Preparation method for silicon-carbon composite anode material of lithium ion battery

A lithium-ion battery, silicon-carbon composite technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of nano-silicon agglomeration, nano-silicon extraction polymerization reaction, instability, etc., to achieve improved bonding strength, good conductivity and Cushioning effect, effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

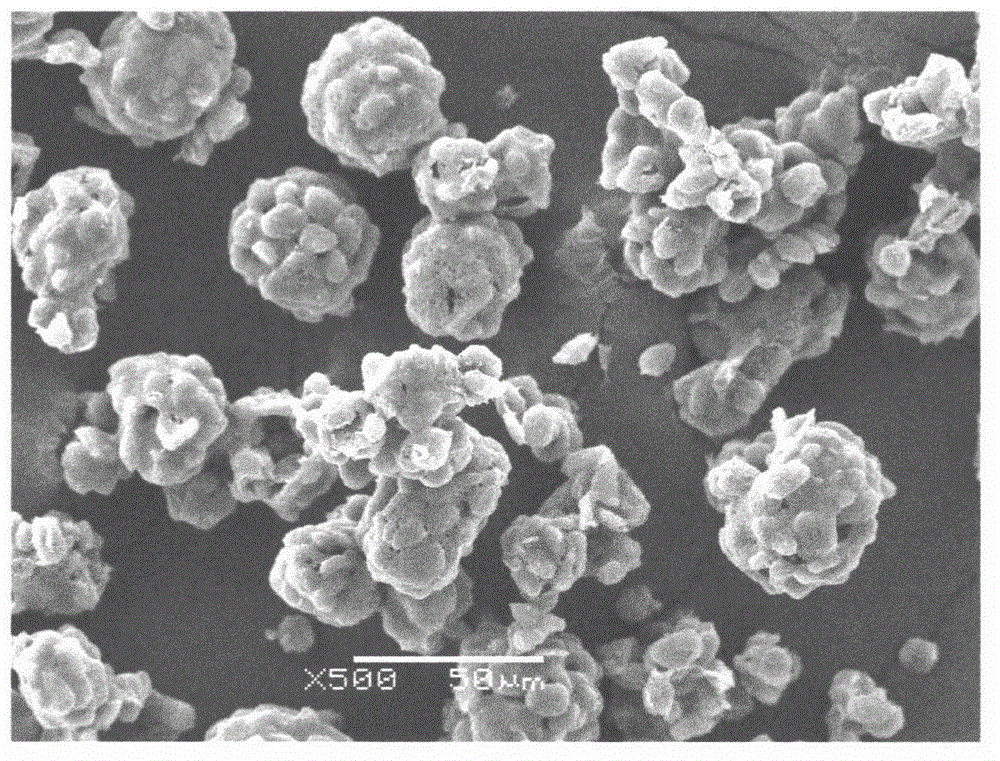

[0053] In the presence of an ethanol dispersion medium, use a ball mill to grind silicon, and add maleic acid to the silicon grinding solution to control the pH value of the silicon grinding dispersion to 5.8 and the mass solid content to 18%, and set aside. The average particle size of the silicon particles in the silicon polishing liquid is 150nm.

[0054] Preparation of polymer / nano-silicon composite microsphere dispersion: Add 58.8 g of 17% polyvinylpyrrolidone ethanol solution, 18% nano Siliconethanol dispersion 111g, ethanol 193.3g, be warming up to 65 ℃, in system, dropwise add the mixed monomer solution containing benzoyl peroxide initiator (5g benzoyl peroxide is dissolved in 60g styrene and 40g acrylonitrile prepared in the mixed monomer), the dropping time is 30min, after the dropping is completed, the insulation reaction is carried out for 7h, and the polymer / nano-silicon composite microsphere dispersion with a solid content of 28.12% and an average particle diamet...

Embodiment 2

[0058] Preparation of nano-silicon dispersion liquid: prepared as in Example 1, the average particle diameter of silicon particles in the silicon grinding liquid is 250nm, and the solid content is 7%.

[0059] The preparation of polymer / nanocomposite silicon microsphere dispersion liquid: in the four port glass reactor that is equipped with reflux condenser, thermometer, nitrogen through pipe, add the ethanol solution 70.5g of 17% polyvinyl butyral PVB successively, 7% nano silicon ethanol dispersion liquid 105g, dehydrated alcohol 180.8g, be warming up to 70 ℃, in system, add dropwise the mixed monomer solution that contains benzoyl peroxide and azobisisobutyronitrile mixed initiator (0.57 g benzoyl peroxide and 1.20 g of azobisisobutyronitrile are dissolved in the mixed monomer of 70 g of styrene and 30 g of acrylonitrile) and the time for the addition is 30 min. The solid content is 26.39%, the average particle size is the polymer / nano-silicon composite microsphere dispersi...

Embodiment 3

[0063] Preparation of nano-silicon dispersion: prepared as in Example 1, the obtained nano-silicon dispersion had a solid content of 9%, and the average particle diameter of silicon particles in the silicon grinding liquid was 220 nm.

[0064] Preparation of polymer / nano-silicon composite microsphere dispersion: In a four-port glass reactor equipped with a reflux condenser, a thermometer, and a nitrogen pipe, add 75 g of 17% polyvinylpyrrolidone PVP ethanol solution, 9% nano Silicon ethanol dispersion 123.6g, ethanol 200g, add the mixed monomer solution containing benzoyl peroxide and azobisisobutyronitrile mixed initiator (2.86g benzoyl peroxide and 3.14g azobisisobutyronitrile are dissolved in 60g of α-methylstyrene and 40g of methacrylonitrile mixed monomer), the titration time is 30min, the temperature is raised to 70°C, and the heat preservation reaction is 7h, and the solid content is 25.36%, and the average particle size is 1200nm polymer / nano-silicon composite microsph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com