Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

362results about "Carboxylic acid halides preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing polyisocyanates by the adiabatic phosgenation of primary amines

ActiveUS20060025556A1Minimal costInhibition formationIsocyanic acid derivatives preparationOrganic compound preparationReaction temperaturePhosgene

A two-stage process for the preparation of organic isocyanates by reacting primary amines with phosgene in which a) in a first stage, amine and phosgene are reacted in an adiabatically managed reaction, in which the temperature of reaction is restricted to values between 100 and 220° C. by actively adjusting the absolute pressure in the reactor to values between 8 and 50 bar by decompression, and the temperature is held at values between 100 and 220° C. until the stoichiometric conversion of phosgene has reached at least 80%, and then b) in a second stage, the reaction mixture from a) is decompressed to an absolute pressure of 1 to 15 bar and the reaction mixture is reacted further at temperatures between 90 and 240° C., optionally with the introduction of heat.

Owner:COVESTRO DEUTSCHLAND AG

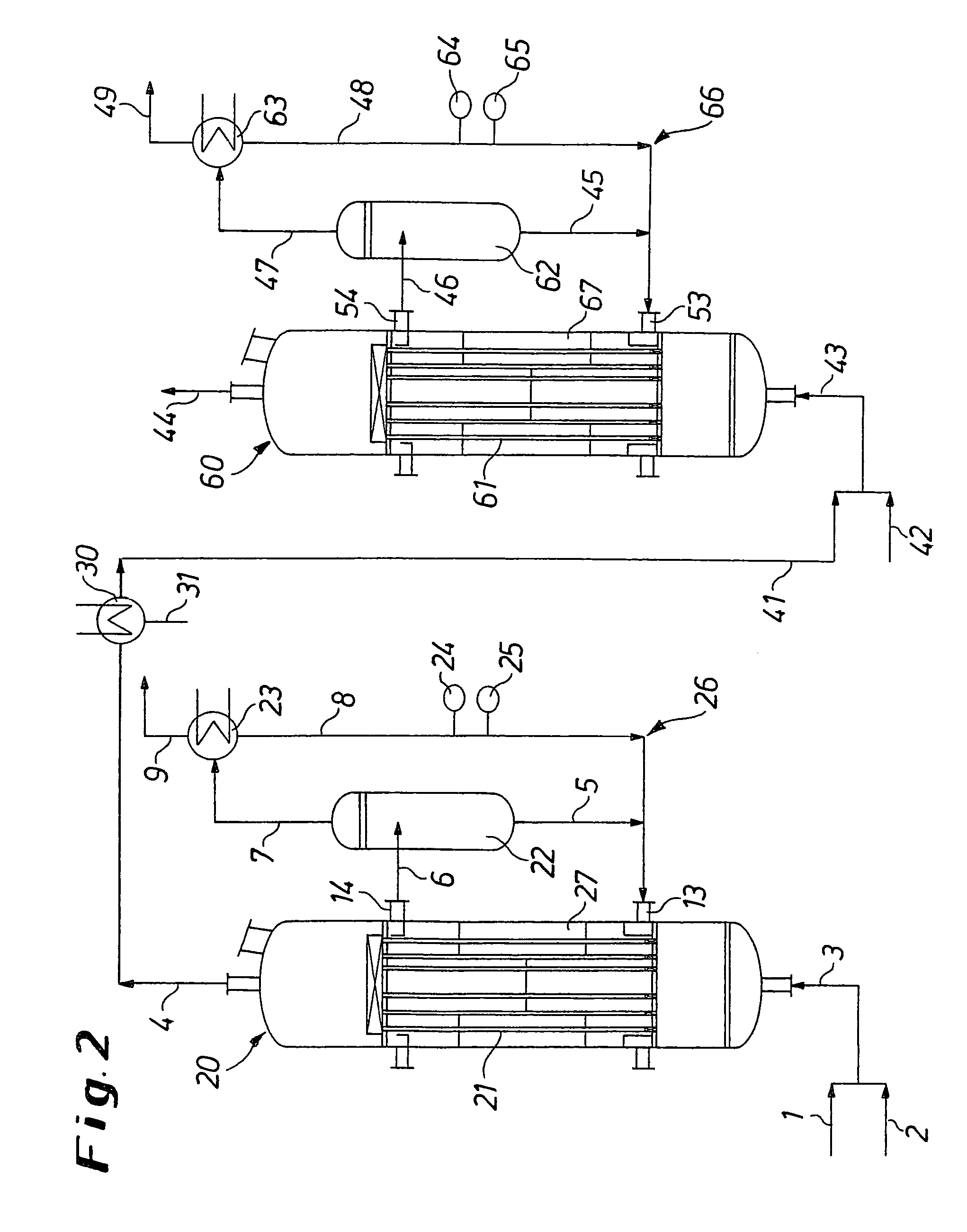

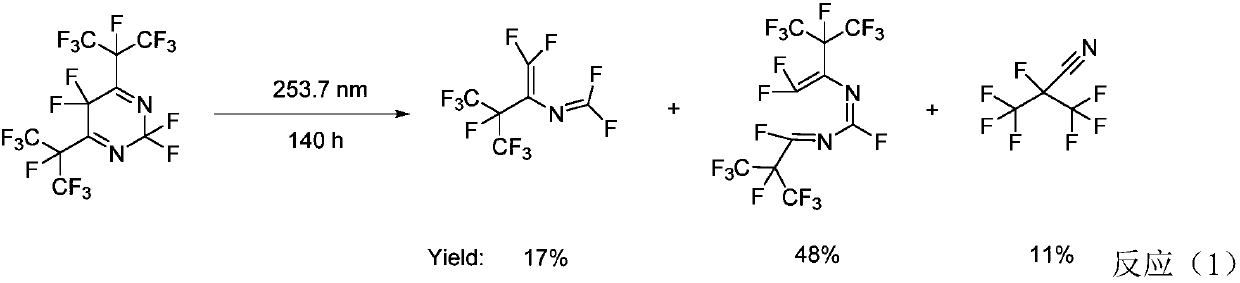

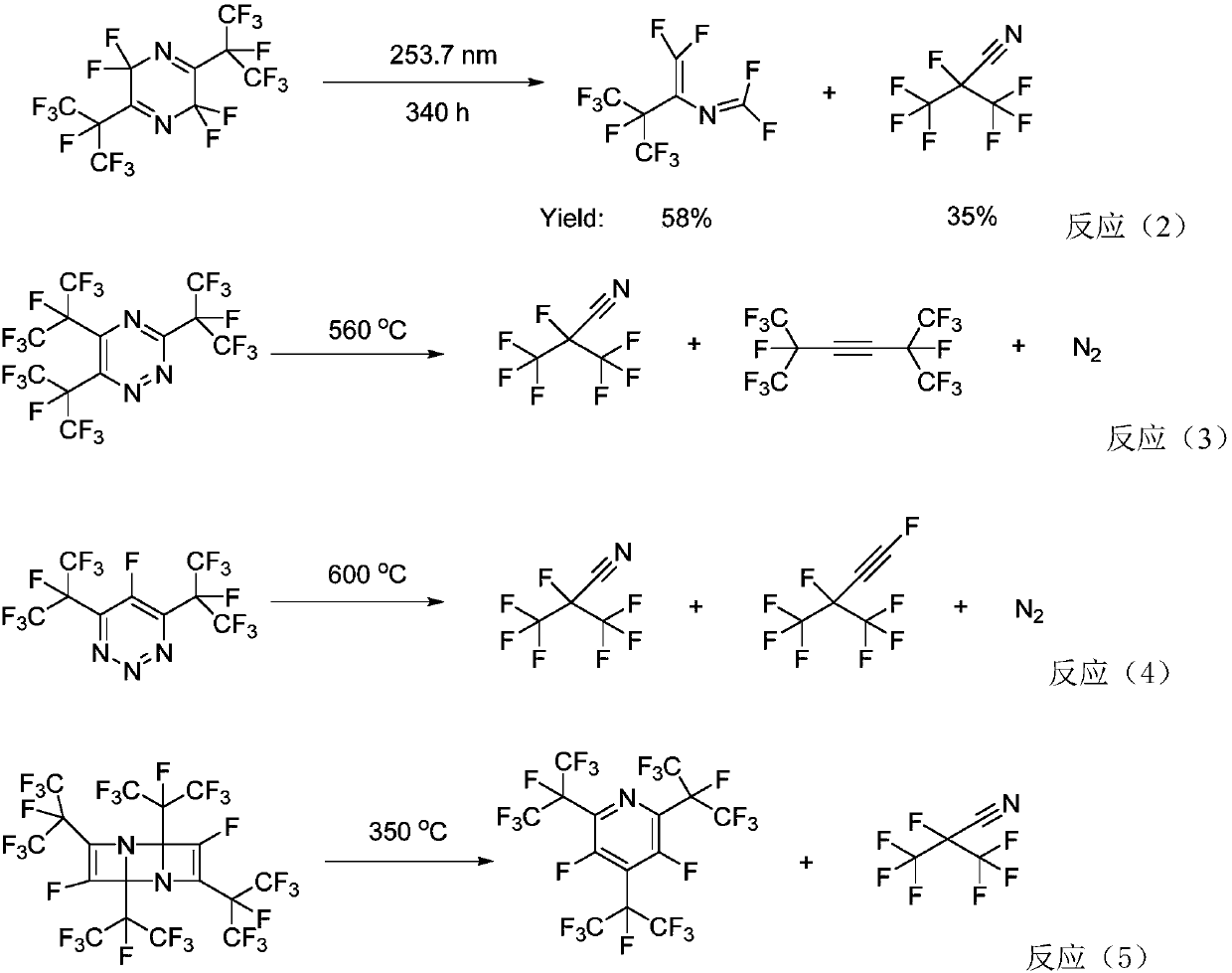

Preparation method of perfluoronitrile

ActiveCN108424375ALow priceHigh yieldOrganic compound preparationCarboxylic acid amides preparationLithiumCarbonyl fluoride

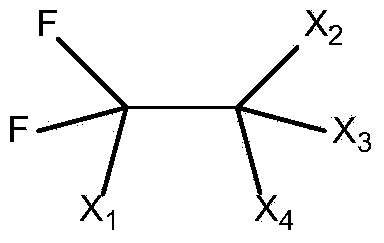

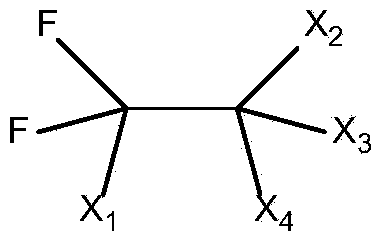

The invention discloses a preparation method of perfluoronitrile. The preparation method comprises the following steps: a, performing a gas-phase addition reaction on perfluoroolefin R1R2C=CR3R4 and carbonyl fluoride to obtain acyl fluoride R1R2(COF)C-CFR3R4 (R1, R2, R3 and R4 have a general formula of a -CnF2n+1 group and n is a nonnegative integer set); b, aminating and dehydrating the acyl fluoride R1R2(COF)C-CFR3R4, acyl fluoride and alkali metal amide or an amine compound R-NH2 (R is lithium, sodium, potassium, rubidium, cesium or a -CmH2m+1 group and m is a nonnegative integer set) to obtain the perfluoronitrile R1R2(CN)C-CFR3R4. By the preparation method, a reaction route is short, the perfluoroolefin and the carbonyl fluoride are easy to obtain and low in price, the overall yield of the perfluoronitrile is high and the route is easy to industrialize.

Owner:泉州宇极新材料科技有限公司

Preparation process of benzoyl chloride

ActiveCN103787874AReduce pollutionSave resourcesPreparation from carboxylic acid halideOrganic compound preparationBenzoic acidPtru catalyst

The invention discloses a preparation process of benzoyl chloride. The preparation process comprises the following steps of synthesis of benzotrichloride: carrying out temperature reaction on methylbenzene and chlorine under the catalytic action of a catalyst to synthetize a crude benzotrichloride product; synthesis of the benzoyl chloride: continuously stirring and heating the crude benzotrichloride product and benzoic acid to prepare a crude benzoyl chloride product after adding the catalyst; refining of the benzoyl chloride: carrying out reduced pressure distillation on the crude benzoyl chloride product to prepare a refined benzoyl chloride product; recovering benzoyl chloride raffinate, adding water to the benzoyl chloride raffinate which is subjected to the reduced pressure distillation, heating and stirring to transform the benzoyl chloride contained in the raffinate into the benzoic acid, cooling, then separating out benzoic acid. The preparation process disclosed by the invention is easy to safe to operate, effectively shortens the reaction time, achieves the purity of the prepared benzoyl chloride by 99.5%, reduces the environmental pollution by recycling residues, saves the resources, reduces the cost, meets the requirements of pharmaceutical chemicals and can carry out massive industrial production.

Owner:YIDU YOUYUAN IND CO LTD

Process for preparing hydrofluoroethers

InactiveUS6023002AFurther reactionAchieve efficiencyOrganic compound preparationEther preparation by compound additionEtherHydrofluoroether

Owner:3M INNOVATIVE PROPERTIES CO

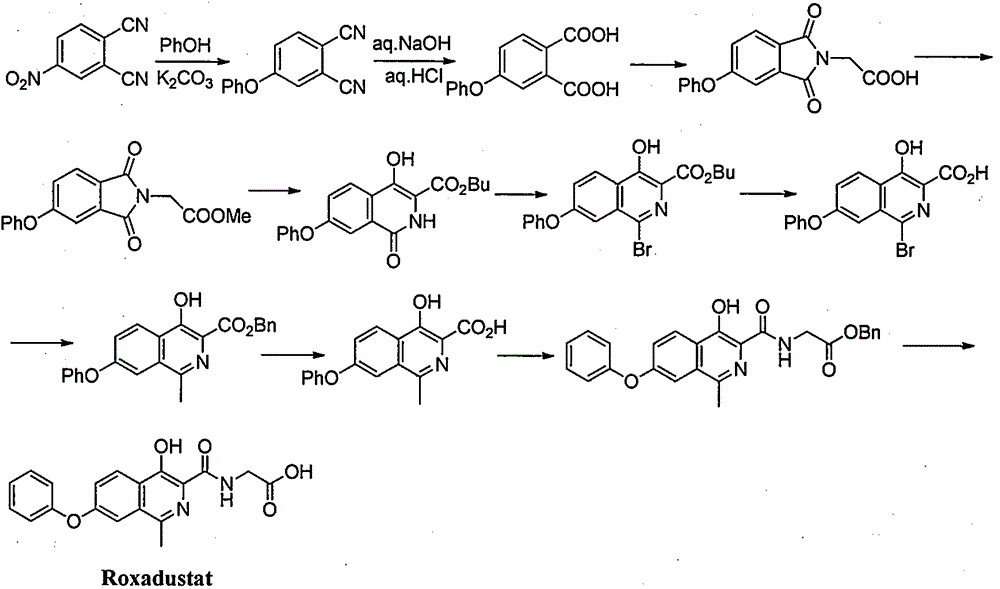

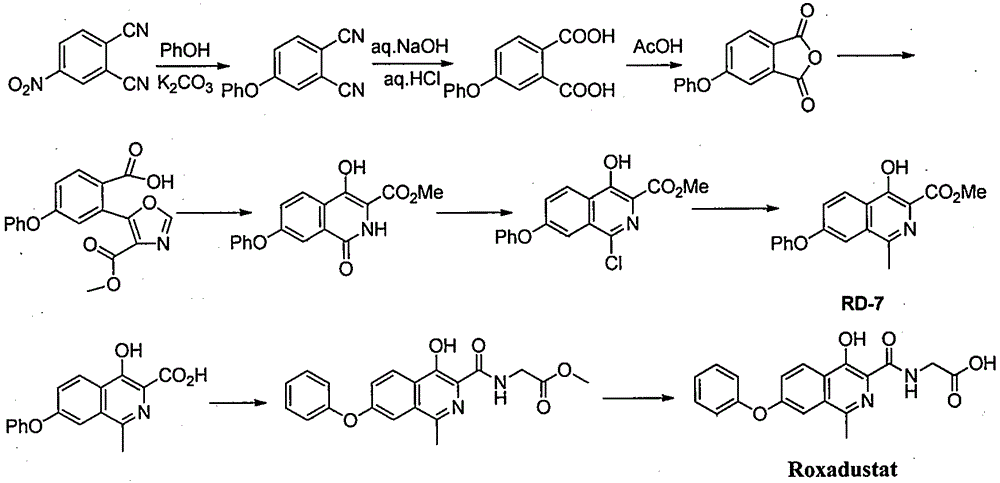

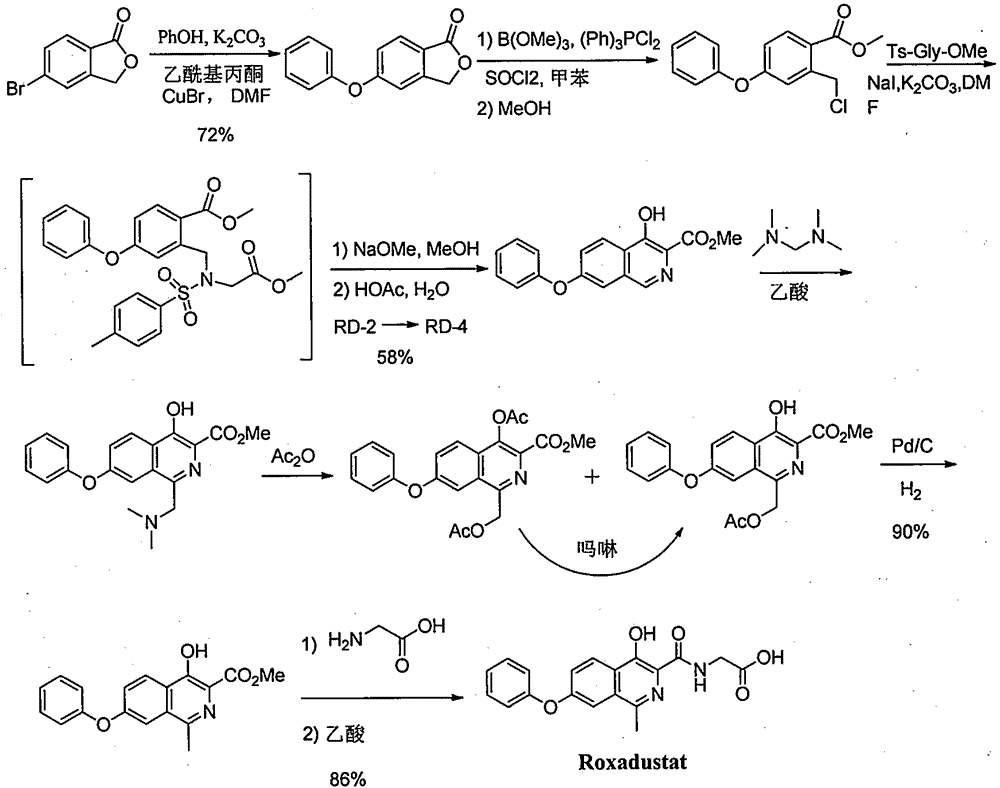

Preparation method for intermediate of Roxadustat

InactiveCN106478503ARaw materials are easy to getSimple processPreparation from carboxylic acid halidesSulfonic acid amide preparationAromatizationPhenol

The invention provides a preparation method for an intermediate VI of Roxadustat. The preparation method comprises the following steps: reacting 3-methyl-5-bromoisobenzofuran-1(3H)-one (I), which serves as a starting raw material, with phenol so as to prepare an intermediate II, then, subjecting the II to a ring-opening substitution reaction so as to prepare a compound III, and subjecting the compound III to a substitution reaction so as to prepare a key intermediate V; and subjecting the V to alkali condensation, deprotection and aromatization, thereby preparing the target intermediate VI. The preparation method for the intermediate VI of the Roxadustat, provided by the invention, has the advantages that the raw materials are readily available, the process is simple, the operation is convenient, the reaction yield is high, the atom utilization ratio is high, and the industrial production is facilitated. The reaction general formula is represented by the formulae shown in the description.

Owner:SHANGHAI XUNHE PHARMA TECH CO LTD

Preparation method of trifluoroacetic acid

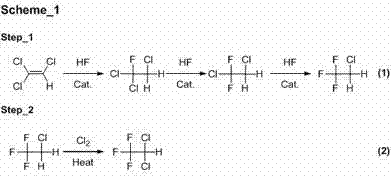

InactiveCN103524325ALow costPreparation from carboxylic acid halideHalogenated hydrocarbon preparationCatalytic oxidationTetrachloroethane

The invention discloses a preparation method of trifluoroacetic acid low in synthesis cost. The preparation method comprises the steps of (1) preparing 1,1-difluoro tetrachloroethane from 1,1-difluoroethane or chloride thereof through ultraviolet catalysis and a chlorine reaction; (2) implementing catalytic oxidation on the 1,1-difluoro tetrachloroethane to obtain 1,1-difluoro-1-chloroacetyl chloride, wherein in the catalytic oxidation, mol ratio of the 1,1-difluoro tetrachloroethane to an oxidizing agent is 1: (2-4), dosage of the catalyst is 0.5-5% of the total weight of an reactant, and reaction temperature is 50-70 DEG C; (3) carrying out hydrogen fluoride (HF) fluoridation on the 1,1-difluoro-1-chloroacetyl chloride under the catalyst to obtain trifluoroacetyl fluoride, wherein mol ratio of the 1,1-difluoro-1-chloroacetyl chloride to the HF is 1: (2-3), reaction temperature is 40-60 DEG C, and the catalyst is either antimony or antimony pentachloride; and (4) hydrolyzing the prepared trifluoroacetyl fluoride to obtain trifluoroacetic acid.

Owner:CHANGSHU 3F ZHENFU NEW MATERIALS CO LTD

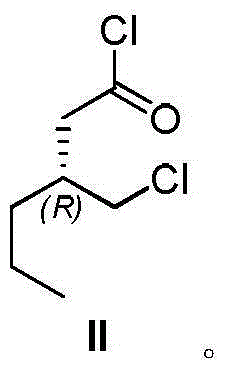

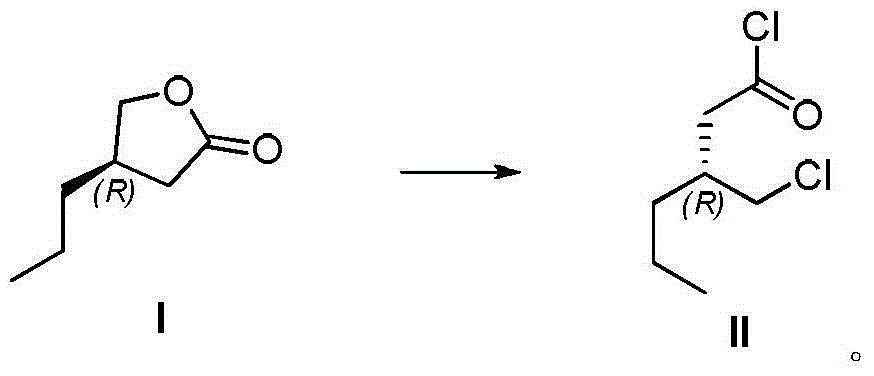

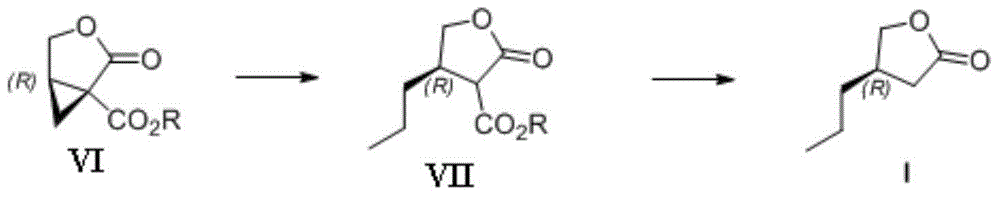

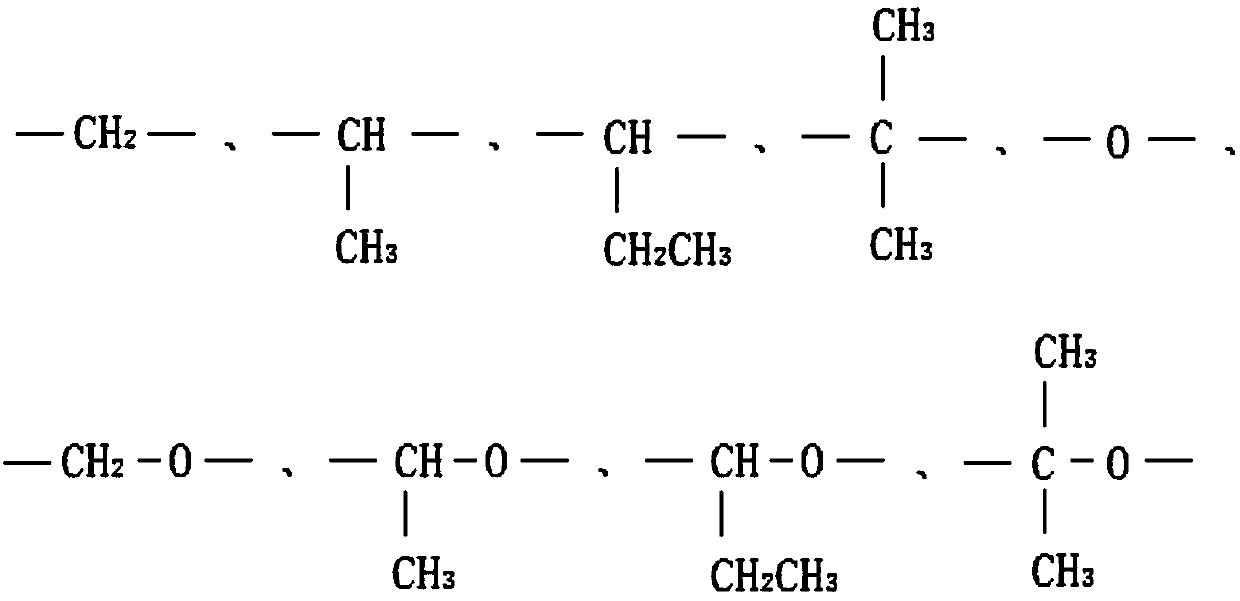

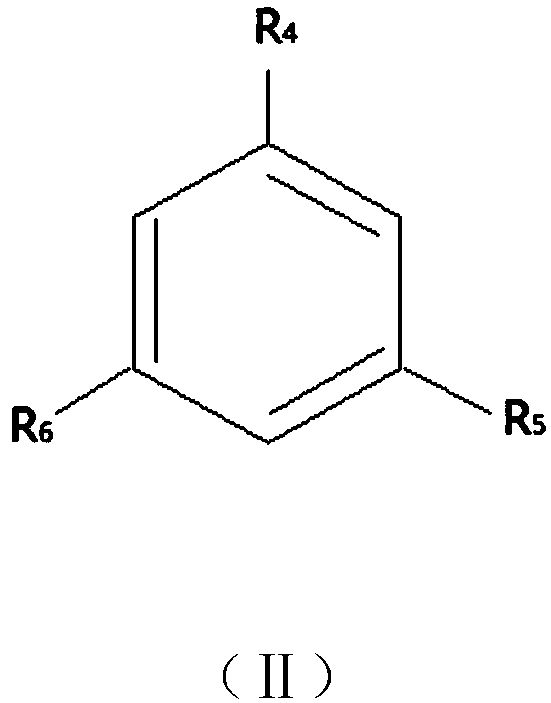

Compounds and preparation methods thereof, and uses of compounds in synthesis of brivaracetam

ActiveCN106365986AAvoid wastingHigh optical purityOrganic compound preparationCarboxylic acid amides preparationSynthesis methodsBrivaracetam

The present invention provides compounds represented by formulas II and IV. The invention further provides uses of the compound represented by the formula II in synthesis of brivaracetam, and a synthesis method. According to the present invention, the used raw materials are easy to obtain and have low price, and the high optical-purity brivaracetam can be prepared. The formulas II and IV are defined in the specification.

Owner:SUZHOU PENGXU PHARM TECH CO LTD

Method for preparing carbonyl fluoride and trifluoroacetyl fluoride simultaneously

InactiveCN102260160AReaction is easy to controlMild conditionsCarboxylic acid halides preparationMetal/metal-oxides/metal-hydroxide catalystsChemical synthesisCarbonyl fluoride

The invention relates to a "preparation method for simultaneously preparing carbonyl fluoride and trifluoroacetyl fluoride" and belongs to the field of chemical synthesis. A method for simultaneously preparing carbonyl fluoride and trifluoroacetyl fluoride is to contact and react oxygen and hexafluoropropylene gas in a reactor under catalyst conditions. The catalyst is silver oxide, activated carbon-supported silver oxide or alumina-supported oxidation gas. silver. The reaction of the invention is easy to control, has mild conditions, and has a high conversion rate. Carbonyl fluoride and trifluoroacetyl fluoride can be simultaneously prepared through a one-step reaction, and is suitable for large-scale preparation of carbonyl fluoride and trifluoroacetyl fluoride.

Owner:张小燕 +1

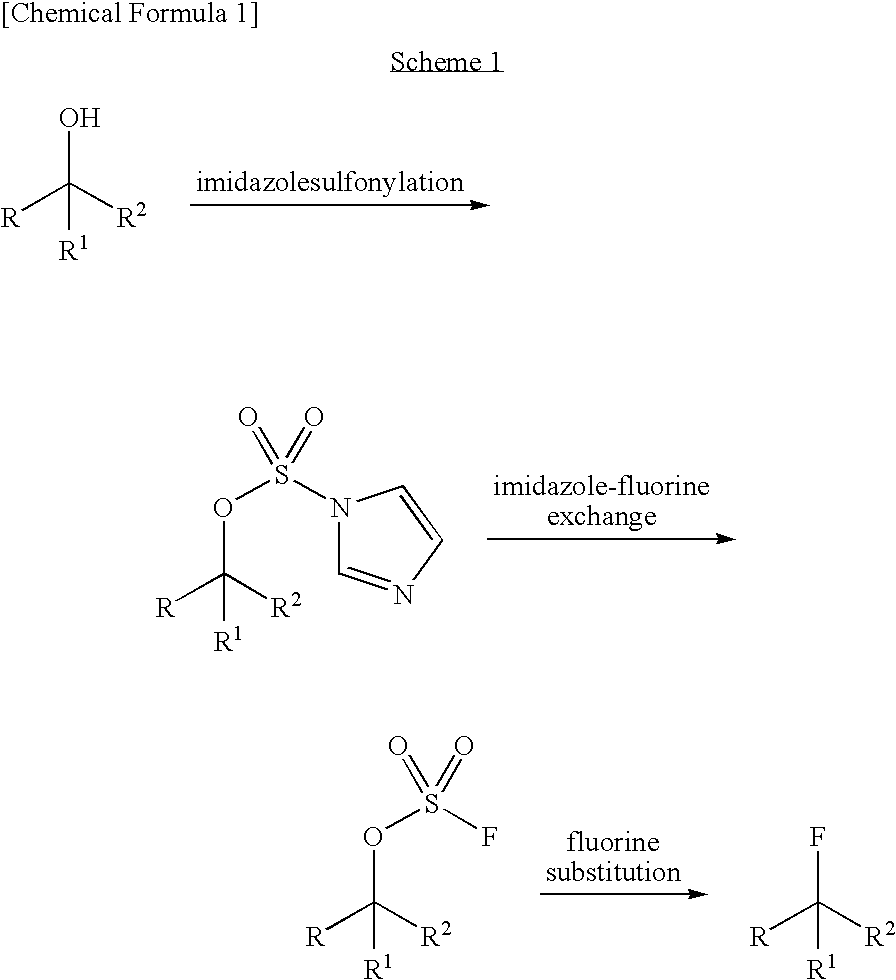

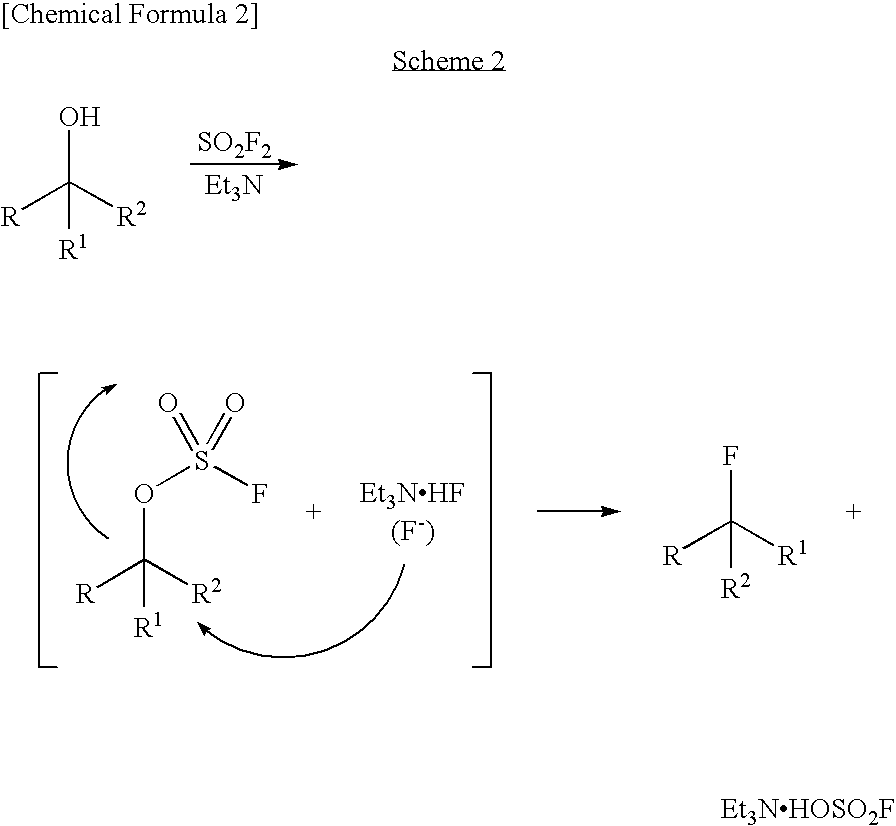

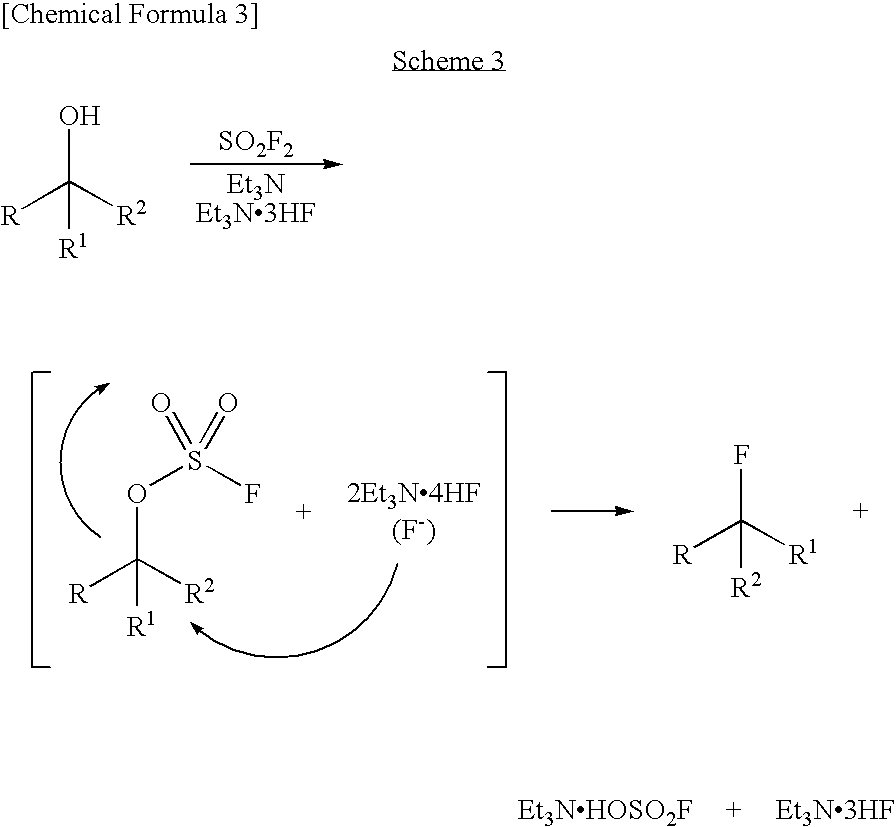

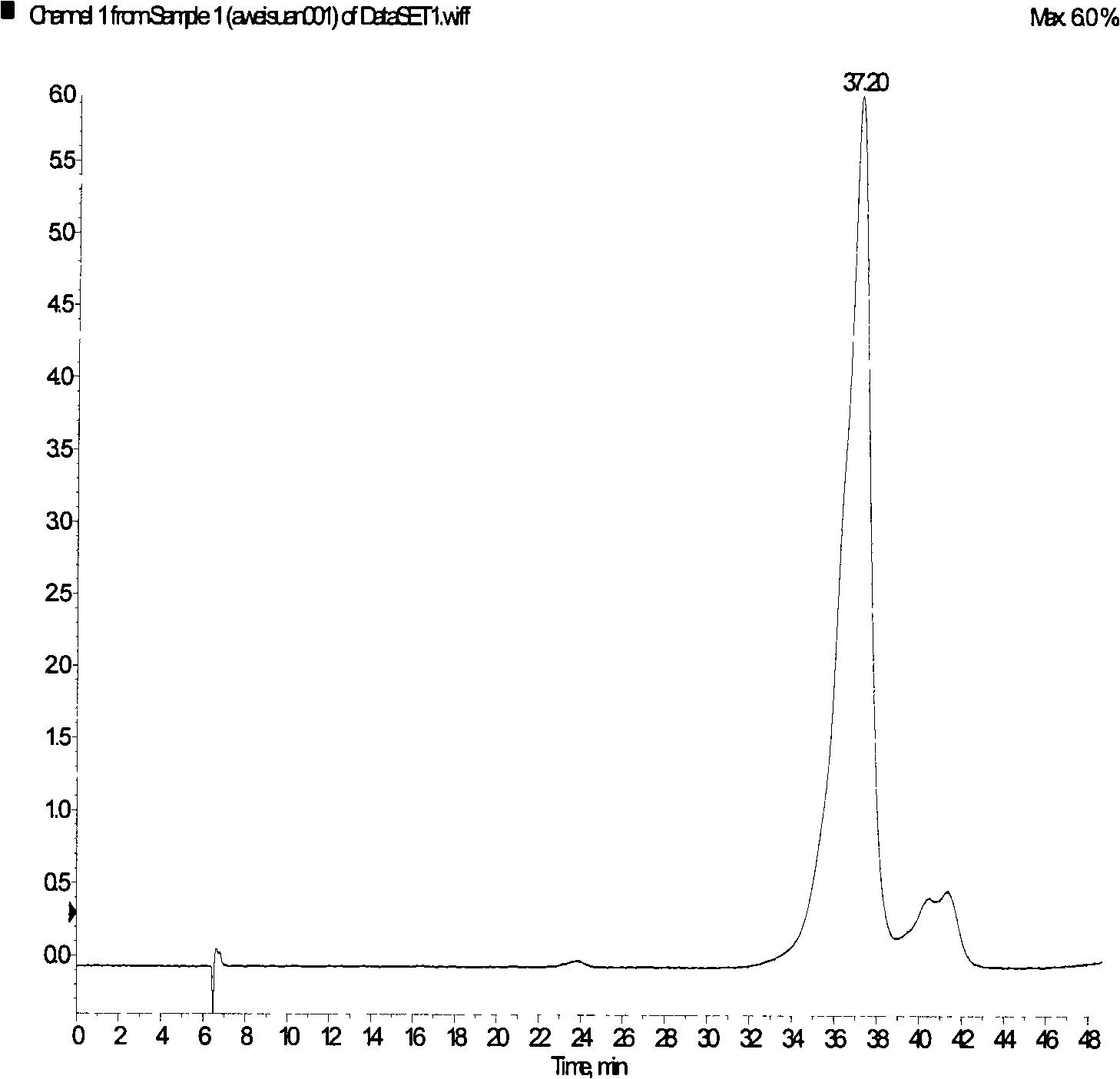

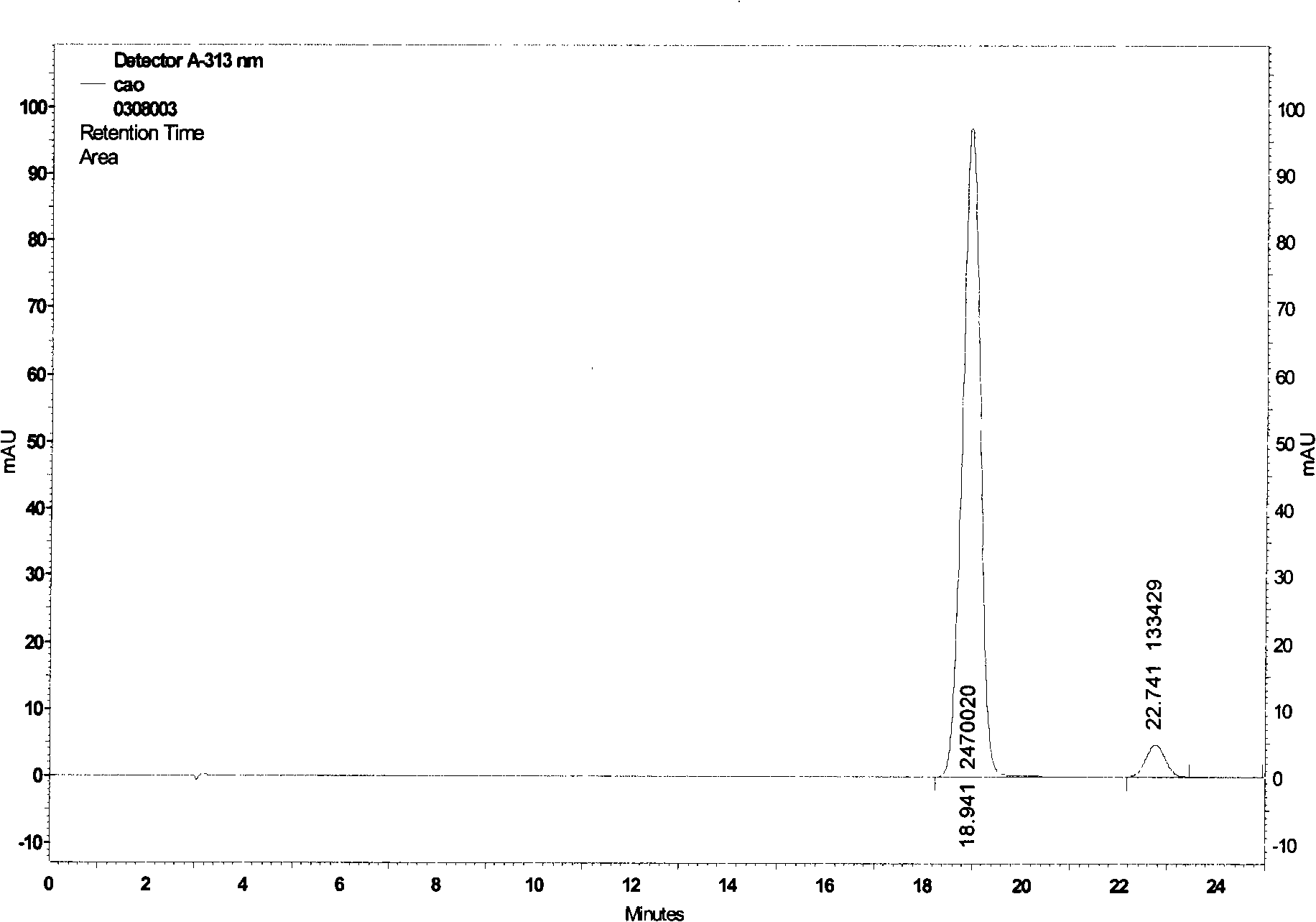

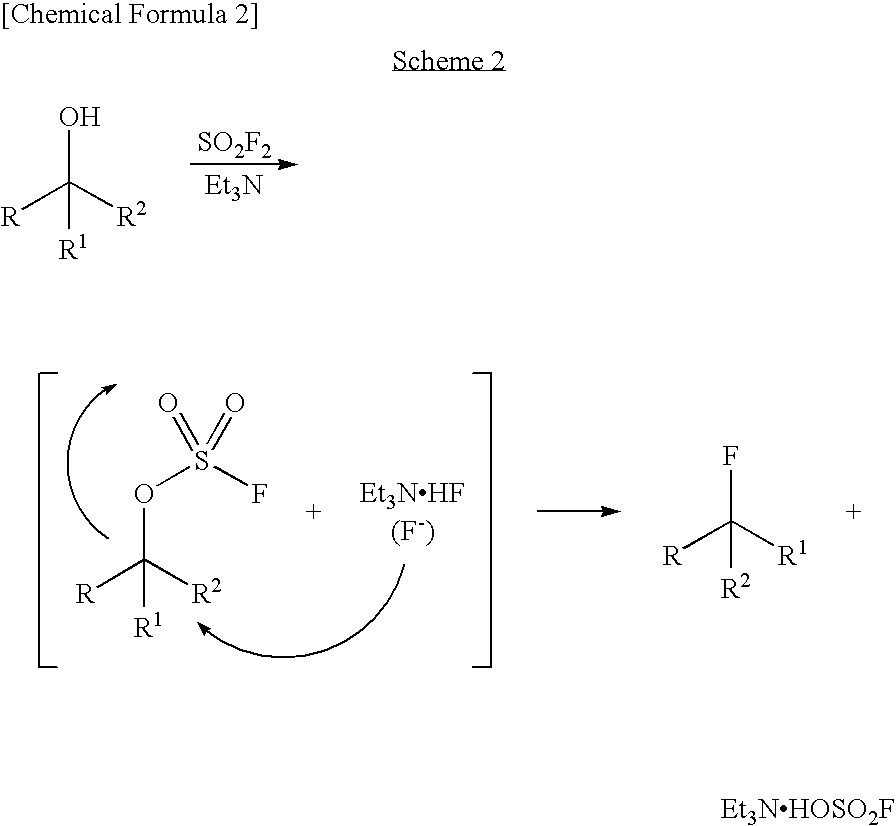

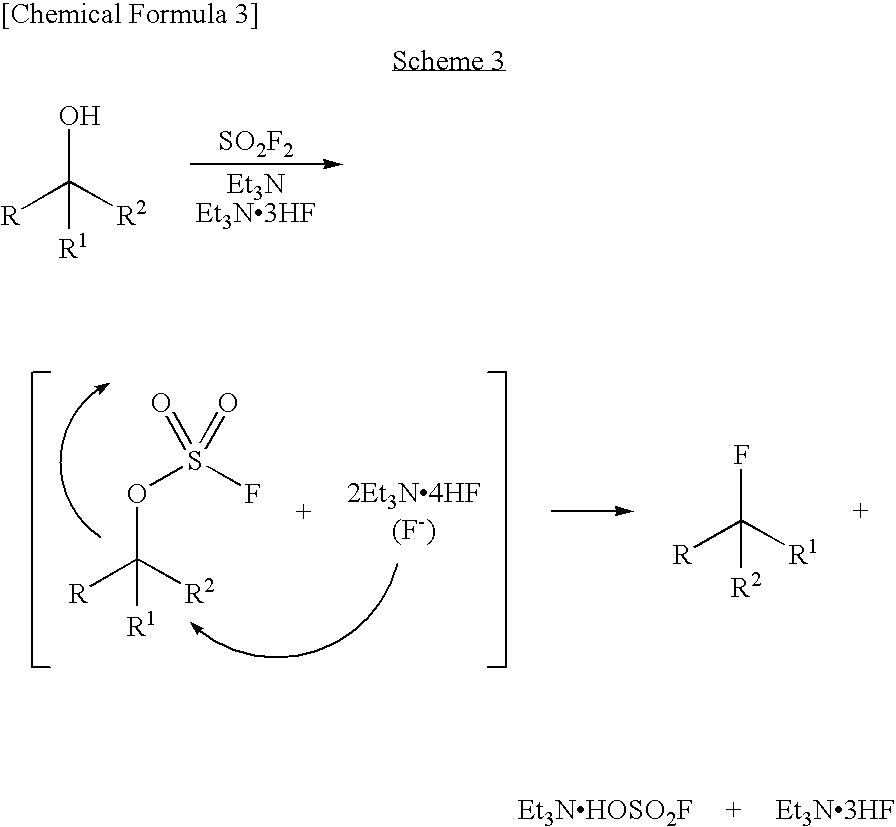

Process for Production of Fluoro Derivative

InactiveUS20080125589A1High selectivityEfficient productionSugar derivativesOrganic compound preparationHydrogen fluorideOrganic base

It was found that a fluoro derivative can be produced by reacting a hydroxy derivative with sulfuryl fluoride (SO2F2) in the presence of an organic base or in the presence of an organic base and “a salt or complex comprising an organic base and hydrogen fluoride”. According to the present production process, it is not necessary to use perfluoroalkanesulfonyl fluoride, which is not preferable in industrial use, and it is possible to advantageously produce optically-active fluoro derivatives, which are important intermediates of medicines, agricultural chemicals and optical materials, specifically 4-fluoroproline derivatives, 2′-deoxy-2′-fluorouridine derivatives, optically-active α-fluorocarboxylate derivatives, and the like, even in a large scale.

Owner:CENT GLASS CO LTD

Reactive graphtic carbon nanofiber reinforced polymeric composites

Composites comprising at least one graphite-carbon nanofiber (GCNF) and a polymer phase covalently linked to a surface thereof.

Owner:LUKEHART CHARLES M +3

Process for preparing polyisocyanates by the adiabatic phosgenation of primary amines

ActiveUS8097751B2Minimal costInhibition formationIsocyanic acid derivatives preparationOrganic compound preparationReaction temperaturePhosgene

A two-stage process for the preparation of organic isocyanates by reacting primary amines with phosgene in which: a) in a first stage, amine and phosgene are reacted in an adiabatically managed reaction, in which the temperature of reaction is restricted to values between 100 and 220° C. by actively adjusting the absolute pressure in the reactor to values between 8 and 50 bar by decompression, and the temperature is held at values between 100 and 220° C. until the stoichiometric conversion of phosgene has reached at least 80%; and then b) in a second stage, the reaction mixture from a) is decompressed to an absolute pressure of 1 to 15 bar and the reaction mixture is reacted further at temperatures between 90 and 240° C., optionally with the introduction of heat.

Owner:COVESTRO DEUTSCHLAND AG

Method for preparing trans-ferulaic acid, p-cumaric acid and pentosan

The invention relates to a method for simultaneously preparing trans-ferulic acid, p-coumaric acid and pentosan, which comprises the following steps: processing a cellulose material with a low-concentration alkali to release coumaric acid, and hydrolyzing with a high-concentration alkali to release ferulic acid and pentosan; ultrafiltering the alkaline hydrolytic solution, precipitating the concentrated solution with ethanol to obtain pentosan; and adsorbing coumaric acid and ferulic acid in the filtrate with cation exchange resin, eluting with an ethanol-acid-water mixed eluent, removing ethanol from the eluent, crystallizing, centralizing or filtering the eluent at a low temperature or a normal temperature to obtain ferulic acid or coumaric acid crystals, and recrystallizing to obtain the high-purity product. The alkaline hydrolytic solution can be recovered and used for hydrolyzing the material, thereby obviating the production of a great amount of wastewater due to the alkaline hydrolysis. The method can produce ferulic acid and coumaric acid widely used in the industries of food, medicine and cosmetics, and pentosan used for producing xylooligosaccharide as food gum by utilizing solid wastes produced in agricultural and food processing, thereby achieving significant economic and social meanings.

Owner:JINAN UNIVERSITY

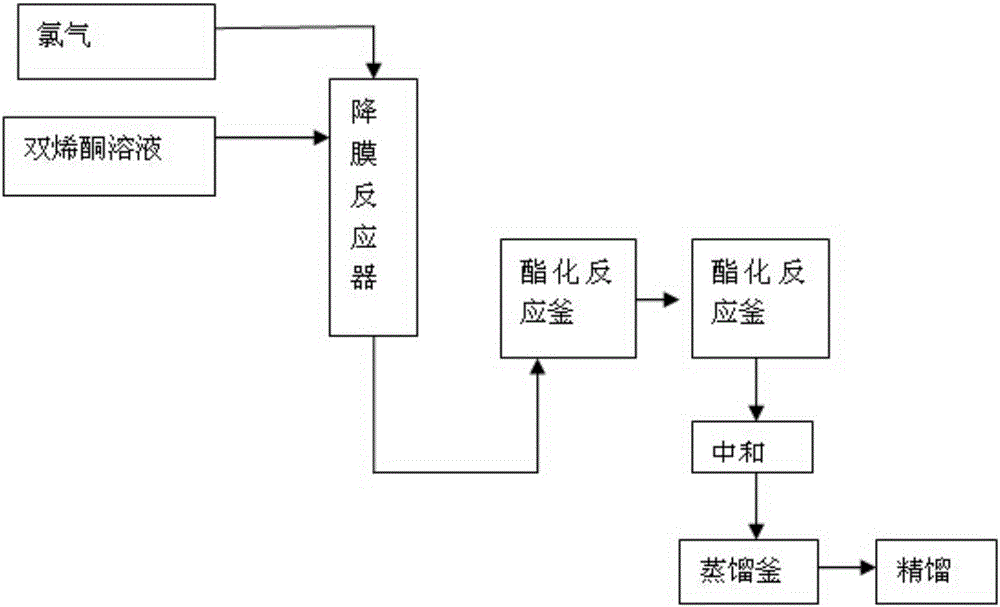

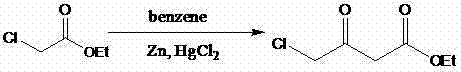

Method for continuously synthesizing ethyl 4-chloroacetoacetates

ActiveCN105693509AReduce volumeIncrease the effective cooling areaPreparation from carboxylic acid halidesCarboxylic acid halides preparationSolventEthyl Chloride

The invention relates to a method for continuously synthesizing ethyl 4-chloroacetoacetates. The method comprises the following steps: pumping a cooled diketene solution into a falling film reactor through a metering pump, and enabling the cooled diketene solution to uniformly form a film through a distributor, and flow into the reactor from a tower top; meanwhile, controlling the flow of chlorine gas through a gas flow meter; introducing the chlorine gas into the reactor through a gas distributor; carrying out a reaction on the diketene and the chlorine gas on the surface of the falling film reactor; after the reaction is finished, enabling reaction liquid to flow out from a tower bottom and enter an esterification reaction kettle; pumping in different alcohols and overflowing into a next esterification reaction kettle to continually react; absorbing hydrogen chloride gas, which is generated in a reaction process, with water; after the reaction is finished, washing with water and neutralizing to remove the residual hydrogen chloride; distilling an organic phase to recycle a solvent and excessive alcohol raw materials to obtain a crude product; rectifying the crude product to obtain an ethyl 4-chloroacetoacetates product. With the adoption of the method, reaction time can be shortened, energy consumption is reduced, polychlorides are controlled, reaction selectivity is improved, rectification is relatively easy, and yield and purity of the product are improved.

Owner:山东德澳精细化学品有限公司

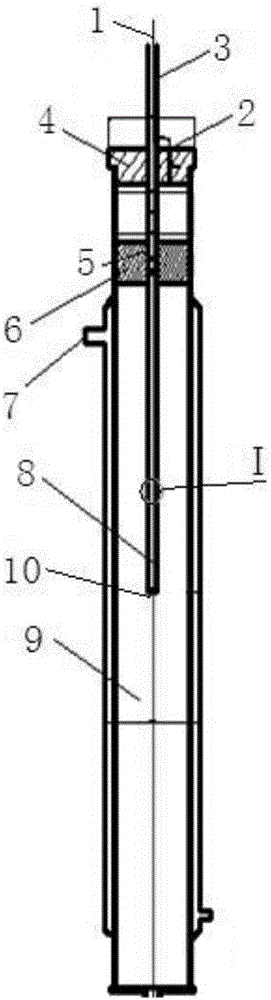

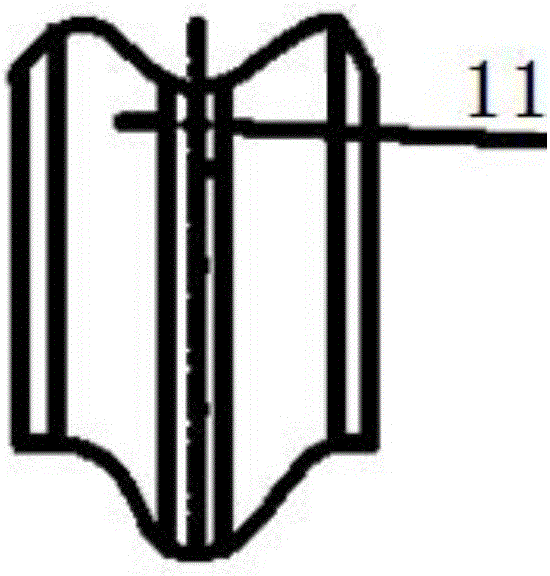

Process and apparatus for the production of phosgene

The invention relates to a process for the production of phosgene, in which chlorine and carbon monoxide are reacted in the presence of an activated charcoal catalyst in a shell-and-tube reactor which contains a plurality of reaction tubes and a coolant space surrounding the reaction tubes, in whicha) cooling of the reaction tubes is from the outside through the coolant space with water by evaporative cooling, andb) operation of the reaction tubes is at a pressure above the pressure in the coolant space.

Owner:COVESTRO DEUTSCHLAND AG

Perfluoro nitrile preparation method

ActiveCN107935884ALow priceImprove solubilityOrganic compound preparationCarboxylic acid amides preparationCarbonyl fluorideMetallole

The invention discloses a perfluoro nitrile preparation method. The perfluoro nitrile preparation method comprises the following steps: an addition reaction is performed on perfluoroolefine R1R2C=CR3R4 and carbonyl fluoride to obtain acyl fluoride R1R2(COF)C-CFR3R4(the general formula of R1,R2,R3 and R4 is -CnF(2n+1) group, and n is a nonnegative integer set); b, performing a reaction on acyl fluoride R1R2(COF)C-CFR3R4, acyl fluoride and an alkali metal amide or an amino compound R-NH2(R is Li, Na, K, Rb, Cs or -CmH(2m+1) group, and m is a nonnegative integer set) to obtain amide R1R2(CONH2)C-CFR3R4; and c, performing a dehydration reaction on amide R1R2(CONH2)C-CFR3R4 to obtain perfluoro nitrile R1R2(CN)C-CFR3R4. The perfluoro nitrile preparation method has a short reaction path, can easily obtain perfluoroolefine and carbonyl fluoride, is low in cost and high in overall yield of perfluoro nitrile, and the reaction path is easy to industrialize.

Owner:泉州宇极新材料科技有限公司

Process for the arylation of olefins

The present invention relates to a process for the arylation of olefins by reaction of haloaromatics or arylsulfonates with olefins in the presence of a palladium catalyst, a bulky nitrogen base and a salt.

Owner:LANXESS DEUTDCHLAND GMBH

Preparation method of 4-chloracetyl ethyl acetate

ActiveCN103787883AReduce generationImprove distillation yieldPreparation from carboxylic acid halidesCarboxylic acid halides preparationAcetic acidSulfate

The invention relates to a preparation method of 4-chloracetyl ethyl acetate. The preparation method comprises the following steps: by taking diketene as an initial raw material, synthesizing a 4-chloracetyl ethyl acetate coarse product in two steps: chlorination and esterification; then, rectifying to obtain a finished product, and adding a stabilizer anhydrous cupric sulfate into the chlorination step, wherein the addition is 0.02-1wt% of diketene. Compared with the prior art, the preparation method provided by the invention has the advantages that 1, by adding the stabilizer anhydrous cupric sulfate, the production of a byproduct 2-chloracetyl ethyl acetate is reduced and the production of the byproduct 2-chloracetyl ethyl acetate in the 4-chloracetyl ethyl acetate coarse product can be controlled below 0.5%, so that the distill yield is greatly improved; 2, the yield of 2-chloracetyl ethyl acetate is over 94.5%, and the cost is greatly lowered.

Owner:SHANDONG HUIHAI PHARMA & CHEM

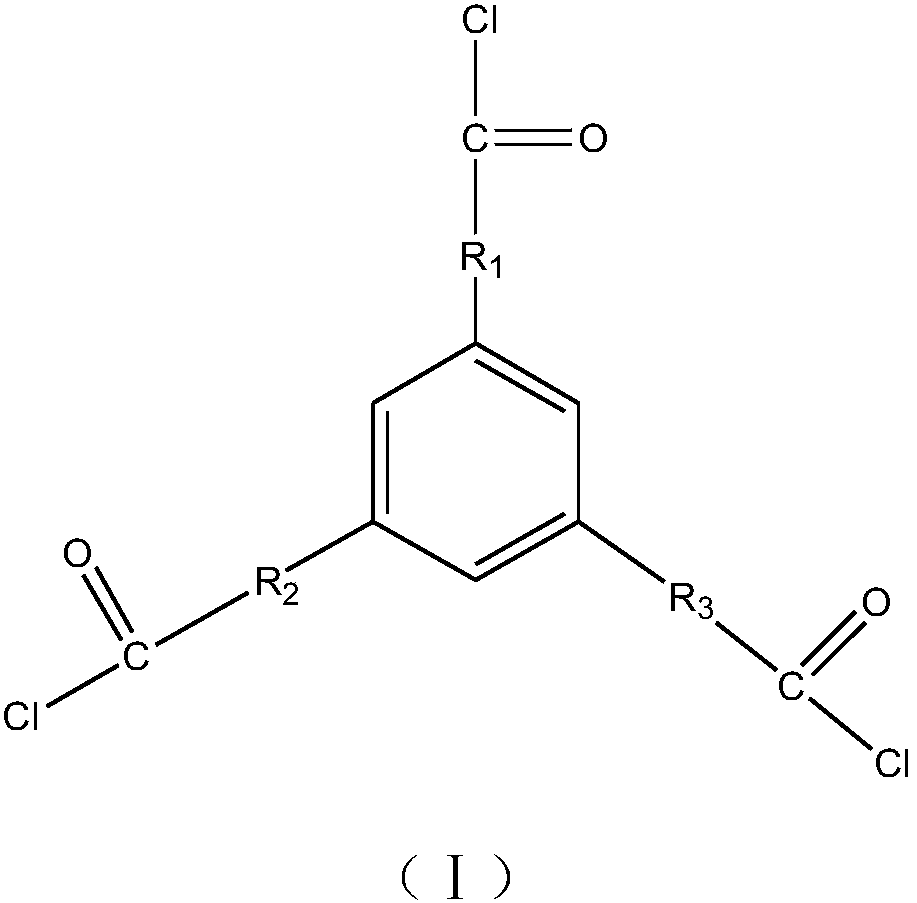

High-performance reverse osmosis composite membrane and preparation method thereof

ActiveCN108043252AImprove performanceSimple structureSemi-permeable membranesCarboxylic acid halides preparationWater volumeFiltration

The invention relates to the technical field of reverse osmosis membrane modification, and in particular relates to a high-performance reverse osmosis composite membrane and a preparation method thereof. The preparation method is characterized in that certain polyvinyl alcohol grafted zwitterionic polymer is doped into an aqueous solution involved in the synthesis of a polyamide desalting layer, and certain polyhydric acid chloride is used in an organic phase to change the structure of the polyamide desalting layer, so that the reverse osmosis composite membrane is prepared. The prepared reverse osmosis composite membrane can still maintain stable high-pass water volume and retention rate after a long period of continuous filtration; and at the same time, the reverse osmosis composite membrane also has a strong membrane structure and excellent anti-pollution ability.

Owner:VONTRON TECH CO LTD

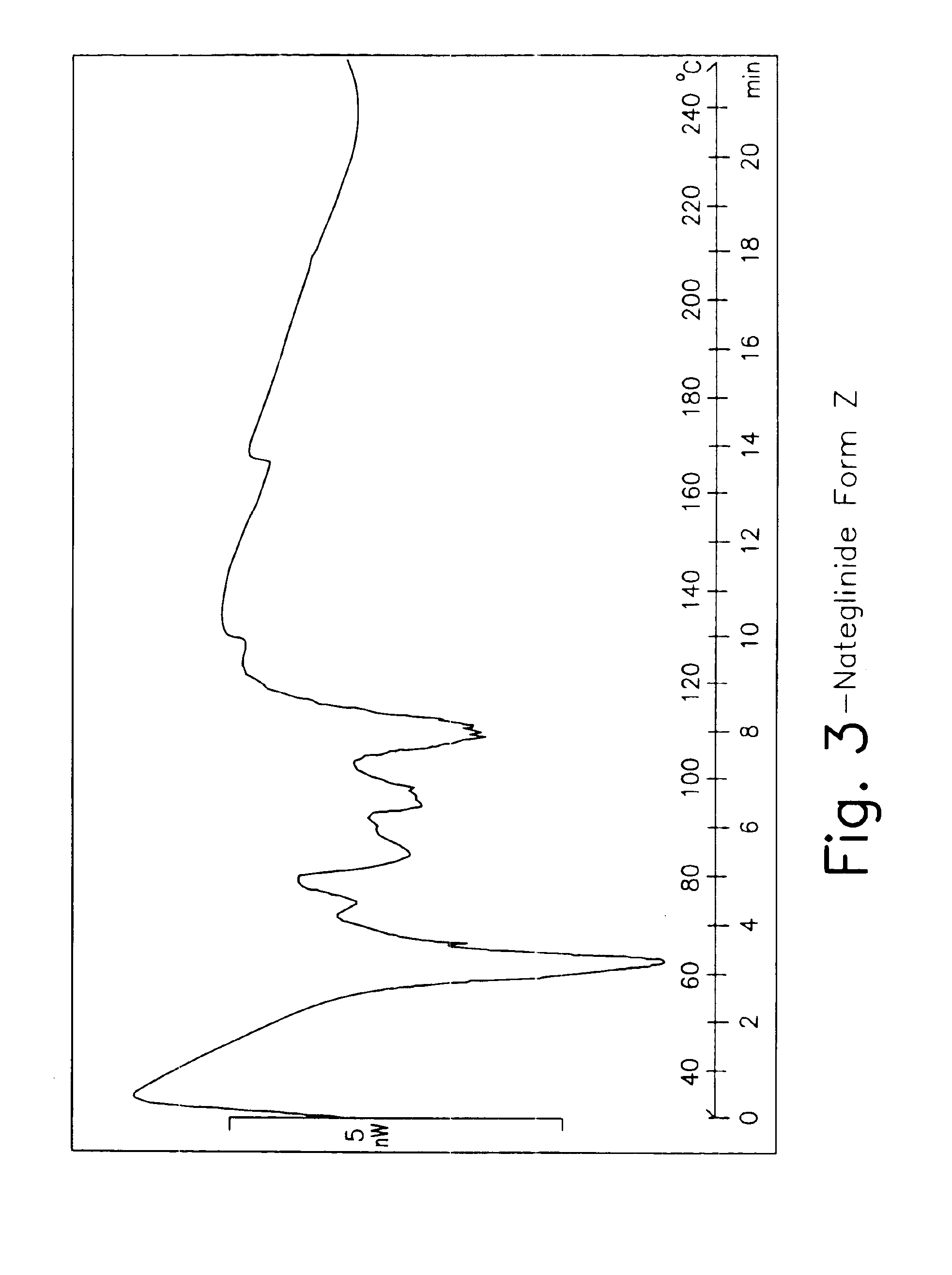

Process for preparing nateglinide and intermediates thereof

Provided is a process for preparation of an intermediate in the synthesis of nateglinide. Trans-4-isopropylcyclohexane acid chloride is formed by reacting 4-isopropylcyclohexanecarboxyl acid with thionyl chloride in the presence of an effective amount of an organic amide.Also provided are processes for preparation of nateglinide by acylation of a suitable salt of D-phenylalanine with trans-4-isopropylcyclohexane acid chloride in both a single and a two phase system, and in water free of a co-solvent.

Owner:TEVA PHARM USA INC

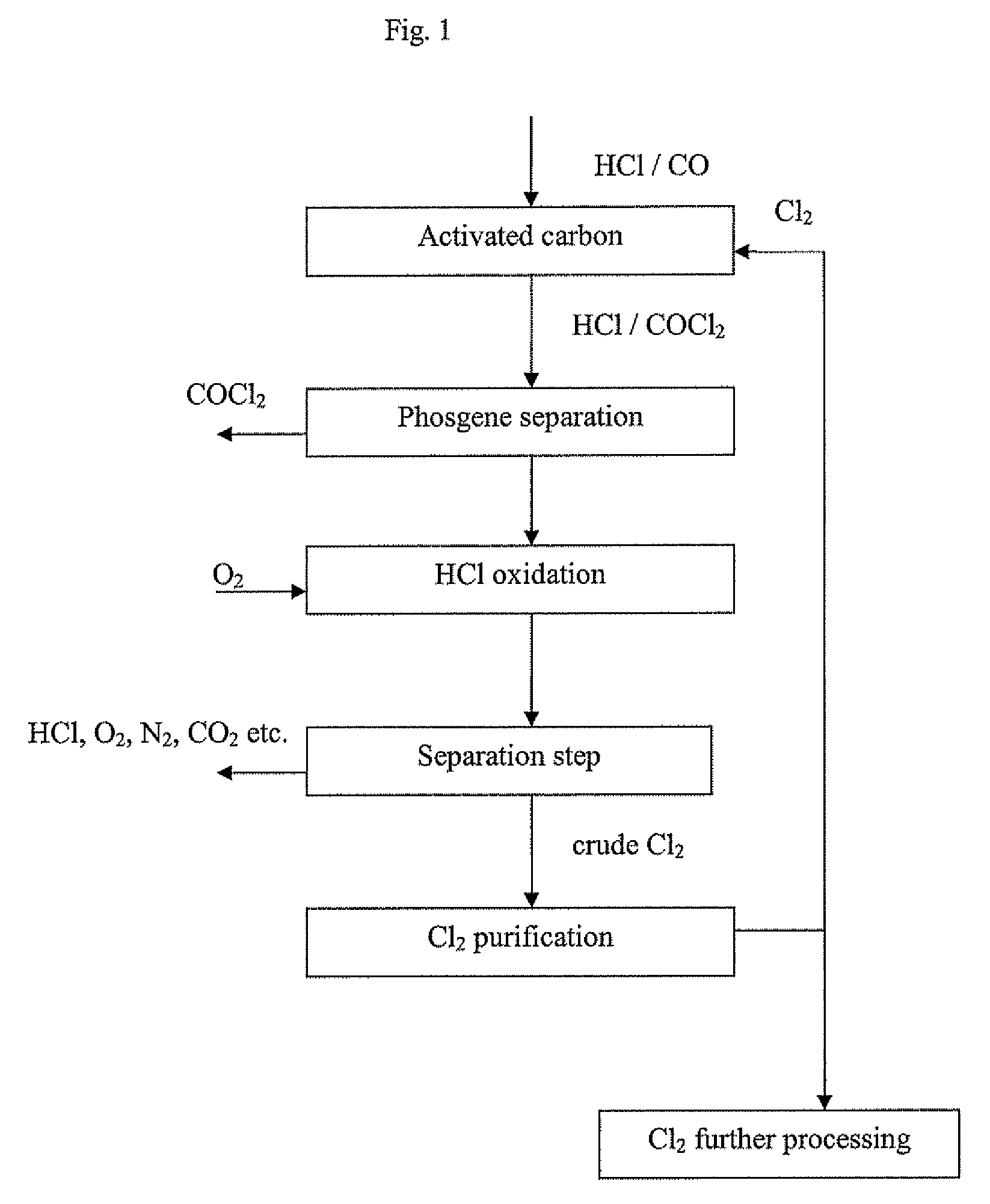

Processes for the production of organic isocyanates

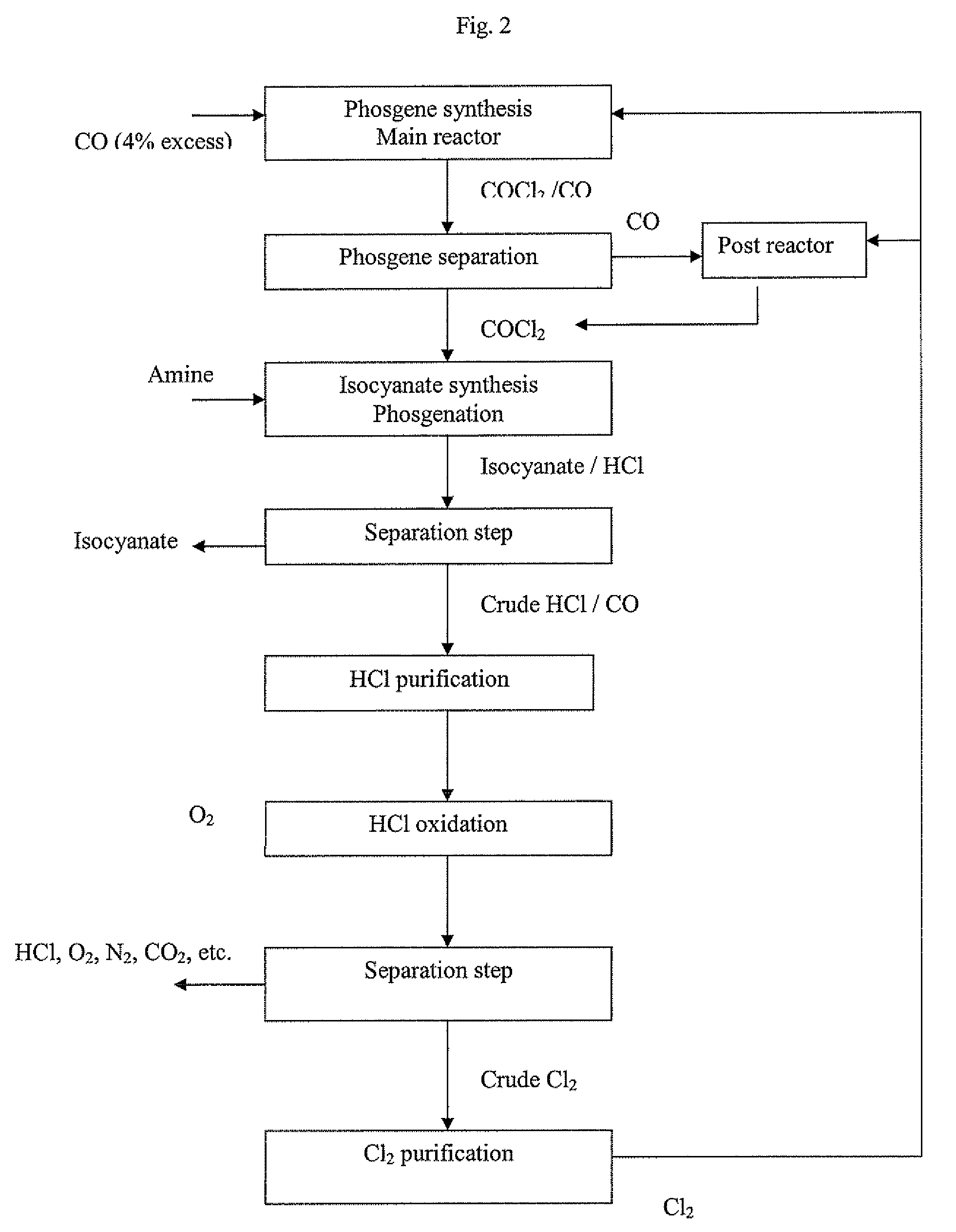

InactiveUS20070276154A1Reduce needReduce riskIsocyanic acid derivatives preparationOrganic compound preparationPhosgeneChlorine

Processes for the production of organic isocyanates, comprising the production of phosgene by reaction of CO with Cl2, the reaction of the phosgene with organic amines to form the organic isocyanates, and the separation of the organic isocyanates, which is characterised in that the carbon monoxide is removed from the HCl-containing waste gas from the isocyanate synthesis by reaction with chlorine to form phosgene. The phosgene can be separated off and can optionally be fed back into an isocyanate synthesis The HCl-containing, CO-depleted gas is preferably subjected to HCl oxidation (Deacon). A closed chlorine cycle can be used in the isocyanate synthesis.

Owner:BAYER MATERIALSCIENCE AG

Method for producing semiconductor gas

InactiveCN102762525AOrganic chemistry methodsNon-surface-active detergent compositionsHalogenSemiconductor

Disclosed is a method for producing monofluoro methane, which involves at least a pyrolysis step in which a 1-methoxy-1,1,2,2-tetrafluoro ethane is pyrolyzed by bringing same into contact with a catalyst, and a step for collecting monofluoro methane from the pyrolysis product. As a consequence, it is possible to efficiently and practically produce monofluoro methane that essentially does not contain halogens except fluorine.

Owner:CENT GLASS CO LTD

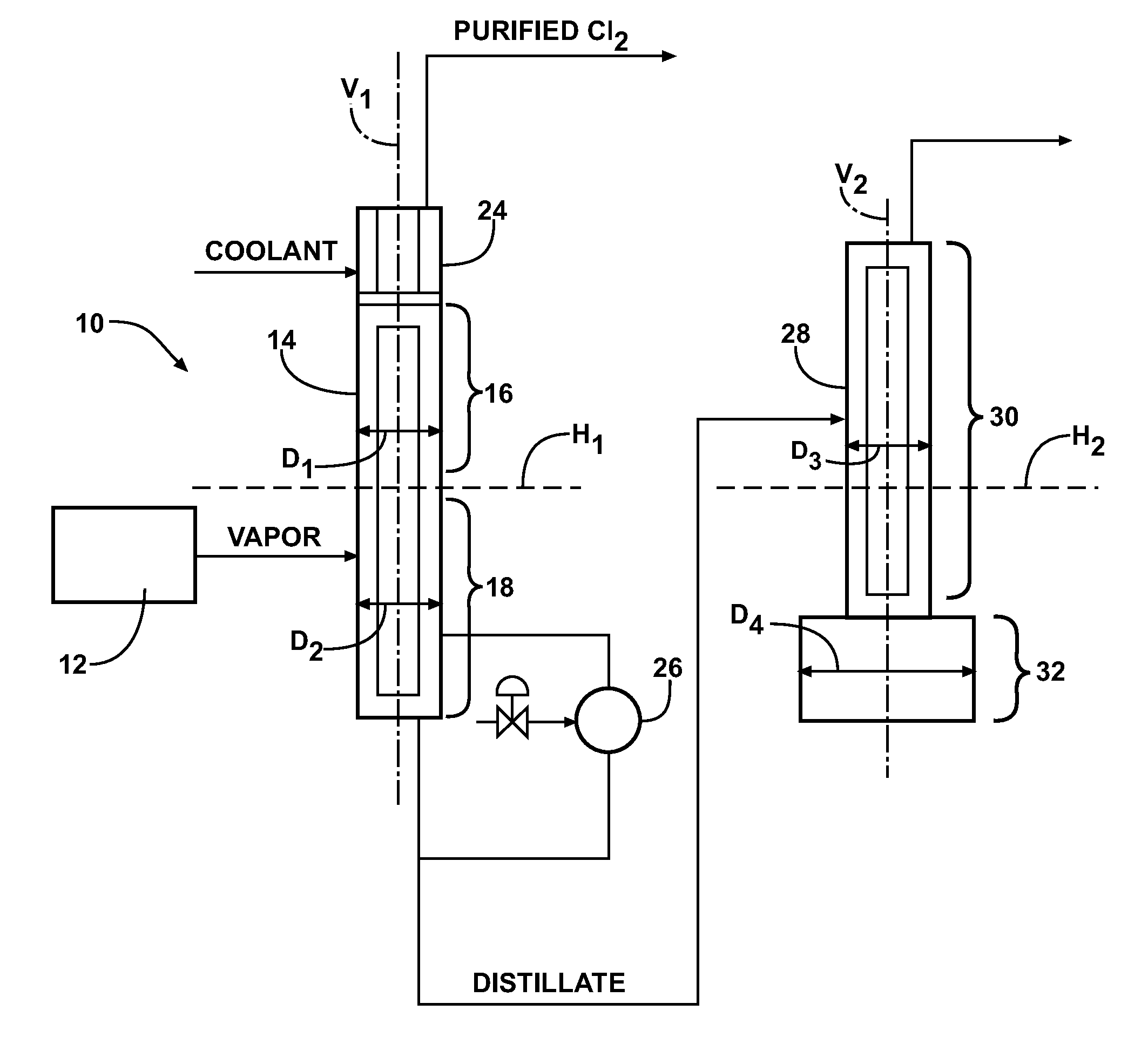

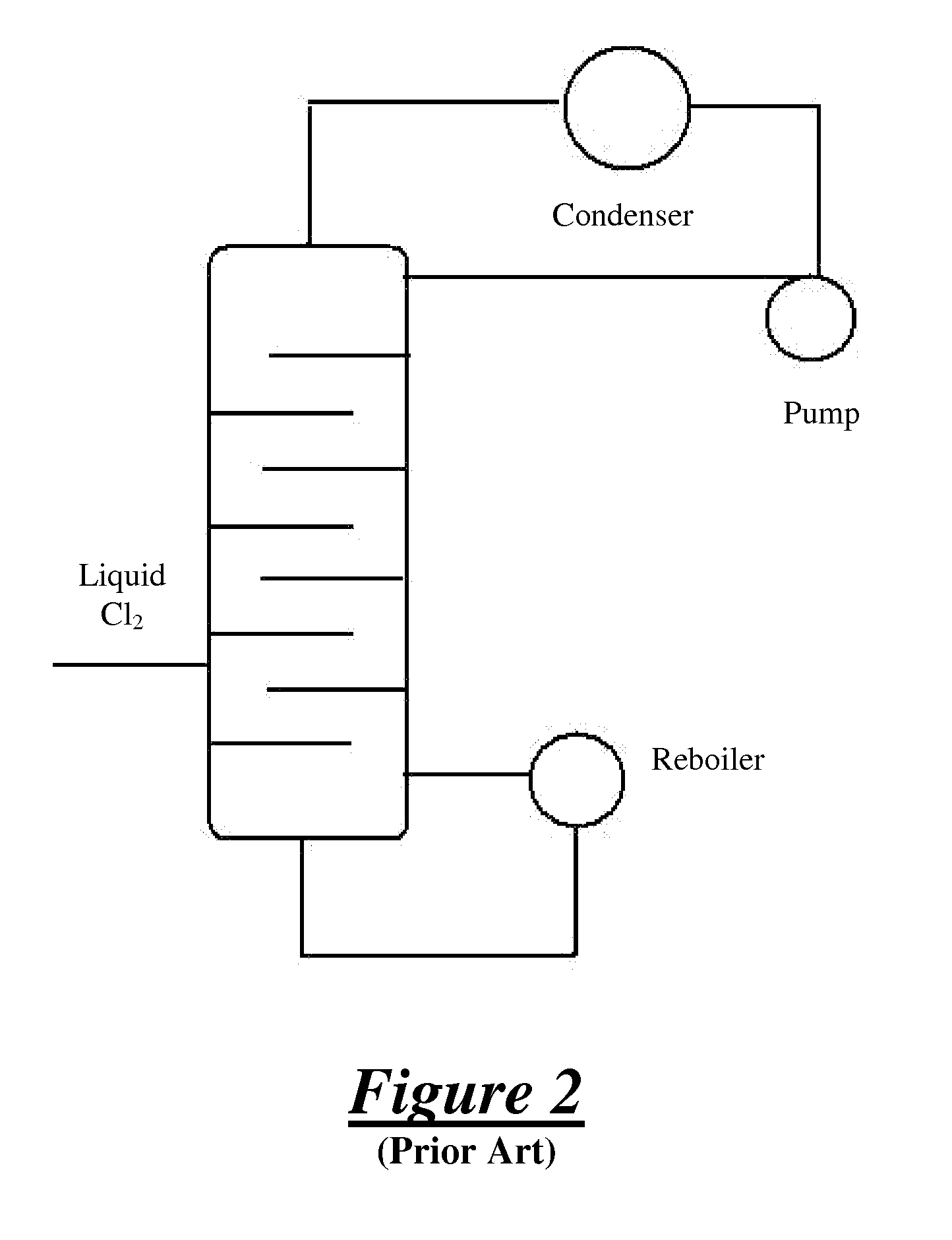

Method for purifying a chlorine supply

ActiveUS20110144381A1Improve energy efficiencyReduce environmental problemsIsocyanic acid derivatives preparationLiquid degasificationRefluxReboiler

This invention provides a method for purifying a chlorine supply that includes a chlorine component, a bromine component, and nitrogen trichloride. The method includes the steps of introducing the chlorine supply into a vaporizer, heating the chlorine supply in the vaporizer to form a vapor, and introducing the vapor into a distillation system to provide purified chlorine gas, a distillate that includes liquid chlorine and the bromine component, and a bottoms component including the nitrogen trichloride. The method also includes the steps of condensing the vapor in a reflux condenser, heating the condensate in a reboiler, removing the purified chlorine gas from the distillation system, and removing the distillate from the distillation system.

Owner:BASF AG

Continuous synthesis system and method of ethyl 4-chloroacetoacetate

InactiveCN106748764AHigh selectivityReduce manufacturing costPreparation from carboxylic acid halidesCarboxylic acid halides preparationEthyl acetateDiketene

The invention relates to a continuous synthesis system and method of ethyl 4-chloroacetoacetate. The method comprises the steps of adopting diketene, chlorine and ethyl alcohol as raw materials and inputting the raw materials into a micro-channel reactor through a metering pump; and carrying out chlorination and esterification and then synthesizing the ethyl 4-chloroacetoacetate. The reaction time is greatly shortened, and the produced product is high in content, low in cost, small in pollution and high in security and meets the requirements of industrial production.

Owner:JIANGSU CHENGXIN PHARMA

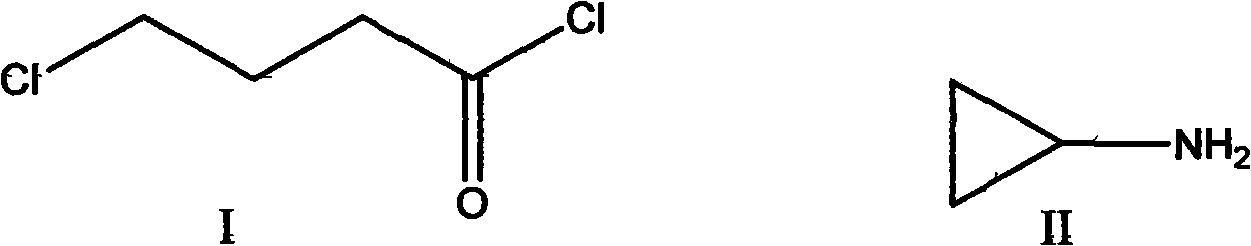

Preparation method of 4-chlorobutyroyl chloride

ActiveCN101624340ALow toxicityNo pollutionOrganic-compounds/hydrides/coordination-complexes catalystsCarboxylic acid halides preparationRoom temperatureChloride

The invention mainly discloses a preparation method of 4-chlorobutyroyl chloride, which comprises the following steps: selecting solid phosgene and Gamma-butyrolactone as raw materials, wherein the mol ratio of the solid phosgene and the Gamma-butyrolactone is 1.01:(1-0.33):1; putting the Gamma-butyrolactone and lewis acid as a catalyst into a three-neck flask, rising the temperature to 100 DEG C, reducing the temperature to the room temperature, putting the solid phosgene, rising the temperature to 60-140 DEG C, keeping the temperature for 4-40h, reducing the pressure and recovering to obtain the 4-chlorobutyroyl chloride. The invention has simple process, mild reaction condition, high yield, low cost, low toxicity of the used raw materials and no pollution to the environment.

Owner:ZHEJIANG GUOBANG PHARMA

Process for production of fluoro derivative

InactiveUS7807858B2Improve solubilityEfficient removalSugar derivativesOrganic compound preparationHydrogen fluorideOrganic base

It was found that a fluoro derivative can be produced by reacting a hydroxy derivative with sulfuryl fluoride (SO2F2) in the presence of an organic base or in the presence of an organic base and “a salt or complex comprising an organic base and hydrogen fluoride”. According to the present production process, it is not necessary to use perfluoroalkanesulfonyl fluoride, which is not preferable in industrial use, and it is possible to advantageously produce optically-active fluoro derivatives, which are important intermediates of medicines, agricultural chemicals and optical materials, specifically 4-fluoroproline derivatives, 2′-deoxy-2′-fluorouridine derivatives, optically-active α-fluorocarboxylate derivatives, and the like, even in a large scale.

Owner:CENT GLASS CO LTD

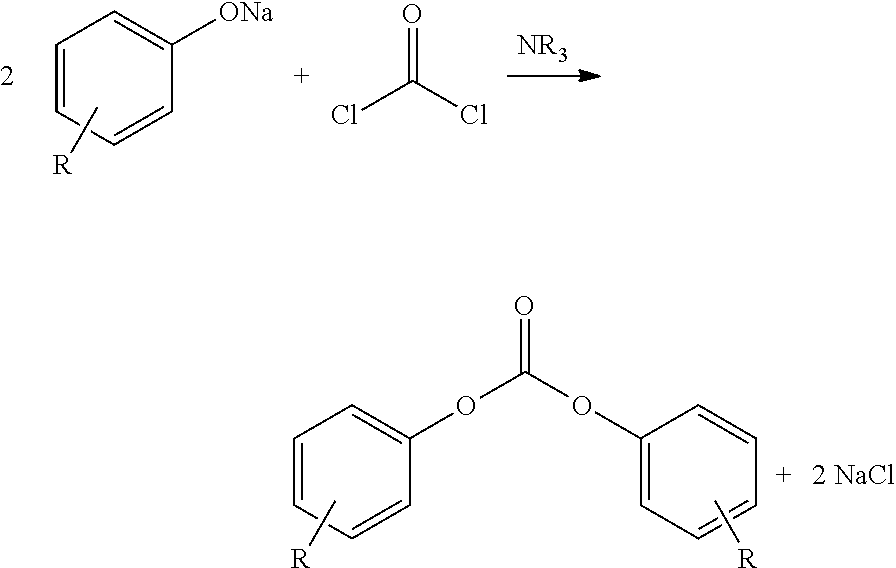

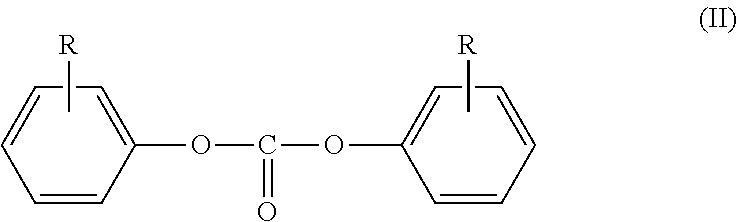

Process for production of diaryl carbonate

The invention relates to a process for production of diaryl carbonate combined with the electrolysis of the resultant alkali metal chloride-containing process wastewater. The process according to the invention makes possible, inter alia, improved utilization in electrolysis of the alkali metal chloride-containing solution obtained in the production of diaryl carbonate.

Owner:COVESTRO DEUTSCHLAND AG

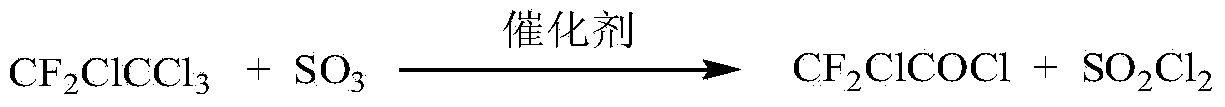

Preparation method of 2-bromo-2,2-difluoroacetyl chloride and 2-bromo-2,2-difluoro acetate and recycling method of waste difluoro trichloroethane

InactiveCN104761446AEnable recyclingIncrease added valuePreparation by hydrogen halide split-offPreparation from carboxylic acid halidesBromoethanePhenol

The invention relates to a preparation method of 2-bromo-2,2-difluoroacetyl chloride and 2-bromo-2,2-difluoro acetate and a recycling method of waste difluoro trichloroethane. The preparation method comprises the following steps: with waste difluoro trichloroethane produced in the production process of dichlorotrifluoroethane as a raw material, carrying out dehydrochlorination to obtain difluoro dichloroethylene, carrying out addition reaction on difluoro dichloroethylene and bromine to obtain difluoro dichlone dibromoethane; reacting difluoro dichlone dibromoethane with sulfur trioxide to obtain 2-bromo-2,2-difluoroacetyl chloride; and reacting 2-bromo-2,2-difluoroacetyl chloride with alcohol or phenol to obtain 2-bromo-2,2-difluoro acetate series products. According to the preparation method and the recycling method, recycling of waste difluoro trichloroethane is realized; 2-bromo-2,2-difluoroacetyl chloride and 2-bromo-2,2-difluoro acetate are prepared by a temperature oscillation method, so that the production cost is reduced; and meanwhile, the preparation method is an environment-friendly technique for producing products.

Owner:JIANGXI SUNWAY CHEM CO LTD

Method for preparation of trifluoro acetyl chloride with trifluoroethane chlorinated mixture

ActiveCN101747176AReduce consumptionThe synthetic route is simpleCarboxylic acid halides preparationAcetyl chlorideGas phase

The invention discloses a method for preparation of trifluoro acetyl chloride with trifluoroethane chlorinated mixture, which comprises the following steps: 1) adding trifluoroethane chlorinated mixture into a reactor, continuously introducing oxygen and chlorine under stirring, irradiating with a mercury lamp for photochemical oxidation, continuously discharging reactants in the form of gas phase from the upper part of the reactor, and continuously supplementing the trifluoroethane chlorinated mixture to maintain the level in the reactor constant; and 2) condensing the gasified trifluoroethane chlorinated mixture in the reactor through a condensation and separation tower and making the condensed trifluoroethane chlorinated mixture return to the reactor to continuously react, discharging the product trifluoro acetyl chloride from the top of the condensation and separation tower and collecting the trifluoro acetyl chloride after compression and condensation. Compared with the existing preparation method, the invention has the advantages that: the trifluoroethane chlorinated mixture can be directly used for preparation of the trifluoro acetyl chloride without separation, the processis advanced and reasonable, the synthesis route is simplified, the time is reduced, the production efficiency is greatly enhanced, and the equipment investment and energy consumption are reduced.

Owner:福建舜跃科技股份有限公司

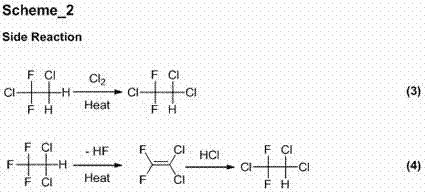

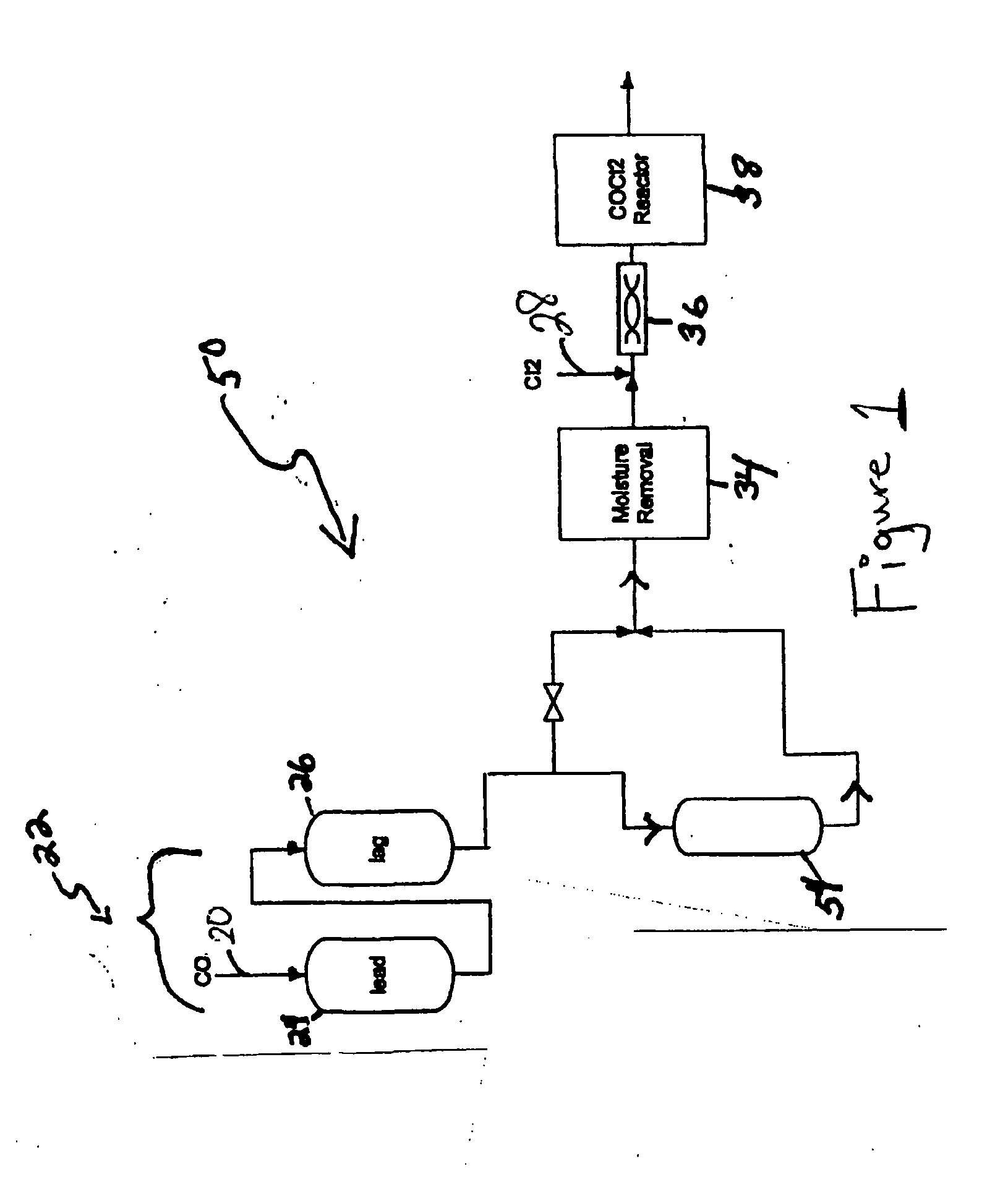

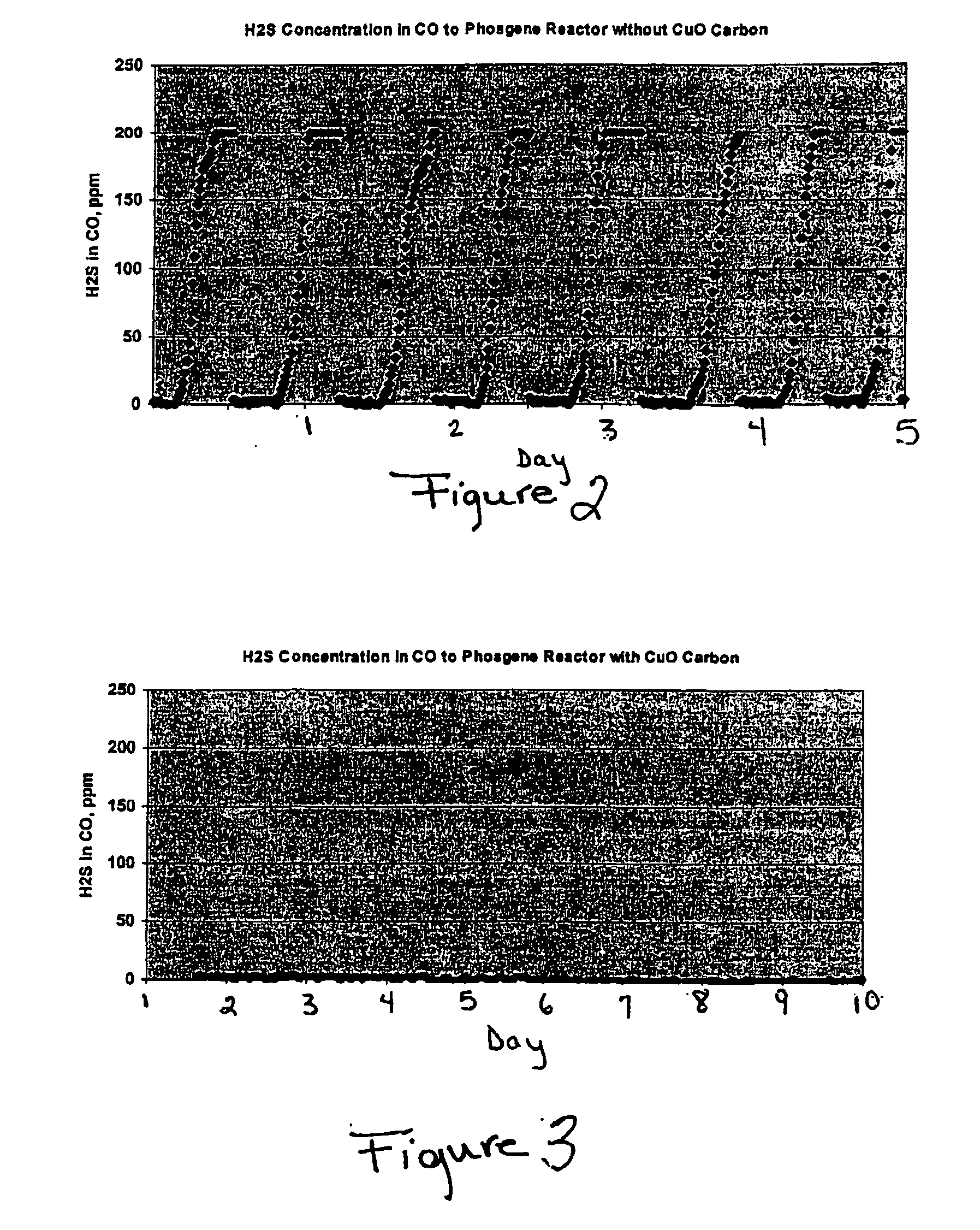

Processes and systems for making phosgene

InactiveUS20050025693A1Reduce the concentration of hydrogen sulfideOrganic compound preparationDispersed particle separationActivated carbonPhosgene

One process for producing phosgene comprises: introducing a carbon monoxide stream to a metal oxide impregnated activated carbon, reducing a hydrogen sulfide concentration in the carbon monoxide stream to produce a cleaned stream, wherein a cleaned stream hydrogen sulfide concentration is less than or equal to about 20 ppm, and reacting carbon monoxide in the cleaned stream with chlorine to produce phosgene.

Owner:SABIC GLOBAL TECH BV

Preparation method of 2,4-dichloro-5-fluorobenzoyl chloride

ActiveCN107118096AEmission reductionBreak through the technical bottleneck of conversionOrganic compound preparationCarbonyl compound preparation by hydrolysisBiopolymerOrganic synthesis

The invention discloses a preparation method of 2,4-dichloro-5-fluorobenzoyl chloride and belongs to the field of organic synthesis. The preparation method comprises the following steps: with 2,4-dichlorofluorbenzene as a raw material, performing friedel-crafts reaction and hydrolyzation to generate an intermediate, 2,4-dichloro-5-fluorobenzoyl chloride; and hydrolyzing, oxidizing and acylating a byproduct, biopolymer (III), generated by the reaction to obtain a final compound (II), wherein the total yield is 88% or above. According to the invention, the raw material conversation ratio is 80% or above, the defects that existing raw materials are hardly available, and the utilization ratio is low are overcome, resources are saved, the production cost is lowered, and the preparation method is simple to operate and easy for amplified production.

Owner:HEADING NANJING PHARMTECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com