Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

814 results about "Stuffing box" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

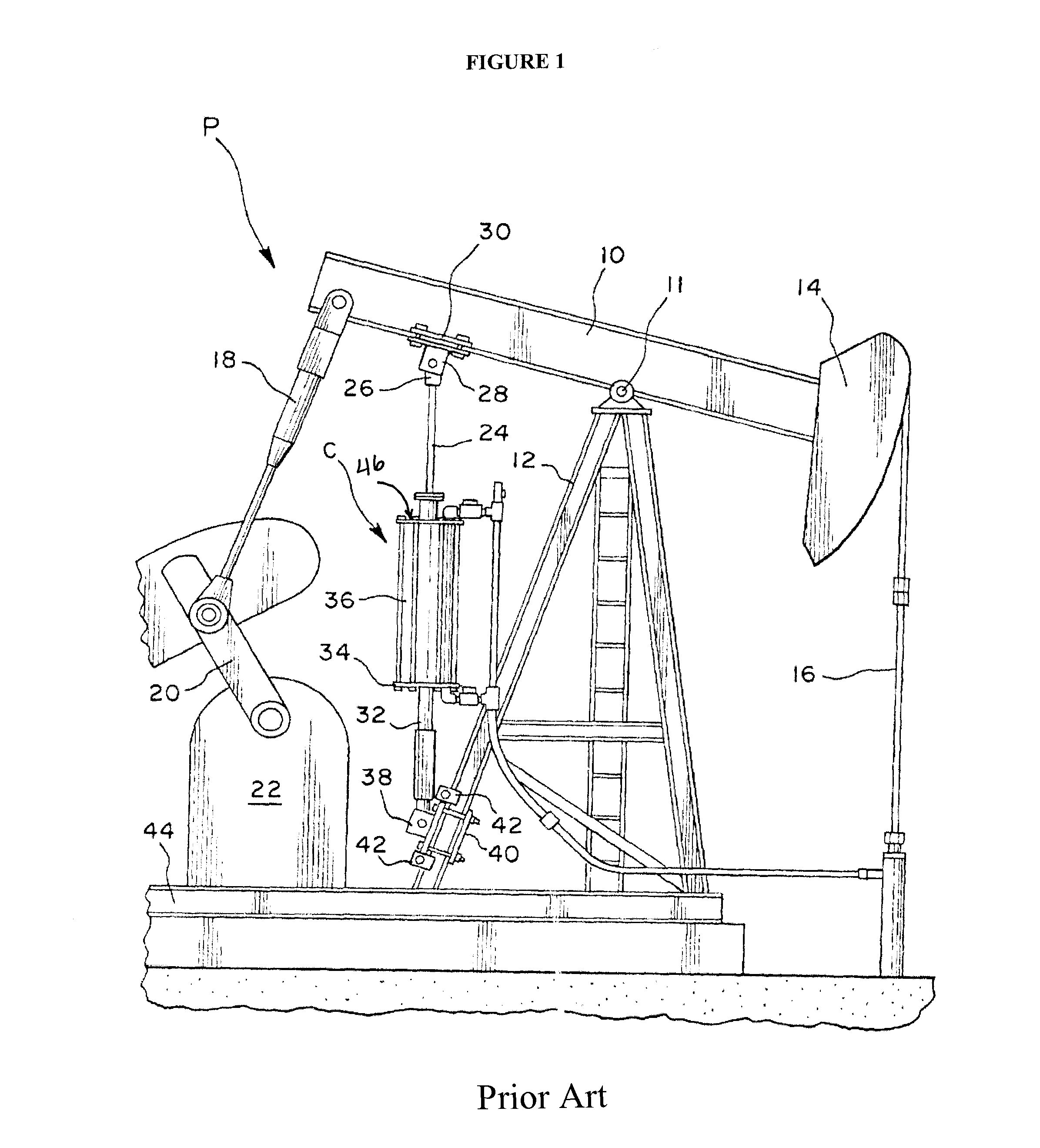

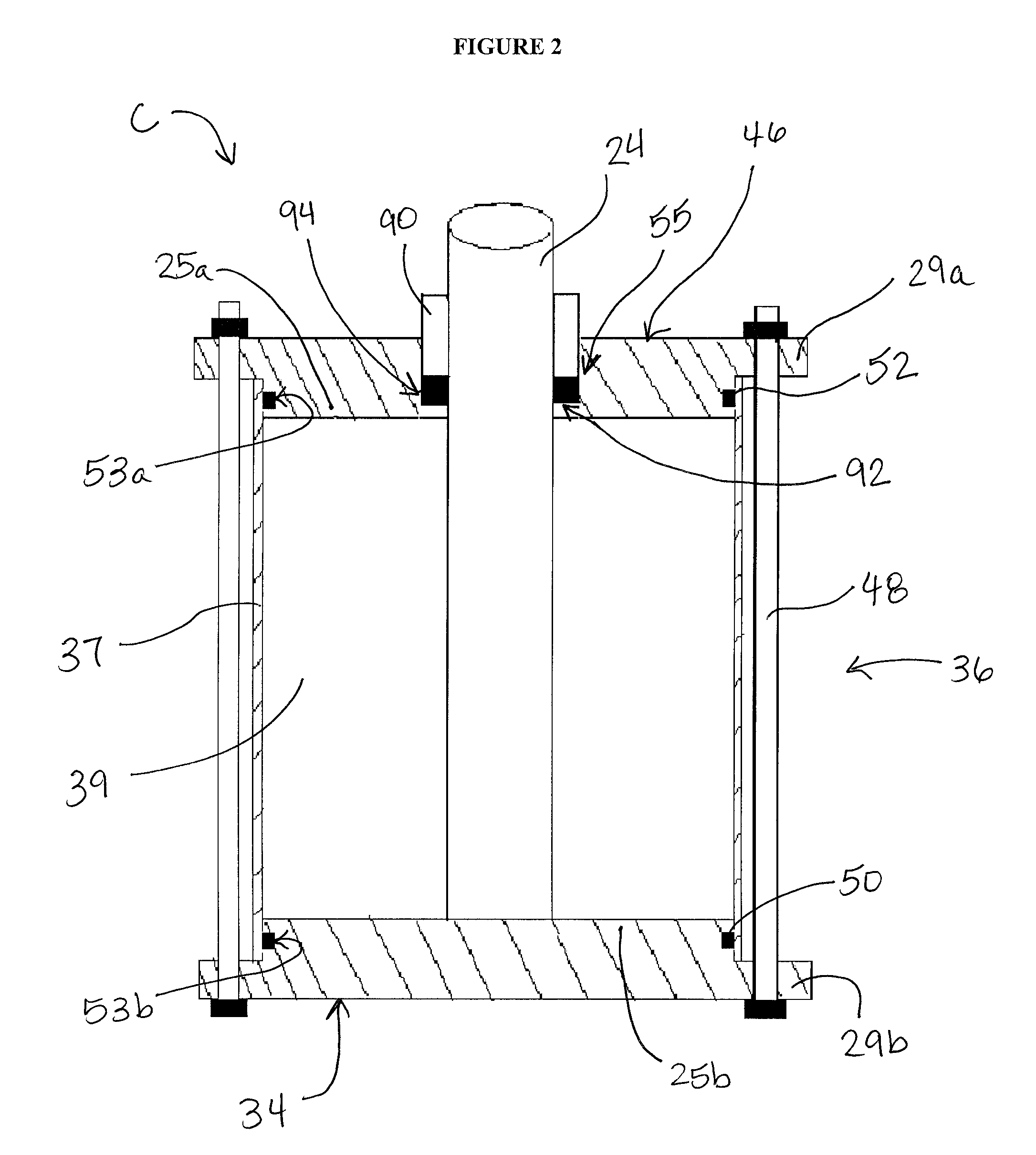

A stuffing box is an assembly which is used to house a gland seal. It is used to prevent leakage of fluid, such as water or steam, between sliding or turning parts of machine elements.

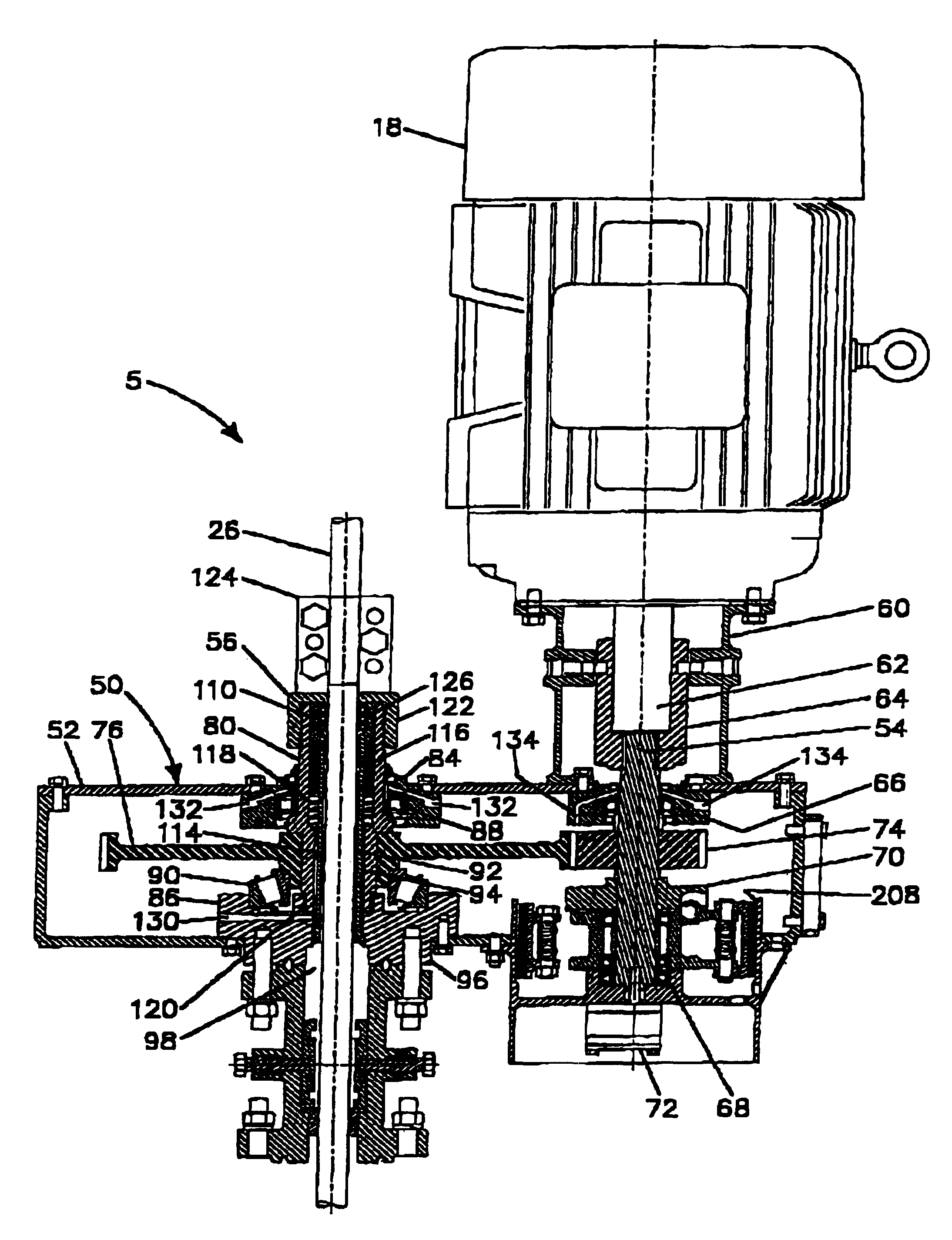

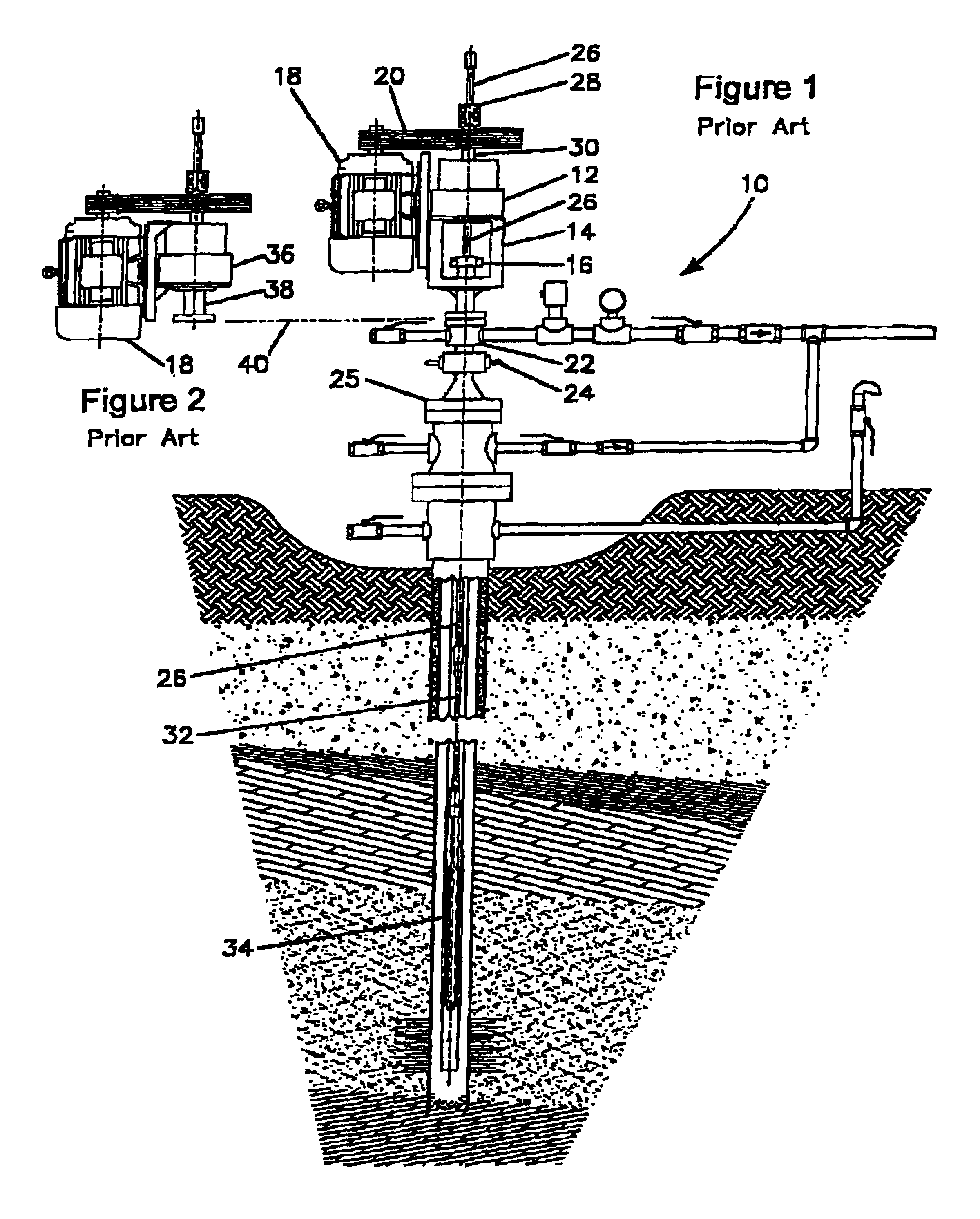

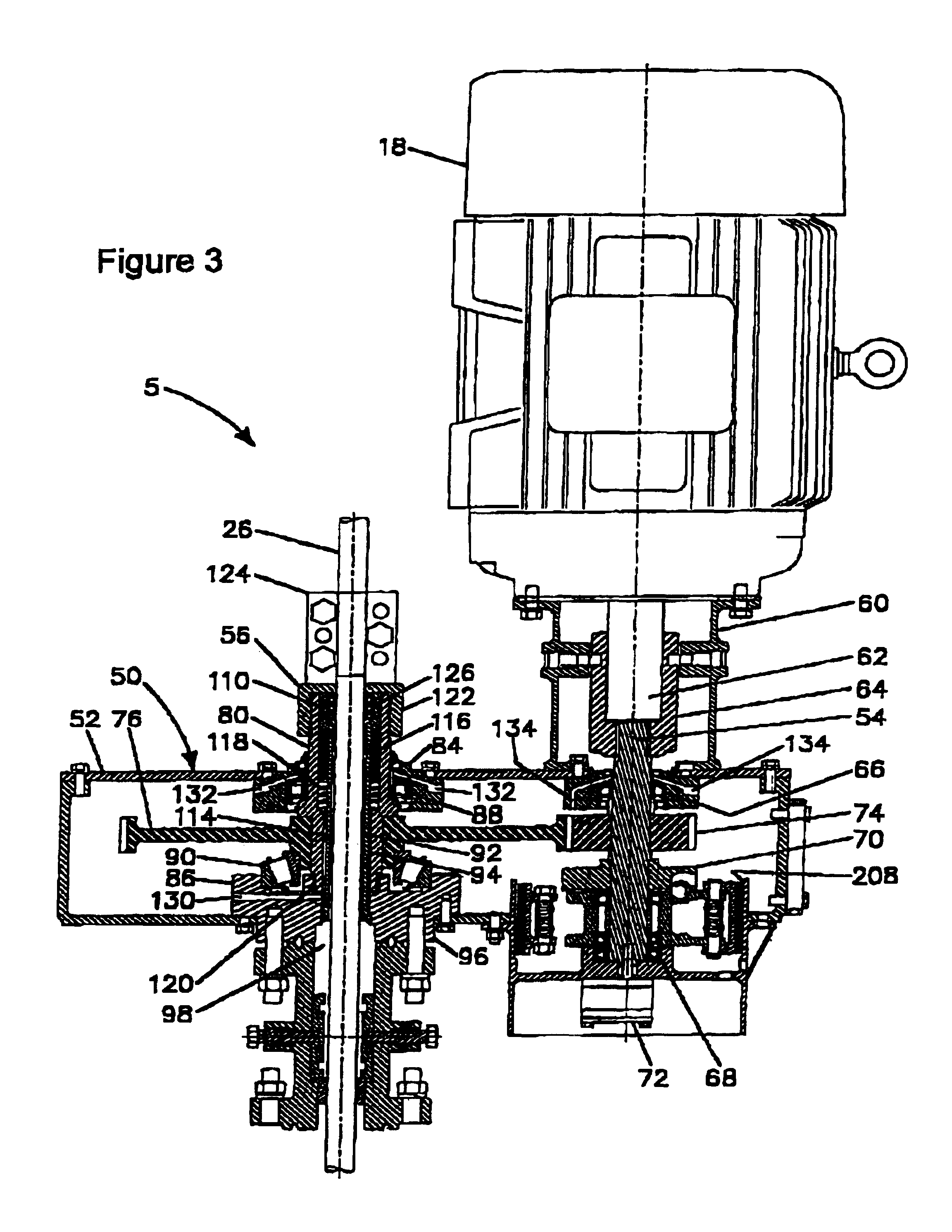

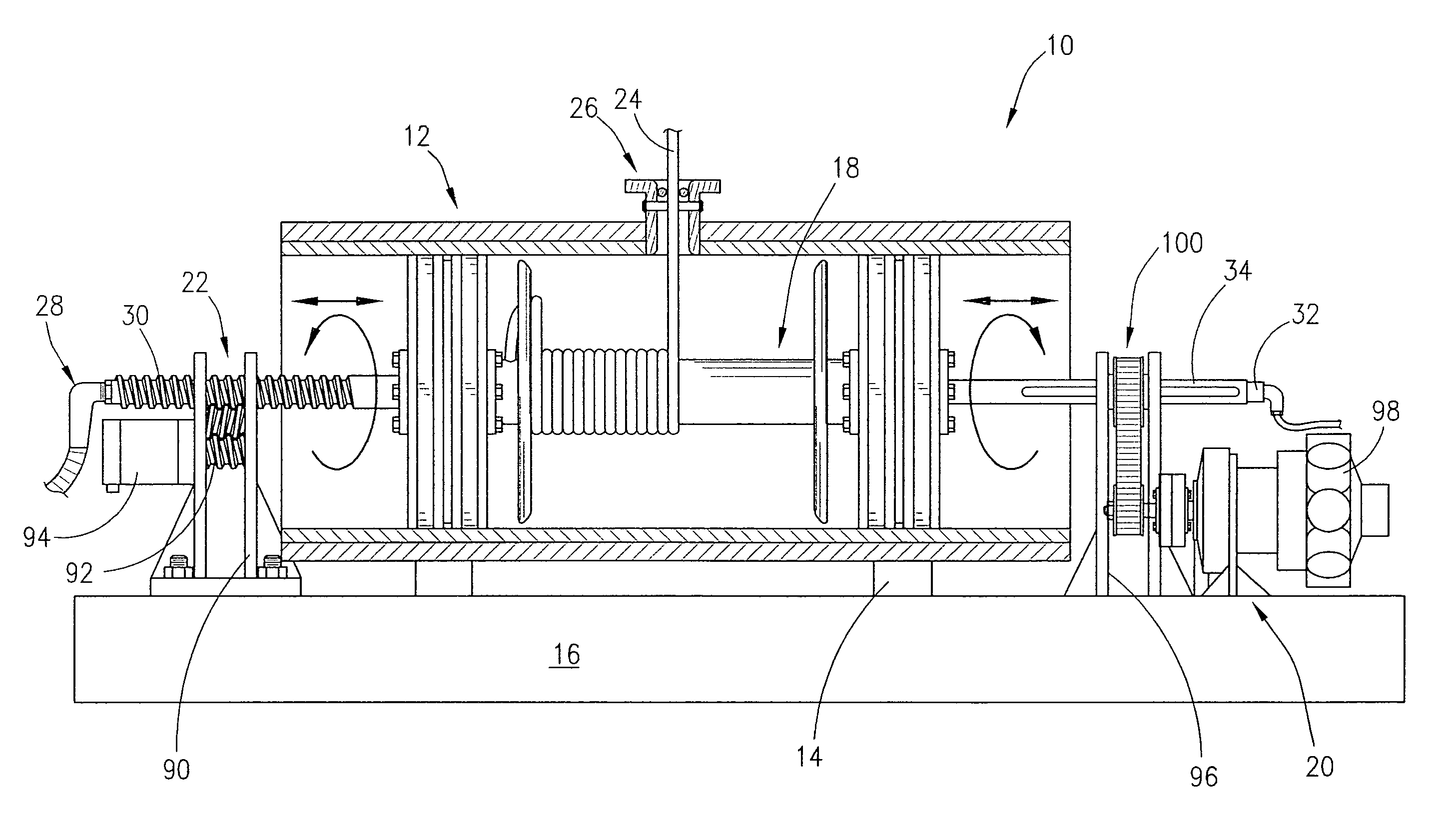

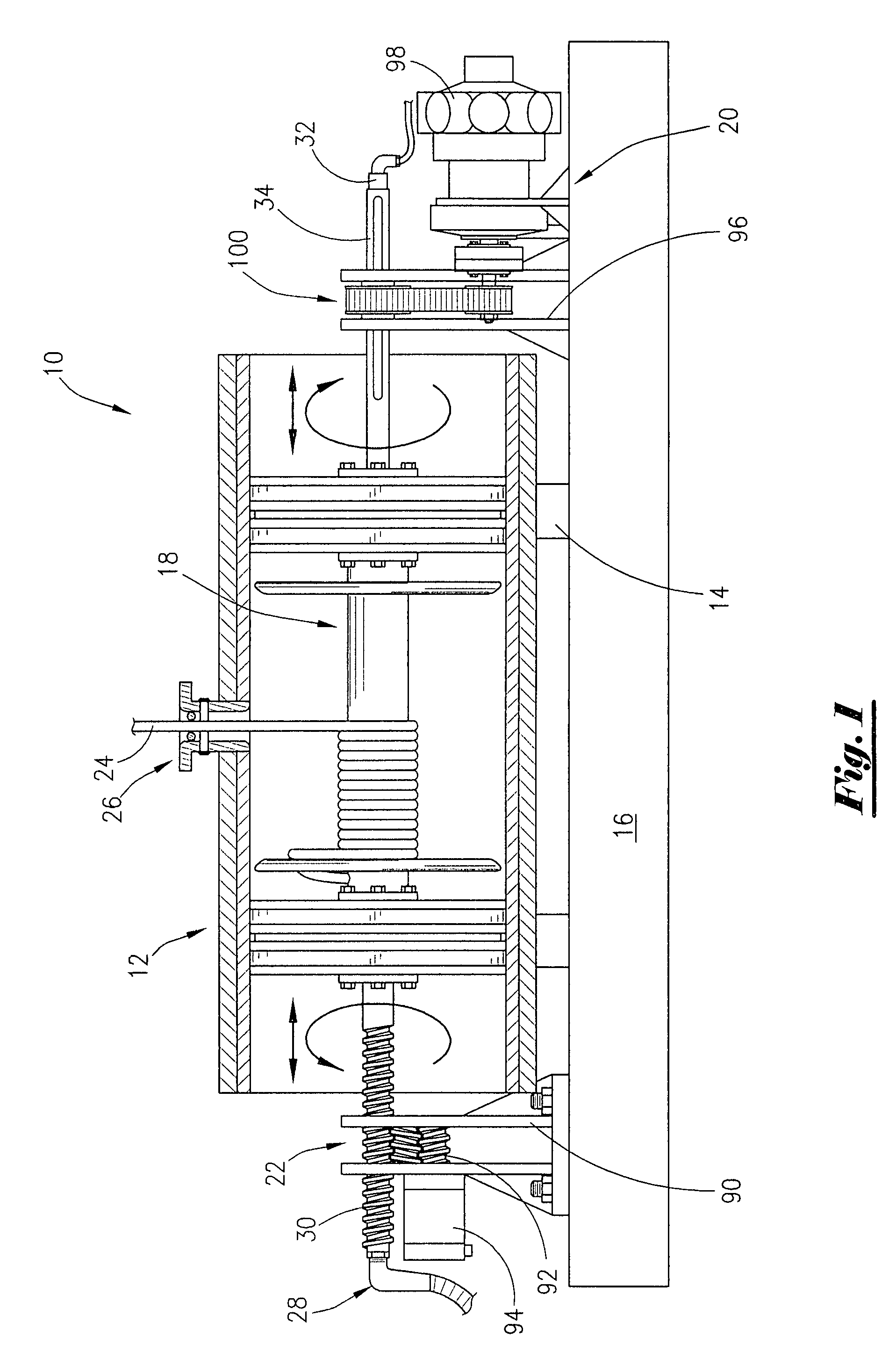

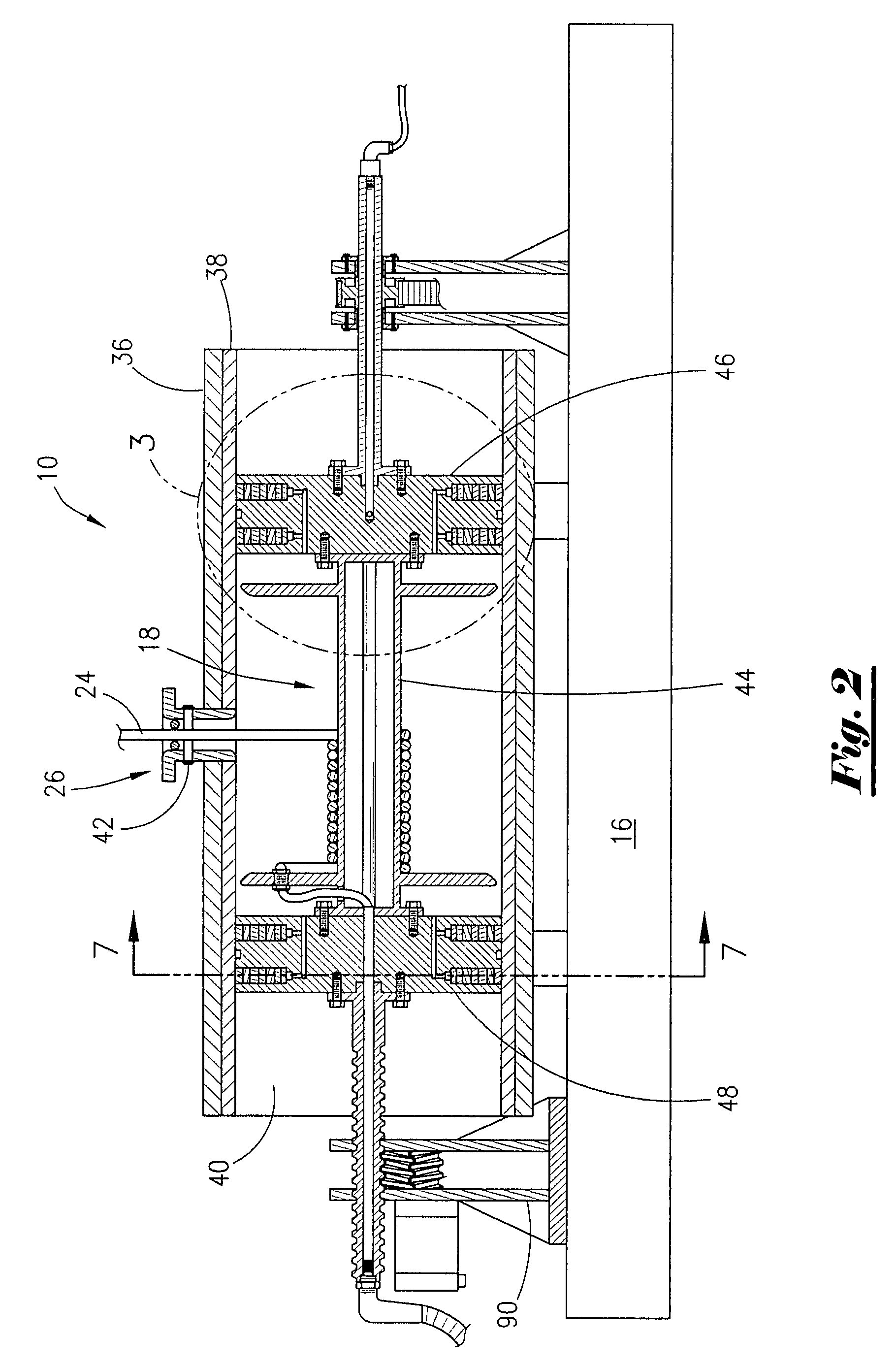

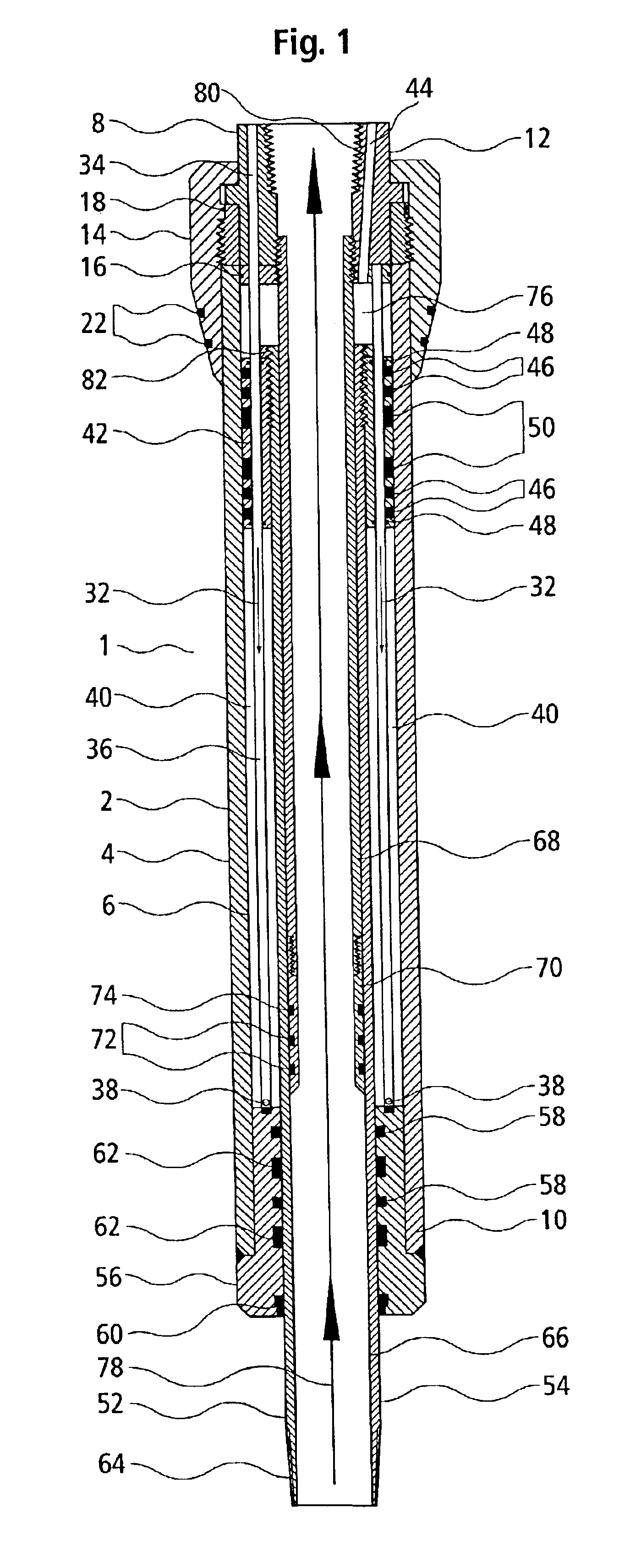

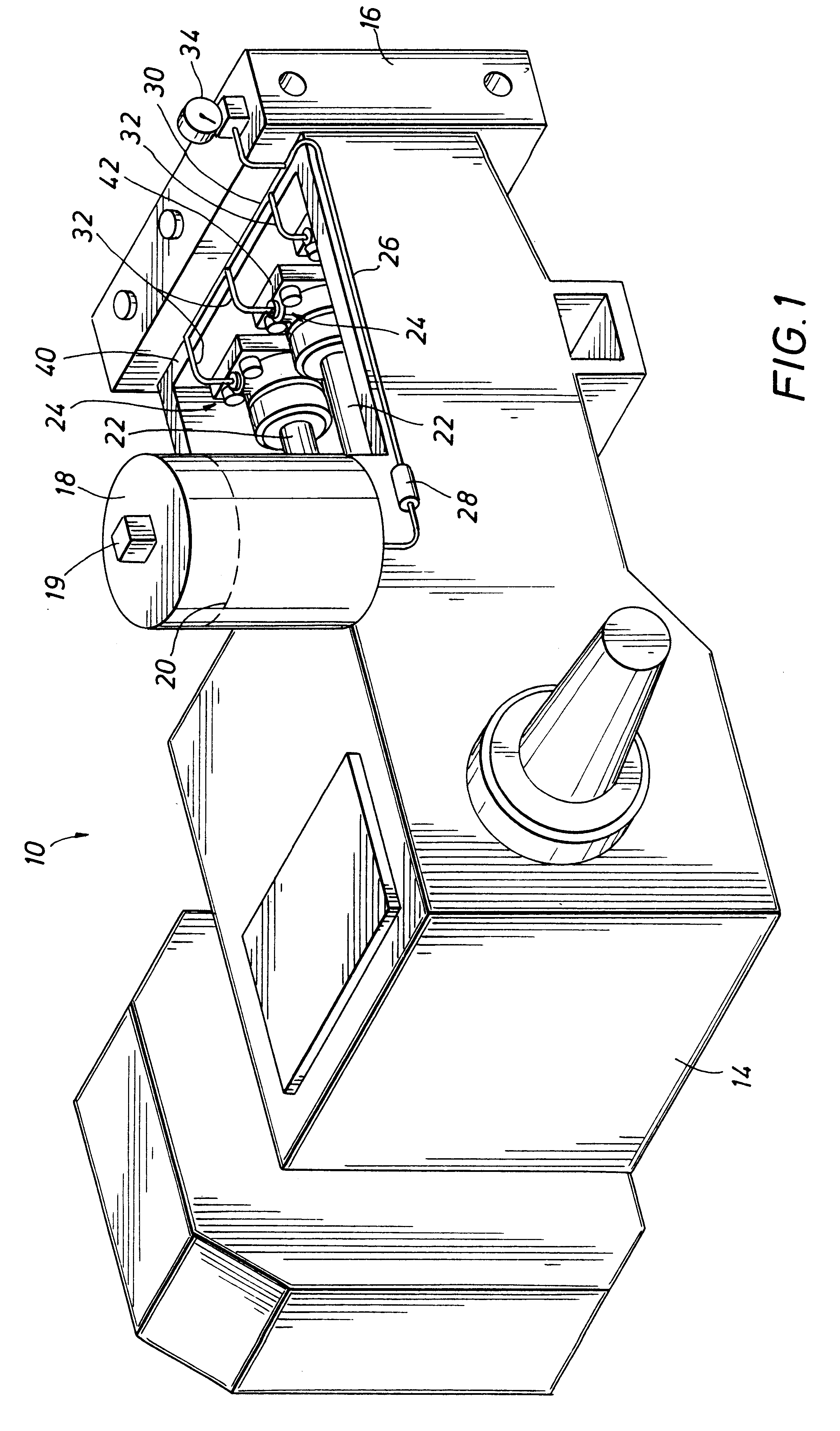

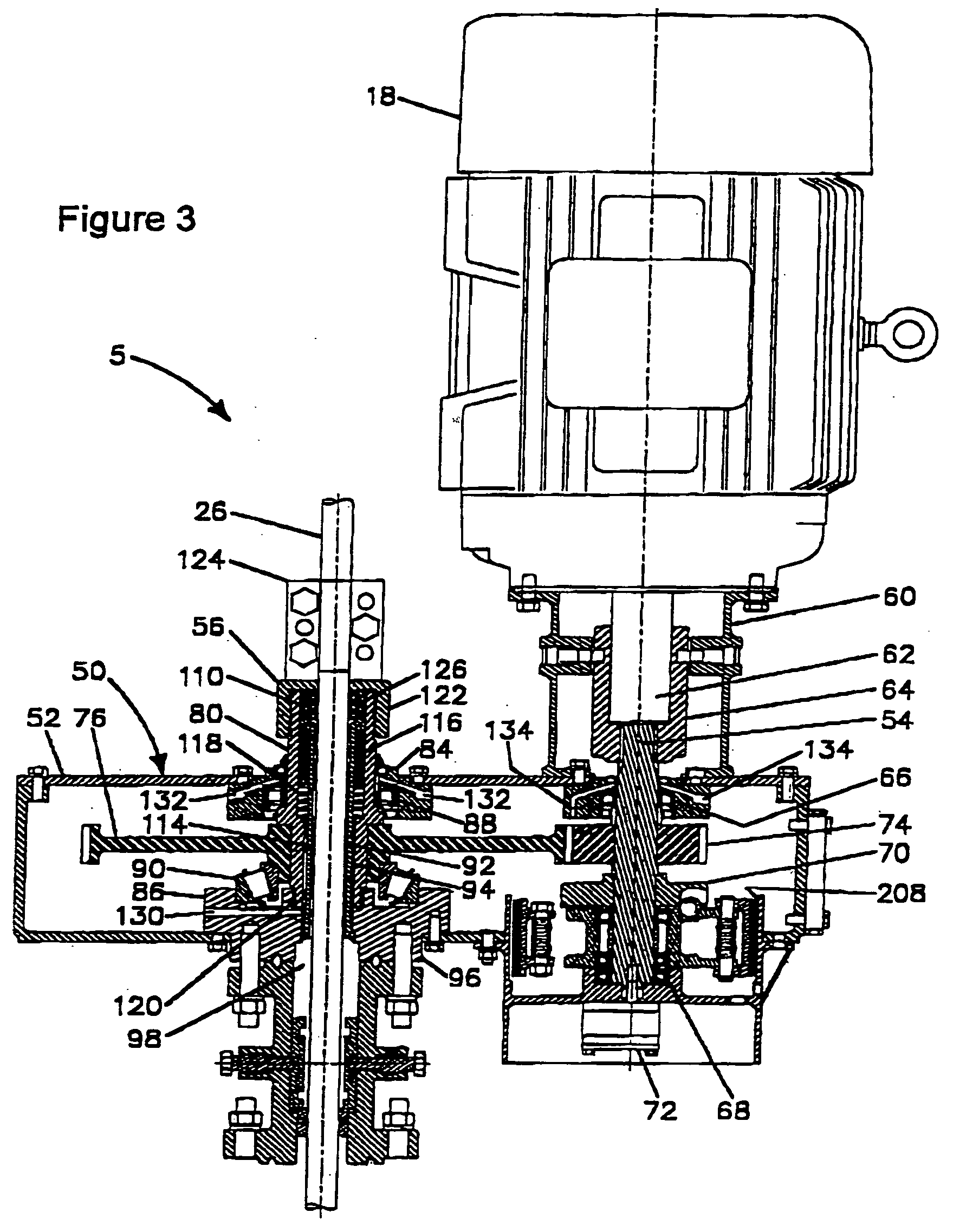

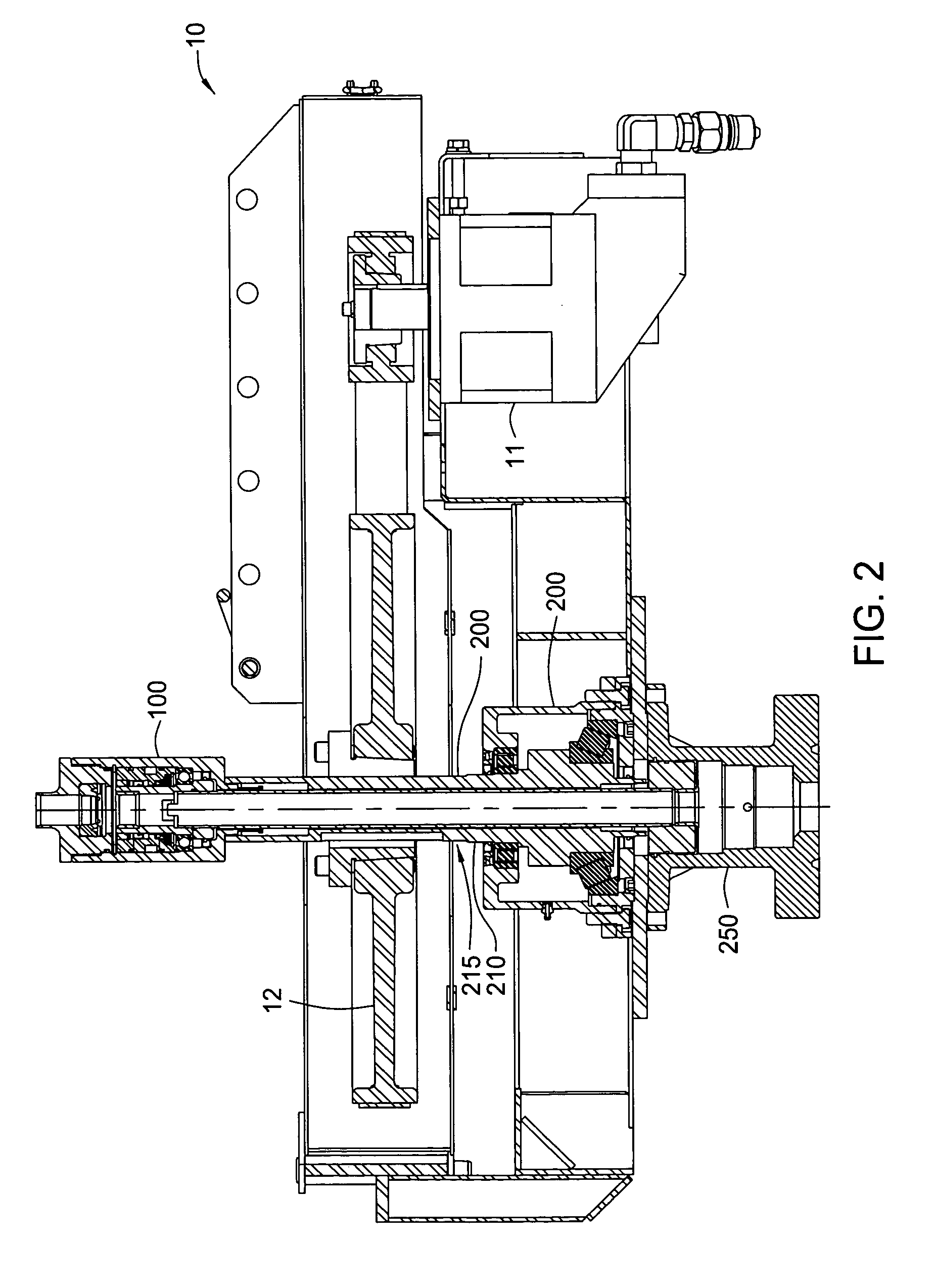

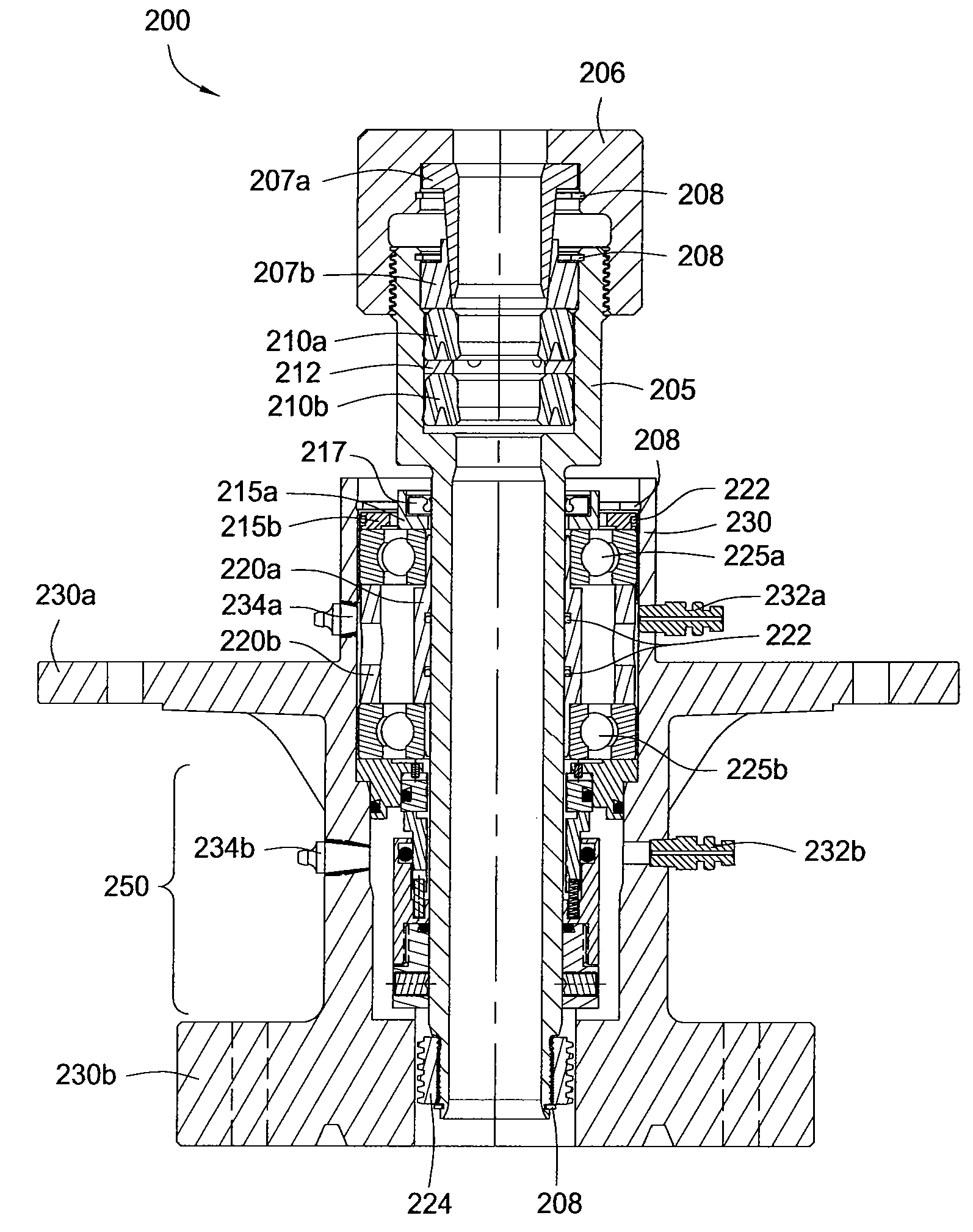

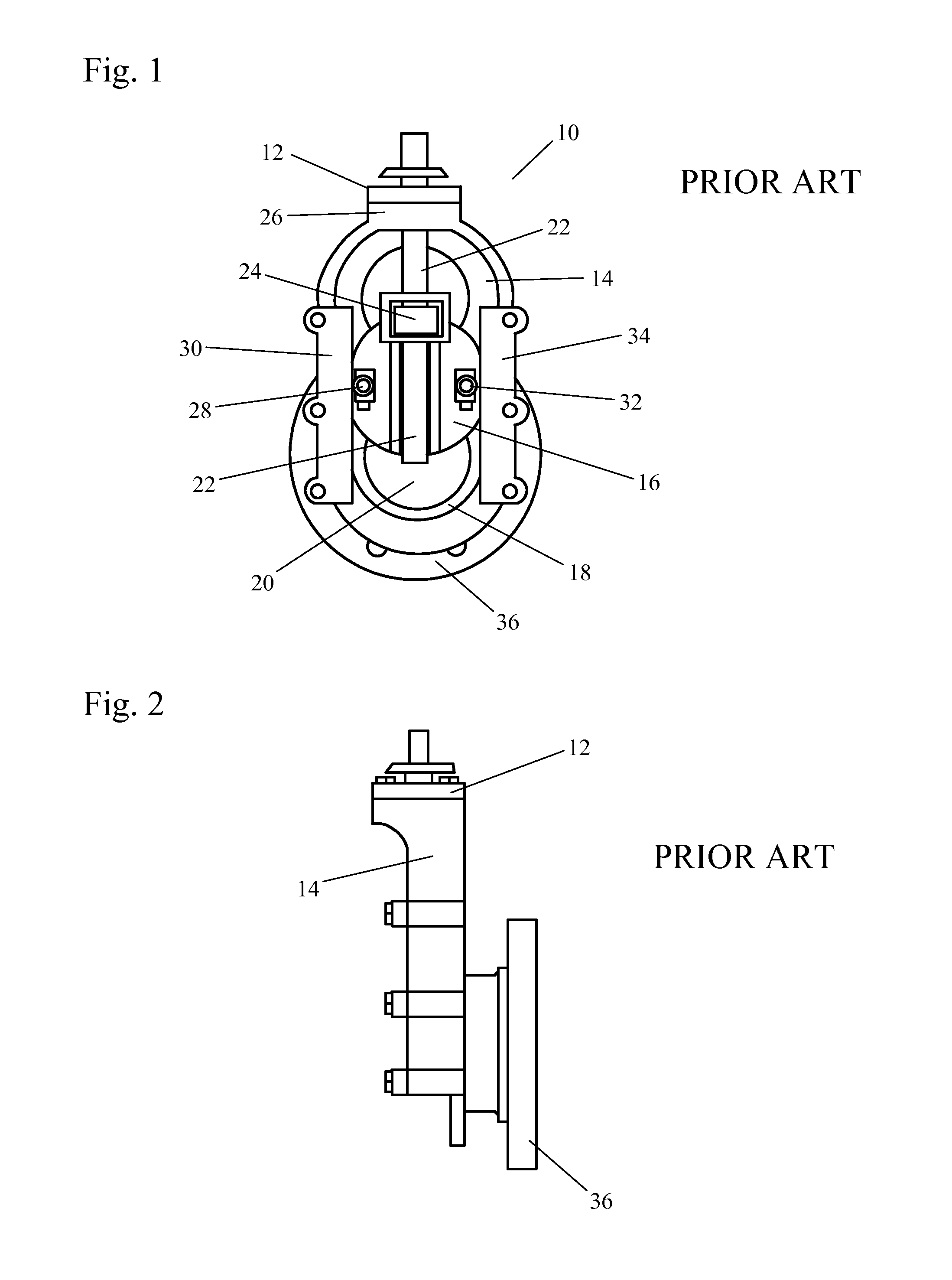

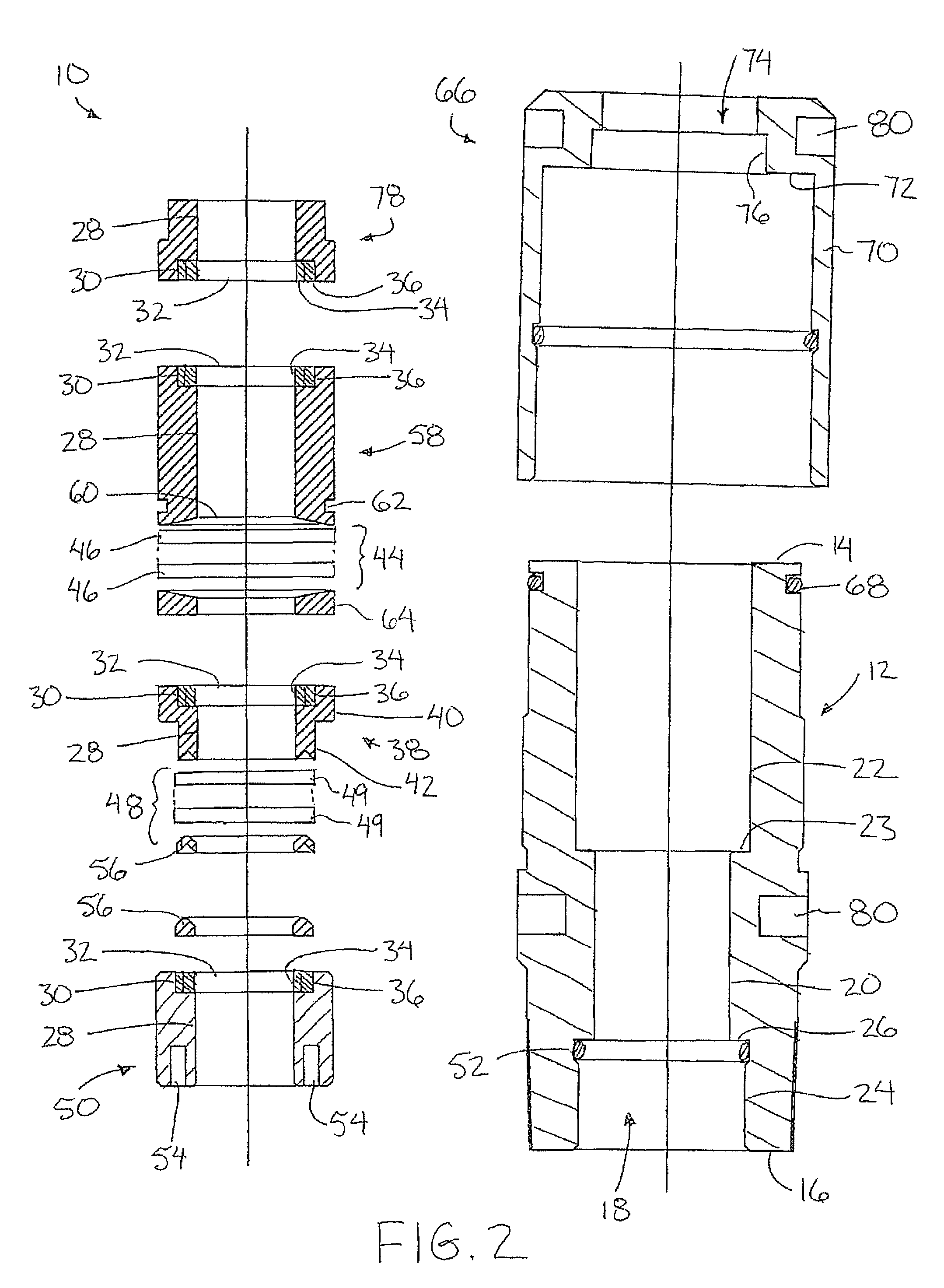

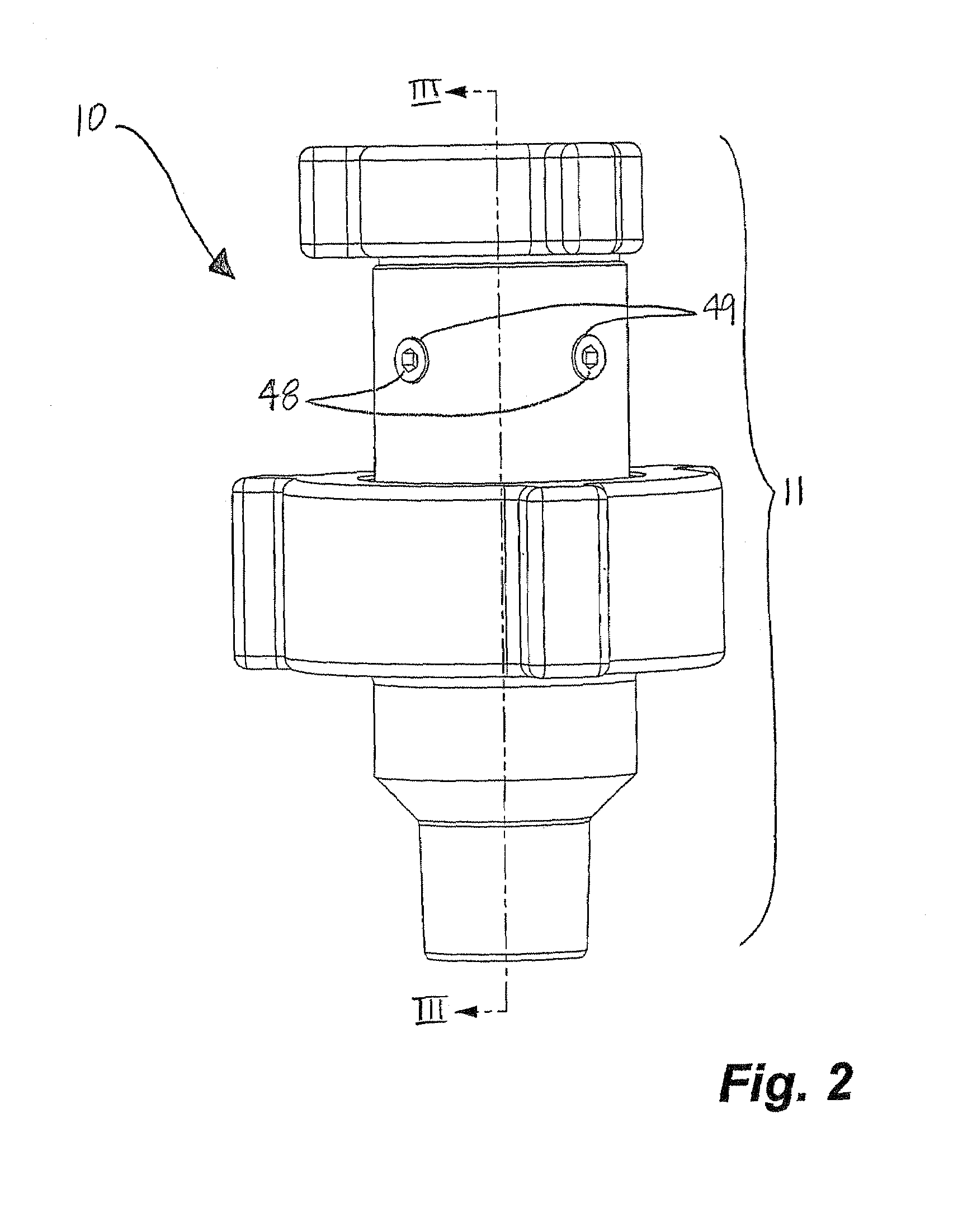

Pump drive head with stuffing box

InactiveUS6843313B2Eliminating belt tensioningEliminate replacementDrilling rodsFluid removalGear driveEngineering

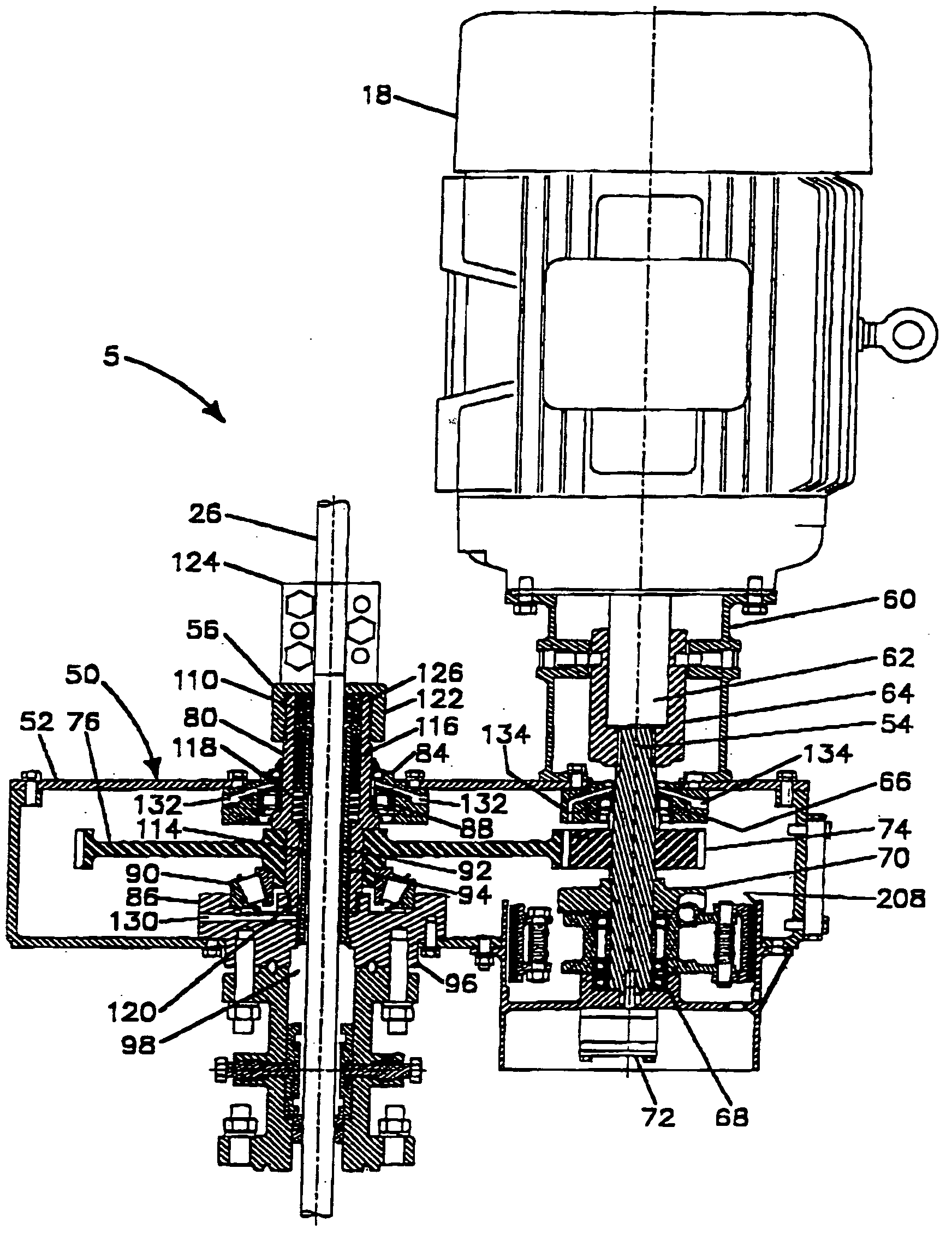

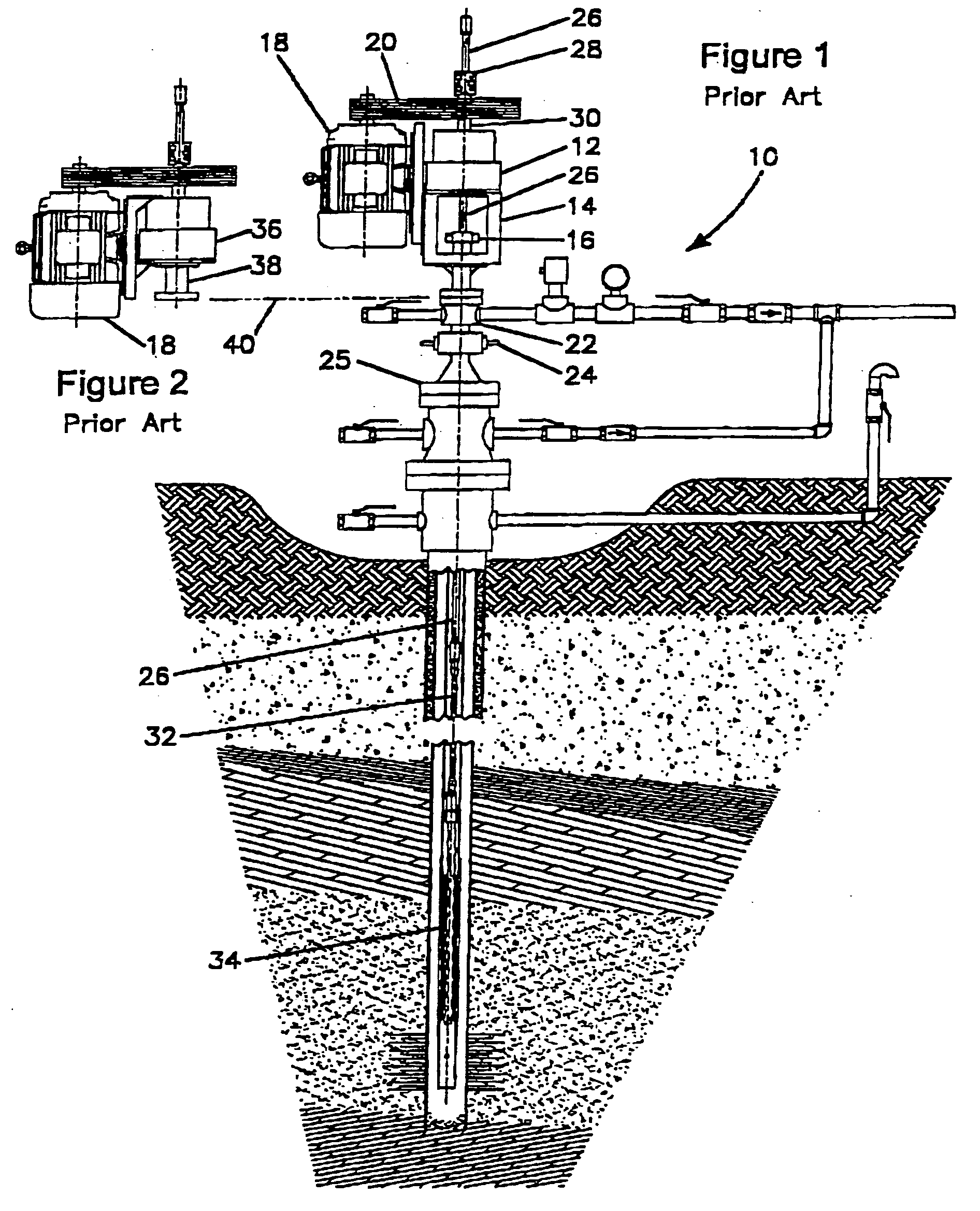

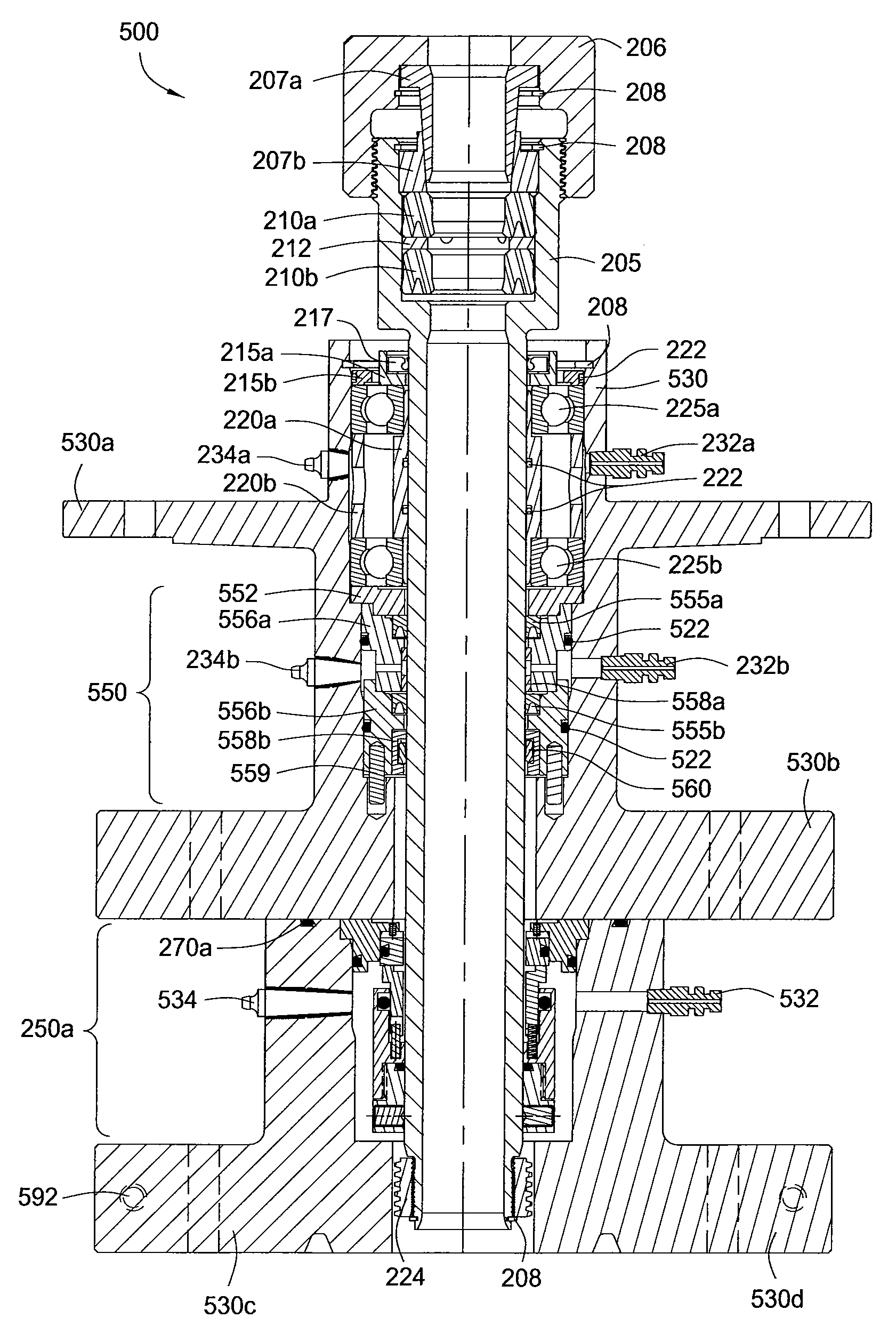

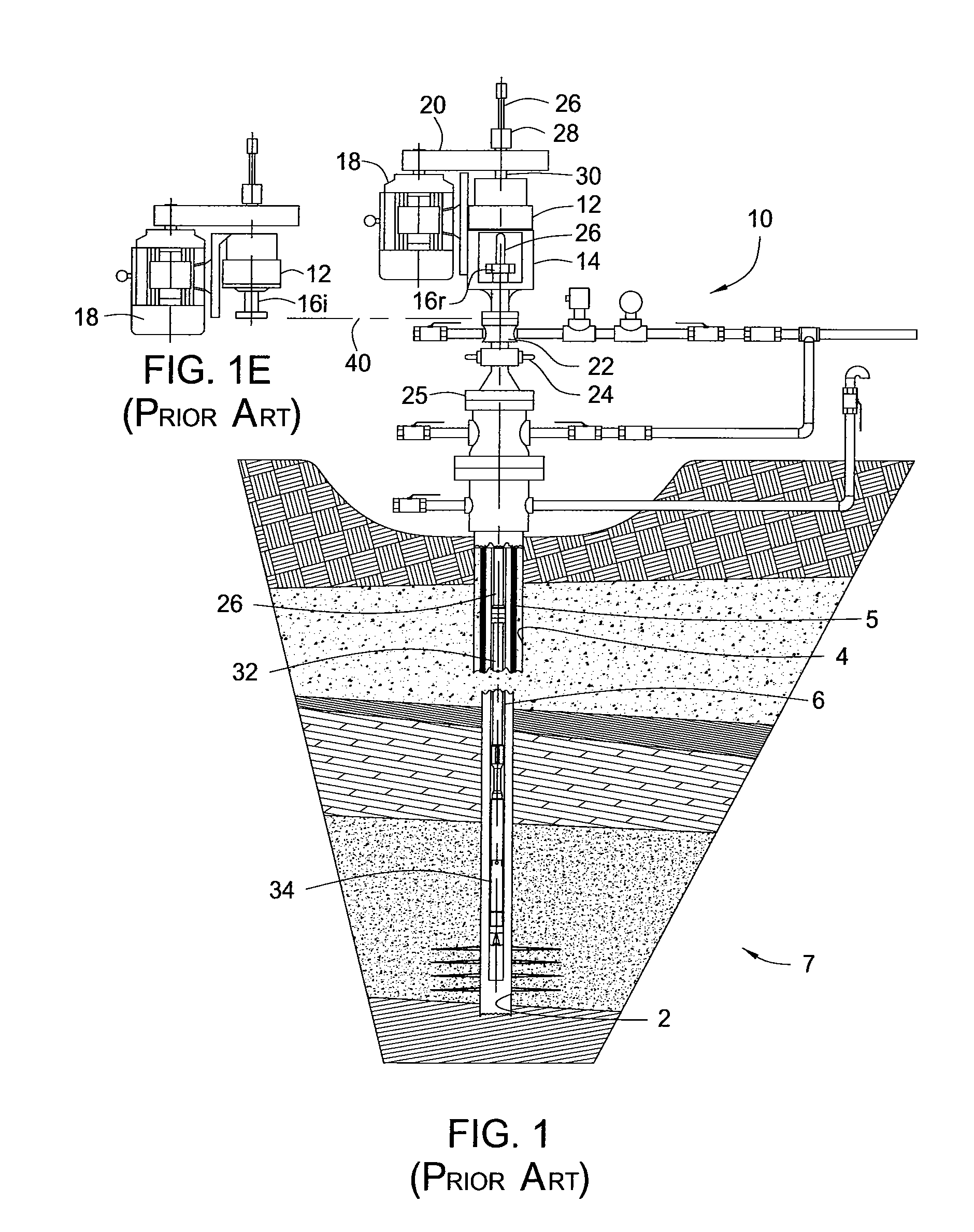

A pump drive head for a progressing cavity pump comprises a top mounted stuffing box rotatably disposed around a compliantly mounted standpipe with a self or manually adjusting pressurization system for the stuffing box. To prevent rotary and vertical motion of the polish rod while servicing the stuffing box, a polished rod lock-out clamp is provided with the pump drive head integral with or adjacent to a blow-out-preventer which can be integrated with the pump drive head to save space and cost. A centrifugal backspin braking system located on the input shaft and actuated only in the backspin direction and a gear drive between the input shaft and output shaft are provided.

Owner:OIL ELEVATOR TECH

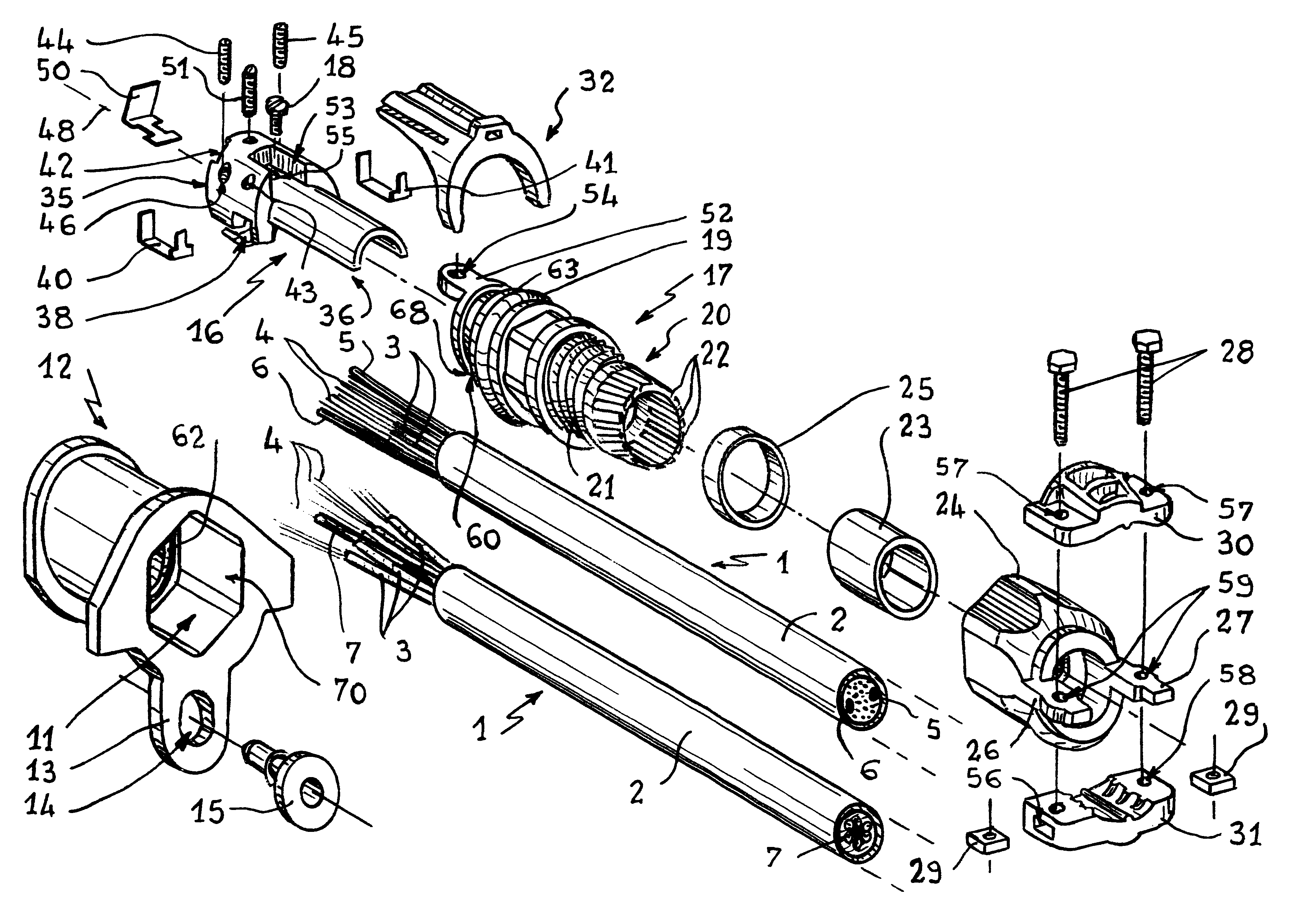

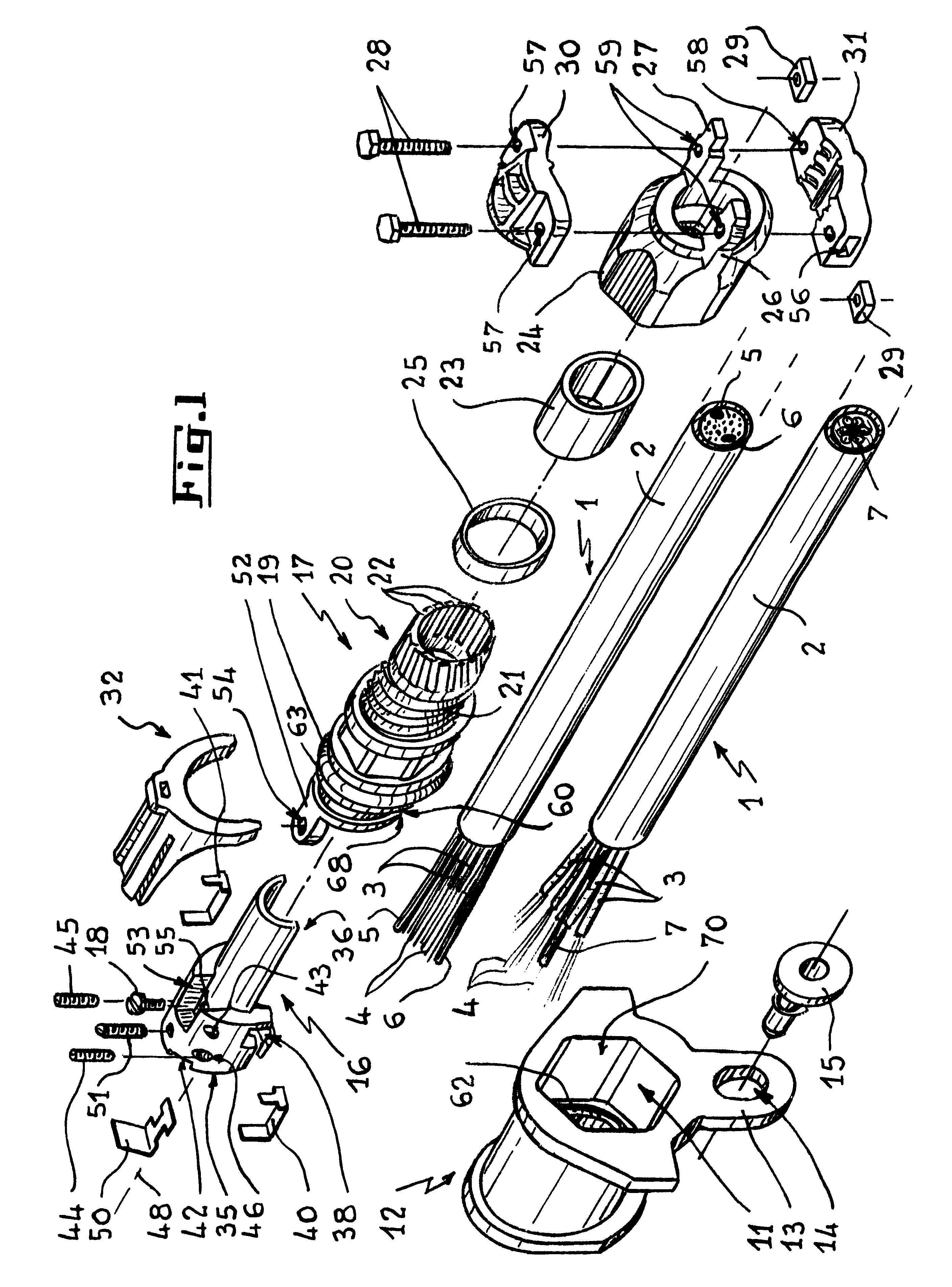

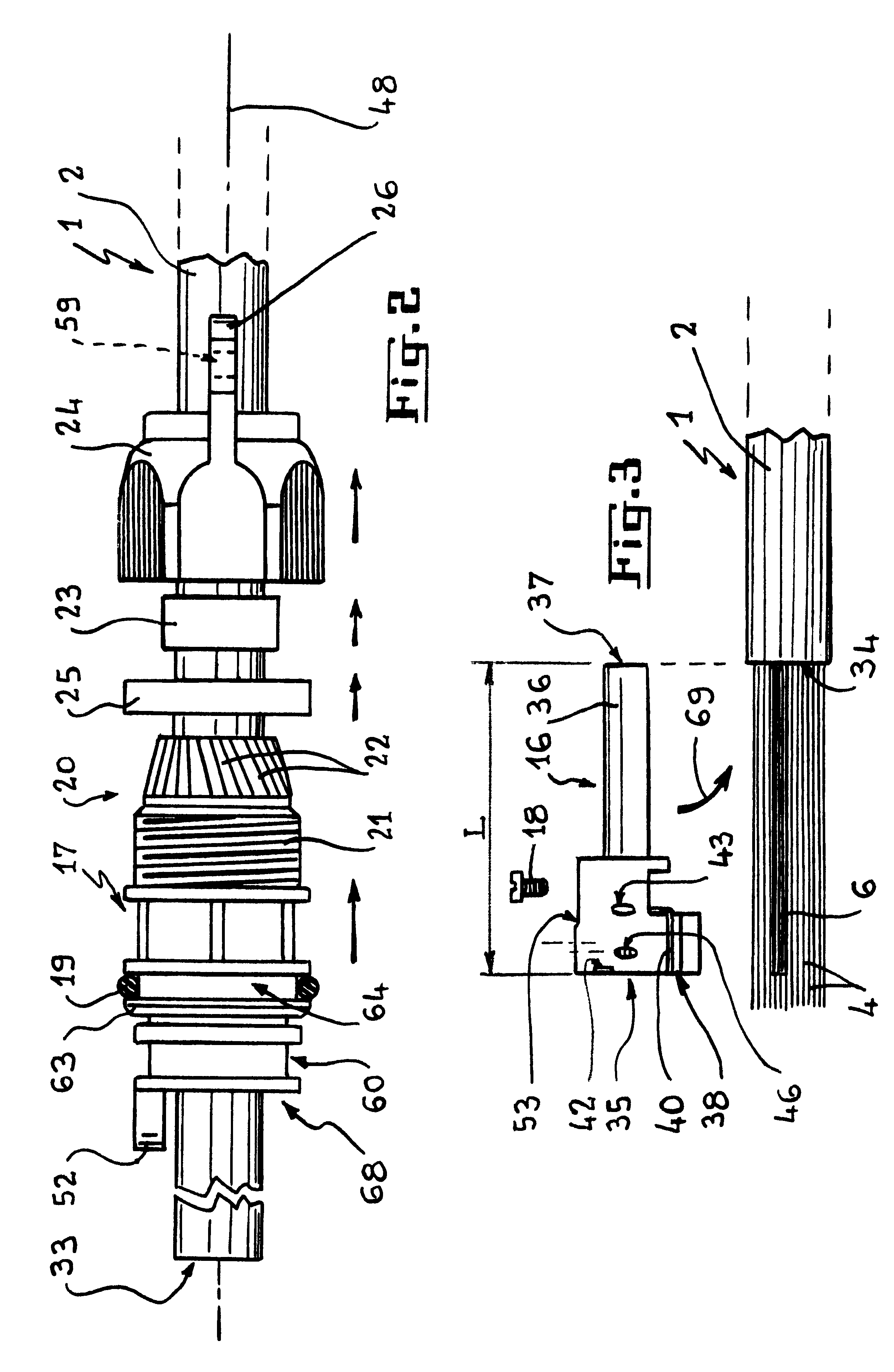

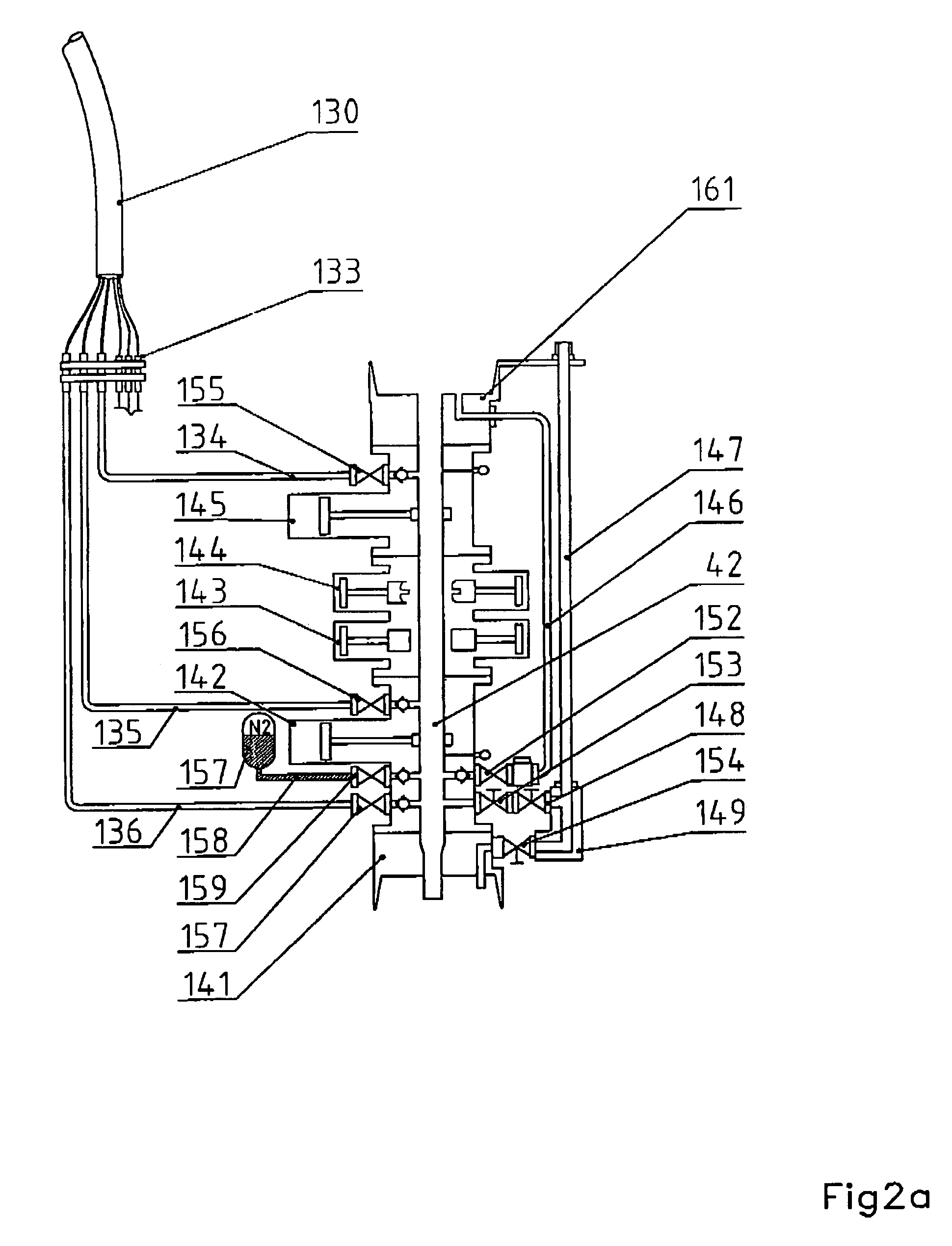

Optical fiber cable inlet device

InactiveUS6487344B1Cable fittingsFibre mechanical structuresUltimate tensile strengthOptical fiber cable

A watertight inlet device for inserting a cable containing optical fibers into a chamber or a container, e.g. into a splice box. The device includes a metal solepiece for securing the strength members of the optical cable, and which plugs into and fixes to a tubular sealing body equipped with an external O-ring gasket and having its rear portion shaped to form a sealing stuffing box on the outer sheath of the cable. The rear of the nut of the stuffing box receives a clamp for retaining the cable. Once the device has been fitted, the resulting assembly is inserted into the inlet passageway until it abuts against a shoulder in the passageway. Then only the head of the securing solepiece and a groove in the body project inside the container, the groove then receiving a key or fork for retaining the assembly.

Owner:CORNING RES & DEV CORP

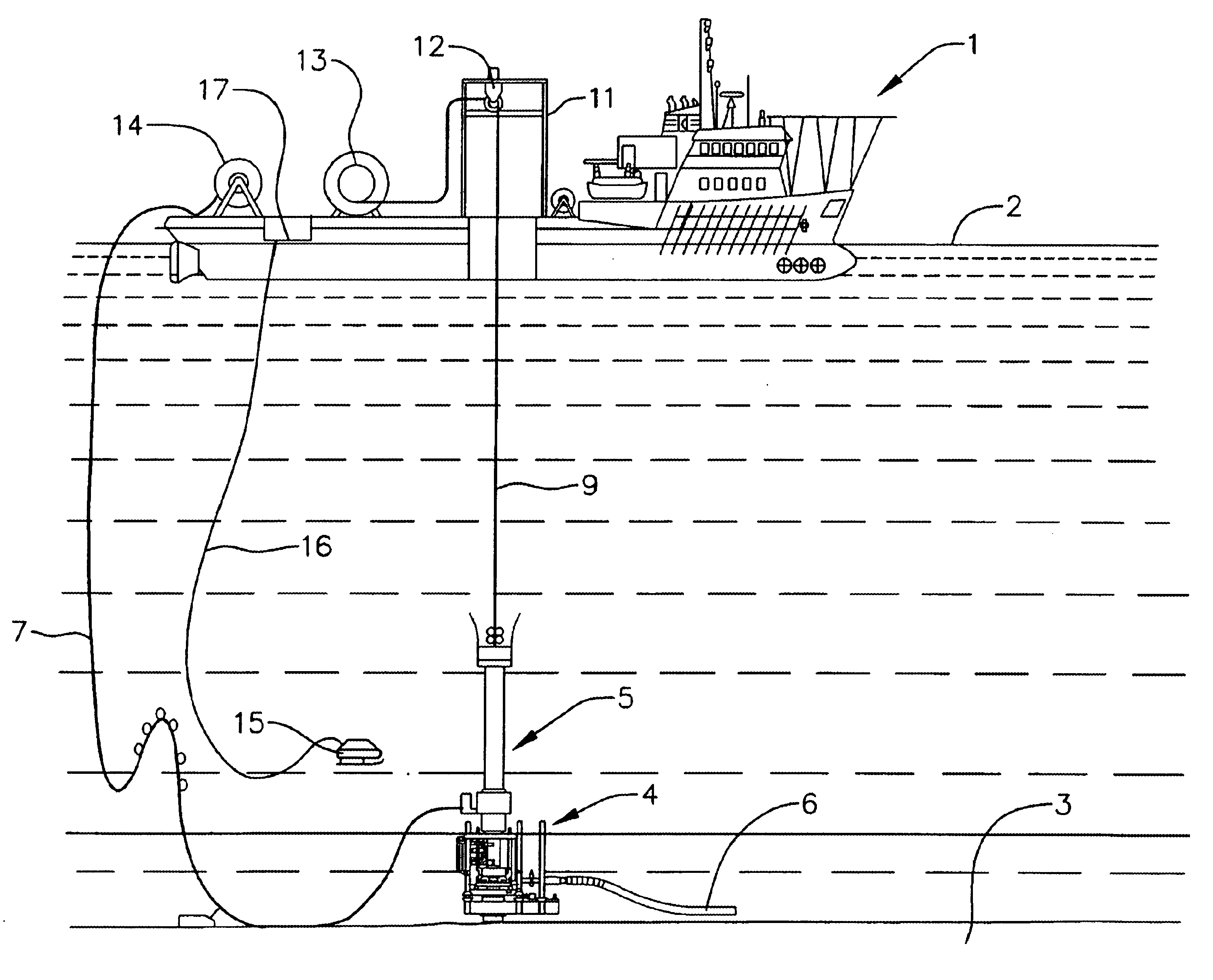

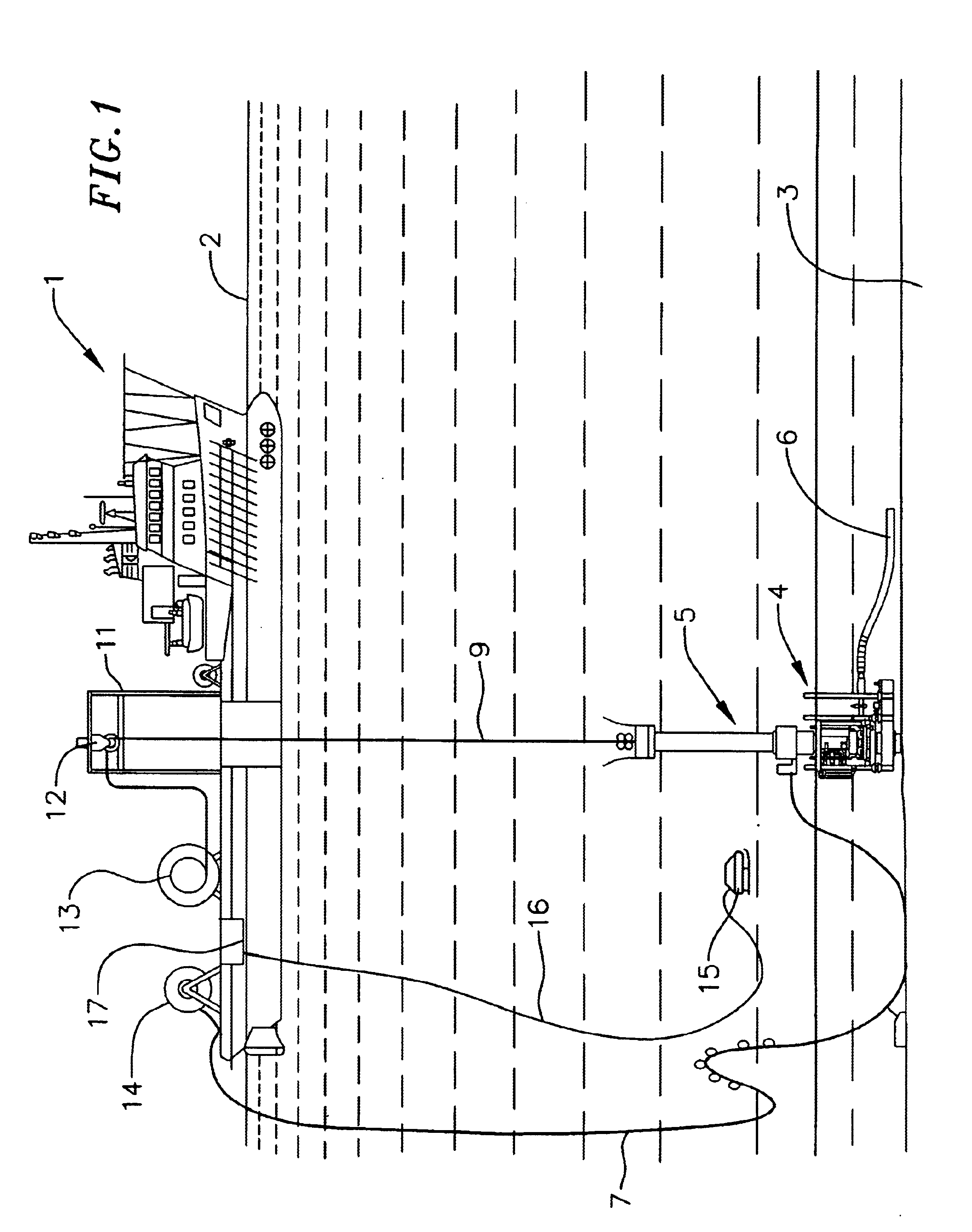

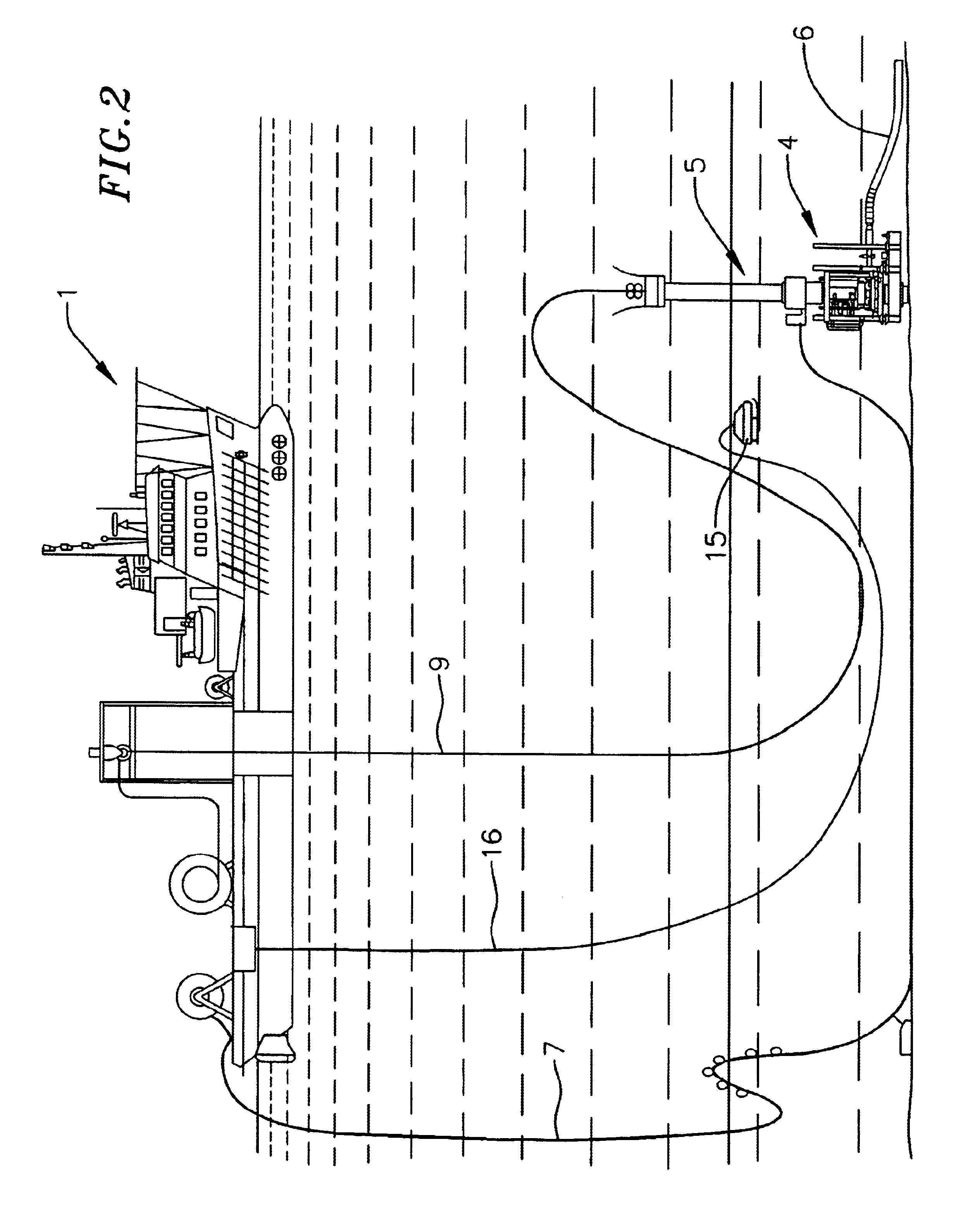

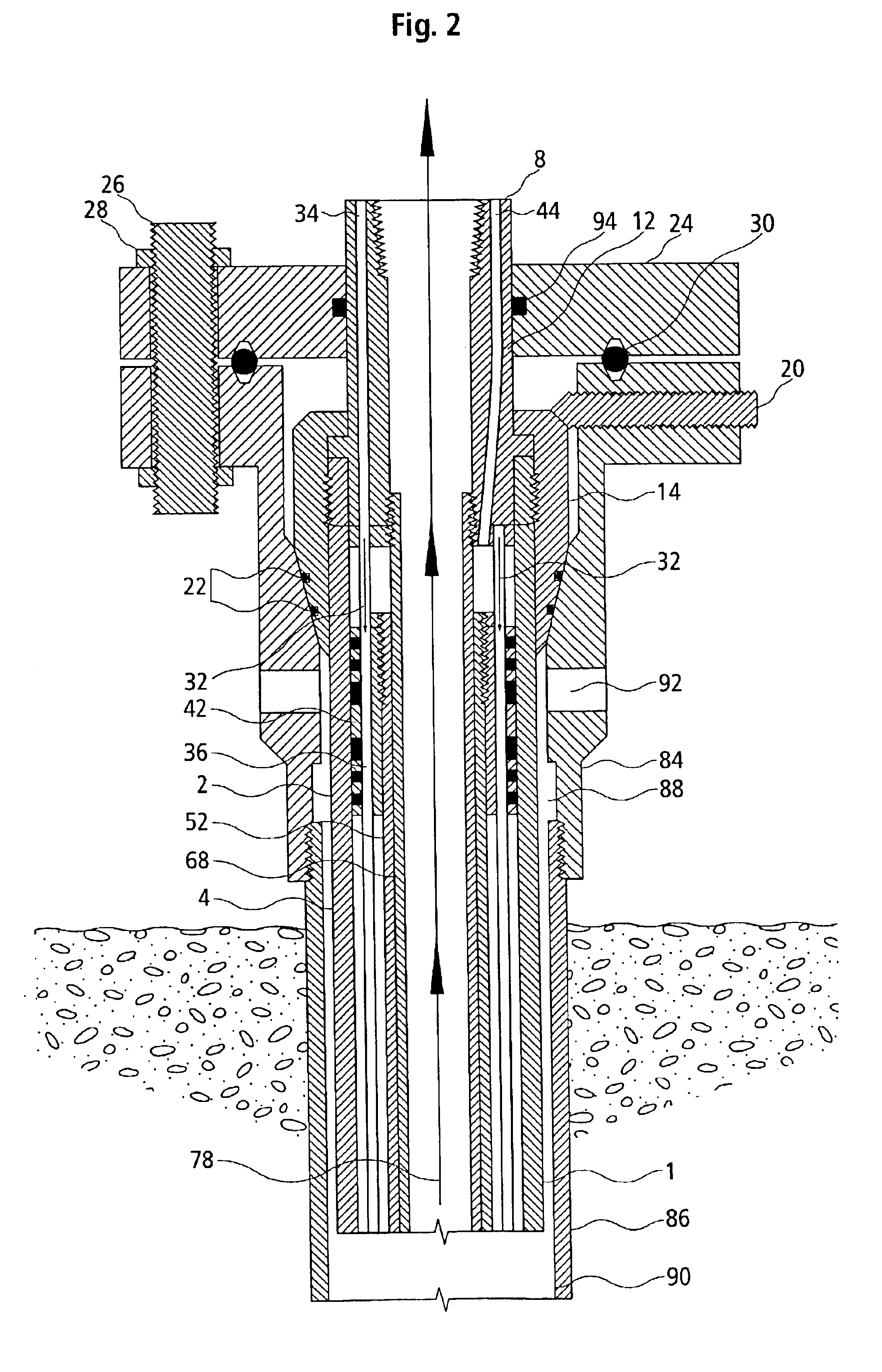

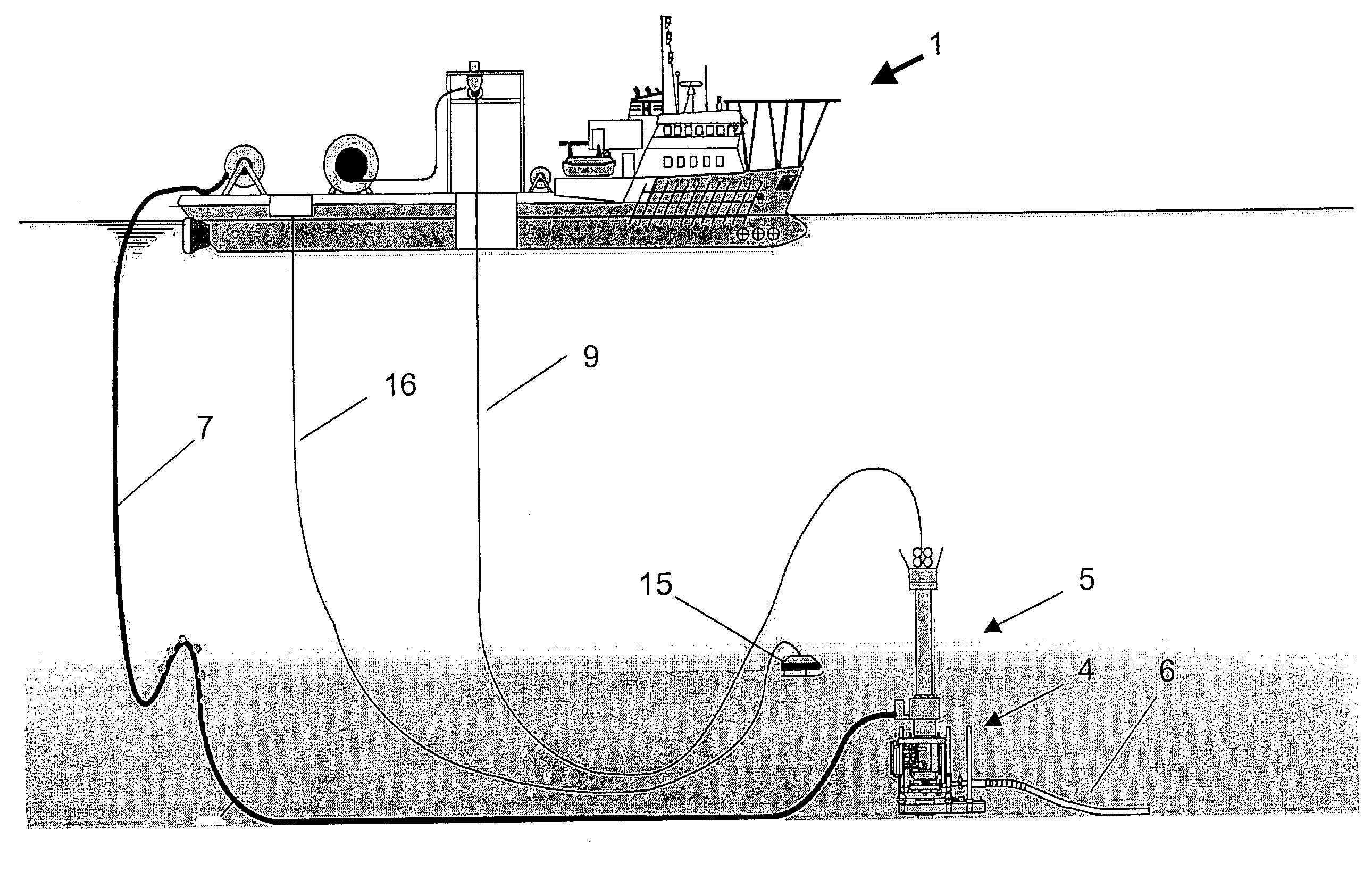

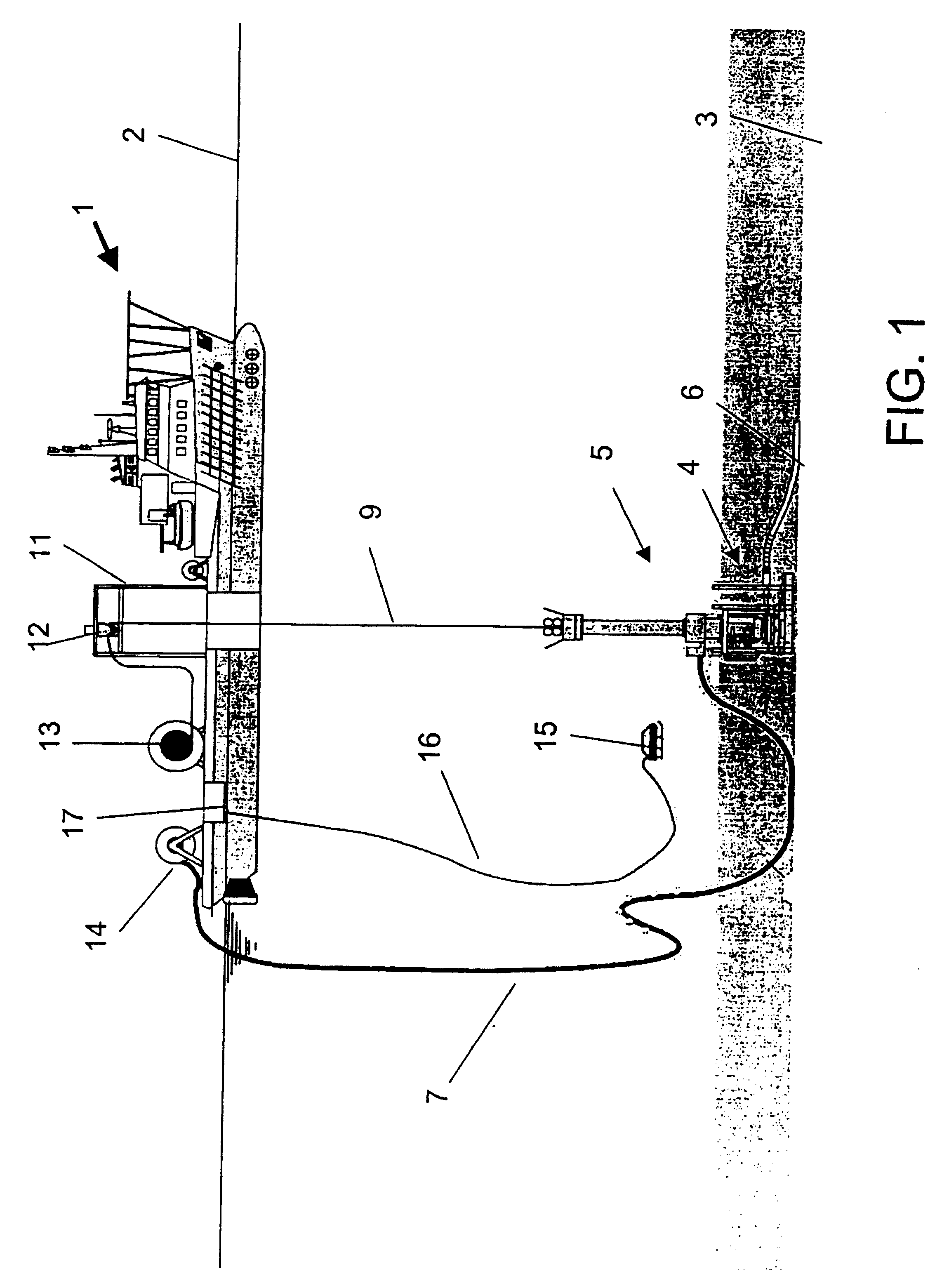

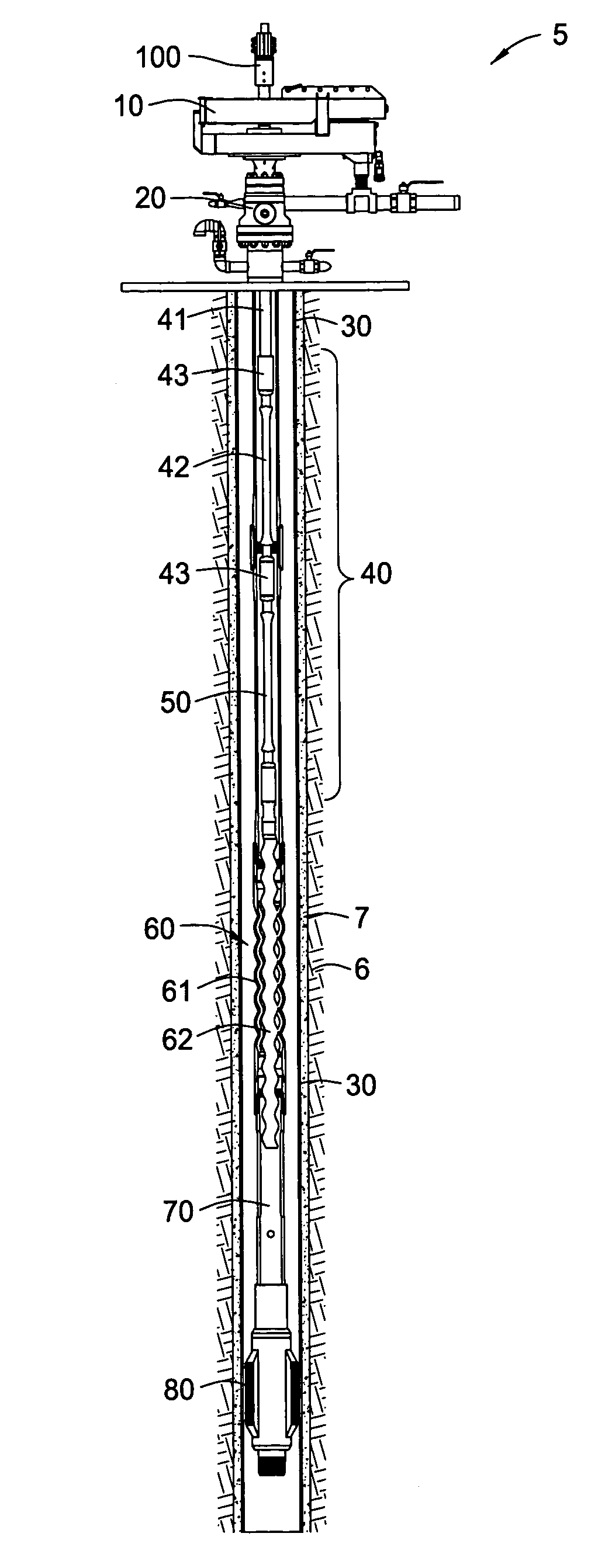

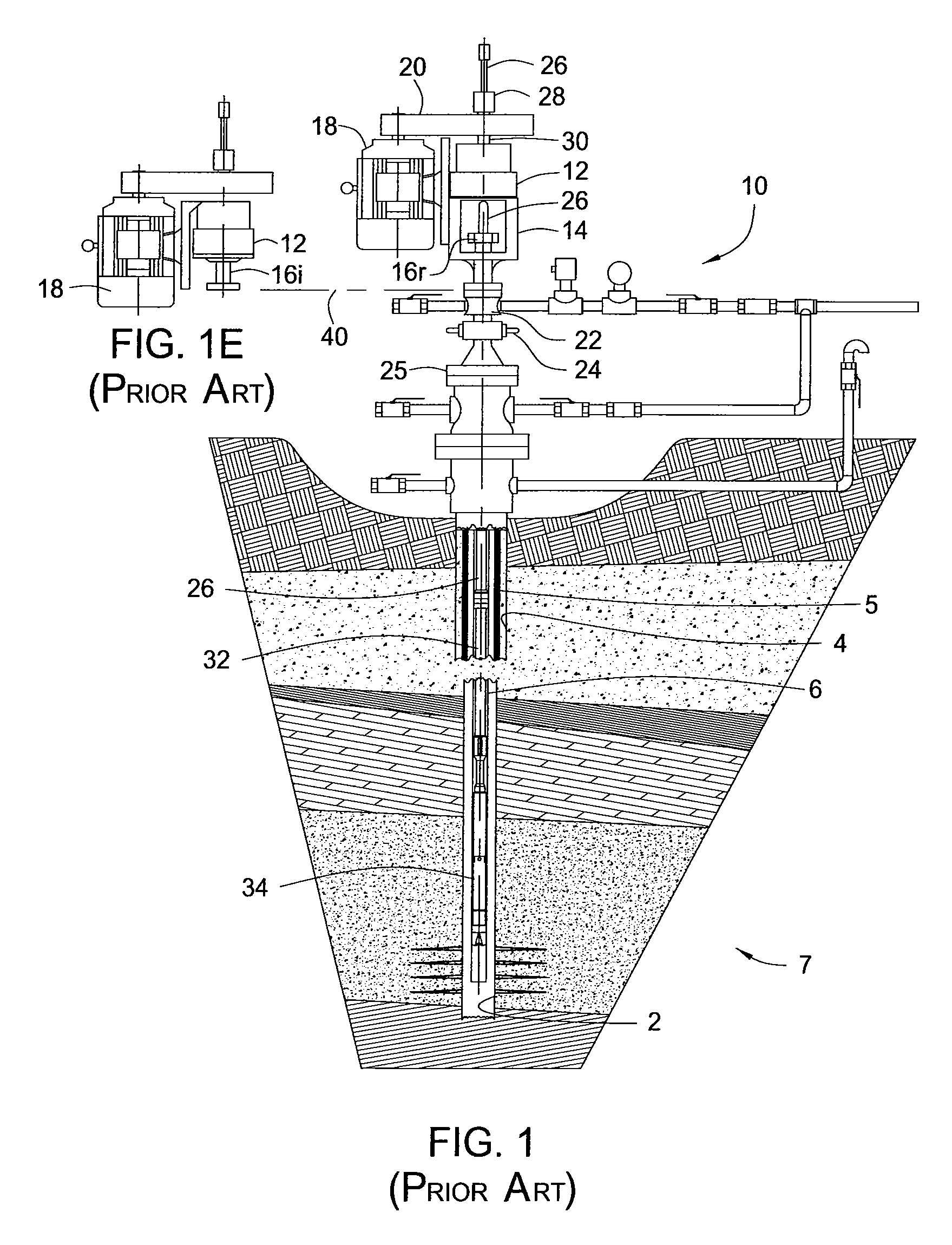

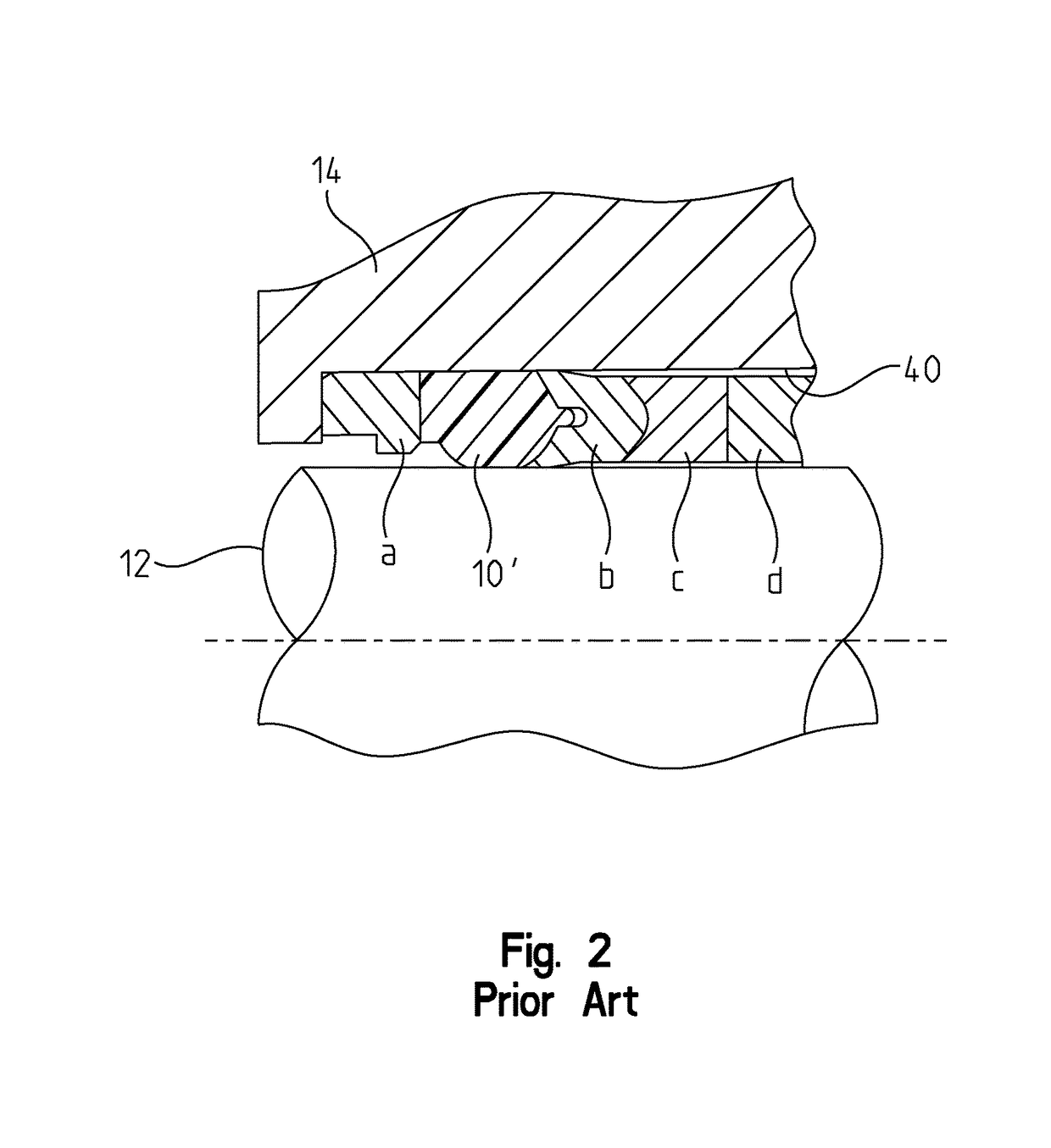

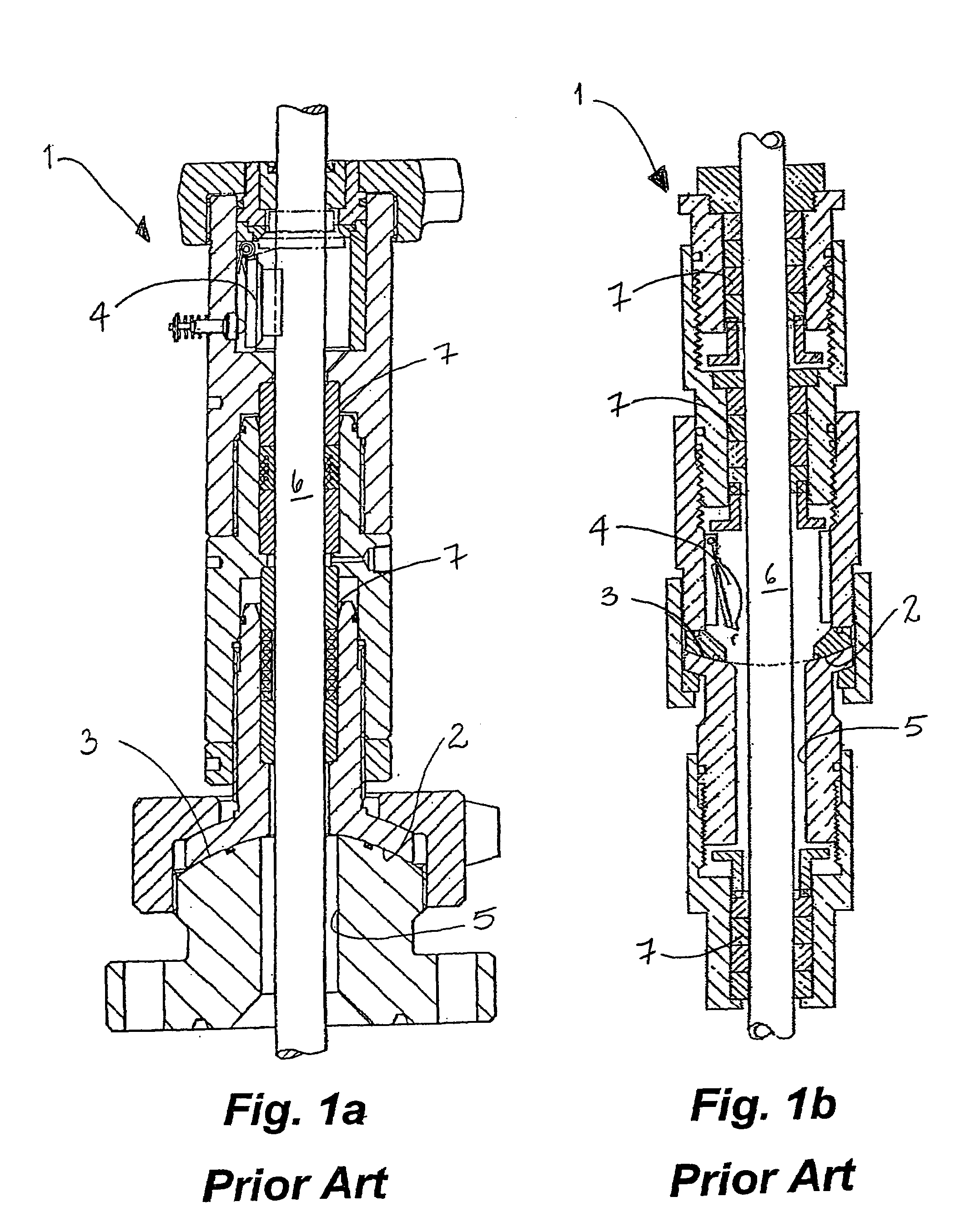

Intervention device for a subsea well, and method and cable for use with the device

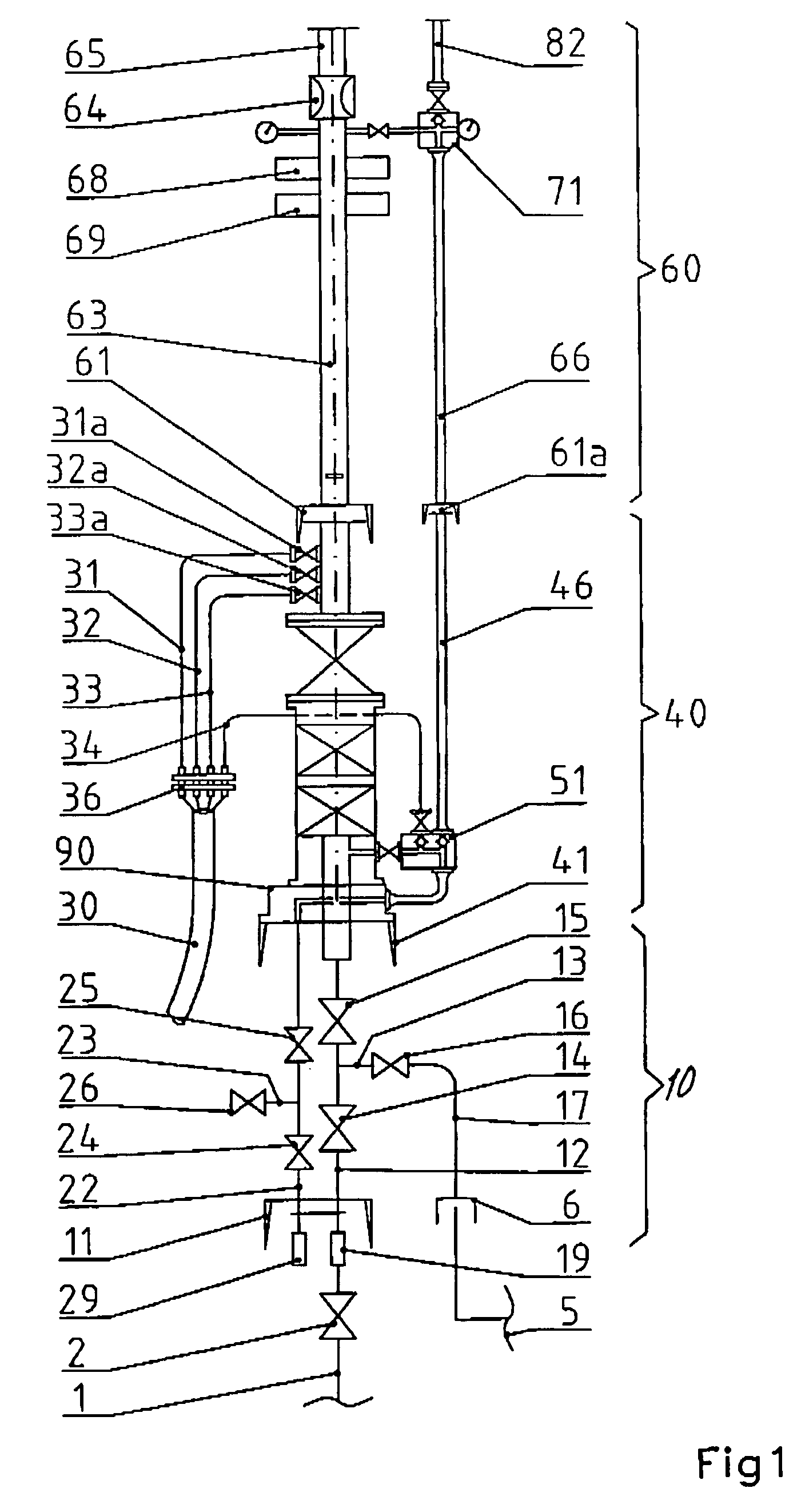

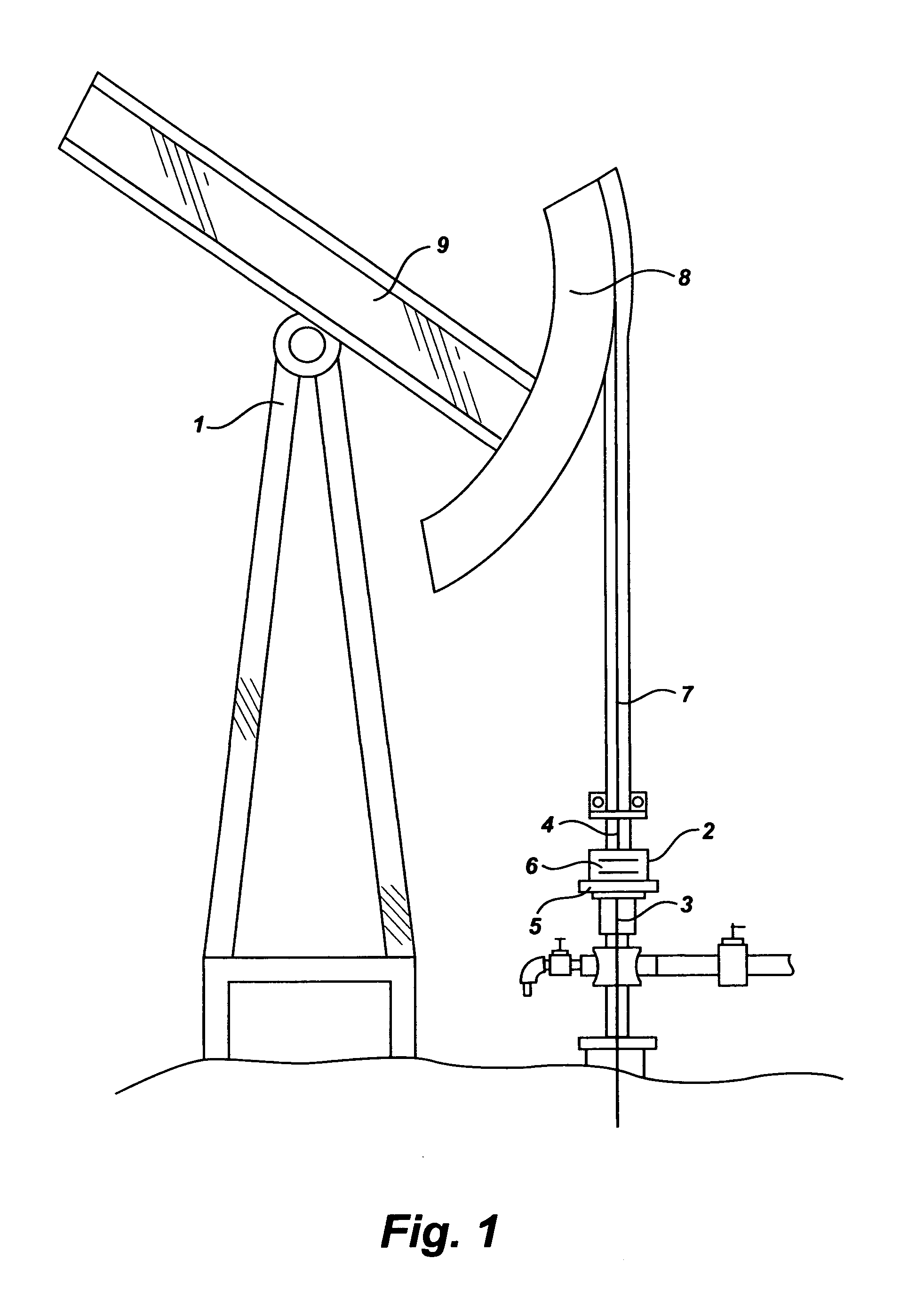

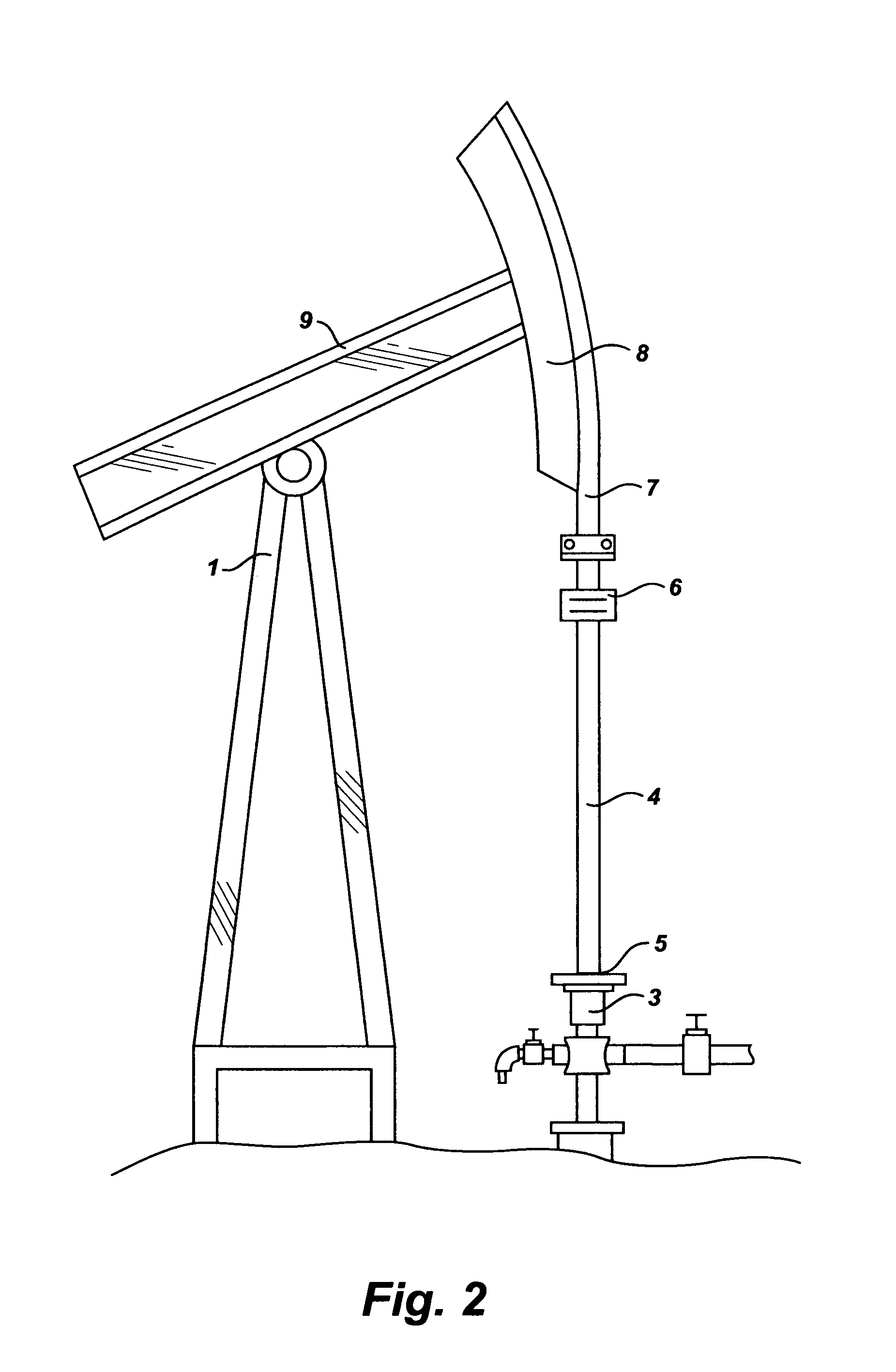

A device for intervention of a subsea oil and / or gas well by means of a tool (8) suspended by a cable (9), fed from or withdrawn to a vessel (1) and driven by a drive mechanism (12) located on the vessel. The device comprises a lubricator (5) having a tool housing for the insertion of the tool into the well, and a stuffing box (40) sealing around the cable after the tool is inserted into the well. According to the invention an injector which drives the cable in the well is located on the lubricator, and is controllable independently of the drive mechanism for the cable located on the vessel. The drive mechanism and the injector may be synchronized in a manner, among others, providing that the cable is hanging in a predetermined arc during the intervention, whereby the vessel may be moved from the well. Moreover, the invention relates to a method and a cable used together with the device.

Owner:FMC KONGSBERG SUS

Pressurized wire line spool and method for using same in conjunction with a universal radial carrier

A well head attachment is provided having an elongated casing or housing structure in which the tool string, including the entire cable or wire line supply, is pressurized, the housing structure being arranged to place the interior thereof in communication with the well bore in a manner whereby well pressure is equalized throughout the assembly during all operations, utilizing a unique pressure-tight adjustably articulated riser assembly with off-set pivotal radial connections for connection between the wellhead attachment and the pressurized cable-supply reel, thus the need for lengthy sinker weights, lubricators and stuffing boxes is reduced or eliminated.

Owner:MORETZ BENNY W +1

Indirect entry cable gland assembly

ActiveUS7115822B1Eliminate needEliminate large costRelieving strain on wire connectionPipesCable glandGrommet

A cable gland assembly adapted to receive a cable and to pass through an opening in a sparking enclosure wall, the cable gland assembly including a cable-receiving gland, a stuffing box, a grommet, an insulator and a cable. The stuffing box has an opening there through, and a grommet-receiving portion having the grommet therein. The grommet-receiving portion is adjacent the cable-receiving gland. The stuffing box also includes a gas terminal portion filled with gas and adjacent the grommet-receiving portion, and an insulator portion having the insulator therein and being adjacent the gas terminal portion.

Owner:JOY GLOBAL UNDERGROUND MINING LLC

Wellhead hydraulic drive unit

InactiveUS6854515B2Eliminate needEliminate alignment issuesDrilling rodsFlexible member pumpsHydraulic cylinderEngineering

The present invention provides a wellhead hydraulic drive unit to operate various styles of downhole pumps, which is installed as an integral part of a wellhead thereby eliminating the need for a stuffing box. The wellhead hydraulic drive unit comprises a hollow hydraulic cylinder having a piston positioned therein, a hydraulic fluid supply attached to the hydraulic cylinder for raising the piston within the hydraulic cylinder, a hollow ram slideably received within the inner wall of the hydraulic cylinder and connected to the piston for reciprocation in response to the piston; and a production tube inserted through the ram for enabling well fluid to be discharged from the well.

Owner:INNOVATIVE PRODN TECH

Intervention device for a subsea well, and method and cable for use with the device

InactiveUS20030155127A1Different lengthEnough timeDrilling rodsFluid removalEngineeringElectric cables

A device for intervention of a subsea oil and / or gas well by means of a tool (8) suspended by a cable (9), fed from or withdrawn to a vessel (1) and driven by a drive mechanism (12) located on the vessel. The device comprises a lubricator (5) having a tool housing for the insertion of the tool into the well, and a stuffing box (40) sealing around the cable after the tool is inserted into the well. According to the invention an injector which drives the cable in the well is located on the lubricator, and is controllable independently of the drive mechanism for the cable located on the vessel. The drive mechanism and the injector may be synchronized in a manner, among others, providing that the cable is hanging in a predetermined arc during the intervention, whereby the vessel may be moved from the well. Moreover, the invention relates to a method and a cable used together with the device.

Owner:FMC KONGSBERG SUS

Stuffing box seal assembly

In accordance with illustrative embodiments of the present invention, the arrangement of a combination stuffing box and pressure transmitter system for use with a reciprocating or rotating rod on pumps or pumping systems is disclosed. The stuffing box assembly includes a housing that holds a primary and second seal that are separated by a lubricating reservoir filled with a refined environmentally friendly sacrificial lubricant from the unknown fluid being pumped. The secondary seal transmits the pressure of the fluid being pumped to the sacrificial lubricant that is being sealed from the atmosphere by the primary seal. The secondary seal has its outside diameter sealing against the housing liner and has its inside diameter sealing on the pump rod. It is free to move with respect to the liner and the rod to transmit the pressure of the fluid being pumped to the sacrificial lubricant between the primary and secondary seals, as well as balance the pressure across the secondary seal. By design, any unbalance of pressure across the secondary seal will always be in the direction of the fluid being pumped. The primary seal operates under optimum conditions to prevent leakage of the refined safe lubricant, having known characteristics, to the environment.

Owner:PALMOUR GRP THE

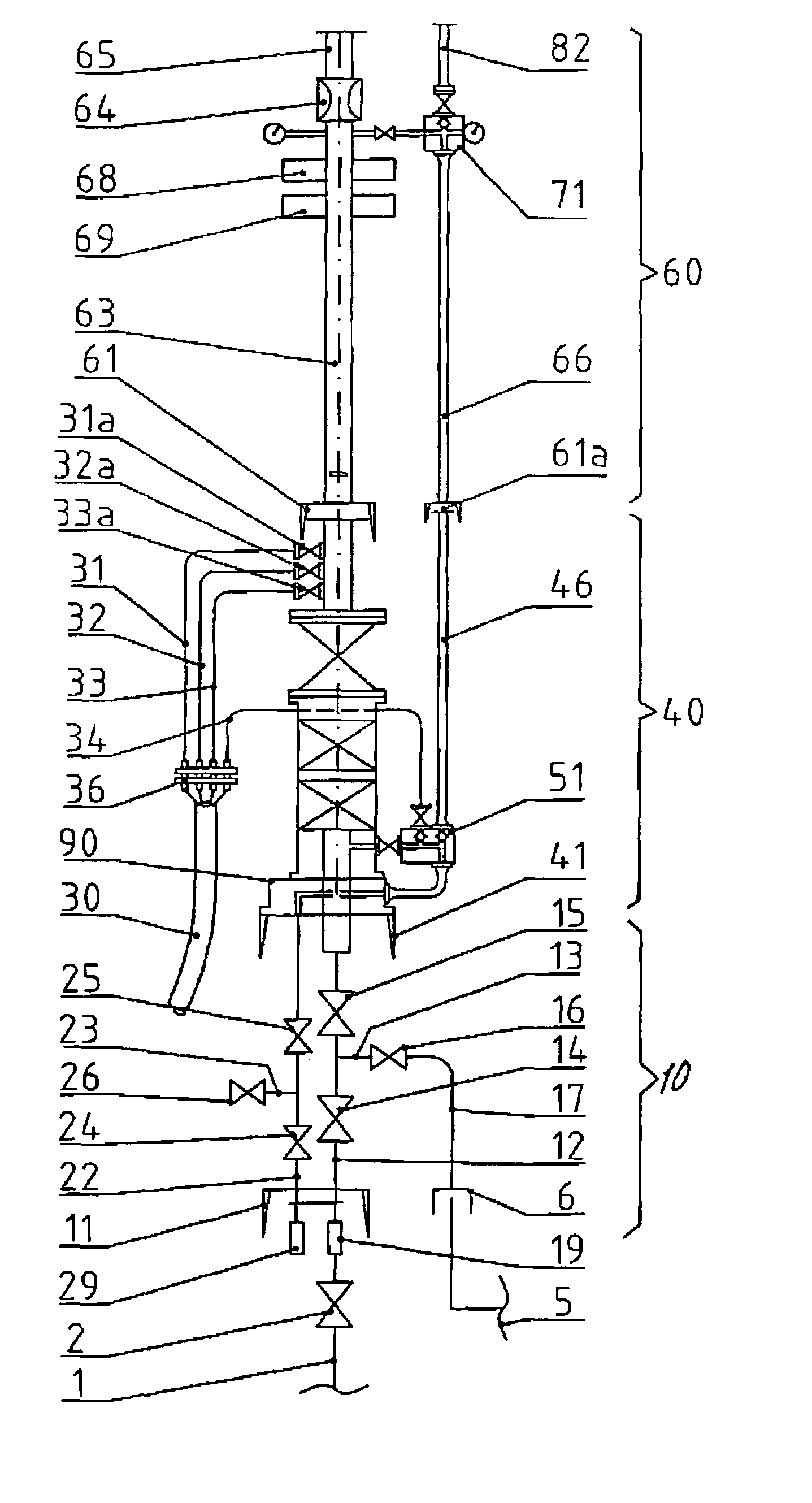

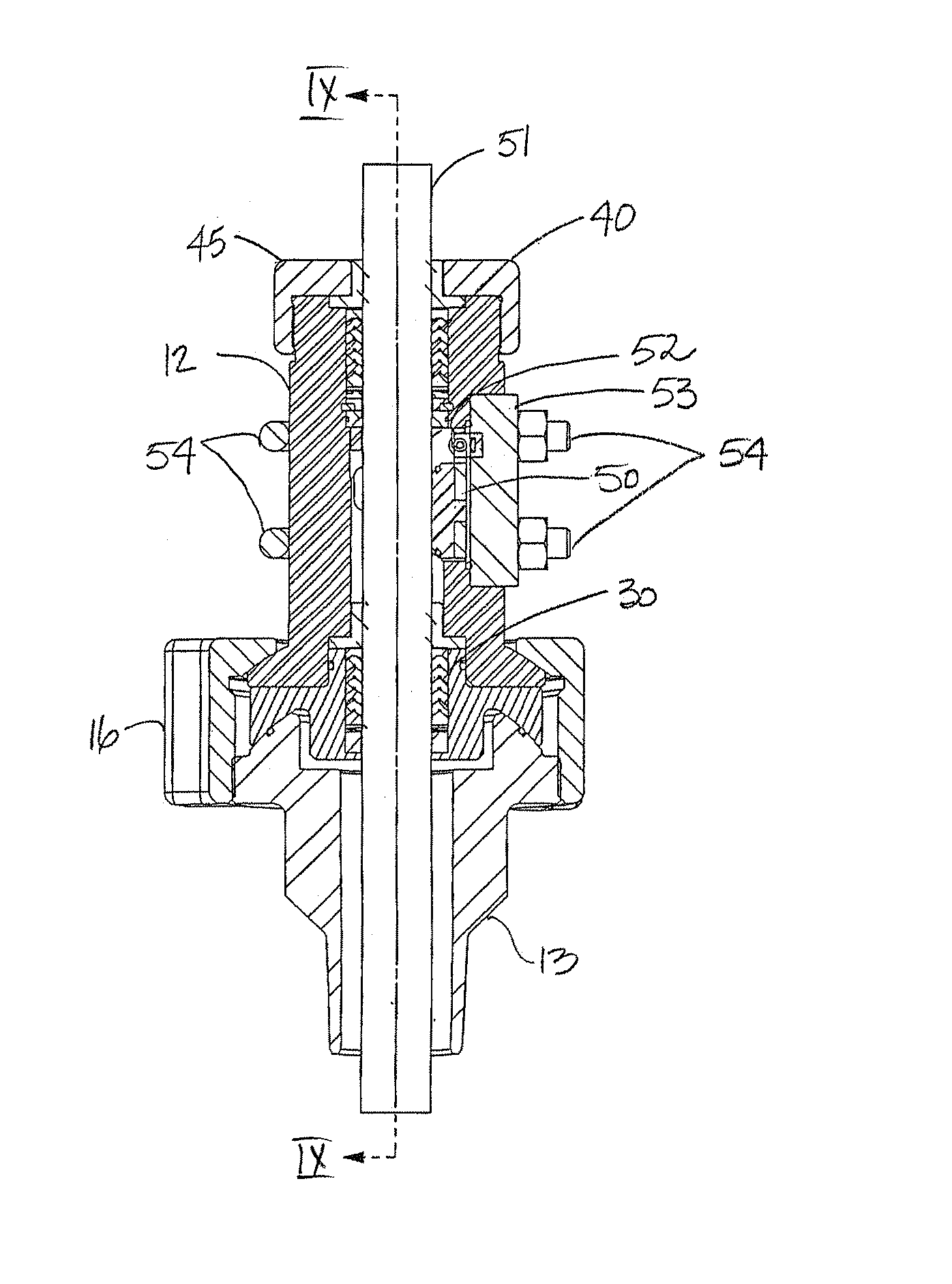

Subsea lubricator device and methods of circulating fluids in a subsea lubricator

InactiveUS7331393B1Preventing hydrate formationPromote circulationSurveyDrilling rodsMarine engineeringBlowout preventer

Subsea lubricator device, comprising a blowout preventer assembly, a tool housing assembly and a stuffing box, intended to be located at a subsea Christmas tree, and methods of circulating fluids in a subsea lubricator. The device comprises a blowout preventer (40) and a lubricator (60). Along the entire length of the device a bypass (46, 66) is located. The bypass communicates fluid with the device via a fluid connection (72) at the upper end of the tool housing and via a valve assembly (51) at the bottom of the blowout preventer. This permits removal of gas or oil being present in the device by circulating the hydrocarbons in the well.

Owner:FMC KONGSBERG SUS

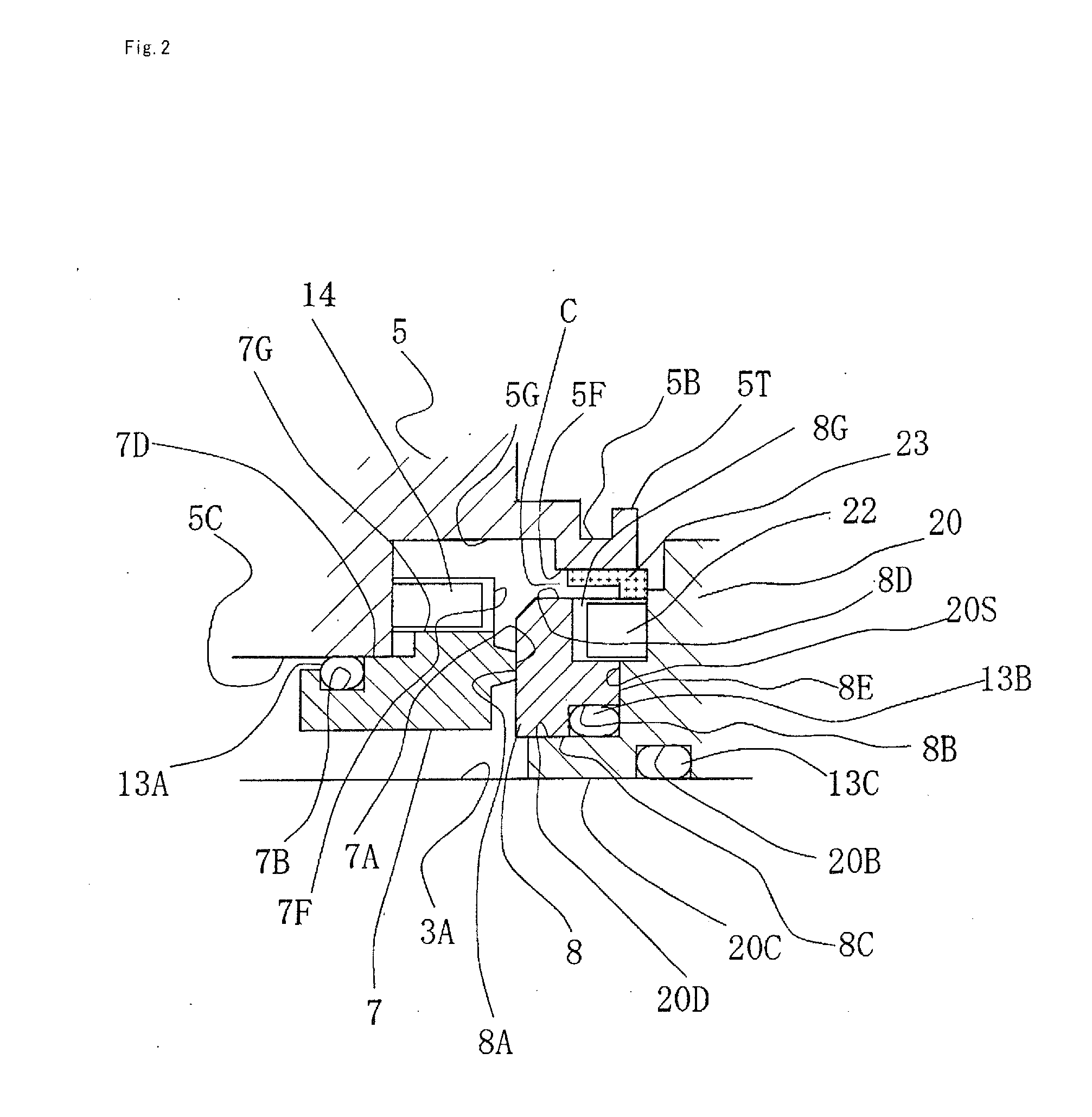

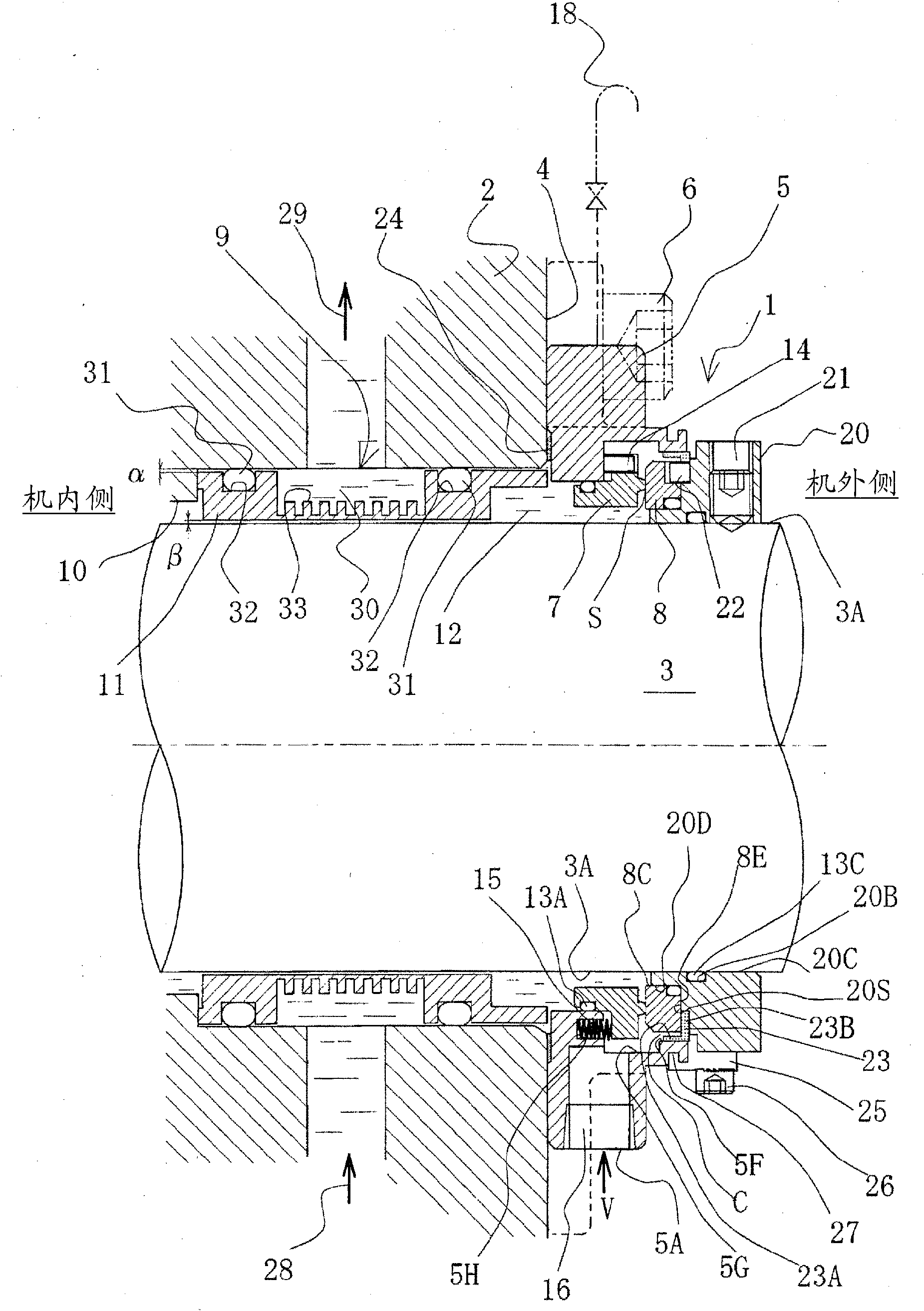

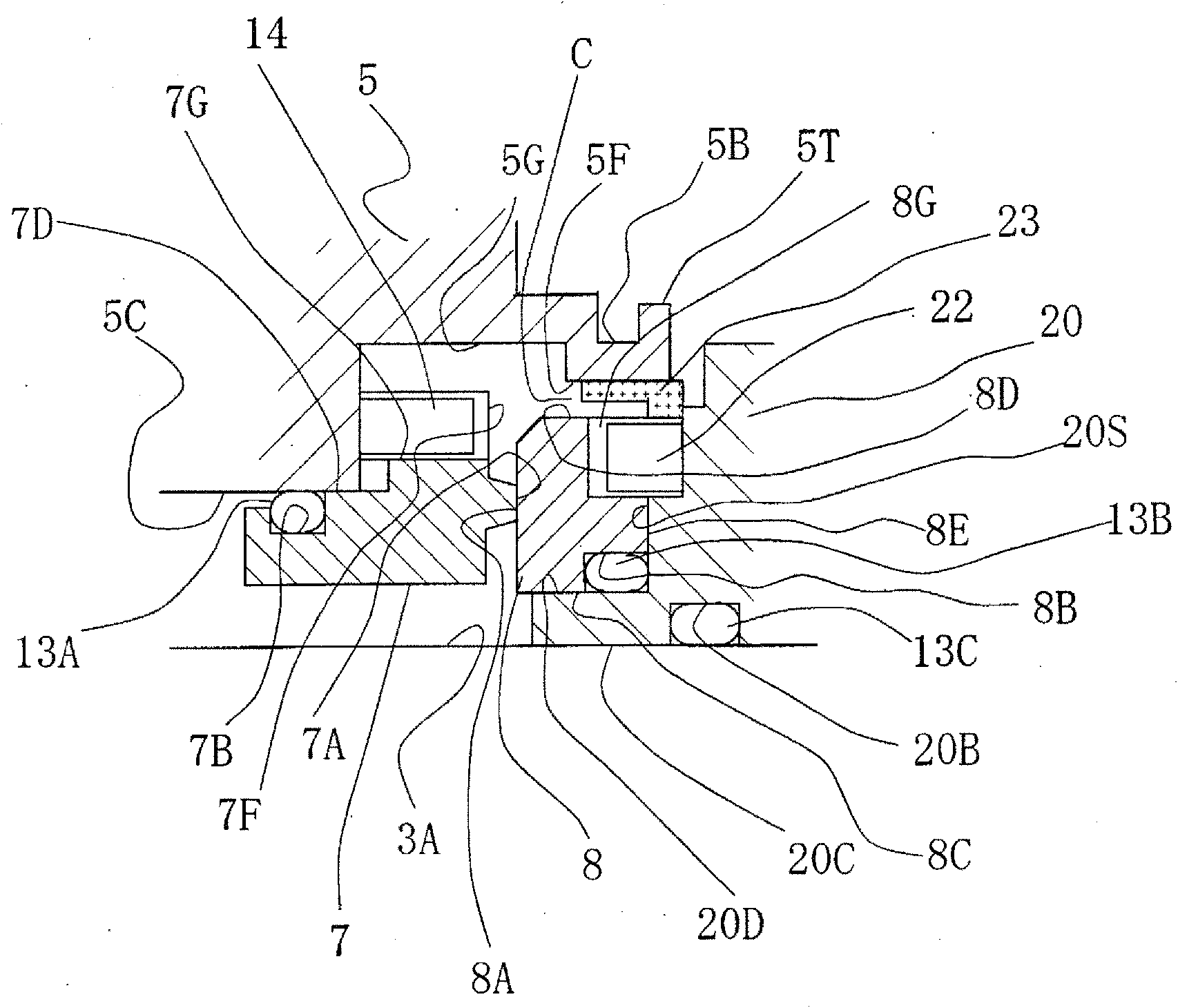

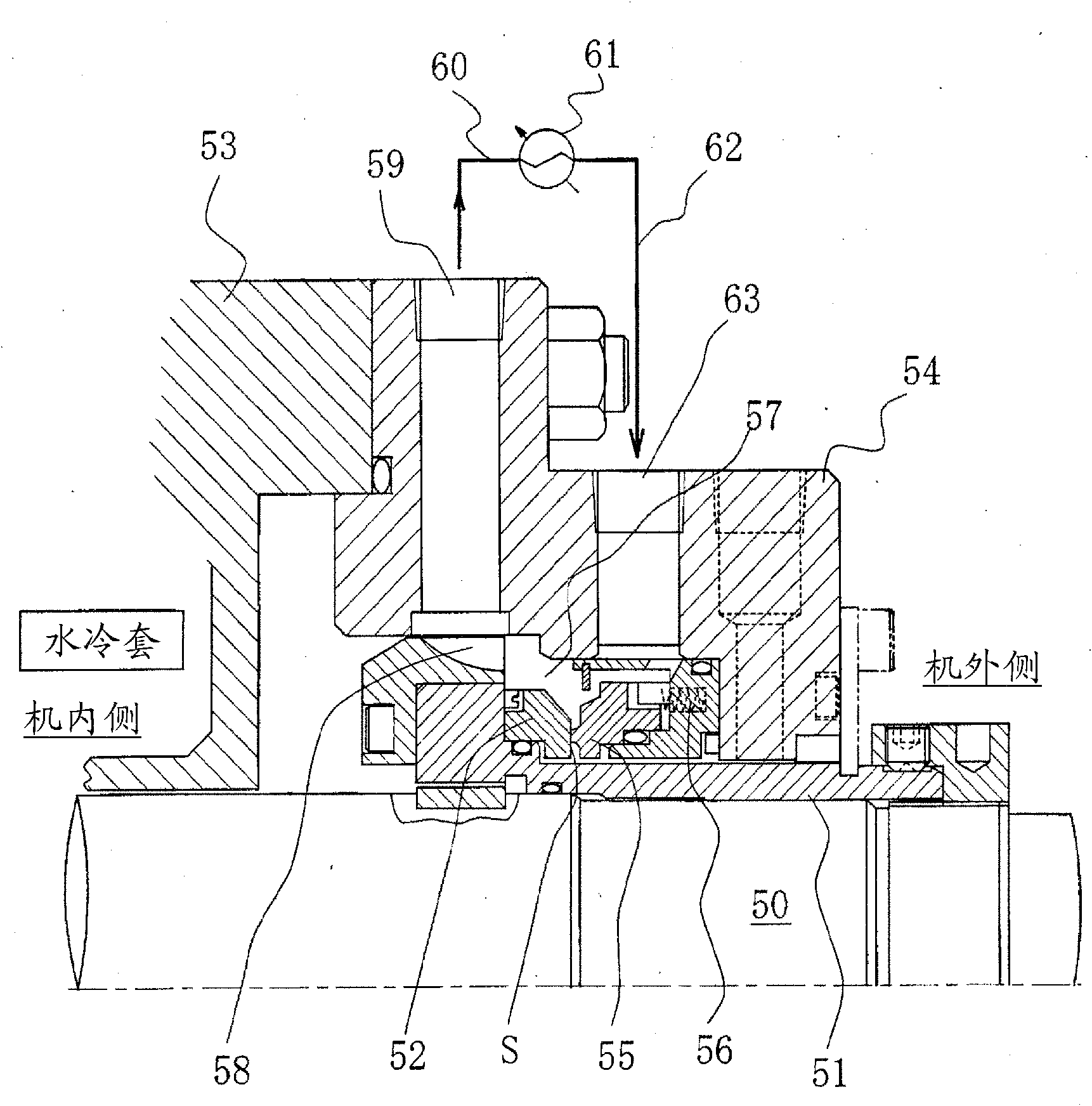

Mechanical seal

ActiveUS20110198813A1Lower initial costReduce water consumptionEngine sealsPump componentsFluid pressureStuffing box

A mechanical seal of an “outside type” for sealing a sealed fluid that may leak from an inside periphery of a sliding face towards an outside periphery is provided. The seal includes a rotating-side sealing element and a stationary-side sealing element disposed so as to be situated externally with respect to a stuffing box. The stationary-side sealing element, which accommodates a spring, is installed on a seal cover that is secured to the housing. The rotating-side sealing element is installed on a collar that is installed directly on the rotating shaft. The rotating side, which comprises the rotating-side sealing element and the collar, is positioned such that rotation takes place in the atmosphere on a machine-exterior side. A balance ratio A2 / A1 is 1 or less, A1 being an axial-direction projection area of the sliding face of the stationary-side sealing element and A2 being an axial-direction projection area that is subjected to a seal fluid pressure acting as a motive force in the axial direction relative to the stationary-side sealing element. An annular cooling jacket is disposed between an inside periphery of the housing and an outside periphery of the rotating shaft.

Owner:EAGLE INDS

Polished rod rotator

Owner:ALI ZADA VAGIF +1

Pump drive head with stuffing box

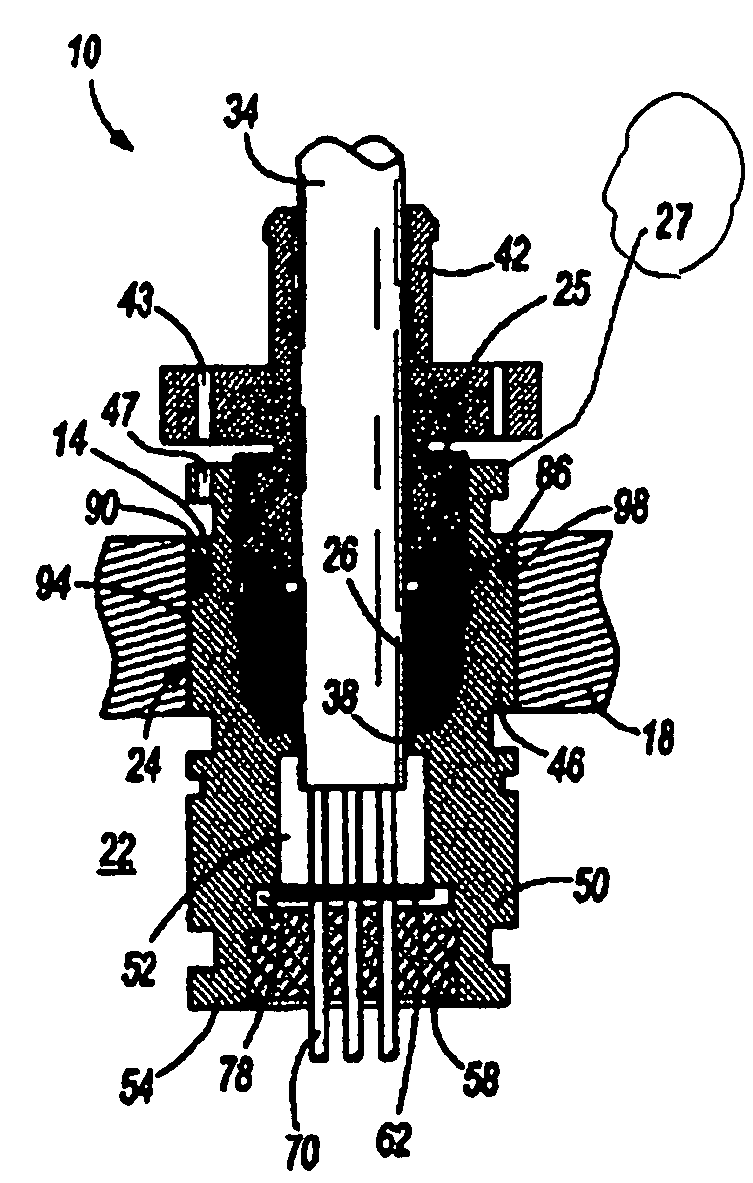

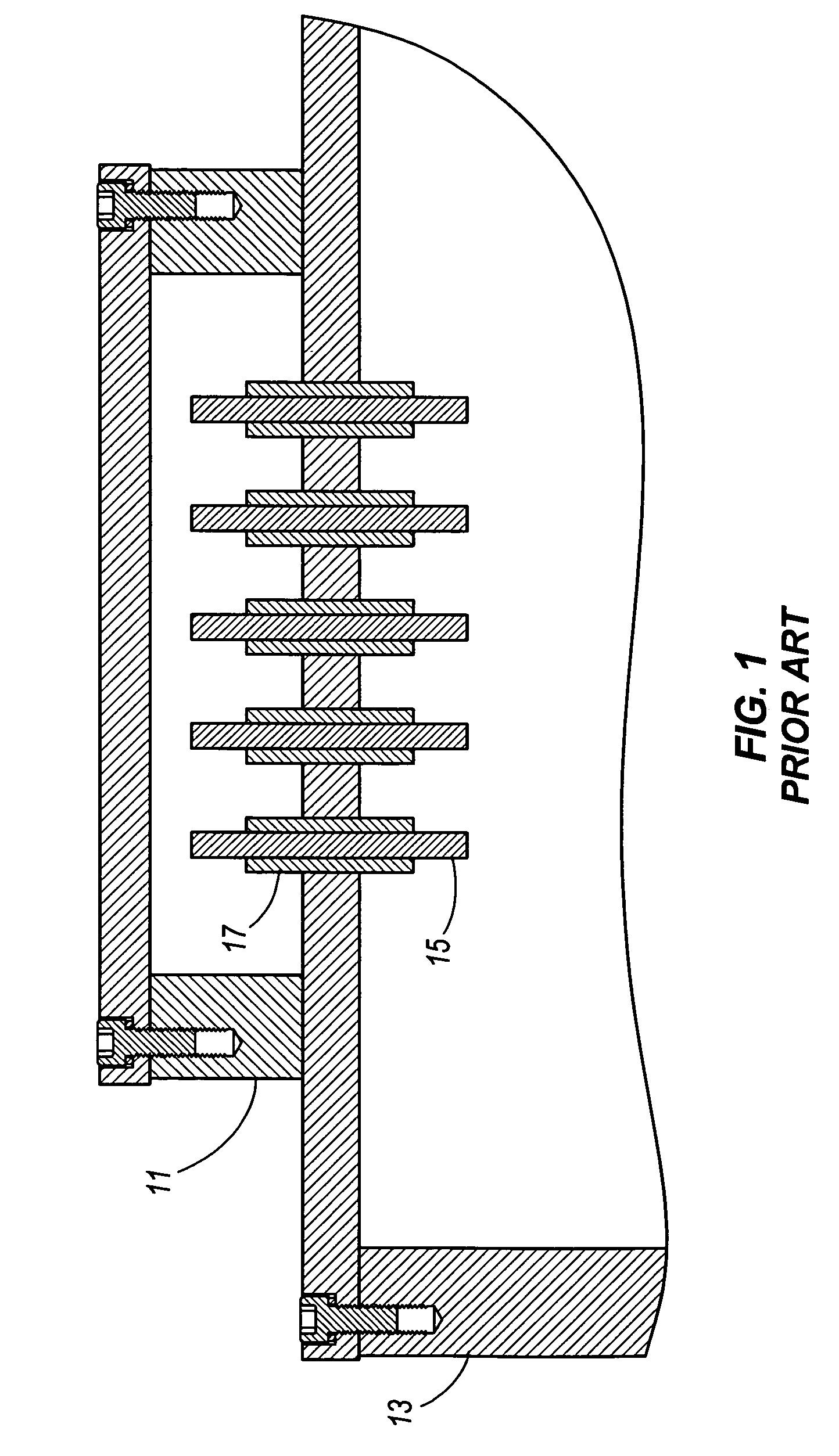

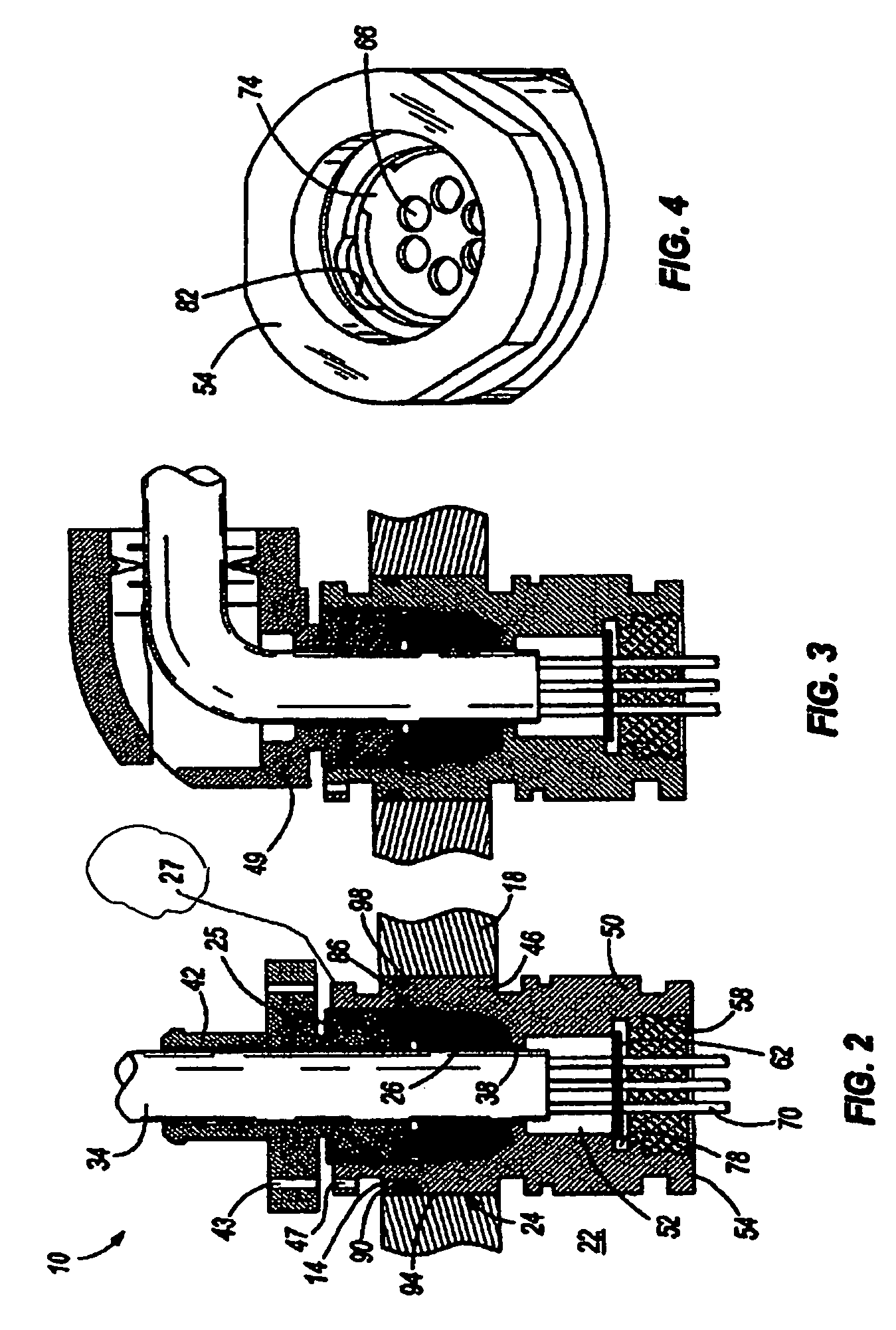

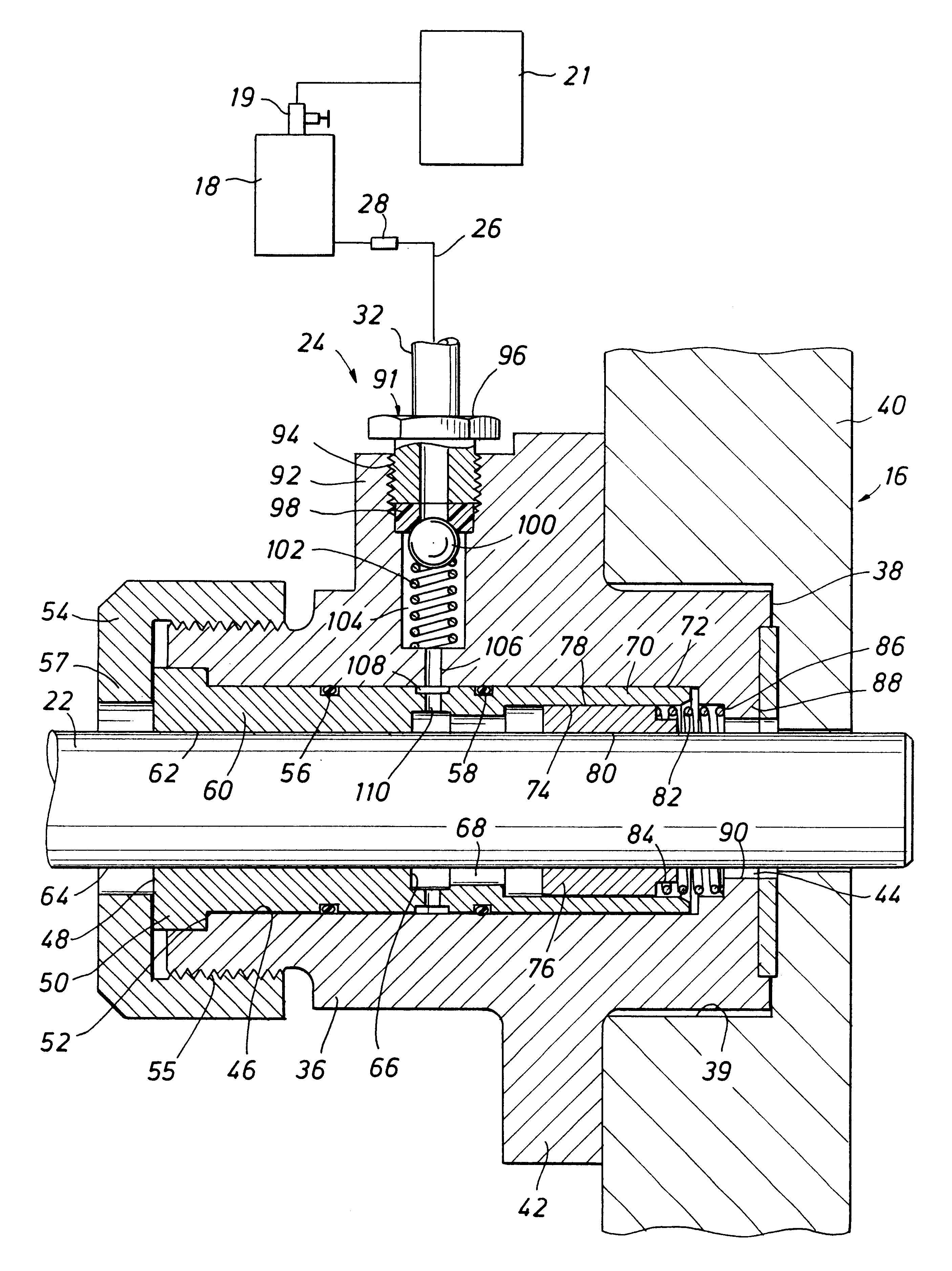

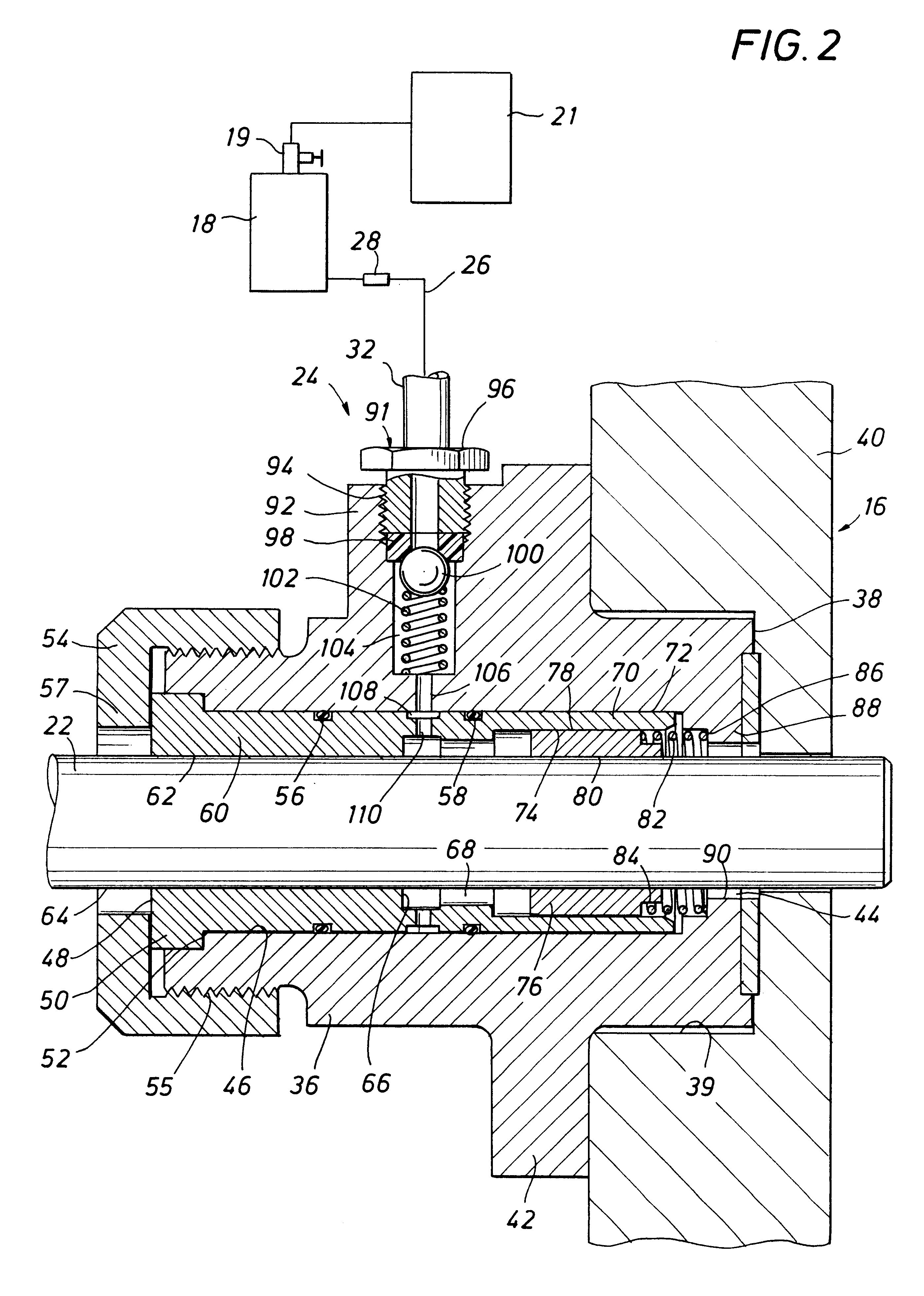

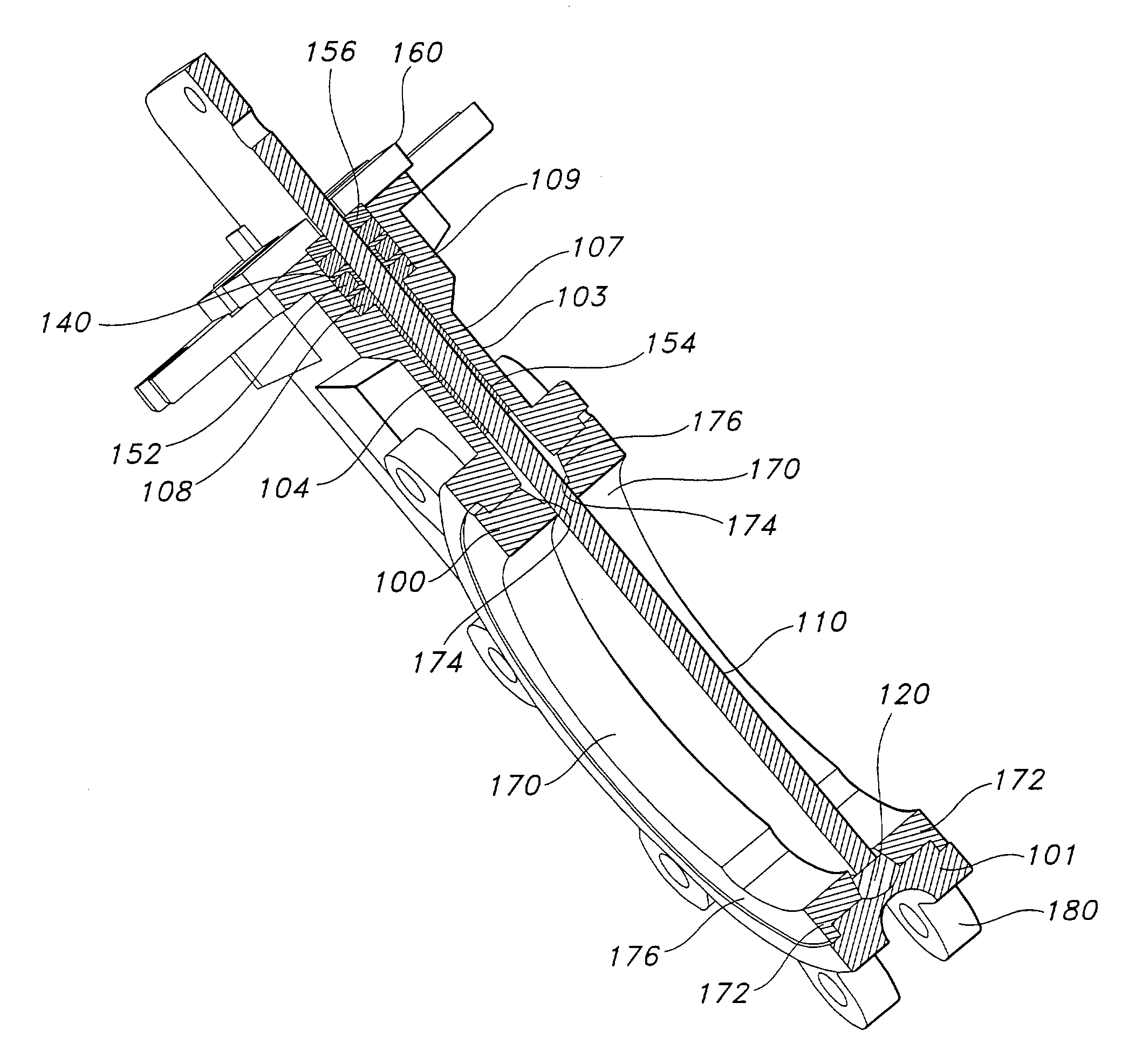

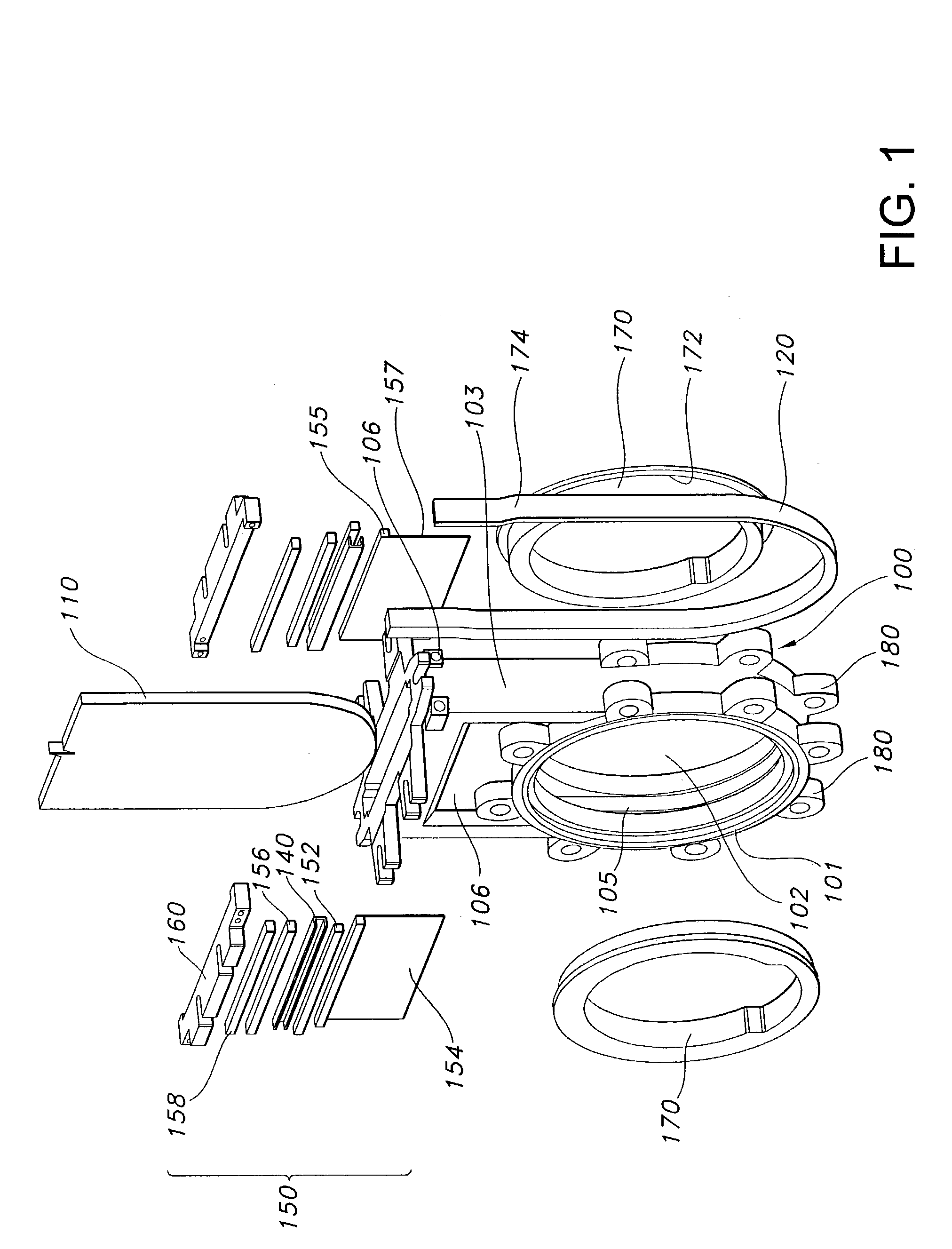

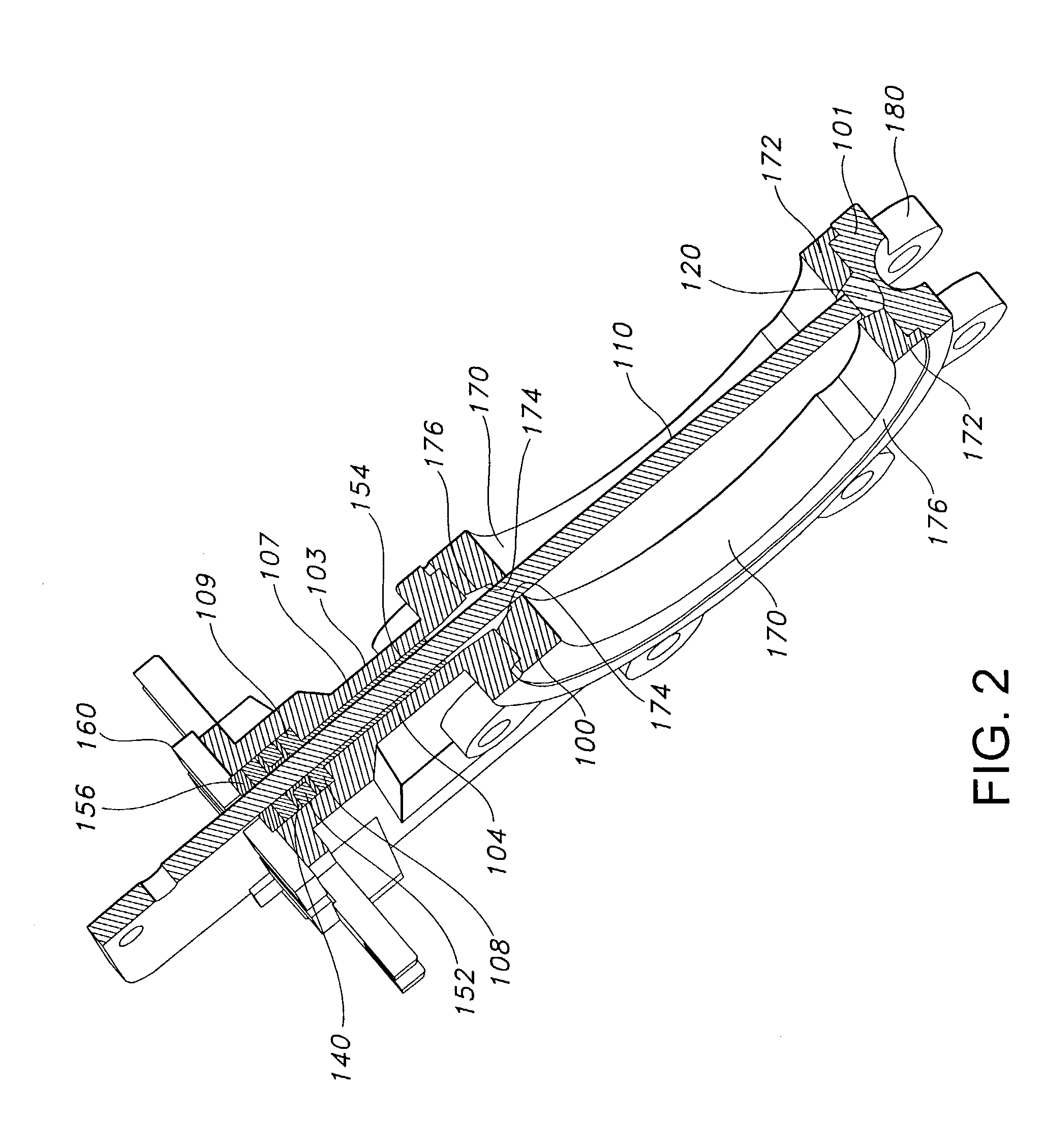

InactiveUS20050045323A1Eliminate replacementRemove tensionDrilling rodsFluid removalGear driveBraking system

A pump drive head for a progressing cavity pump comprises a top mounted stuffing box rotatably disposed around a compliantly mounted standpipe with a self or manually adjusting pressurization system for the stuffing box. To prevent rotary and vertical motion of the polish rod while servicing the stuffing box, a polished rod lock-out clamp is provided with the pump drive head integral with or adjacent to a blow-out-preventer which can be integrated with the pump drive head to save space and cost. A centrifugal backspin braking system located on the input shaft and actuated only in the backspin direction and a gear drive between the input shaft and output shaft are provided.

Owner:OIL ELEVATOR TECH

Mechanical seal

ActiveCN102112785AAvoid damageGood effectEngine sealsPositive displacement pump componentsProject areaEngineering

Owner:EAGLE INDS

Injectable packing unit in a single knife gate body

InactiveUS6959912B2Prevent leakageMinimize movementSpindle sealingsOperating means/releasing devices for valvesEngineeringFluid system

A knife gate valve is provided, comprising: a unitary valve body having a flow channel extending there through, a guide segment and a stuffing box. A knife gate is located in the guide segment, the stuffing box and the flow channel and is slideable between an open and closed position. Lateral seals are provided in the stuffing box and can be replaced while the valve body is connected in its associated fluid system. These seals include an injectable sealing material contained in the stuffing box. A knife gate seat is provided in the valve body for sealing the knife gate and it can be replaced without completely removing the valve body from its associated fluid system.

Owner:ITT MFG ENTERPRISES LLC

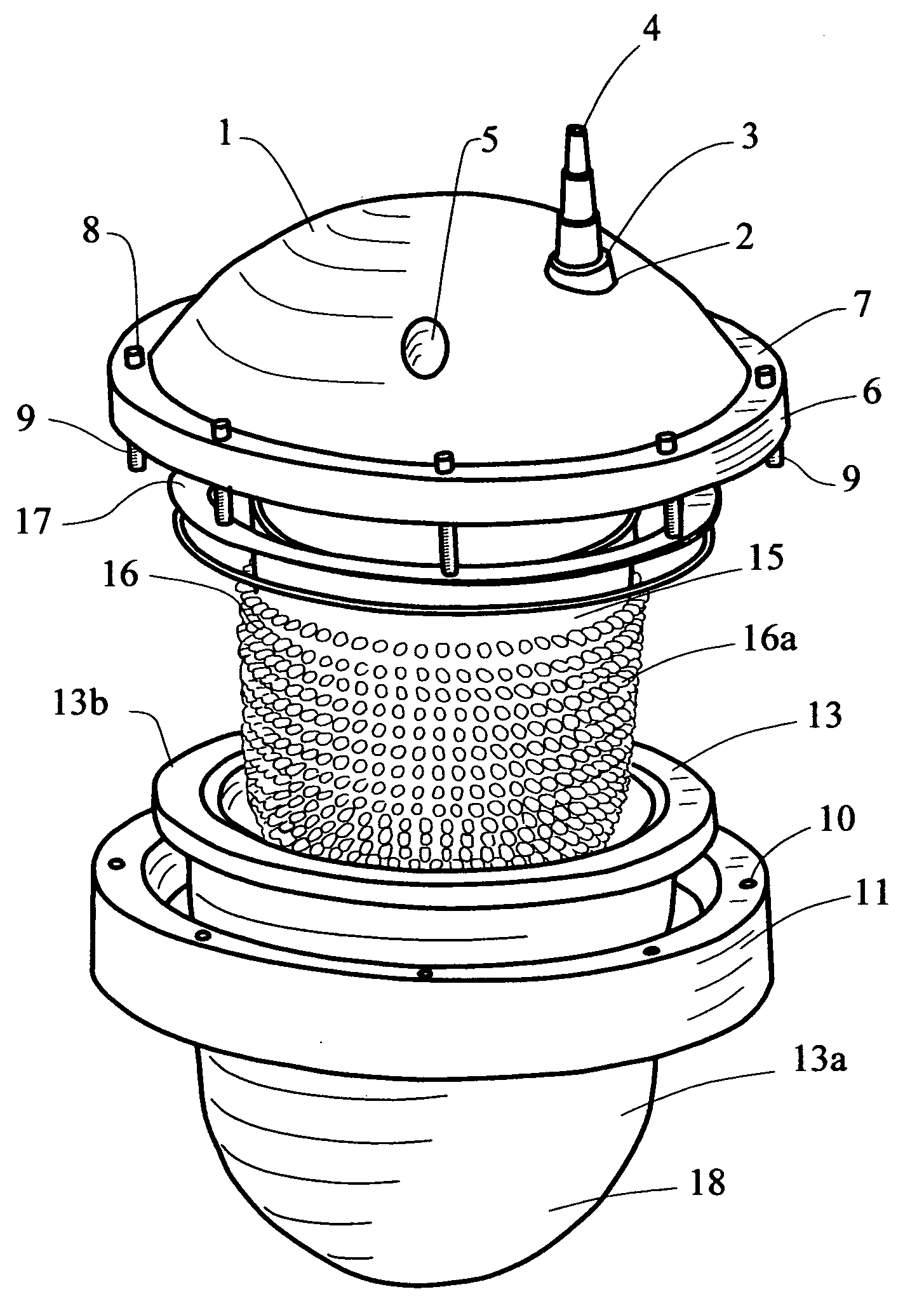

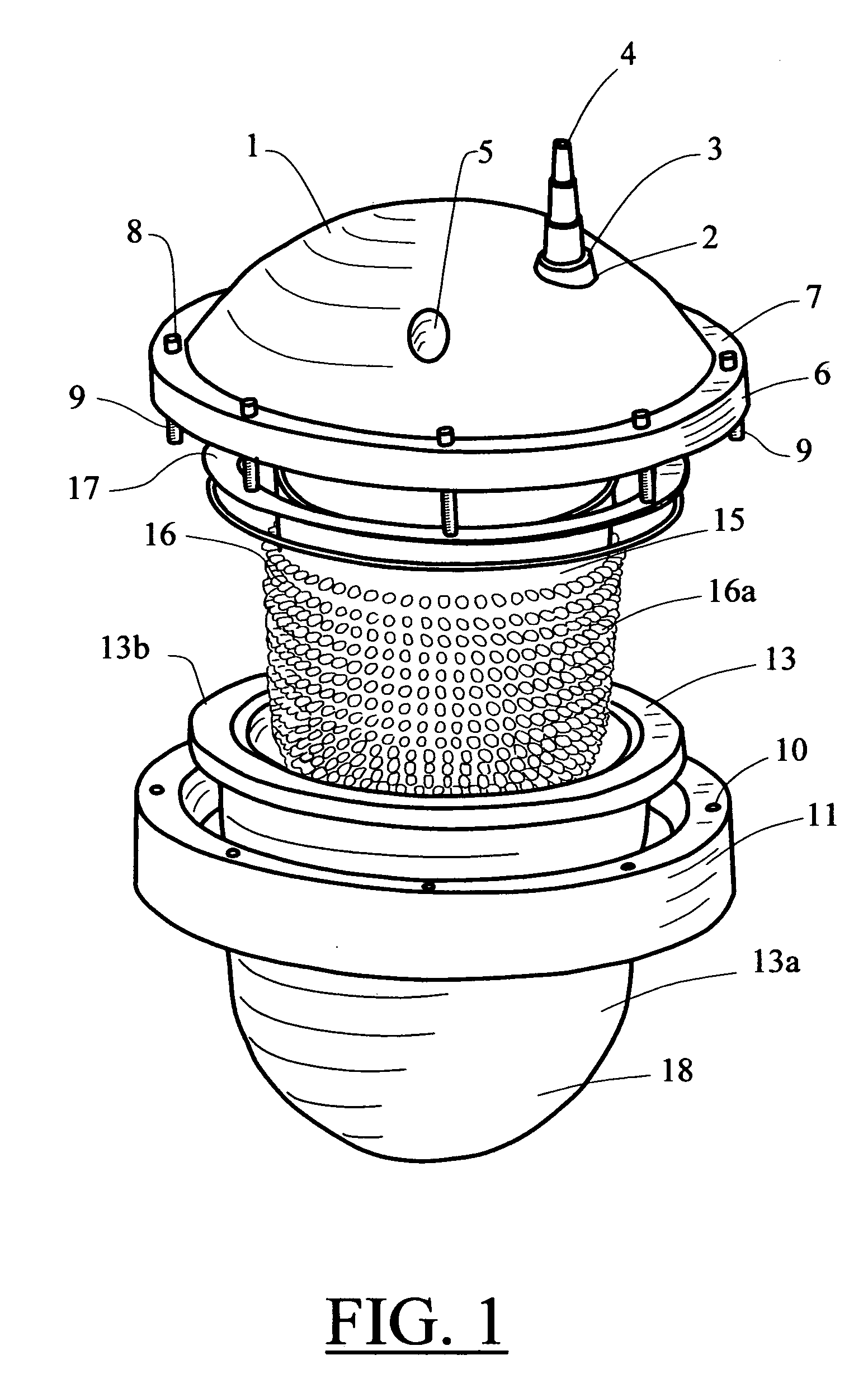

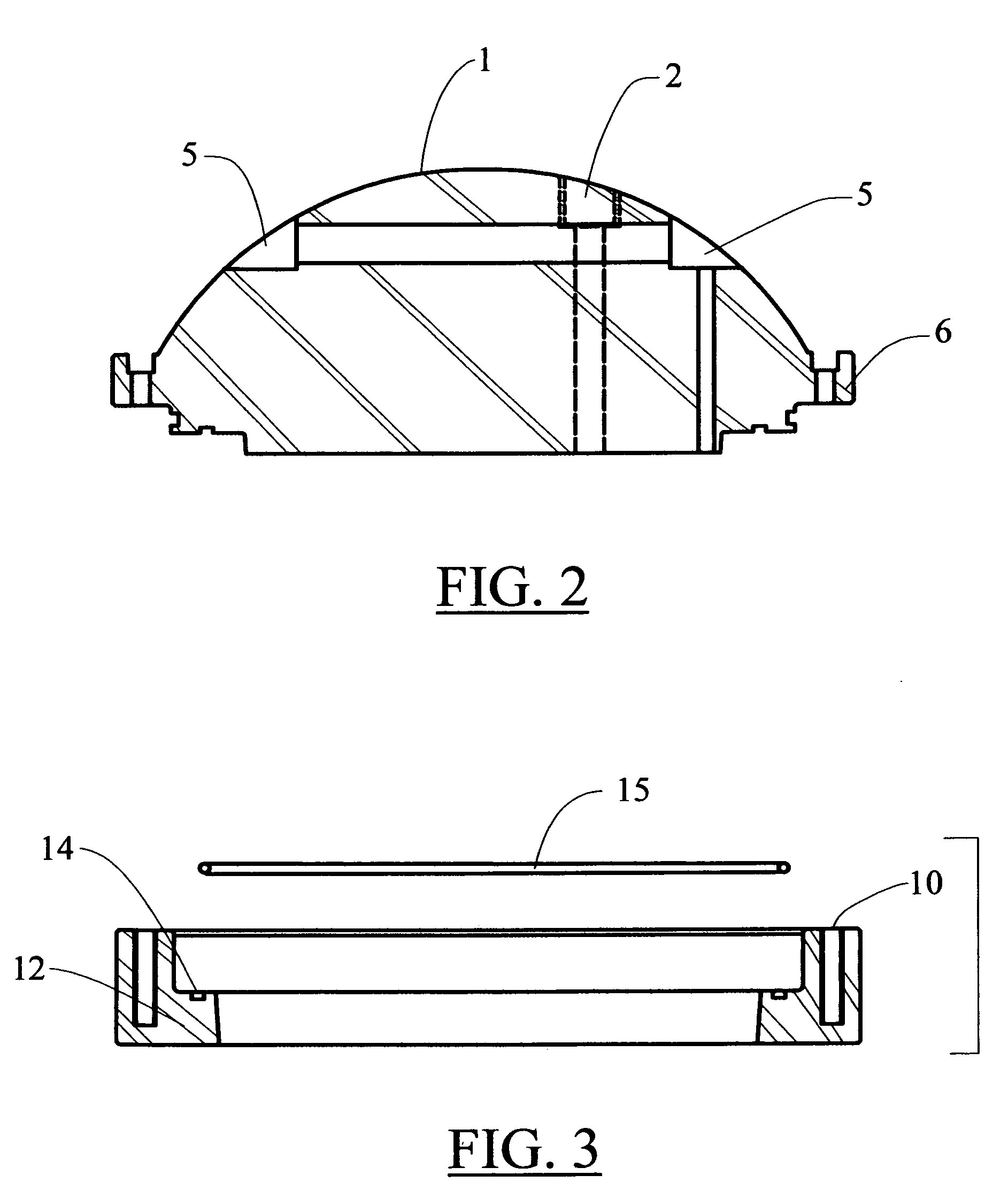

Submersible lamp for use in fotoperiod in processes of handling of salmon species

A submergible lamp for its use or application in photoperiod in processes of smolting, feeding and optimum handling of the reproductive process of salmon species, whose source of illumination are a group of green LED luminaries issuing light with an intensity of 500 to 550 nanometres, by means that allow for a lower consumption than the lamps currently in use and which not only represent economies in terms of costs, but also a favorable environmental impact in terms of a lower consumption of fuel or batteries, which might eventually represent a danger to the environment, becoming waste and by demanding a substantial infrastructure in their installation. The lamp consists of a semi-spherical casing with top side exit for the power cable covered by a threaded stuffing box through which the three-phase cable emerges, with an inner lining on the surface, transverse to said semi-spherical casing has a tunnel, which permits the affixing and installation of the lamp surrounded by a peripheral ring and base walls both of which have equidistant orifices which allow for joining and affixing by means of screw bolts, with the orifices of the central piece with a cylindrical cross section equipped on the inside with a peripheral body or projection that serves as support for the upper edge of the exterior body or glass cupola, with the upper zone of that peripheral body or projection. In turn, the peripheral projection has a central grooving where an “O” ring is placed that prevents water from entering the lamp; also, said lamp has another interior body or LED holder made of plastic, equipped with LEDs, said interior body is placed inside the exterior body of glass.

Owner:NAVARRO ALVAREZ MARIA CRISTINA

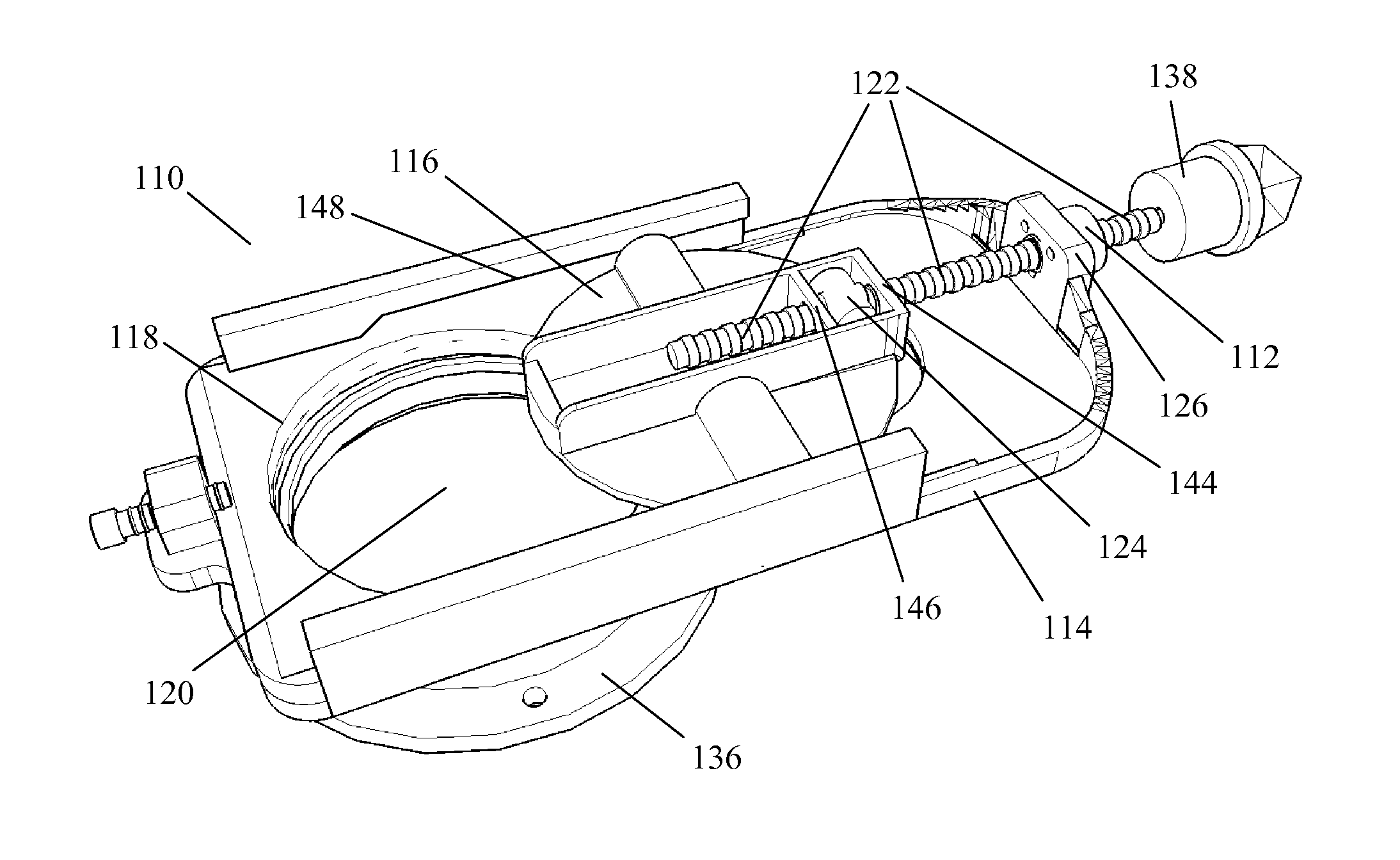

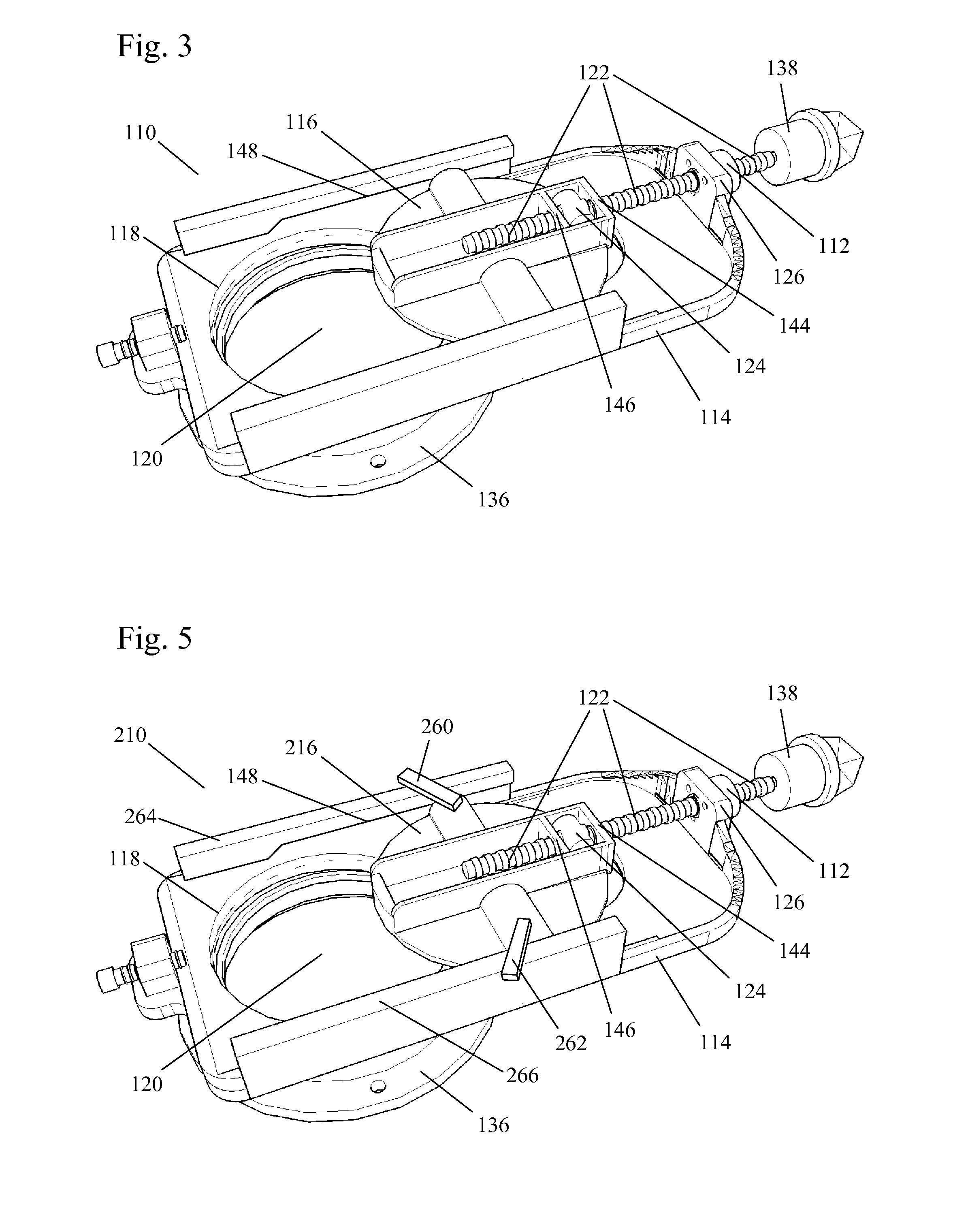

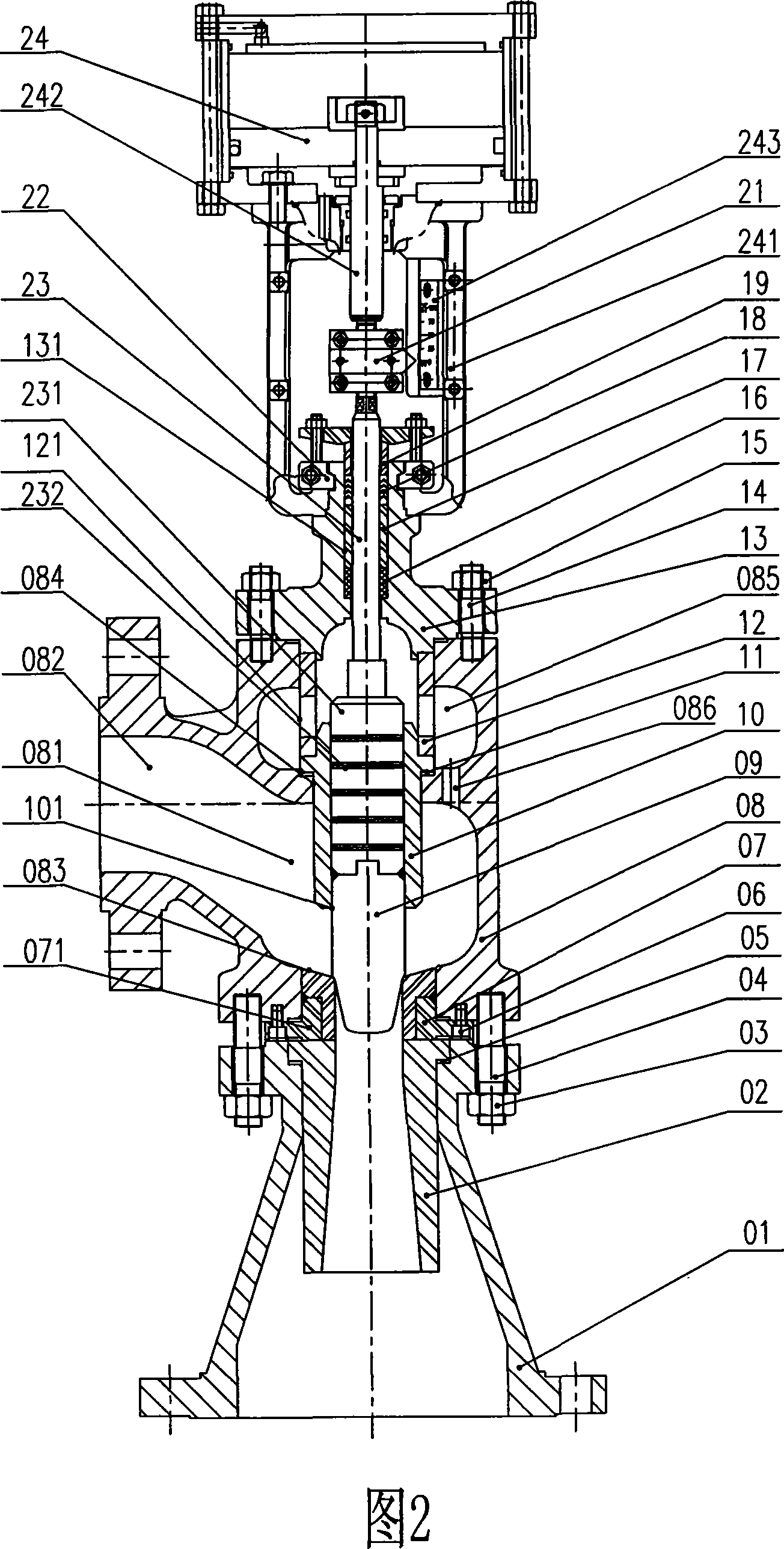

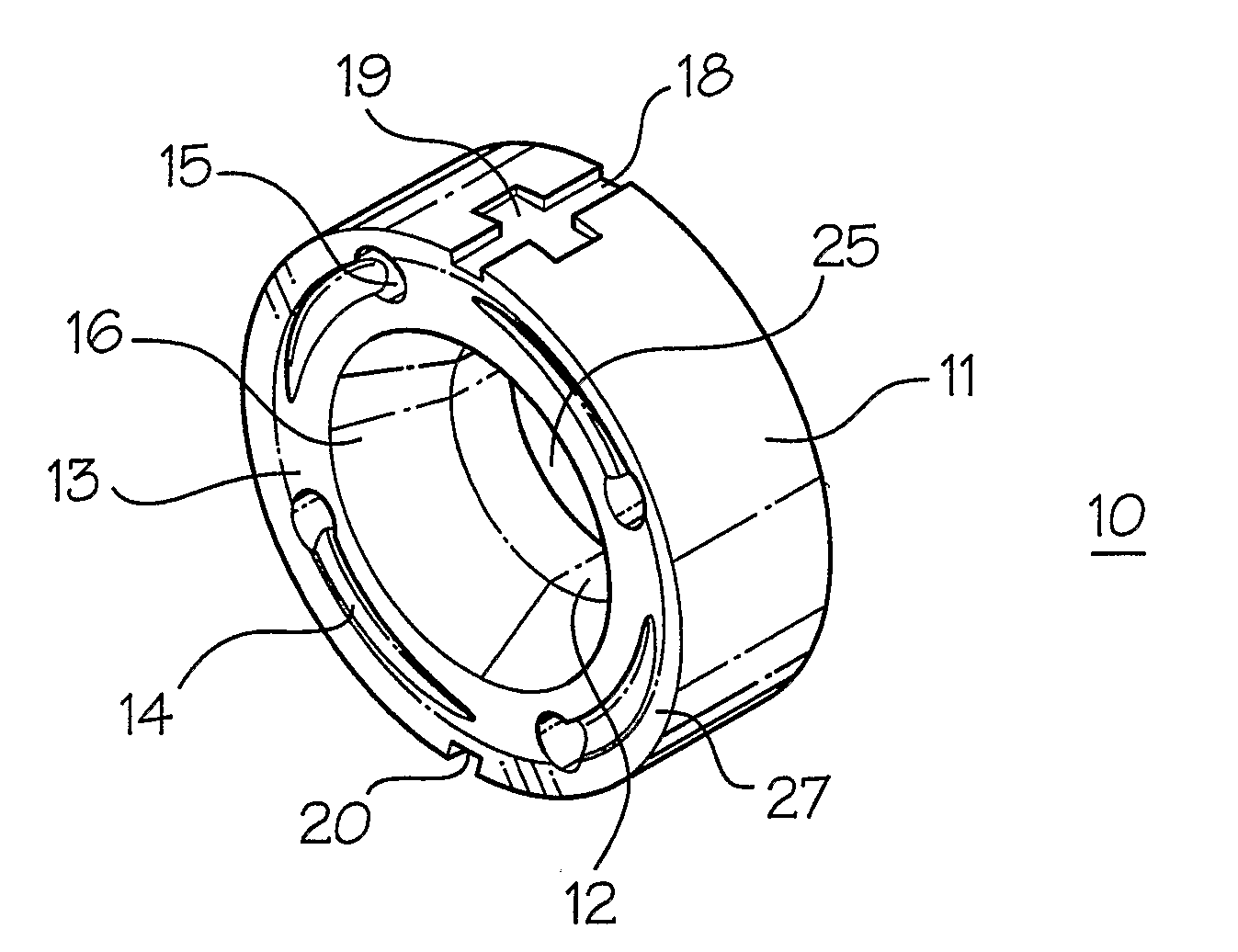

Rotating stuffing box with split standpipe

A system comprising a top mounted rotating stuffing box is provided for use with downhole pump (e.g., Progressing Cavity Pump) applications. The system also includes a split standpipe configuration that allows the stuffing box to be quickly installed or removed as needed. The split standpipe feature combined with the top-mounted aspect of the stuffing box allow for the corresponding drive units to stay intact while the stuffing box is being installed or removed.

Owner:WEATHERFORD TECH HLDG LLC

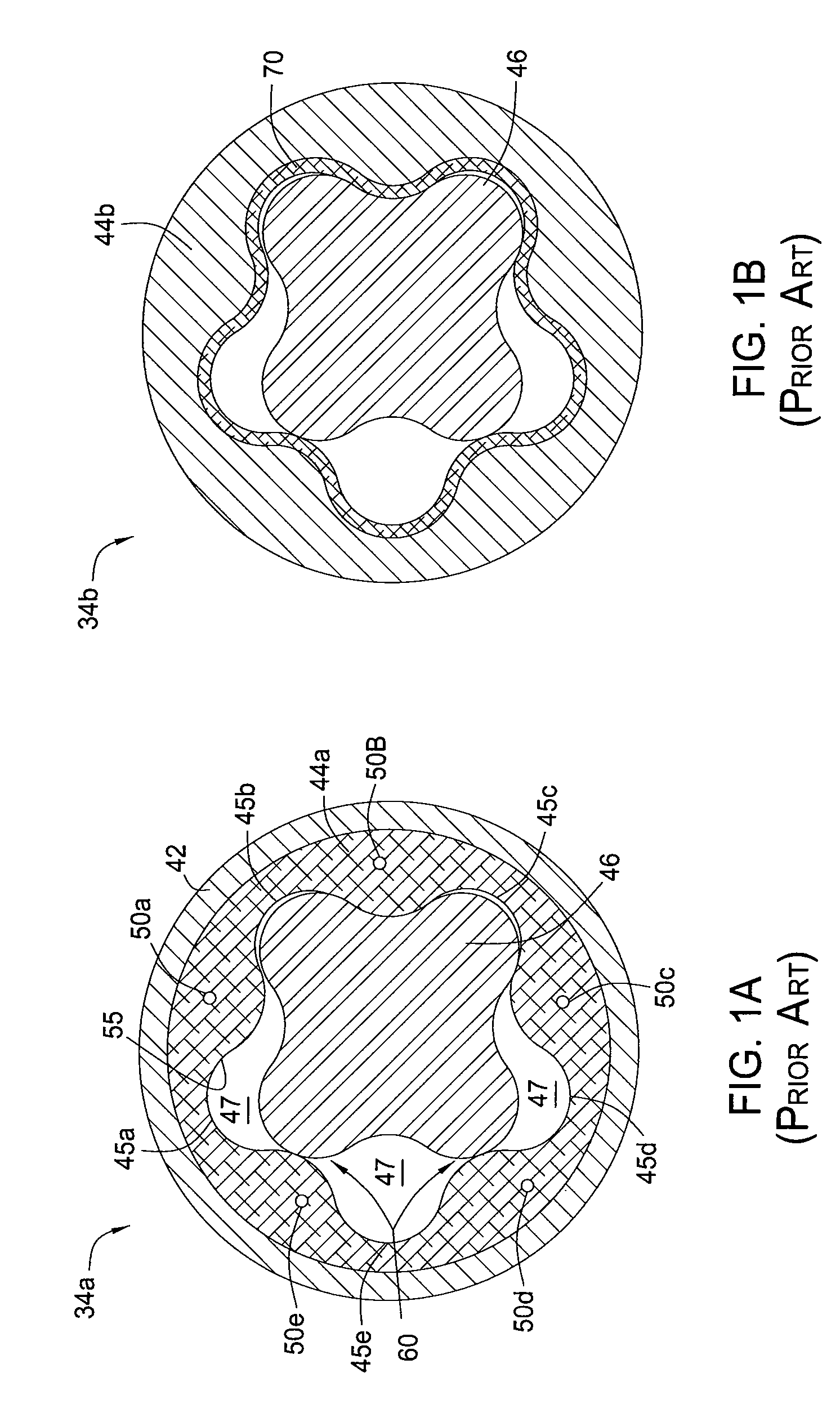

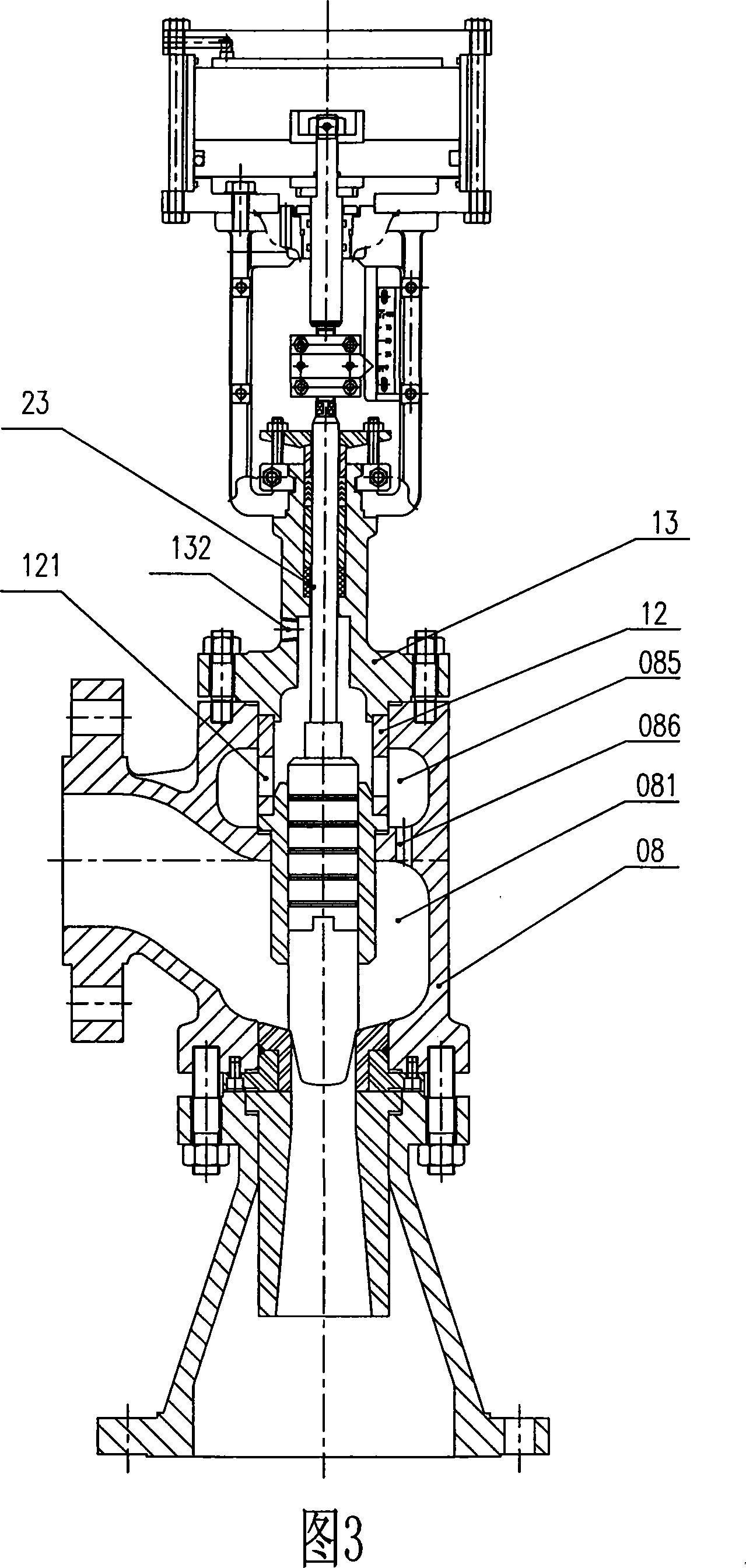

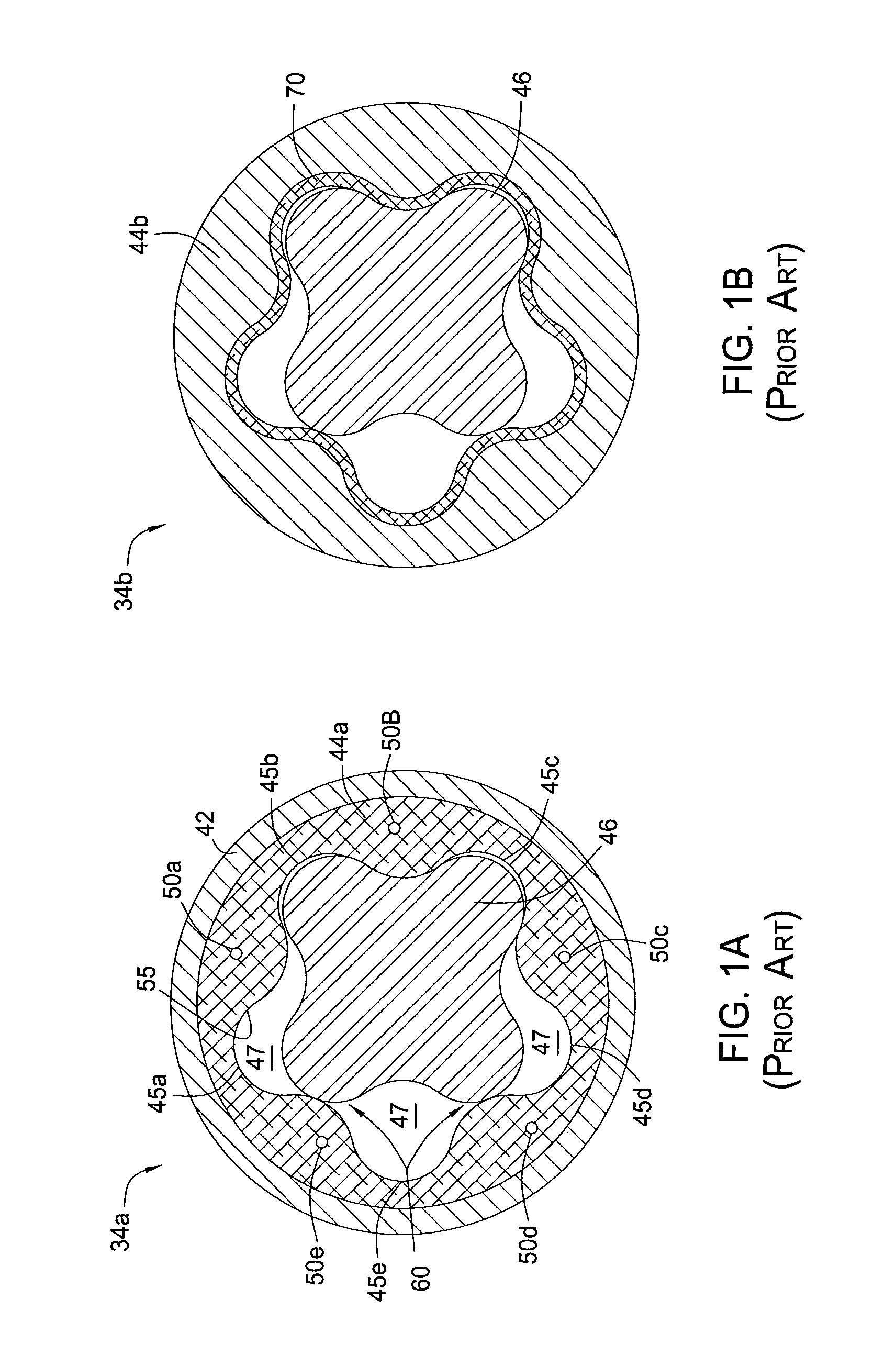

Progressive cavity pump (PCP) drive head stuffing box with split seal

The present invention relates to a split seal for a progressive cavity pump (PCP) drive head stuffing box. In one embodiment, a mechanical seal assembly for a pump is provided. The mechanical seal assembly includes a seal housing; first and second semi-annular mechanical seals, each at least partially disposed in the seal housing bore, and a seal sleeve rotatable relative to the seal housing; third and fourth semi-annular mechanical seals, each disposed at least partially in the seal sleeve bore, at least one of the third and fourth seals rotationally coupled to the seal sleeve; and one or more biasing members biasing the mechanical seals into engagement.

Owner:WEATHERFORD TECH HLDG LLC

Sluice gate valve

The sluice gate valve includes at least one binding reduction mechanism to reduce binding during actuation of the sluice gate. In one embodiment the mechanism includes a the guide elements and the tracks, the guide elements and the tracks being arranged such that a predetermined amount of rotational motion of the gate around the stem is permitted during actuation of the valve to reduce valve binding. In another embodiment the mechanism includes a stuffing box assembly including a stuffing box, a bushing, and a collar, where a convex curved surface of the collar slides on a concave curved surface of the bushing such that a predetermined amount of pivoting of the stem up to a predetermined cone angle is allowed. In a preferred embodiment the sluice gate valve includes both mechanisms.

Owner:PENN TROY MACHINE

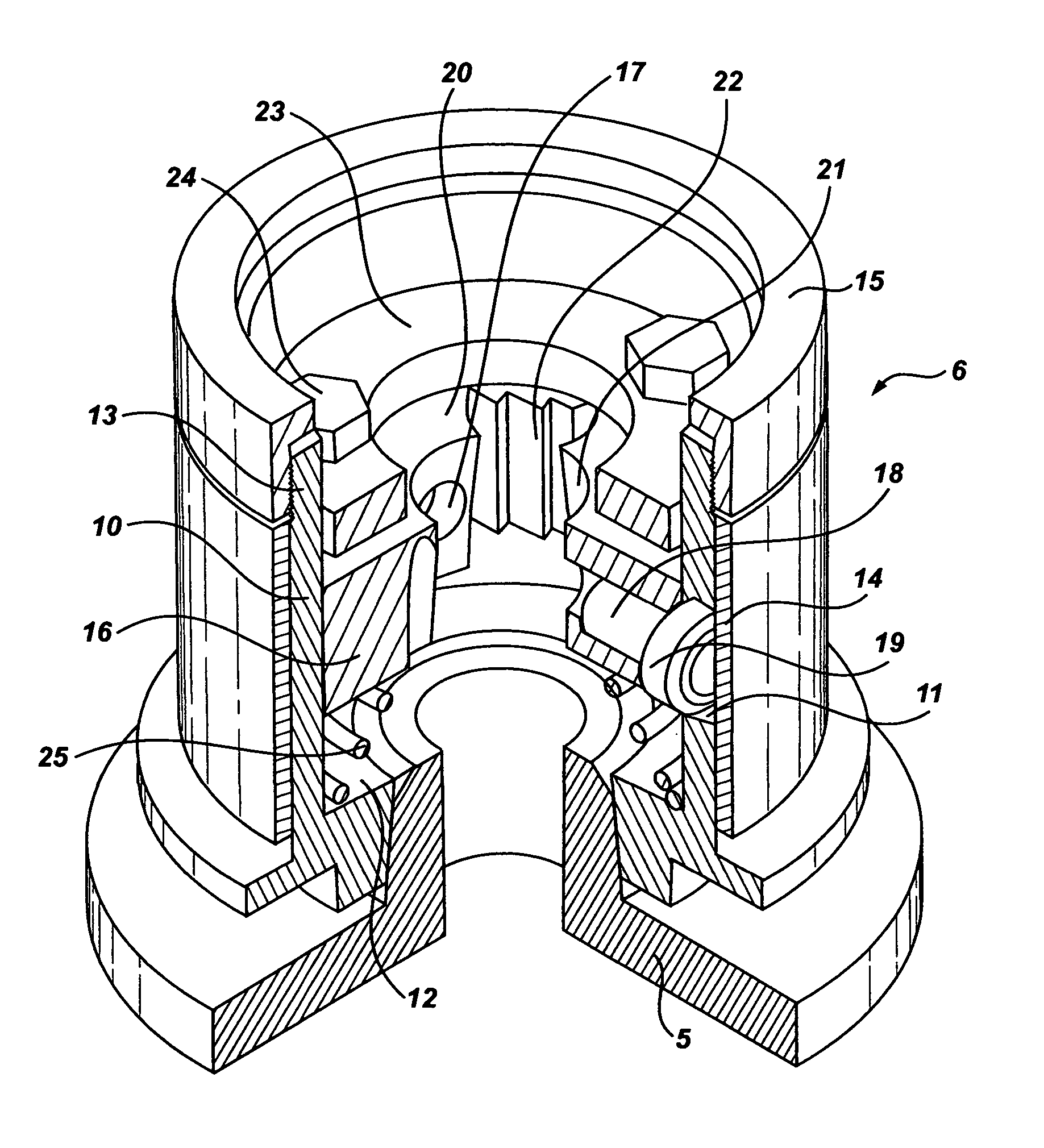

Stuffing box apparatus

A stuffing box apparatus for sealing between a polish rod in a hydrocarbon production well comprises a tubular housing arranged for connection to the well which has a bore therethrough to receive the polish rod. Sealing members are supported in the bore of the housing in an upper stack and a lower stack of smaller outer diameter separated by an intermediate bushing. An upper bushing compresses the upper stack against the intermediate bushing. The lower bushing fixes the lower stack against the bottom of the intermediate bushing. Each of the bushings includes a counter bore formed at one end which receives a wiper member arranged for sealing engagement between the bushing and the polish rod.

Owner:KK TOPCON

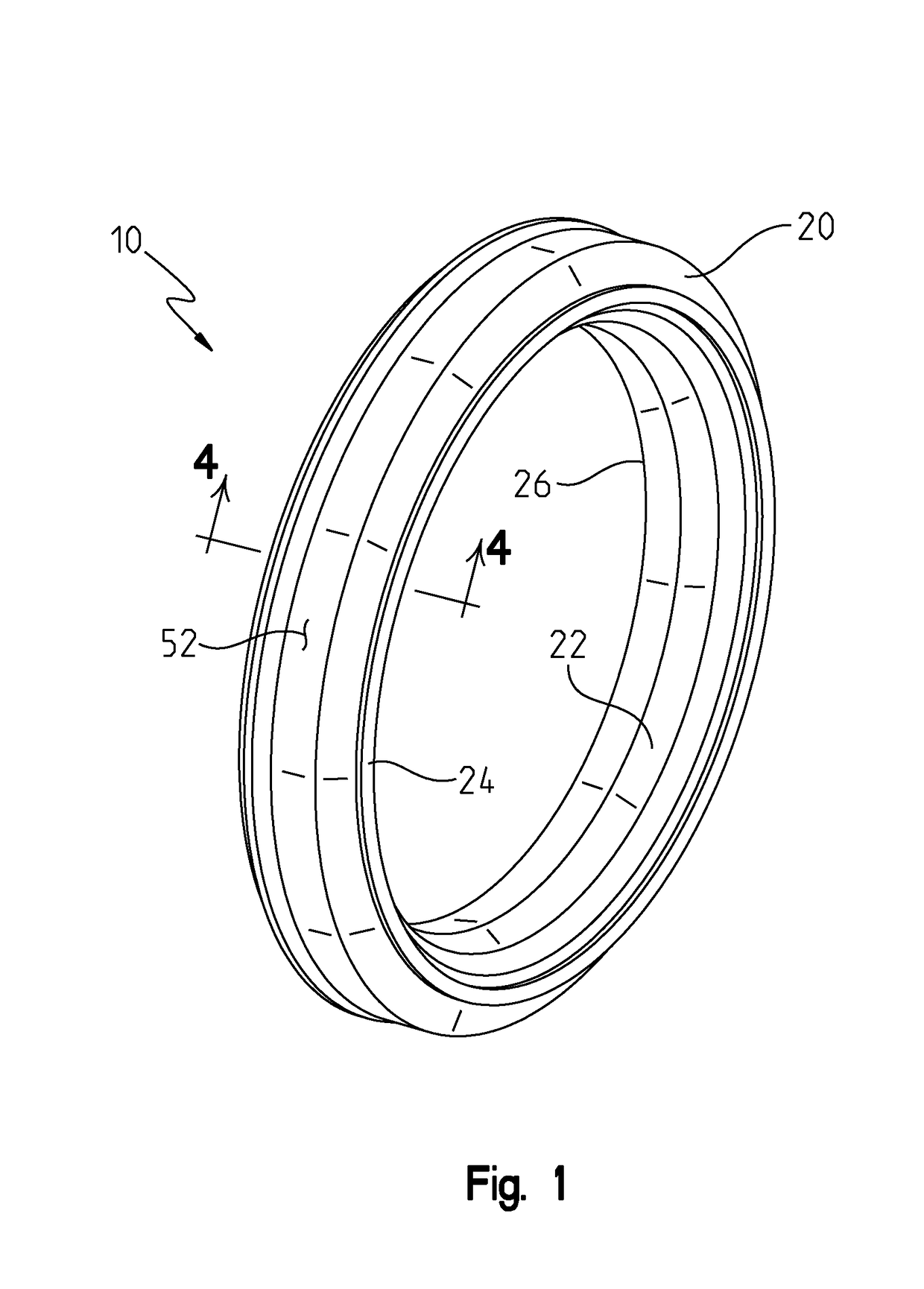

Header ring for reciprocating pump

A new header ring useful in downhole packing sets automatically cleans the cylinder plunger wall during use and forms an improved seal having long duration. The new header ring has a ring shaped body. The body includes a side wall defining an open top, an open bottom, and an inner wall portion with an inner wall surface for contacting a plunger. The inner wall portion includes an outwardly extending annular undercut, which defines an overhang and radius that helps wipe clean the plunger wall and form a better seal. The body also has an outer wall portion with an outer wall surface for contacting a stuffing box wall. The outer wall has a flat upper portion, a flat lower portion, and an outwardly sloped annular middle portion connecting the top and lower portions. The outer wall also has an inwardly extending annular ledge formed in its bottom. The inner wall portion is formed from a high wear resistance elastomer, and the outer wall portion is formed from a nonabrasive elastomer.

Owner:FAST GRP HOUSTON

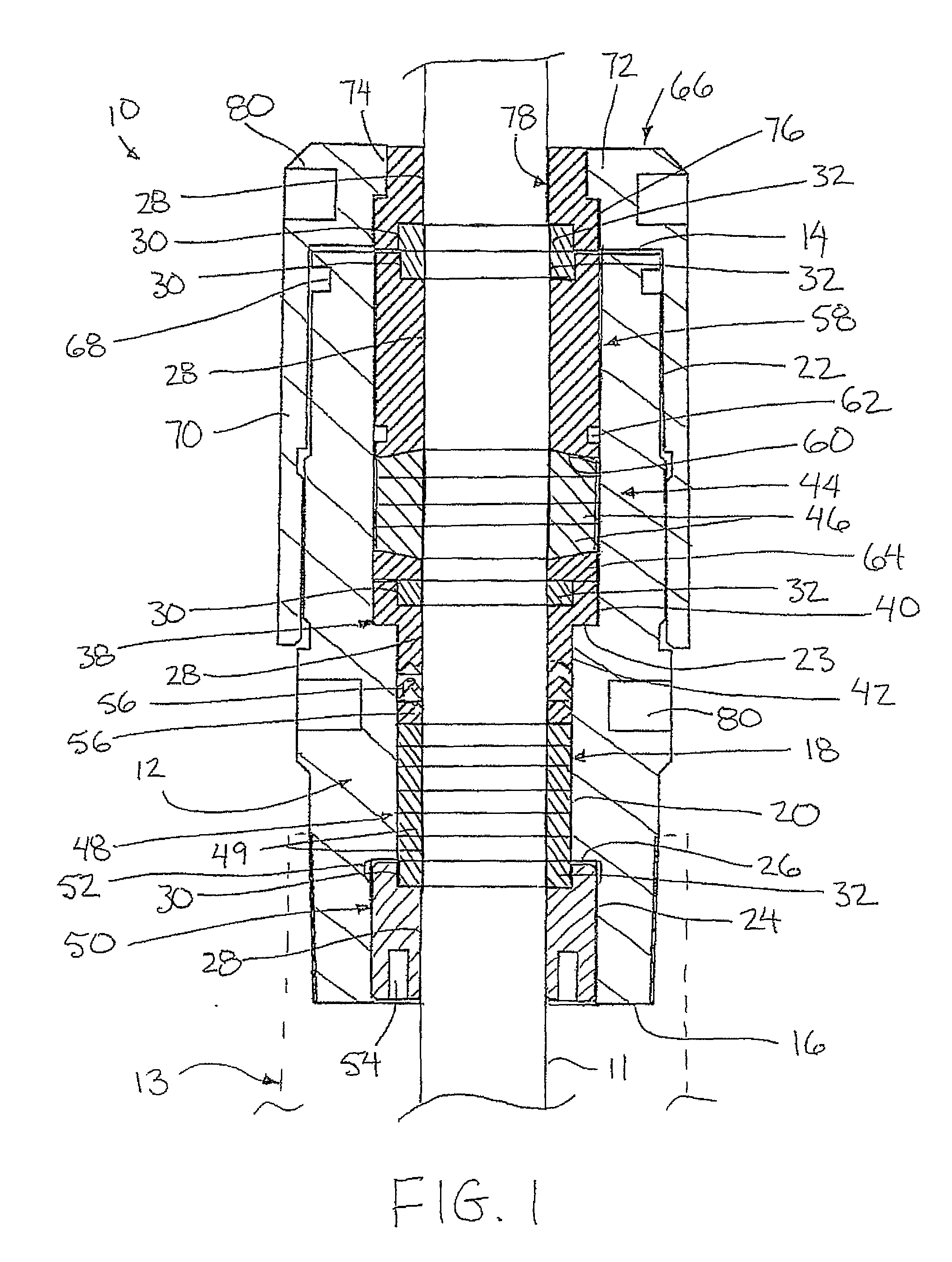

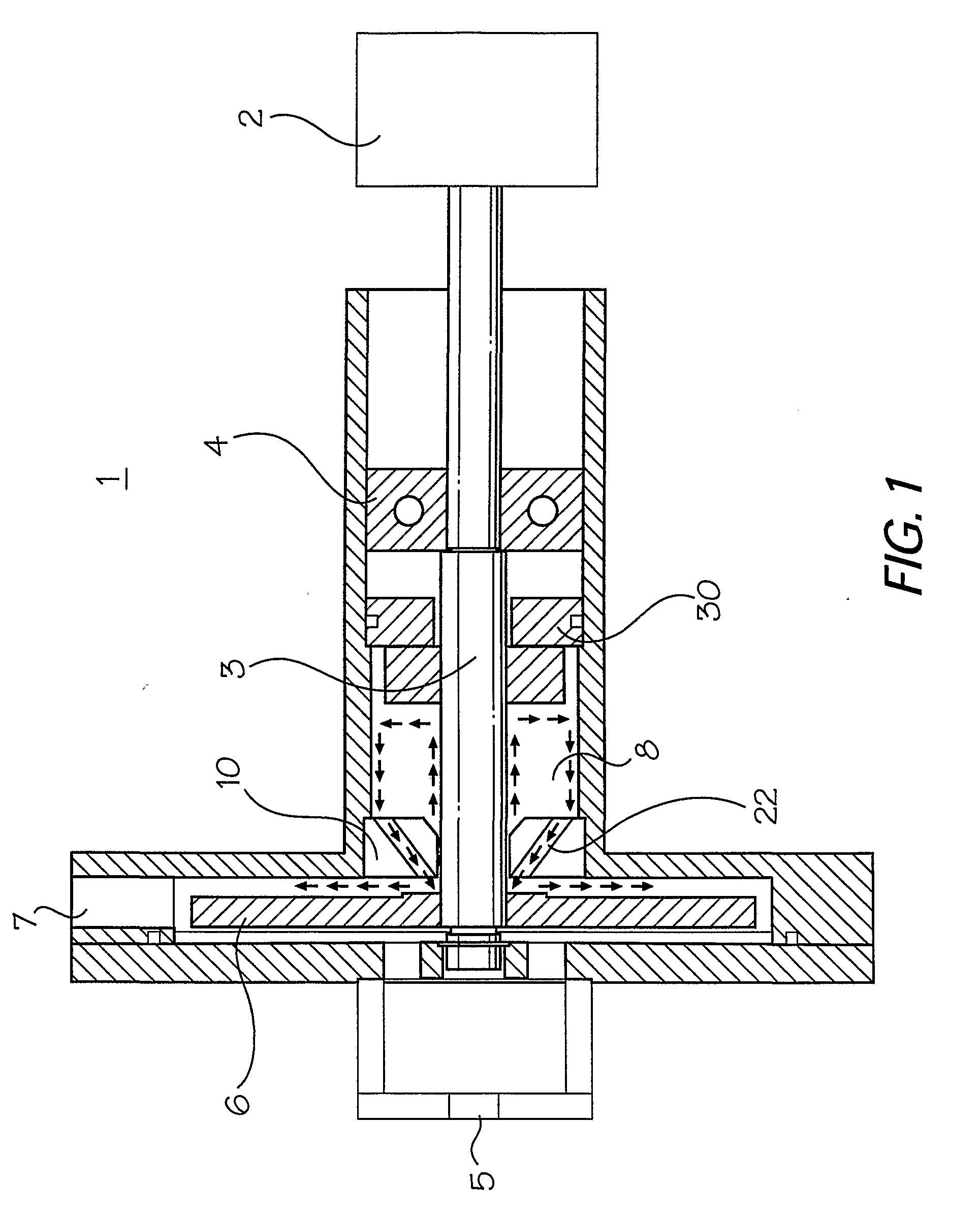

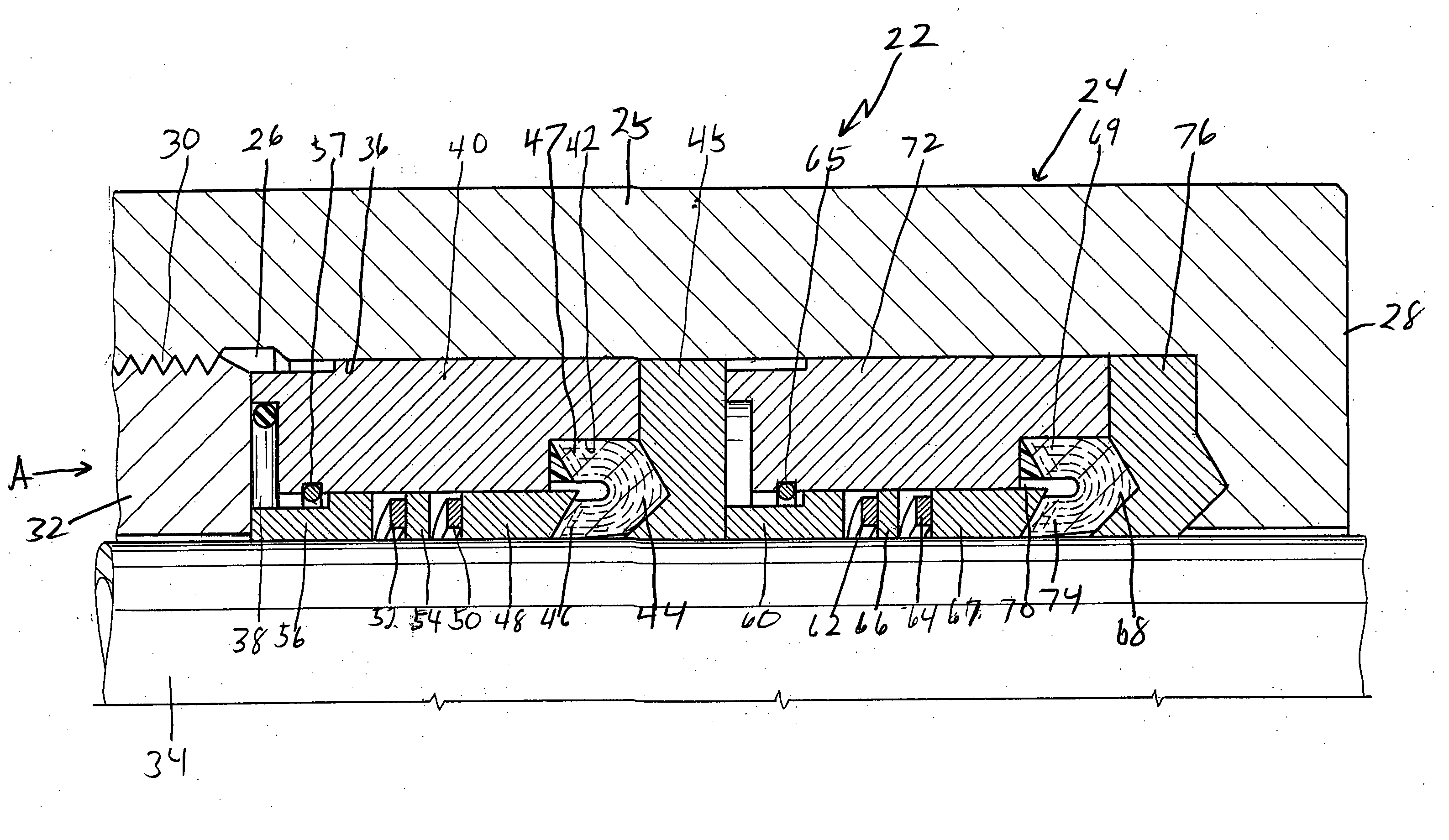

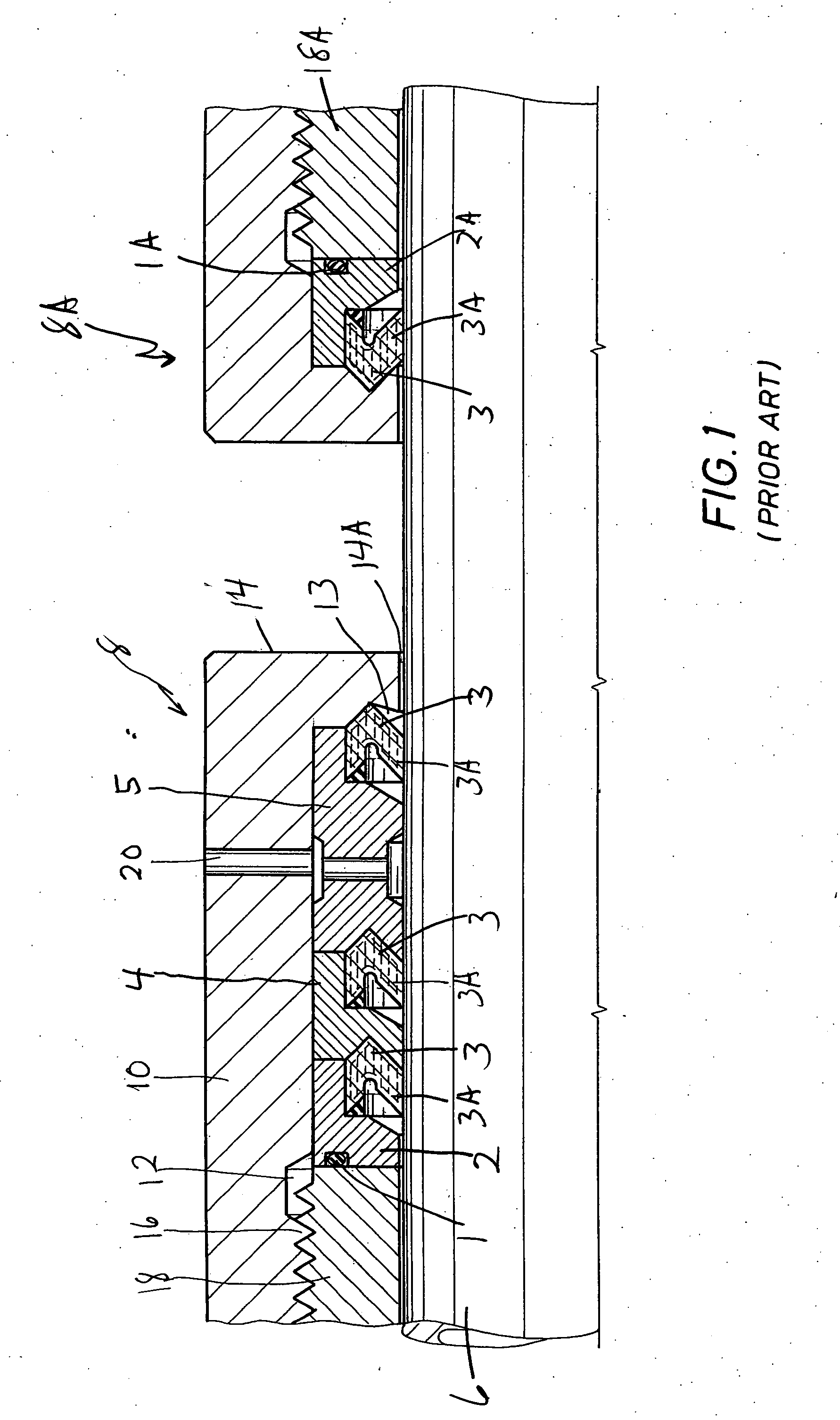

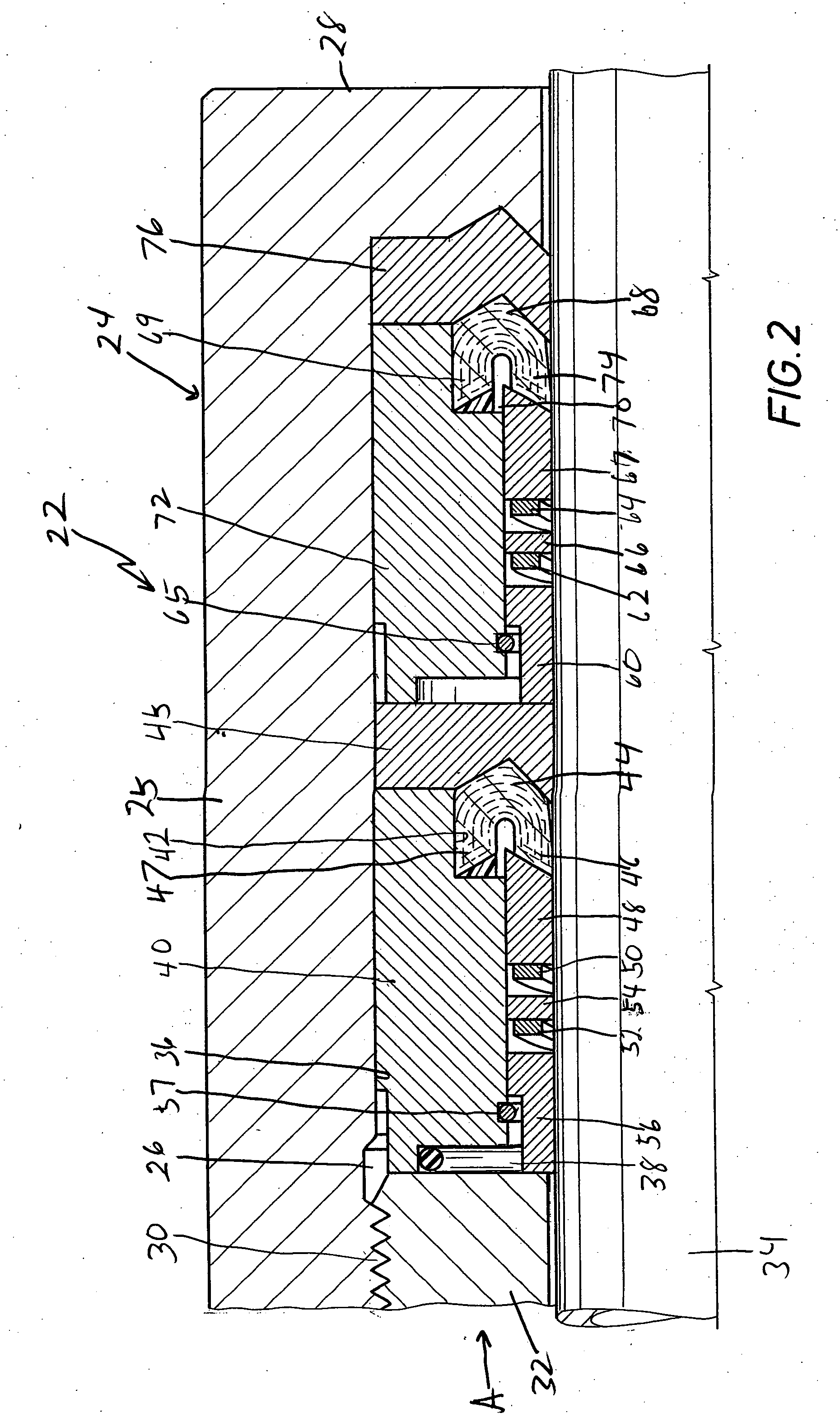

Self-aligning shaft support

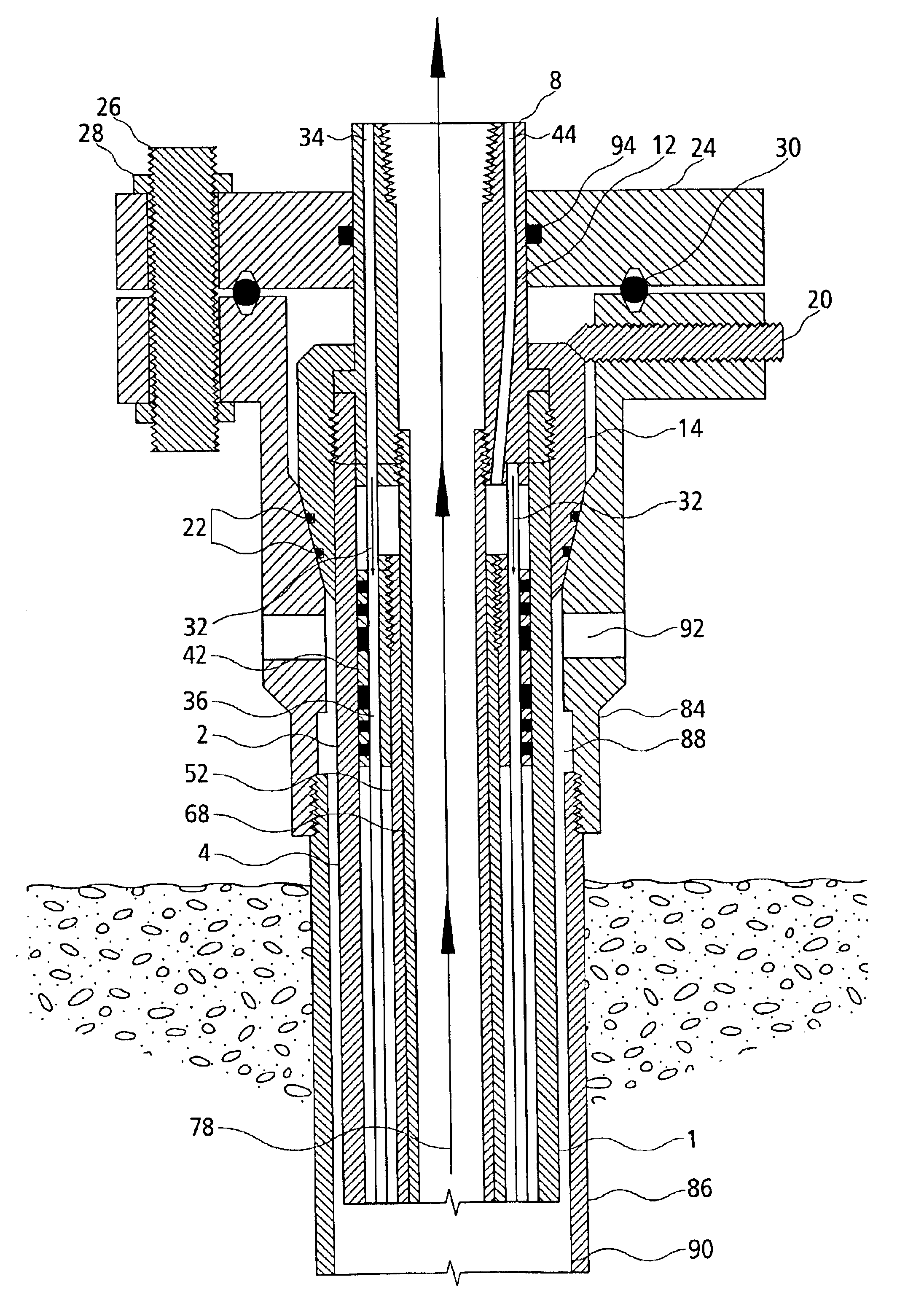

InactiveUS6585416B1Engine sealsPositive displacement pump componentsSpherical bearingReciprocating motion

A guide to support a shaft such as a pump pull rod (11) which is capable of both rotary and reciprocal motion. The guide prevents any misalignment of rod (11) damaging a seal, e.g. a stuffing box, held in space (24). Guide element (18) has central portion (19) and annular flange (25). Element (18) can move laterally with respect to housing (12) and can also pivot, along with the cap (15) of the housing (12), with respect to the lower portion (14) thereof. The latter is achieved via movements of part-spherical bearing element (28) and similarly shaped faces (26, 37, 38) of housing 9120. Further seals (33, 34) prevents entry of pumped fluid into chamber (13).

Owner:HARBISON FISCHER

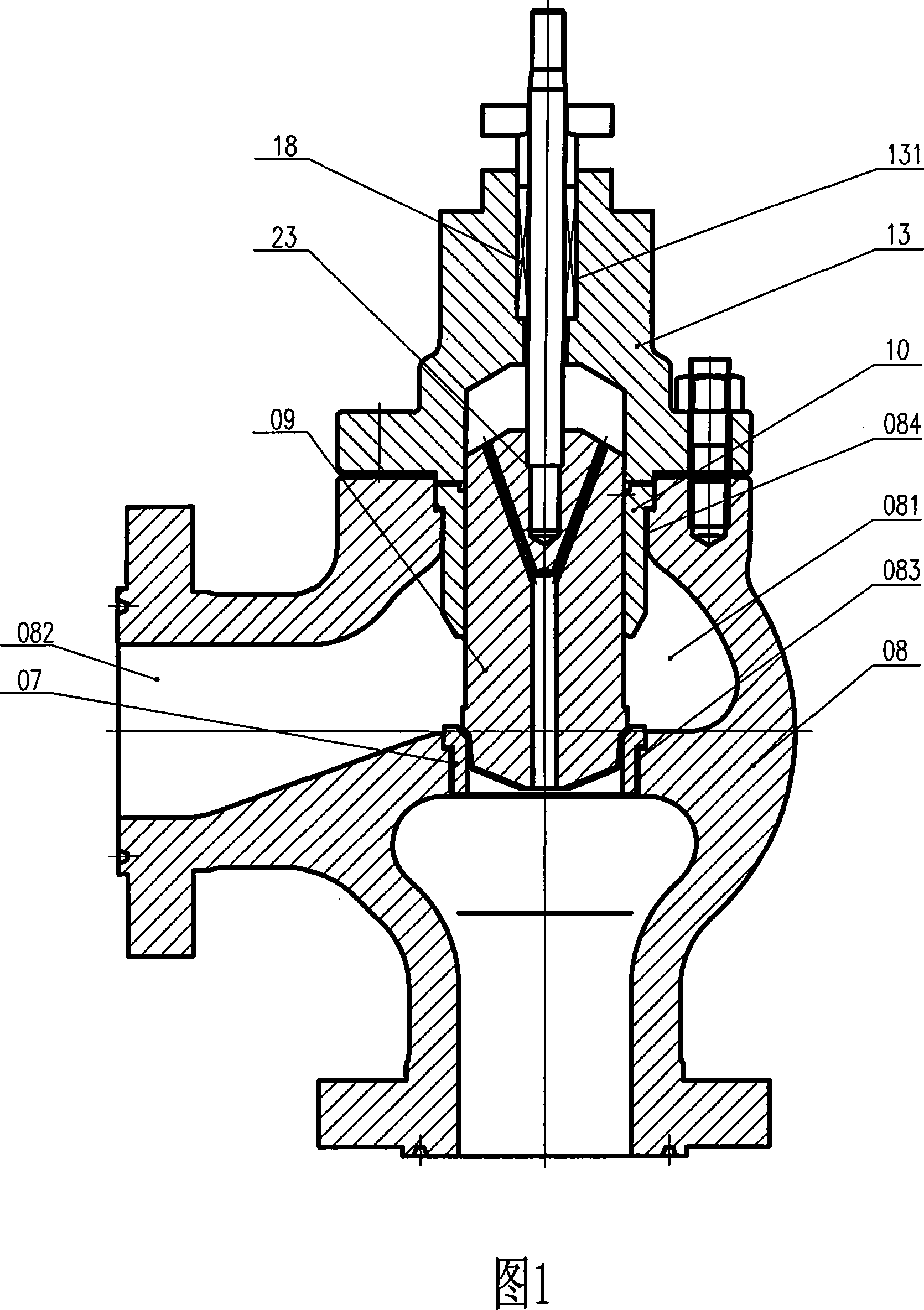

Corniform regulating valve

ActiveCN101220865APrevent leakageExtended service lifeLift valveValve housingsEngineeringLower upper

The invention discloses an angular adjusting valve, comprising a valve body, a valve seat, a valve core, a valve rod, and a valve cover. The valve body is internally provided with a valve chamber; the side part, the lower part and the upper part are respectively provided with an inlet, an outlet and a guide sleeve mouth; the valve rod is arranged on the upper part of the valve body; a guide sleeve is fixed inside the guide sleeve mouth; the lower end of the valve rod is connected with the valve core which motions in the guide sleeve; the upper end of the valve rod passes through out of a stuffing box on the valve cover; the lower end of the valve rod is a connecting head; the valve core is fixed on the connecting head; the surface of the connecting head is provided with a plurality of garbage troughs intermittently. By adopting the technical proposal, the angular adjusting valve of the invention has a self-cleaning function and can avoid that the garbage grains are blocked and abraded in the guide sleeve.

Owner:施大钟

Progressive cavity pump (PCP) drive head stuffing box with split seal

The present invention relates to a split seal for a progressive cavity pump (PCP) drive head stuffing box. In one embodiment, a mechanical seal assembly for a pump is provided. The mechanical seal assembly includes a seal housing; first and second semi-annular mechanical seals, each at least partially disposed in the seal housing bore, and a seal sleeve rotatable relative to the seal housing; third and fourth semi-annular mechanical seals, each disposed at least partially in the seal sleeve bore, at least one of the third and fourth seals rotationally coupled to the seal sleeve; and one or more biasing members biasing the mechanical seals into engagement.

Owner:WEATHERFORD TECH HLDG LLC

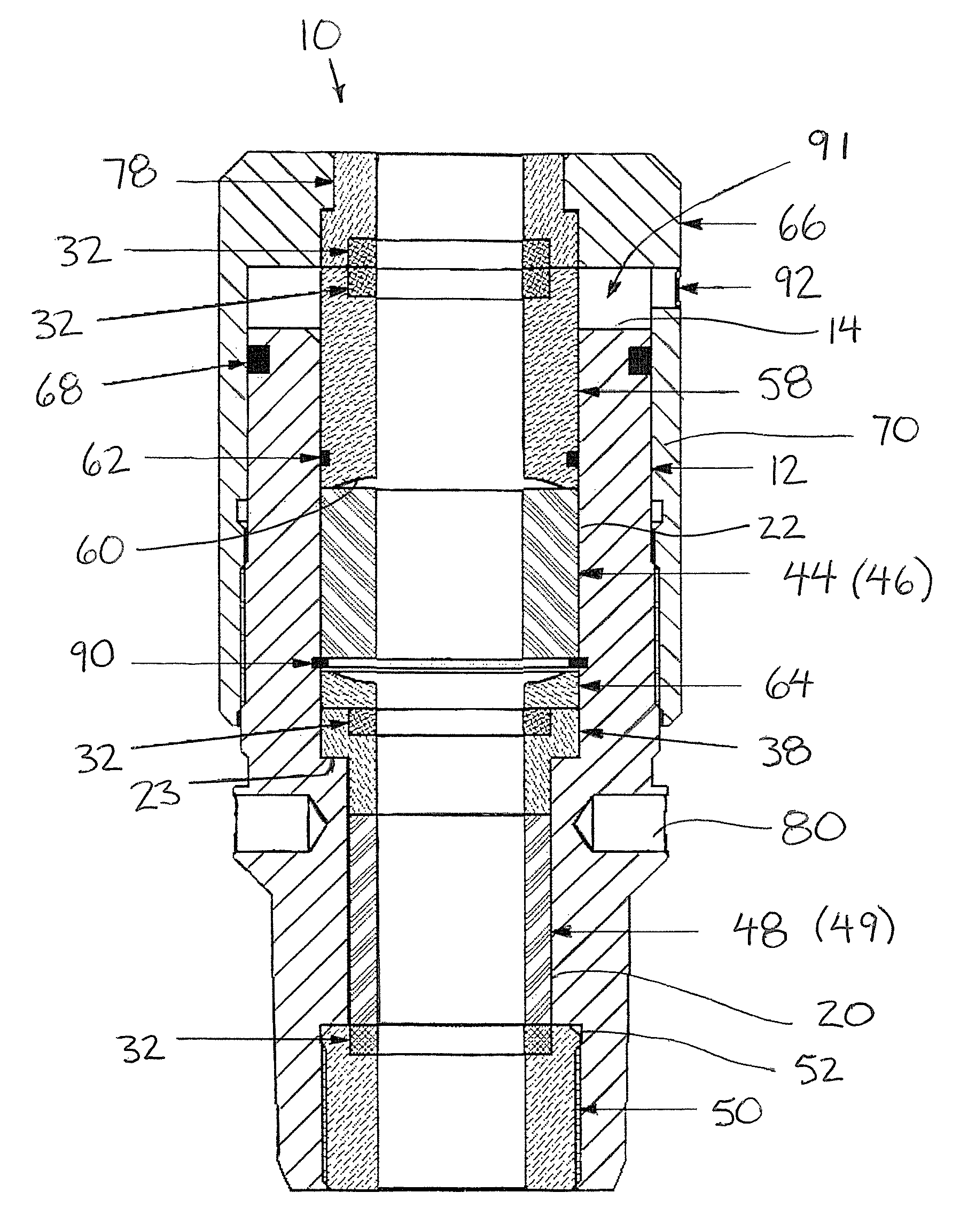

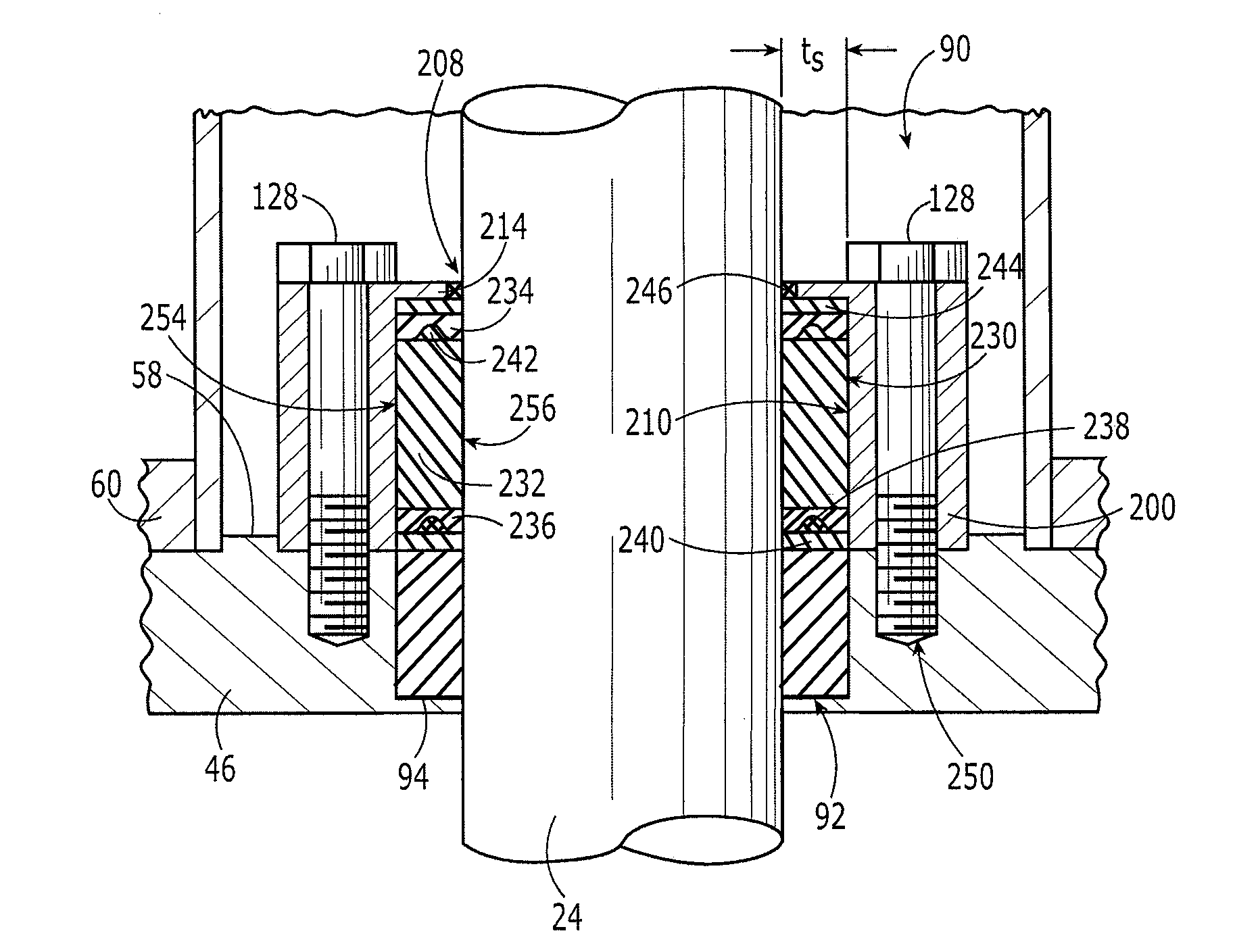

Bushing and Lantern Ring for Rotary Fluid Pumping Equipment

InactiveUS20090045589A1Reduce the amount requiredEffective fluid transferEngine sealsPump componentsFree rotationLantern

A throat bushing (10, 54) for use in a seal chamber (8) or stuffing box (56) of rotary fluid equipment. The throat bushing defines a first face (13, 60) and a second face (21, 62), an outer surface (11) dimensioned to be received with a tight fit within a throat or bore of the seal chamber (8) or stuffing box (56), and a bore (25) therethrough dimensioned to receive a rotary shaft (3) with clearance to permit free rotation of the rotary shaft (3) therein. The throat bushing comprises at least one tangential channel (22) therethrough leading tangentially from the first face (13, 60) proximal to the outer surface (11), through to the second face (21, 62), proximal to an inner annular surface (12) of the throat bushing bore (25).

Owner:PATTON CHRISTOPHER S +2

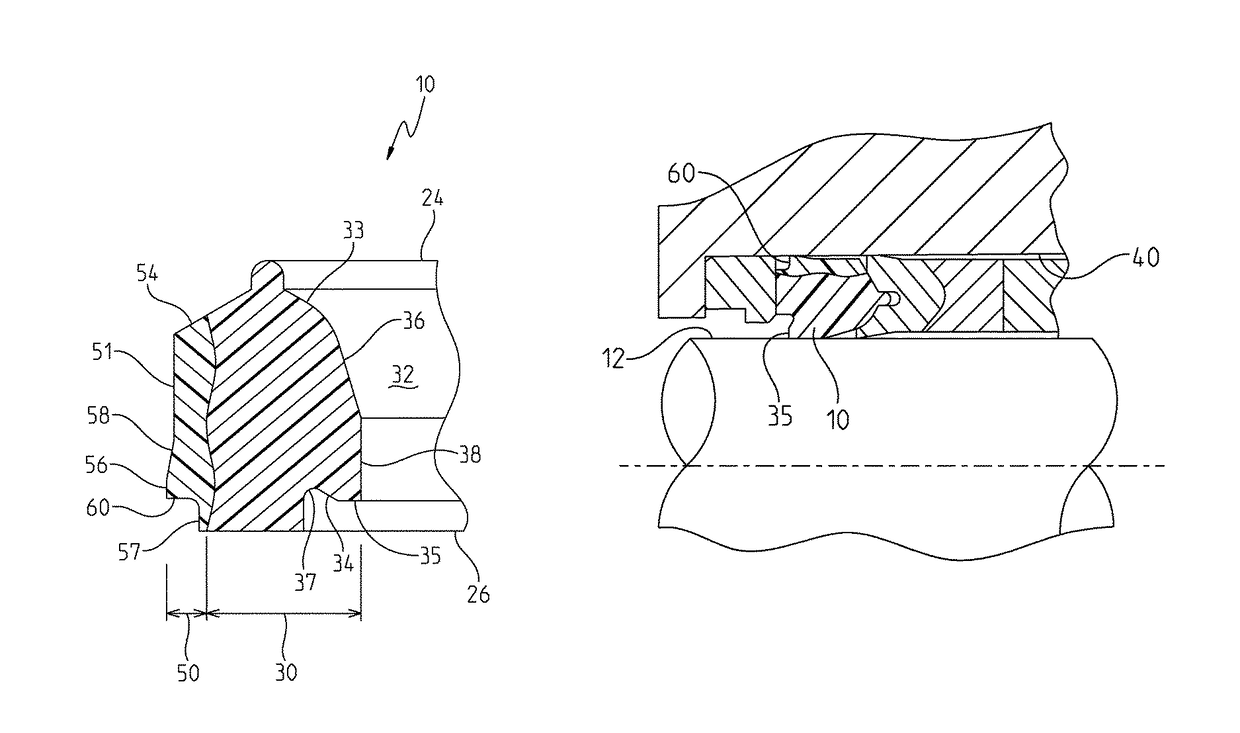

Self-aligning stuffing box

InactiveUS7284602B2Avoid lateral loadReduce the overall heightEngine sealsDrilling rodsSpherical jointEngineering

A self-aligning stuffing box having a spherical joint between the upper and lower portions of the housing permits universal movement of the upper portion relative to the lower portion to permit a rod to pass through the bore if the axis of the rod is misaligned relative to the axis of the bore in each of the upper and lower housing portions. An energized seal in the upper housing resides at or below the spherical joint due to a downwardly depending central portion of the upper housing which extends into a recess formed in the lower housing permitting the height of the stuffing box to be relatively short. A second seal is positioned above the first seal and may be spaced sufficiently above the first seal to permit a flapper valve to be installed between the seals. The flapper valve is mounted through a port in the upper housing which is accessible without disassembly of the stuffing box, the seals or the wellhead.

Owner:MSI MACHINEERING SOLUTIONS INC

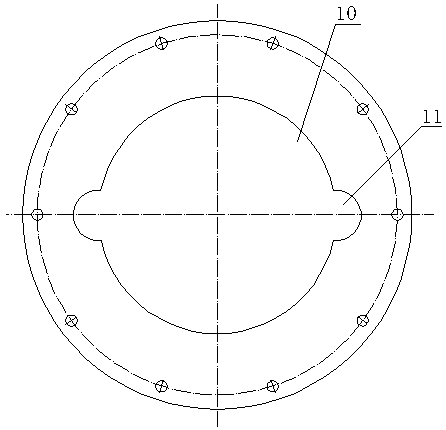

Magnetic drive cleaning device of ultraviolet sterilizing device

InactiveCN101670347AReal-time online cleaningSolve corrosiveHollow article cleaningUv disinfectionEngineering

The invention belongs to the technical field of ultraviolet device cleaning and particularly relates to a piece of magnetic drive cleaning device of an ultraviolet sterilizing device, wherein a screwrod is provided and fixed with an inner magnet ring and a driving device is arranged on the outer wall of the ultraviolet sterilizing device and at the end part of the screw rod and used for driving the screw rod to rotate; a middle support cylinder is sheathed outside the screw rod and the inner magnet ring; an outer magnet ring is placed in an outer magnet box and sheathed on the middle supportcylinder so that the outer magnet ring is opposite to the inner magnet ring in position; a big cleaning plate is sheathed and fixed in the middle of the outer magnet box and a quartz sleeve penetratesthrough a stuffing box on the big cleaning plate; and the inner magnet ring is driven by the screw rod to move back and forth and drives the outer magnet ring and the big cleaning plate to do reciprocating sliding movement through magnetic attraction, thus realizing the purpose of cleaning the quartz sleeve. The device realizes real-time online cleaning, solves the traditional problems that the cleaning assembly does not resist corrosion and the driving device is difficult in motive seal, and is simple in structure, convenient for implementation and easy for promotion.

Owner:TSINGHUA UNIV +1

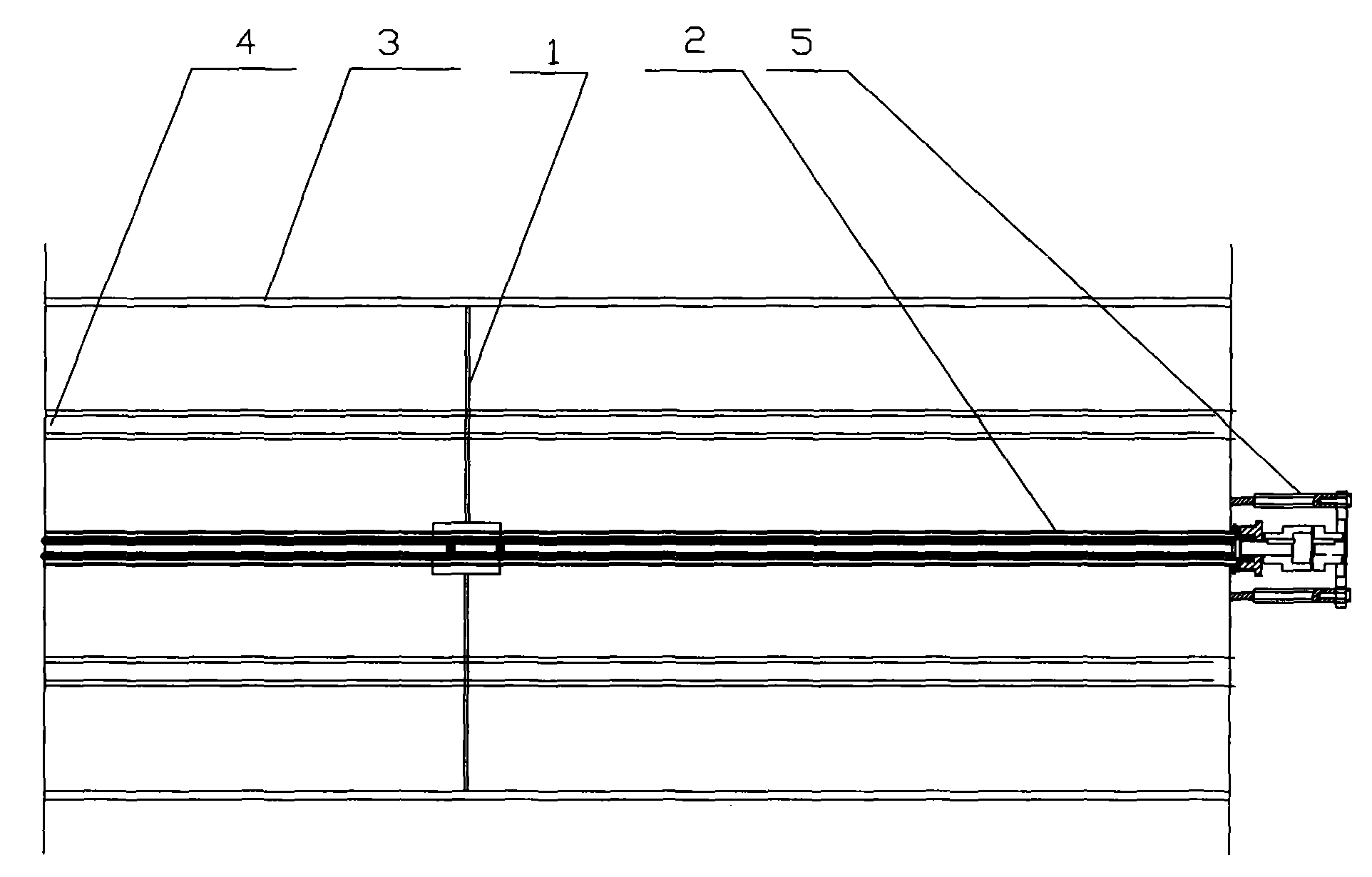

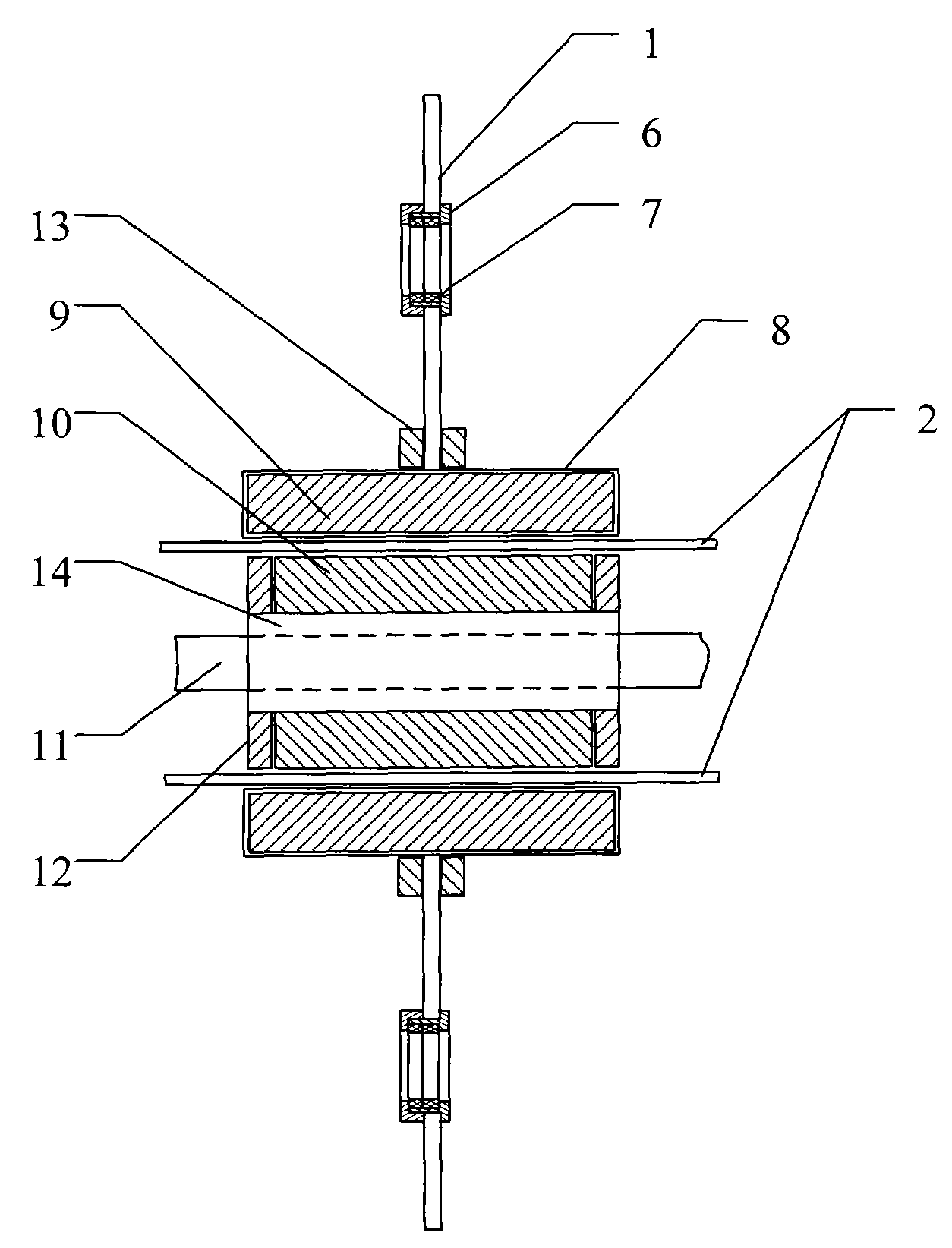

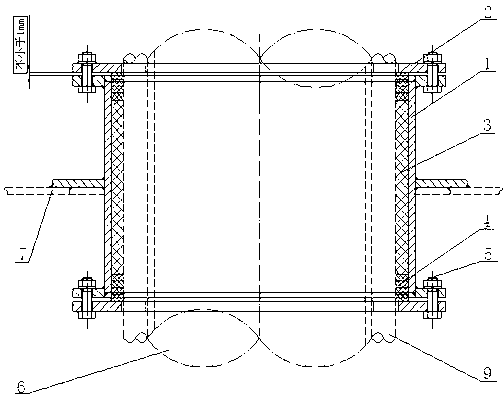

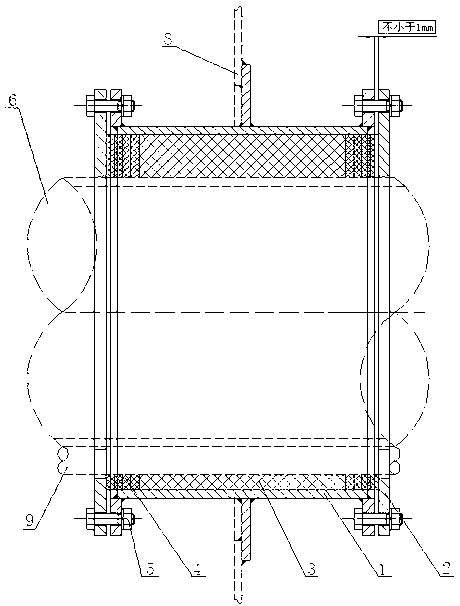

High temperature fluid pipeline sealed heat insulation cabin penetrating device and installation method thereof

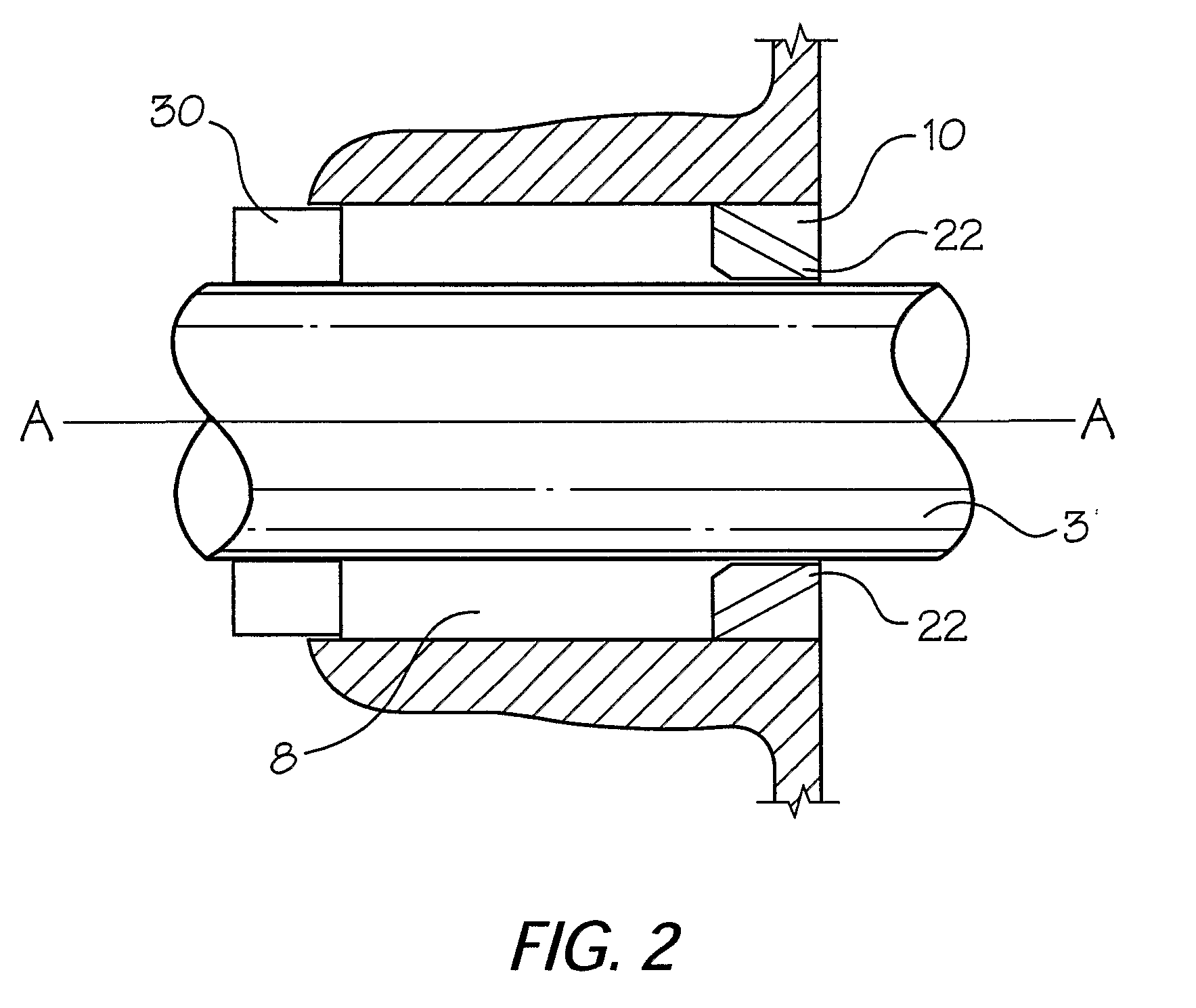

InactiveCN103234084AGuaranteed airtightGuaranteed watertightThermal insulationPipesEngineeringGraphite

The invention provides a high temperature fluid pipeline sealed heat insulation cabin penetrating device and an installation method thereof. The high temperature fluid pipeline sealed heat insulation cabin penetrating device comprises a high temperature fluid pipe (6), a stuffing box (1) and a stuffing box pressing box (2), the high temperature fluid pipe (6) is sleeved in the stuffing box (1) and penetrates through an inner hole (10) on the stuffing box pressing cover (2), a uniform gap is reserved between the high temperature fluid pipe (6) and the hole wall of the inner hole (10), the stuffing box (1) penetrates through a deck (7) or a cabin wall (8) to be welded to the deck (7) or the cabin wall (8), muddy fillers (3) are filled in the remaining space of the inner portion of the stuffing box (1), graphite packing (4) is filled at two ends of the stuffing box (1), and the graphite packing (4) extends out of the end face of the stuffing box (1) to be tightly contacted with the end face of the stuffing box pressing cover (2). The installation method includes the following steps: rust removal and painting of the stuffing box (1) and the stuffing box pressing cover (2), through installation of the stuffing box (1), through installation of the high temperature fluid pipe (6), filling of sealing fillers, inspection and heat insulation wrapping.

Owner:武汉南华黄冈江北造船有限公司

Stuffing box assembly and sealing assembly for use therein

A stuffing box assembly for use in sealing between a fixed housing and a rotatable member extending through the fixed housing comprising a housing forming a sealing assembly chamber, a rotatable member extending through the housing and a sealing assembly received in the chamber, the sealing assembly including an annular seal ring carrier, an annular seal ring carried by the carrier, the seal ring having an annular radially outer portion and an annular radially inwardly extending sealing lip, an annular seal ring spreader operatively engaged with the seal ring, an elastic biasing member operatively engaged with the seal ring spreader and an annular adjustable follower selectively axially immovable with respect to the housing, the spreader exerting a greater force on the sealing lip than the radially outer portion of the seal lip when the spreader is biased towards the seal ring.

Owner:UTEX IND

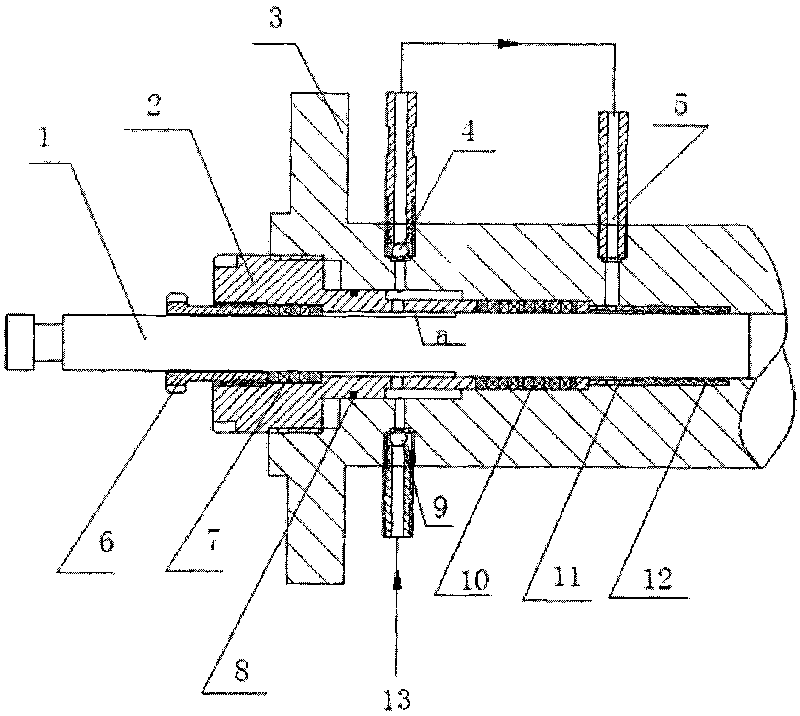

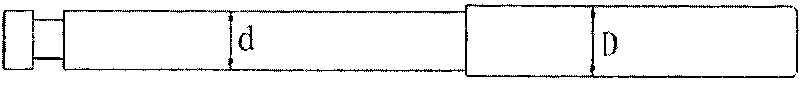

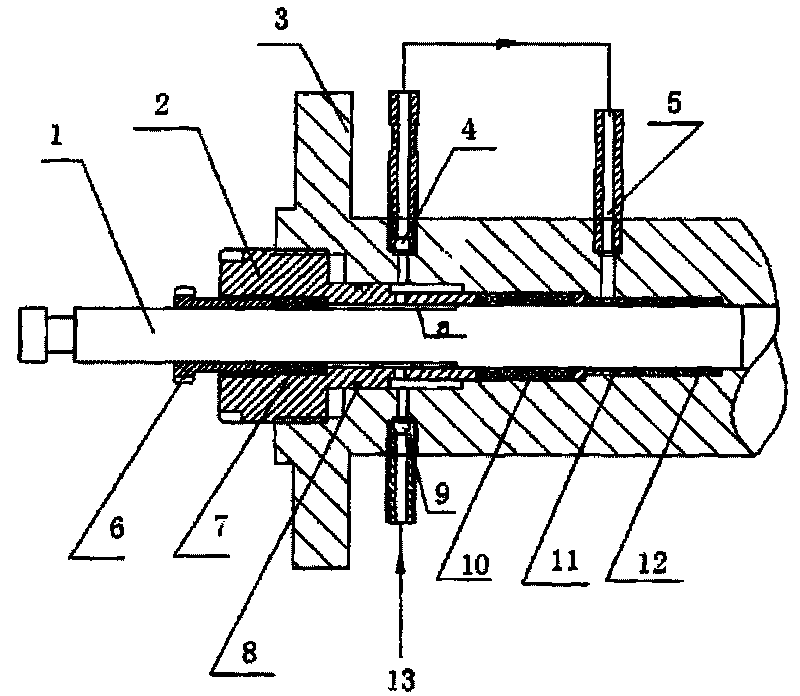

Solid medium contained plunger pump stuffing sealing device

InactiveCN101725521AAvoid wear and tearExtend the life cyclePositive displacement pump componentsLiquid fuel engine componentsPump headBiomedical engineering

Owner:CHINA COAL RES INST +1

Stuffing box for walking beam compressor

Various methods and devices are provided for use in a walking beam compressor used with an oil well pump. In general, an injectable fibrous sealant is provided for use in a stuffing box to form a seal around a piston rod that couples to a walking beam for pumping oil out of the ground. The injectable fibrous sealant can be configured to form a gas tight seal around the piston rod, while allow reciprocal longitudinal movement of the piston rod therethrough. The injectable fibrous sealant is particularly advantageous as it has an extended life, eliminating the need to replace the seal, and repairs can be performed on-site by injecting additional sealant into the stuffing box.

Owner:OIL FLOW USA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com