Rough surface profiled fiber and preparation method and application thereof

A special-shaped fiber, rough surface technology, applied in the fiber field, can solve problems such as poor practicability, inability to be widely used, and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The invention provides a method for preparing a shaped fiber with a rough surface, the method comprising the following steps:

[0046] Step 1. Spinning with a special-shaped spinneret to obtain a fiber primary product;

[0047] Step 2, corroding the obtained fiber primary product;

[0048] Step 3, cleaning and drying after the corrosion treatment to obtain the final fiber product, that is, the irregular fiber with a rough surface.

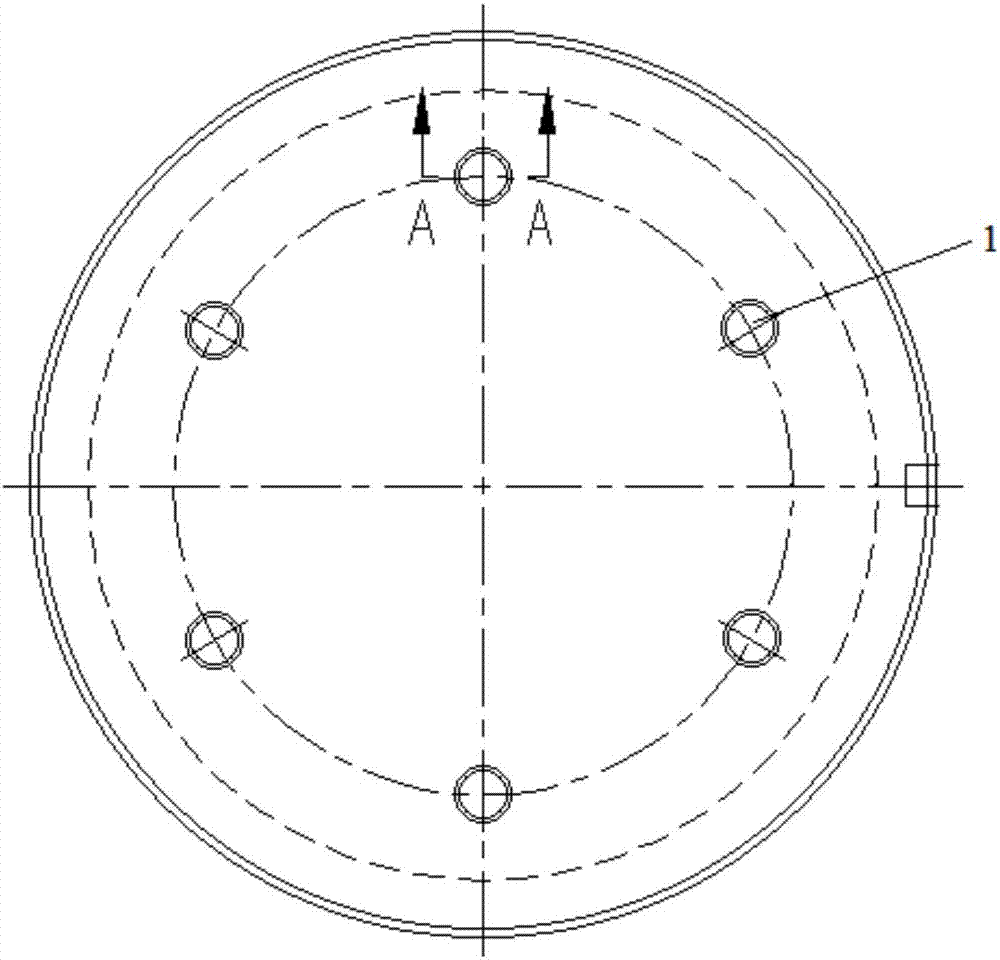

[0049] According to a preferred embodiment of the present invention, a plurality of spinneret holes 1 are arranged on the special-shaped spinneret, such as figure 1 As shown, the spinneret holes 1 are evenly arranged in corolla along the center of the spinneret, that is, they are arranged in concentric circles with the center of the spinneret as the center, and the distances between the connected spinneret holes 1 are equal.

Embodiment approach

[0050] According to a preferred embodiment of the present invention, there are 4 to 8 spinneret holes 1 .

[0051] In a further preferred embodiment, there are six spinneret holes 1 .

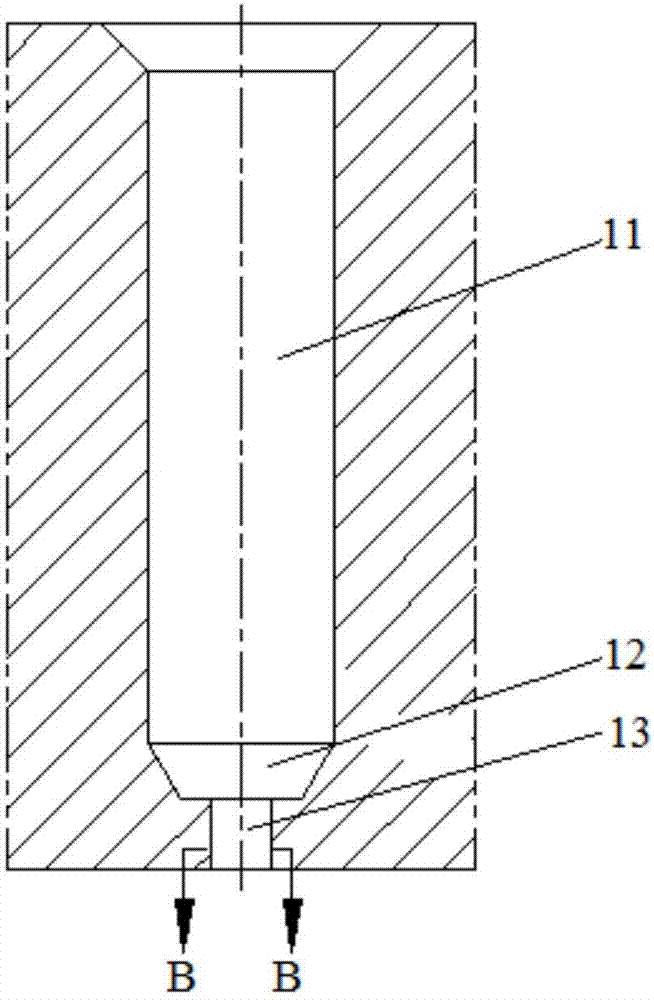

[0052] According to a preferred embodiment of the present invention, such as figure 2 As shown, along the melt flow direction, the spinneret hole 1 includes a guide hole 11, a tapered hole 12 and a microhole 13.

[0053] In a further preferred embodiment, the indexing cone angle of the tapered hole 12 is 30° to 60°.

[0054] In a further preferred embodiment, the indexing cone angle of the tapered hole 12 is 60°.

[0055] According to a preferred embodiment of the present invention, such as image 3 As shown, the outer contour of the microhole 13 is a star structure 131, and the star structure 131 includes a plurality of star arms 1311.

[0056] Among them, the micropores are set in a star-shaped structure, so that the fibers with a star-shaped cross-section can be extruded, so that the fi...

Embodiment 1

[0152] Nylon 6 granules (viscosity 2.4) produced by Guangdong Xinhui Meida were used as raw material to spin at 230°C to obtain the primary fiber product. Figure 8 The spinneret shown, meanwhile, controls the spinning speed to be 30 m / min, and the frequency of the metering pump is 10 Hz.

[0153] Scanning electron microscope test is carried out to the fiber initial product that obtains, and the result is as follows: Figure 9a , as shown in Figure 9b, it can be seen from the figure that the radial cross-section of the obtained fiber primary product has a hexagonal star structure, and the thickness is uniform along the longitudinal direction, and the surface morphology is good.

[0154] Put the raw fiber product obtained above into a 1mol / L sulfuric acid solution for corrosion treatment for 5 seconds, then wash and dry to obtain the final fiber product, namely the shaped fiber.

[0155] Carry out scanning electron microscope test to the surface of the special-shaped fiber tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com