Preparation method of aldehyde-free textile color fixing agent

A color-fixing agent and a technology of preparation steps, which are applied in the field of preparation of formaldehyde-free textile color-fixing agents, can solve the problems of further improvement in the fastness to wet rubbing, and achieve the goal of improving color fastness to washing, improving dyeing performance, and reducing water solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

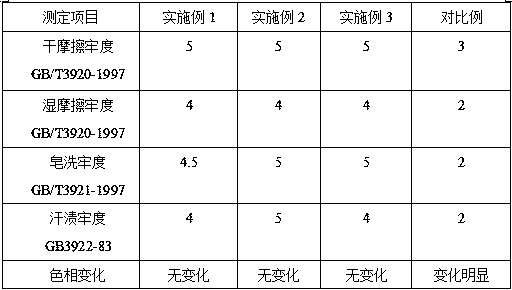

Examples

Embodiment 1

[0039] In parts by weight, weigh 40 parts of cotton pulp, 120 parts of absolute ethanol, 20 parts of sodium hydroxide, and 40 parts of chloroacetic acid, put the cotton pulp in a powerful pulverizer, and pulverize at room temperature for 40 minutes to obtain pulverized Put the crushed cotton pulp and sodium hydroxide in anhydrous ethanol in an ultrasonic cleaning machine, and ultrasonicate at a constant temperature for 2 hours at 40 ° C and 3000 Hz to obtain an alkalized solution. Add monochloroacetic acid to the alkali In the chemical solution, stir etherification at 200r / min in a water bath at 70°C for 3h, filter, and take the solid to obtain crude carboxymethyl cellulose, which is mixed with acetic acid solution with a mass concentration of 1%. Wash until neutral, then wash 3 times with absolute ethanol, place in an oven and dry at 40°C for 30 minutes to obtain carboxymethyl cellulose, and then weigh 50 parts of carboxymethyl cellulose in parts by weight element, 10 parts o...

Embodiment 2

[0041] In terms of parts by weight, weigh 45 parts of cotton pulp, 135 parts of absolute ethanol, 23 parts of sodium hydroxide, and 45 parts of chloroacetic acid, put the cotton pulp in a powerful pulverizer, and pulverize at room temperature for 50 minutes to obtain pulverized Put the crushed cotton pulp, sodium hydroxide and absolute ethanol in an ultrasonic cleaning machine, and ultrasonicate at a constant temperature for 2.5 hours under the adjustment of 45°C and 3500Hz to obtain an alkalized solution, and add monochloroacetic acid In the alkalization solution, stir etherification at 220r / min in a water bath at 75°C for 4h, filter, and take the solid to obtain crude carboxymethyl cellulose, which is treated with acetic acid with a mass concentration of 1%. The solution was washed to neutrality, then washed 4 times with absolute ethanol, placed in an oven and dried at 45°C for 35 minutes to obtain carboxymethyl cellulose, and weighed 55 parts by weight of carboxymethyl cellu...

Embodiment 3

[0043] In parts by weight, weigh 50 parts of cotton pulp, 150 parts of absolute ethanol, 25 parts of sodium hydroxide, and 50 parts of chloroacetic acid, put the cotton pulp in a powerful pulverizer, and pulverize at room temperature for 60 minutes to obtain pulverized Put the crushed cotton pulp and sodium hydroxide in anhydrous ethanol in an ultrasonic cleaning machine, and ultrasonicate at a constant temperature for 3 hours at 50°C and 4000 Hz to obtain an alkalized solution. Add monochloroacetic acid to the alkali In the chemical solution, stir etherification at 240r / min in a water bath at 80°C for 5h, filter, and take the solid to obtain crude carboxymethyl cellulose, which is mixed with acetic acid solution with a mass concentration of 1%. Wash until neutral, then wash 5 times with absolute ethanol, place in an oven and dry at 50°C for 40 minutes to obtain carboxymethyl cellulose, and then weigh 60 parts of carboxymethyl cellulose in parts by weight element, 12 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com