New method for preparing monoclinic structure ZnZrNb2O8 microwave dielectric ceramic through low temperature sintering

A technology of microwave dielectric ceramics and sol-gel method, which is applied in the field of nZrNb2O8 microwave dielectric ceramics, can solve the problems of unfavorable ceramic sintering, large particle size of powder synthesized at temperature, etc., and achieve good microwave dielectric properties, single phase, and high activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

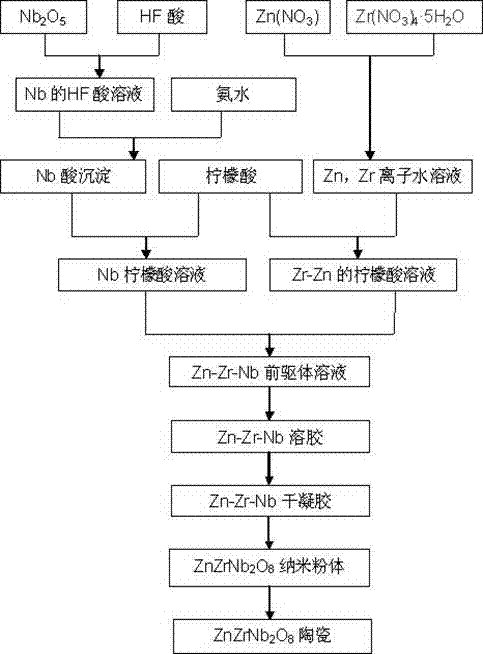

[0037] according to figure 1 Preparation of ZnZrNb by Sol-Gel Process 2 o 8 Ceramic process flow diagram with the following steps:

[0038] 1) Prepare the aqueous citric acid solution of Zr and Zn ions

[0039] (a) According to ZnZrNb 2 o 8 The stoichiometric ratio of the microwave ceramic phase, adjust ZnO (or Zn(NO 3 ) 2 .6H 2 O) / Zr(NO 3 ) 4 ·5H 2 O / Nb 2 o 5 The molar ratio is 1+x / 1 / 1 (03 ) 2 .6H 2 O is 9.0139 grams, weigh 0.03mol of Zr(NO 3 ) 4 ·5H 2 A total of 12.8772 grams of O, dissolved in 200ml of ionized water, magnetically stirred to form a transparent solution;

[0040] (b) take by weighing 34.5852 grams of citric acid, add in the above-mentioned solution and stir, impel citric acid to form a complex with Zr, Zn ion, make transparent Zn and Zr ion citric acid aqueous solution;

[0041] 2) prepare the aqueous citric acid solution of Nb ion

[0042] (a) According to ZnZrNb 2 o 8 The stoichiometric ratio of the microwave ceramic phase, weigh 7.97...

Embodiment 2

[0052] according to figure 1 Preparation of ZnZrNb by Sol-Gel Process 2 o 8 Ceramic process flow diagram with the following steps:

[0053] 1) Prepare the aqueous citric acid solution of Zr and Zn ions

[0054] (a) According to ZnZrNb 2 o 8 The stoichiometric ratio of the microwave ceramic phase, adjust ZnO (or Zn(NO 3 ) 2 .6H 2 O) / Zr(NO 3 ) 4 ·5H 2 O / Nb 2 o 5 The molar ratio is 1+x / 1 / 1 (03 ) 2 .6H 2 O is 9.37 grams, weigh 0.03mol of Zr(NO 3 ) 4 ·5H 2 A total of 12.8772 grams of O, dissolved in 200ml of ionized water, magnetically stirred to form a transparent solution;

[0055] (b) take by weighing 57.642 grams of citric acid, add in the above-mentioned solution and stir, impel citric acid to form a complex with Zr, Zn ion, make transparent Zn and Zr ion citric acid aqueous solution;

[0056] 2) prepare the aqueous citric acid solution of Nb ion

[0057] (a) According to ZnZrNb 2 o 8 The stoichiometric ratio of the microwave ceramic phase, weigh 7.974 g...

Embodiment 3

[0067] according to figure 1 Preparation of ZnZrNb by Sol-Gel Process 2 o 8 Ceramic process flow diagram with the following steps:

[0068] 1) Prepare the aqueous citric acid solution of Zr and Zn ions

[0069] (a) According to ZnZrNb 2 o 8 The stoichiometric ratio of the microwave ceramic phase, adjust ZnO (or Zn(NO 3 ) 2 .6H 2 O) / Zr(NO 3 ) 4 ·5H 2 O / Nb 2 o5 The molar ratio is 1+x / 1 / 1 (03 ) 2 .6H 2 O is 9.1924 grams, weigh 0.03mol of Zr(NO 3 ) 4 ·5H 2 A total of 12.8772 grams of O, dissolved in 200ml of ionized water, magnetically stirred to form a transparent solution;

[0070] (b) take by weighing 46.1136 grams of citric acid, add in the above-mentioned solution and stir, impel citric acid to form a complex with Zr, Zn ion, make transparent Zn and Zr ion citric acid aqueous solution;

[0071] 2) prepare the aqueous citric acid solution of Nb ion

[0072] (a) According to ZnZrNb 2 o 8 The stoichiometric ratio of the microwave ceramic phase is to weigh 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com