Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94 results about "Carbonyl fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbonyl fluoride is a chemical compound with the formula COF₂. This gas, like its analog phosgene, is colourless and highly toxic. The molecule is planar with C₂ᵥ symmetry.

Preparation method of perfluoronitrile

ActiveCN108424375ALow priceHigh yieldOrganic compound preparationCarboxylic acid amides preparationLithiumCarbonyl fluoride

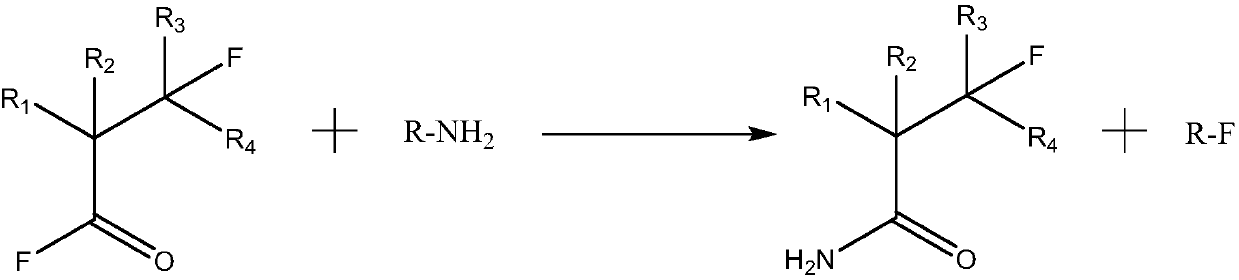

The invention discloses a preparation method of perfluoronitrile. The preparation method comprises the following steps: a, performing a gas-phase addition reaction on perfluoroolefin R1R2C=CR3R4 and carbonyl fluoride to obtain acyl fluoride R1R2(COF)C-CFR3R4 (R1, R2, R3 and R4 have a general formula of a -CnF2n+1 group and n is a nonnegative integer set); b, aminating and dehydrating the acyl fluoride R1R2(COF)C-CFR3R4, acyl fluoride and alkali metal amide or an amine compound R-NH2 (R is lithium, sodium, potassium, rubidium, cesium or a -CmH2m+1 group and m is a nonnegative integer set) to obtain the perfluoronitrile R1R2(CN)C-CFR3R4. By the preparation method, a reaction route is short, the perfluoroolefin and the carbonyl fluoride are easy to obtain and low in price, the overall yield of the perfluoronitrile is high and the route is easy to industrialize.

Owner:泉州宇极新材料科技有限公司

Method for preparing carbonyl fluoride and trifluoroacetyl fluoride simultaneously

InactiveCN102260160AReaction is easy to controlMild conditionsCarboxylic acid halides preparationMetal/metal-oxides/metal-hydroxide catalystsChemical synthesisCarbonyl fluoride

The invention relates to a "preparation method for simultaneously preparing carbonyl fluoride and trifluoroacetyl fluoride" and belongs to the field of chemical synthesis. A method for simultaneously preparing carbonyl fluoride and trifluoroacetyl fluoride is to contact and react oxygen and hexafluoropropylene gas in a reactor under catalyst conditions. The catalyst is silver oxide, activated carbon-supported silver oxide or alumina-supported oxidation gas. silver. The reaction of the invention is easy to control, has mild conditions, and has a high conversion rate. Carbonyl fluoride and trifluoroacetyl fluoride can be simultaneously prepared through a one-step reaction, and is suitable for large-scale preparation of carbonyl fluoride and trifluoroacetyl fluoride.

Owner:张小燕 +1

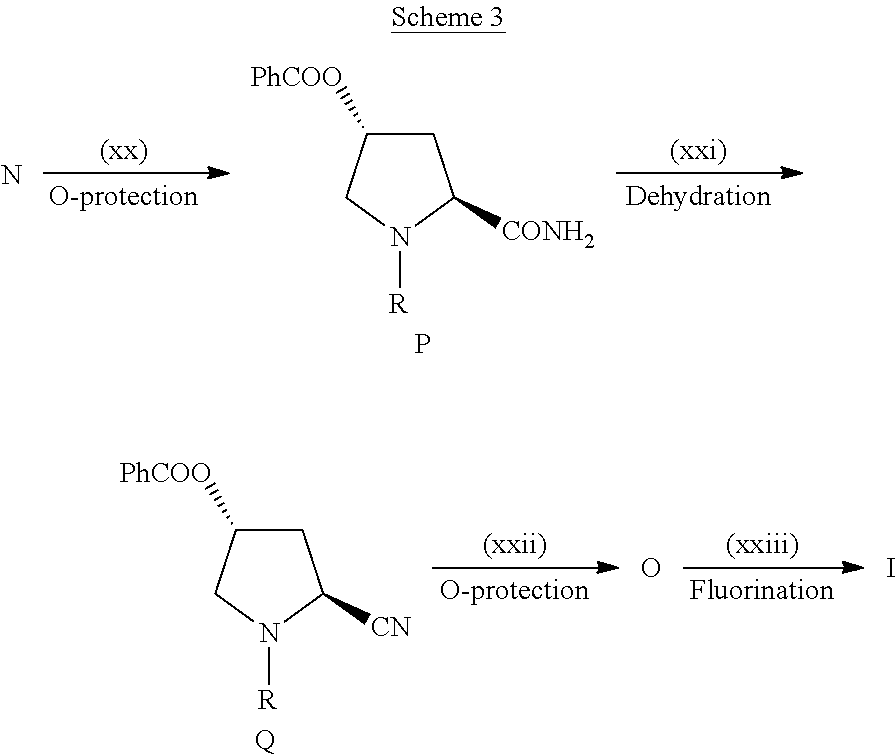

Perfluoro nitrile preparation method

ActiveCN107935884ALow priceImprove solubilityOrganic compound preparationCarboxylic acid amides preparationCarbonyl fluorideMetallole

The invention discloses a perfluoro nitrile preparation method. The perfluoro nitrile preparation method comprises the following steps: an addition reaction is performed on perfluoroolefine R1R2C=CR3R4 and carbonyl fluoride to obtain acyl fluoride R1R2(COF)C-CFR3R4(the general formula of R1,R2,R3 and R4 is -CnF(2n+1) group, and n is a nonnegative integer set); b, performing a reaction on acyl fluoride R1R2(COF)C-CFR3R4, acyl fluoride and an alkali metal amide or an amino compound R-NH2(R is Li, Na, K, Rb, Cs or -CmH(2m+1) group, and m is a nonnegative integer set) to obtain amide R1R2(CONH2)C-CFR3R4; and c, performing a dehydration reaction on amide R1R2(CONH2)C-CFR3R4 to obtain perfluoro nitrile R1R2(CN)C-CFR3R4. The perfluoro nitrile preparation method has a short reaction path, can easily obtain perfluoroolefine and carbonyl fluoride, is low in cost and high in overall yield of perfluoro nitrile, and the reaction path is easy to industrialize.

Owner:泉州宇极新材料科技有限公司

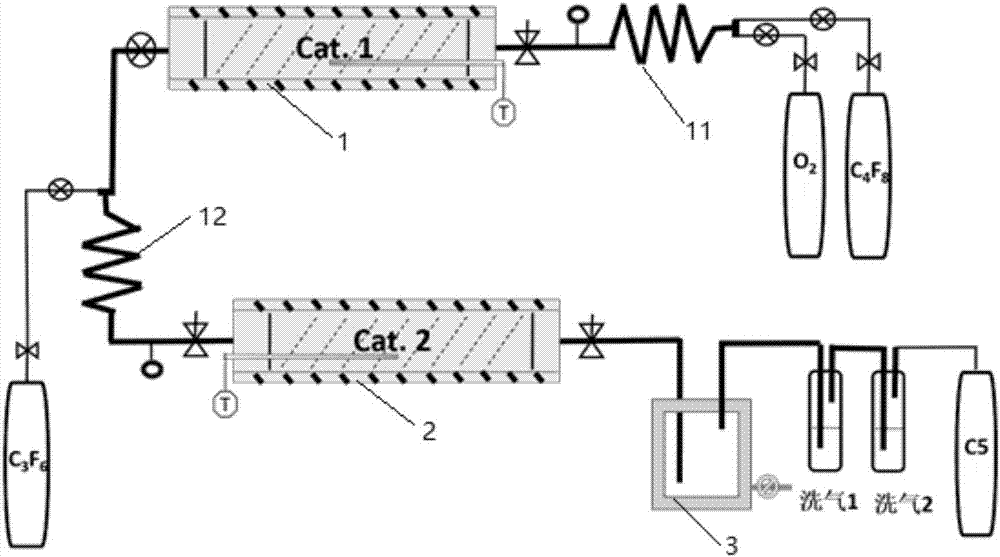

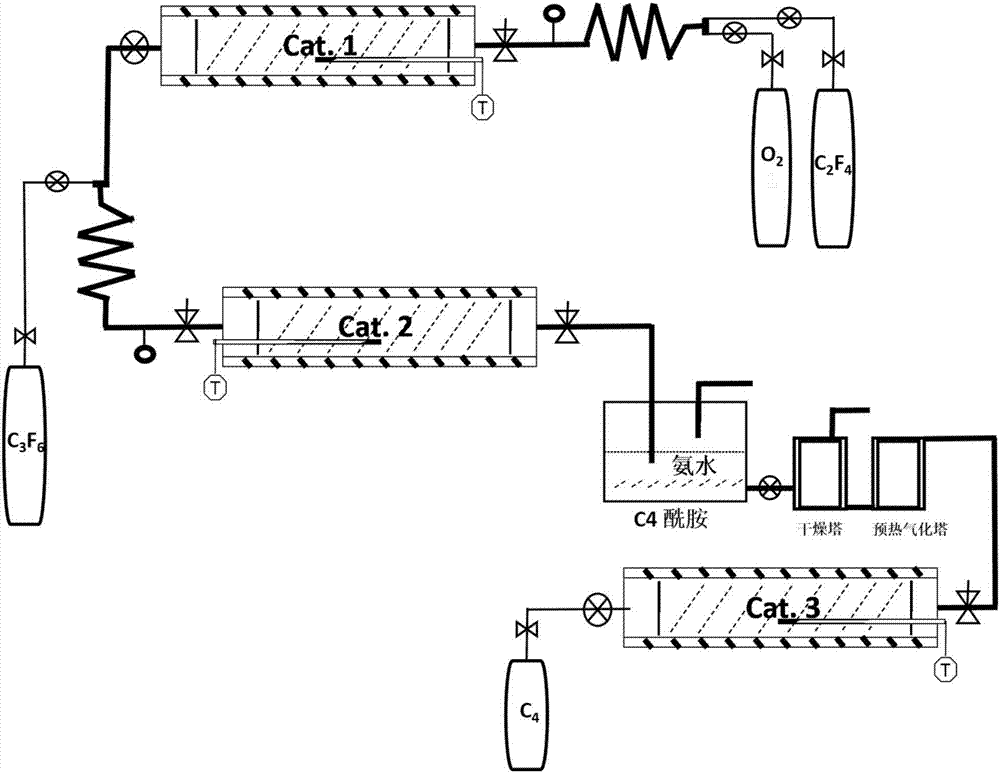

Production technology for environment-friendly insulating gas and industrial production device

ActiveCN106986757AImprove economyReduce manufacturing costOrganic compound preparationPreparation by carboxylic acid amide dehydrationChemistryFluorocarbon

The invention discloses a production technology for an environment-friendly insulating gas and an industrial production device. The production technology comprises the following steps: 1) performing contact reaction on oxygen and symmetric perfluoroolefine under a catalyst condition or catalyst-free condition in a first fixed bed reactor; 2) mixing the gas product flowing from the first fixed bed reactor with gaseous olefin, and then entering into a second fixed bed reactor and performing contact reaction under the catalyst effect in the fixed bed reactor, thereby generating fluoroketone compounds or perfluorocarbon fluorocarbons; and 3) scrubbing the fluoroketone compounds, thereby acquiring a corresponding fluoroketone environment-friendly insulating gas; performing ammonolysis treatment on the perfluorocarbon fluorocarbons and then converting into a perfluorinated nitrile environment-friendly insulating gas under the effect of a dewatering agent or the catalyst in a third fixed bed reactor. The production technology disclosed by the invention is characterized by simple reaction condition, high atom economical efficiency, low cost and continuous and easy large-scale production.

Owner:STATE GRID CORP OF CHINA +3

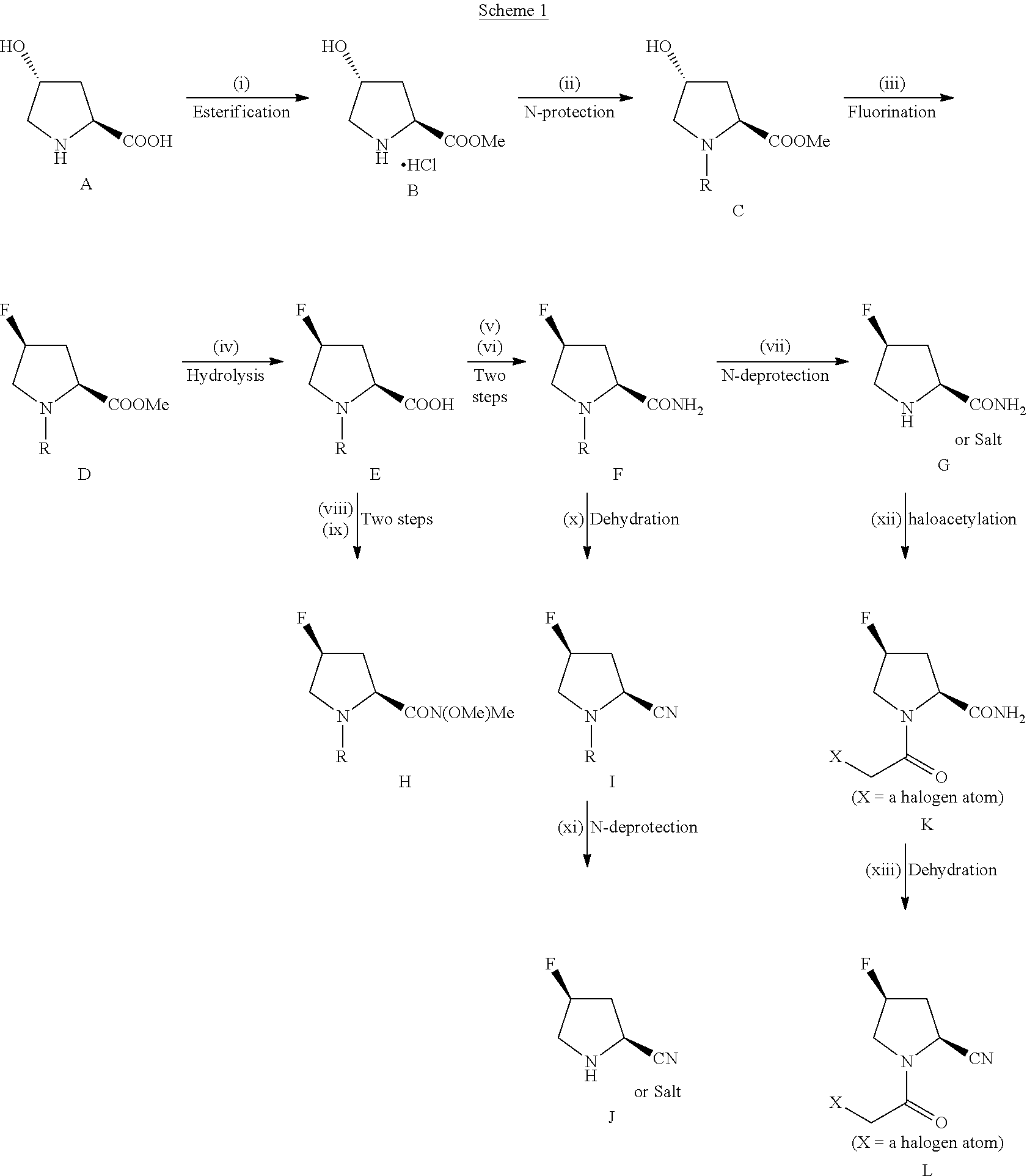

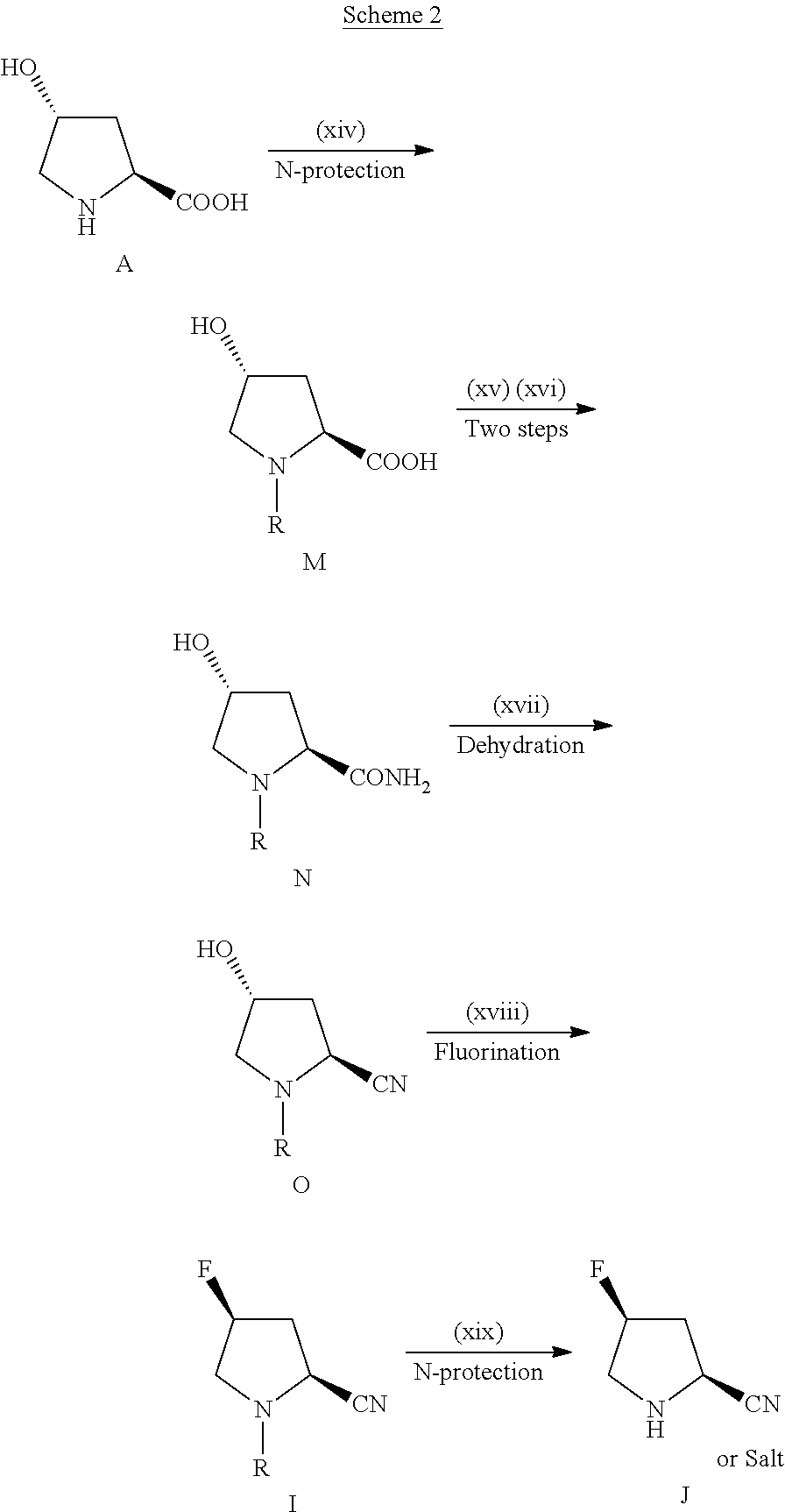

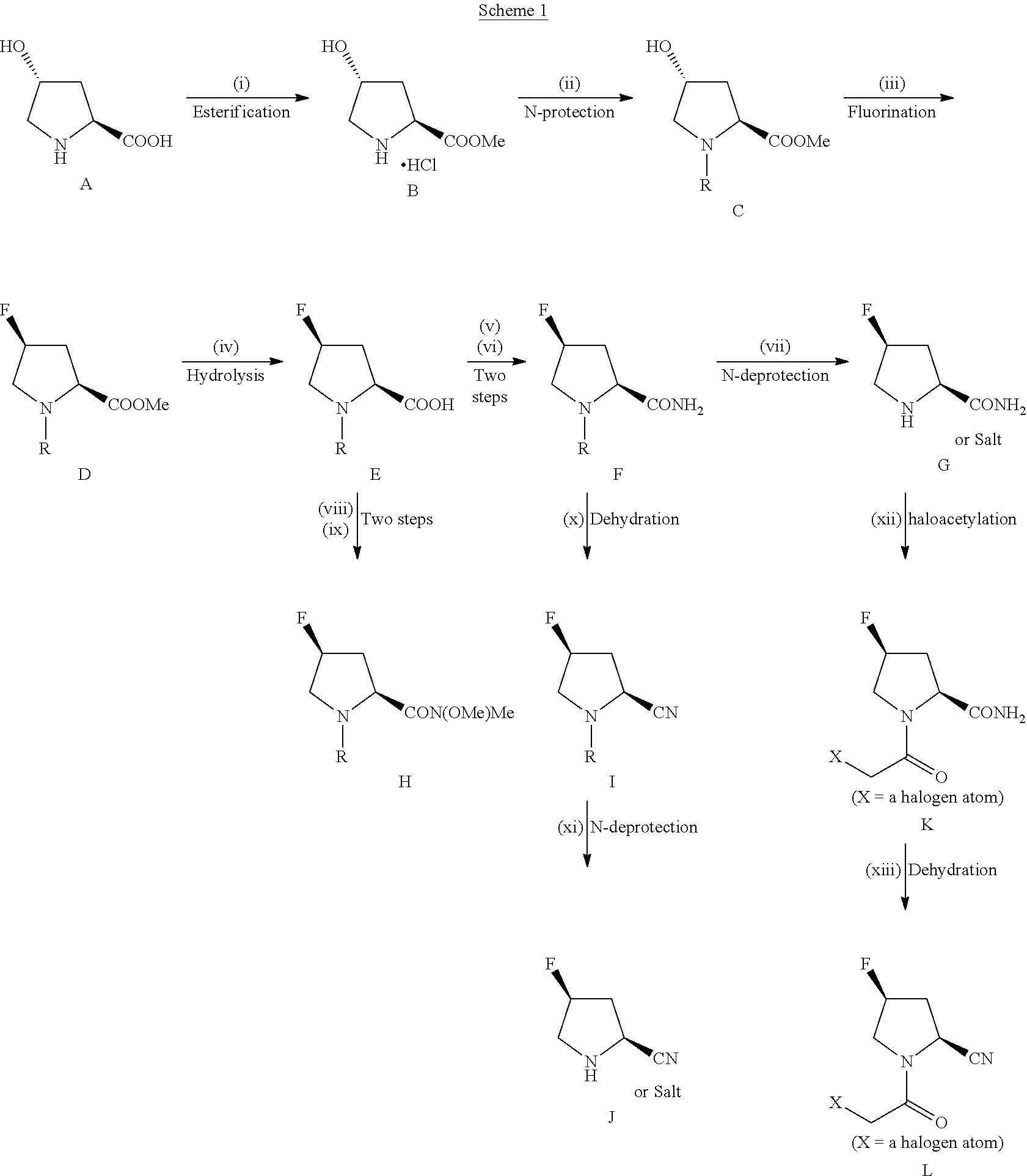

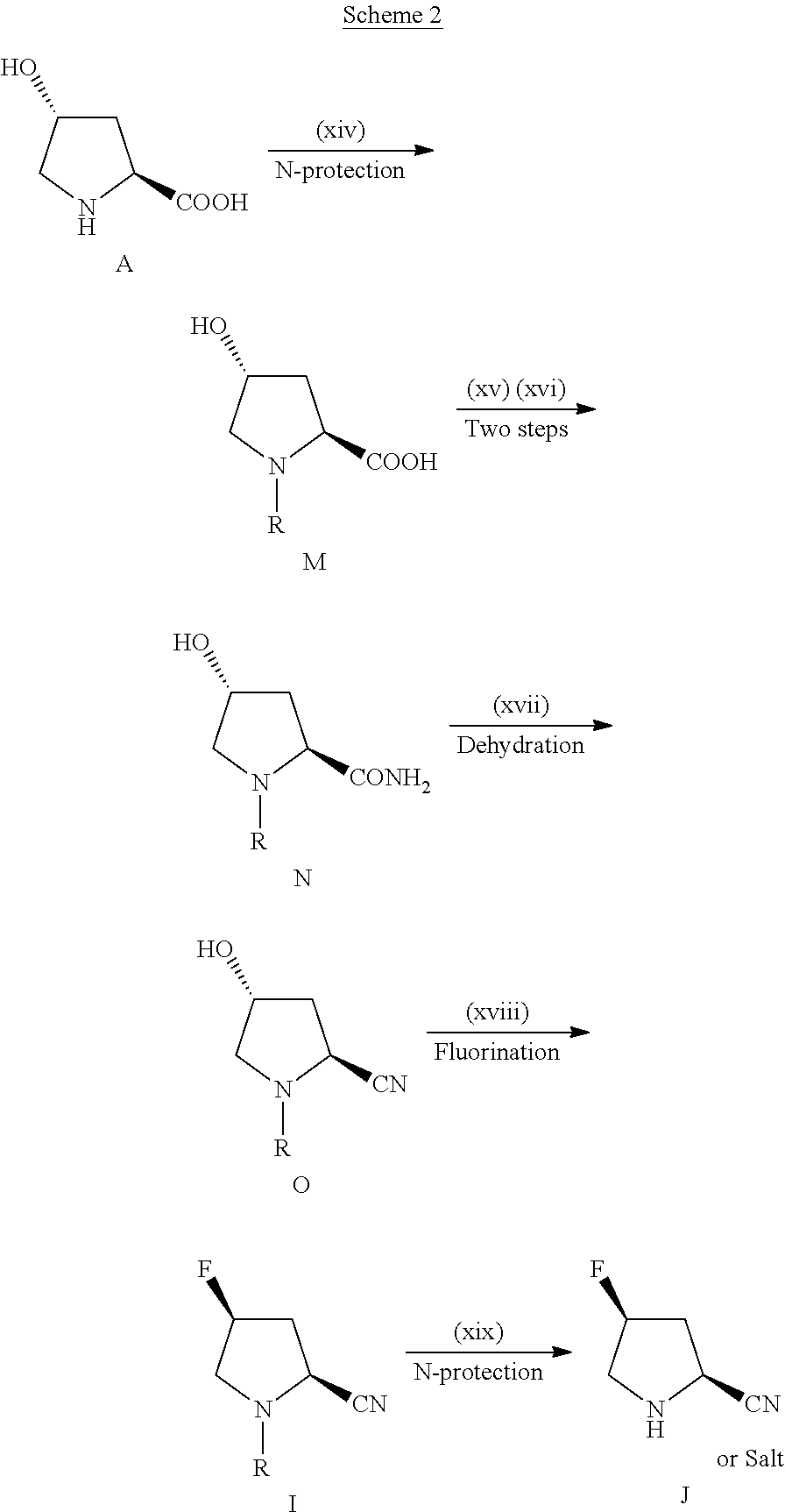

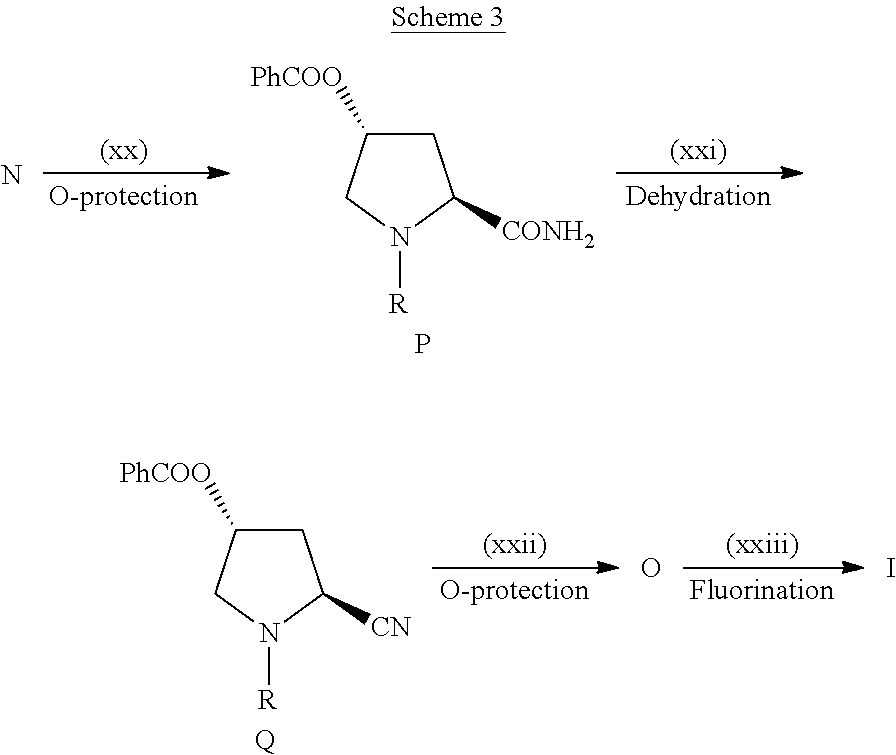

Novel 4-Fluoropyrrolidine-2-Carbonyl Fluoride Compounds and Their Preparative Methods

InactiveUS20110275833A1Silicon organic compoundsOrganic chemistryCarbonyl fluorideCombinatorial chemistry

Novel 4-fluoropyrrolidine-2-carbonyl fluoride compounds as useful fluorinated intermediates are disclosed. Their preparative methods are also disclosed. Useful applications of the 4-fluoropyrrolidine-2-carbonyl fluorides are shown.

Owner:UBE IND LTD

Method for preparing pentafluoride ethyl perfluoro isopropyl ketone through gas phases

ActiveCN108314614ALow priceEasy to produceOrganic compound preparationCarboxylic acid halides preparationPentafluorideCarbonyl fluoride

The invention discloses a method for preparing pentafluoride ethyl perfluoro isopropyl ketone through gas phases. The method is characterized in that under the existence of addition catalysts, hexafluoropropylene and hexafluoropropylene oxide or pentafluoropropionyl fluoride take gas phase addition reaction to obtain the pentafluoride ethyl perfluoro isopropyl ketone, or tetrafluoroethylene and heptafluorobutyl fluoride take gas phase addition reaction to obtain the pentafluoride ethyl perfluoro isopropyl ketone. The method has the advantages that the reaction route is short; in addition, rawmaterials such as the hexafluoropropylene, the tetrafluoroethylene, the hexafluoropropylene oxide and carbonyl fluoride can be easily obtained; the cost is low; the yield of the pentafluoride ethyl perfluoro isopropyl ketone is high; the continuous large-scale industrial production can be realized through the route.

Owner:泉州宇极新材料科技有限公司

Method for the production of 5-fluoro-1,3-dialkyl-1H-pyrazol-4-carbonyl fluorides

ActiveUS7714144B2Organic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCarbonyl fluoridePyrazole

The present invention relates to a novel process for preparing known 5-fluoro-1,3-dialkyl-1H-pyrazole-4-carbonyl fluorides which can be used as starting materials for active fungicidal ingredients by a halex reaction.

Owner:BAYER INTELLECTUAL PROPERTY GMBH

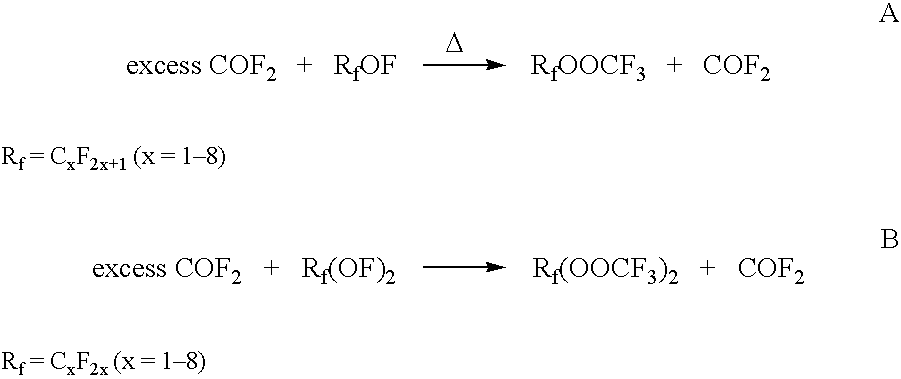

Preparation of high purity fluorinated peroxides

InactiveUS20070049774A1Hazard reductionOrganic compound preparationPeroxy compound preparationCarbonyl fluorideGas phase

This invention is directed to an improvement in a process for producing high-purity fluorinated peroxides typically formed by the reaction of a carbonyl fluoride with a hypofluorite. The improvement resides in a simplified process for the synthesis and recovery of high purity fluorinated high purity peroxide product and comprises the steps: (a) reacting the carbonyl fluoride with the hypofluorite under conditions such that a gaseous reaction product comprised of the fluorinated peroxide and unreacted carbonyl fluoride which is essentially free of unreacted hypofluorite is formed; (b) removing unreacted carbonyl fluoride and by products from the gaseous reaction product under gas phase conditions thereby generating a gaseous product stream containing the fluorinated peroxide; and then, (c) collecting the fluorinated peroxide from step (b) in gas phase.

Owner:AIR PROD & CHEM INC

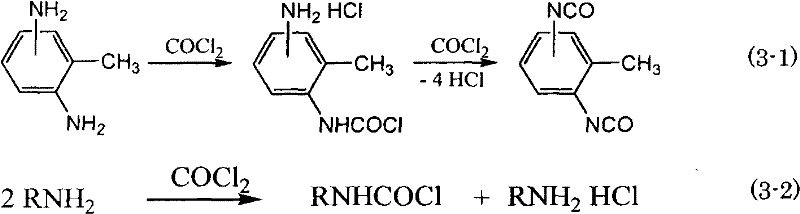

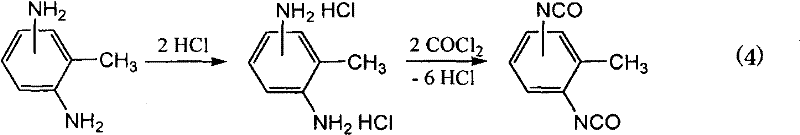

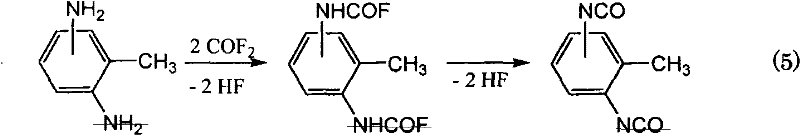

Method for producing isocyanate compound

InactiveCN102056895AIncreased toxicityLow toxicityOrganic compound preparationPreparation from carbamatesCarbonyl fluorideReaction temperature

Disclosed is a method for efficiently producing an isocyanate compound at a low reaction temperature at a low reaction pressure without using a highly toxic phosgene and without going through a complicated process. Specifically, an isocyanate compound is produced by reacting a carbonyl fluoride and an organic amine. A carbamoyl fluoride is produced by reacting the carbonyl fluoride and the organic amine, and then the carbamoyl fluoride is converted into an isocyanate. The carbamoyl fluoride is converted into the isocyanate by heating.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Andhydrous hydrogen fluoride composition and method of producing the same

InactiveUS20070098624A1Reduce hydrogen contentEasy to separateHydrogen fluorideHydrogen fluorideCarbonyl fluoride

A method of reducing the water content of anhydrous hydrogen fluoride wherein crude anhydrous hydrogen fluoride having a first concentration of water impurity is contacted with carbonyl fluoride to produce anhydrous hydrogen fluoride having a second concentration of water impurity, wherein the second concentration is lower than the first concentration.

Owner:HONEYWELL INT INC

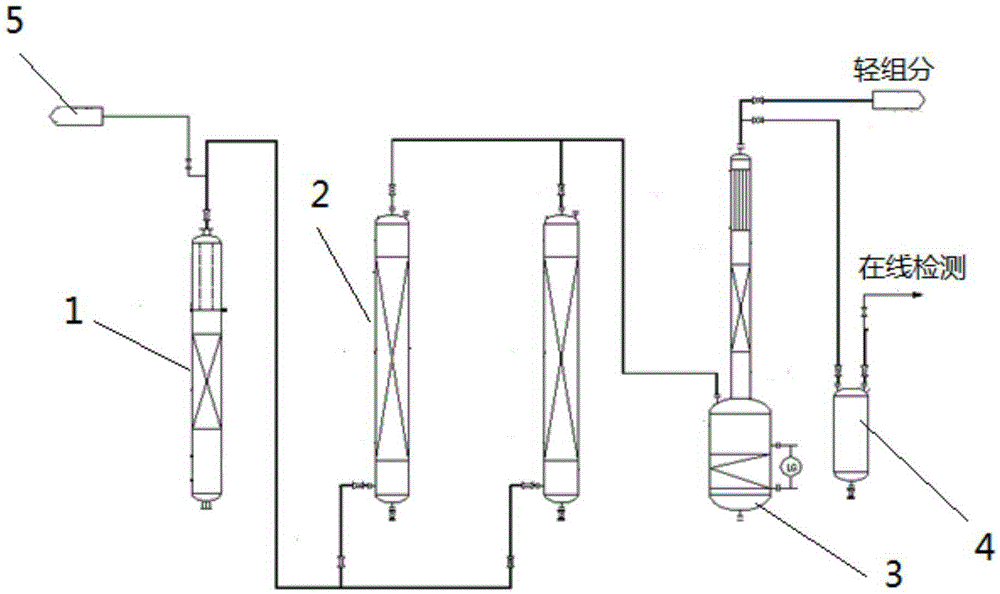

Carbonyl fluoride purifying method

ActiveCN103303894AHigh purityEfficient separationPhosgeneFractional distillationCarbonyl fluorideChemical industry

The invention relates to a carbonyl fluoride purifying method and belongs to the technical field of fluorine chemical industry and electronic industry gases. The purifying method comprises the following steps of: firstly, performing light component removal and heavy component removal treatment on the crude product gas of COF2, wherein during the light component removal treatment, the temperature at the bottom of a purifying device ranges from -112 to 48 DEG C, the pressure at the bottom ranges from 0.01 to 0.6 MPa, and the temperature of the top is 0.5-30 DEG C lower than that of the bottom, during the heavy component removal treatment, the temperature at the bottom of the purifying device ranges from minus 81 to 80 DEG C, the pressure at the bottom ranges from 0.01 to 0.6 MPa, and the temperature of the top is 0.5-30 DEG C lower than that of the bottom; then obtaining an initial refined mixed gas; performing secondary refining purification, wherein the temperature at the bottom of the purifying device ranges from minus 123 to 36 DEG C, the pressure at the bottom ranges from 0.01 to 1.03 MPa, and the temperature of the top is 0.2-45 DEG C lower than that of the bottom; then obtaining the purified gas. The purifying method is especially suitable for the crude product gas of COF2 high in CO2 content; the COF2 purity in the purified gas is greater than or equal to 99%, and the CO2 content therein is less than 1000 ppm.

Owner:PERIC SPECIAL GASES CO LTD

Fluorinated graphene with carbonyl fluoride semi-ionic bonds and lithium battery positive pole material

InactiveCN107720730AHigh specific powerIncrease specific energyGraphenePositive electrodesIon contentCarbonyl fluoride

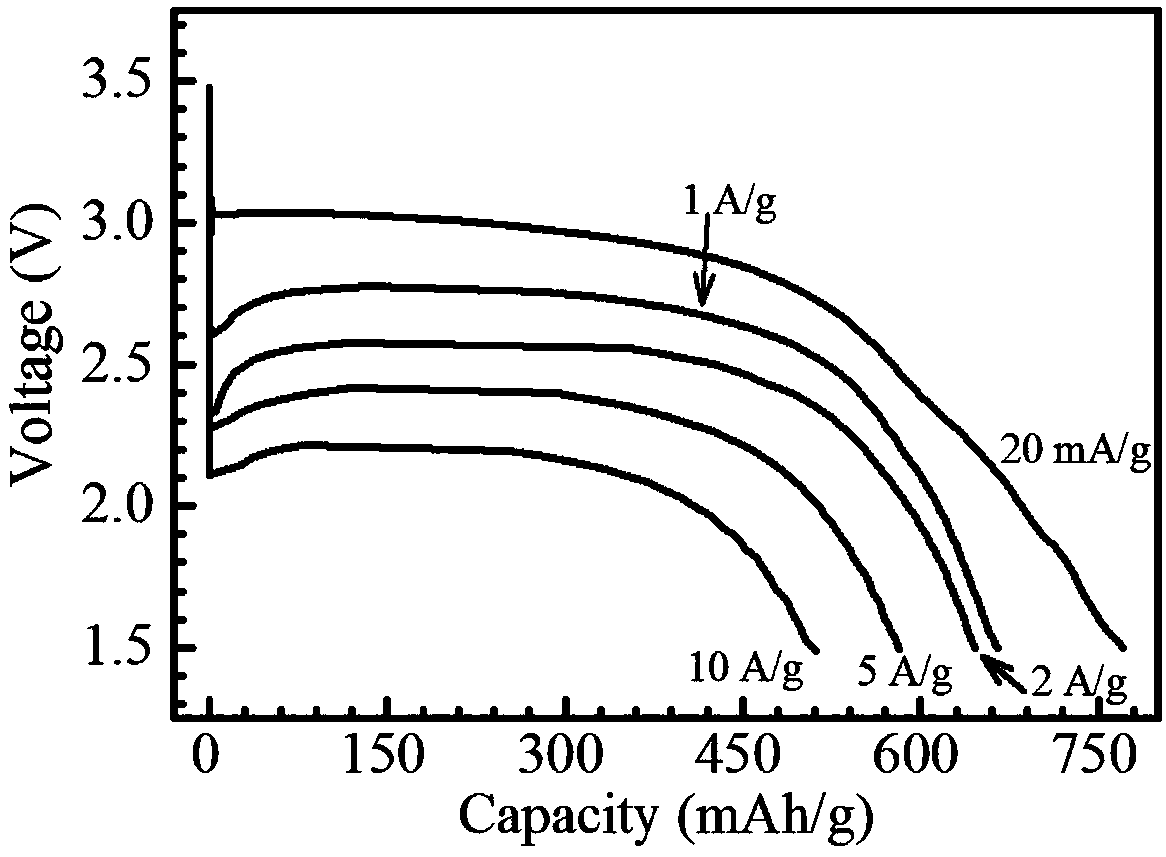

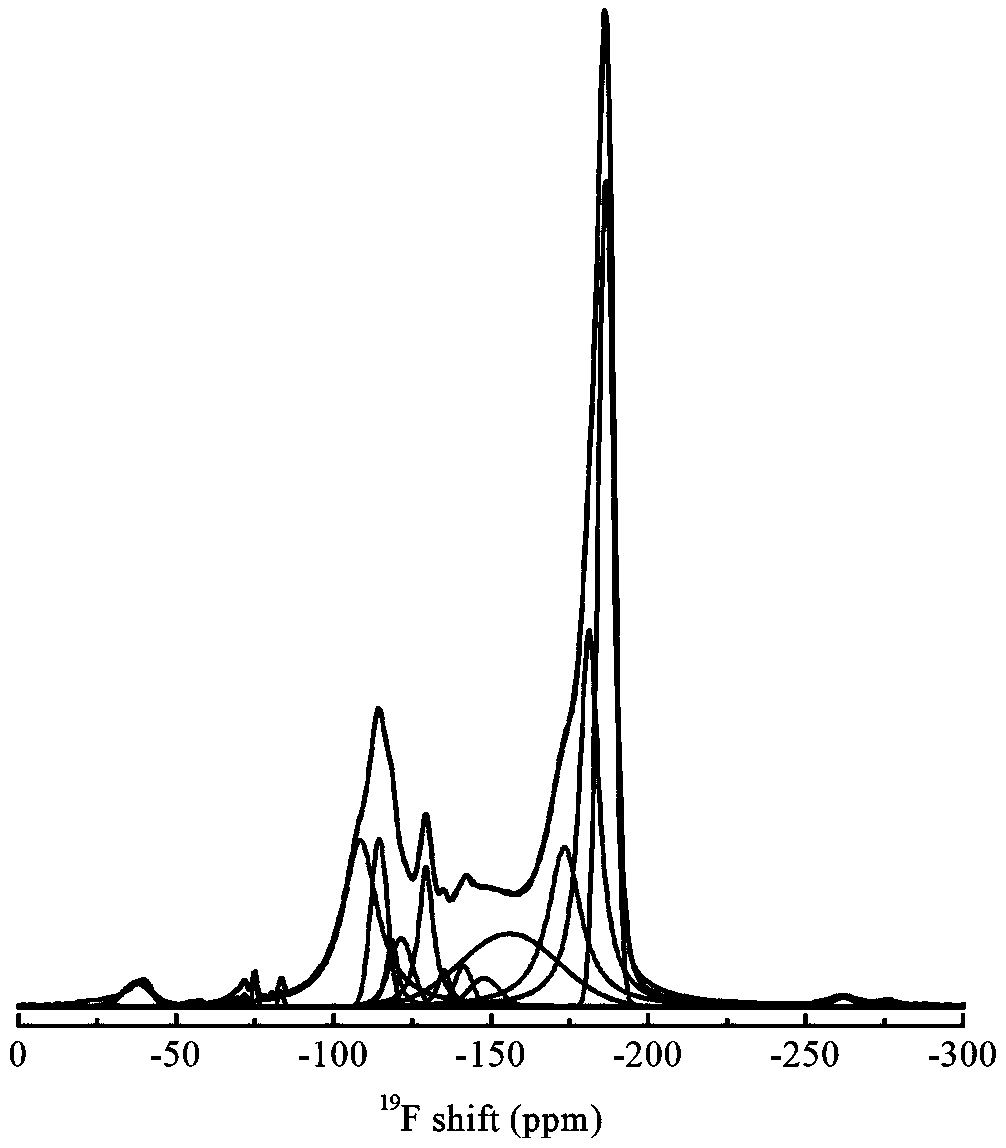

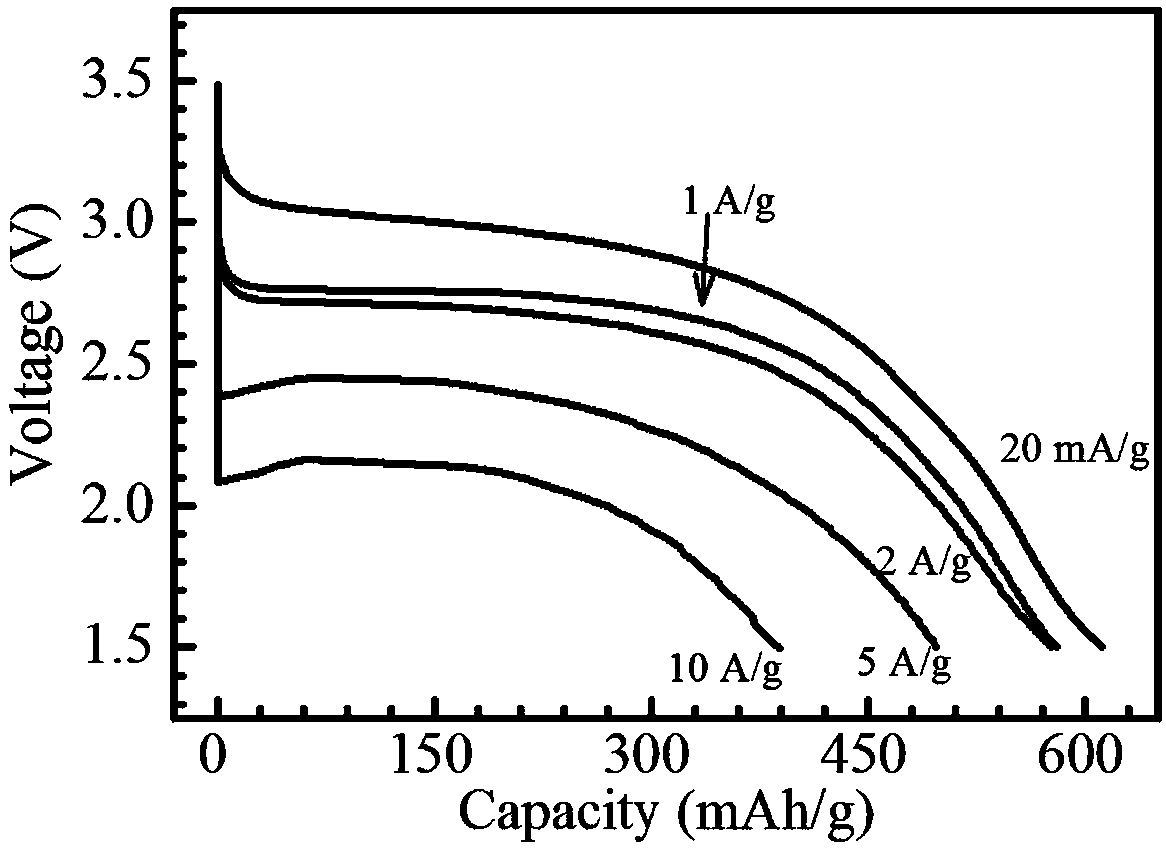

The invention discloses fluorinated graphene with carbonyl fluoride semi-ionic bonds. The fluorinated graphene is characterized in that the fluorinated graphene is prepared after graphene is fluorated, and the proportion of the semi-ion content to fluorine content in the fluorinated graphene body is 21-35%. The invention further comprises a lithium battery positive pole material. The fluorinated graphene with the carbonyl fluoride semi-ionic bonds has the advantages of high specific power and high specific energy, according to the lithium battery positive pole material of the fluorinated graphene material, discharging can be achieved under the current of 10 A / g at the highest, the specific energy is larger than 1,000 Wh / kg, the specific power is larger than 21,000 W / kg, and the fluorinatedgraphen can be applied to disposable usage of the lithium battery positive pole material.

Owner:XIAMEN INST OF RARE EARTH MATERIALS

Method for preparing fluorine-containing ether

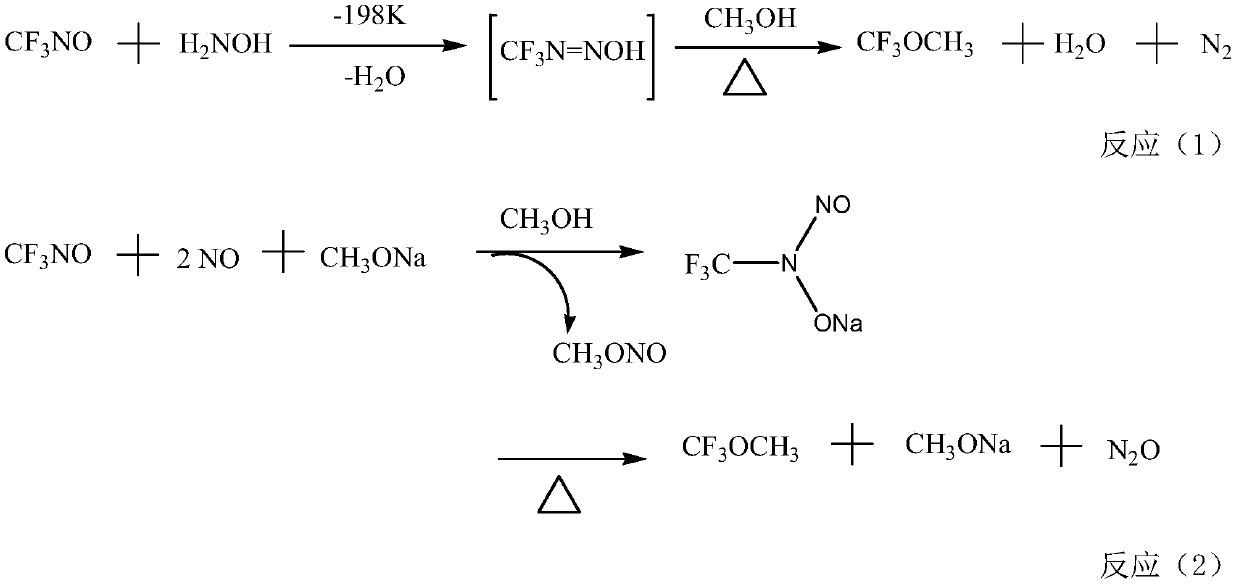

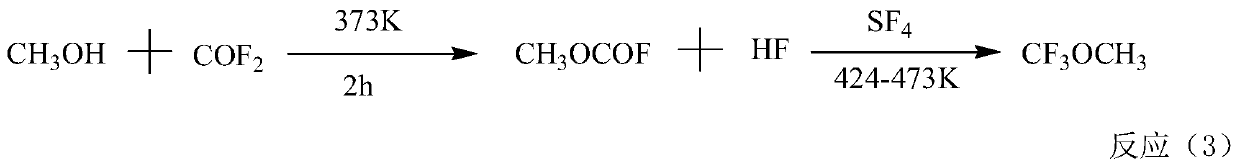

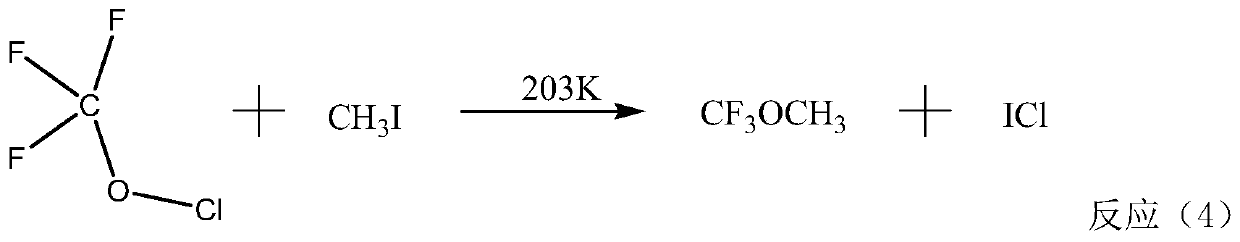

ActiveCN110002968AHigh yieldProcess safetyPreparation of metal alcoholatesEther preparation by ester reactionsChemical synthesisCarbonyl fluoride

The invention relates to a 'method for preparing fluorine-containing ether', and belongs to the field of chemical synthesis. The method comprises the steps that under a nitrile solvent condition, carbonyl fluoride, trifluoroacetyl fluoride, pentafluoropropionyl fluoride, heptafluoro-n-butyryl fluoride, heptafluoro-iso-butyryl fluoride and other acyl fluorides are taken as raw materials to have anaddition reaction with metal fluorides to obtain perfluoroalkoxide, then under water catalysis, the perfluoroalkoxide and a low-toxic or even non-toxic harmless alkylating agent are subjected to an alkylation reaction to obtain the fluorine-containing ether. The method for preparing the fluorine-containing ether has the advantages that not only is the reaction condition mild, the yield of the fluorine-containing ether is high, but also the low-toxic or even non-toxic harmless alkylating agent is taken as a safe alkylation agent, the process is safe and reliable, and effective separation can beperformed by an ordinary distillation means in the industry.

Owner:泉州宇极新材料科技有限公司

Water removal method for silicon tetrafluoride

The invention discloses a water removal method for silicon tetrafluoride, and belongs to the field of fluorine chemical and electronic industry gas. The method comprises the following steps: introducing silicon tetrafluoride, diluent gas and carbonyl fluoride in a water removal tower filled with a filler, carrying out a reaction through the contact of the carbonyl fluoride and water in the silicon tetrafluoride, removing the water in the silicon tetrafluoride to obtain a product 1; carrying out condensation treatment on the product 1 to obtain a product 2; carrying out adsorption and low-temperature fractionation treatment on the product 2 in sequence; and collecting the silicon tetrafluoride to complete water removal of the silicon tetrafluoride. The water removal method is simple in operation; the water in the silicon tetrafluoride can be effectively removed; and through detection, the purity of the silicon tetrafluoride product is as high as 99.999%, water is not detected, and the content of hexafluoride disiloxane ((SiF3)2O) is as low as at most 20 ppb.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

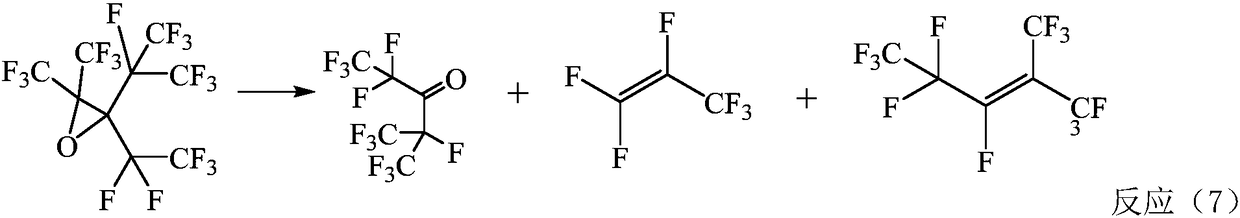

Method for comprehensively utilizing byproducts produced in HFPO (hexafluoropropylene oxide) preparation based on oxygen oxidation method

PendingCN109678700AReduce investmentEasy to operatePreparation from carboxylic acid halideTransportation and packagingCarbonyl fluorideHexafluoropropylene

The invention belongs to the field of fluorine chemical and particularly relates to a method for comprehensively utilizing byproducts produced in HFPO (hexafluoropropylene oxide) preparation based onan oxygen oxidation method. The method comprises following steps: 1), oxygen and hexafluoropropylene are taken as raw materials, and HFPO is prepared under the action of a fluoride solvent, and the fluoride solvent is recycled; 2), when content of the byproducts in the recycled fluoride solvent is lower than 40wt%, ultraviolet irradiation is performed every 10-30 h; 3), when content of the byproducts is higher than or equal to 40wt%, water is added to the fluoride solvent, and a carboxylic acid product is obtained. On one hand, an important chemical intermediate carbonyl fluoride in the fluorine chemical can be obtained, on the other hand, the byproducts can be converted into a perfluoro surfactant or fluorine-containing fluid for further application, and therefore, the byproducts producedin the HFPO preparation process based on the oxygen oxidation method are comprehensively utilized.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD

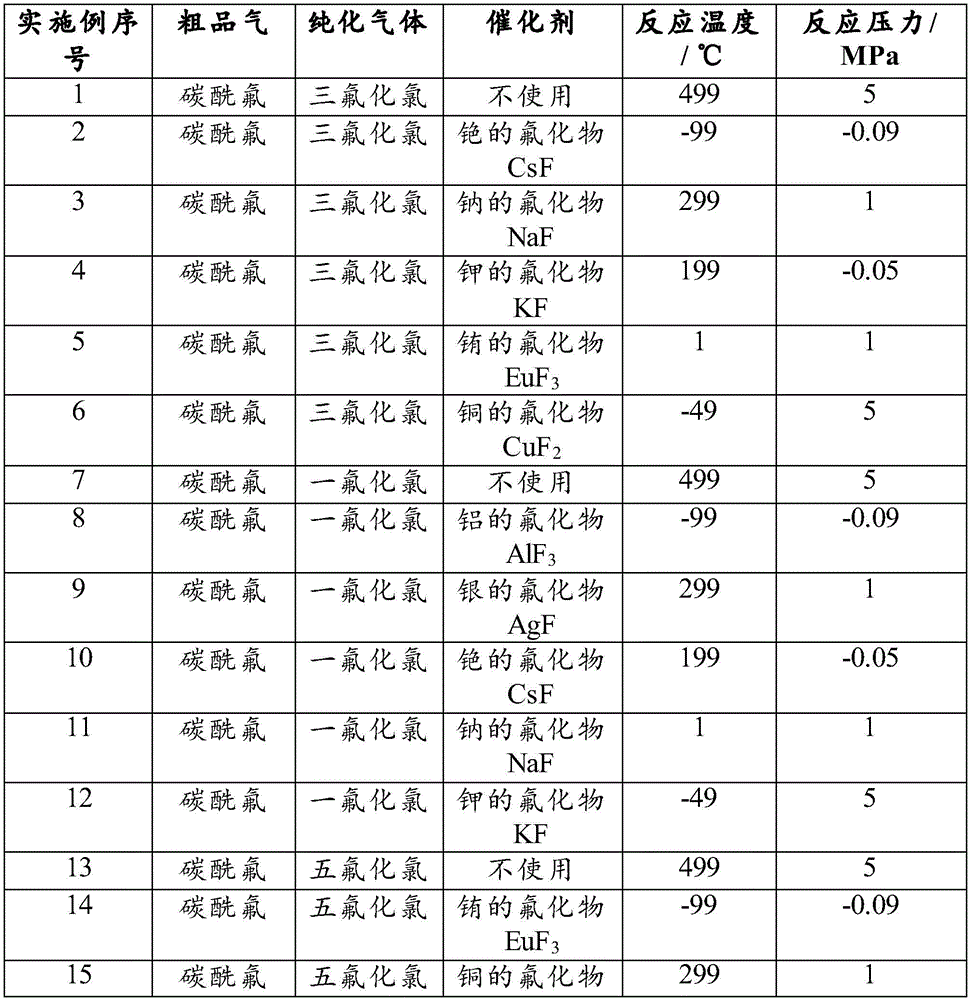

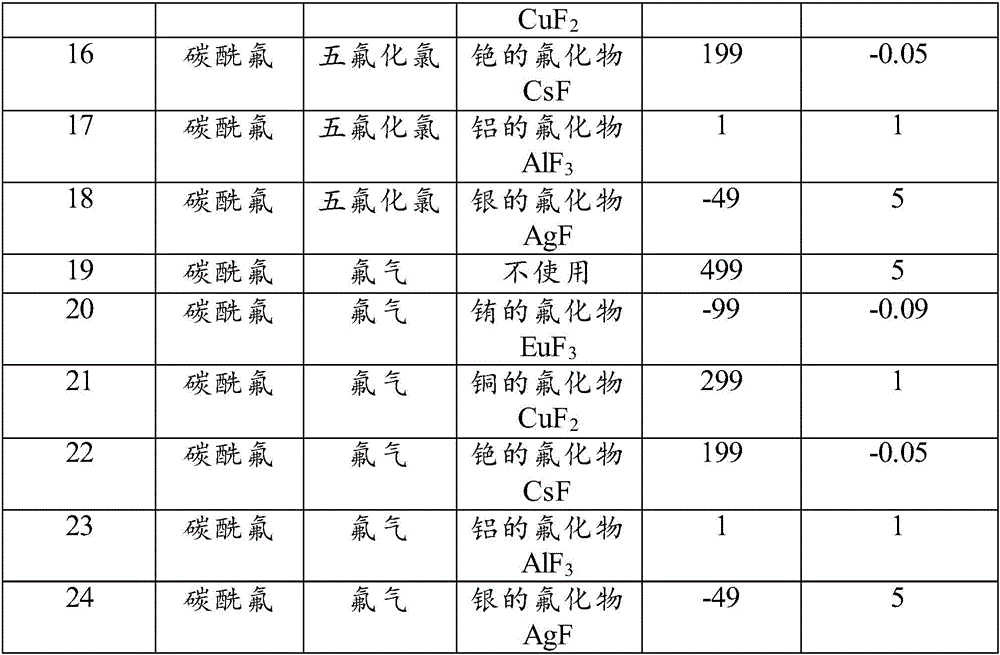

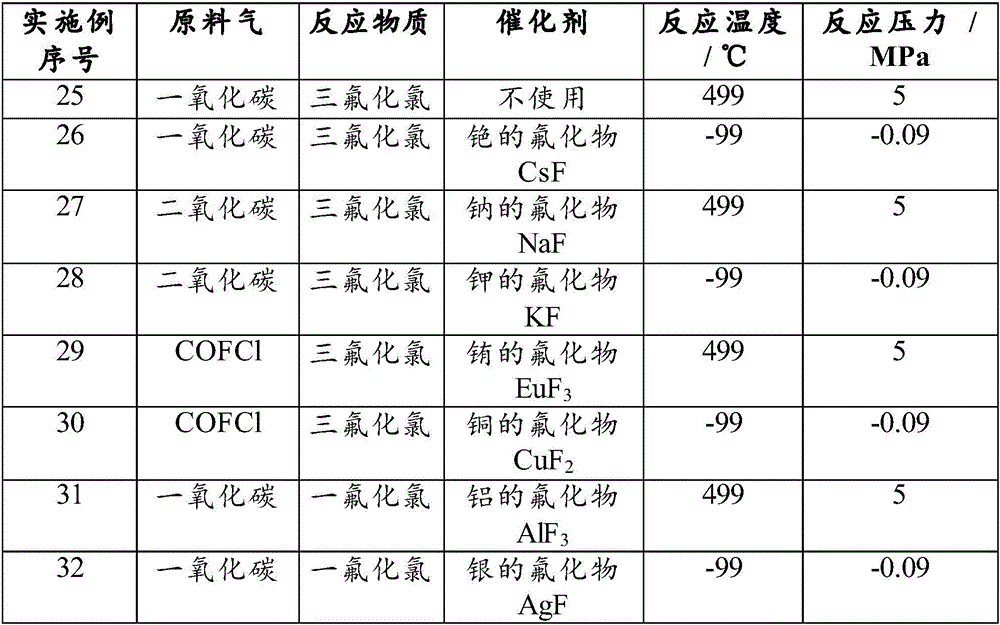

Purification method and preparation method for carbonyl fluoride

The invention provides a purification method for carbonyl fluoride. The purification method comprises the steps that purifying gas is used for reacting with impurities in gas of a crude carbonyl fluoride product to remove the impurities in the gas of the crude carbonyl fluoride product, wherein the purifying gas is any one or more of ClF, ClF3, ClF5 and F2. According to the purification method, the crude carbonyl fluoride reaction product is purified, any one or more of ClF, ClF3, ClF5 and F2 are adopted as the purifying gas to react with the crude carbonyl fluoride reaction product in a purification device, various impurities, especially CO2, CO, H2O, phosgene COCl2, N2O and the like, except carbonyl fluoride are removed, and the content of impurities is greatly reduced. In purified fine carbonyl fluoride gas, the purity of COF2 is larger than or equal to 99.95%, the content of CO2 is smaller than or equal to 150*10<-6> (the volume ratio), and the content of COCl2 is smaller than or equal to 150*10<-6> (the volume ratio).

Owner:PERIC SPECIAL GASES CO LTD

Process for purifying a fluorine compound

InactiveUS20100099931A1Improve responseEasy to separatePhosphorus halides/oxyhalidesFluoride preparationCarbonyl fluorideOxygen compound

Provided is a process for purifying a fluorine compound capable of yielding a highly pure fluorine compound by removing at least oxygen from a fluorine compound containing an oxygen compound as an impurity. In a process according to the present invention for purifying a fluorine compound, the following is brought into contact with the fluorine compound, which contains an oxygen compound as an impurity, thereby removing at least oxygen: carbonyl fluoride in an amount of a 0.1-fold equivalent or more and a 100-fold equivalent or less of oxygen atoms in the fluorine compound.

Owner:STELLA CHEMIFA CORP

Manufacturing method for carbonyl fluoride

The present invention provides a manufacturing method for carbonyl fluoride. The method is a novel method for safely and effectively getting carbonyl fluoride through reacting tetrafluoroethylene with oxygen. The carbonyl fluoride is obtained by reacting tetrafluoroethylene with oxygen and heating in the presence of air, wherein the amount of air is more than eight times of tetrafluoroethylene gas in moles.

Owner:DAIKIN IND LTD

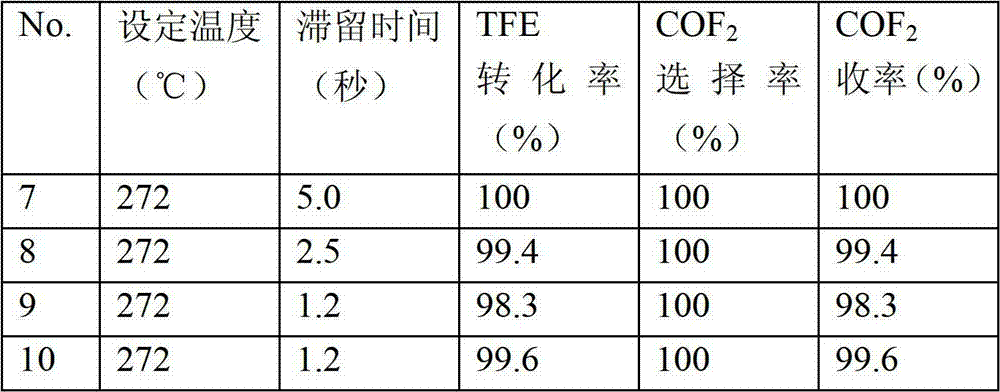

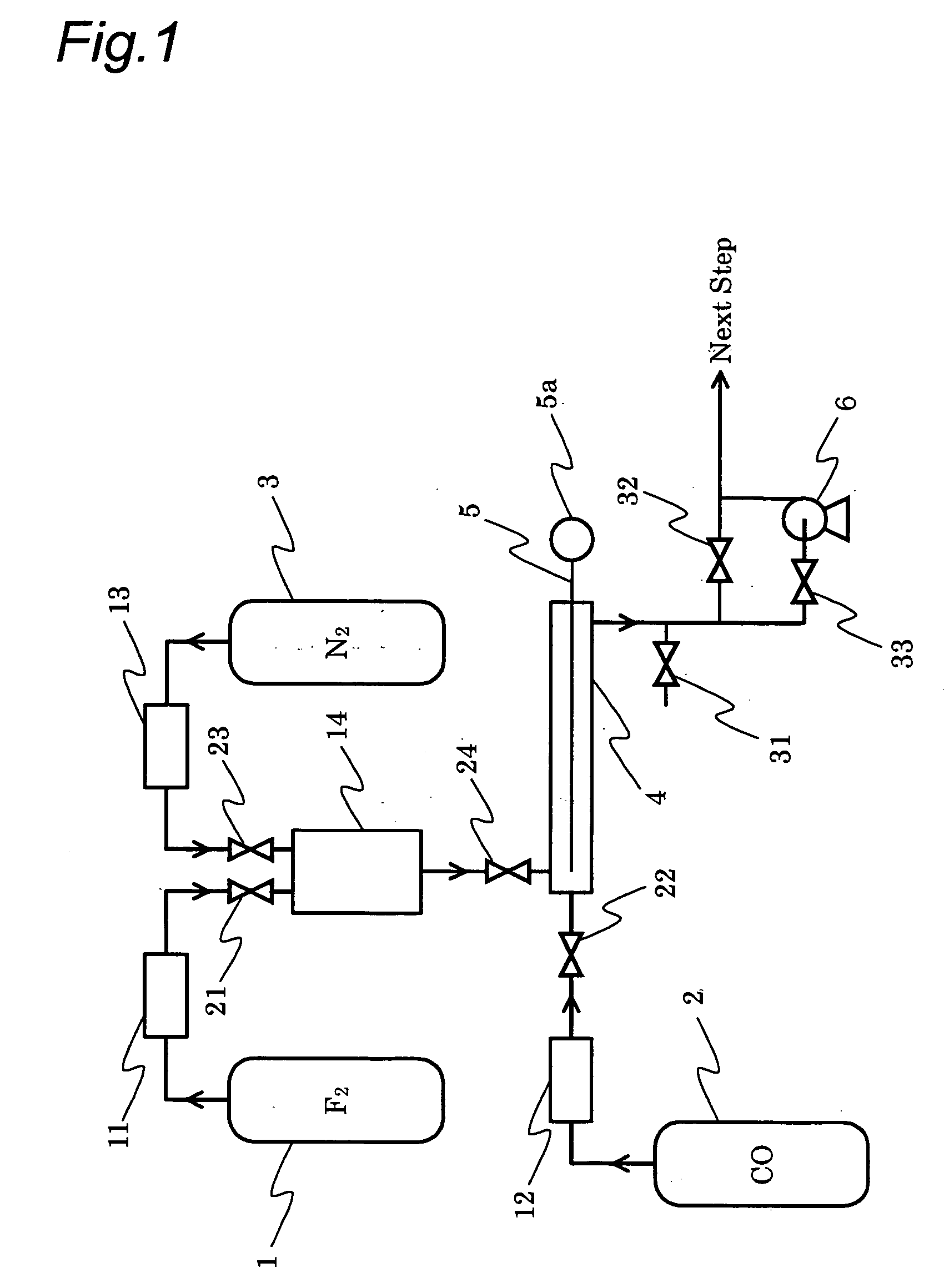

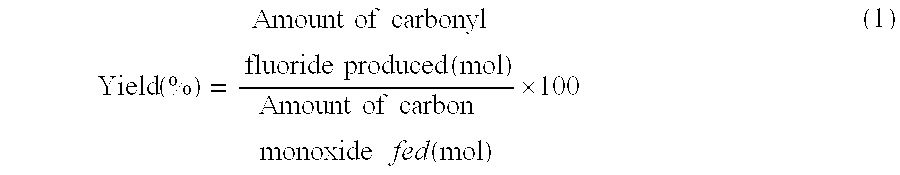

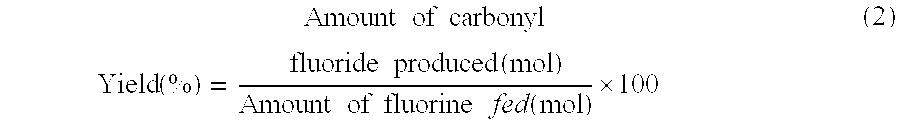

Process for producing carbonyl fluoride

ActiveUS20060194985A1Produced safely and easilyReduce pressureOrganic compound preparationPhosgeneInternal pressureCarbonyl fluoride

The process for producing carbonyl fluoride according to the invention is a process for safely and easily producing high-purity carbonyl fluoride having a low content of carbon tetrafluoride, and comprises feeding carbon monoxide and fluorine to a reactor and allowing carbon monoxide to react with fluorine under the conditions of a reactor internal pressure of less than atmospheric pressure.

Owner:NAT INST OF ADVANCED IND SCI & TECH +5

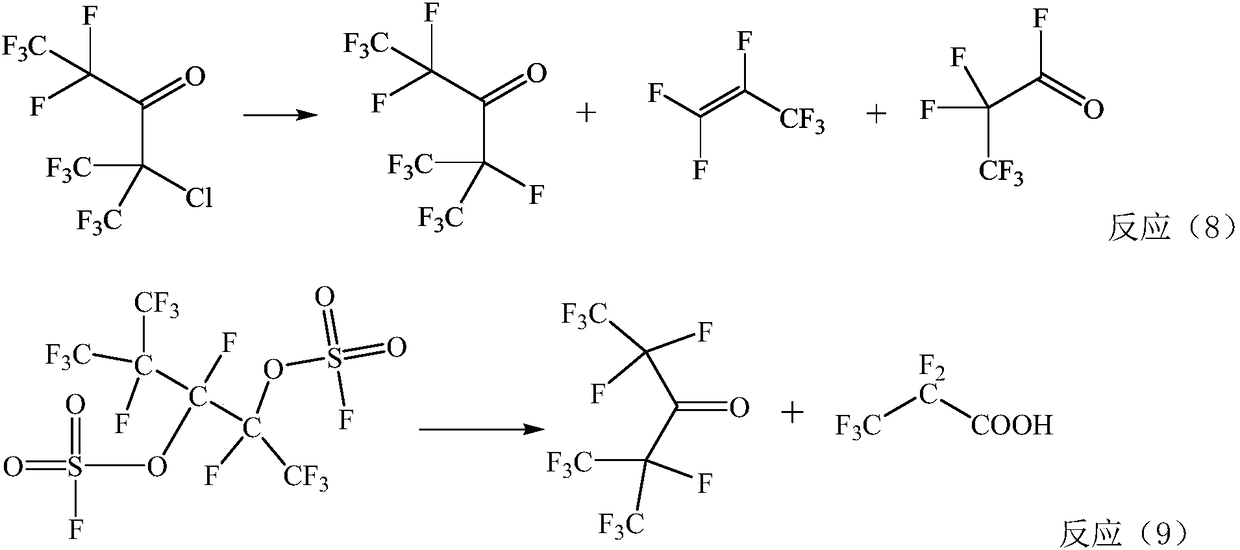

Method for preparation of carbonyl fluoride by cracking of perfluorinated compound and carbonyl fluoride

ActiveCN109607507AExpand preparation channelsIncrease profitCarbon compoundsChemical industryCarbonyl fluoride

Belonging to the field of fine fluorine chemical industry, the invention in particular relates to a method for preparation of carbonyl fluoride by cracking of a perfluorinated compound and carbonyl fluoride. The following compounds are adopted as the reactant for reaction with oxygen in the presence or absence of a catalyst to produce carbonyl fluoride. The compounds include: 1) perfluoroolefine;2) perfluoroacyl fluoride; and 3) perfluorocarbonyl fluoride. The method of cracking the perfluorinated compound into carbonyl fluoride can convert all the raw materials into carbonyl fluoride, the by-product is few, and the follow-up product separation requirement is low, at the same time toxic and harmful substances in the organofluorine compound can be converted into useful basic raw materials,thus greatly enhancing the utilization of carbon atoms and fluorine atoms, the reaction operation is simple, the safety is greatly improved, and at the same time, the method expands the preparation channels of carbonyl fluoride.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD

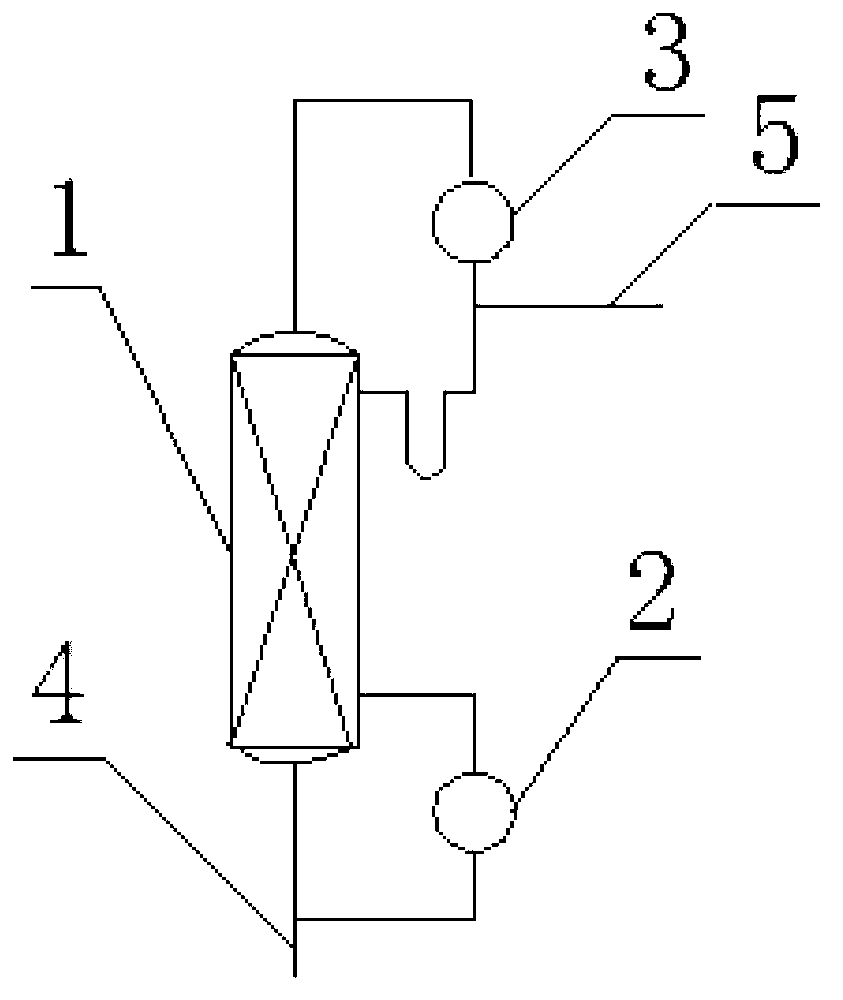

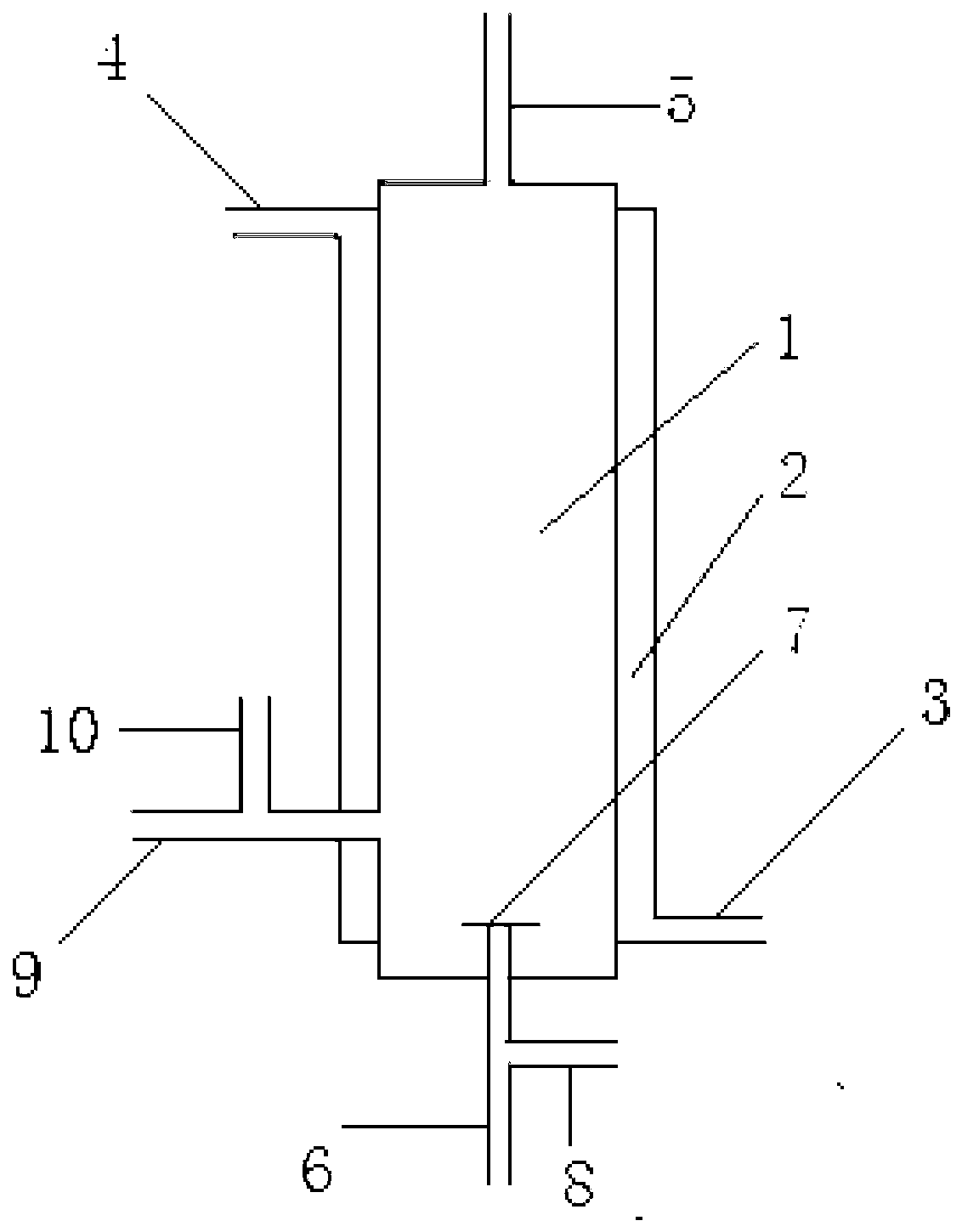

Device and method for synthesizing carbonyl fluoride

The invention belongs to the fields of fluorine chemical engineering and electronic industrial gases, and particularly relates to a method and a device for synthesizing carbonyl fluoride. The method comprises the following steps of using perfluoroalkyl iodide as a raw material, and making the perfluoroalkyl iodide be in an oxygen atmosphere to obtain the carbonyl fluoride in a heating condition. The heating condition is that the heating temperature is 250 DEG C to 650 DEG C; the concentration of oxygen is 20 to 100 percent; the speed at which the oxygen is introduced is 100ml / min to 500ml / min. According to the method and the device for synthesizing the carbonyl fluoride, the perfluoroalkyl iodide is adopted as a reactant; a brand-new method is provided for producing the carbonyl fluoride; the use of strong-corrosion and high-toxicity gases of fluorine, phosgene and the like is avoided; the use of such a greenhouse gas of trifluoromethane is also avoided; a reaction process is relatively mild; a too high temperature is not needed; further, risks of explosions do not exist; crucially, gas-phase by-products of carbon dioxide or hydrogen fluoride and the like are not generated in a reaction product; the obtaining of high-purity carbonyl fluoride is facilitated.

Owner:天津长芦新材料研究院有限公司

Preparation method of carbonyl fluoride

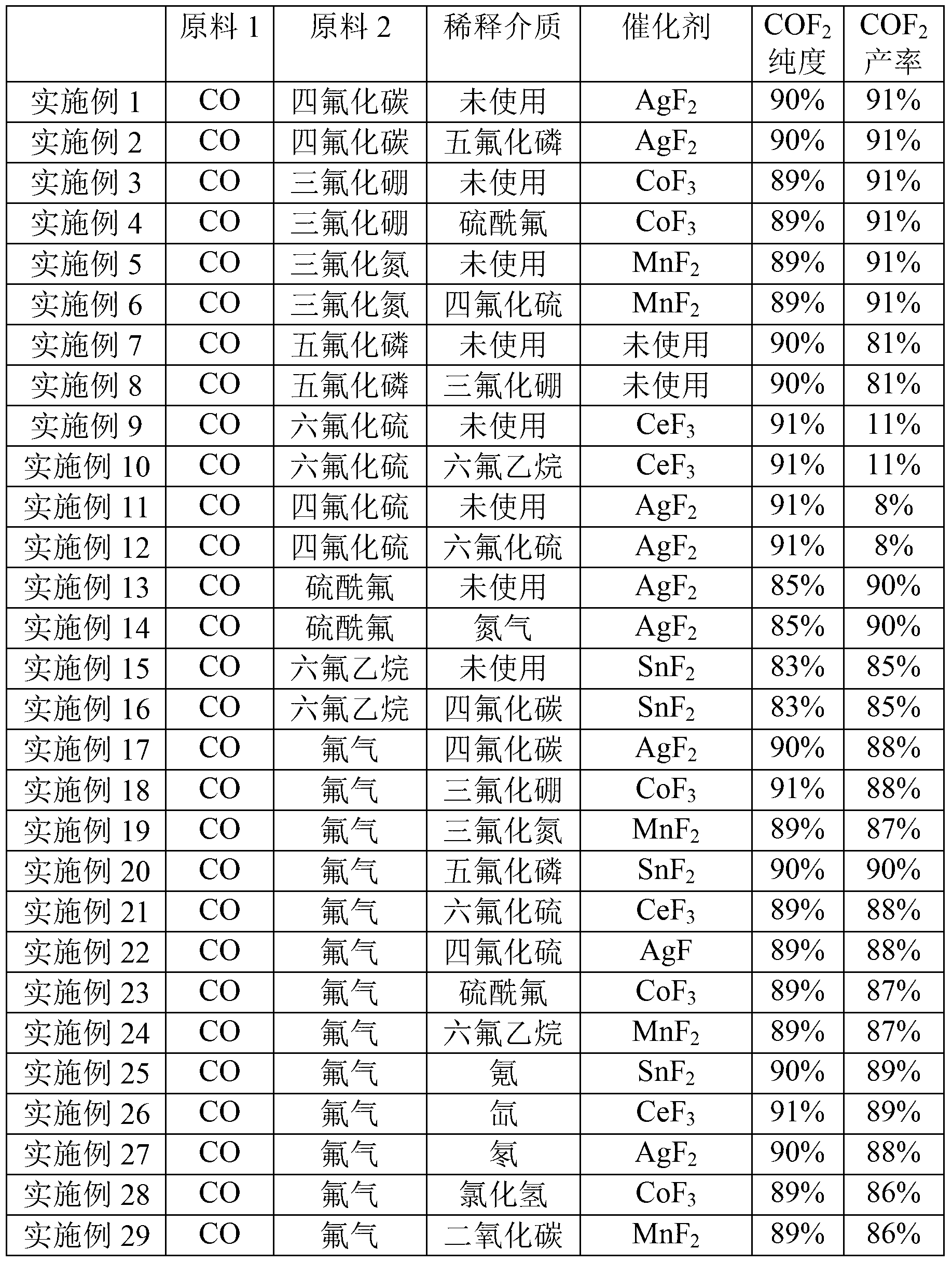

ActiveCN103213965ASafe preparationEconomical and efficient to prepareCarbon compoundsHexafluoroethanePhosphorus trifluoride

The invention relates to a preparation method of carbonyl fluoride and belongs to the fluorine chemical field and the field of electronic industrial gas. The preparation method is used for preparing carbonyl fluoride through the reaction of carbon monoxide and fluorine-containing substance, wherein the fluorine-containing substance is at least one of carbon tetrafluoride, boron trifluoride, nitrogen trifluoride, sulfur tetrafluoride, sulfur hexafluoride, phosphorus trifluoride, phosphorus pentafluoride, sulfuryl fluoride or hexafluoroethane; the favourable conditions including temperature, pressure, a proportion of fluorine-containing substance to carbon monoxide and gas supply flow rate of the fluorine-containing substance are selected; dilution medium is further added in the method for diluting or carrying out catalytic reaction by virtue of catalyst. The preparation method of the carbonyl fluoride is free of fluorine gas, capable of lowering the corrosion to a reactor, reaction heat, reaction intensity, potential explosive risk and yield drop caused by side reaction, and capable of safely, economically and effectively preparing the carbonyl fluoride. The invention further provides dilution medium which is used in the preparation of the carbonyl fluoride through the reaction of carbon monoxide and fluorine gas.

Owner:PERIC SPECIAL GASES CO LTD

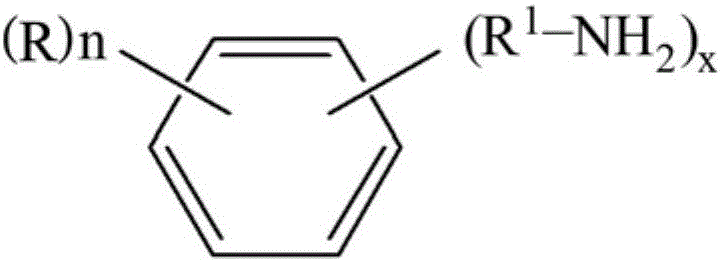

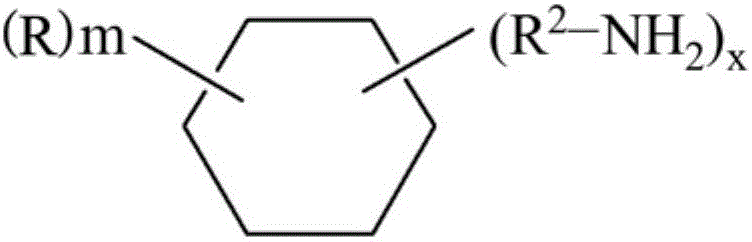

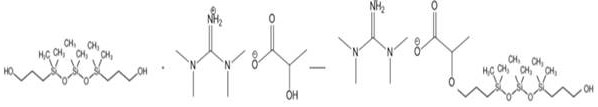

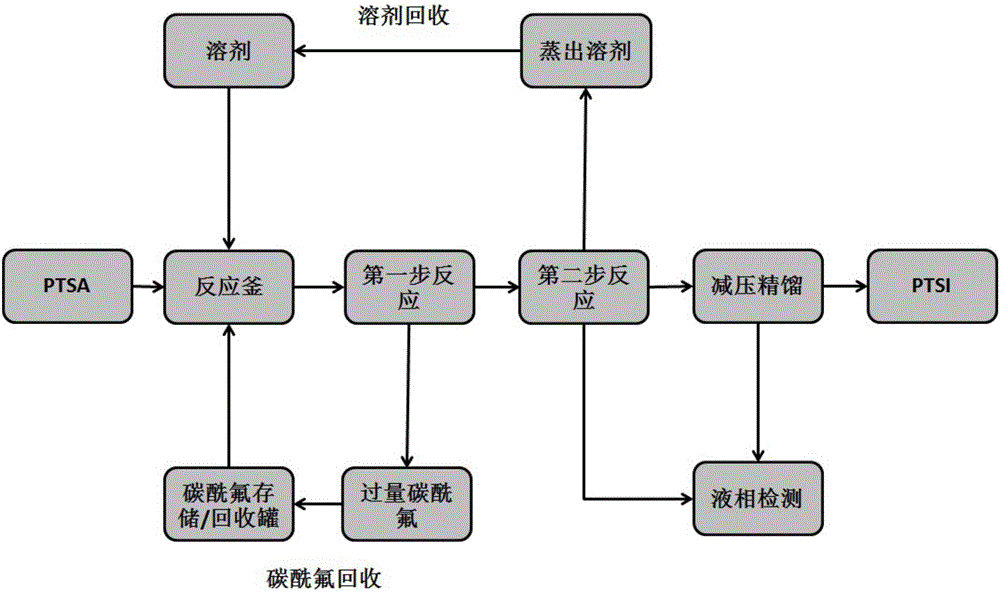

Method for preparing isocyanate by using amine and carbonyl fluoride

ActiveCN106631899AMild reaction conditionsLow costOrganic compound preparationSulfonic acid amide preparationCarbonyl fluorideOrganic solvent

The invention discloses an efficient synthesis method for preparing corresponding isocyanate by enabling carbonyl fluoride to directly react with amine. The efficient synthesis method mainly comprises the following two steps: carrying out acylation reaction on the amine and the carbonyl fluoride according to a preferable proportion in an anhydrous inertial organic solvent under a sealed environment and a proper reaction condition, thus generating an intermediate-carbamyl fluoride; (2) carrying out dehydrofluorination on the intermediate-carbamyl fluoride under normal pressure and the proper reaction condition, thus obtaining the target isocyanate. During a reaction process, addition of a catalyst is not needed, the reaction conditions are mild, excessive carbonyl fluoride and a used solvent during the reaction process can be efficiently recycled and reused, and a by-product HF can be commercially sold after being collected and refined.

Owner:泉州宇极新材料科技有限公司

Method for purifying fluorine compound

InactiveCN101558008AImprove responseEasy to separateAmino compound purification/separationPhosphorus halides/oxyhalidesCarbonyl fluorideOxygen compound

Provided is a process for purifying a fluorine compound capable of yielding a highly pure fluorine compound by removing at least oxygen from a fluorine compound containing an oxygen compound as an impurity. In a process according to the present invention for purifying a fluorine compound, the following is brought into contact with the fluorine compound, which contains an oxygen compound as an impurity, thereby removing at least oxygen: carbonyl fluoride in an amount of a 0.1-fold equivalent or more and a 100-fold equivalent or less of oxygen atoms in the fluorine compound.

Owner:STELLA CHEMIFA CORP

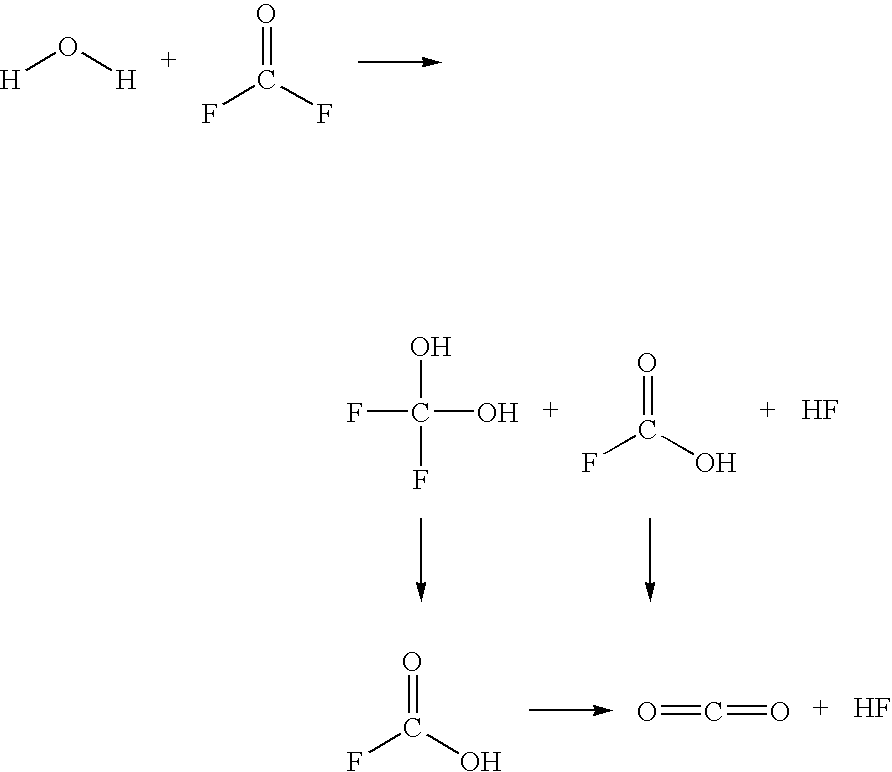

Reactive ultrasonic rectification and purification method for HF electronic gas

PendingCN111807325ATo achieve the purpose of dehydration and purificationPromote escapeSilicon organic compoundsHydrogen fluorideCarbonyl fluorideAnalytical chemistry

The invention relates to the field of high-purity gas purification, in particular to a reactive ultrasonic rectification and purification method for HF electronic gas. According to the reactive ultrasonic rectification and purification method for the HF electronic gas, a small amount of carbonyl fluoride and thionyl chloride are added into liquefied HF containing trace water respectively, and CO2or SO2 generated by a reaction of carbonyl fluoride or thionyl chloride with water is removed through rectification, so the purpose of HF dehydration and purification is achieved; besides, the liquefied HF is placed in an ultrasonic field for rectification and purification, so the reaction of carbonyl fluoride, thionyl chloride and trace moisture in the liquefied HF can be promoted, the escape ofCO2 or SO2 from the liquefied HF is accelerated, and the residue of CO2 or SO2 in the liquefied HF is effectively reduced; and the method belongs to a reactive conversion-ultrasonic degassing coupledmethod for water, and has the advantages of high purity and extremely low water content.

Owner:ZHEJIANG KAISN FLUOROCHEM +1

Environment-friendly synthesis method of high-yield perfluoromethylvinyl ether (PMVE)

ActiveCN103724167BHigh yieldEasy to separateOrganic compound preparationCarboxylic compound preparationVinyl etherSynthesis methods

The invention relates to an environment-friendly synthesis method of high-yield perfluoromethylvinyl ether (PMVE). The method comprises the following steps: preparing an alkali metal fluoride, 1-butyl-3-methyl imidazolium tetrafluoroborate and a polarity organic solvent into a catalyst solution under nitrogen protection; reducing the temperature to be 0-5 DEG C, and uniformly stirring; introducing carbonyl fluoride and hexafluoropropylene oxide into the catalyst solution, and carrying out an addition reaction at the temperature of 10 DEG C below zero to 20 DEG C; introducing the obtained addition product into a cracking tower filled with carbonate for cracking, thereby obtaining the PMVE. The synthesis method is high in reaction efficiency and high in product yield, the solvent used in the reaction can be recycled, and the used ionic liquid promoter is easy to separate and is environmental friendly.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

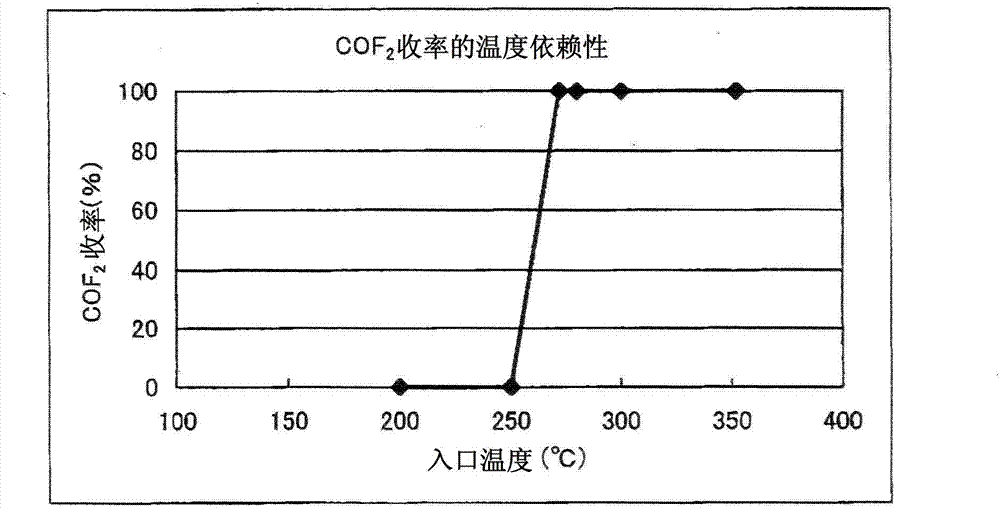

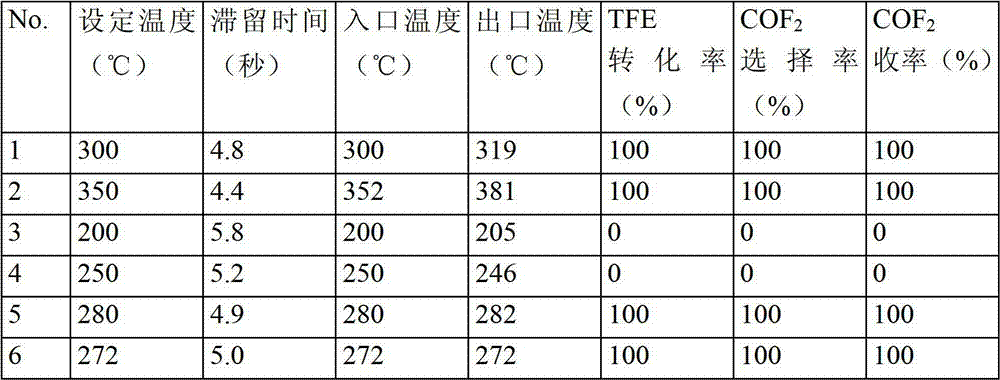

Process for production of carbonyl fluoride

ActiveUS8513458B2Inexpensively and efficiently and safely and continuously producingHigh yieldOrganic compound preparationPhosgeneTetrafluoroethyleneCarbonyl fluoride

The present invention provides a method for inexpensively, efficiently, safely, and continuously producing COF2, without using highly toxic raw materials such as phosgene or difficult-to-get raw materials, with no risk of explosion or the like. Tetrafluoroethylene gas and oxygen gas are introduced into a reactor, and they are then heated in a gas phase in the absence of nitrogen gas for reaction, so as to produce carbonyl fluoride. The reactor is preferably a tubular reaction tube. As such tetrafluoroethylene gas, unpurified or purified tetrafluoroethylene gas obtained by heating HCFC-22 gas for thermal decomposition can be used. According to the present invention, COF2 that is useful as cleaning gas for CVD devices (chemical vapor deposition method) can be inexpensively, efficiently, and safely produced.

Owner:NAT INST OF ADVANCED IND SCI & TECH

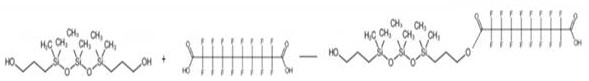

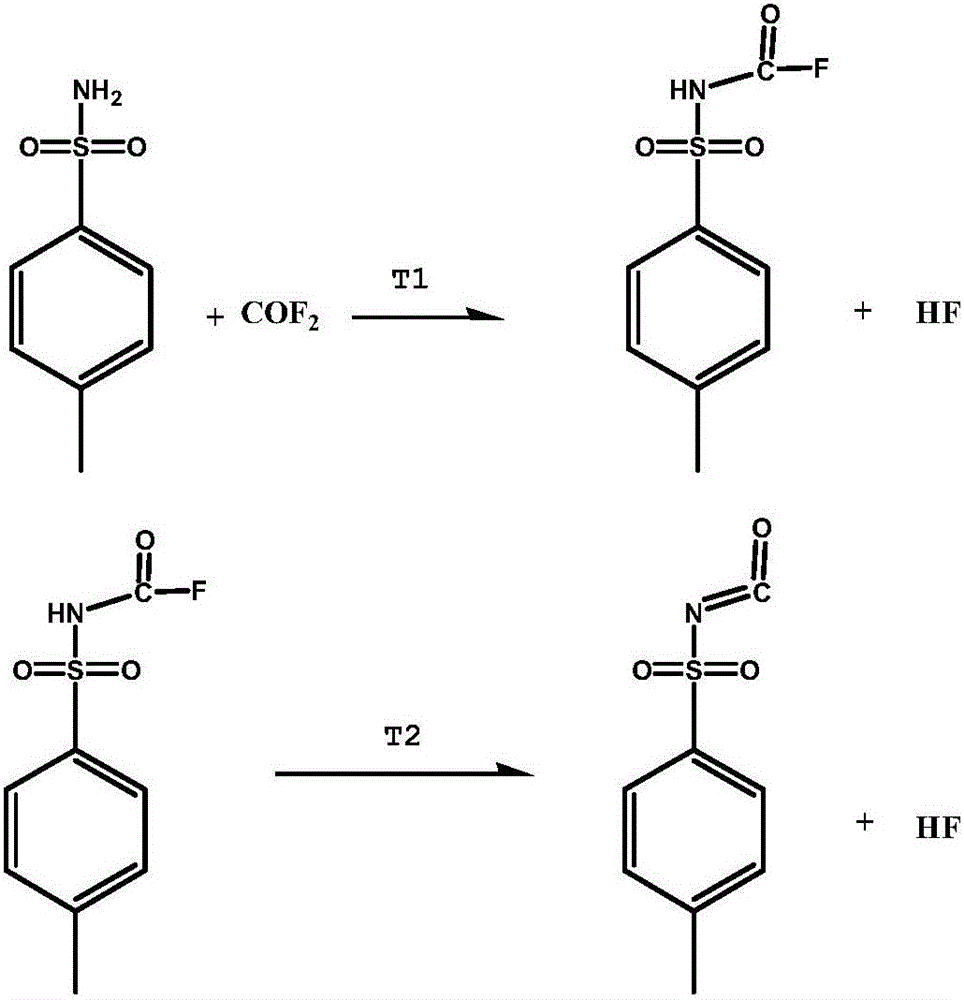

Method for preparing p-toluenesulfonyl isocyanate with carbonyl fluoride

InactiveCN105837475AHigh yieldZero pollutionSulfonic acid amide preparationCarbonyl fluorideTosylhydrazone

The invention discloses a method for preparing p-toluenesulfonyl isocyanate with carbonyl fluoride. The method includes the following steps that firstly, under pressure, toluene sulfonamide and carbonyl fluoride react in a liquid phase to generate a fluorine-containing intermediate; secondly, at normal pressure, the one-molecule HF production target product p-toluenesulfonyl isocyanate is removed from the fluorine-containing intermediate at high temperature. In the reaction process, catalyst catalysis is not needed, excessive carbonyl fluoride and solvents used in reaction can be recycled and reused, and HF generated due to reaction can be sold as commodities after being absorbed. The method is mainly used for preparation of p-toluenesulfonyl isocyanate.

Owner:BEIJING YUJI SCI & TECH +1

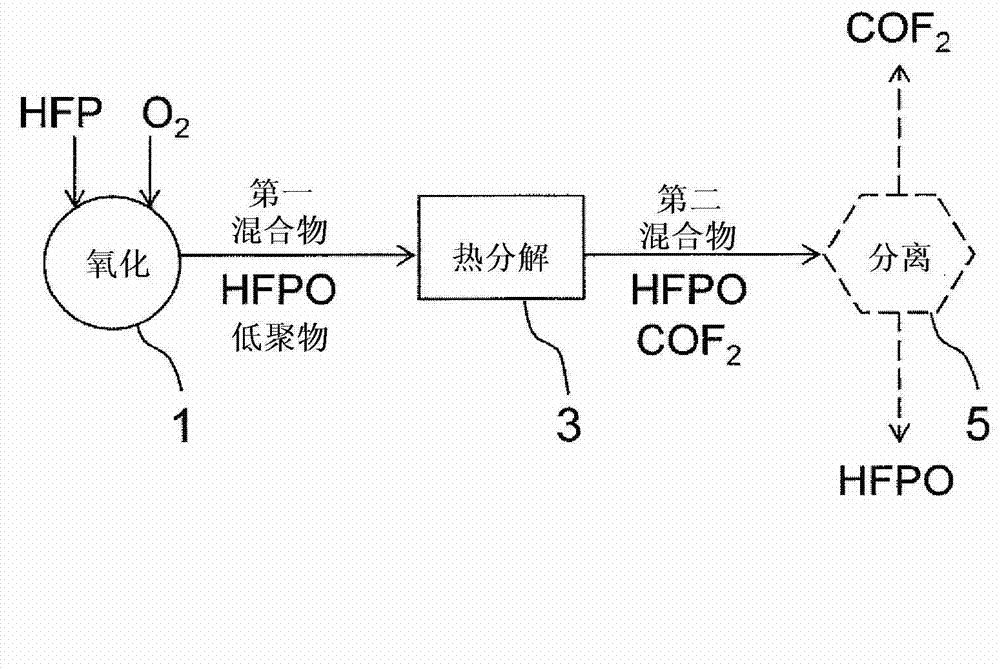

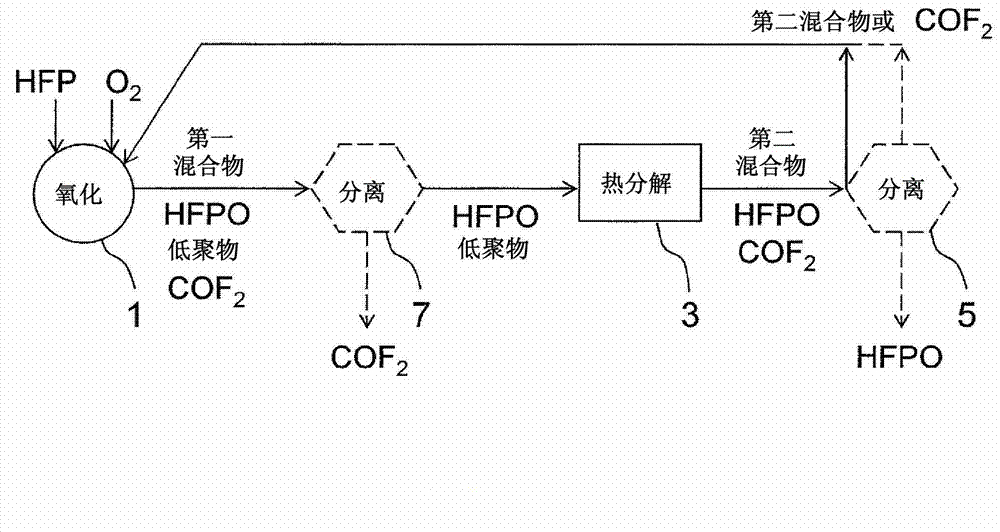

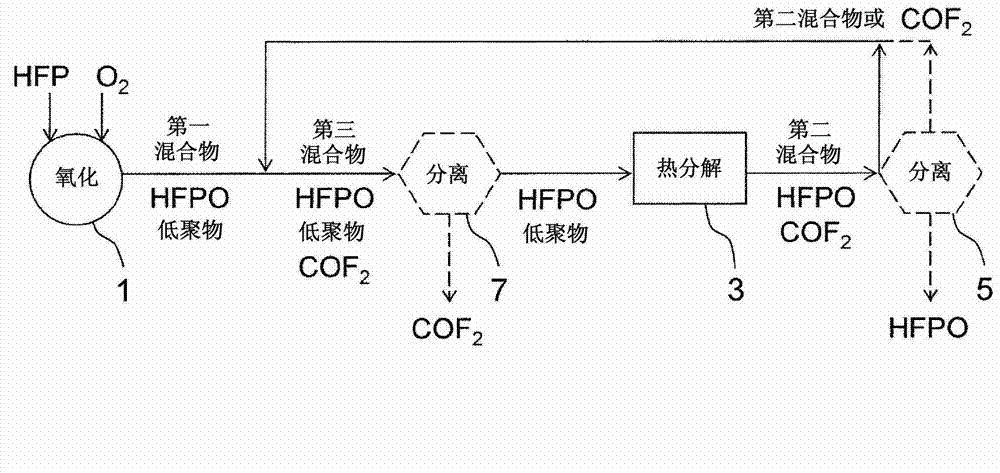

Method for producing carbonyl fluoride and hexafluoropropylene oxide

Disclosed is a method for efficiently jointly producing carbonyl fluoride and hexafluoropropylene oxide. Specifically disclosed is a method for producing carbonyl fluoride and hexafluoropropylene oxide wherein a step (a) for obtaining a first mixture containing hexafluoropropylene oxide, from the oxidation of hexafluoropropylene by oxygen, and an oligomer represented by the general formula CF3O(CF2O)n-R (wherein, -R indicates -COF, -OCOF or -CF2COF, and n indicates an integer of 0 - 50) and a step (b) for obtaining a second mixture containing carbonyl fluoride and hexafluoropropylene oxide by thermal decomposition of the oligomer in the presence of the hexafluoropropylene oxide are carried out.

Owner:DAIKIN IND LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com