Low-smoke-density flame-retardant PC composition

A technology of smoke density and composition, applied in the field of low smoke density flame retardant PC composition, can solve the problems such as the inability to reflect the performance advantages of PC, the change of material properties, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with specific examples.

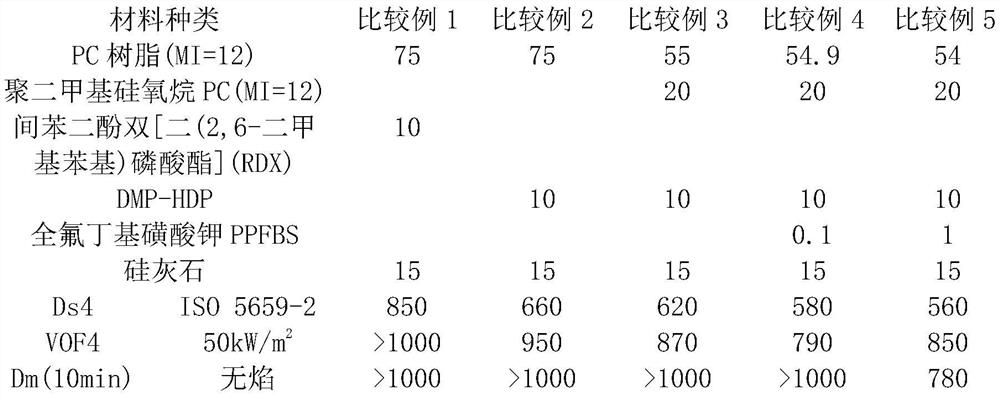

[0018] Table 1: Comparative Examples 1-5.

[0019]

[0020] Conclusion 1: It can be seen from Table 1 that the function of PPFBS is to catalyze the isomerization of PC, reduce the potential energy of PC material decomposition, promote carbon formation, and improve the flame retardant efficiency of phosphorus-based flame retardants. DMP-HDP has a high decomposition temperature, and under the same heat flux, it degrades slowly in the PC matrix, which can produce a continuous carbon-forming effect. The addition of too much PPFBS will not reduce the smoke density. The reason is that the P flame retardant is the main material in the material, and the carbonization of PC has reached the limit. Adding too much flame retardant will not reduce the smoke density. lower.

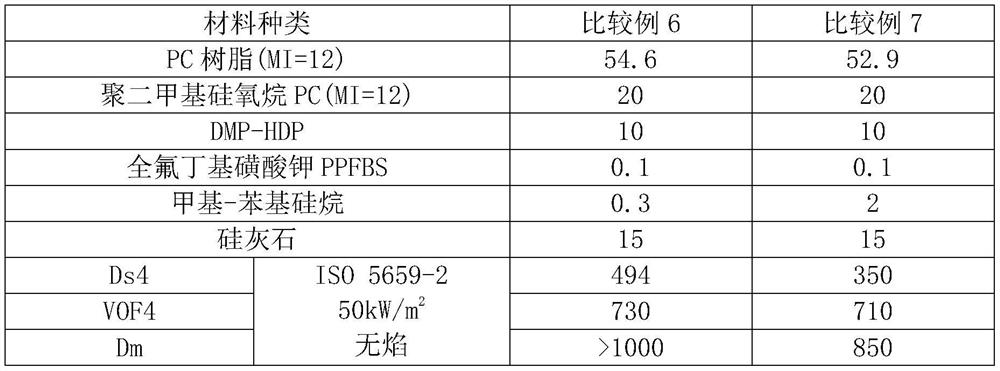

[0021] Table 2: Comparative Examples 6-7.

[0022]

[0023] Conclusion 2: Methyl-phenylsilane can diffuse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com