Method for fine synthesis of Ba(Zn1/3Nb2/3)O3 dielectric ceramic nano-powder through utilizing water-soluble sol-gel method

A technology of sol-gel and dielectric ceramics, which is applied in the field of finely synthesizing BaO3 dielectric ceramic nano-precursor powders by using wet chemical technology, which can solve the problems of synthesis difficulties and achieve good repeatability, low synthesis temperature, and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

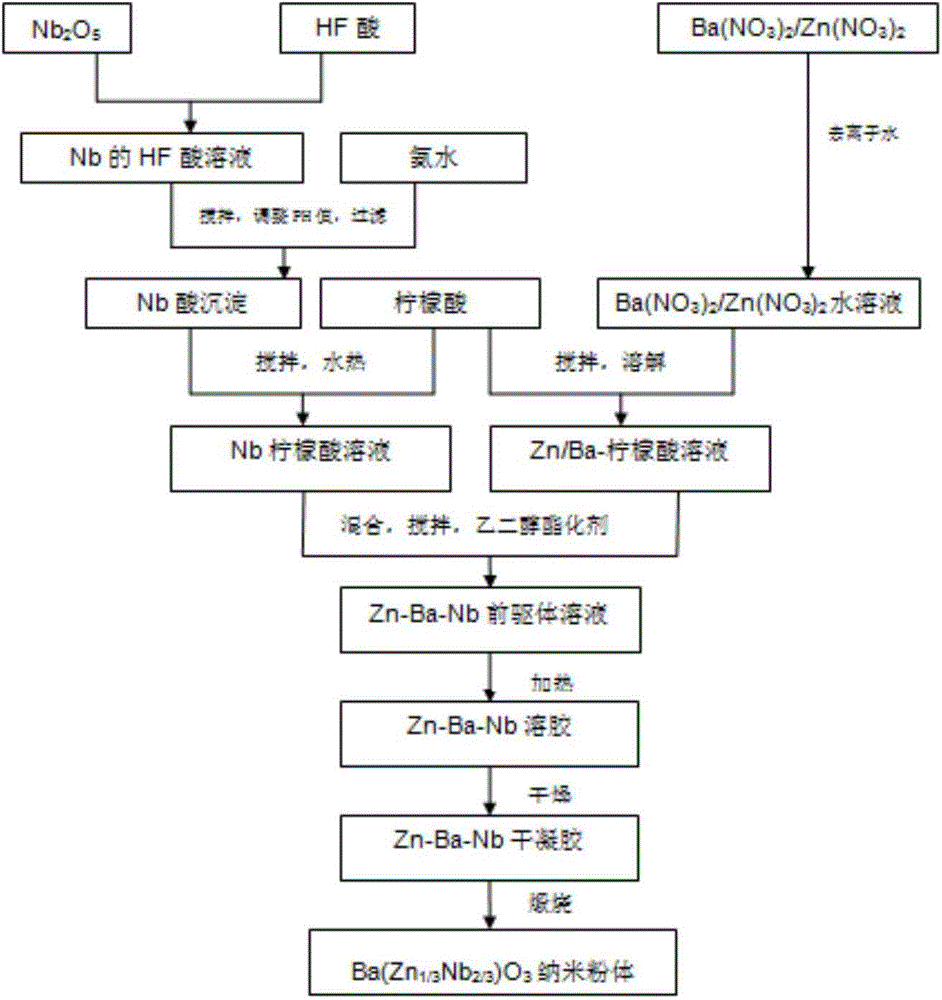

[0034] according to figure 1 Preparation of Ba(Zn 1 / 3 Nb 2 / 3 )O 3 The process flow chart of ceramic nano-precursor powder has the following steps:

[0035] (1) prepare the citric acid aqueous solution of Zn, Ba ion

[0036] (a) According to Ba(Zn 1 / 3 Nb 2 / 3 )O 3 For the stoichiometric ratio of the ceramic phase, adjust the molar ratio of Ba / Zn / Nb elements to 3 / 1+x / 2, where x is: 03 ) 2 .6H 2 A total of 2.9749 grams of O, Ba(NO 3 ) 2 A total of 7.8405 grams, dissolved in 200ml of ionized water, magnetically stirred to form a colorless and transparent solution;

[0037] (b) take by weighing 34.58 grams of citric acid, add in the above-mentioned solution and stir, impel citric acid to form a complex with Zn, Ba ion, make colorless transparent Zn, Ba ion citric acid aqueous solution;

[0038] (2) prepare the citric acid aqueous solution of Nb

[0039] (a) According to Ba(Zn 1 / 3 Nb 2 / 3 )O 3 For the stoichiometric ratio of the ceramic phase, 5.316 grams of niobium oxi...

Embodiment 2

[0048] according to figure 1 Preparation of Ba(Zn 1 / 3 Nb 2 / 3 )O 3 The process flow chart of ceramic nano-precursor powder has the following steps:

[0049] (1) prepare the citric acid aqueous solution of Zn, Ba ion

[0050] (a) According to Ba(Zn 1 / 3 Nb 2 / 3 )O 3 For the stoichiometric ratio of the ceramic phase, adjust the molar ratio of Ba / Zn / Nb elements to 3 / 1+x / 2, where x is: 03 ) 2 .6H 2 A total of 5.9498 grams of O, Ba(NO 3 ) 2 A total of 15.681 grams, dissolved in 200ml of ionized water, magnetically stirred to form a colorless and transparent solution;

[0051] (b) take by weighing 38.428 grams of citric acid, add in the above-mentioned solution and stir, impel citric acid to form a complex with Zn, Ba ion, make colorless transparent Zn, Ba ion citric acid aqueous solution;

[0052] (2) prepare the citric acid aqueous solution of Nb

[0053] (a) According to Ba(Zn 1 / 3 Nb 2 / 3 )O 3 For the stoichiometric ratio of the ceramic phase, weigh 2.987 grams of niob...

Embodiment 3

[0062] (1) prepare the citric acid aqueous solution of Zn, Ba ion

[0063] (a) According to Ba(Zn 1 / 3 Nb 2 / 3 )O 3 For the stoichiometric ratio of the ceramic phase, adjust the molar ratio of Ba / Zn / Nb elements to 3 / 1+x / 2, where x is: 03 ) 2 .6H 2 A total of 8.9247 grams of O, Ba(NO 3 ) 2 A total of 23.5215 grams, dissolved in 200ml of ionized water, magnetically stirred to form a colorless and transparent solution;

[0064] (b) take by weighing 96.07 grams of citric acid, add in the above-mentioned solution and stir, impel citric acid and Zn ion to form complex, make colorless transparent Zn ion citric acid aqueous solution;

[0065] (2) prepare the citric acid aqueous solution of Nb

[0066] (a) According to Ba(Zn 1 / 3 Nb 2 / 3 )O 3 For the stoichiometric ratio of the ceramic phase, weigh 4.4805 grams of niobium oxide, place them in a ceramic medium reactor, add 80ml of hydrofluoric acid, seal it, and then use an oven for high temperature 130°C hydrothermal treatment fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com