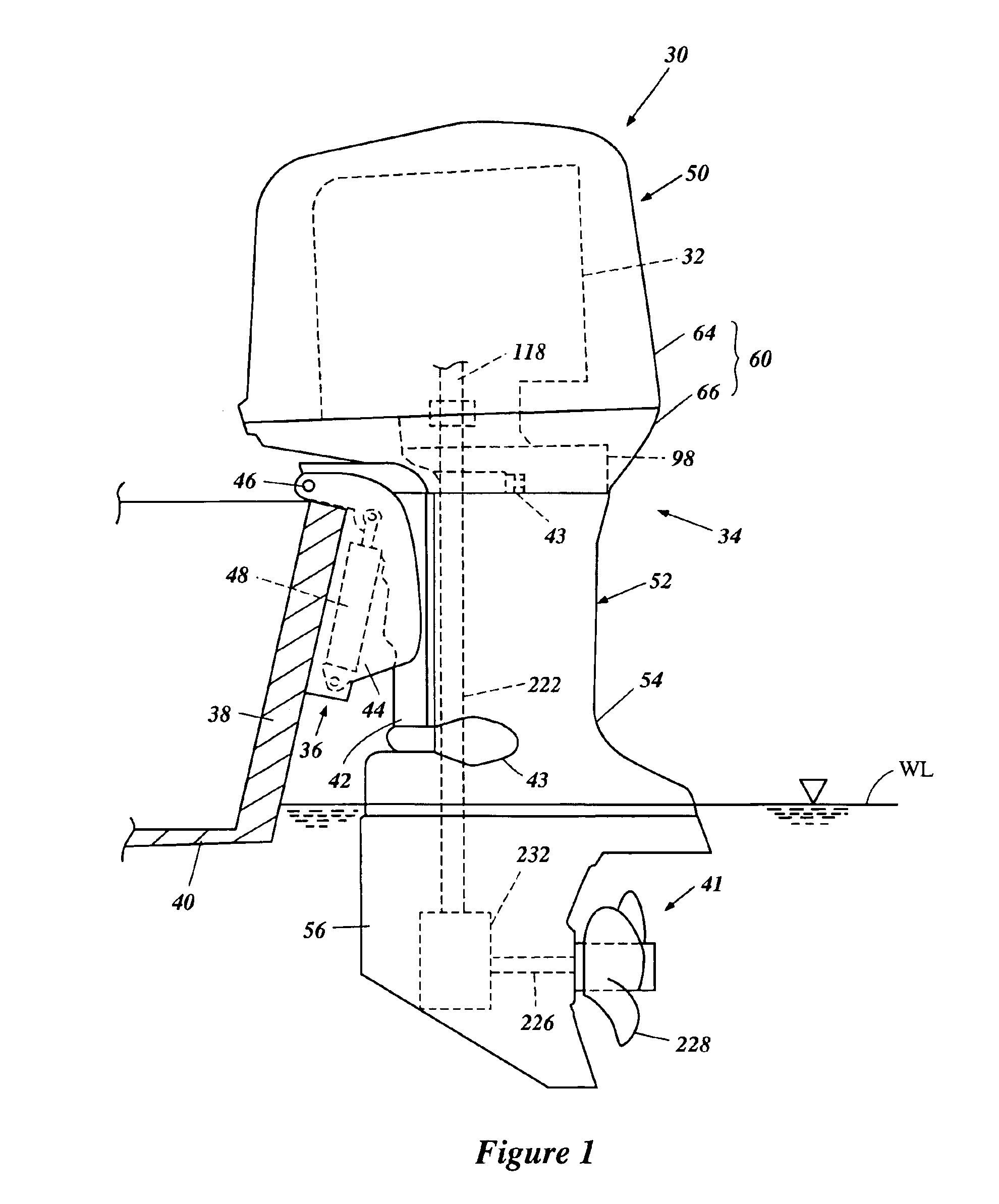

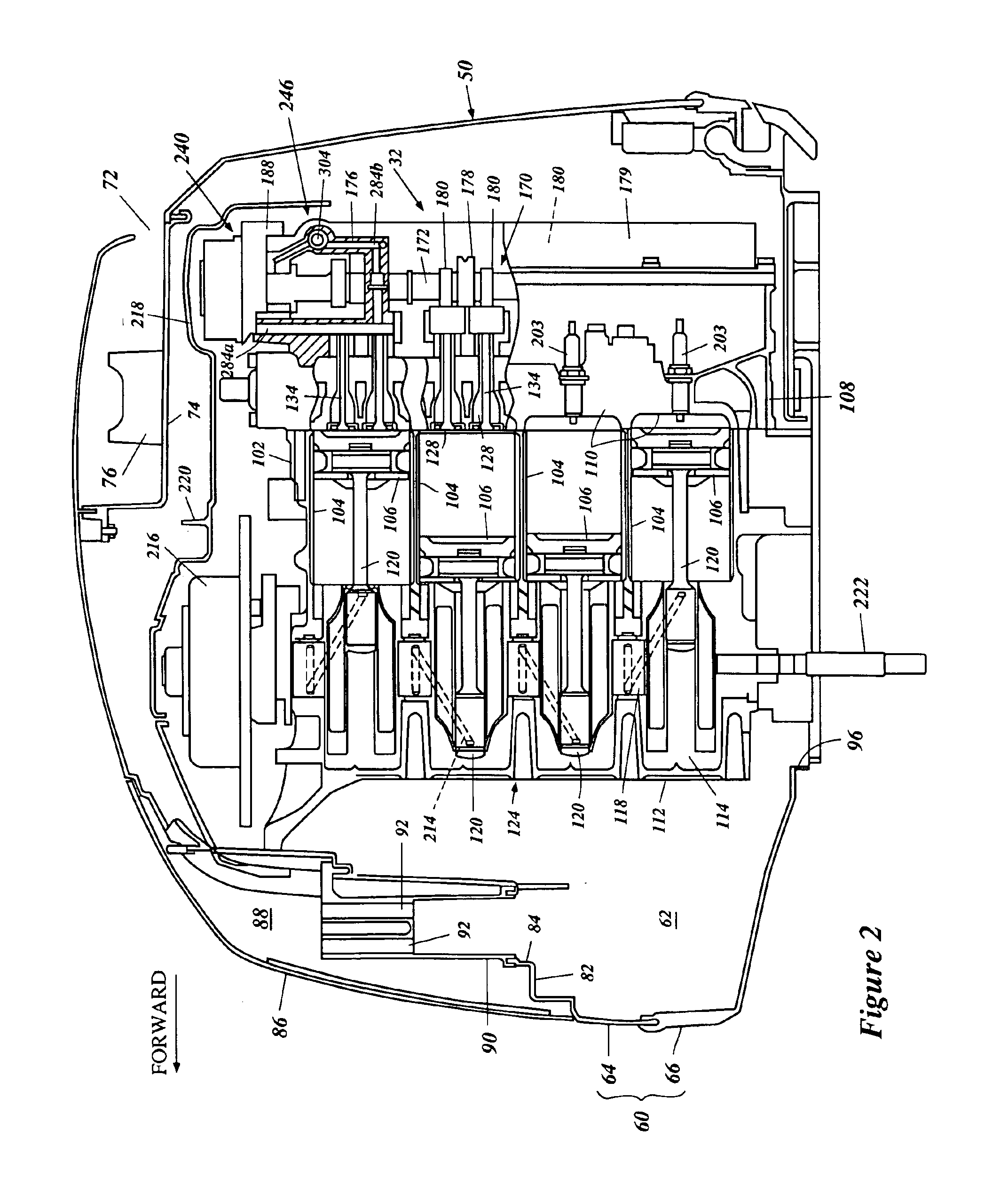

Valve timing control for marine engine

InactiveUS6957635B2Accurately follow commandLow viscosityCamsValve arrangementsExhaust valveCombustion chamber

An engine for a marine drive has a combustion chamber. An engine body of the engine defines intake and exhaust ports communicating with the combustion chamber. An air induction system communicates with the combustion chamber through intake ports. An exhaust system communicates with the combustion chamber through the exhaust ports. Intake valves move between an opening position and a closing position of the intake ports. Exhaust valves move between an opening position and a closing position of the exhaust ports. Camshafts actuate the intake and the exhaust valves. A hydraulic VVT mechanism changes an actuating timing of the camshaft at which the camshaft actuates the intake valves or the exhaust valves. An ECU controls the VVT mechanism based upon a control characteristic. A temperature sensor, such as an oil temperature sensor, a water temperature sensor and an engine body temperature sensor, senses a temperature of oil of the VVT or a temperature relating to the temperature of the oil and sends a temperature signal to the ECU. The ECU adjusts the control characteristic when the temperature is lower than a preset temperature.

Owner:YAMAHA MARINE KK

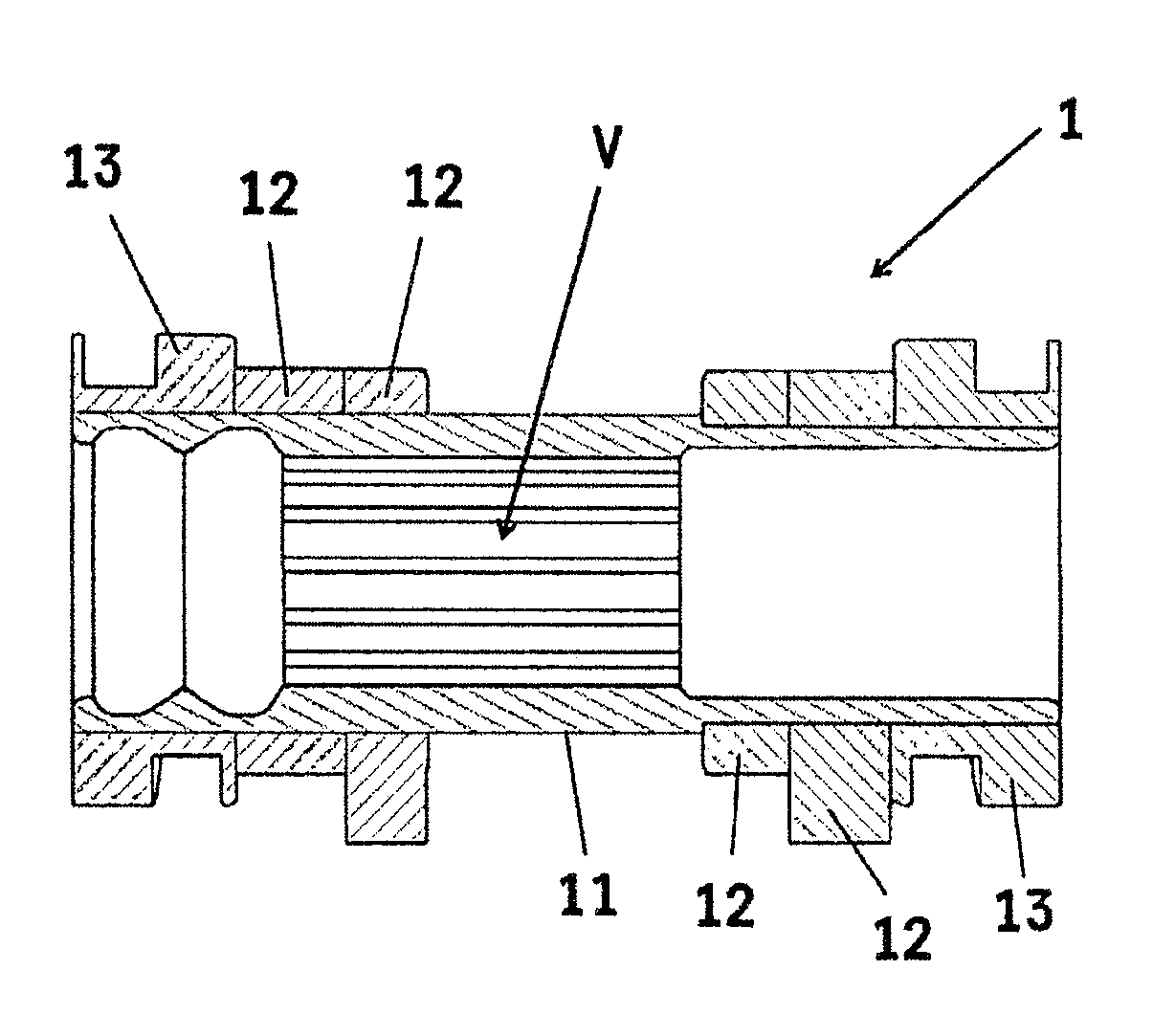

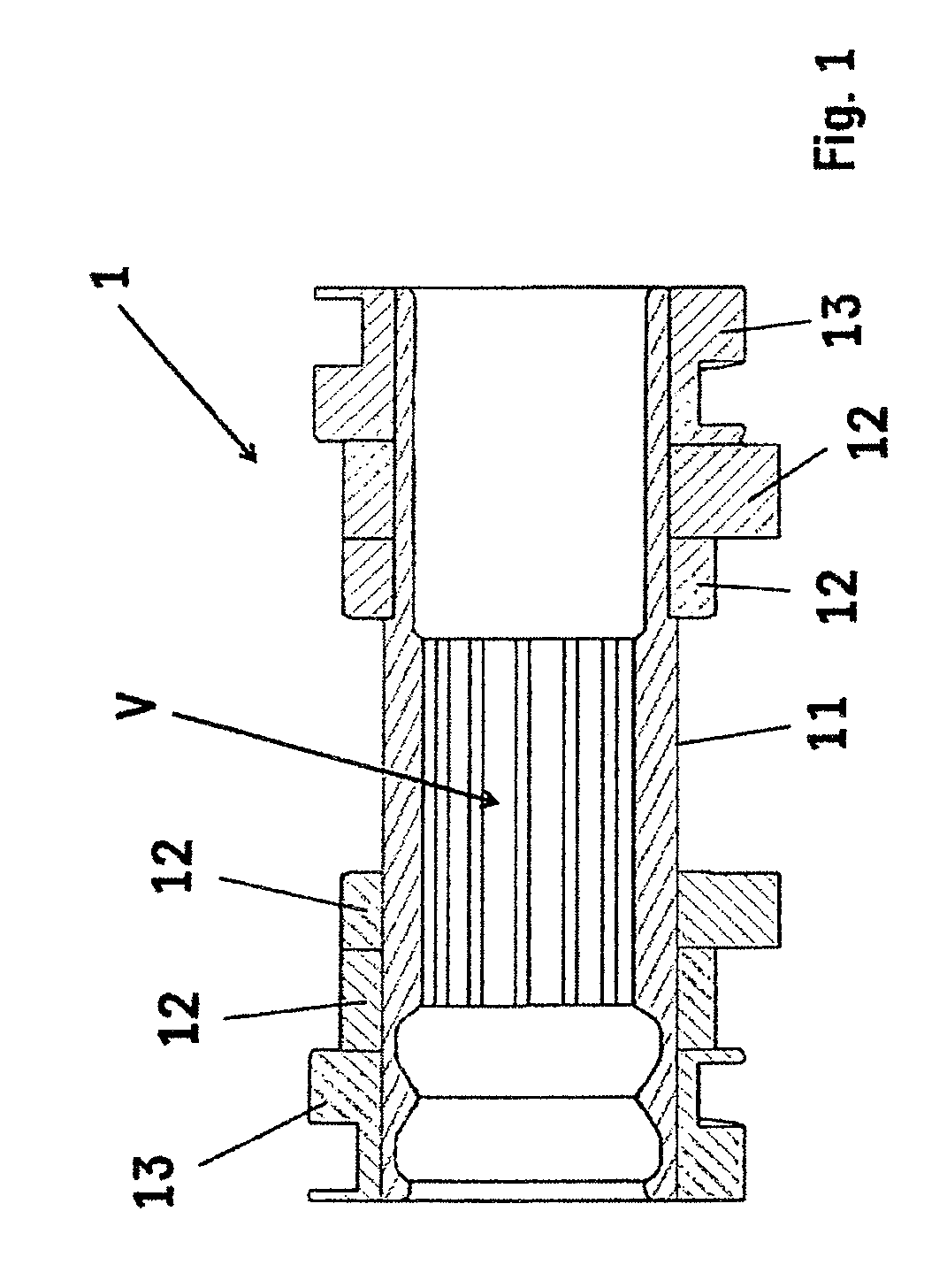

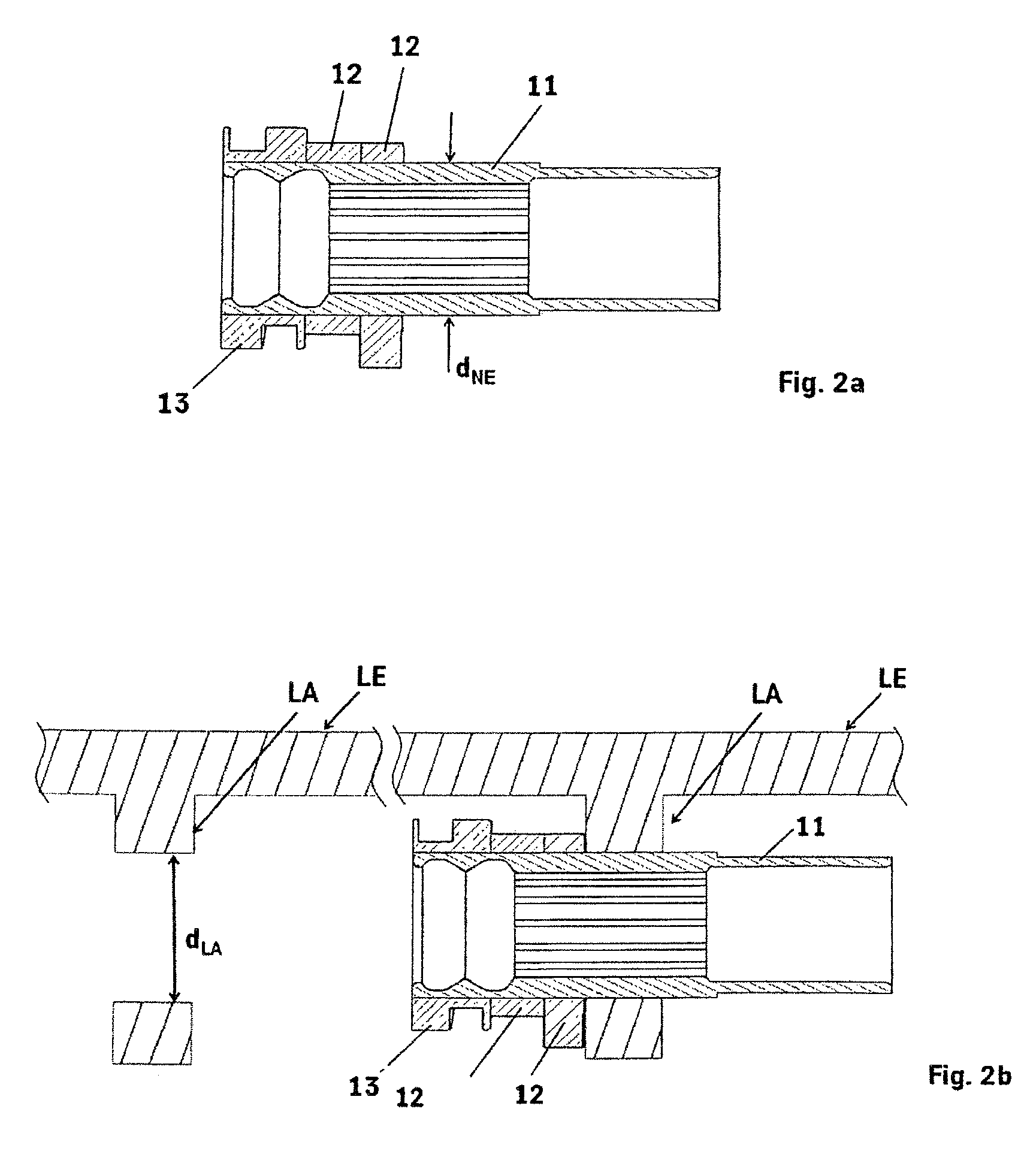

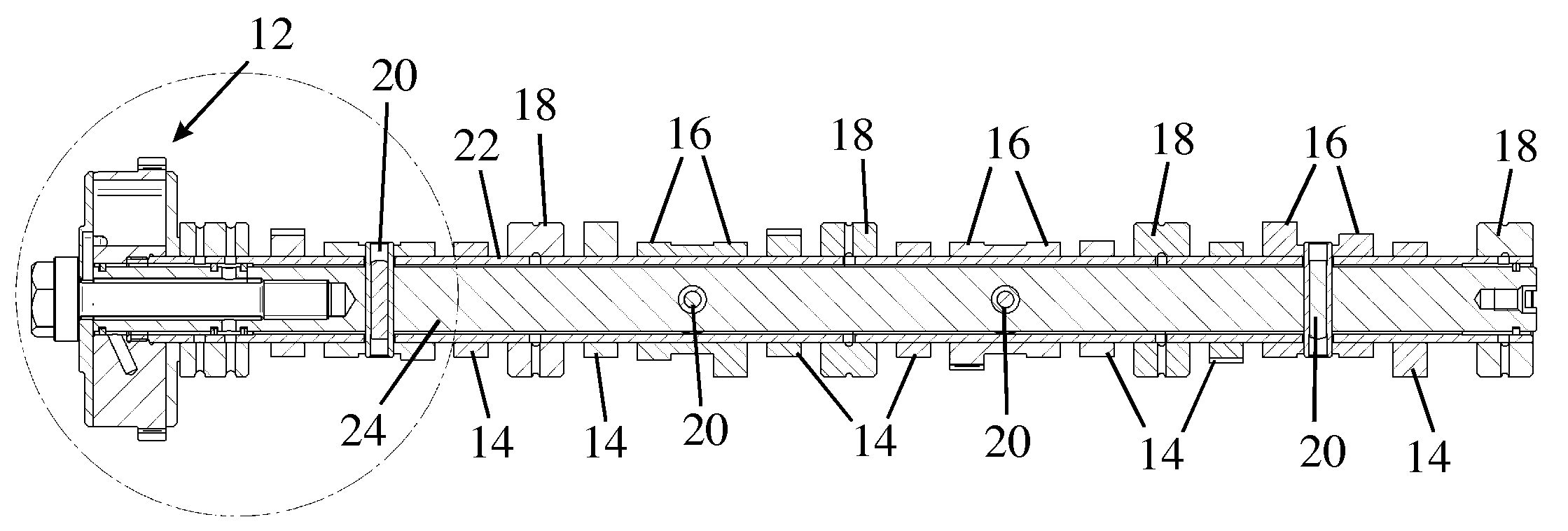

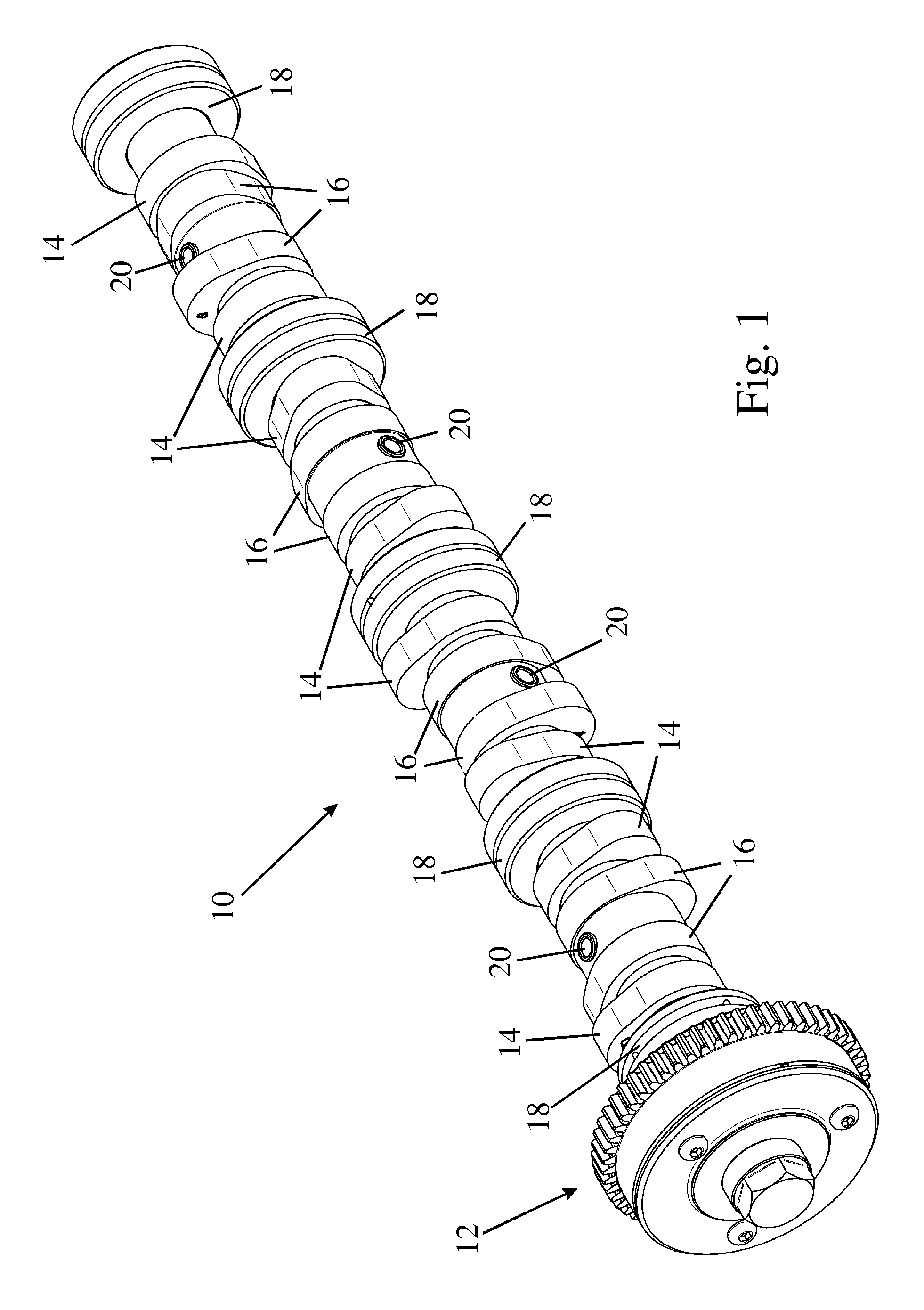

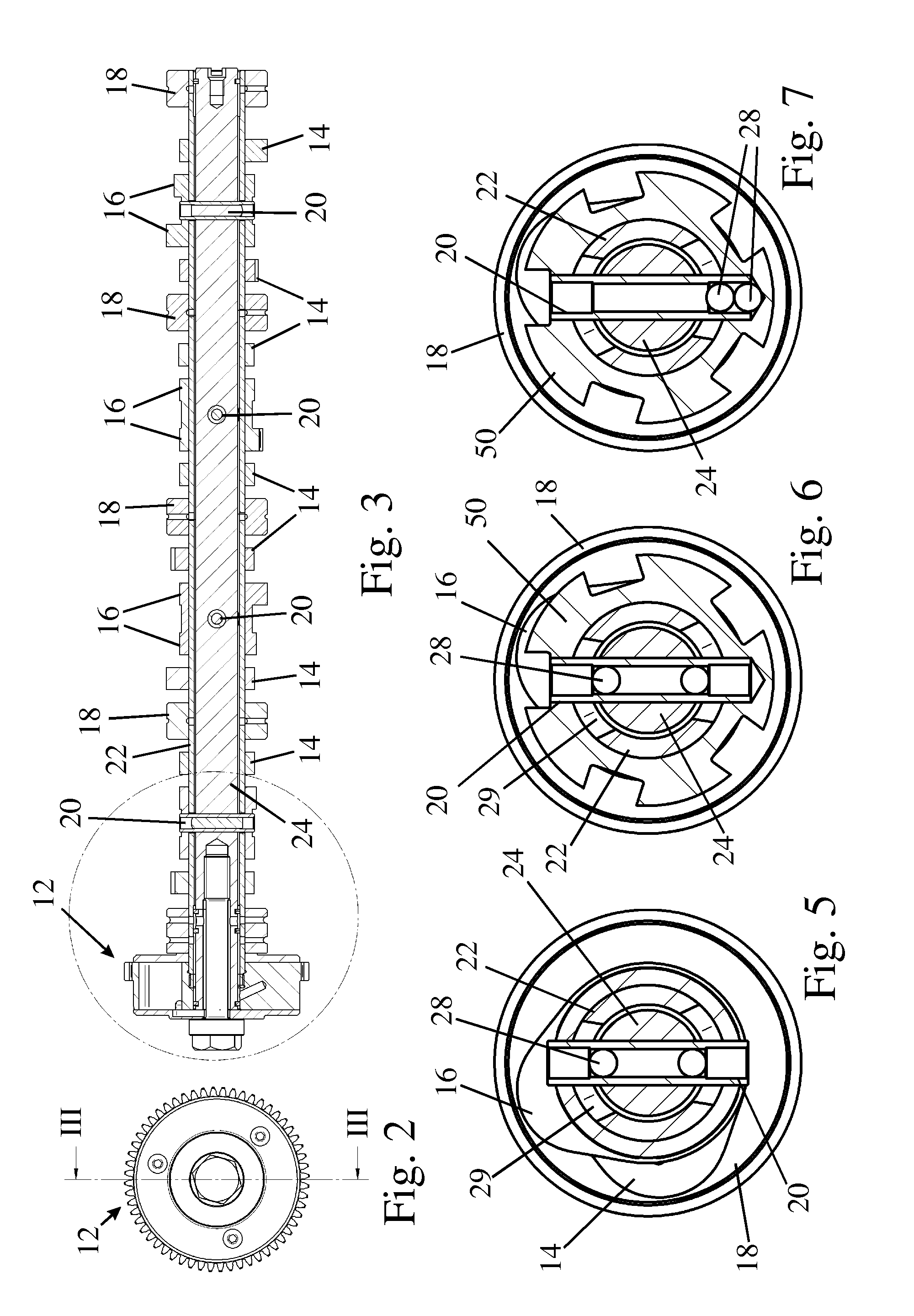

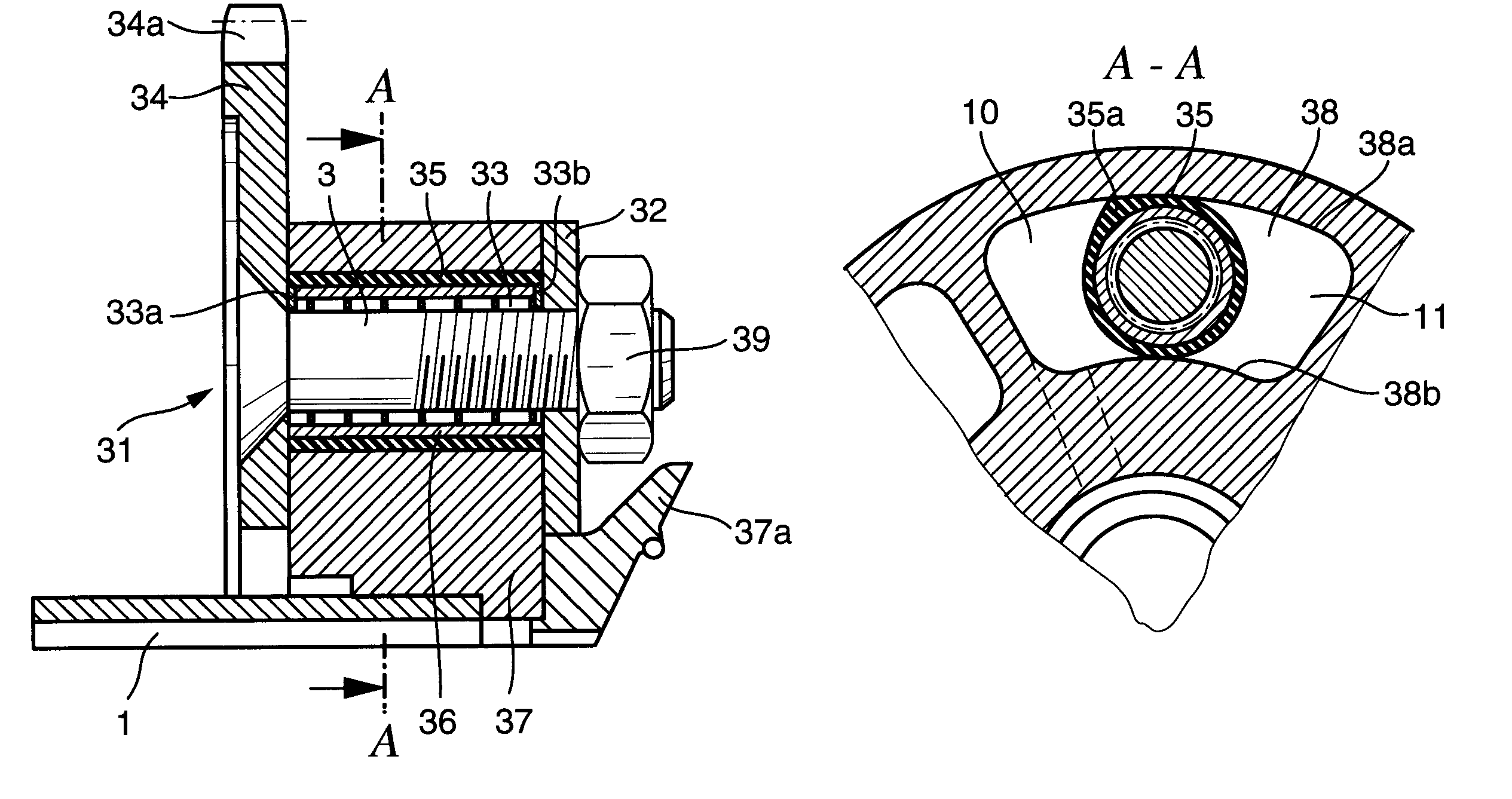

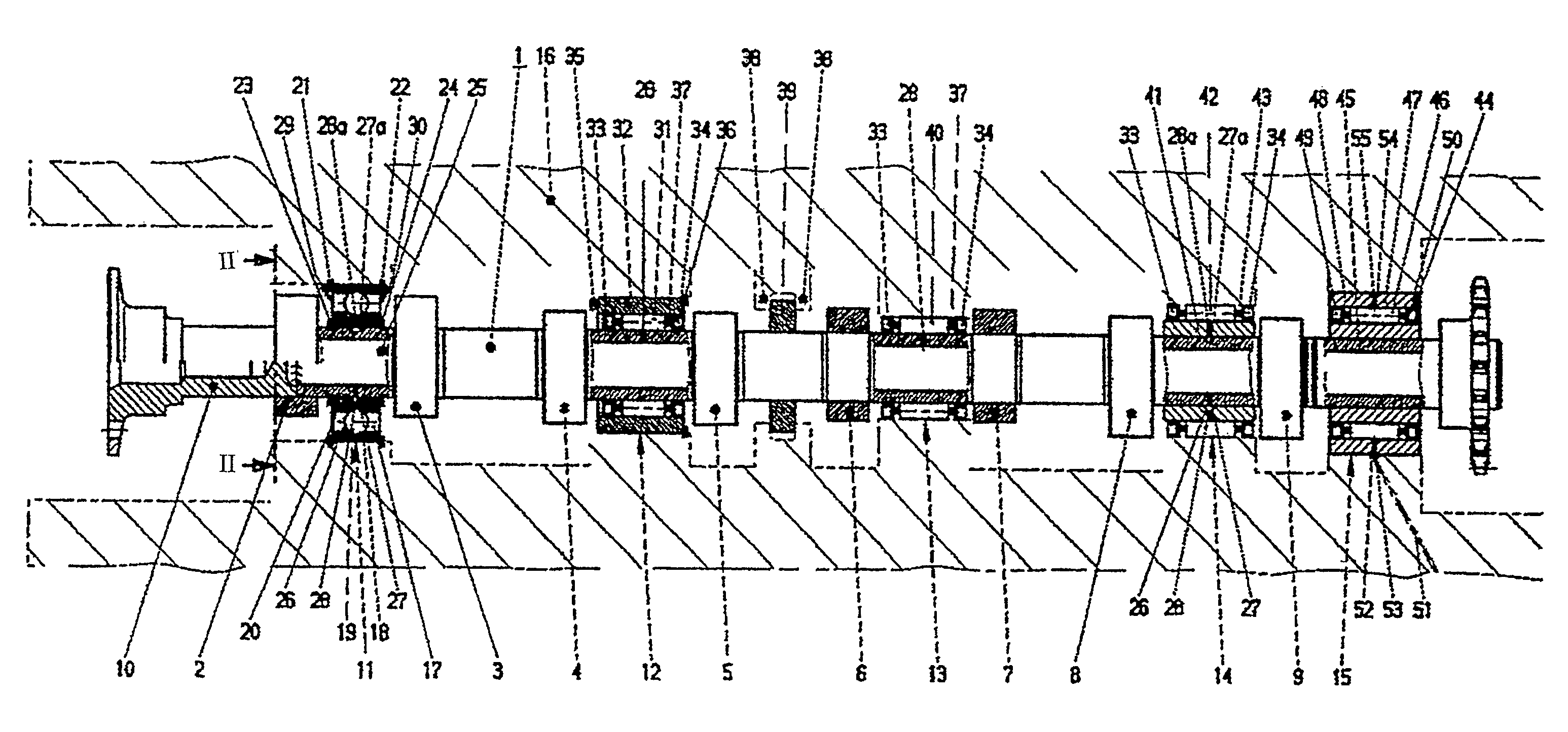

Shaft with functional bodies such as camshafts for internal combustion engines, method of producing them and engines equipped therewith

ActiveUS7992533B2Lower assembly costsLow costCamsRoller bearingsCombustionExternal combustion engine

A shaft comprising functional elements, such as an assembled camshaft for an internal combustion engine, a method for producing such shafts, and internal combustion engines equipped with such shafts. The functional elements each have a bore and are produced separately from the shaft main body, and the bore is subsequently press fit onto the shaft body to attach the functional element in an axially and rotationally fixed manner. The shaft is also provided with at least one roller bearing that includes at least one undivided roller bearing element which is mounted on the shaft body between two functional elements, for example, by press fitting.

Owner:NEUMAYER TEKFOR ENG GMBH

Valve timing control system

ActiveUS20080066572A1Improve accuracyReduce component countCamsYielding couplingSpool valveControl system

A phase control valve, which supplies a drive hydraulic pressure to an advance chamber or a retard chamber, is integrated with a drain switch valve, which controls opening and closing of an advance drain control valve and opening and closing of a retard drain control valve, to form a solenoid spool valve. The advance drain control valve is provided in an advance check valve bypass passage, which bypasses an advance check valve, and is driven by a pilot hydraulic pressure to open and close the advance check valve bypass passage. The retard drain control valve is provided in a retard check valve bypass passage, which bypasses a retard check valve, and is driven by a pilot hydraulic pressure to open and close the retard check valve bypass passage.

Owner:DENSO CORP +1

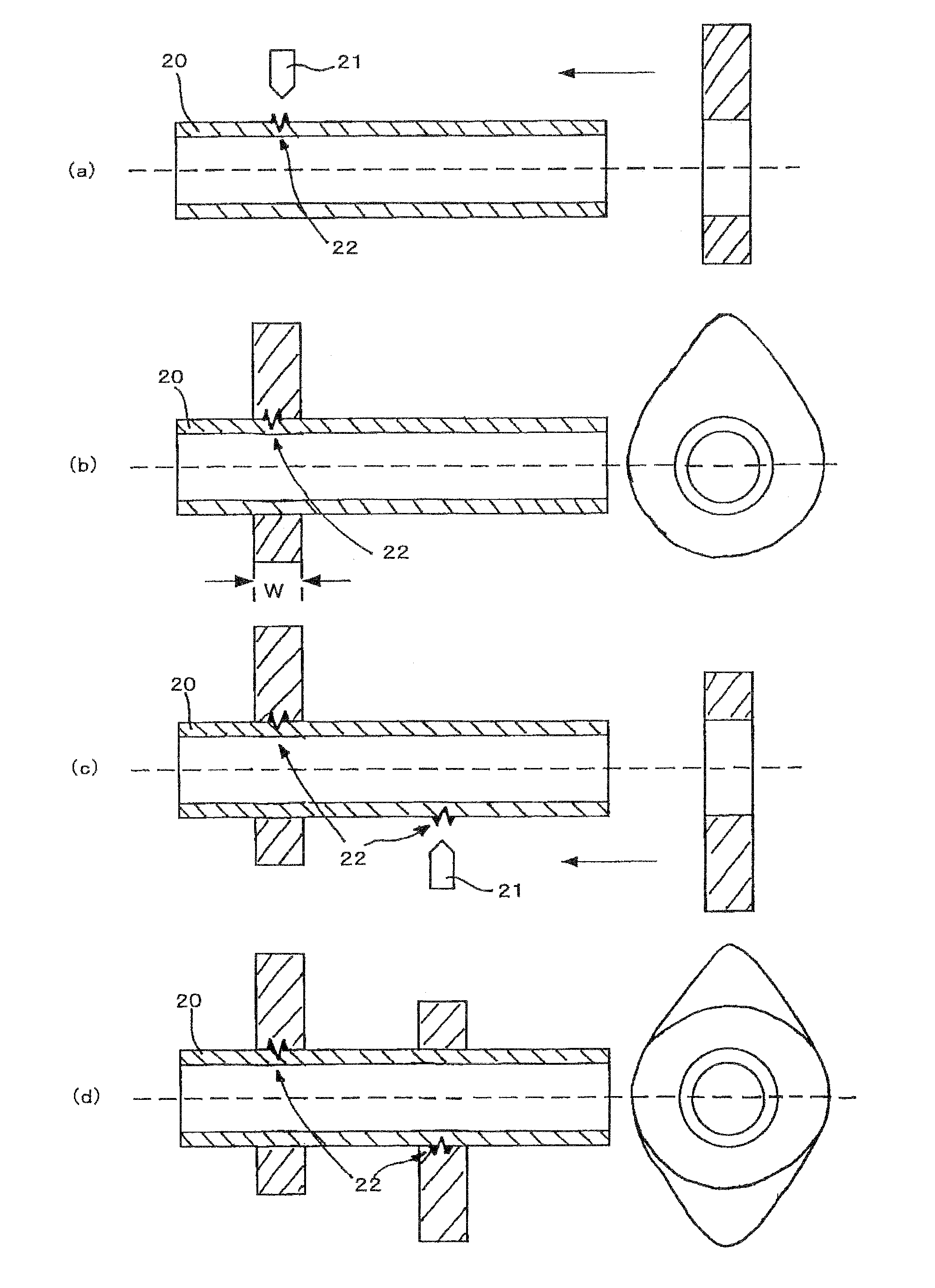

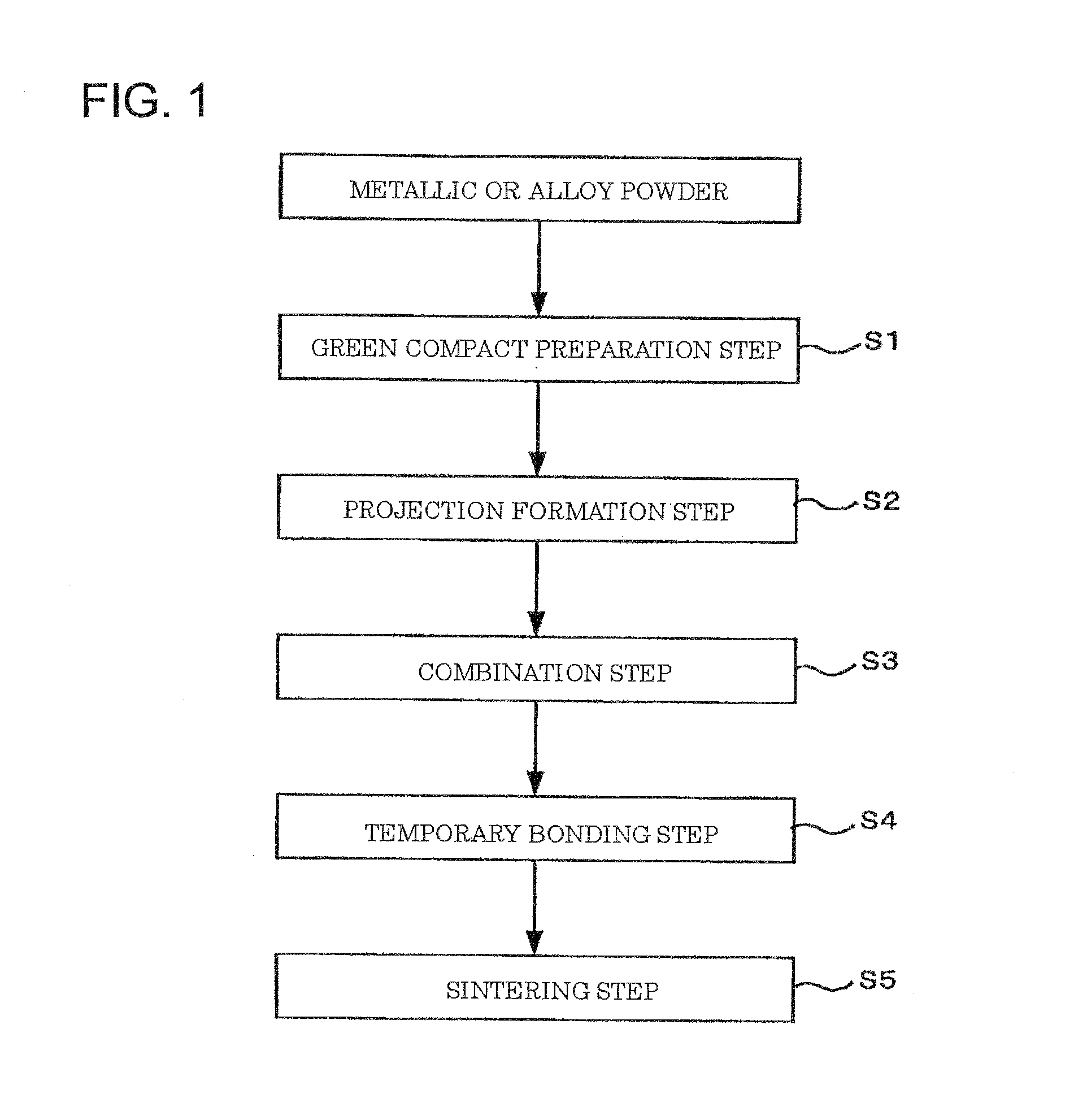

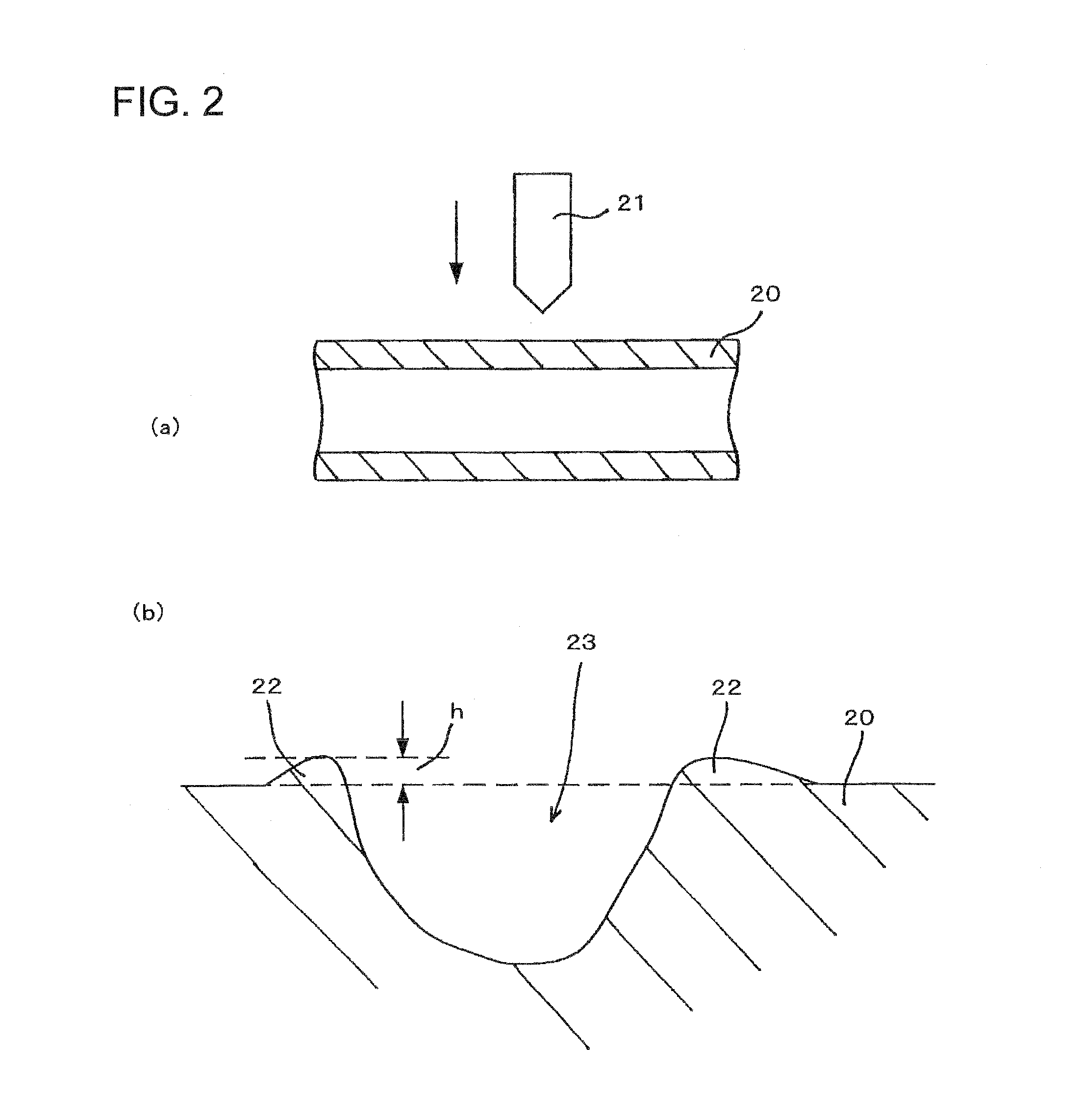

Method for manufacturing a shaft member having a sintered part bonded thereto and a camshaft for an internal combustion engine

InactiveUS20100224146A1Improve processing yieldReduce intensityCamsValve drivesCompression moldingAlloy

A method for manufacturing a shaft member having a sintered part bonded thereto is simple and provides an increased process yield and a high accuracy in position and angle of the sintered part. A green compact is prepared by subjecting a metal or alloy powder to a compression molding. A projection formed on an outer peripheral surface of the shaft member is embedded into the green compact, while chipping partially the green compact with the projection, to combine the green compact with the shaft member. Then, a sintering is carried out.

Owner:NIPPON PISTONRING CO LTD

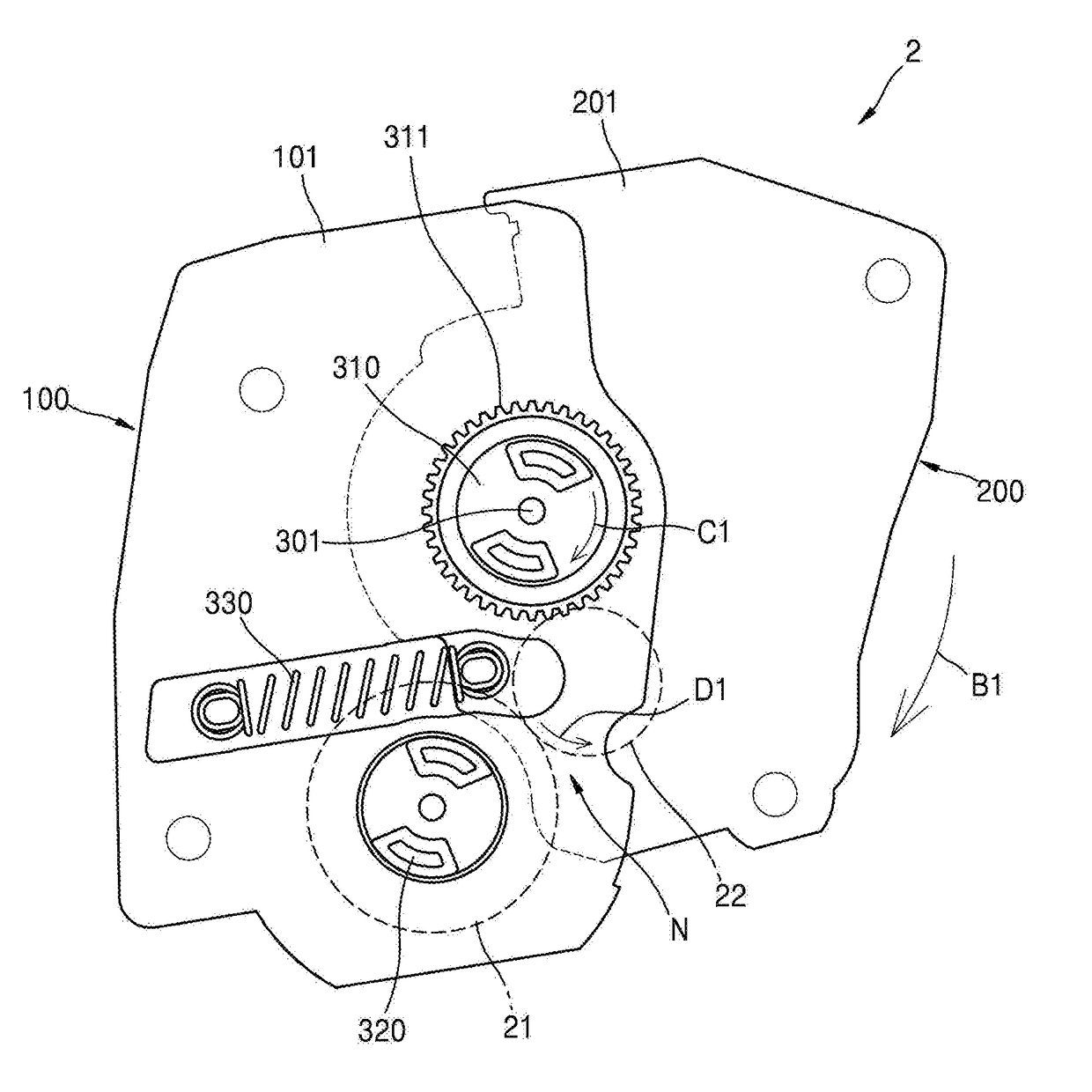

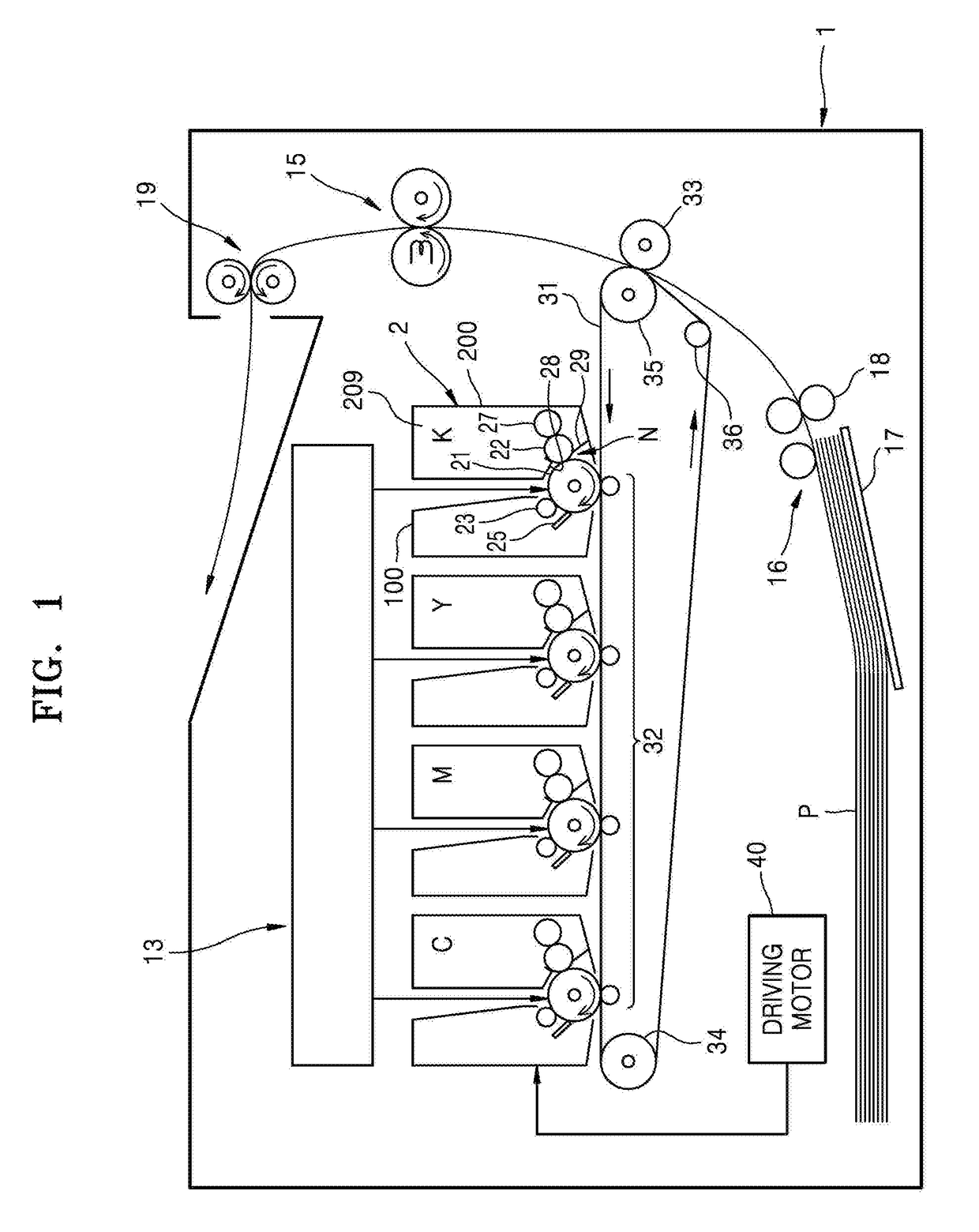

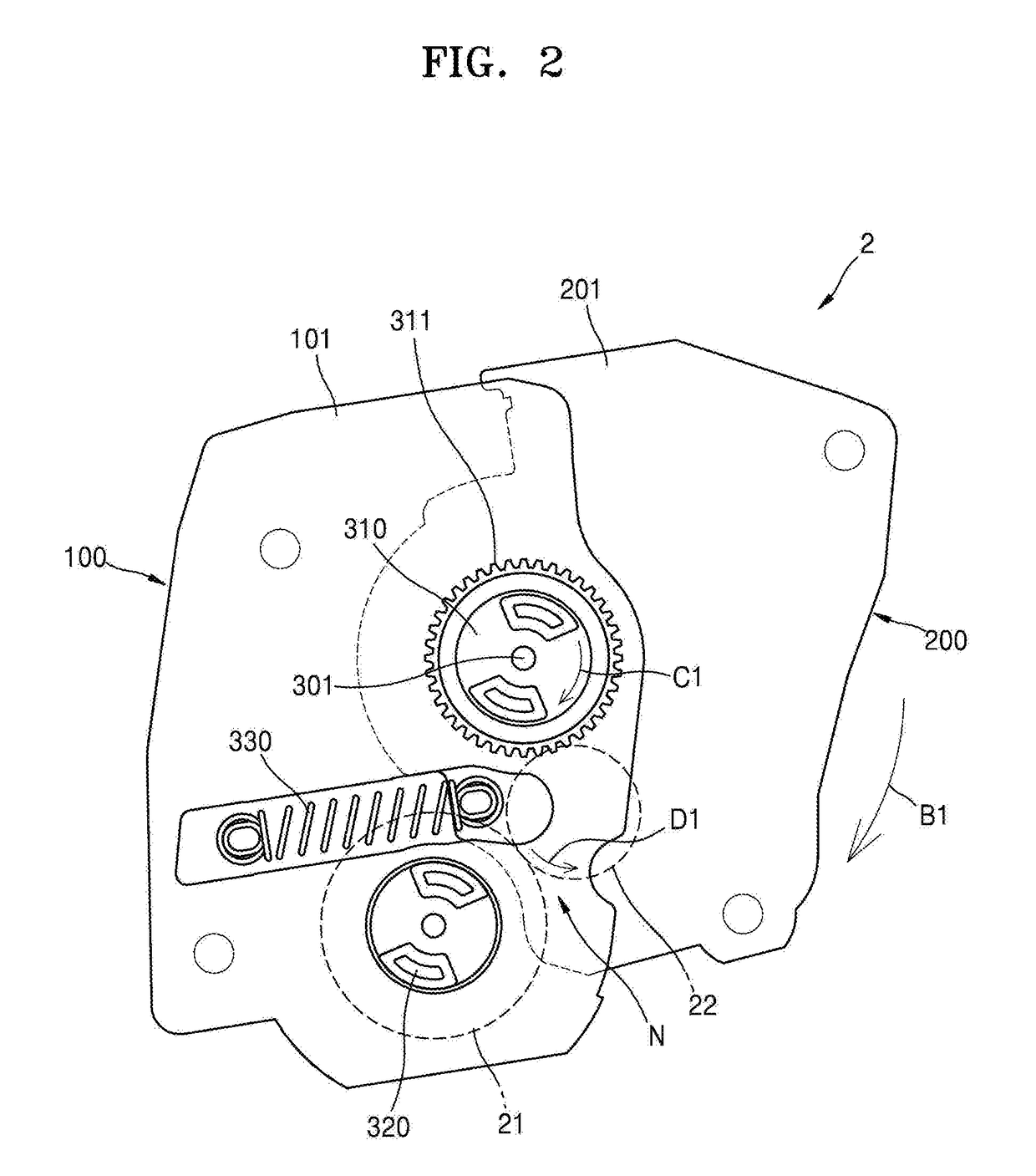

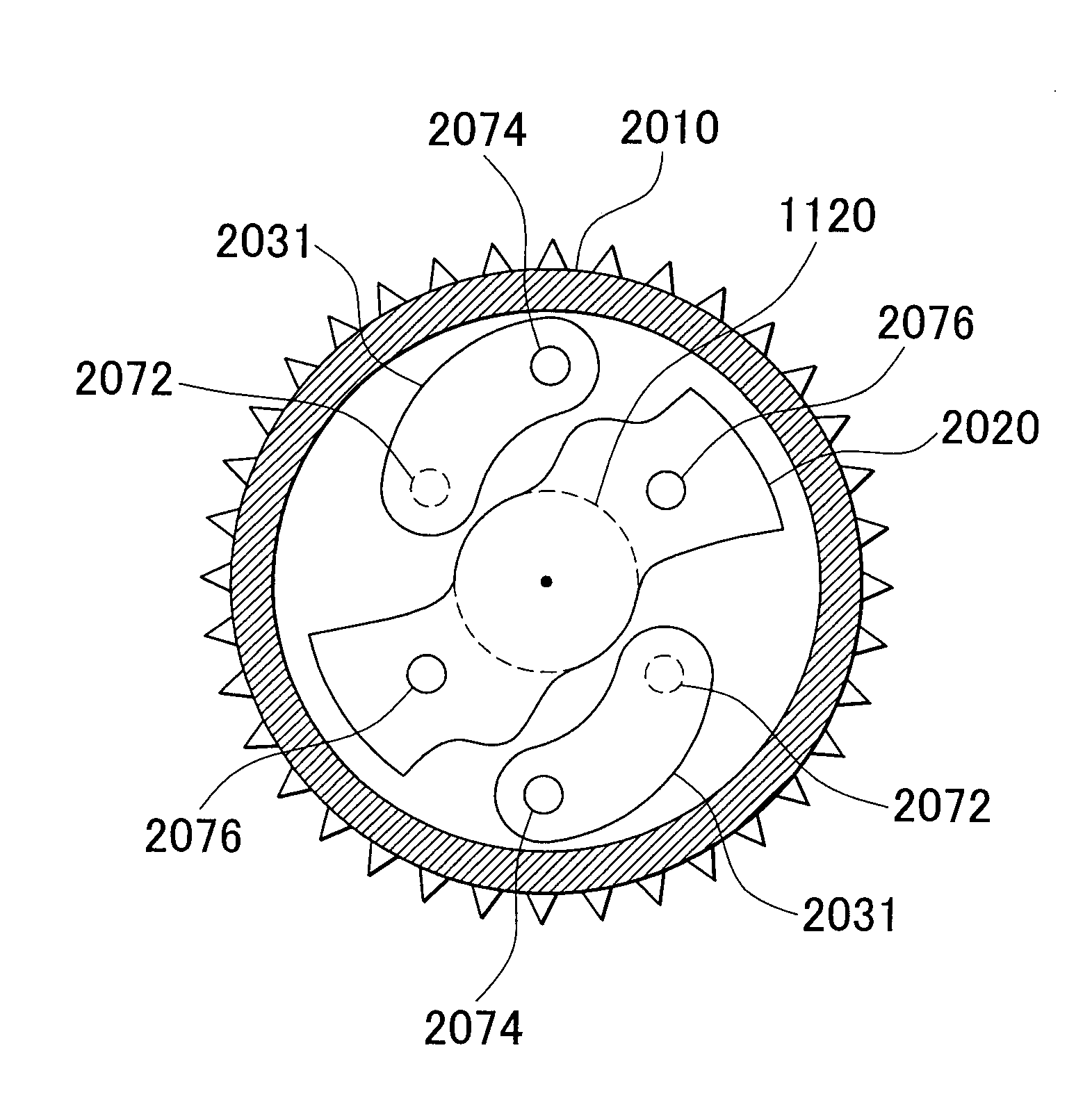

Development cartridge and electrophotographic image forming apparatus using the same

Provided is a development cartridge mounted on a main body of an image forming apparatus. The development cartridge includes a photoconductive unit, a developing unit coupled to the photoconductive unit so as to rotate to a development position and a release position, and an elastic member that provides an elastic force to maintain the developing unit at the development position. A switching member is mounted on a rotation shaft of the developing roller to be rotatable about a rotation shaft of a developing roller. The switching member is switched to a first state where the switching member contacts an interfering portion of the photoconductive unit and rotates the developing unit to the release position and to a second state where the switching member is separated from the interfering portion and allows the developing unit to rotate to the development position due to the elastic force of the elastic member.

Owner:HEWLETT PACKARD DEV CO LP

Variable valve timing system and method for controlling the same

ActiveUS20080053269A1Without reducing combustion stabilityReduced stabilityCamsValve drivesCombustionVariable valve timing

An intake valve phase setting unit sets the target valve phase used in the variable valve timing control based on the engine operating state, and a control target value setting unit sets the control target value based on the target valve phase. An actuator operation amount setting unit prepares the rotational speed command value for an electric motor that serves as an actuator of a variable valve timing system based on the deviation of the current value from the control target value. A phase change rate control unit sets the rate of change in the valve phase to a lower value when the variable valve timing control moves the valve phase away from the reference phase (the phase when the engine is idling) at which combustion takes place stably in engine than when the variable valve timing control causes the valve phase to the reference phase.

Owner:TOYOTA JIDOSHA KK +1

Method for Assembling an Engine Module

A method for assembling a module for a motor vehicle engine in which the components, such as e.g. cams, sensor wheels etc., which are to be attached to the support shaft, are positioned, prior to insertion of the support shaft, merely at those axial positions that do not correspond to the axial positions occupied by these components on the fully constructed camshaft.

Owner:THYSSENKRUPP PRESTA TECCENTER AG

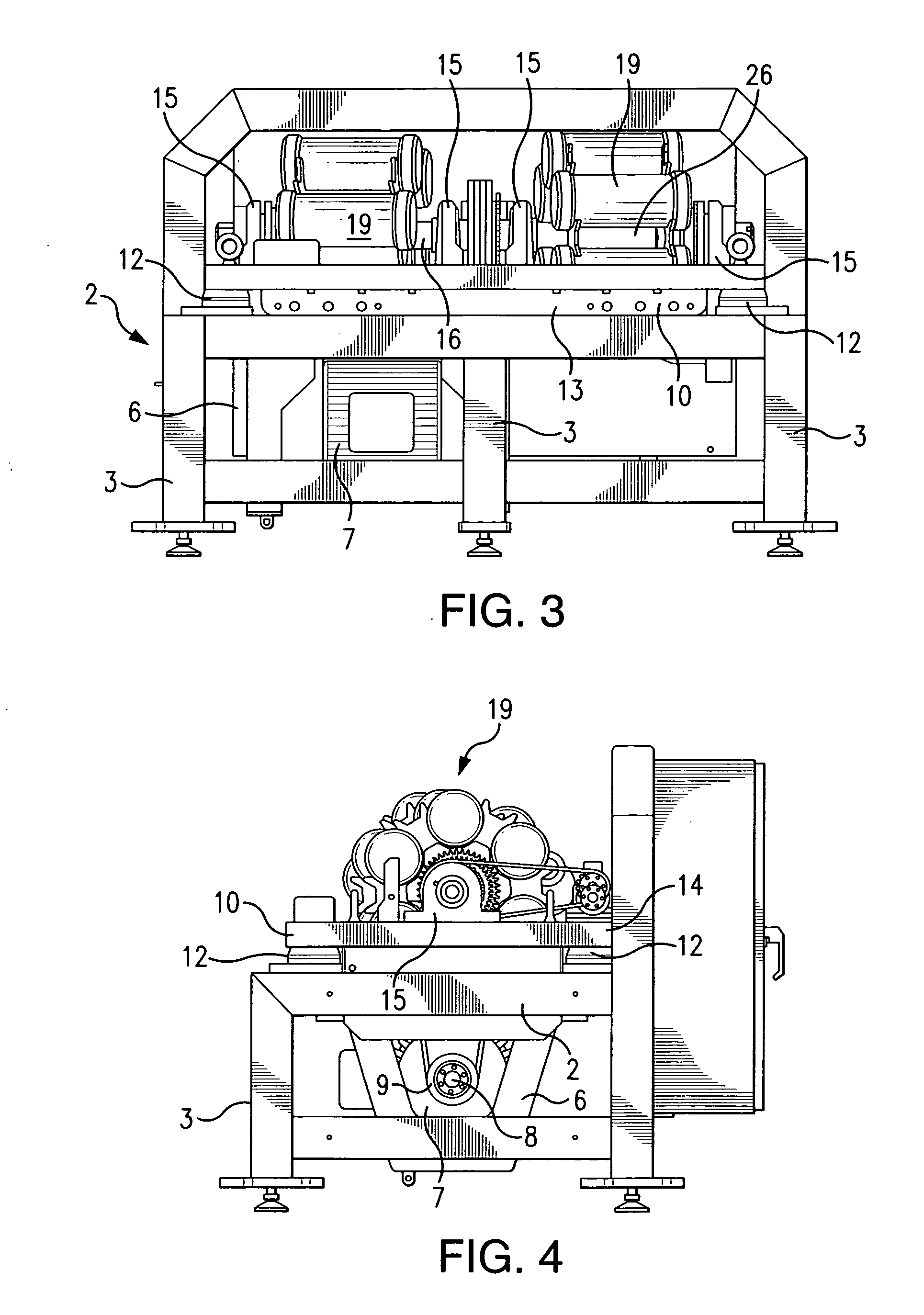

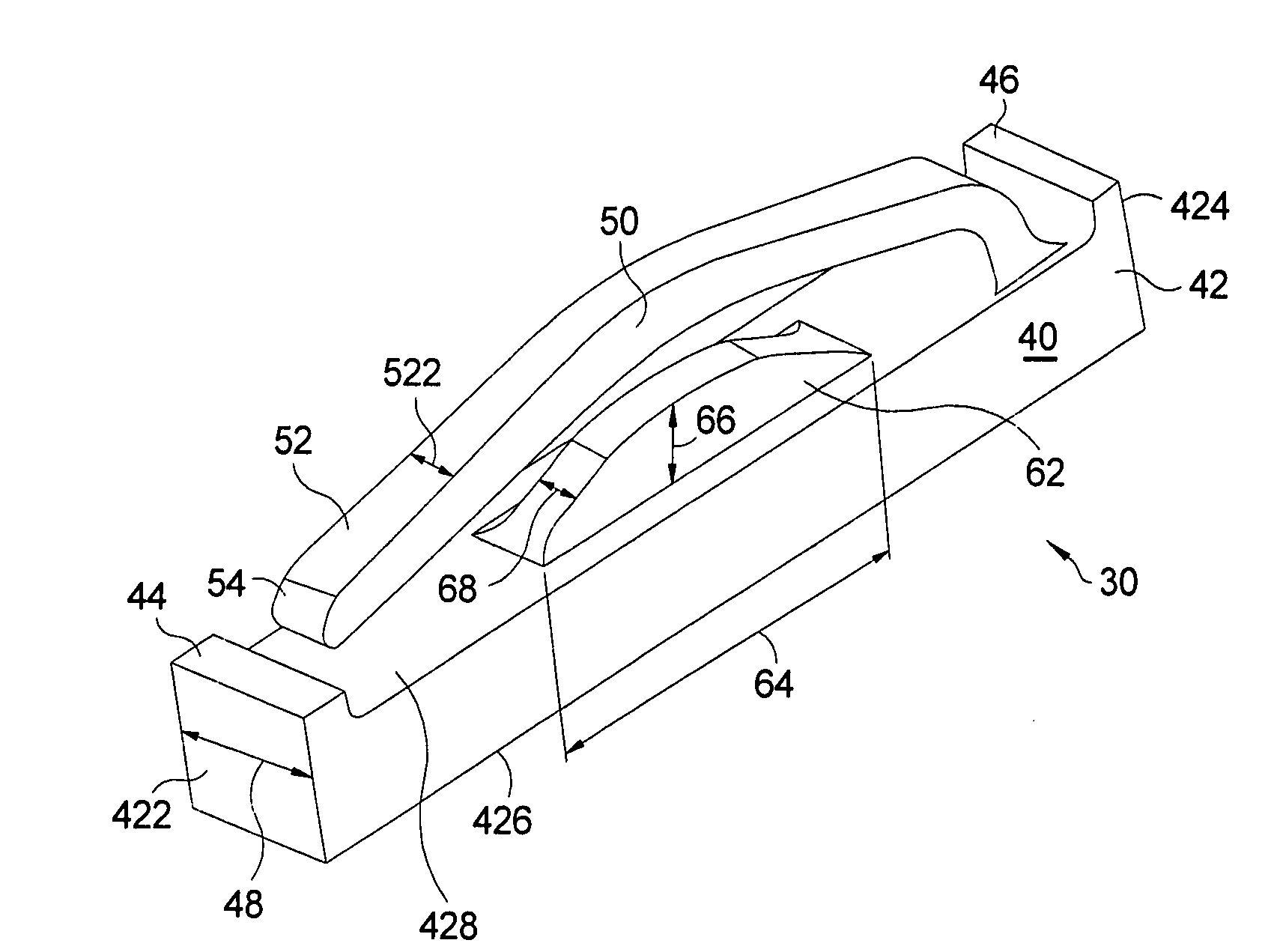

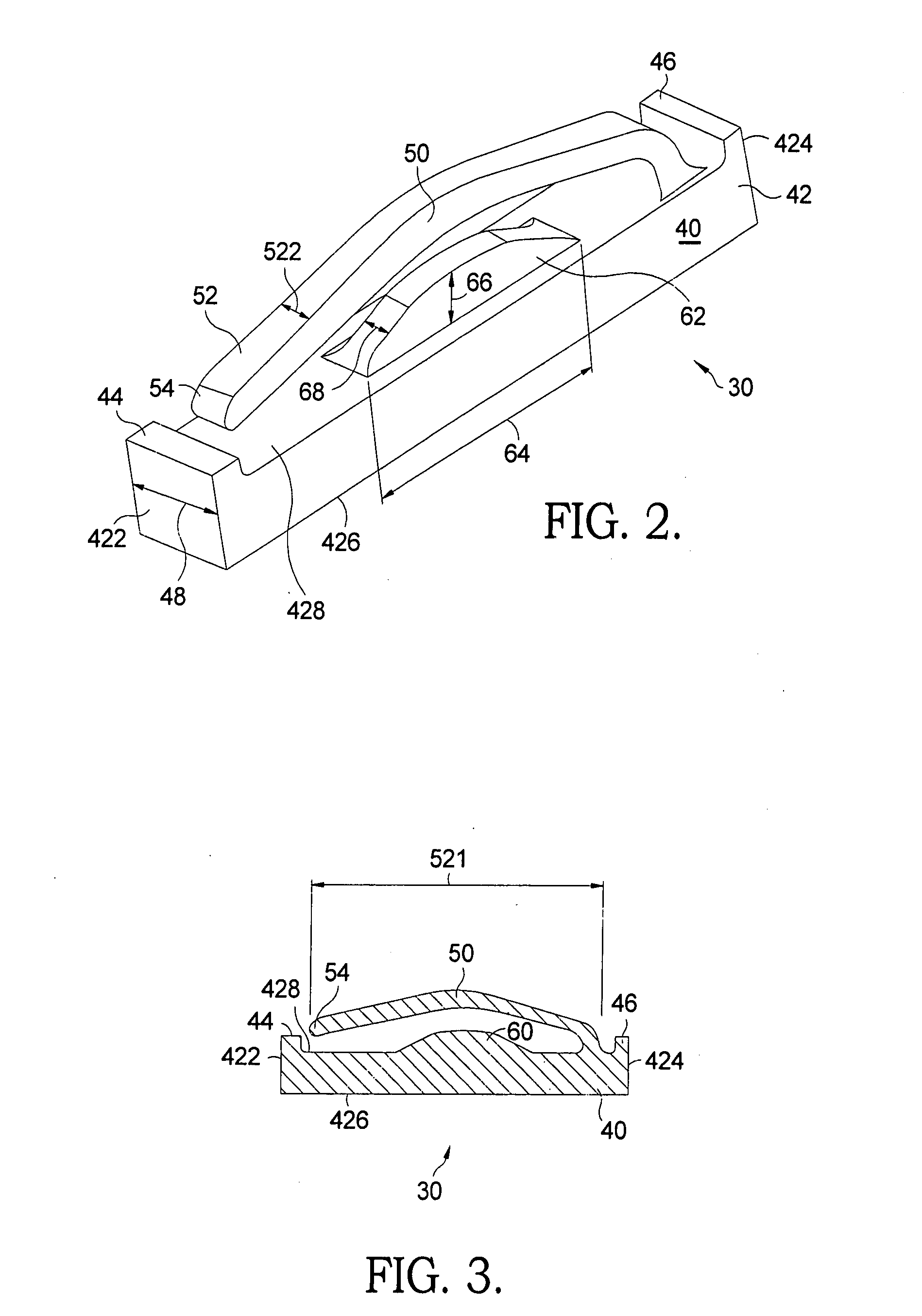

Camshaft phaser wiper seal with integral spring

A wiper seal for preventing leakage of oil between advance and retard chambers formed between rotor vanes and stator lobes in a vane-type camshaft phaser is a monolithic structure made from a single material that includes a wiper element and a compressible spring element extending from the wiper element. The spring element is designed as a cantilevered arm and provides a sealing pressure to the wiper element. The wiper seal may further include a rib element as part of the monolithic structure that vertically extends the wiper element towards the spring element. The rib element assists in preventing over-compression of the cantilevered arm and in preventing tangling of a plurality of wiper seals during handling and shipping. The wiper seal is provided at the tip of each rotor vane and / or stator lobe of a vane-type camshaft phaser for varying the timing of combustion valves in an internal combustion engine.

Owner:DELPHI TECH INC

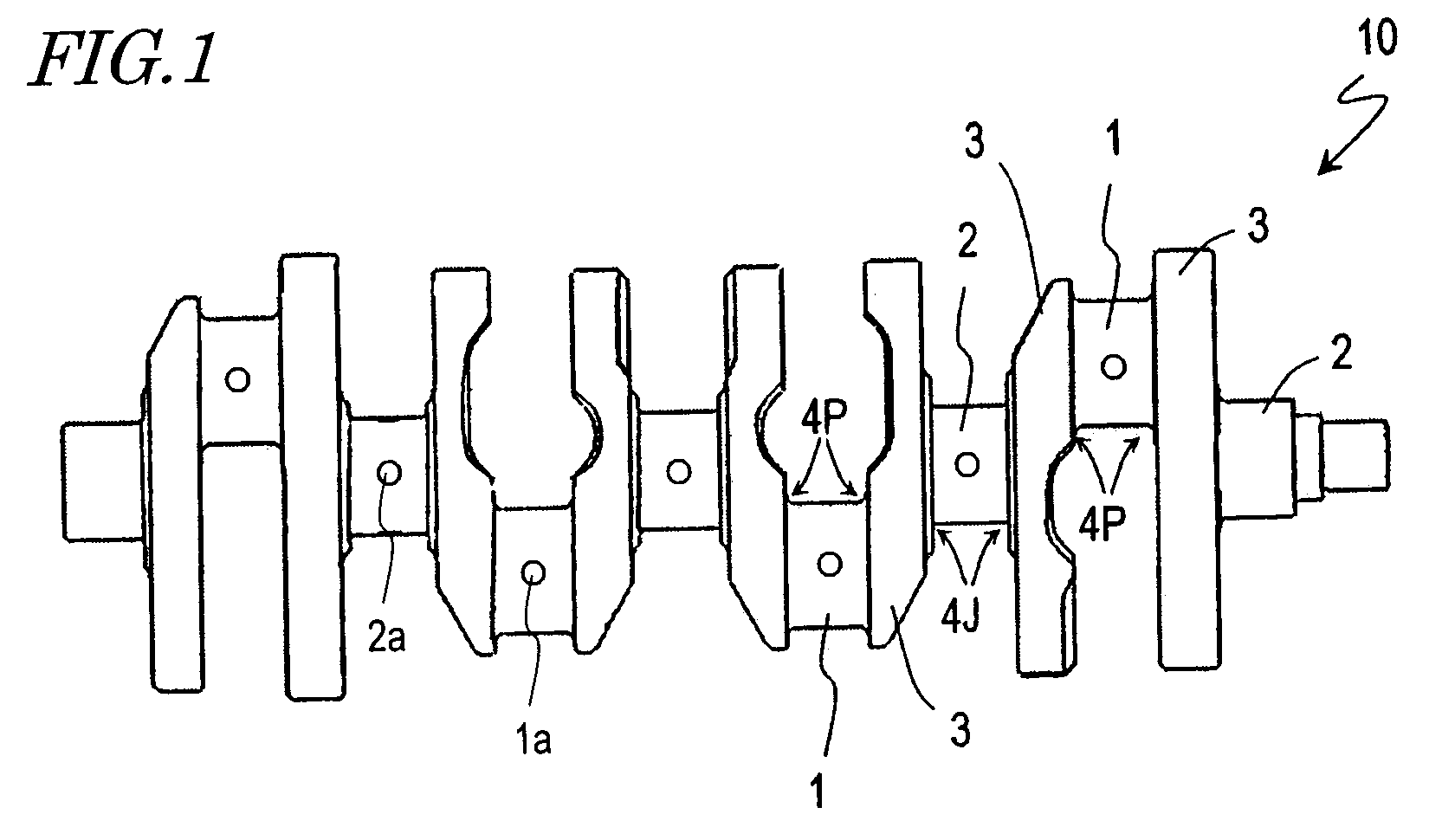

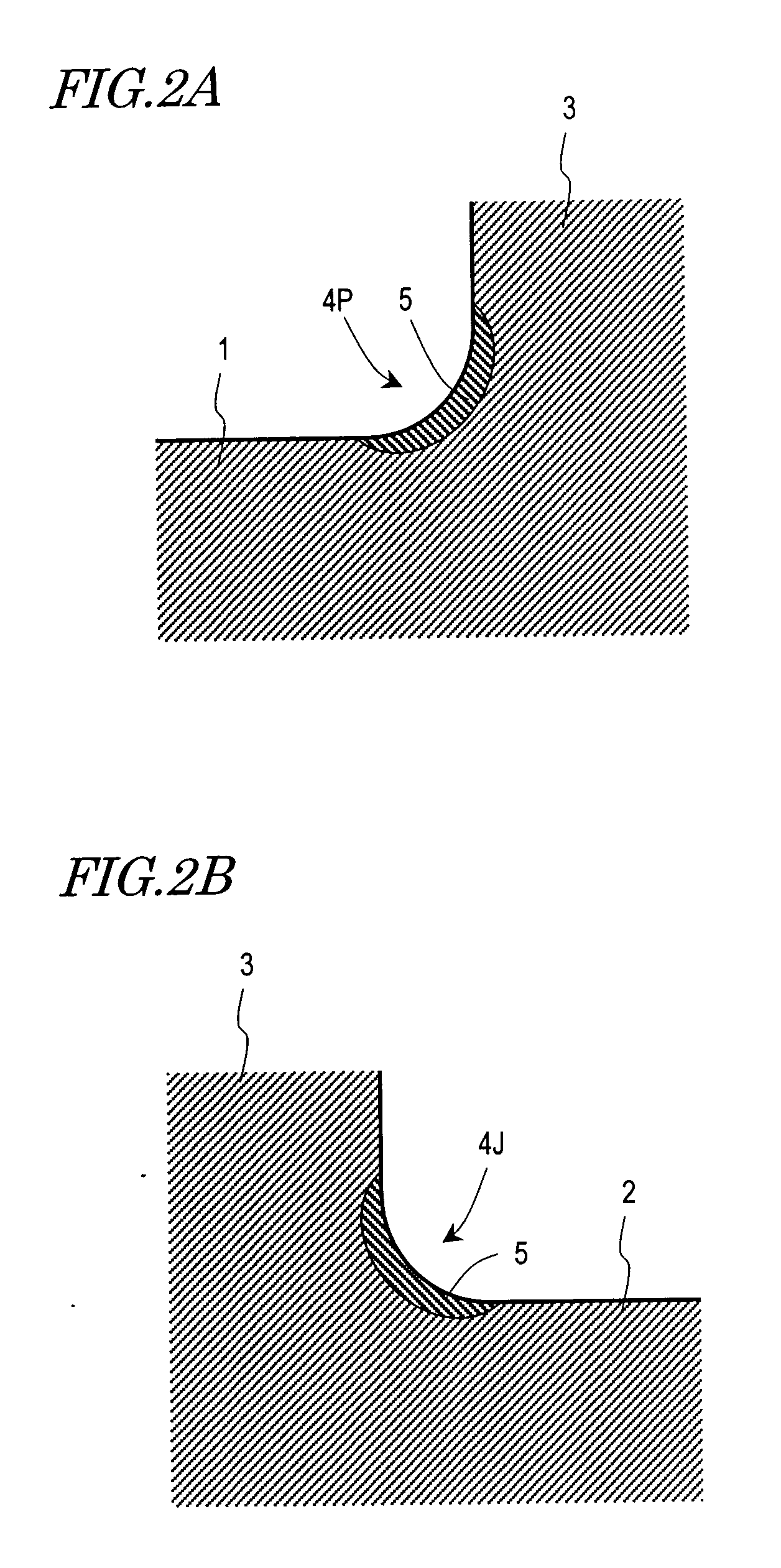

Crankshaft, internal combustion engine, transportation apparatus, and production method for crankshaft

InactiveUS20080229877A1High strengthSmall overall deformationCamsCrankshaftsEngineeringInternal combustion engine

A crankshaft having a crankpin, a crank journal, and a crank arm for linking the crankpin and the crank journal, includes a pin fillet portion located between the crankpin and the crank arm, and a journal fillet portion located between the crank journal and the crank arm. At least one of the crankpin and the crank journal has a diameter of no less than about 20 mm and no more than about 40 mm. At least one of the pin fillet portion and the journal fillet portion contains a quench-hardened layer having a thickness of no less than about 1 mm and no more than about 2 mm in the vicinity of a surface thereof. The crankpin and the crank journal substantially do not contain any quench-hardened layer having a thickness exceeding about 2 mm in the vicinity of a surface thereof.

Owner:YAMAHA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com