Automatic discharging mechanism for roller burnishing of universal joint transmission shaft levers

A universal joint drive shaft and automatic unloading technology, which is applied to conveyor objects, transportation and packaging, roller tables, etc. damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The content of the present invention will be described below in conjunction with specific embodiments.

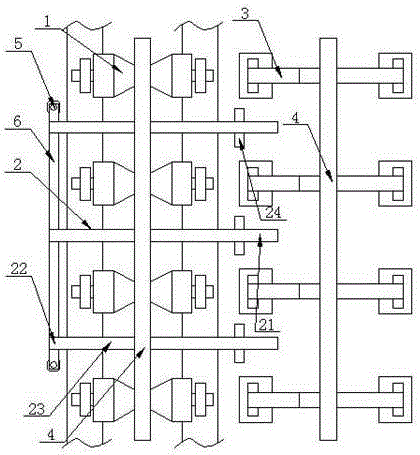

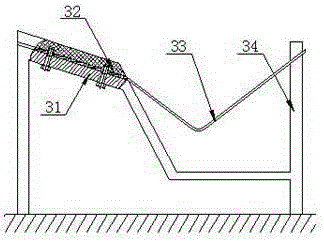

[0014] Such as figure 1 and figure 2 As shown, it is a structural schematic diagram of the automatic unloading mechanism for rolling the universal joint transmission shaft rod according to the present invention. The automatic unloading mechanism of universal joint transmission shaft rod rolling according to the present invention includes: axial feeding wheel 1, radial flip bar 2 and lateral material holding bracket 3, said axial feeding wheel 1 is several and Arranged in line along the conveying direction of the universal joint transmission shaft 4, the axial directions of several axial feeding wheels 1 are horizontal and parallel to each other; The shaft rods 4 are arranged in the same line in the conveying direction, and the several lateral material holders 3 are arranged on one side of the several axial feeding wheels 1; The feeding end 21 and the lifting end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com