Method for low-cost preparation of high-purity fixed-proportion mixed lithium salt, and application of mixed lithium salt to lithium ion battery

A lithium ion battery and mixed lithium salt technology, applied in secondary batteries, carboxylate preparation, chemical instruments and methods, etc., can solve the problem of increasing the cost of mixed salt electrolyte, high equipment and technical requirements, and difficulty in separating the two It can improve the cycle performance at room temperature and high temperature, reduce the cost, and simplify the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

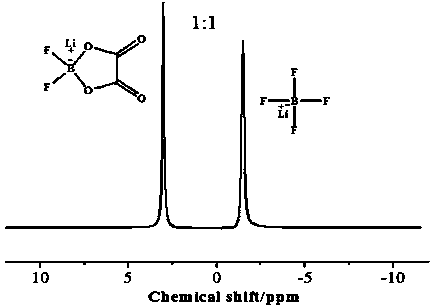

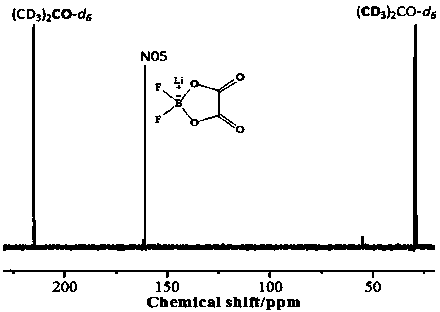

Image

Examples

Embodiment 1

[0063] (1) Purification of lithium oxalate

[0064] Weigh 150g of industrial-grade lithium oxalate, add an appropriate amount of ultrapure water, and stir to prepare a suspension; weigh 0.4 g of ethylenediaminetetraacetic acid (EDTA), and dissolve it in a small amount of ultrapure water; add EDTA aqueous solution to oxalic acid In the lithium suspension, after stirring for 30 minutes, the lithium oxalate solid was obtained by suction filtration; the lithium oxalate solid was cleaned with ultrapure water and suction filtered, and this was repeated 3 times, and finally cleaned with ethanol, suction filtered, and placed in an oven at 120°C After drying, the obtained white powder is the purified lithium oxalate solid (96%).

[0065] (2) Preparation of auxiliary purification filter membrane

[0066] Ethanol, polyethylene glycol diacrylate, 1,1'-(methylenebis-4,1-phenylene)bis[2-hydroxy-2-methyl-1-propanone], trifluoromethyl Scandium sulfonate, dimethyl 2-(3-nitro-2-pyridine) malo...

Embodiment 2

[0072] (1) Preparation of auxiliary purification filter membrane

[0073] Ethanol, polyethylene glycol diacrylate, 1,1'-(methylenebis-4,1-phenylene)bis[2-hydroxy-2-methyl-1-propanone], trifluoromethyl Scandium sulfonate, dimethyl 2-(3-nitro-2-pyridine) malonate, and potassium benzofuran-2-trifluoroborate were added to the reaction in a ratio of 100:125:7:0.2:0.25:0.35 In the container, stir at a constant temperature of 80°C with nitrogen for 120 minutes, pour the mixture on a glass plate, and then cover the quartz glass plate on the top of the mixture, control the thickness of the mixture to 200 μm, irradiate with ultraviolet light for 120s, wash with acetone for 20 hours, and stand to dry to obtain The described auxiliary purification filter membrane.

[0074] (2) Synthesis of mixed lithium salts

[0075] Add 500 mL of ethyl acetate (EA) to the three-necked reaction flask, and add 102 g of lithium oxalate under vigorous stirring. Raise the temperature to 85°C and stir for ...

Embodiment 3

[0079] (1) Preparation of auxiliary purification filter membrane

[0080] Ethanol, polyethylene glycol diacrylate, 1,1'-(methylenebis-4,1-phenylene)bis[2-hydroxy-2-methyl-1-propanone], trifluoromethyl Scandium sulfonate, dimethyl 2-(3-nitro-2-pyridine) malonate, and potassium benzofuran-2-trifluoroborate were added to the reaction in a ratio of 100:150:10:0.3:0.4:0.5 In the container, stir at a constant temperature of 78°C with nitrogen for 150 minutes, pour the mixture on a glass plate, and then cover the quartz glass plate on the top of the mixture, control the thickness of the mixture to 300 μm, irradiate with ultraviolet rays for 120s, wash with acetone for 24 hours, and stand to dry to obtain The described auxiliary purification filter membrane.

[0081] (2) Synthesis of mixed lithium salts

[0082] Add 500 mL of acetonitrile into the three-neck reaction flask, and add 102 g of lithium oxalate under vigorous stirring. Raise the temperature to 85°C and stir for 1 h to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com