Production technology of sponge iron for water purifying agent

A production process, technology of sponge iron, applied in the direction of water pollutants, water/sewage treatment, biological water/sewage treatment, etc., can solve the problem of poor spontaneous micro-electrolysis function, low pollutant removal efficiency, low C content of sponge iron, etc. problem, to achieve the effect of improving spontaneous micro-electrolysis function, high specific surface energy, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

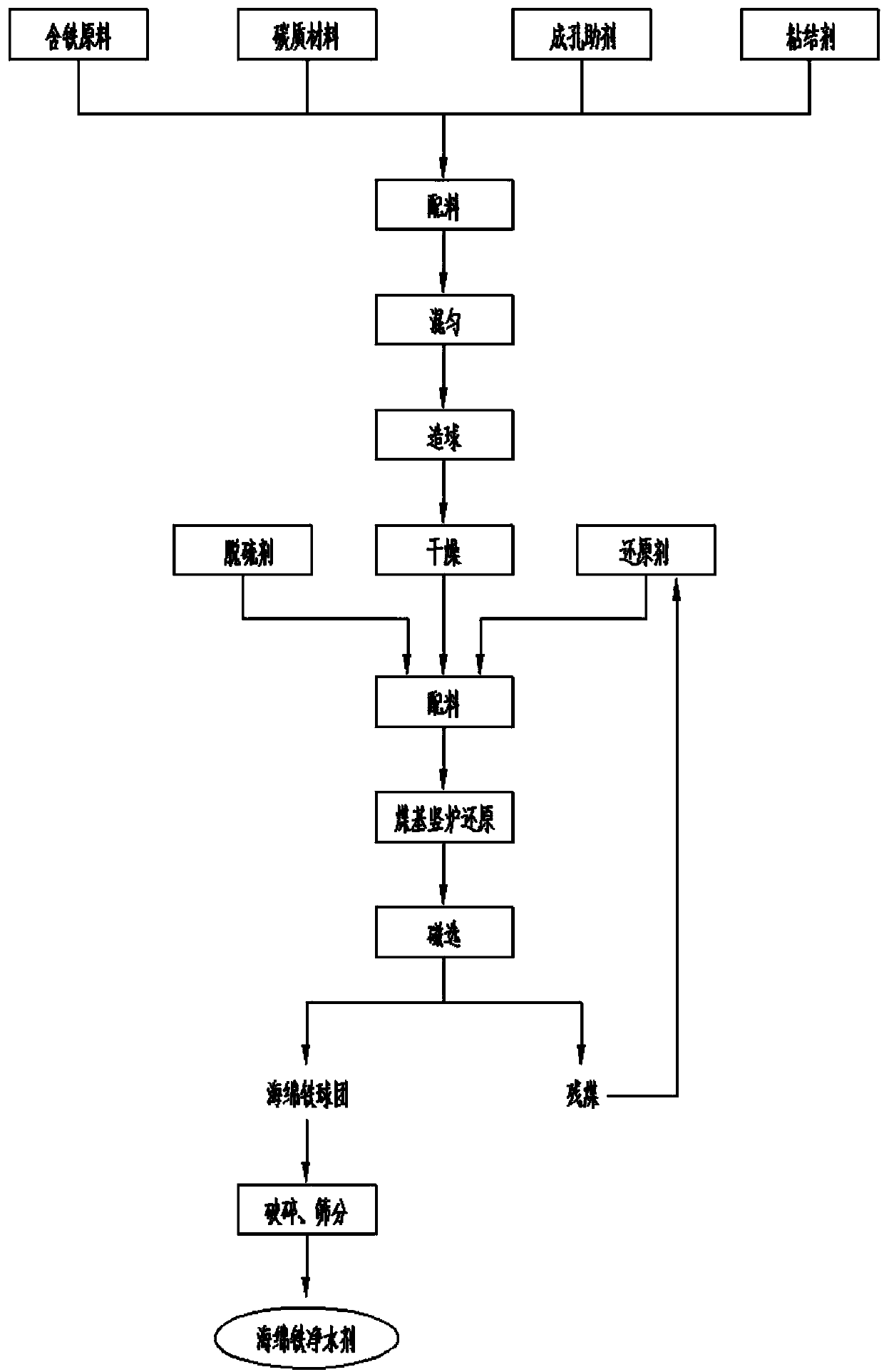

Method used

Image

Examples

Embodiment 1

[0056] Example 1: A production process of sponge iron water purifier, the active ingredients of sponge iron are C, Fe and some Fe 3 C, TFe content ≥ 92%, C content and impurity content ≤ 8%, metallization rate ≥ 95%, the main production steps are:

[0057] (1) The iron scales are dried and finely ground until the particle size is less than 100 mesh for later use;

[0058] (2) Mix iron scale, carbonaceous material (caramel), pore-forming aid (siderite) and binder according to the mass ratio of 75%: 12%: 10%: 3% and press the ball, The particle size of green pellets is 12-35mm, and the water content of green pellets is ≤8%;

[0059] (3) Use the combustion-supporting air preheated by the high-temperature flue gas in the coal-based shaft furnace combustion chamber to dry the green pellets in the drying facility, and the moisture content of the green pellets after drying is ≤3%;

[0060] (4) Mix the dried green pellets with anthracite and limestone, wherein the amount of anthraci...

Embodiment 2

[0064] Example 2: A production process of sponge iron water purifier, the active ingredients of sponge iron are C, Fe and some Fe 3 C, TFe content ≥ 85%, C and impurities ≤ 15%, metallization rate ≥ 95%, the main production steps are:

[0065] (1) Iron scale and TFe≥67 iron fine powder are respectively dried and finely ground until the particle size is less than -100 mesh for later use;

[0066] (2) Prepare spare iron scale, iron fine powder, carbonaceous material (graphite: caramel = 0.5:0.5), pore-forming aid (siderite) and binder according to 15%: 57%: 15%: 10 %: 3% mass ratio, mix and press the ball, the particle size of the green ball is 12-35mm, and the water content of the green ball is ≤8%;

[0067] (3) Use the combustion-supporting air preheated by the high-temperature flue gas in the coal-based shaft furnace combustion chamber to dry the green pellets in the drying facility, and the moisture content of the green pellets after drying is ≤3%;

[0068] (4) Mix the dri...

Embodiment 3

[0072] Example 3: A production process of sponge iron water purifier, the active ingredients of sponge iron are C, Fe and some Fe 3 C, TFe content ≥ 70%, C and impurity content ≤ 30%, metallization rate ≥ 95%, the main production steps are:

[0073] (1) TFe≥67% iron concentrate powder is dried and finely ground to a particle size of less than 100 mesh for subsequent use;

[0074] (2) Mix iron powder, anthracite, pore-forming aid (siderite:clay=0.8:0.2) and binder according to the mass ratio of 60%:25%:10%:5% and press the ball , the particle size of green pellets is 12-35mm, and the water content of green pellets is ≤8%;

[0075] (3) Use the combustion-supporting air preheated by the high-temperature flue gas in the coal-based shaft furnace combustion chamber to dry the green pellets in the drying facility, and the moisture content of the green pellets after drying is ≤3%;

[0076] (4) Mix the dried green pellets with anthracite and limestone, wherein the amount of anthracit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com