Highly filled low-density polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, which is applied in the field of high-filling and low-density polypropylene composite materials and its preparation, can solve the problem of high density, the inability to effectively reduce the density of high-filling polypropylene materials, and the easy entry of polypropylene molecular chains into micropores Internal and other problems, to achieve the effect of reducing material weight, good rigidity and toughness, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

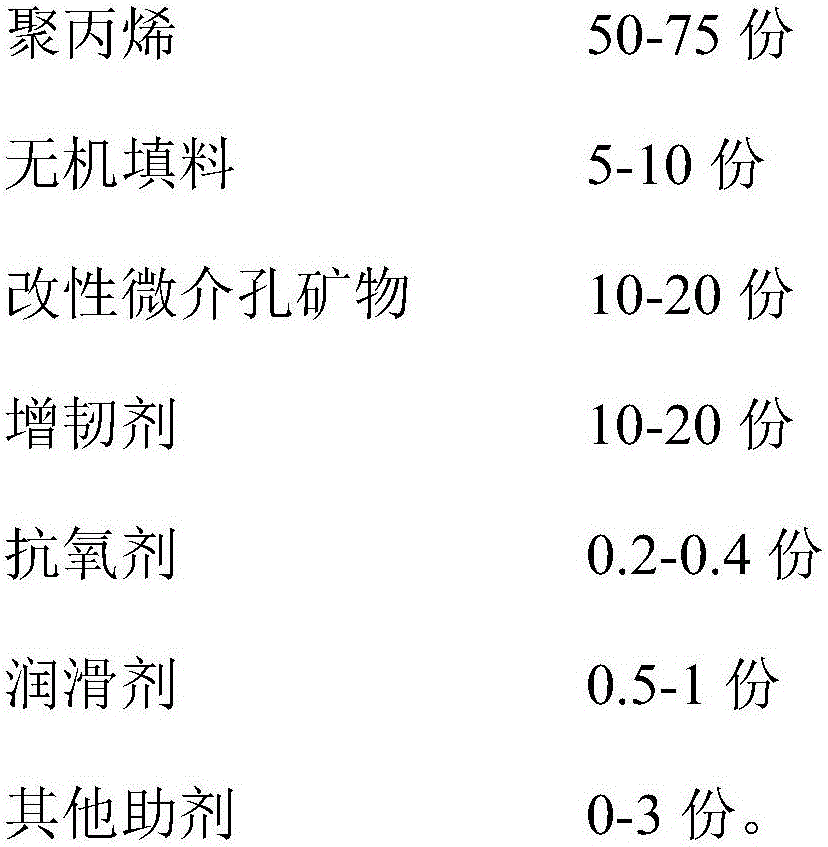

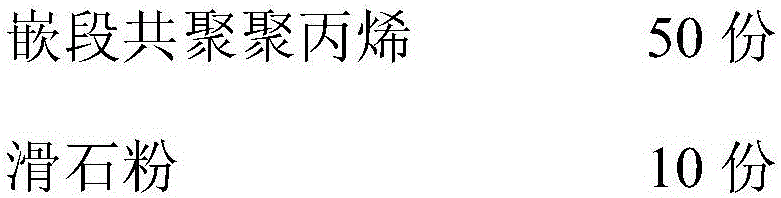

[0027] The high-filling low-density polypropylene composite material in the present embodiment is made up of following raw materials by weight:

[0028]

[0029]

[0030] Concrete preparation method comprises the following steps:

[0031] (1) Preparation of modified diatomite: in 1m 3 Add 0.7m to the volumetric reactor 3 Purified water, adding excess sodium bicarbonate to make a saturated solution, adding 1% citric acid in the amount of sodium bicarbonate to the saturated sodium bicarbonate solution, stirring for 10 minutes, then adding diatomaceous earth, heating at 80°C and stirring for 2 hours, centrifuging, and The centrifuged product was placed in a vacuum drying oven at 80°C for 4 hours, and the dried product was crushed and ground to obtain modified diatomite;

[0032] (2) 20 parts of modified diatomite prepared in step (1), 50 parts of block copolymerized polypropylene, 10 parts of talcum powder, 20 parts of POE elastomer, 0.1 part of antioxidant 1010, 0.1 part...

Embodiment 2

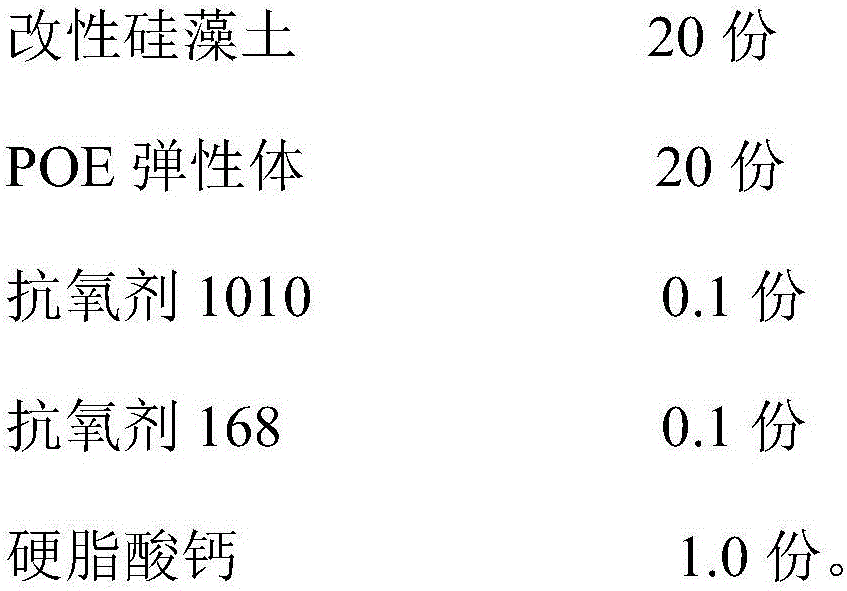

[0034] The high-filling low-density polypropylene composite material in the present embodiment is made up of following raw materials by weight:

[0035]

[0036]

[0037] Concrete preparation method comprises the following steps:

[0038] (1) Preparation of modified calcium silicate: in 1m 3 Add 0.7m to the volumetric reactor 3 Pure water, add excess sodium bicarbonate to make a saturated solution, add sodium bicarbonate 1% citric acid to the saturated sodium bicarbonate solution, stir for 10 minutes, then add calcium silicate, heat at 80°C and stir for 2 hours, centrifuge, and The centrifuged product was placed in a vacuum drying oven at 80°C for 4 hours, and the dried product was crushed and ground to obtain modified calcium silicate;

[0039] (2) 10 parts of modified calcium silicate prepared in step (1), 35 parts of random copolymerized polypropylene, 40 parts of homopolypropylene, 5 parts of calcium carbonate, 10 parts of POE elastomer, 0.2 part of antioxidant 101...

Embodiment 3

[0041] The high-filling low-density polypropylene composite material in the present embodiment is made up of following raw materials by weight:

[0042]

[0043]

[0044] Concrete preparation method comprises the following steps:

[0045] (1) Preparation of modified zeolite powder: in 1m 3 Add 0.7m to the volumetric reactor 3Pure water, add excess sodium bicarbonate to make a saturated solution, add sodium bicarbonate 1% citric acid to the saturated sodium bicarbonate solution, stir for 10 minutes, then add zeolite powder, heat at 80°C and stir for 2 hours, centrifuge, and centrifuge The product was placed in a vacuum drying oven at 80°C for 4 hours, and the dried product was crushed and ground to obtain modified zeolite powder;

[0046] (2) 15 parts of modified zeolite powder prepared by step (1), 65 parts of block copolymerized polypropylene, 5 parts of barium sulfate, 15 parts of POE elastomer, 0.15 part of antioxidant 1010, 0.15 part of antioxidant 168, After putt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com