Quick automatic cut-off instrument valve

An automatic shut-off and instrument valve technology, applied in the field of instrument valves, can solve problems such as waste of resources, welding defects, and wear resistance, and achieve the effects of improving sealing performance, long service life, and strong corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

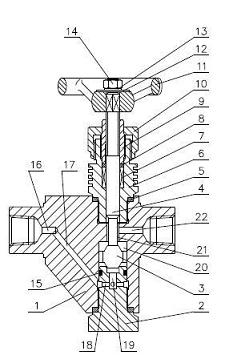

[0035] Such as Figure 1-3 The straight-through quick automatic shut-off instrument valve shown is mainly composed of the valve body 1, the valve base 2, the valve cover 6, the stuffing box assembly, the valve stem 4 and the valve clapper 3. The valve stem 4 is sleeved in the valve cover 6, and the valve stem 4 The operating end is equipped with a hand wheel 11 through a hand wheel nut 14 and a hand wheel washer 13. The hand wheel is equipped with a nameplate 12, and the outer wall of the valve cover 6 has heat dissipation fins. The upper valve seat end of the valve body 1 and the valve cover adopt Thread and gasket 5 are connected and sealed. The other end of the valve body and the valve base are connected and sealed with threads and gaskets and O-ring 15. The valve body is provided with a medium flow passage hole, and the bottom end of the valve stem is inserted in the valve. In the flow passage hole 21 at the cover end, packing 7 and packing 8 are installed between the valve ...

Embodiment 2

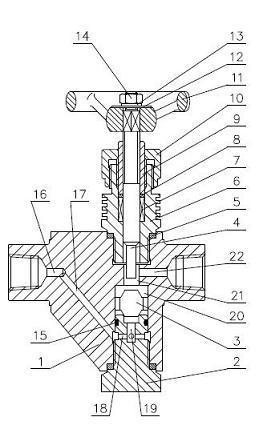

[0045] Such as Figure 4-6 The angle-type quick automatic shut-off instrument valve shown is similar in structure to that in Example 1, except that the medium inlet 16 and the medium outlet 22 are at a 90 degree angle. The valve body is made of austenitic stainless steel valve body, and the internal parts are made of F51. . The processing technology is the same as in Example 1.

Embodiment 3

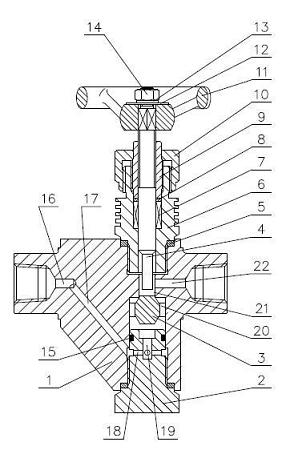

[0047] Such as Figure 7-9 The Z-type quick automatic shut-off instrument valve shown is similar in structure to that in Example 1, except that the medium inlet 16 and the medium outlet 22 are Z-shaped, in which the valve body is an austenitic stainless steel valve body, and the internal parts are F51 . The processing technology is the same as in Example 1.

[0048] When the present invention is in use, the valve is opened first, as long as the valve stem is rotated, the valve flap is pushed to separate it from the upper valve seat, the pressure before and after the valve is balanced, and the valve stem is rotated; when the pipeline connecting the instrument leaks and the medium is gushing out, There is a pressure difference between the valve disc and the upper valve seat port, which pushes the valve disc to move to the upper valve seat quickly, and the valve disc and the upper valve seat are sealed to cut off the medium. The maintenance personnel can rush to the site to replac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com