Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about "Tretrafluoboric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing waterless lithium terafluoroborate

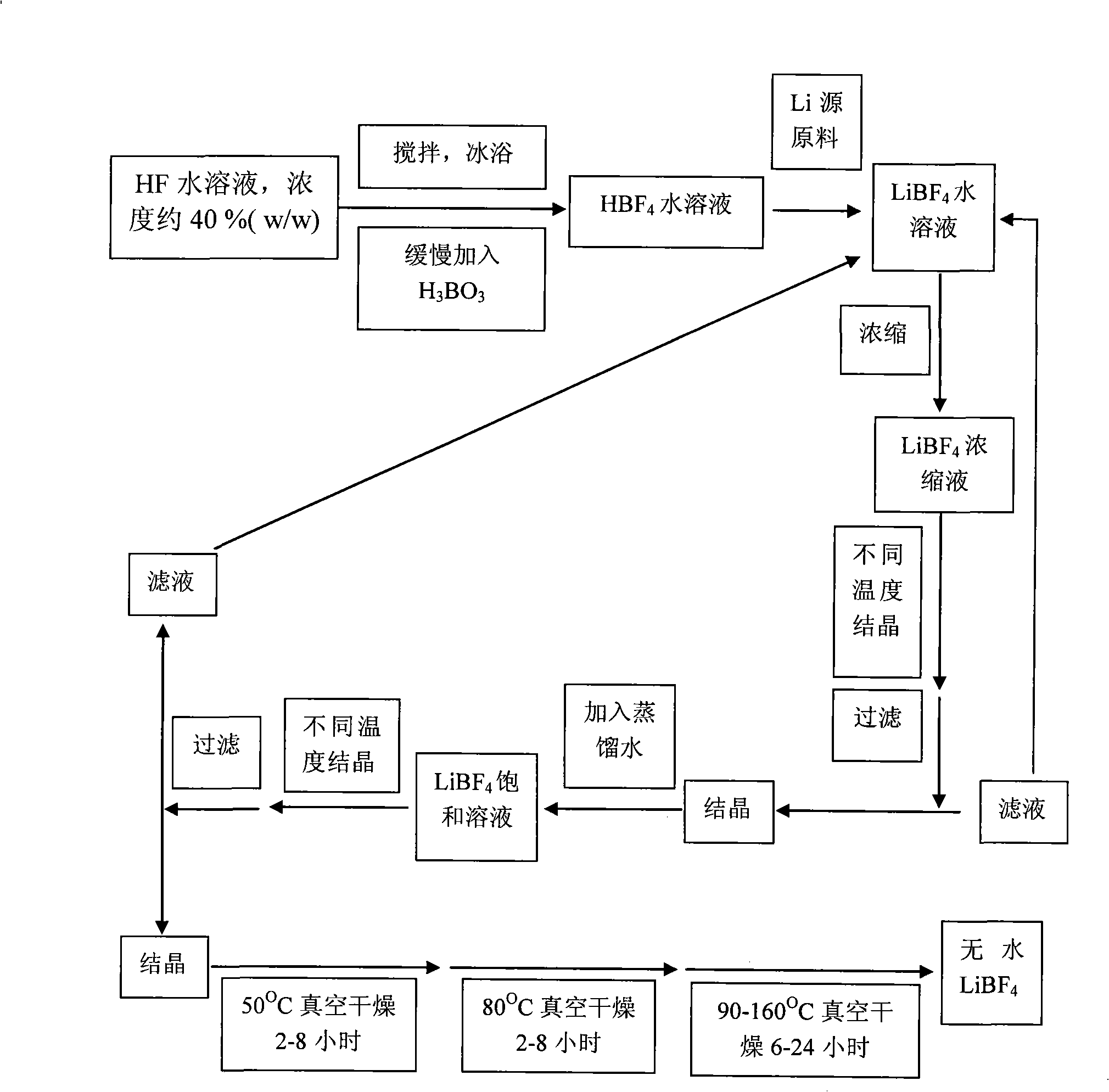

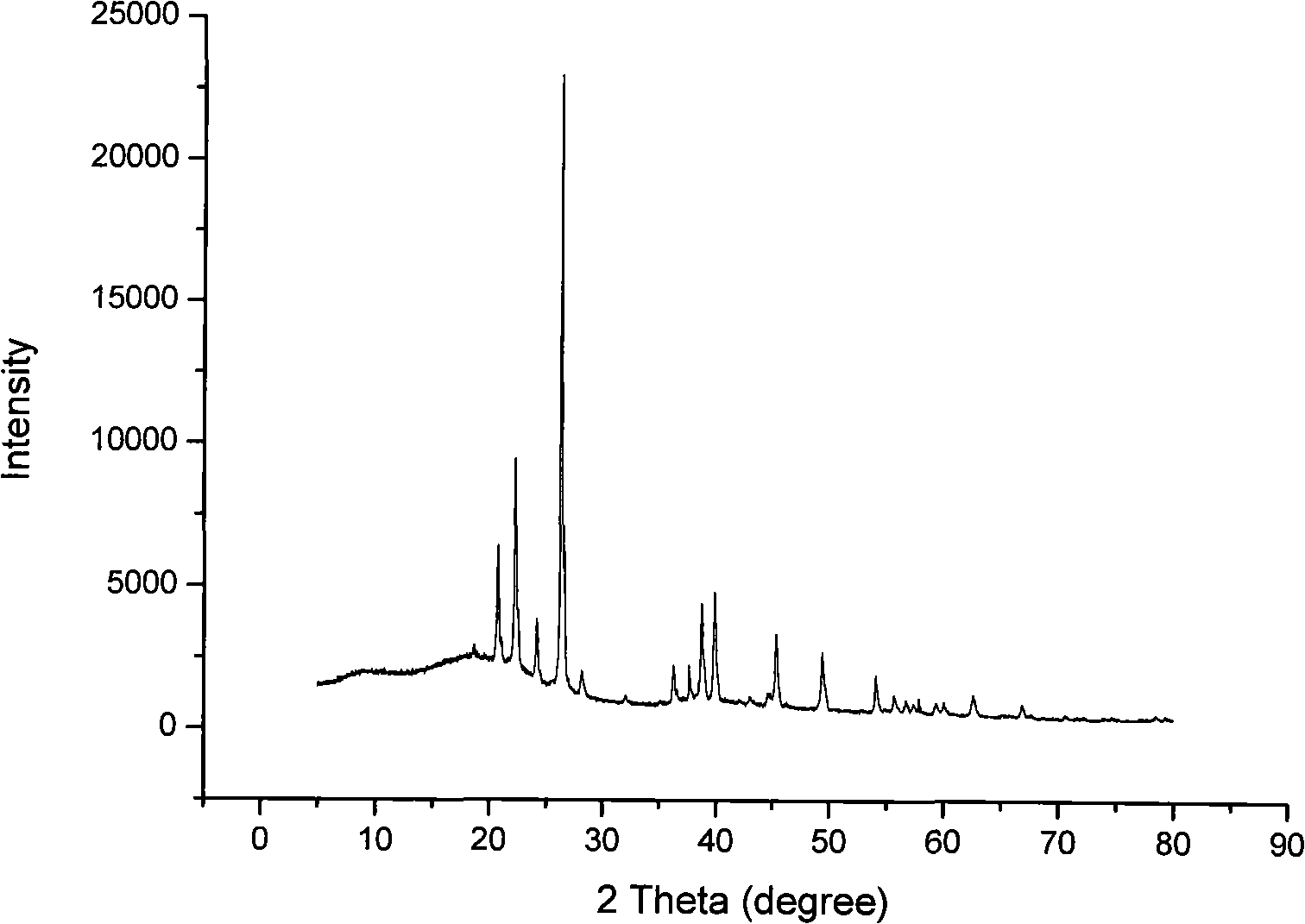

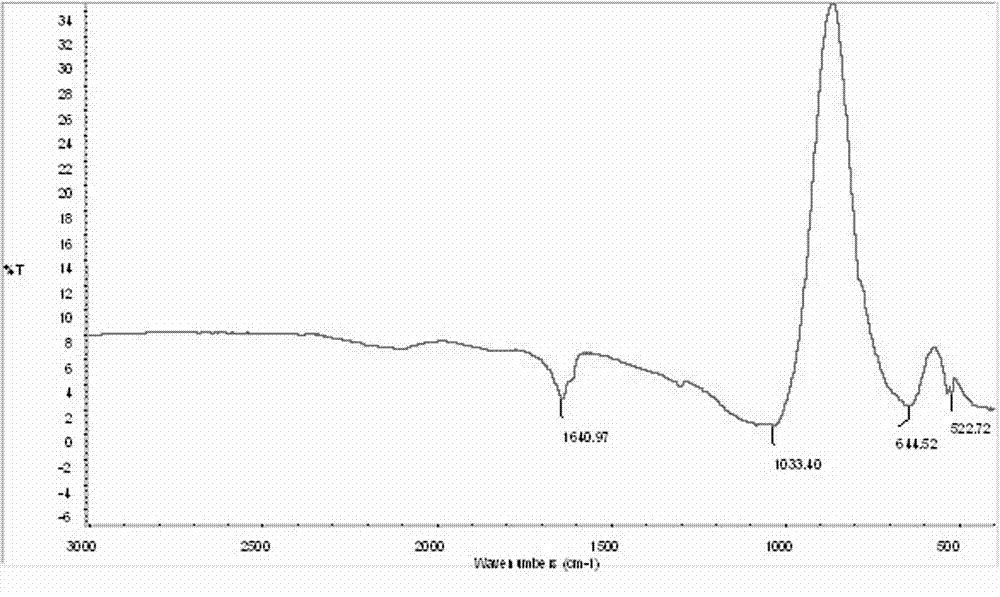

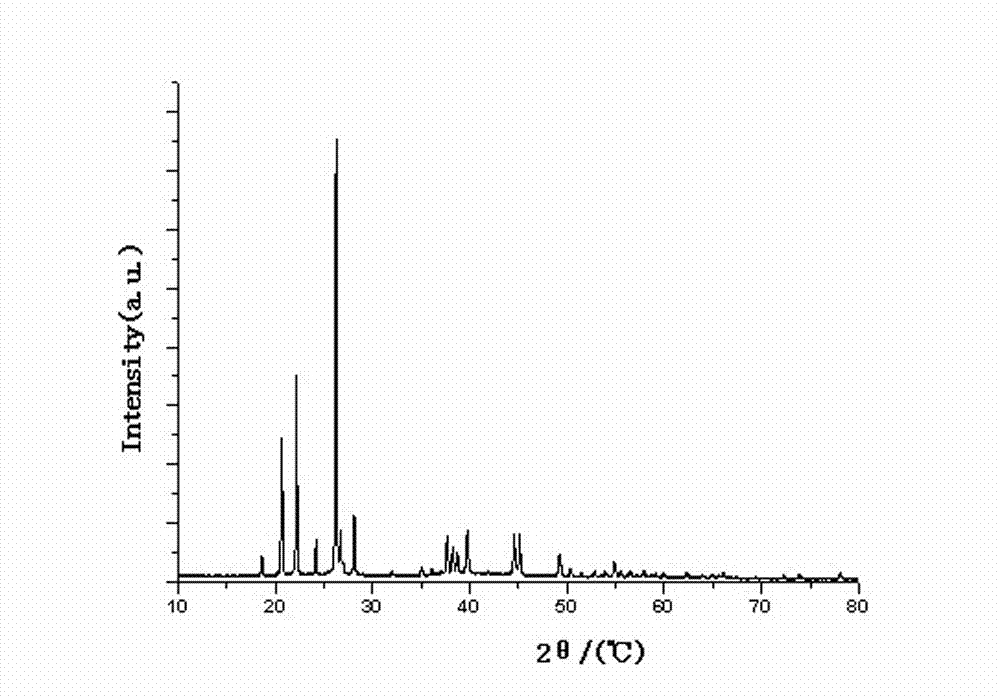

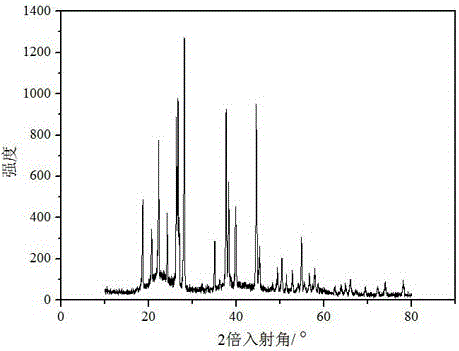

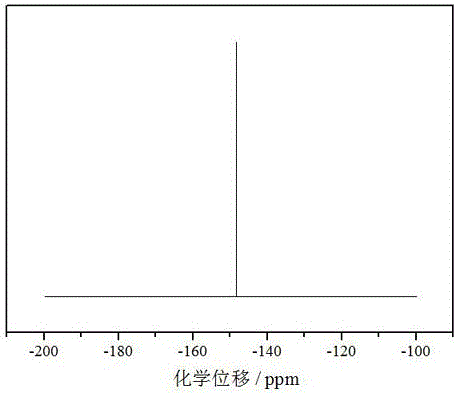

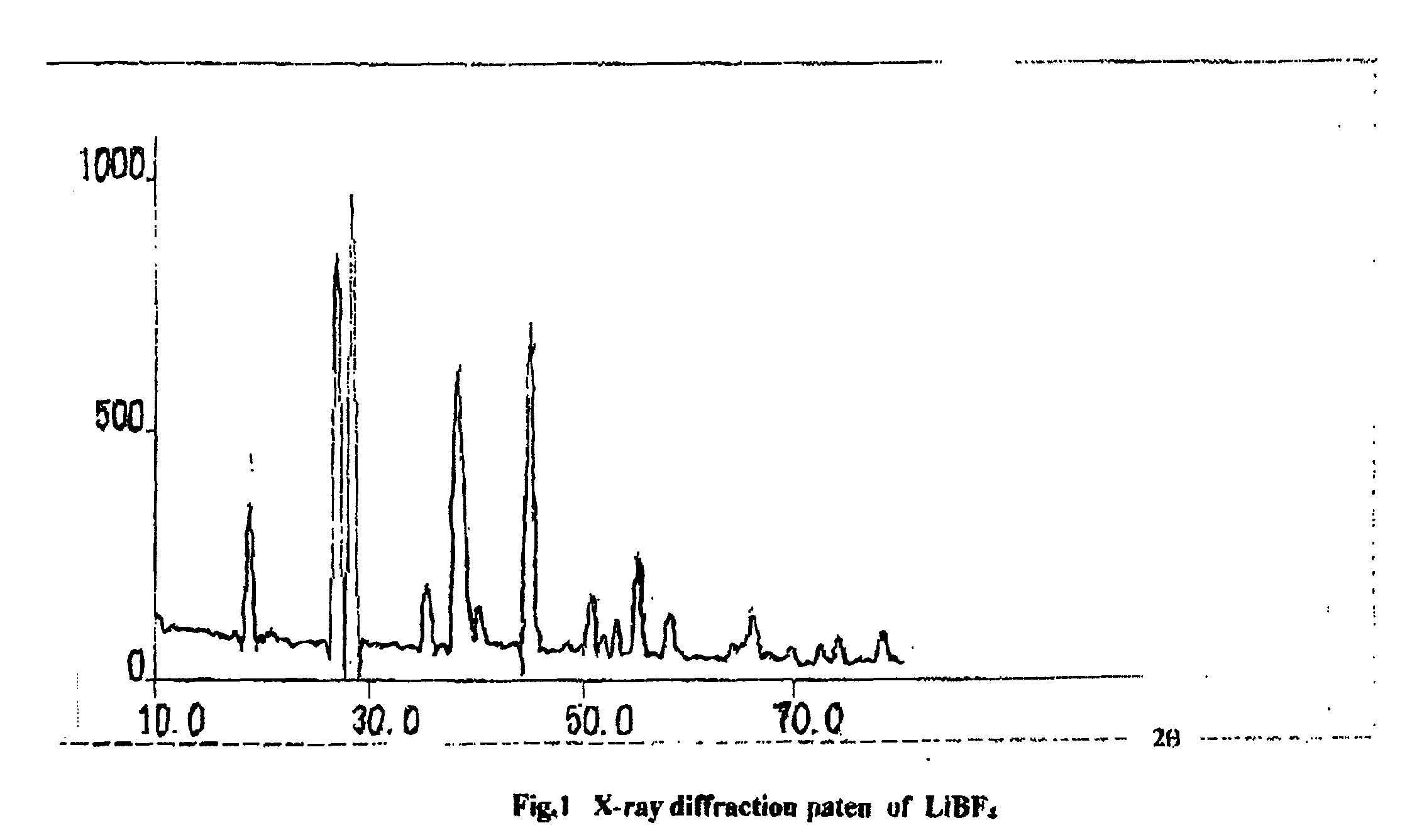

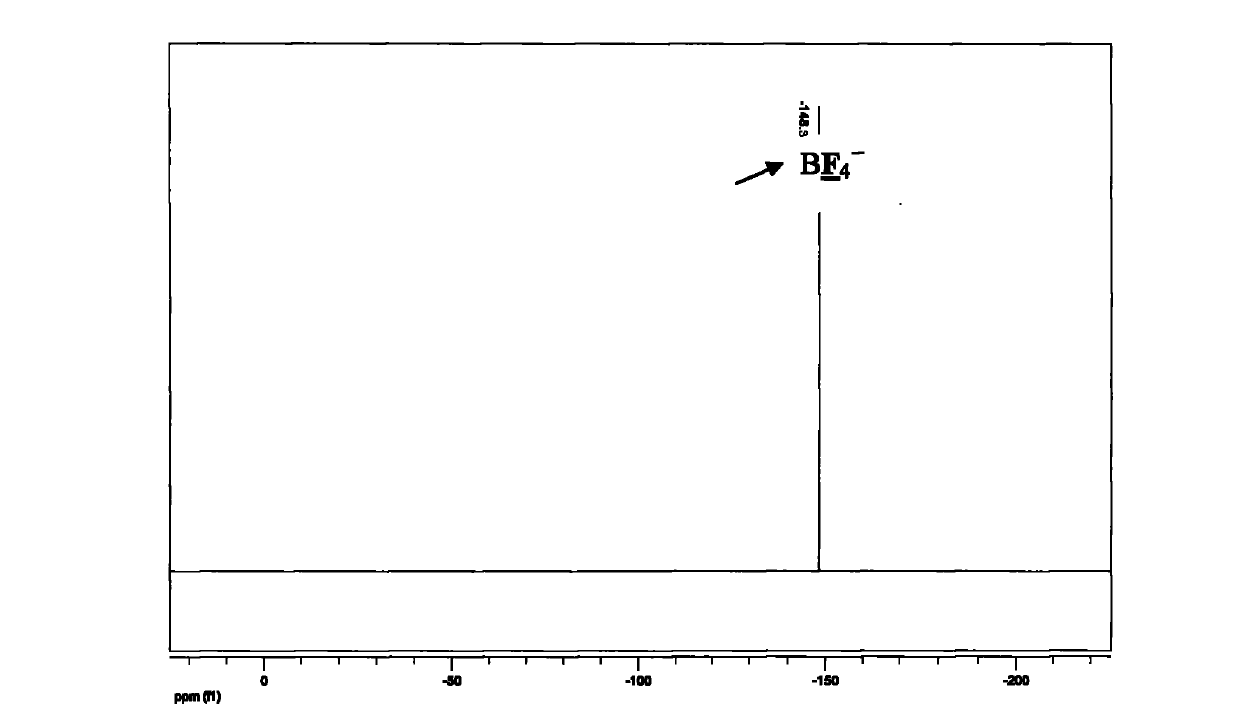

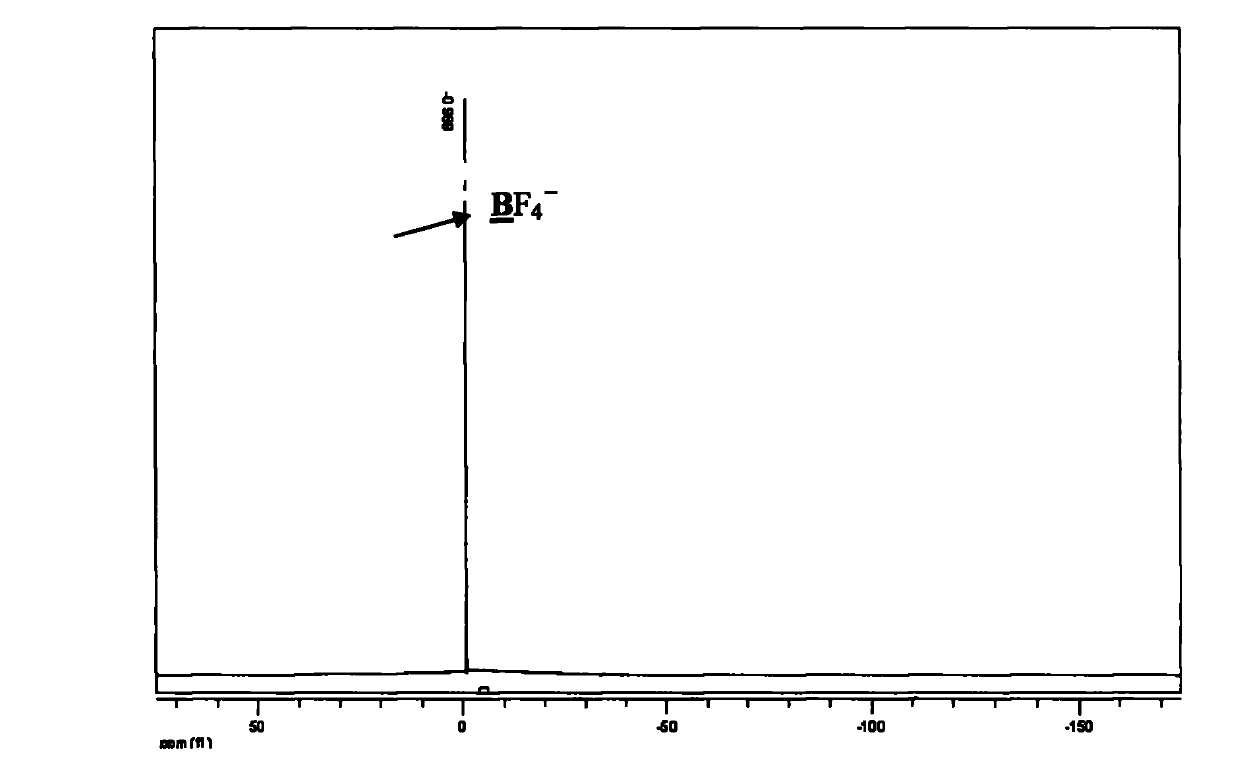

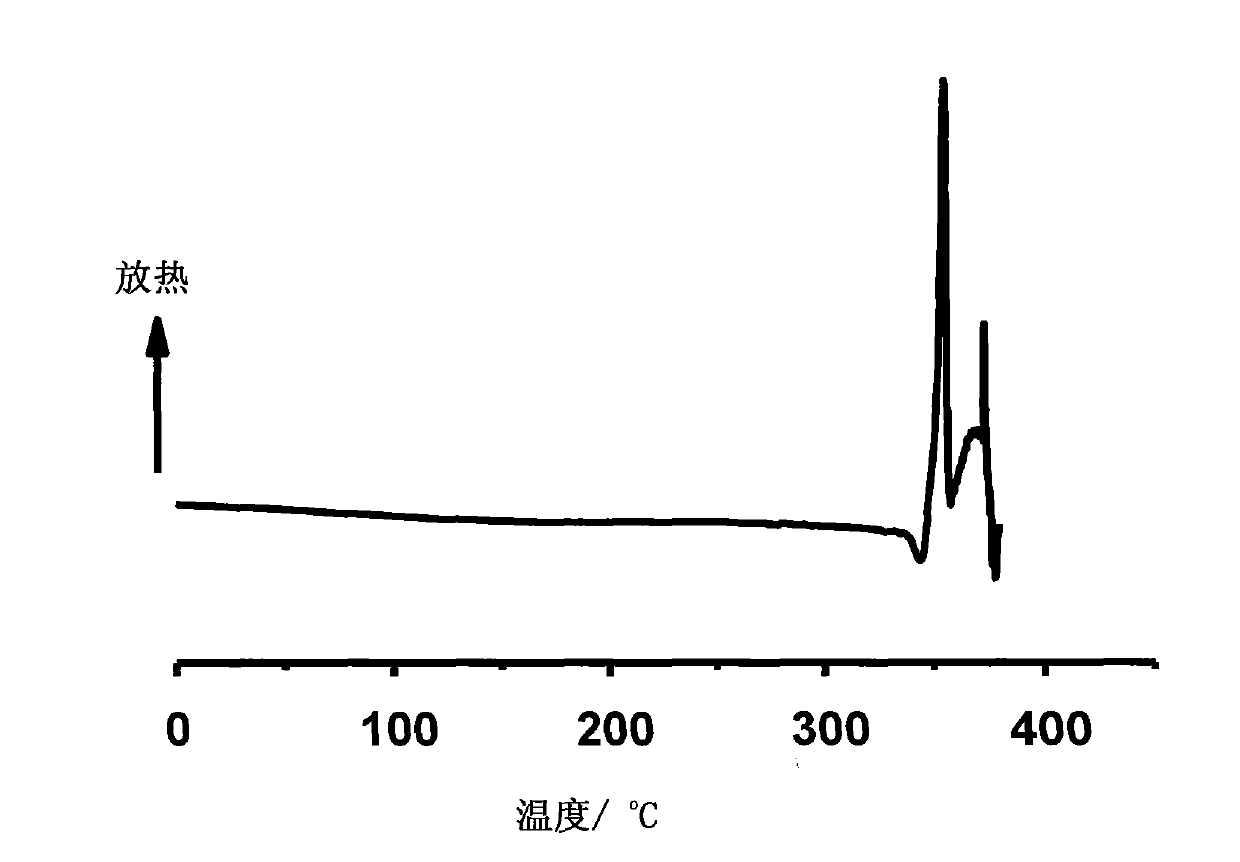

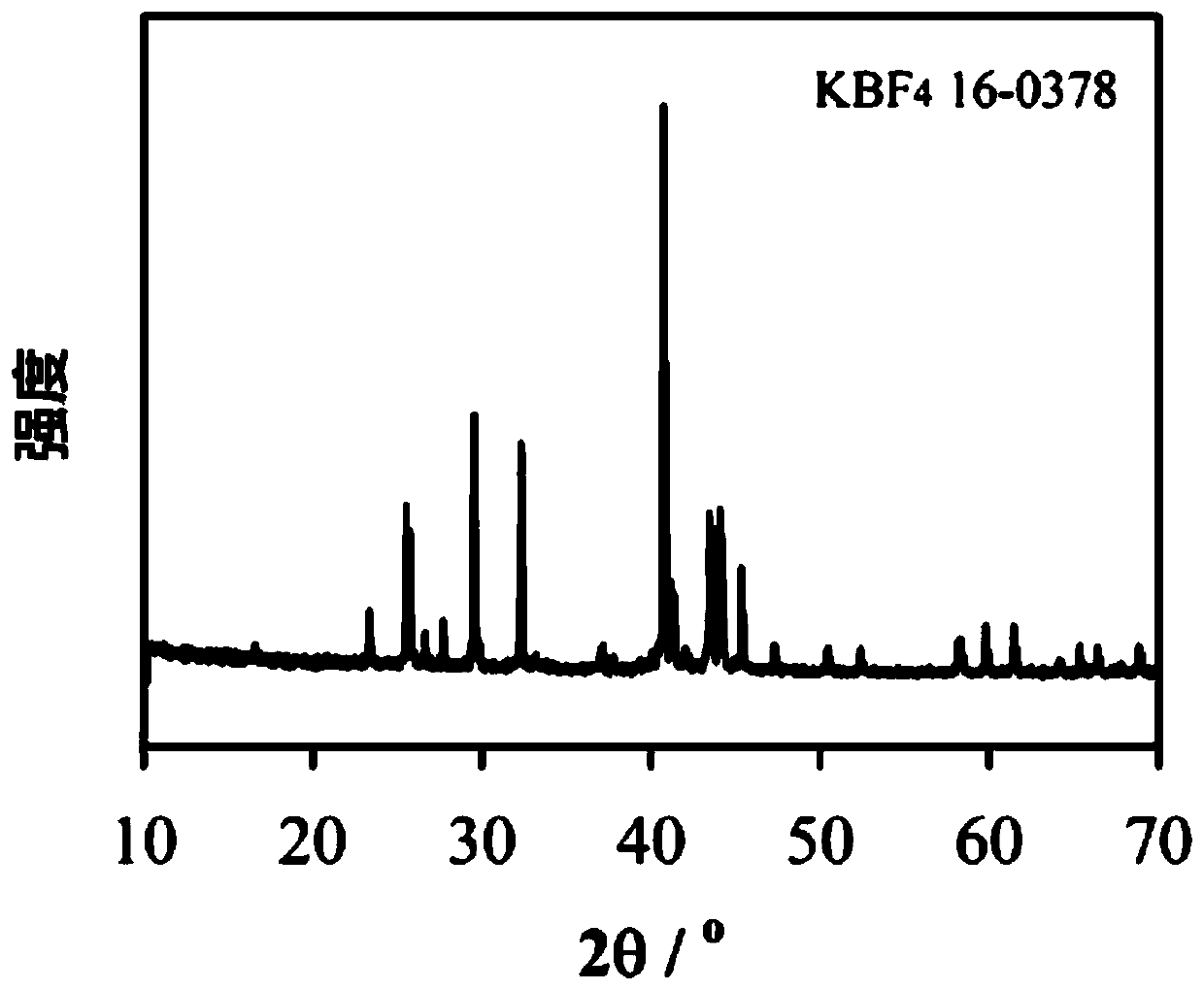

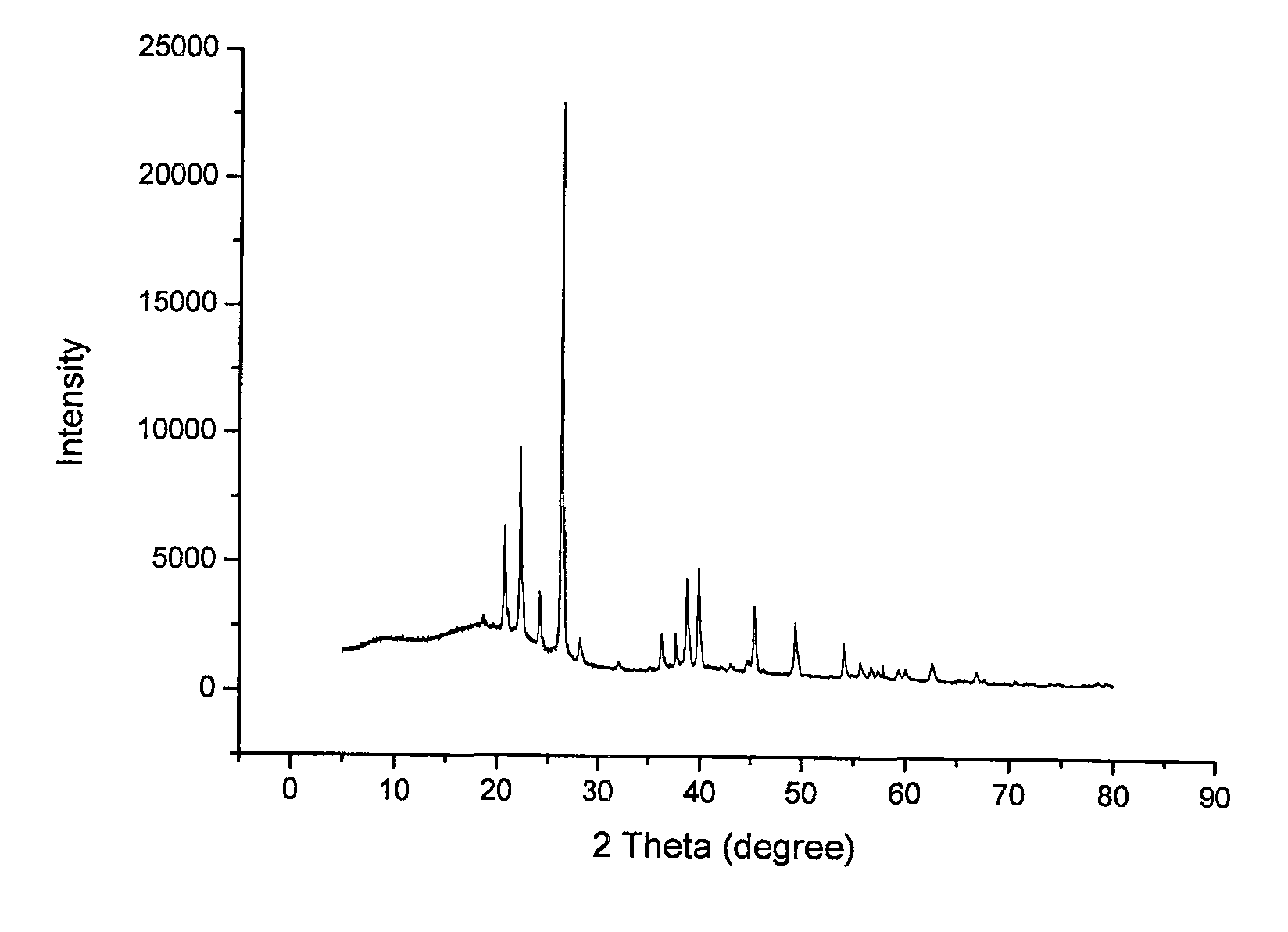

InactiveCN101318664AThe product quality is quiteEfficient removalTretrafluoboric acidLithium hydroxideX-ray

The invention relates to a method for preparing an anhydrous lithium tetrafluoroborate which comprises the following steps: a lithium source including lithium hydroxide, lithium carbonate, and the like, reacts with fluorine hydride and boric acid to obtain lithium tetrafluoroborate solution, then the lithium tetrafluoroborate solution is condensed, crystallized and recrystallized, ground, and vacuum dried to obtain the anhydrous lithium tetrafluoroborate. The method of the invention adopts a staged temperature rise control, the process of the preparation is simple, raw materials are cheap and the preparation cost is low, no organic solvent is used during the synthetic process, no poison is produced, therefore, the method accords with the concept of green environmental protection, the anhydrous lithium tetrafluoroborate prepared by the method is determined by a X-ray diffraction map, the diffraction peak is clear and sharp and completely matches the standard card, which shows that the product prepared by the method of the invention is anhydrous LiBF4 with complete crystal form, the quality of the product is equal to the quality of the anhydrous lithium tetrafluoroborate prepared by the reaction of lithium fluoride and boron trifluoride.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Preparation method of high-purity lithium tetrafluoroborate

The invention provides a preparation method of high-purity lithium tetrafluoroborate; and the method comprises the following steps that high-purity lithium fluoride and a boron trifluoride coordination compound react in chain carbonate organic solvent, and lithium tetrafluoroborate is obtained after filtration, concentration, extractive crystallization, washing and drying. In the preparation method of high-purity lithium tetrafluoroborate, the boron trifluoride coordination compound has wide sources of raw materials and is low in price, the linear carbonate organic solvent has low toxin and is environment-friendly, the synthetic reaction conditions are mild, the operation is simple, the equipment investment is low, the lithium tetrafluoroborate productivity is high, the yield is high, the energy consumption is low, the post-treatment is simple, and the method is applicable to large-scale production.

Owner:GUANGZHOU TINCI MATERIALS TECH +1

Method for producing highly pure LiBF4

InactiveUS6537512B1Simple and cost-effectiveReduce solubilityNon-aqueous electrolyte accumulatorsTretrafluoboric acidCombinatorial chemistryDiethyl ether

Highly pure LiBF4 is prepared by preparing a solution of BF3 etherate in diethyl ether, suspending LiF in this solution, reacting to give solid LiBF4, and then separating off the solid LiBF4 formed. The LiBF4 prepared is used for producing lithium ion batteries.

Owner:BASF AG

Method for producing lithium tetrafluoroborate solution

ActiveCN103733416AEasy to controlReduced concentration of acidic impuritiesFinal product manufactureLi-accumulatorsBoron trifluorideWater concentration

This method for producing a lithium tetrafluoroborate solution for lithium battery electrolyte solutions comprises: a reaction step wherein lithium fluoride and boron trifluoride are reacted with each other in a chain carbonic acid ester that serves as a solvent, thereby producing lithium tetrafluoroborate and obtaining a reaction solution that is obtained by dissolving the lithium tetrafluoroborate in the solvent; a water removal step wherein a water remover is added into the reaction solution; an acidic impurity removal step wherein acidic impurities are removed by concentrating the reaction solution after the water removal step; and a dilution step wherein the concentrated solution after the acidic impurity removal step is diluted. This production method is capable of providing a method for producing a lithium tetrafluoroborate solution for lithium battery electrolyte solutions, said lithium tetrafluoroborate solution having an acidic impurity concentration reduced to 50 ppm by mass or less and a water concentration reduced to 15 ppm by mass or less.

Owner:ZHEJIANG SINO NITROGEN KANGPENG CHEM CO LTD

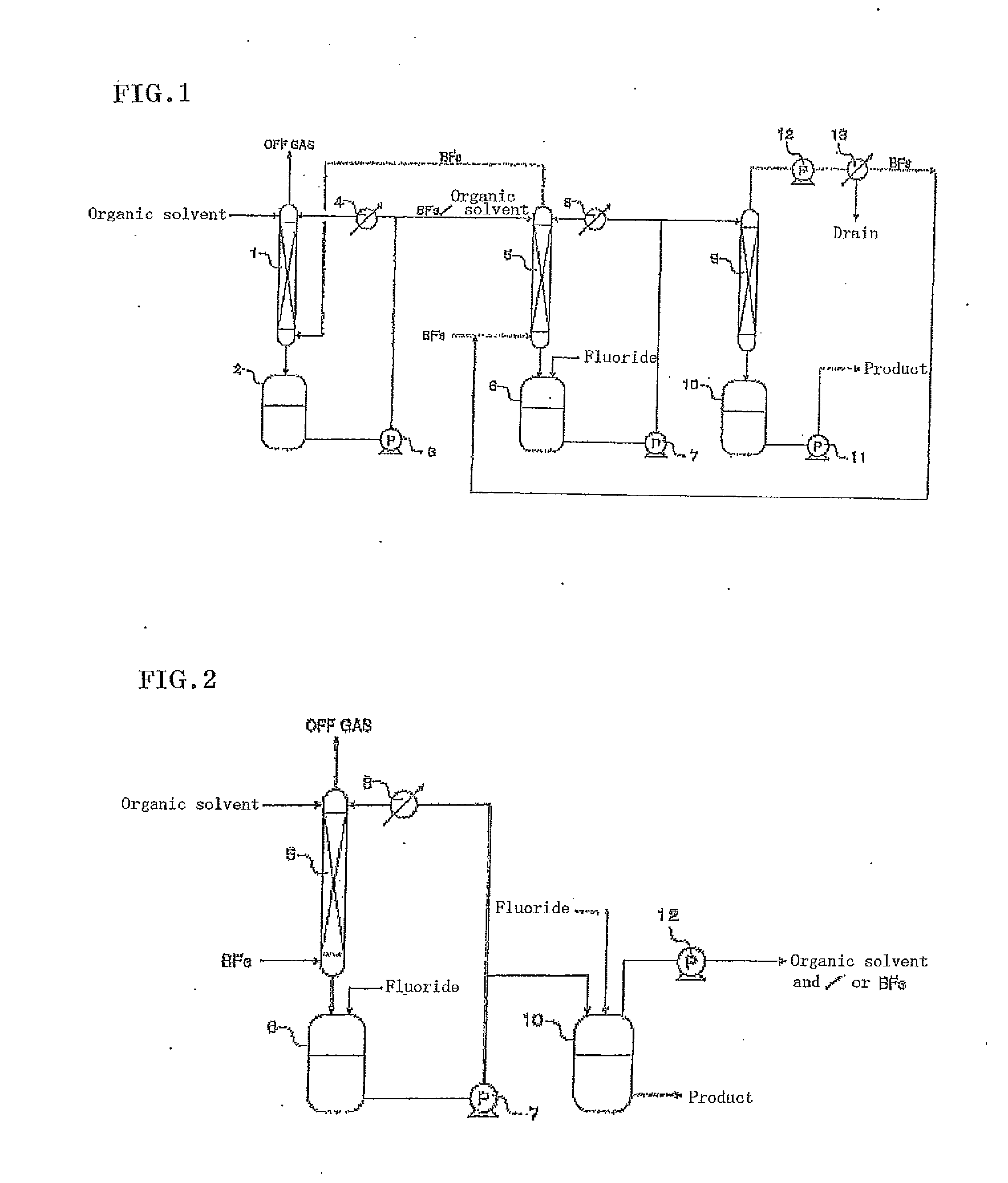

Method for producing tetrafluoroborate

InactiveUS20120082608A1Good effectFinal product manufactureSecondary cellsOrganic solventTetrafluoroborate

An object of the invention is to provide a tetrafluoroborate producing method that allows high-yield, high-efficiency production of a tetrafluoroborate by a continuous process, a tetrafluoroborate-containing electrolyte, and an electrical storage device including such an electrolyte. The invention provides a method for producing a tetrafluoroborate, which includes: a first step including dissolving boron trifluoride gas in an organic solvent; a second step including adding, to the organic solvent, a fluoride (MFn, wherein M represents a metal or NH4, and 1≦n≦3) in an amount stoichiometrically equivalent to or less than the amount of the boron trifluoride so that a tetrafluoroborate solution is produced; and a third step including circulating the tetrafluoroborate solution through the first step so that the boron trifluoride gas is dissolved in the tetrafluoroborate solution instead of the organic solvent.

Owner:STELLA CHEMIFA CORP

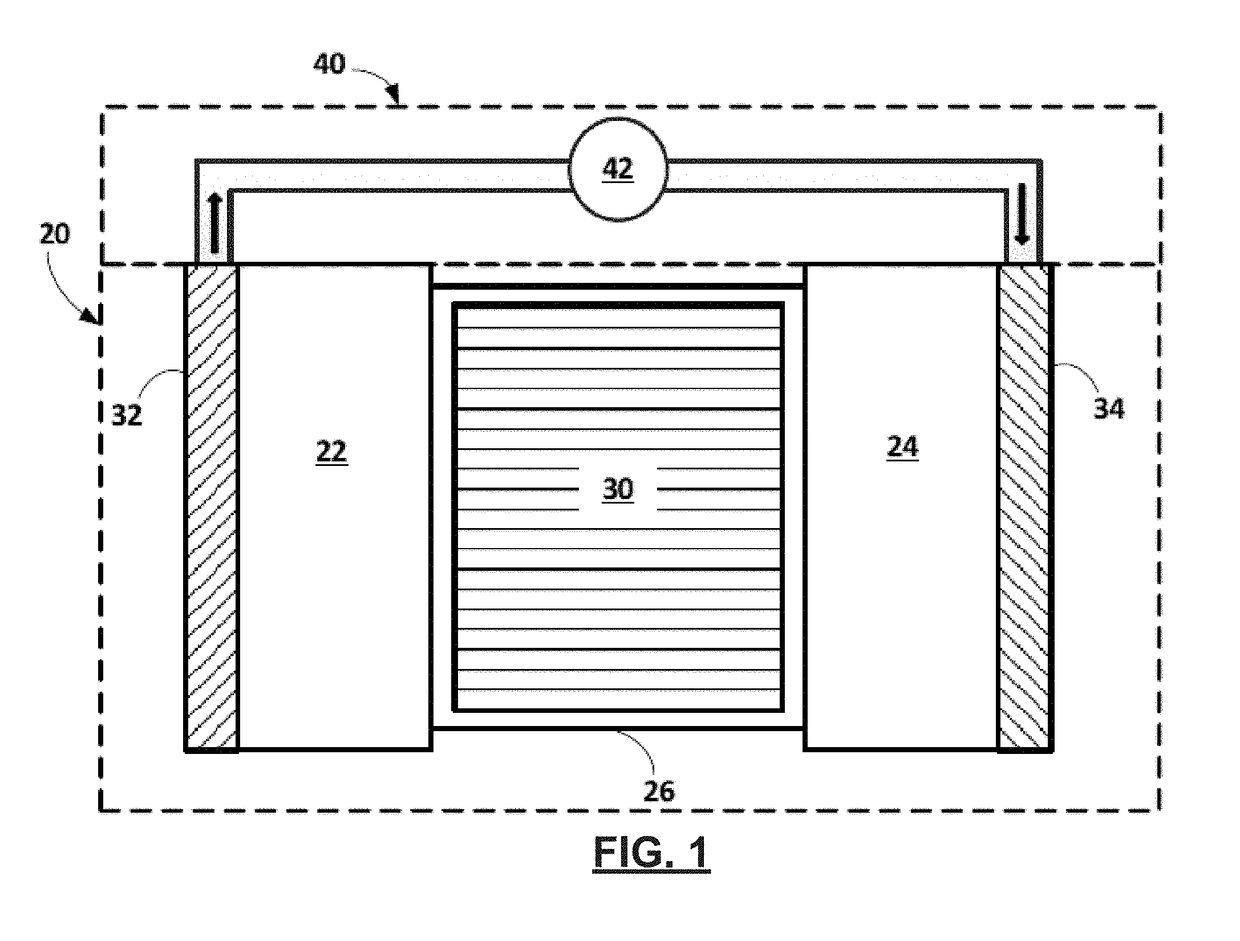

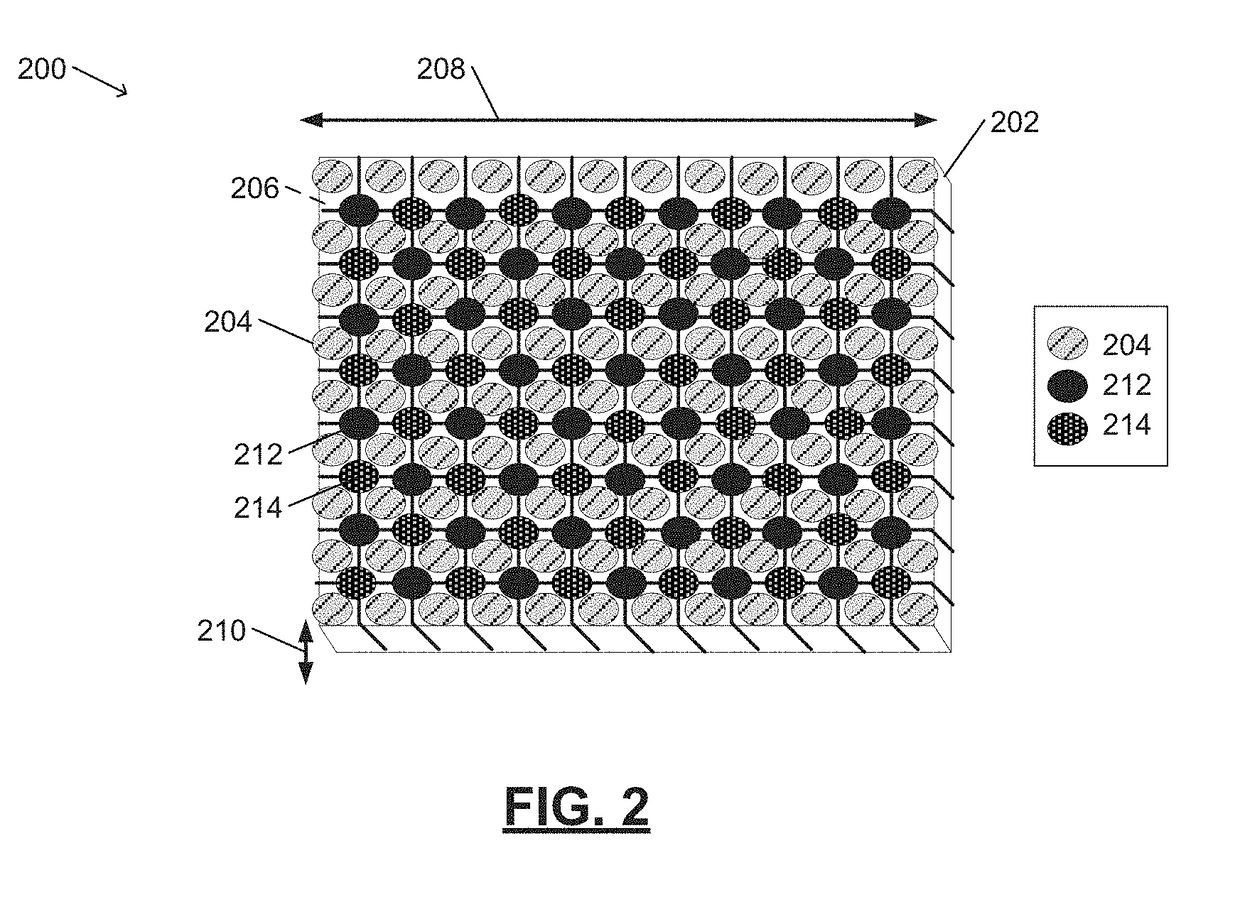

Hybrid metal-organic framework separators for electrochemical cells

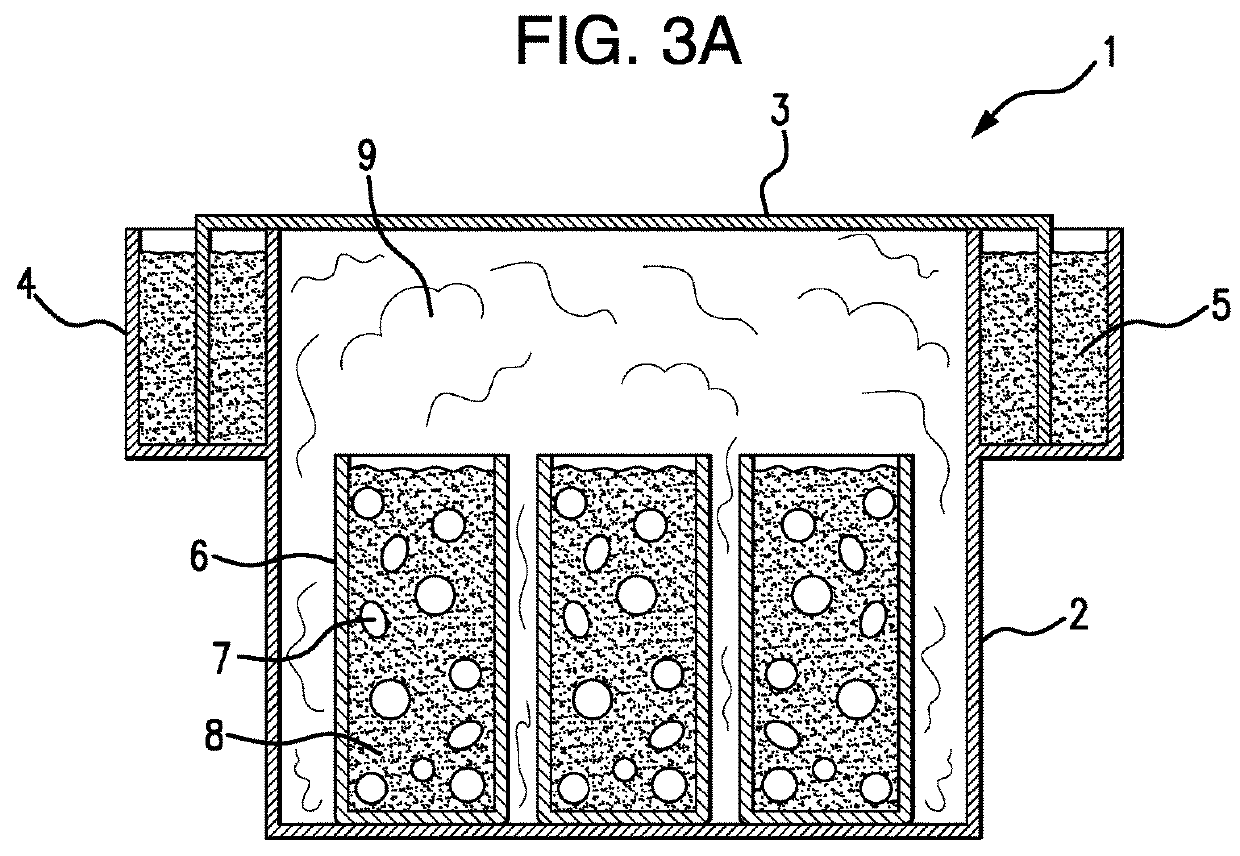

ActiveUS20190089006A1High bulk densityImprove structural stabilityLithium organic compoundsCell seperators/membranes/diaphragms/spacersLithiumIndium

A hybrid separator for an electrochemical cell is provided, along with methods of making the hybrid separator. The hybrid separator includes a first metal-organic framework comprising copper and having a plurality of first pores and a second distinct metal-organic framework comprising indium or zinc and having a plurality of second pores. The hybrid separator is capable of adsorbing one or more lithium salts in at least one of the plurality of first pores or the plurality of second pores so as to be ionically conductive. The hybrid separator may have a conductivity greater than or equal to about 0.1 mS / cm to less than or equal to about 1 mS / cm and is substantially free of any polymeric binder.

Owner:GM GLOBAL TECH OPERATIONS LLC

Preparation method for lithium tetrafluoroborate

The invention provides a preparation method for lithium tetrafluoroborate. The preparation method comprises the following steps: uniformly mixing compounds containing lithium weak acid salts and BF3 in an aprotic nonpolar or aprotic slightly-polar solvent according to a mol ratio of lithium to boron to fluorine of 1: 1: 4 to 1: 2: 5, wherein a mol ratio of the solvent to element is 3: 1 to 6: 1; carrying out a reflux reaction at 0 to 70 DEG C for 1 to 24 h and then carrying out solid-liquid separation; and drying the solvent in the liquid obtained in the previous step through distillation so as to obtain a crude solid LiBF4 product. As the crude solid LiBF4 product is subjected to purification and separation once, a LiBF4 product has yield of 96% or above and purity of 99% or above; and after purification and separation a plurality of times, the purity of the LiBF4 product can be further improved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Process for the preparation of LiBF4

InactiveUS20020172634A1Simple chemical reactionHigh yieldTretrafluoboric acidHalogen/halogen-acidsChemistryAqueous solution

The present invention describes a process for the preparation of LiBF4 by reacting LiBO2 with 10 to 48% HF solution in aqueous solution at ambient temperature, concentrating the product and recrystallizing to obtain high purity LiBF4.

Owner:COUNCIL OF SCI & IND RES

Fluoroborate exchange crystallization recovery technology for cephalosporin fluorine-containing waste liquid

InactiveCN109354034AReduce manufacturing costAvoid corrosionTretrafluoboric acidAmmonium chlorideSolubilityFiltration

The invention discloses a fluoroborate exchange crystallization recovery technology for a cephalosporin fluorine-containing waste liquid. The technology comprises the following steps that (1) the pH of the cephalosporin fluorine-containing waste liquid is adjusted to 7.0-14.0; (2) potassium chloride is added for salt exchange, and potassium fluoroborate is separated out in the form of crystals during a reaction because of low solubility; (3) filtration, washing and drying are conducted to obtain pure potassium fluoroborate; (4) due to the removal of fluorine compounds, the waste liquid can bedirectly distilled to recover an organic solvent so as to avoid corrosion of equipment, and residual liquid is concentrated and crystallized to recover ammonium chloride. According to the technology,fluoroborates are effectively separated, potassium fluoroborate is an important raw material for producing boron trifluoride, the production cost is reduced, and the technology has the advantages of being simple in process operation, low in equipment requirement, high in recovery yield and environmentally friendly, so that the recovery purpose of preventing cephalosporin from producing the fluorine-containing waste liquid is achieved.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD +2

Method for Synthesis of Boron Nitride Nanopowder

InactiveUS20120063983A1Increase productionAvoid cloggingMaterial nanotechnologyNitrogen compoundsTetrafluoroborateBoronic acid

A reaction is carried in a gaseous phase between ammonia (NH3) and boron trifluoride (BF3) in a cooled reactor under atmospheric pressure. A boron trifluoride-ammonia complex (NH3.BF3) obtained in this reaction is thermally decomposed at a temperature in the range of 125 to 300° C. into boron nitride and ammonium tetrafluoroborate in accordance with the following scheme:125-300° C.4NH3.BF3→BN+3NH4.BF4 BN is then separated from the mixture of BN with 3NH4.BF4 by combining the mixture with deionized water, forming a suspension, and separating the suspended BN nanoparticles by centrifugation.

Owner:MALAXIT +1

Preparation method of high-purity lithium tetrafluoroborate

InactiveCN104310421AEfficient removalLow impurity contentTretrafluoboric acidLithium compoundLithium-ion battery

The invention belongs to the technical field of electrolyte lithium salts for lithium ion batteries, and particularly discloses a preparation method of high-purity lithium tetrafluoroborate. The preparation method comprises the following steps: synthesizing lithium tetrafluoroborate by taking hydrofluoric acid, boric acid and lithium compound as raw materials, carrying out concentration, crystallization and secondary drying on lithium tetrafluoroborate to obtain the crude product of the lithium tetrafluoroborate; dissolving the crude product of the lithium tetrafluoroborate in anhydrous hydrogen fluoride again, and feeding high-purity fluorine into the solution for purifying and removing impurities; then, carrying out cooling crystallization, filtering and drying to obtain the high-purity lithium tetrafluoroborate product, wherein the purity of the product reaches up to more than 99.99%. According to the preparation method, the high-purity fluorine is used for purifying, and the high-purity lithium tetrafluoroborate product with high purity and low water content can be prepared. The raw materials are easy to obtain, the whole production process is mild in conditions, high in operability, high in raw material utilization rate and free from discharge of 'three wastes', and the preparation method is suitable for large-scale industrial production.

Owner:DO FLUORIDE CHEM CO LTD

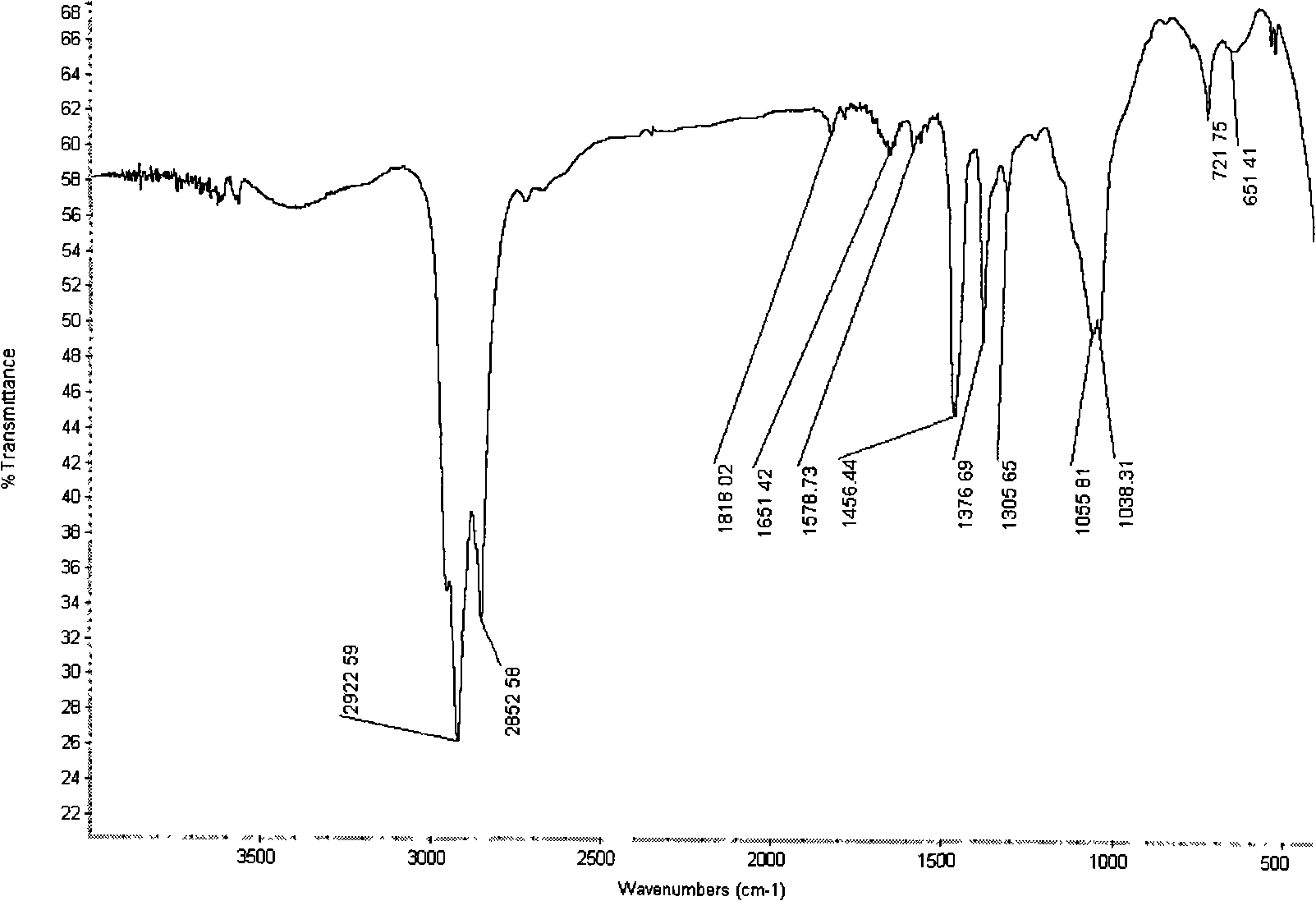

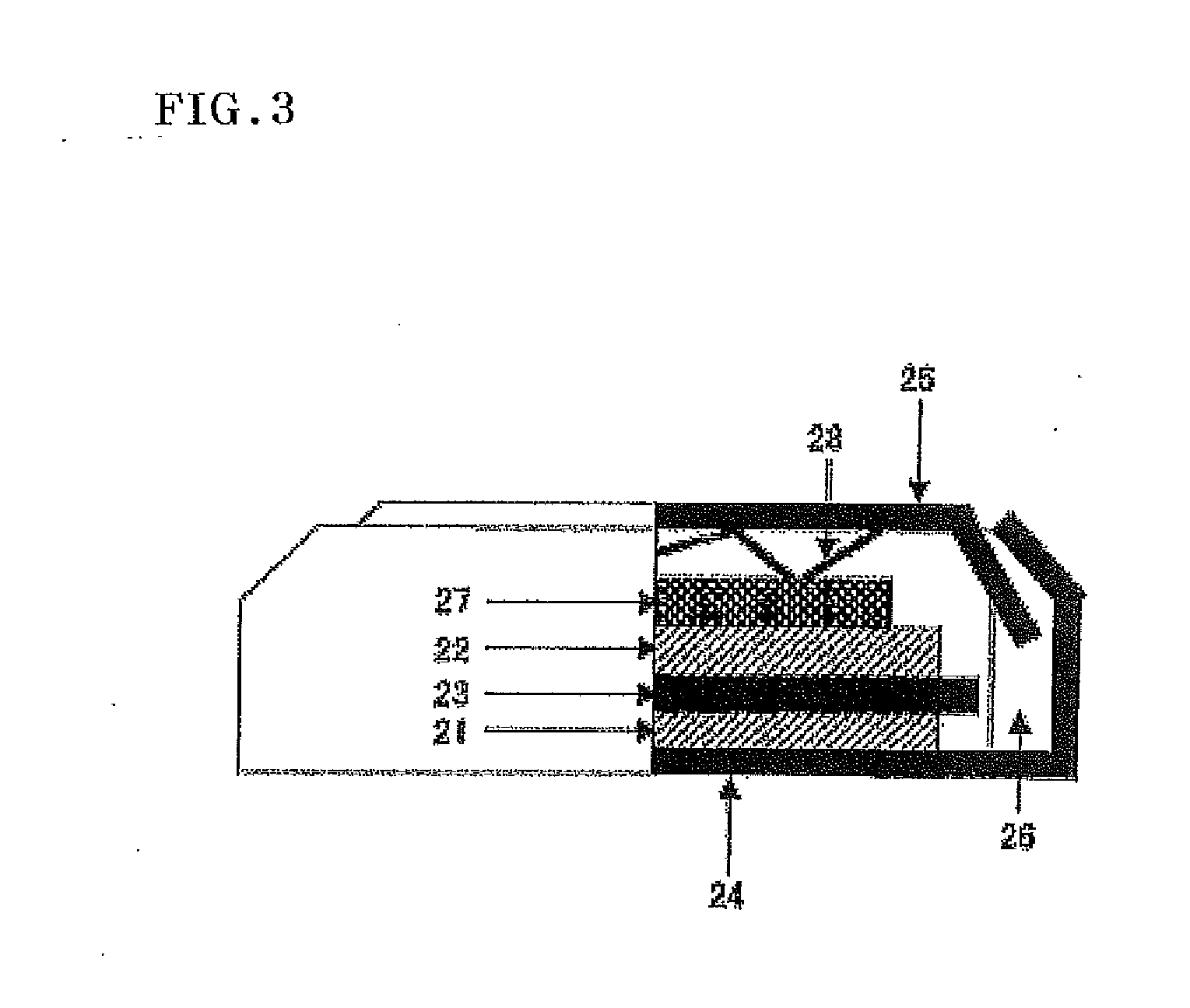

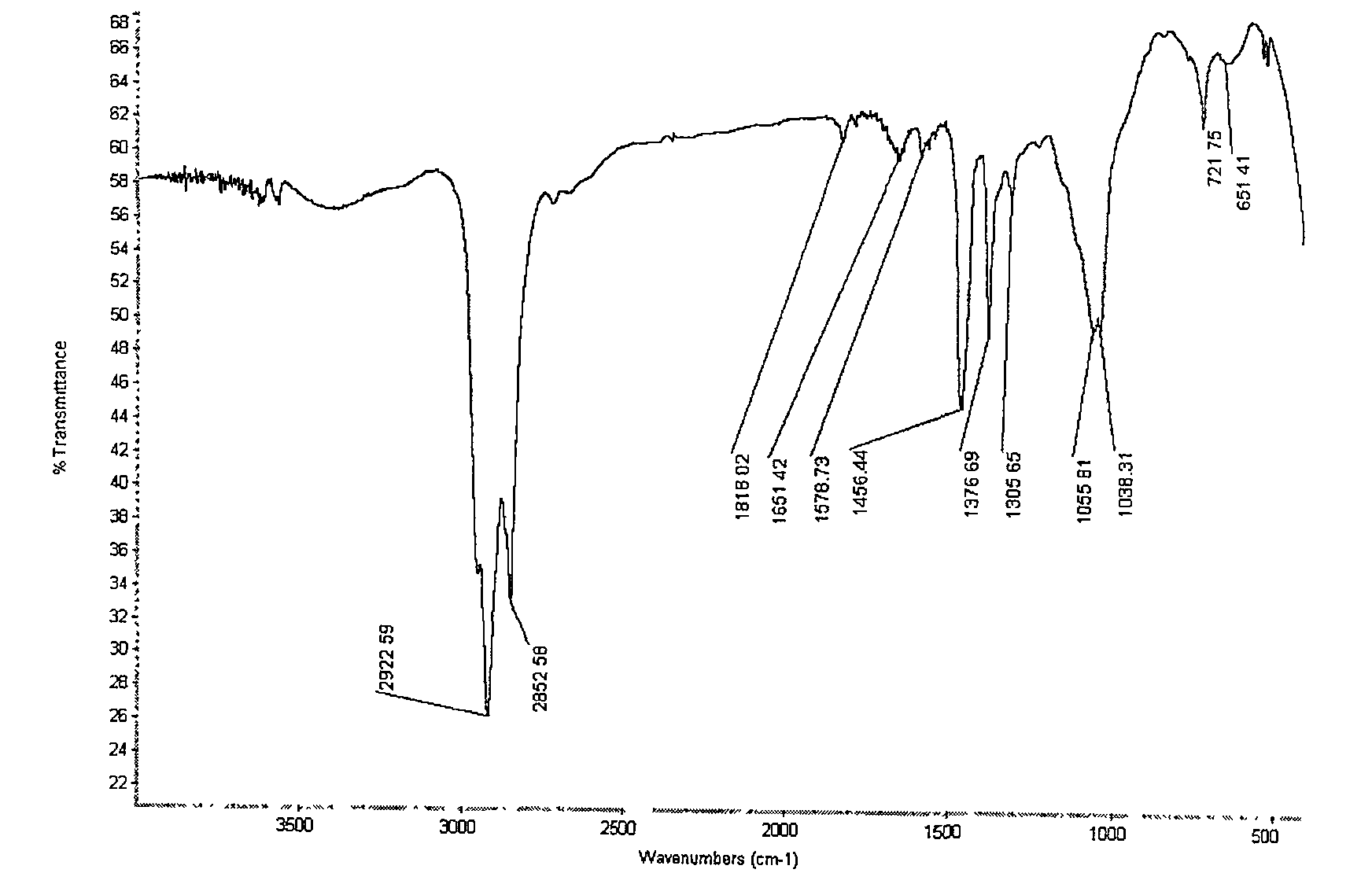

Preparation method of high-purity conductive salt for super capacitor

ActiveCN101987824AEasy to operateAvoid pollutionHybrid capacitor electrolytesTretrafluoboric acidTetrafluoroborateInternal resistance

The invention relates to a preparation method of quaternary alkylammonium salt tetrafluoroborate of which the structure is expressed by general formula (1), wherein QA+ represents quaternary ammonium salt positive ions. The preparation method is characterized in that monomethyl carbonic ester of which the structure is expressed by (QA+)(CH3OCO2-) reacts with ammonium fluoride, and then the mixture reacts with a complex compound formed by boron trifluoride and Louis basic organic solvent after being filtered, and the obtained solid product is dried and recrystallized, so as to obtain the quaternary alkylammonium salt tetrafluoroborate of which the structure is expressed by the general formula (1). In preparation method provided by the invention, the operation step is simple, the productivity is high, the purity of the products can reach more than 99.9 percent, the moisture of the products is low, the content of halogen negative ions is less than 5ppm, and no pollution of foreign ions such as BF3OH-, BF2(OH)2-, BF(OH)3- and the like generates. The quaternary alkylammonium salt tetrafluoroborate prepared by the method is used for preparing electrolyte, thus the obtained super capacitor has high capacity, low internal resistance and low capacity attenuation at high temperature. The formula (1) is shown in specification.

Owner:岳阳凯门科技有限公司

Combined preparation method of lithium difluorophosphate and lithium tetrafluoroborate

ActiveCN107226463ATretrafluoboric acidSecondary cells servicing/maintenanceDifluorophosphateChemical synthesis

The invention relates to the field of chemical synthesis, in particular to a preparation method of two kinds of fluorine-containing lithium salts (lithium difluorophosphate and lithium tetrafluoroborate). The invention provides a combined preparation method of lithium difluorophosphate and lithium tetrafluoroborate. The method comprises the following steps that lithium hexafluorophate, lithium carbonate and boron trifluoride react under the condition of reaction solvent existence; the lithium difluorophosphate and the lithium tetrafluoroborate are obtained through preparation. The novel combined preparation method of the lithium difluorophosphate and the lithium tetrafluoroborate provided by the invention has the advantages that two kinds of high-quality lithium salt products are obtained through one-step reaction and simple separation purification; the reaction solvents are properly recovered and repeatedly recovery can also be realized; three wastes are basically not generated; the environment-friendly effect is achieved; the preparation method is suitable for industrial production.

Owner:SHANGHAI CHEMSPEC CORP +1

Process for purifying a fluorine compound

InactiveUS20100099931A1Improve responseEasy to separatePhosphorus halides/oxyhalidesFluoride preparationCarbonyl fluorideOxygen compound

Provided is a process for purifying a fluorine compound capable of yielding a highly pure fluorine compound by removing at least oxygen from a fluorine compound containing an oxygen compound as an impurity. In a process according to the present invention for purifying a fluorine compound, the following is brought into contact with the fluorine compound, which contains an oxygen compound as an impurity, thereby removing at least oxygen: carbonyl fluoride in an amount of a 0.1-fold equivalent or more and a 100-fold equivalent or less of oxygen atoms in the fluorine compound.

Owner:STELLA CHEMIFA CORP

Hydrothermal purification method of lithium tetraborate

InactiveCN104609438AHigh energy consumptionSimplify the experimental processTretrafluoboric acidBoratesLithiumPurification methods

The invention discloses a hydrothermal purification method of lithium tetraborate. The method comprises the following steps: (1) mixing commercial anhydrous lithium tetraborate with deionized water at the ratio; (2) packing the mixed sample into a hydrothermal reaction kettle, and sealing at a constant temperature of 90-200 DEG C for 1-12 hours; and (3) naturally cooling, carrying out solid-liquid separation, washing and drying a solid-phase material to obtain purified lithium tetraborate, and returning a liquid phase to the hydrothermal reaction kettle to use in cycle, or discharging the liquid phase according to the purity requirements. According to the hydrothermal purification method, the processes of dissolving lithium tetraborate and preparing a supersaturated solution are omitted; stirring and reflux condensation are not needed; the technological process is simplified; equipment is simple and easy to operate; volume production can be carried out; the technical problems that an existing purification method is complicated, low in cost, not ideal in purification effect and the like are effectively solved; the production cost can be greatly reduced; and the hydrothermal purification method has a relatively good industrial prospect.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method for recovering cerium and fluorine from bastnaesite leachate

ActiveCN111484064AAvoid cloggingAvoid churnCerium oxides/hydroxidesTretrafluoboric acidPregnant leach solutionPhysical chemistry

The invention relates to a method for recovering cerium and fluorine from bastnaesite leachate, and the method comprises the following steps: taking sulfuric acid leachate of bastnaesite or bastnaesite and monazite mixed ore as a raw material solution, and adding 0.02-10g / L of boric acid into the raw material solution; extracting cerium in the raw material solution by using an extracting agent, and then carrying out reverse extraction, precipitation, separation and roasting to obtain CeO2; and then taking trialkyl phosphine oxide as an extracting agent to extract F in the extraction raffinate,and carrying out reverse extraction by using a KOH solution to obtain KBF4. According to the method disclosed by the invention, the cerium and the fluorine are separately recovered, and the F is prepared into the KBF4 in strip liquor, so that the problems that a mixing clarification tank is easily blocked in the operation process of a cerium fluoride precipitate in an extraction section, and an organic phase is lost due to the fact that the cerium fluoride precipitate carries the organic phase are avoided. According to the method, the Ce is recovered by using the extraction agents P507 and P204, so that the consumption of Cyanex923 is reduced, and the cost is reduced. Compared with a CeF3 product, the KBF4 product has more definite market requirements and higher additional value, and themethod better meets the market requirements and enterprise requirements.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of lithium tetrafluoroborate

InactiveCN104692405AIncrease profitEfficient removalTretrafluoboric acidLithium compoundFluoboric acid

The invention discloses a preparation method of lithium tetrafluoroborate. The preparation method comprises the following steps: 1) adding boric acid into hydrofluoric acid and reacting to obtain a fluoboric acid solution; 2) adding a lithium compound into the fluoboric acid solution and reacting to obtain a lithium tetrafluoroborate solution; 3) concentrating the lithium tetrafluoroborate solution, cooling, crystallizing and filtering to obtain lithium tetrafluoroborate crystals; 4) drying the lithium tetrafluoroborate crystals to obtain a lithium tetrafluoroborate crude product; and 5) putting the lithium tetrafluoroborate crude product into a reactor, introducing fluorine gas or fluorine-nitrogen mixed gas and reacting to obtain lithium tetrafluoroborate. According to the preparation method of lithium tetrafluoroborate disclosed by the invention, the deficiencies of the existing preparation method are made up, the process is simple to operate, no organic solvent is introduced, and the obtained lithium tetrafluoroborate product is high in purity and low in water content; and the whole preparation process is strong in operability and high in utilization rate of raw materials, has no emission of three wastes, and is suitable for large-scale industrial production.

Owner:DO FLUORIDE CHEM CO LTD

Catalytic synthesis method of lithium tetrafluoroborate

InactiveCN106335907APrevent volatilizationReduce oxygenSecondary cellsTretrafluoboric acidMaterials preparationLithium chloride

The invention relates to a catalytic synthesis method of lithium tetrafluoroborate and belongs to the technical field of new energy material preparation. The method comprises the specific steps that 1, all production reaction vessels are subjected to high-purity nitrogen displacement and then put under the protection of high-purity nitrogen, and materials are added; 2, dry quantitative anhydrous tetrafluoroborate and quantitative anhydrous lithium chloride are added into an organic solvent in a stirring reactor to be dissolved, and a solution is prepared; 3, a quantitative catalyst is added into the stirring reactor, and heating and stirring are carried out at specified temperature for a sufficient reaction of the materials; 4, after the reaction is completed, filtering is conducted, solid byproducts are separated, and an organic solution of lithium tetrafluoroborate is obtained; 5, the organic solution of lithium tetrafluoroborate is concentrated, the organic solvent is separated, and high-purity lithium tetrafluoroborate crystals are obtained after recrystallization purification and vacuum drying. The catalytic synthesis method of lithium tetrafluoroborate is safe, simple, high in yield and good in quality, simplifies the technological process and has good application prospects in the field of new energy materials.

Owner:LUOYANG HEMENG TECH CO LTD

A joint preparation method of lithium difluorophosphate and lithium tetrafluoroborate

ActiveCN107226463BTretrafluoboric acidSecondary cells servicing/maintenanceChemical synthesisBoron trifluoride

The invention relates to the field of chemical synthesis, in particular to a preparation method of two kinds of fluorine-containing lithium salts (lithium difluorophosphate and lithium tetrafluoroborate). The invention provides a combined preparation method of lithium difluorophosphate and lithium tetrafluoroborate. The method comprises the following steps that lithium hexafluorophate, lithium carbonate and boron trifluoride react under the condition of reaction solvent existence; the lithium difluorophosphate and the lithium tetrafluoroborate are obtained through preparation. The novel combined preparation method of the lithium difluorophosphate and the lithium tetrafluoroborate provided by the invention has the advantages that two kinds of high-quality lithium salt products are obtained through one-step reaction and simple separation purification; the reaction solvents are properly recovered and repeatedly recovery can also be realized; three wastes are basically not generated; the environment-friendly effect is achieved; the preparation method is suitable for industrial production.

Owner:SHANGHAI CHEMSPEC CORP +1

Method for purifying fluorine compound

InactiveCN101558008AImprove responseEasy to separateAmino compound purification/separationPhosphorus halides/oxyhalidesCarbonyl fluorideOxygen compound

Provided is a process for purifying a fluorine compound capable of yielding a highly pure fluorine compound by removing at least oxygen from a fluorine compound containing an oxygen compound as an impurity. In a process according to the present invention for purifying a fluorine compound, the following is brought into contact with the fluorine compound, which contains an oxygen compound as an impurity, thereby removing at least oxygen: carbonyl fluoride in an amount of a 0.1-fold equivalent or more and a 100-fold equivalent or less of oxygen atoms in the fluorine compound.

Owner:STELLA CHEMIFA CORP

A kind of preparation method of lithium tetrafluoroborate

The invention relates to a preparation method of lithium tetrafluoroborate, which is characterized in that borane and fluorine gas react to generate boron trifluoride, and the boron trifluoride reacts with halogenated lithium salt dissolved in hydrogen fluoride to generate lithium tetrafluoroborate. The method comprises the following steps: putting LiF in a stainless steel reaction vessel, sufficiently dissolving the LiF in HF, and introducing a certain amount of borane, wherein the mole ratio of the boron element in the borane to the lithium element in the halogenated lithium salt is (1.2-1):1; slowly introducing fluorine gas, sufficiently reacting, and continuing stirring for 2-6 hours, wherein the reaction temperature is -20-15 DEG C; and after the reaction finishes, concentrating the reaction solution to 40-80% of the original volume by heating, filtering to obtain a LiBF4 crystal, and drying to obtain the lithium tetrafluoroborate product.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

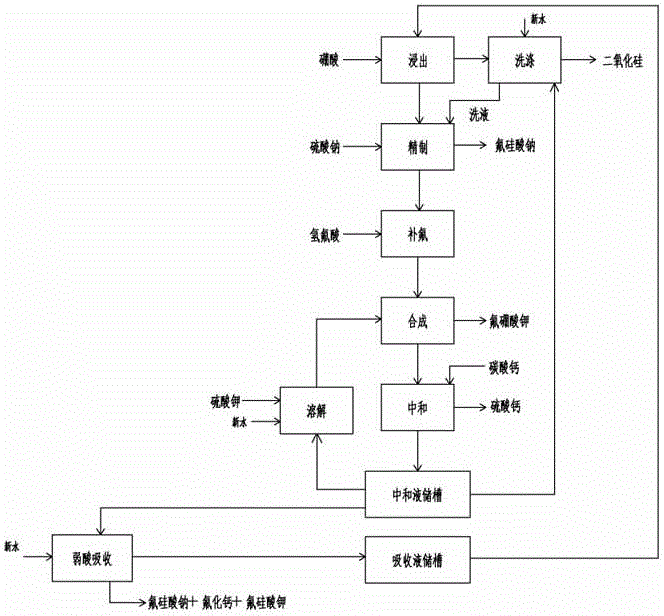

Method for preparing potassium fluoborate by recycling mother liquor

ActiveCN106587089AAchieve recyclingSolve accumulated problemsSilicaCalcium/strontium/barium sulfatesHexafluorosilicic acidFluoboric acid

The invention discloses a method for preparing potassium fluoborate by recycling a mother liquor. The method comprises the steps of injecting new water into a weak acid absorption apparatus of a hydrofluoric acid production system; adjusting the content of fluosilicic acid and hydrofluoric acid in the system; adding solid boric acid into a solution to obtain a silicon dioxide byproduct and a coarse fluoboric acid solution; adding solid sodium sulfate into the coarse fluoboric acid solution to obtain sodium fluosilicate and a refined fluoboric acid solution; adding hydrofluoric acid and potassium sulfate solutions to obtain potassium fluoborate crystals and the mother liquor; and adding calcium carbonate solid into the mother liquor to obtain a calcium sulfate byproduct, wherein one part of the mother liquor is used for absorbing tail gas in the hydrofluoric acid system, one part of the mother liquor is used for dissolving potassium sulfate, and one part of the mother liquor is used for washing silicon dioxide, so that the recycling of the mother liquor of the potassium fluoborate production system is realized. The method realizes recycling of wastewater, solves the problems of difficulty in treating potassium fluoborate wastewater and high cost, is environment-friendly, and has very high economic benefits.

Owner:南通金星氟化学有限公司

Method of preparing waterless lithium terafluoroborate

The invention relates to a method for preparing an anhydrous lithium tetrafluoroborate which comprises the following steps: a lithium source including lithium hydroxide, lithium carbonate, and the like, reacts with fluorine hydride and boric acid to obtain lithium tetrafluoroborate solution, then the lithium tetrafluoroborate solution is condensed, crystallized and recrystallized, ground, and vacuum dried to obtain the anhydrous lithium tetrafluoroborate. The method of the invention adopts a staged temperature rise control, the process of the preparation is simple, raw materials are cheap andthe preparation cost is low, no organic solvent is used during the synthetic process, no poison is produced, therefore, the method accords with the concept of green environmental protection, the anhydrous lithium tetrafluoroborate prepared by the method is determined by a X-ray diffraction map, the diffraction peak is clear and sharp and completely matches the standard card, which shows that the product prepared by the method of the invention is anhydrous LiBF4 with complete crystal form, the quality of the product is equal to the quality of the anhydrous lithium tetrafluoroborate prepared bythe reaction of lithium fluoride and boron trifluoride.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Boronizing powder compositions for improved boride layer quality in oil country tubular goods and other metal articles

ActiveUS20180265364A1Reduced boriding potentialSurface boron concentrationBoron/boridesCorrosion preventionGraphiteChloride

A powder boronizing composition comprising:a. 0.5 to 4.5 wt % of a boron source selected from B4C, amorphous boron, calcium hexaboride, borax or mixtures thereof;b. 45.5 to 88.5 wt % of a diluent selected from SiC, alumina or mixtures thereof;c. 1.0 to 20.0 wt % of an activator selected from KBF4, ammonia chloride, cryolite or mixtures thereof; andd. 10.0 to 30.0 wt % of a sintering reduction agent selected from carbon black, graphite or mixtures thereof.

Owner:BWT LLC

Lithium tetrafluoroborate preparation method

ActiveCN104326482ARaw materials are easy to getNot corrosiveTretrafluoboric acidBoratesLithium metaborateLithium carbonate

The invention discloses a lithium tetrafluoroborate preparation method comprising the following steps: mixing lithium carbonate, lithium hydroxide monohydrate or anhydrous lithium hydroxide and boric acid and boric oxide to obtain lithium metaborate, crushing the lithium metaborate to obtain lithium metaborate powder, and mixing the lithium metaborate powder and ammonium fluoride or ammonium bifluoride for vacuum negative pressure burning reaction to obtain the lithium tetrafluoroborate product. The lithium tetrafluoroborate preparation method uses a solid lithium source and a solid boron source as raw materials for preparation of the lithium tetrafluoroborate, the process has the advantages that raw materials are easily obtained, non-toxic and non-corrosive, product quality is high, no side reaction is produced, and the method is environmentally friendly and high in efficiency, and the like.

Owner:SHANGHAI CHINA LITHIUM INDAL

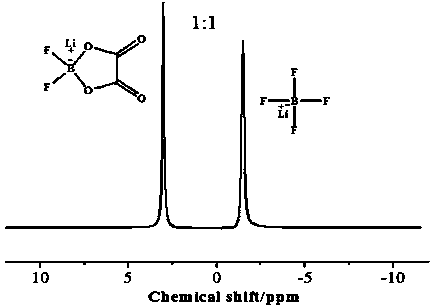

Method for low-cost preparation of high-purity fixed-proportion mixed lithium salt, and application of mixed lithium salt to lithium ion battery

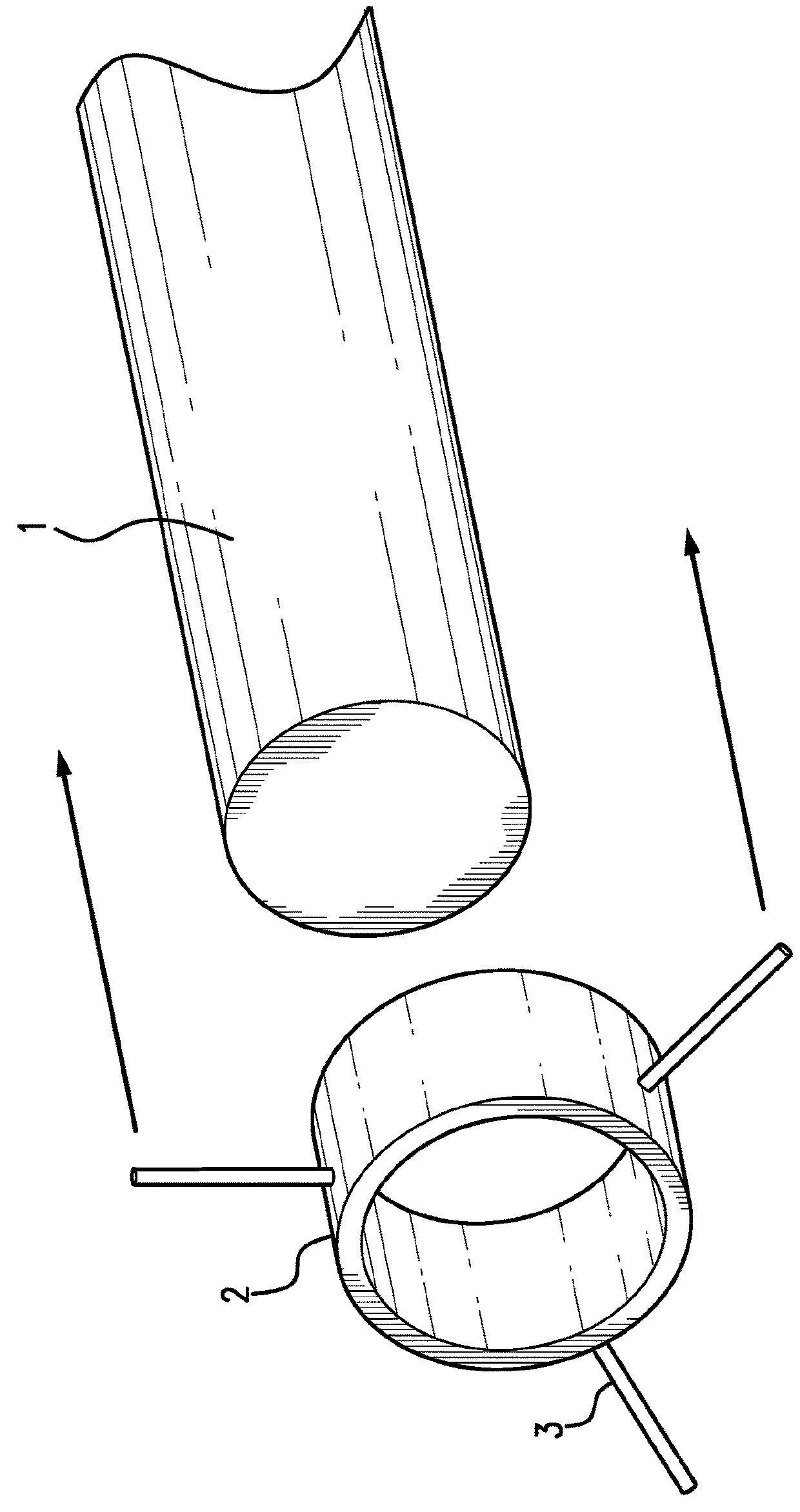

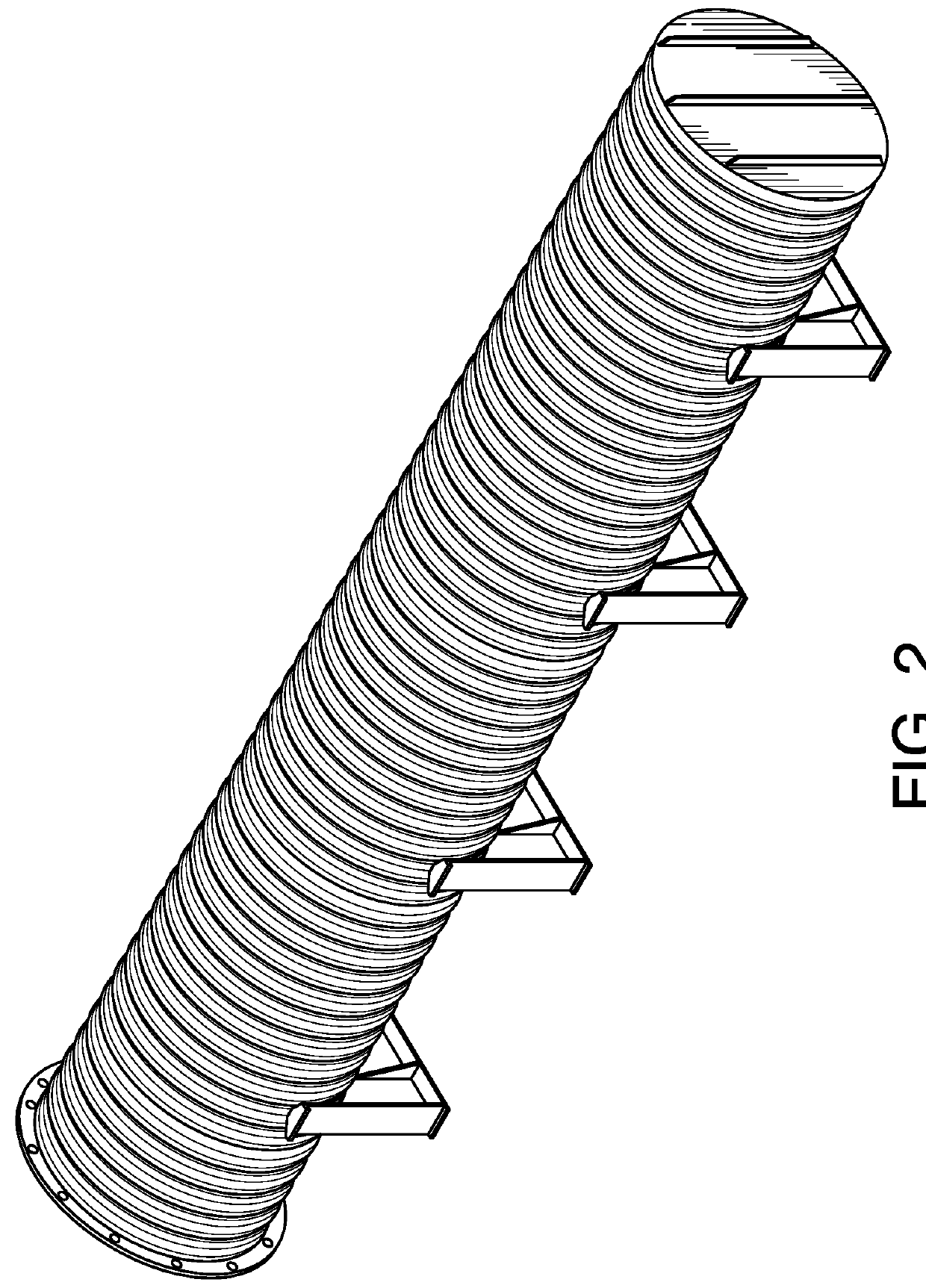

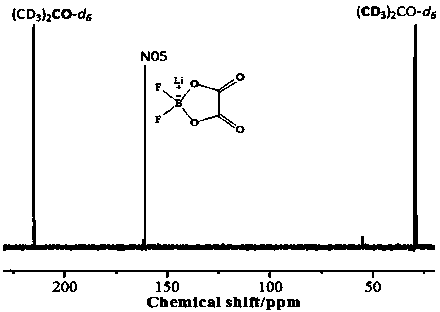

ActiveCN110343125AEasy to separateReduce purificationSemi-permeable membranesMembranesOxalateBoron trifluoride

The invention discloses a method for low-cost preparation of fixed-proportion mixed lithium salt. The method comprises the following steps: (1) lithium oxalate is purified; (2) the lithium oxalate andboron trifluoride.etherate react to prepare the 1:1 fixed-proportion mixed lithium salt of LiODFB and LiBF4; and (3) the fixed-proportion mixed lithium salt is purified. The product yield and purityare increased, and the technological process is simplified.

Owner:新亚杉杉新材料科技(衢州)有限公司

Fluorine waste liquid treatment method

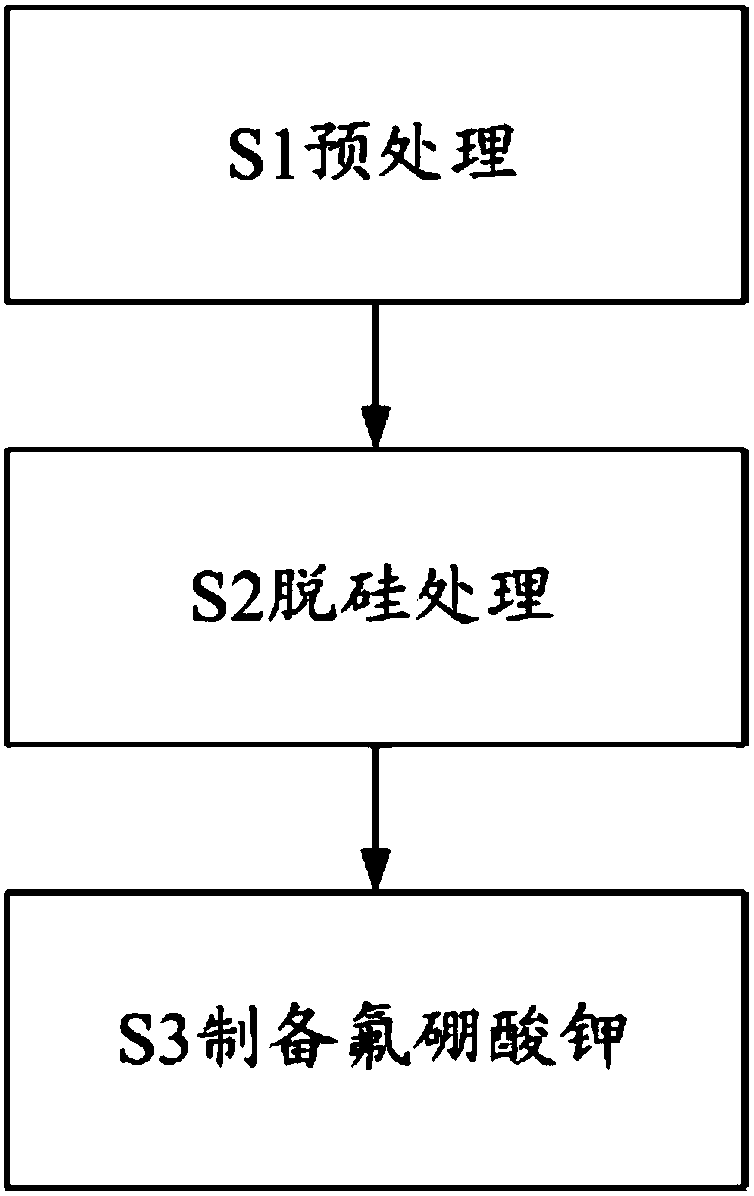

ActiveCN107902665AFully recyclePromote sustainable developmentTretrafluoboric acidFluosilicic acidFiltrationPotassium

The invention discloses a fluorine waste liquid treatment method. The method comprises the following steps: S1, pretreating; S2, desiliconizing: reacting a boric acid solution with a fluorine waste liquid to obtain a turbid solution A, carrying out suction filtration and washing on the turbid solution A, ageing the obtained filtrate to obtain a supernatant and a lower turbid solution, returning the lower turbid solution, carrying out suction filtration, and cyclically washing the obtained filter residues to obtain a filtrate A; and S3, preparing potassium fluoroborate: stirring the filtrate Aand a potassium hydroxide solution, adjusting the pH value of the obtained solution to 5-7, carrying out a reaction to obtain a turbid solution B, carrying out suction filtration and washing on the turbid solution B, centrifuging the obtained residues, and drying the centrifuged filter residues to obtain the potassium fluoroborate. The method fully recovers and utilizes the fluorine waste liquid,so the environmental protection pressure is alleviated, the treatment cost of the fluorine waste liquid is reduced, and the economic benefit is improved.

Owner:JIANGXI DONGYAN PHARMA

Preparation method of lithium tetrafluoroborate

InactiveCN109264736AQuality improvementSimple processSecondary cellsTretrafluoboric acidHigh energyFiltration

The invention relates to a preparation method of lithium tetrafluoroborate. According to the technical scheme, the preparation method comprises the following steps that 1, under the ambient temperature and pressure, lithium fluoride is added into an esters solvent to obtain a lithium fluoride turbid liquid; 2, boron trifluoride gas is introduced into the lithium fluoride turbid liquid, and reaction is carried out for 1-2 h to obtain a lithium tetrafluoroborate solution; 3, unreacted trace lithium fluoride of the solution obtained in step 2 is filtered through a microporus filter; 4, the liquidafter filtration in step 3 is completed is subjected to concentration and degassing; 5, the solution after concentration is completed in step 4 is subjected to cooling crystallization, filtration anddrying to obtain a lithium tetrafluoroborate finished product. The preparation method of the lithium tetrafluoroborate has the advantages that adopted boron trifluoride is an industrial grade raw material, and is low and easy to obtain; the lithium fluoride forms the turbid liquid in the esters solvent, so that reaction is easily carried out, the operation is simple and convenient, the safety isimproved, and the problems of the risk in reaction and preparation when hydrogen fluoride is adopted as a solvent, excessive amount of free acid of the product, high energy consumption of ultralow-temperature crystallization and the like are avoided.

Owner:东营石大胜华新能源有限公司

Preparation method of silver tetrafluoroborate

ActiveCN113955765AWide applicabilityAvoid too toxic problemsTretrafluoboric acidTetrafluoroborateOrganosolv

The invention relates to a preparation method of silver tetrafluoroborate, which comprises the steps of mixing and reacting a fluoboric acid source and silver salt in a reaction medium to obtain the silver tetrafluoroborate, wherein the fluoboric acid source is selected from at least one of tetrafluoroborate and tetrafluoroboric acid; and the reaction medium is a mixed solvent of a first organic solvent and water or water, and the first organic solvent is selected from at least one of diethyl ether, nitromethane and methylbenzene. The preparation method is wide in raw material applicability, the raw materials are low in toxicity and easy to obtain, the problem that the toxicity is too high when silver fluoride and boron trifluoride serve as reaction raw materials is solved, the reaction can be carried out at the room temperature, the reaction condition is mild, the reaction is easy to operate, the needed time is short, the requirement for equipment is low, and the production safety problem is guaranteed.

Owner:SUZHOU SINOCOMPOUND TECH

Method For Producing Lithium Tetrafluoroborate Solution

ActiveUS20140162144A1Reduce acid impurity content contentReduce water contentFinal product manufactureOrganic electrolyte cellsBoron trifluorideCarbonate ester

Disclosed is a production method of a lithium tetrafluoroborate solution for use as a lithium battery electrolytic solution, including: a reaction step of forming lithium tetrafluoroborate by reaction of lithium fluoride and boron trifluoride in a chain carbonate ester solvent and thereby obtaining a reaction solution of the lithium tetrafluoroborate dissolved in the chain carbonate ester solvent; a water removal step of adding a water removing agent to the reaction solution; an acidic impurity removal step of removing an acidic impurity component from the reaction solution by concentrating the reaction solution after the water removal step; and a dilution step of diluting the concentrated solution after the acidic impurity removal step. It is possible by this method to obtain the lithium tetrafluoroborate solution whose acidic impurity content and water content are reduced to be 50 mass ppm or lower and 15 mass ppm or lower, respectively.

Owner:CENT GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com