Incompletely-fused glass group and making method thereof

A glass and fusion technology, applied in glass manufacturing equipment, glass forming, glass reshaping, etc., to achieve the effect of solving flatness, saving costs, and ensuring the quality of curved surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

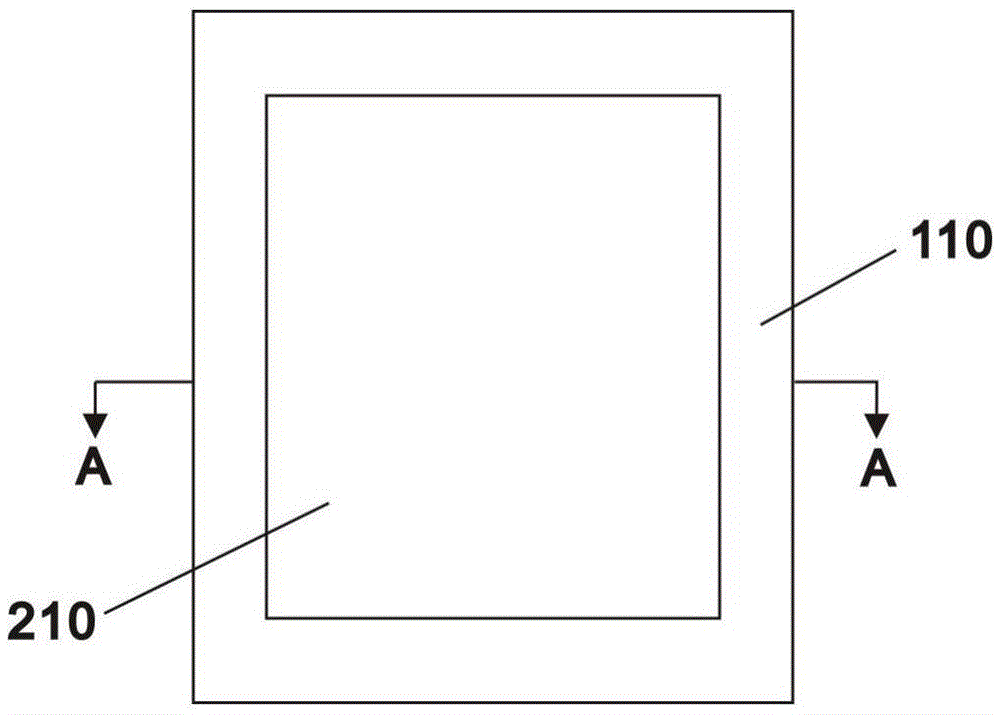

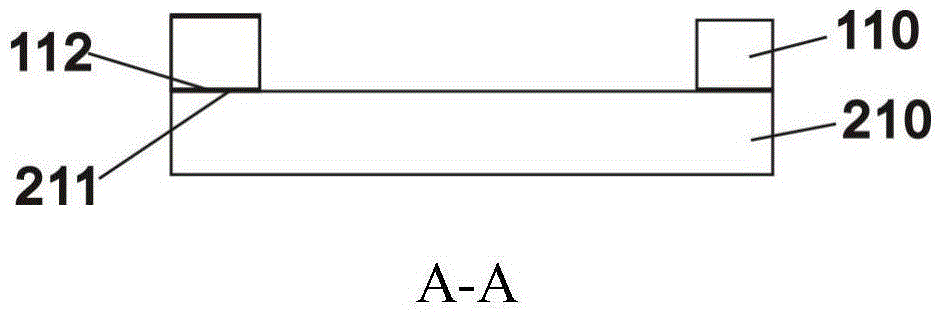

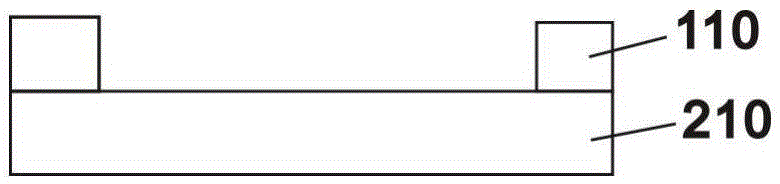

Image

Examples

preparation example Construction

[0049] The preparation method of the above-mentioned incompletely fused glass group comprises the following steps,

[0050] S1. Clean the glass surface first;

[0051] S2. Contacting the glass surfaces;

[0052] S3. Apply force to the glass group to make the contact part form a van der Waals force fit;

[0053] S4. Baking and heating the glass group, the heating temperature is 240-600°C, and the time is 0.5-48h;

[0054] S5. The state of the glass group in which the fusion fault can be seen under the microscope is the incompletely fused glass group.

[0055] Among them, the function of S1 is to remove impurities, so that the surface is free from dirt and micro particles, such as dust;

[0056] The function of S2-S3 is to form van der Waals bonding between the glasses.

[0057] The function of S4 is to make the fusion force of the glass greater than the breaking force of the glass, but the glass does not reach a completely molten state.

[0058] Still taking two pieces of ...

Embodiment 1

[0069] Corning Glass vs. Corning Glass

[0070] First clean the two glass surfaces; then contact the glass surfaces; then apply force to the glass group to form a van der Waals force bond between the contact parts; then bake the glass group at a temperature of 550°C for 1 hour and 30 minutes. Finally, under a high-power microscope, such as 100 times magnification, the glass group state of the fusion fault can be seen, which is the incompletely fused glass group.

Embodiment 2

[0072] Schott glass and Schott glass:

[0073] First clean the two glass surfaces; then contact the glass surfaces; then apply force to the glass group to form a van der Waals force bond on the contact part; then bake the glass group at a temperature of 530°C for 1 hour and 50 minutes. Finally, under a high-power microscope, such as 100 times magnification, the glass group state of the fusion fault can be seen, which is the incompletely fused glass group.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com