Solvent-free coumarone modified epoxy heavy-duty anticorrosive coating

A kind of anti-corrosion coating, Coumarone's technology, applied in the field of coatings, can solve the problems of coating manufacturing and coating construction personnel's health hazards, slow curing speed at room temperature, and inability to coat other light-colored coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0031] The distribution ratio table of group A of the primer:

[0032]

[0033] The distribution ratio table of group B of the primer:

[0034]

[0035] Group C distribution ratio of topcoat:

[0036]

[0037] Group B distribution ratio table for topcoat:

[0038]

example 2

[0040] The distribution ratio table of group A of the primer:

[0041]

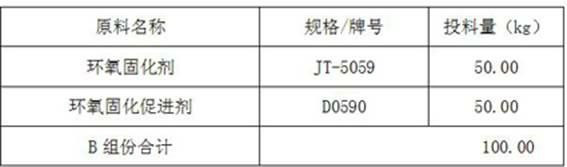

[0042] The distribution ratio table of group B of the primer:

[0043]

[0044] Group C distribution ratio of topcoat:

[0045]

[0046] Group B distribution ratio table for topcoat:

[0047]

example 3

[0049] The distribution ratio table of group A of the primer:

[0050]

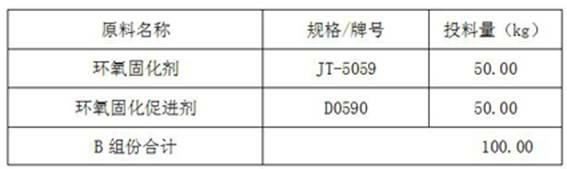

[0051] The distribution ratio table of group B of the primer:

[0052]

[0053] Group C distribution ratio of topcoat:

[0054]

[0055] Group B distribution ratio table for topcoat:

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com