Patents

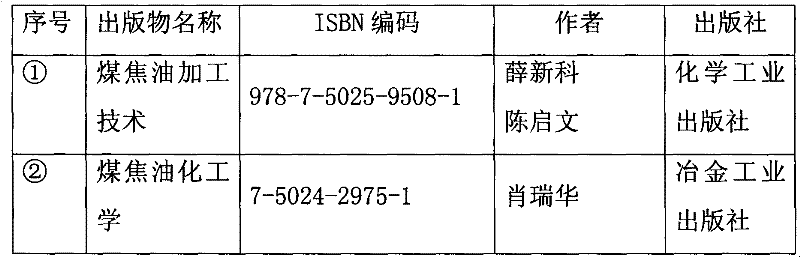

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce the concentration of hydrogen sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

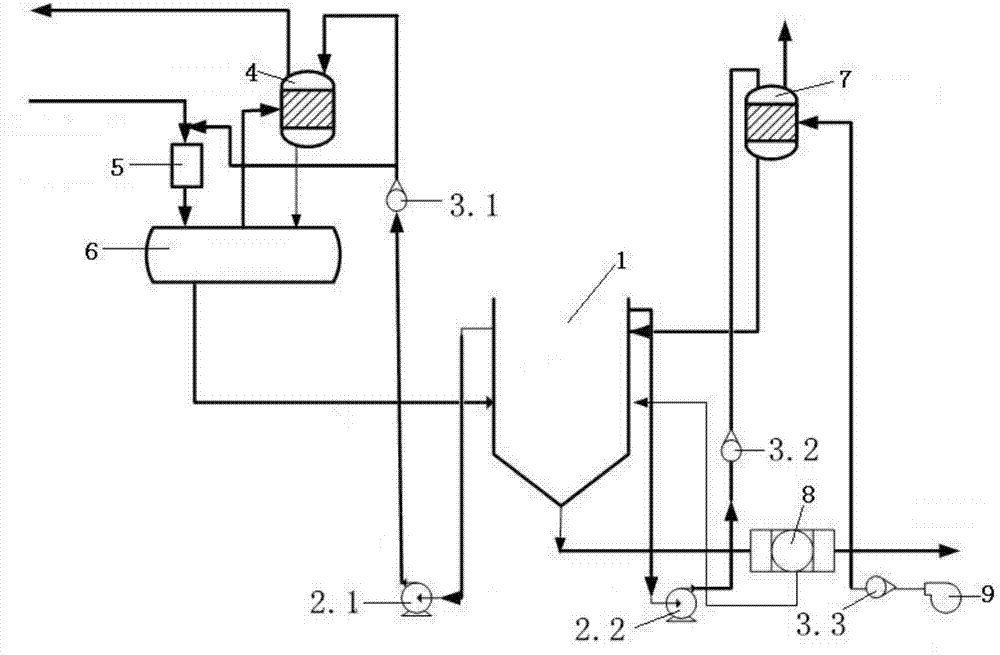

Method and device for removing hydrogen sulfide in gas phase through oxidation

InactiveCN103111177AShort regeneration timeAvoid cloggingDispersed particle separationGas phaseProcess engineering

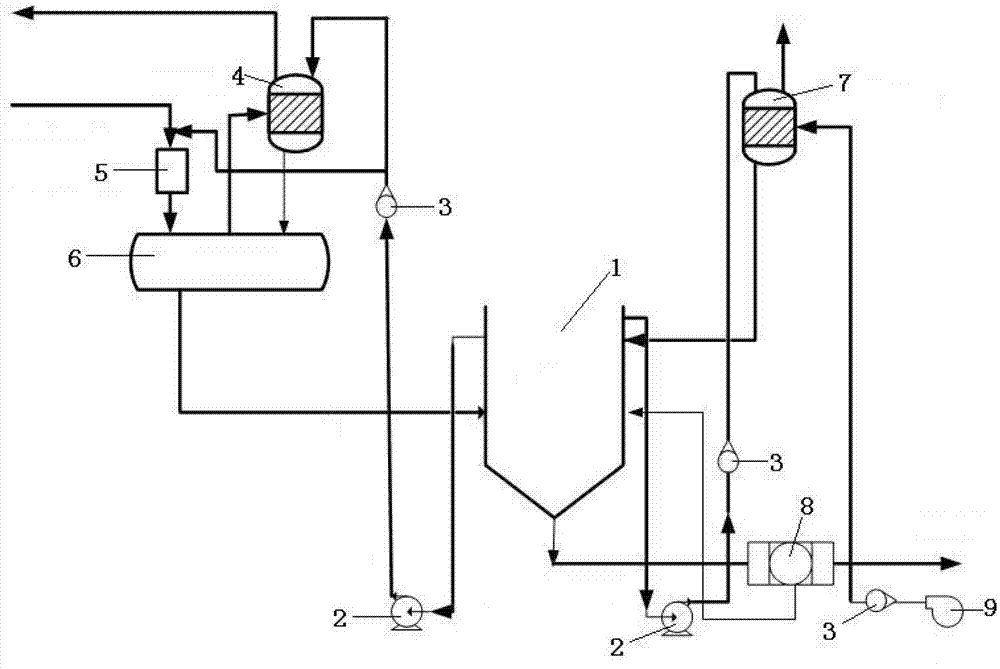

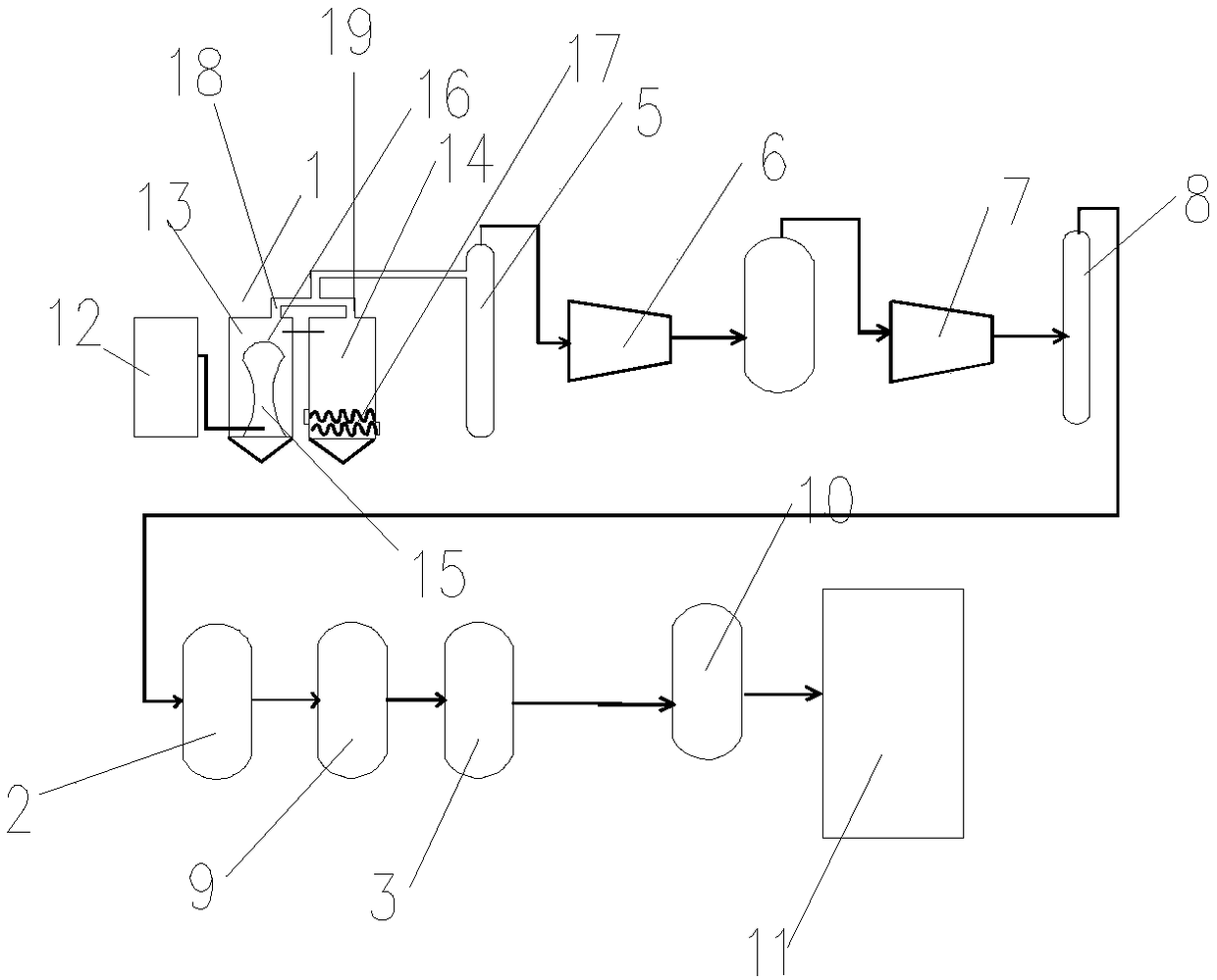

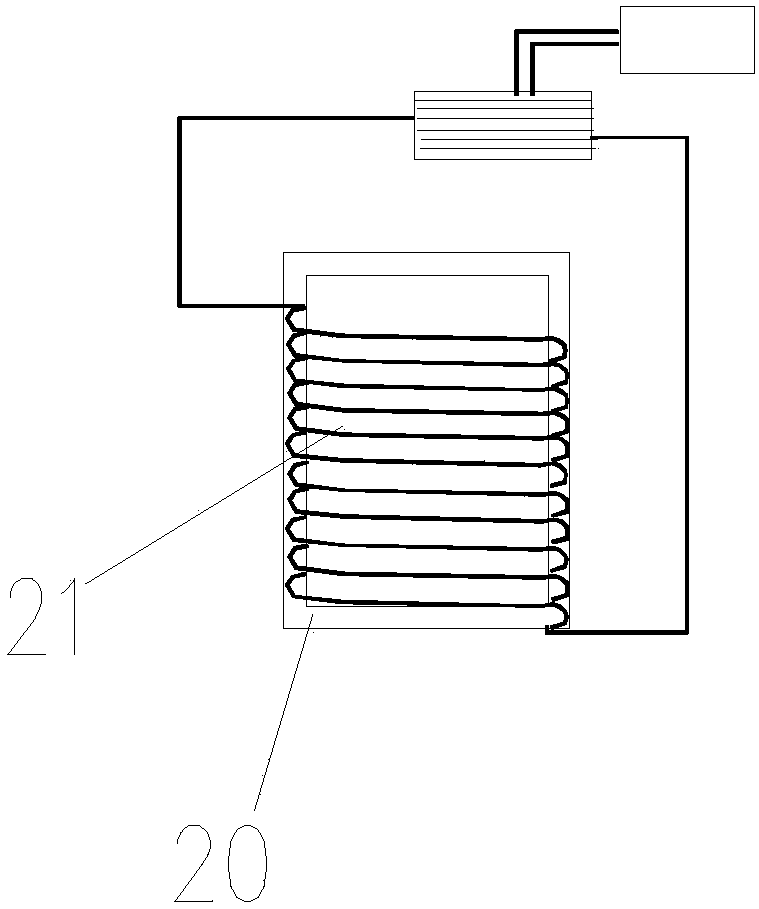

The invention discloses a method and a device for removing hydrogen sulfide in a gas phase through oxidation. The device comprises a settling tank, an extracting pump, a filtering membrane, an ultra gravity rotary packed bed, a separator, a balanced tank and a regeneration ultra gravity machine, wherein the extracting pump and the filtering membrane are sequentially connected between the settling tank and the ultra gravity rotary packed bed; the balanced tank is connected between the settling tank and the separator; the ultra gravity rotary packed bed is communicated with the balanced tank; the settling tank and the separator are sequentially connected with the extracting pump and the filtering membrane; and the extraction pump and the filtering membrane are sequentially connected between the settling tank and the regeneration ultra gravity machine. A technology flow of pre-oxidation sweetening, ultra oxidation sweetening, sulfur settlement, and regeneration is adopted for the method. According to the method and the device, the ultra gravity machine is adopted to replace the traditional low-mass-transfer-efficiency reactor, and the ultra gravity rotary packed bed reactor is adopted both in hydrogen sulfide oxidation and catalyst regeneration, the process mass transfer efficiency is intensified greatly, and the regeneration time oxidation sulfur removing time and the desulfurizing agent regenerating time are shortened.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD

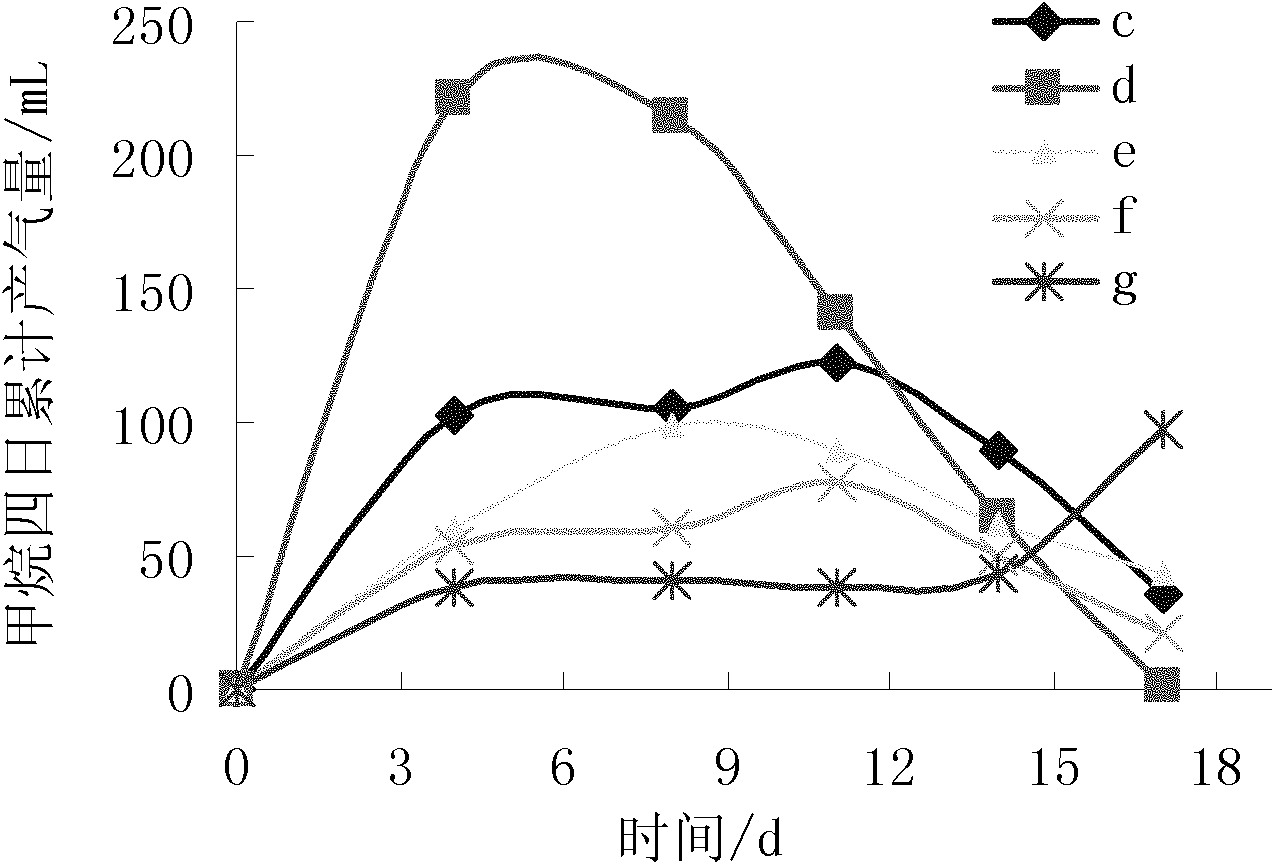

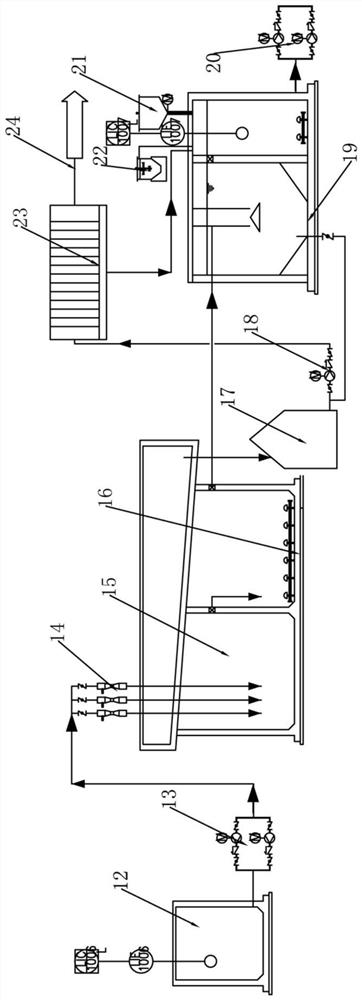

Two-phase anaerobic fermentation method for kitchen waste

ActiveCN103695472AReduce outputImprove organic degradation rateBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationOil and grease

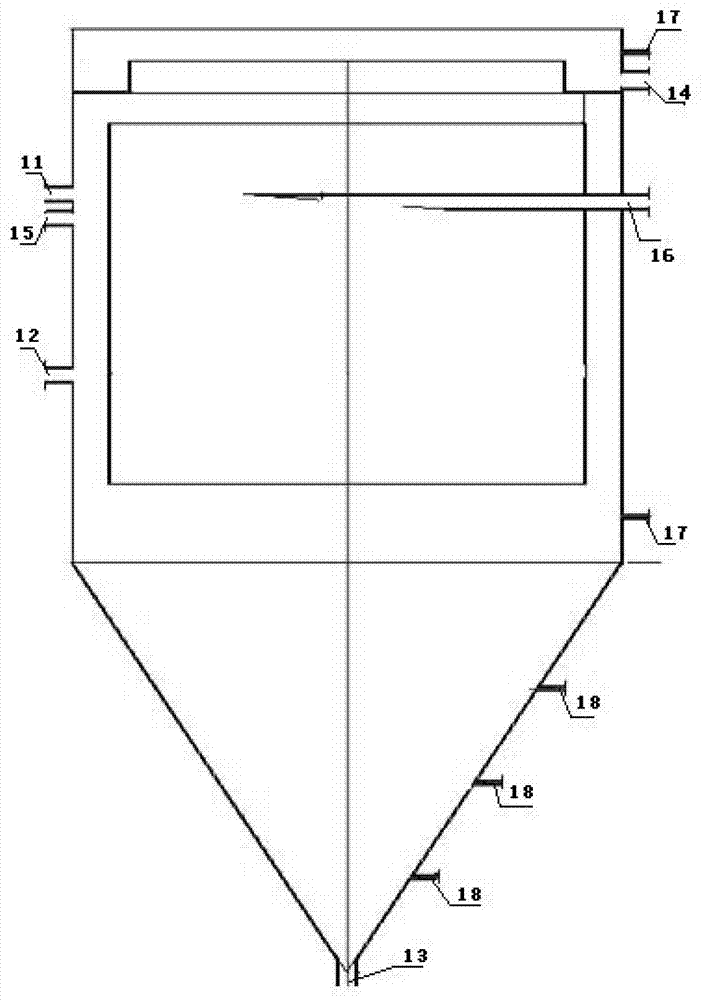

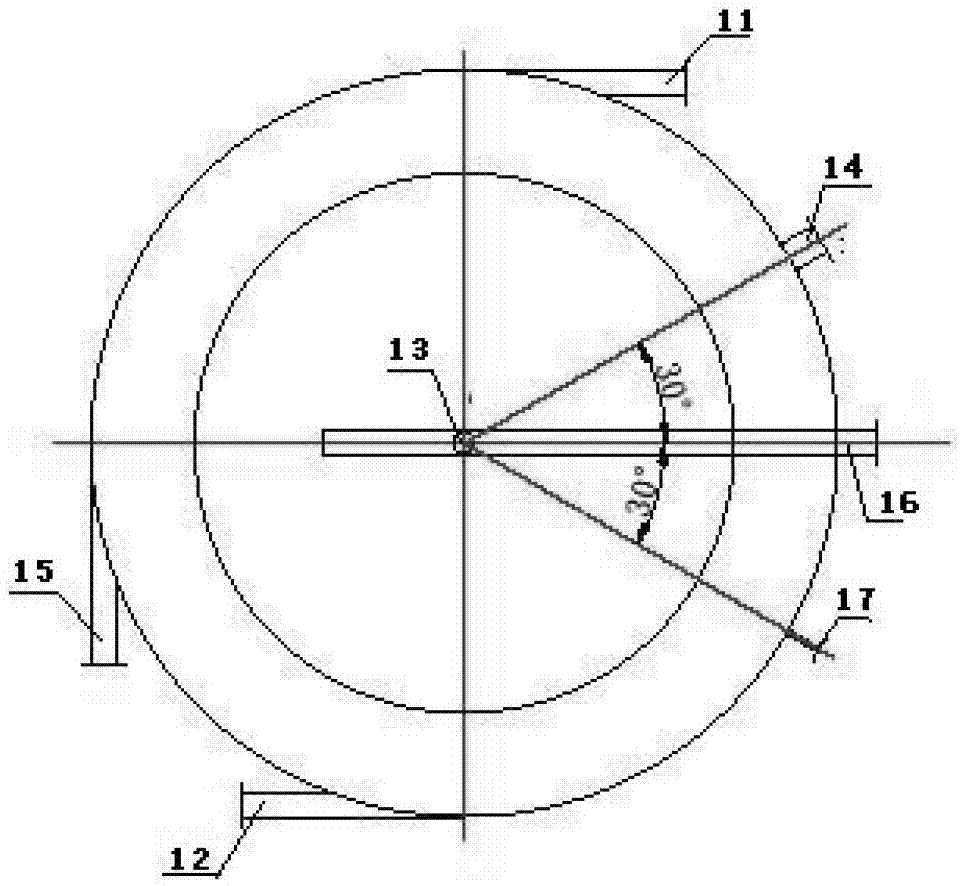

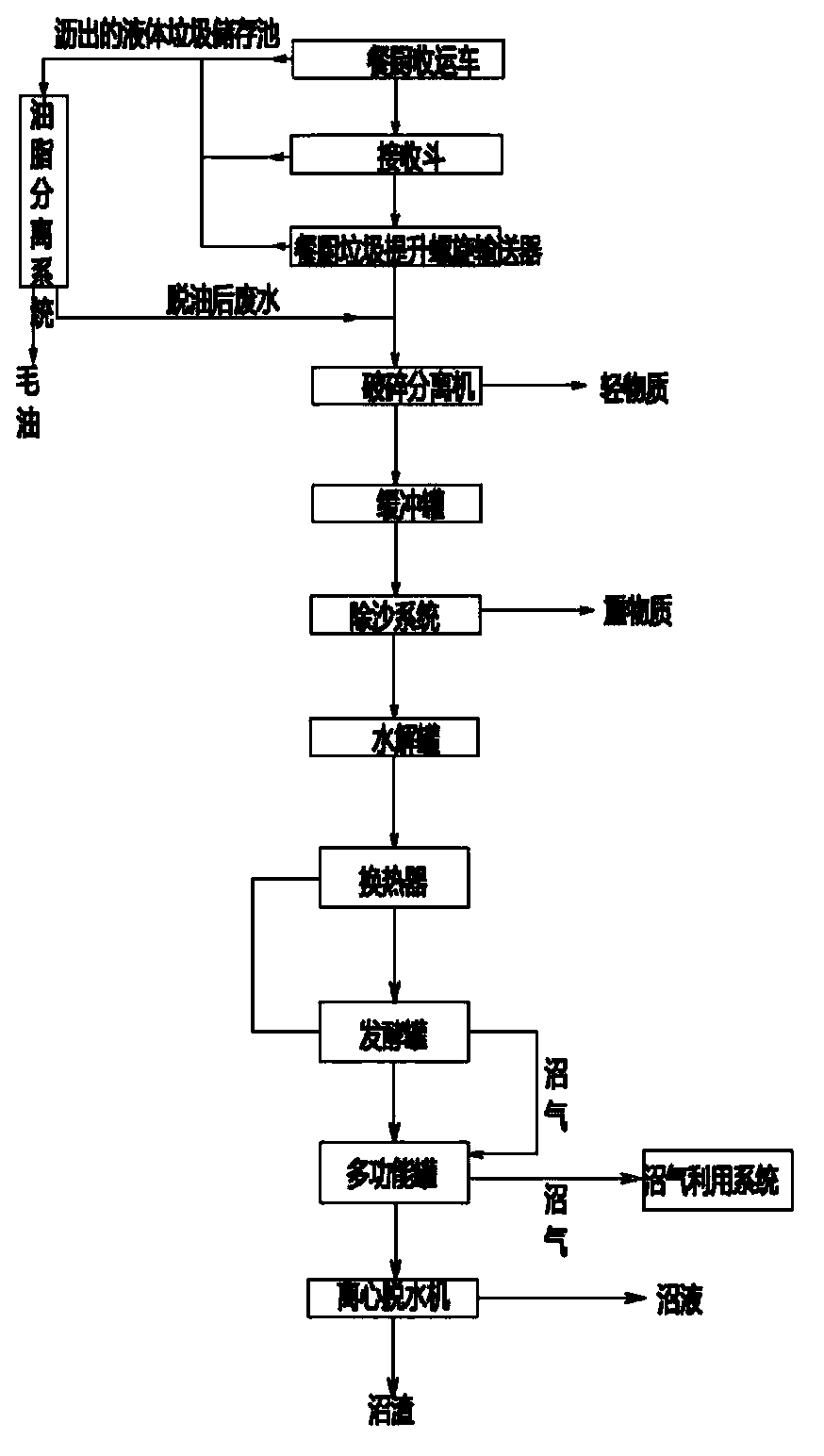

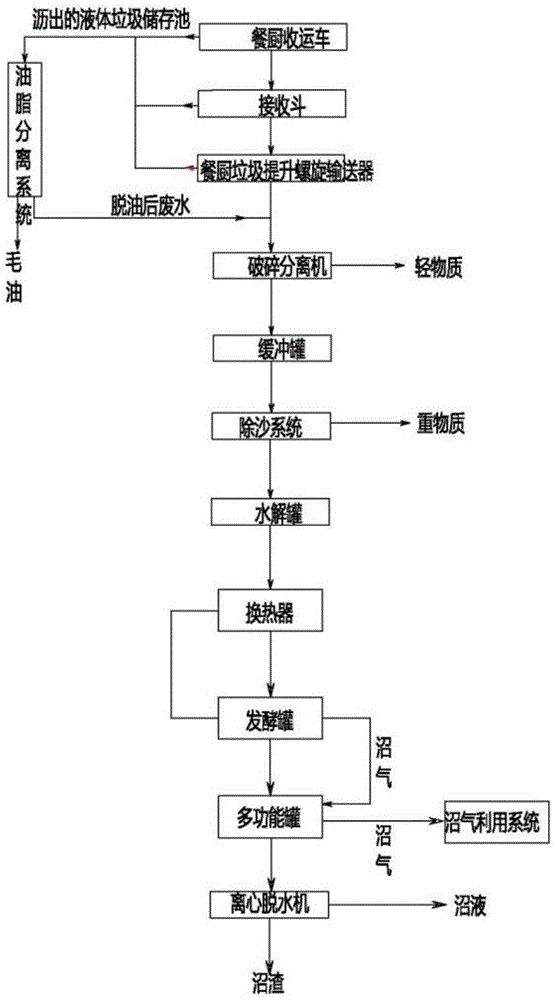

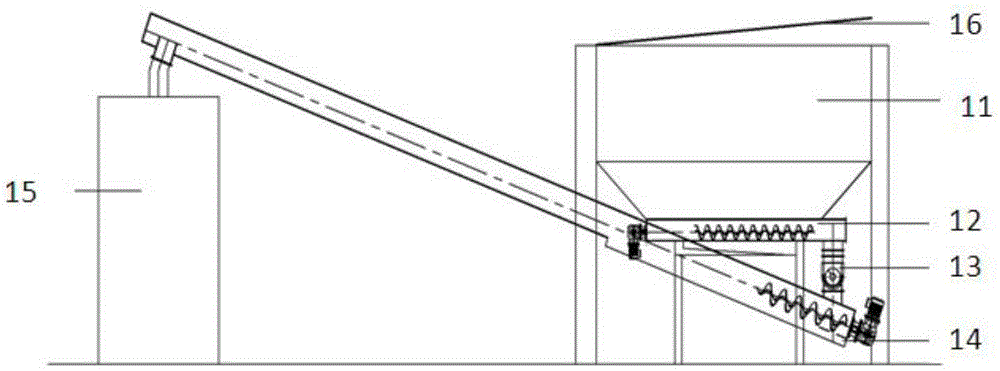

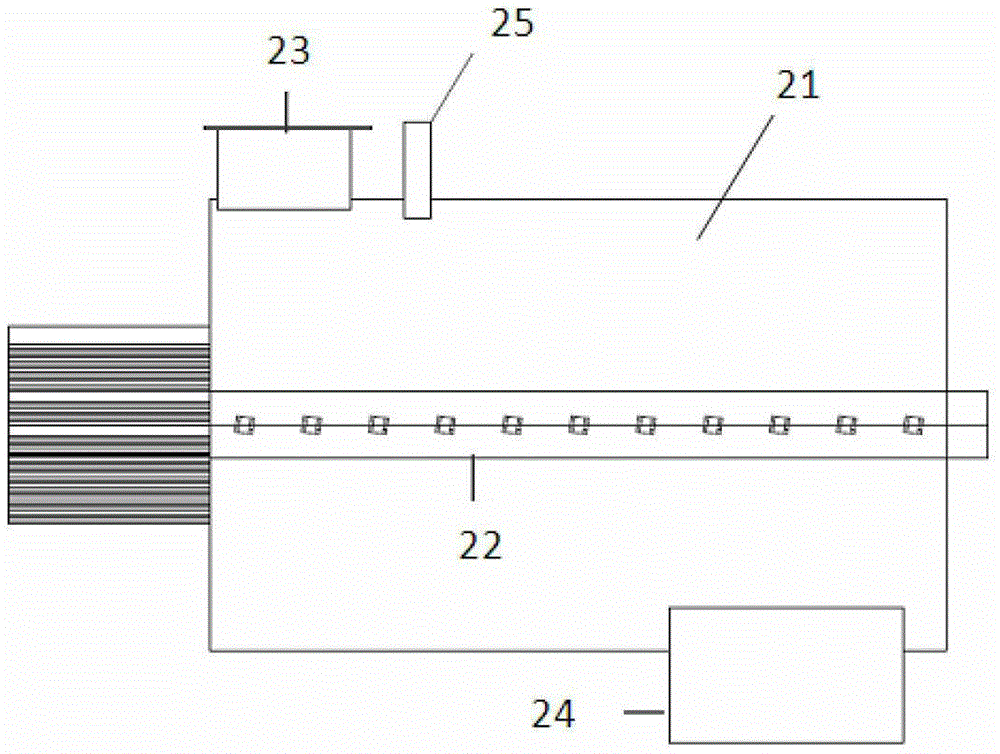

The invention relates to the kitchen waste treatment field, in particular to a two-phase anaerobic fermentation method for kitchen waste. The two-phase anaerobic fermentation method for kitchen waste includes the steps of: 1) sending leached oil water into a grease separation system to undergo grease separation, recovering the separated grease, and carrying the separated wastewater and the kitchen waste conveyed by a lifting screw conveyor to a crushing separation system; 2) carrying out crushing and separation; 3) conducting hydrolytic acidification; 4) inputting the waste slurry subjected to hydrolytic acidification in a hydrolysis tank into a heat exchanger, performing heating, then sending the waste slurry into a fermentation tank to undergo anaerobic fermentation; 5) conducting re-fermentation, and subjecting biogas to desulfurization treatment; and 6) recovering biogas residue and biogas. The method provided by the invention applies the two-phase anaerobic technology to the kitchen waste industry, and can effectively avoid the easy acidification phenomenon of high concentration organic waste anaerobic fermentation. The multifunctional tank integrating gas production, gas storage and desulfurization is adopted in the invention, and the gas production efficiency is improved.

Owner:北京时代桃源环境科技股份有限公司

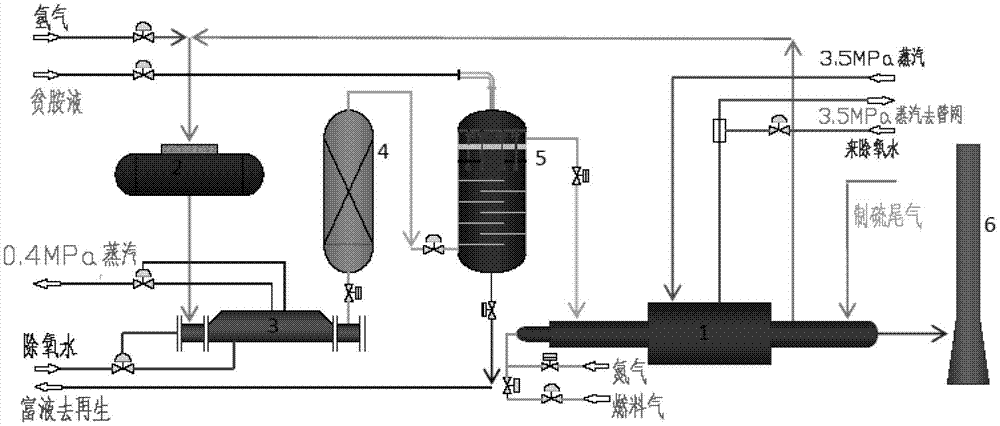

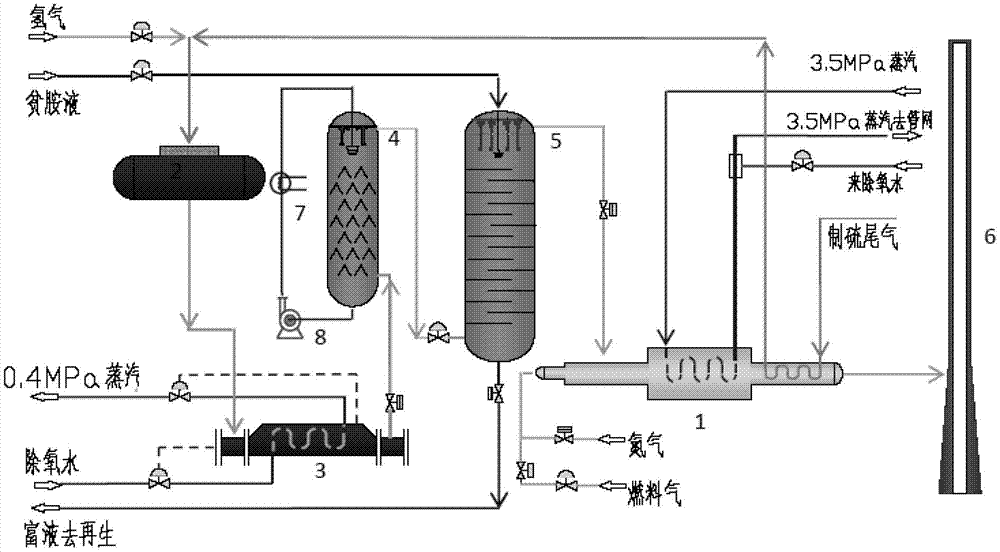

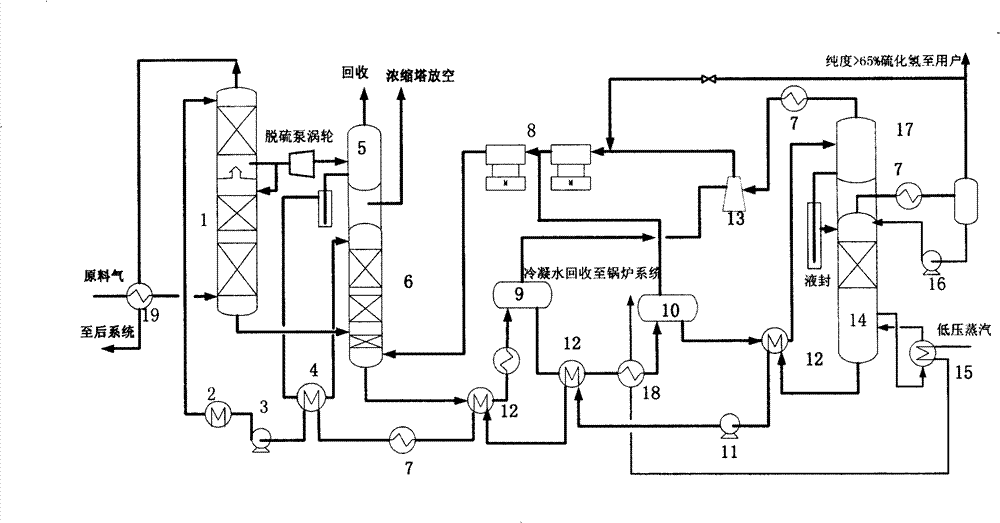

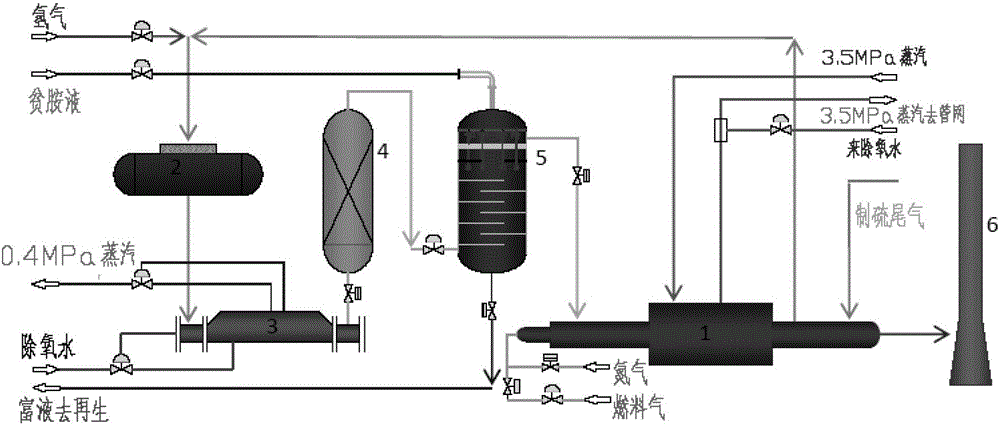

Rotational flow strengthening method and device for purifying sulfur production tail gases by Claus method

ActiveCN103170223AReduce sulfur contentProblems with increased energy loadDispersed particle separationIncinerator apparatusExhaust gasChemistry

The invention relates to a rotational flow strengthening method and device for purifying sulfur production tail gases by the Claus method, and provides a rotational flow strengthening method for purifying sulfur production tail gases by the Claus method. The method comprises the following steps of: (i) after heat exchange treatment for sulfur production tail gases by the Claus method, mixing the treated tail gases with hydrogen for hydrogenation reaction so as to reduce and hydrolyze elemental sulfur, SO2, COS and CS2 carried in tail gases to H2S; (ii) primarily cooling gases obtained in step (i) and absorbing H2S by countercurrent to remove waterdrops entrained in the gases while performing secondary cooling; (iii) absorbing H2S by countercurrent from the gases obtained in step (ii) for rotational flow separation so as to further remove H2S, and meanwhile rotationally separating amine liquid entrained; and (iv) burning the purified tail gases obtained in step (iii), and cooling to be discharged to atmosphere. The invention further provides a rotational flow strengthening device for purifying sulfur production tail gases by the Claus method.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

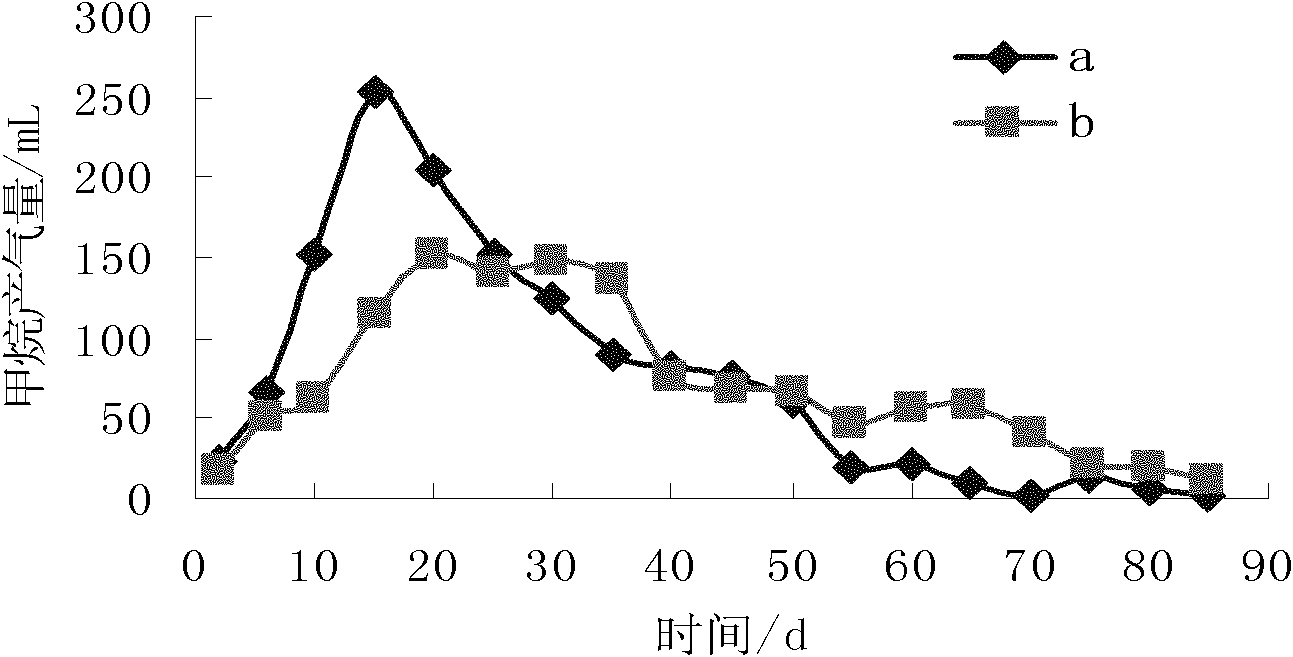

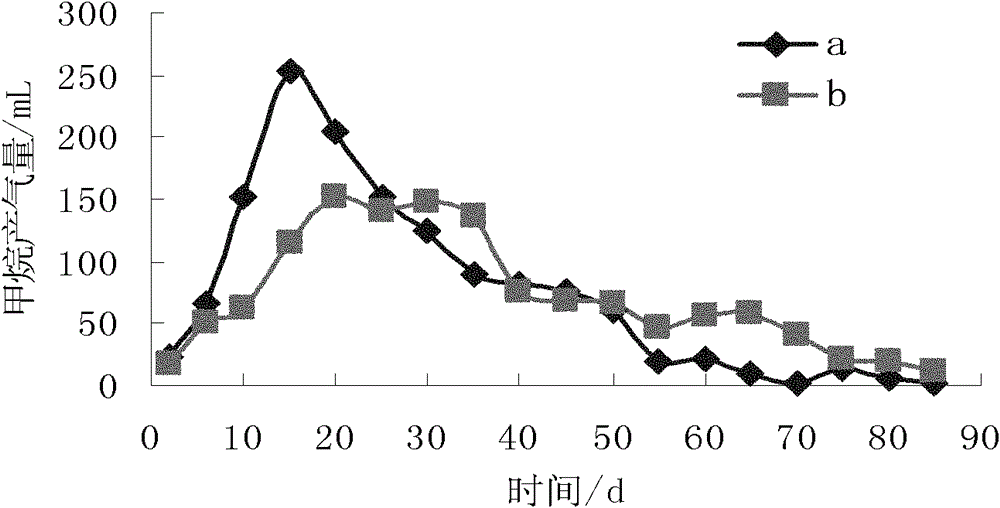

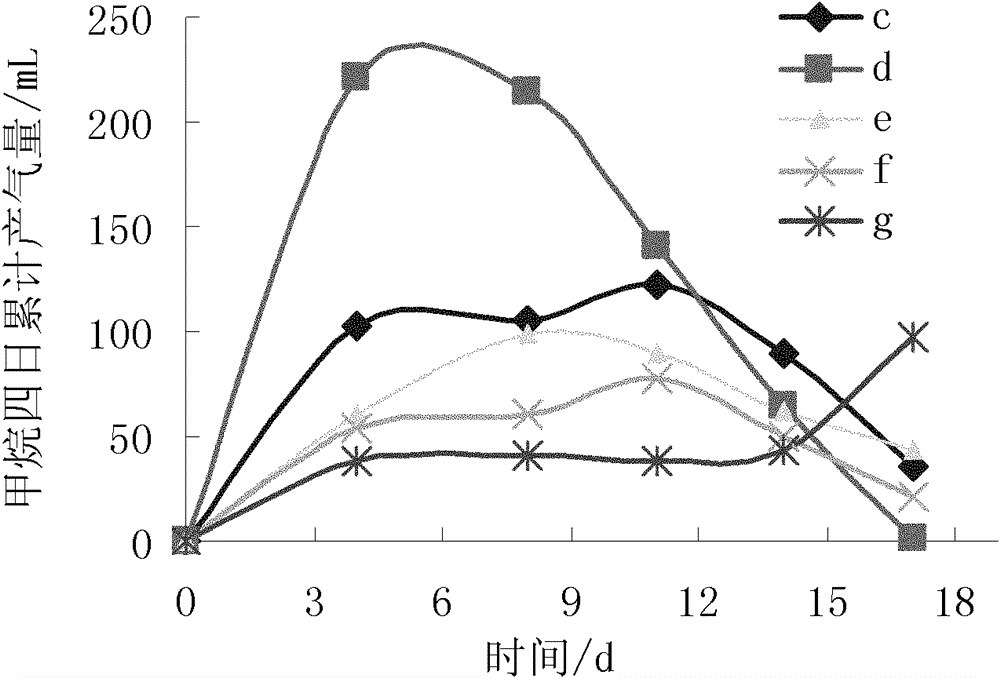

Method for increasing methane production efficiency in organic waste anaerobic process

ActiveCN102140001APromote hydrolysisImprove metabolic activityGas production bioreactorsWaste based fuelGeneration rateFeces

The invention discloses a method for increasing methane production efficiency in organic waste anaerobic process. The method is characterized in that powder containing no less than 15% of free ferric iron oxides is added into an anaerobic biochemical system to be uniformly blended, wherein the anaerobic biochemical system produces methane by utilizing organic wastes; and ferric ions released when microbes reduce the ferric iron oxides in the anaerobic process can promote the activity of anaerobic bacteria such as methane bacteria and the like, thus increasing the production rate and yield of methane by utilizing organic wastes. The method can be widely used for increasing the methane production rate and yield of an energy utilization system for biogas production of municipal domestic waste, agriculture product processing wastes, excess sludge of sewage treatment plants, feces of intensifying raising farms and the like and improves the utilization rate of renewable energy sources of organic wastes.

Owner:HEFEI UNIV OF TECH

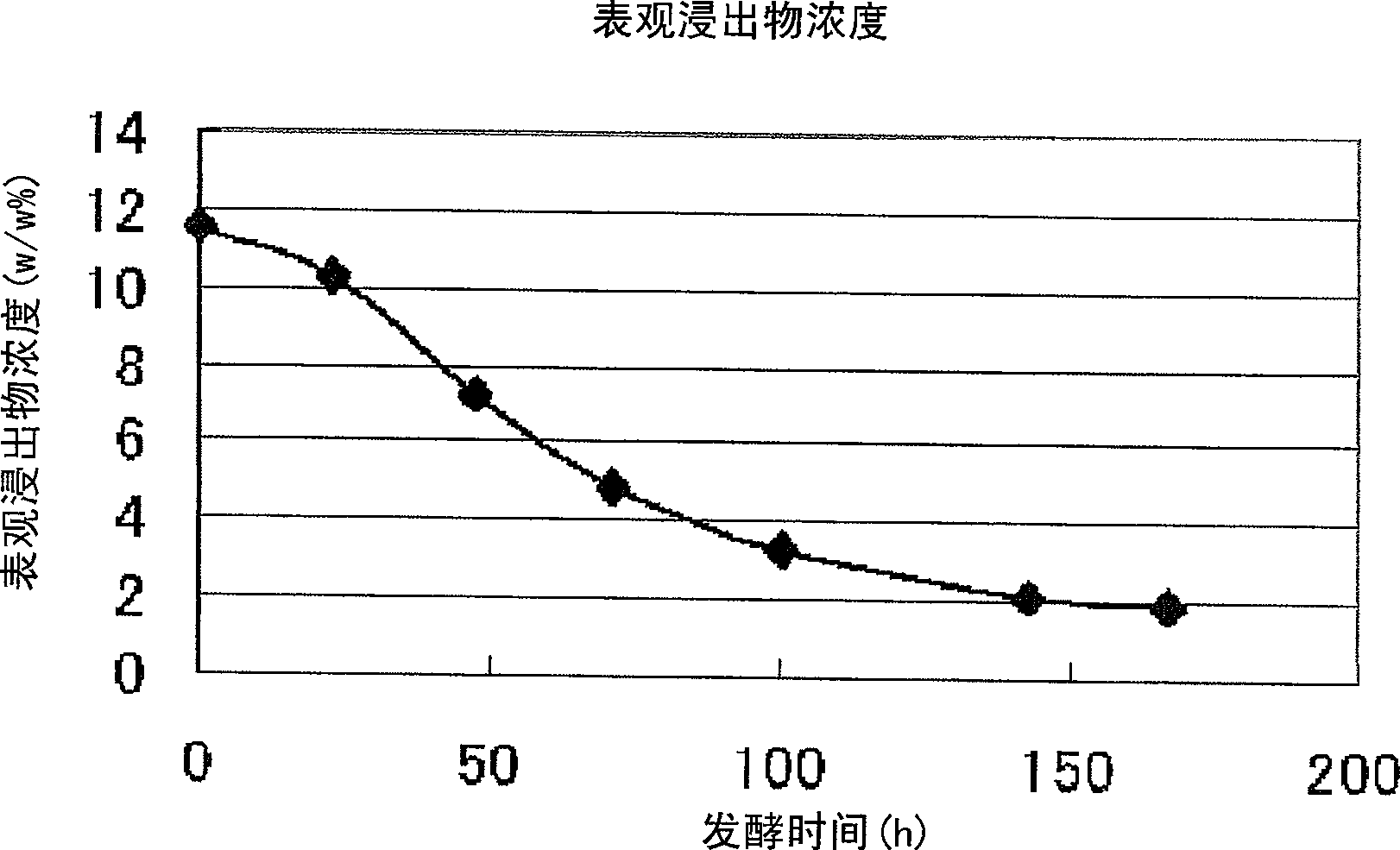

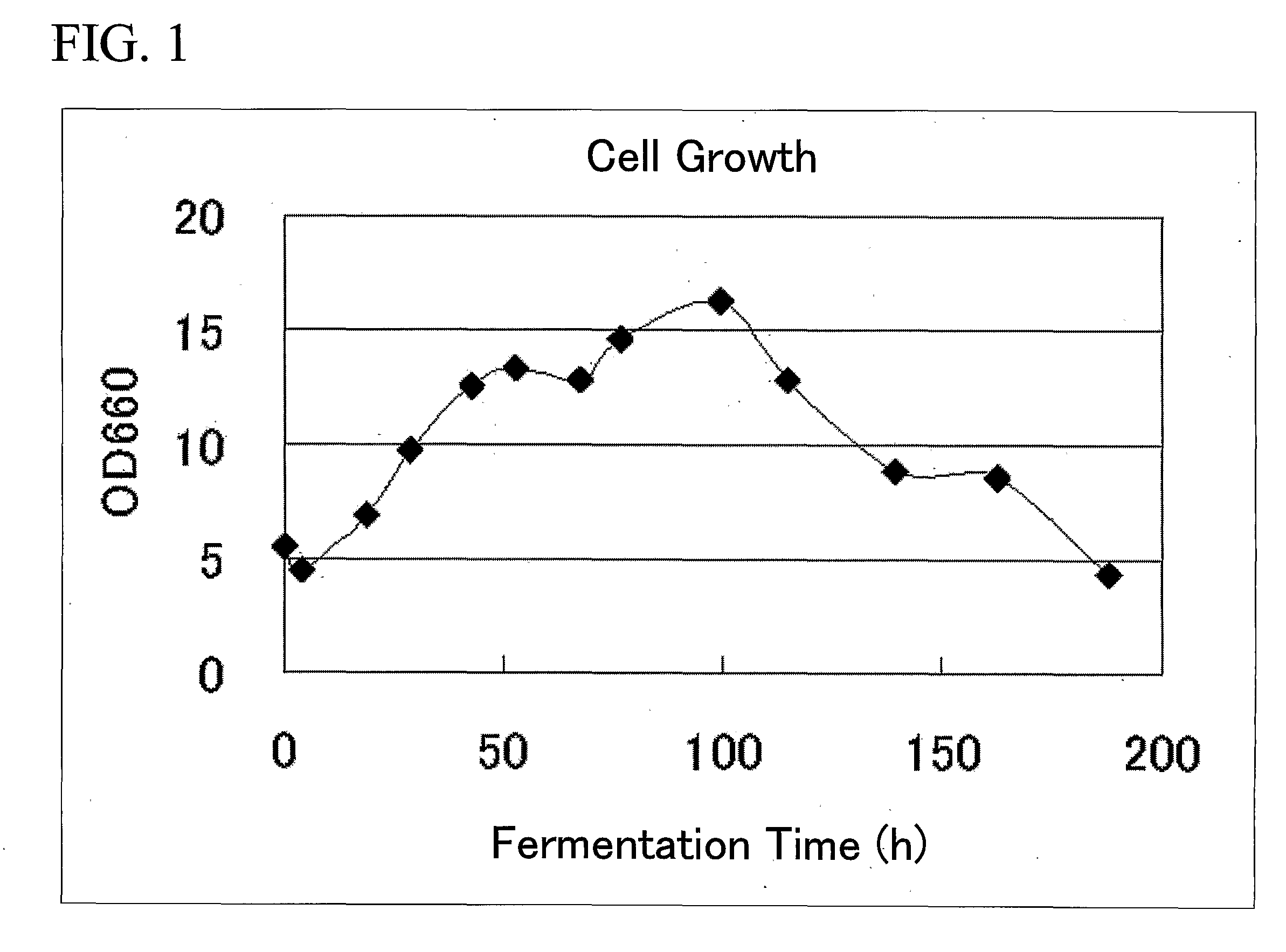

Method for identifying useful proteins of brewery yeast

InactiveCN101432427AEfficient identificationBrewing characteristics can be controlledMicrobiological testing/measurementBiological testingYeastProtein target

The invention relates to a method for identifying a useful protein of brewery yeast. More specifically, the invention relates to (a) cultivating yeast under a predetermined cultivation condition; (b) extracting a protein sample from the cultivation product of the yeast; (c) separating the protein sample by a protein separation means, selecting a target peak or spot, and recovering the target protein or a fragment thereof contained in the peak or spot; (d) determining the amino acid sequence of the target protein; (e) comparing the amino acid sequence determined in step (d) with the amino acid sequence determined in advance based on all or a part of genome sequence information of bottom fermenting yeast; (f) identifying the target protein and the gene encoding the target protein based on the results of comparison; and (g) analyzing functions of the identified gene to identify characters given to the yeast by the gene.

Owner:SUNTORY HLDG LTD

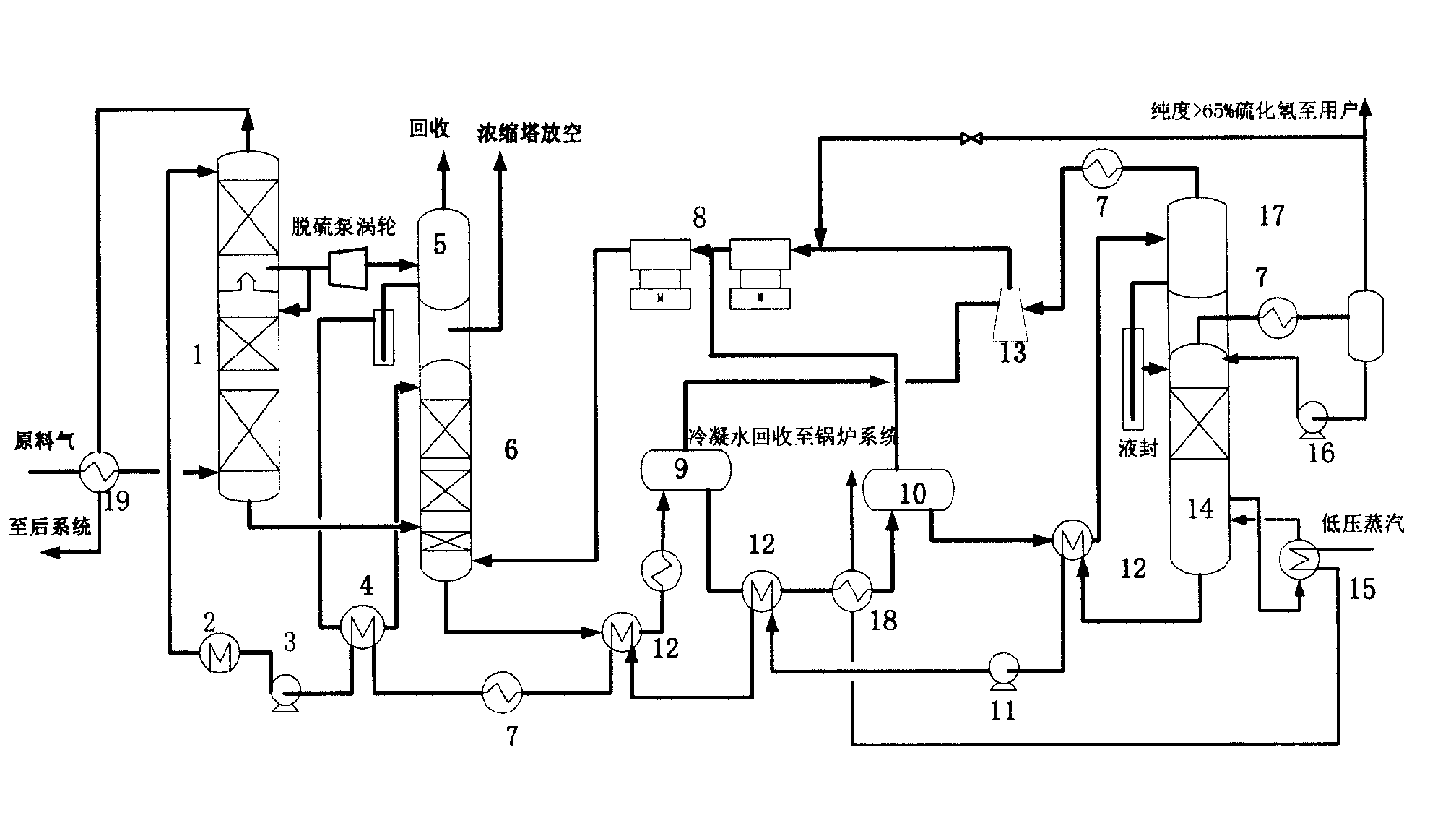

Desulfurization and decarburization integrated absorption process for polyglycol dimethyl ether

InactiveCN101492616ALess investmentSimple processCombustible gas purificationPoly(ethylene glycol) dimethyl etherTower

The invention discloses an NHD desulphurization-decarbonization absorption process. The invention is characterized in that the NHD desulphurization and decarbonization are finished in one absorption tower, systemic circulation is low, running equipment is less, and hydrogen sulphide at the outlet of the absorption tower is not more than or equal to 2ppm and CO2 index can be less than or equal to 5% according to follow-up product requirement. The concentration of the hydrogen sulphide in regenerated acid gas is over 70%, and the hydrogen sulphide can be directly used by downstream products. The invention has the advantages of simple process, reasonable energy utilization, convenient operation, low investment and small occupied space, and is suitable for the purification system for producing methanol, synthetic ammonia or other gases.

Owner:YANKUANG LUNAN CHEM FERTILIZER PLANT

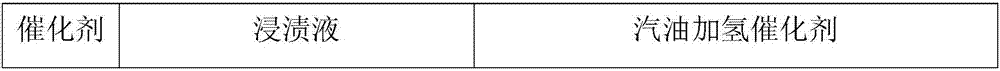

Vulcanization type gasoline hydrogenation upgrading catalyst and method for preparing same

ActiveCN107185597AEasy to introduceEasy to implementMolecular sieve catalystsCatalyst activation/preparationVulcanizationRare earth

The invention relates to a method for preparing a vulcanization type gasoline hydrogenation upgrading catalyst. Gasoline hydrogenation catalysts are treated by vulcanizing agents with multiple sulfur ions and organic nitride which is used as a passivator at the low temperatures, active components in the gasoline hydrogenation catalysts comprise a type or a plurality of types of Mo and W of VI B groups and Co and Ni of VIII B groups, and stabilizers comprise a type or a plurality of types of Zn and Cd of II B groups, Na and K of I A groups and rare earth metal La and Ce. The method has the advantages that cascade full vulcanization can be carried out on metal oxide or precursors of the metal oxide, and strong acidic sites in ZSM-5 molecular sieve composite carriers can be selectively passivated; the vulcanization type gasoline hydrogenation upgrading catalyst prepared by the aid of the method is short in on-stream time, high in hydrogenation and olefin reduction upgrading activity, selectivity, carbon deposition resistance and liquid yield and low in octane number loss, and accordingly the method and the vulcanization type gasoline hydrogenation upgrading catalyst are particularly applicable to producing clean gasoline components from inferiorly catalytically cracked gasoline by means of hydrogenation and olefin reduction upgrading at a low cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

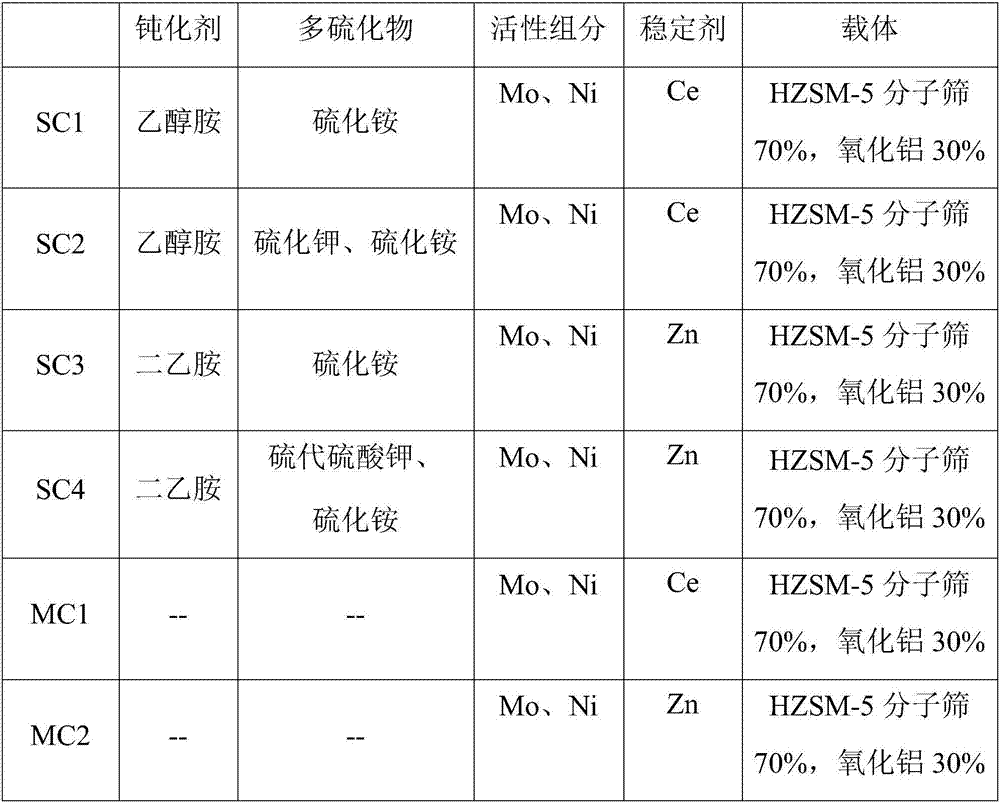

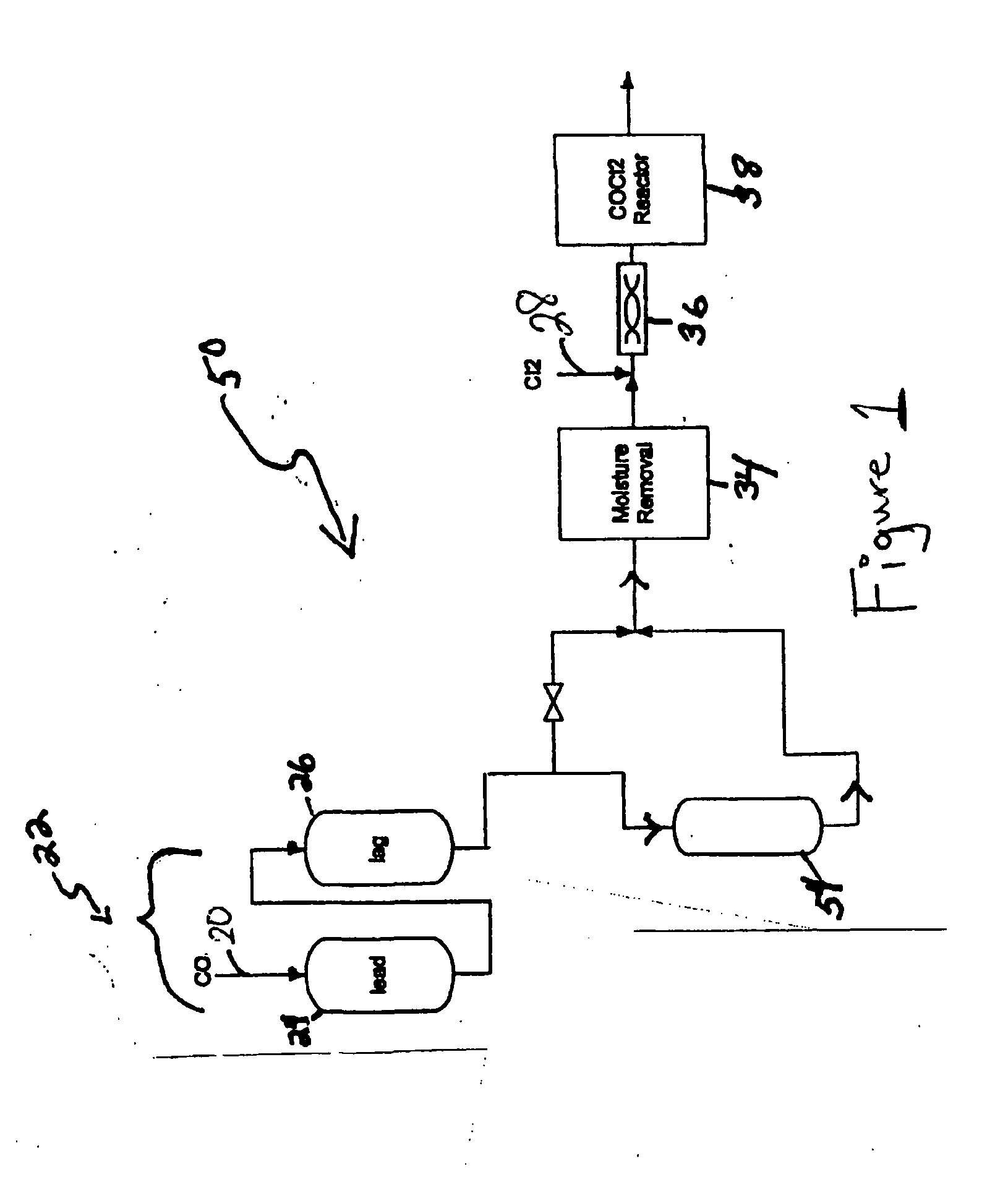

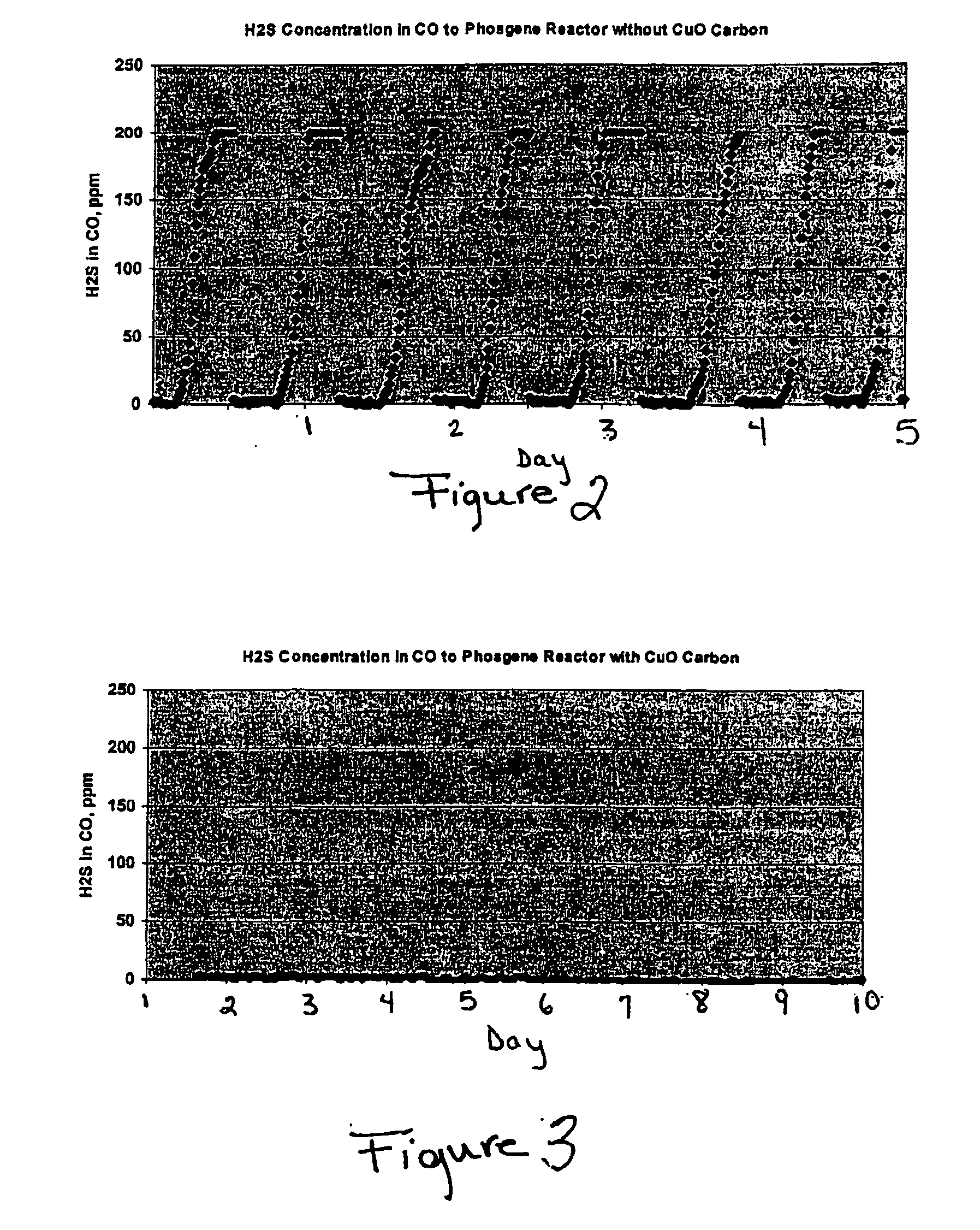

Processes and systems for making phosgene

InactiveUS20050025693A1Reduce the concentration of hydrogen sulfideOrganic compound preparationDispersed particle separationActivated carbonPhosgene

One process for producing phosgene comprises: introducing a carbon monoxide stream to a metal oxide impregnated activated carbon, reducing a hydrogen sulfide concentration in the carbon monoxide stream to produce a cleaned stream, wherein a cleaned stream hydrogen sulfide concentration is less than or equal to about 20 ppm, and reacting carbon monoxide in the cleaned stream with chlorine to produce phosgene.

Owner:SABIC GLOBAL TECH BV

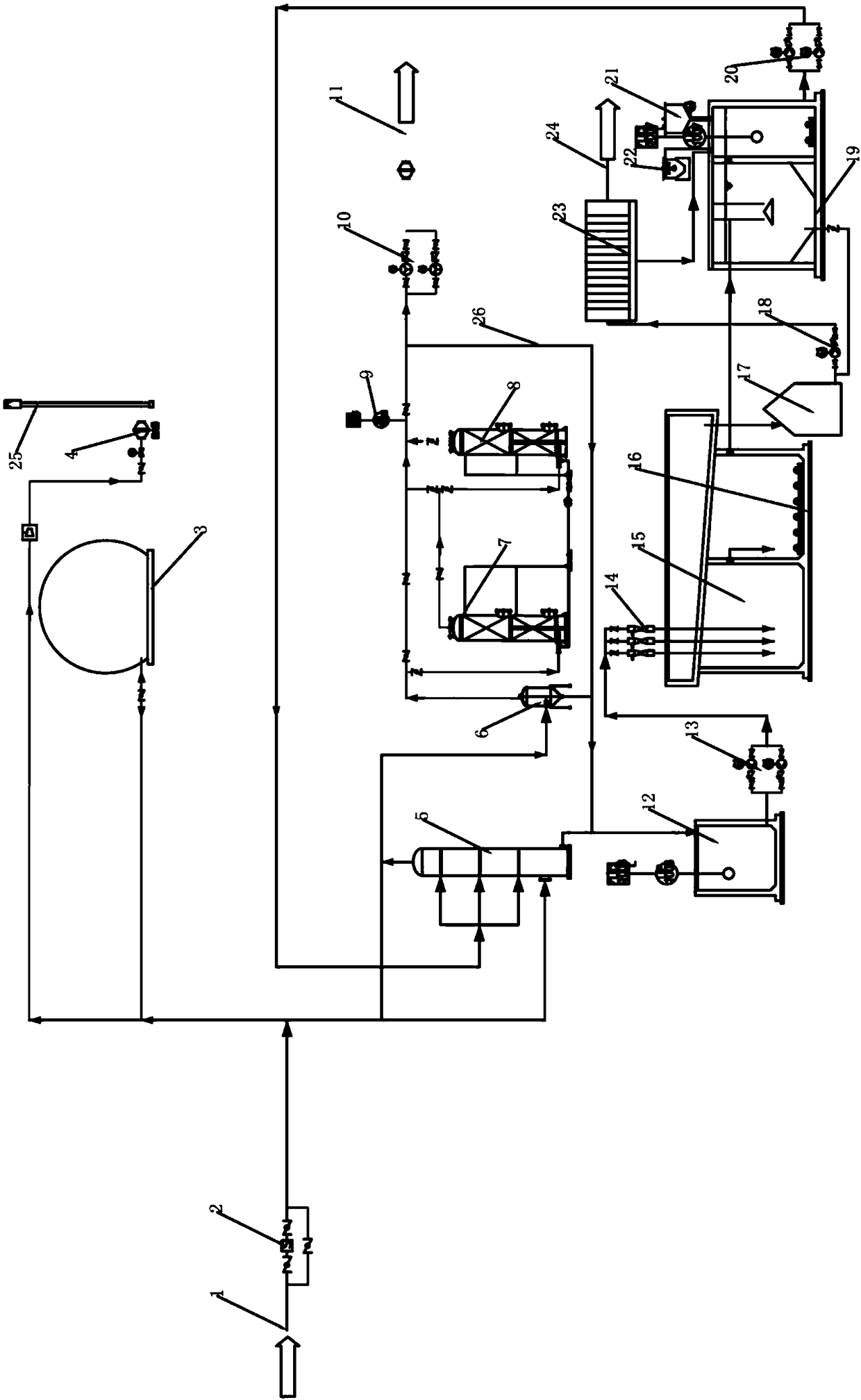

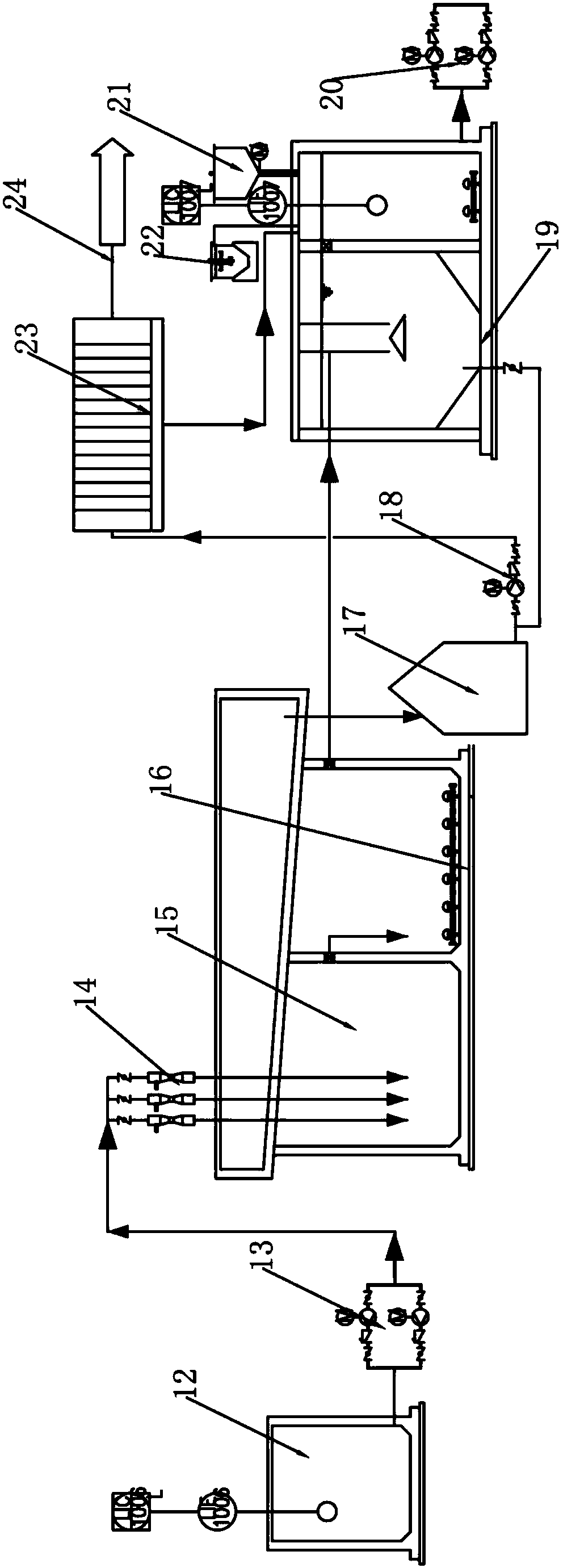

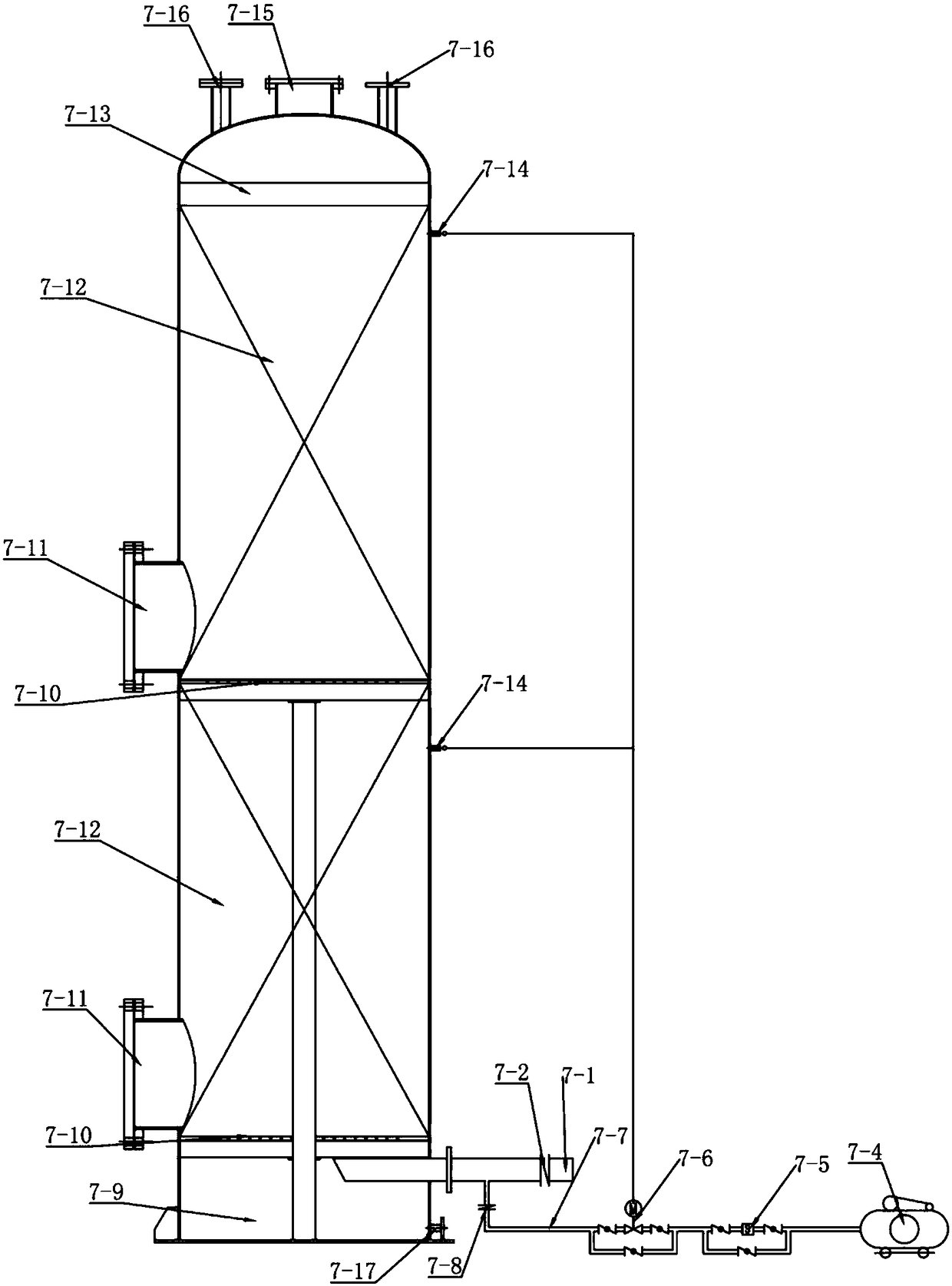

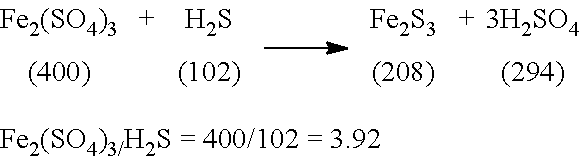

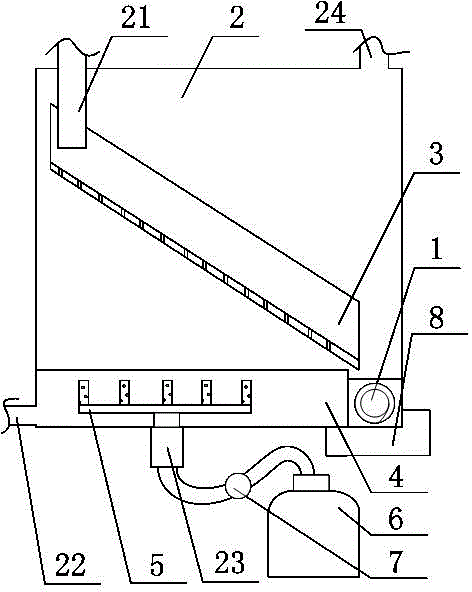

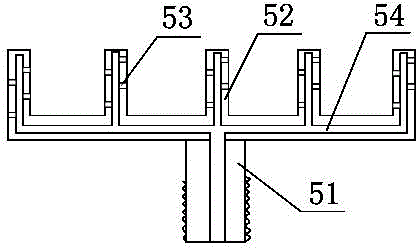

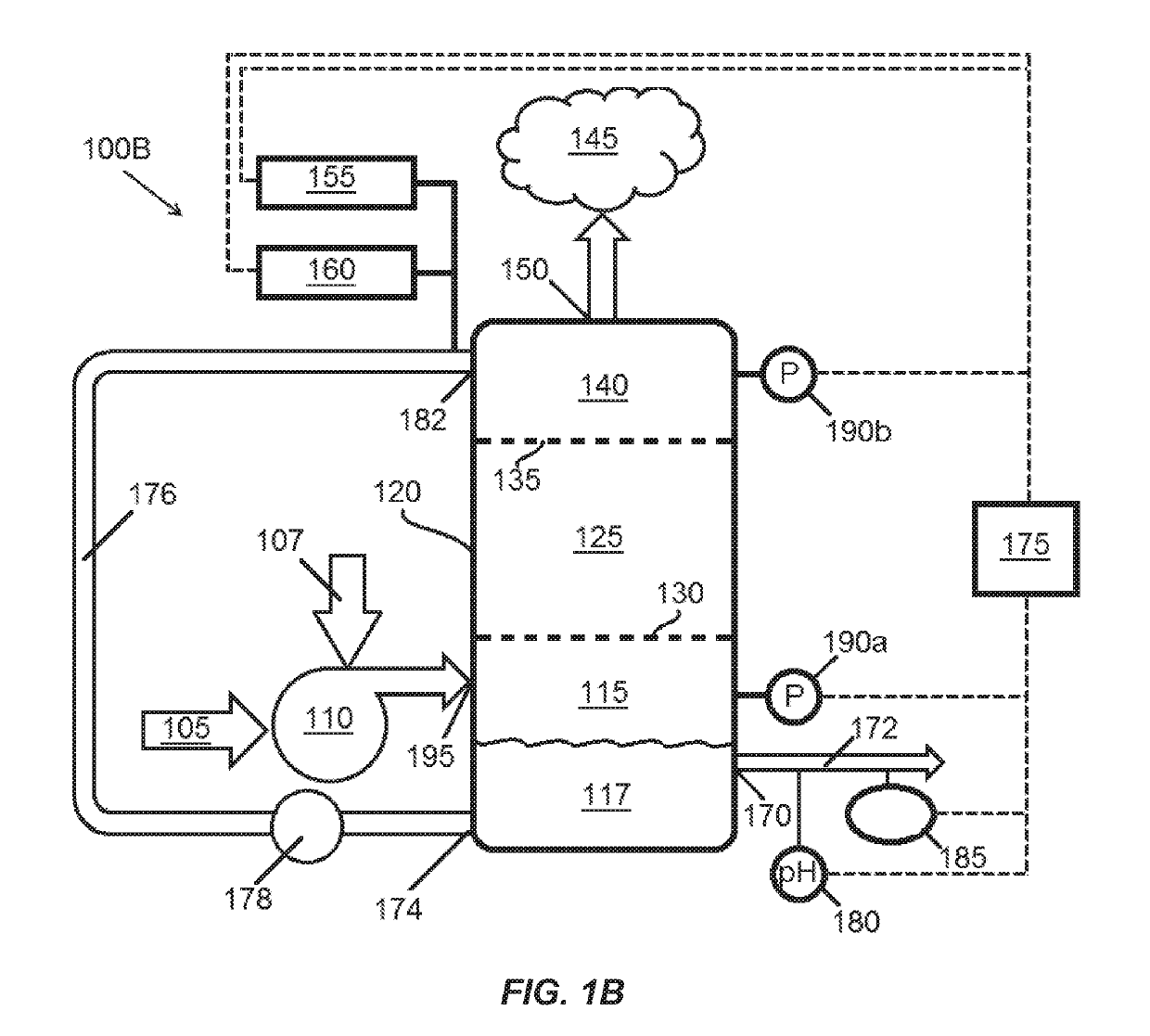

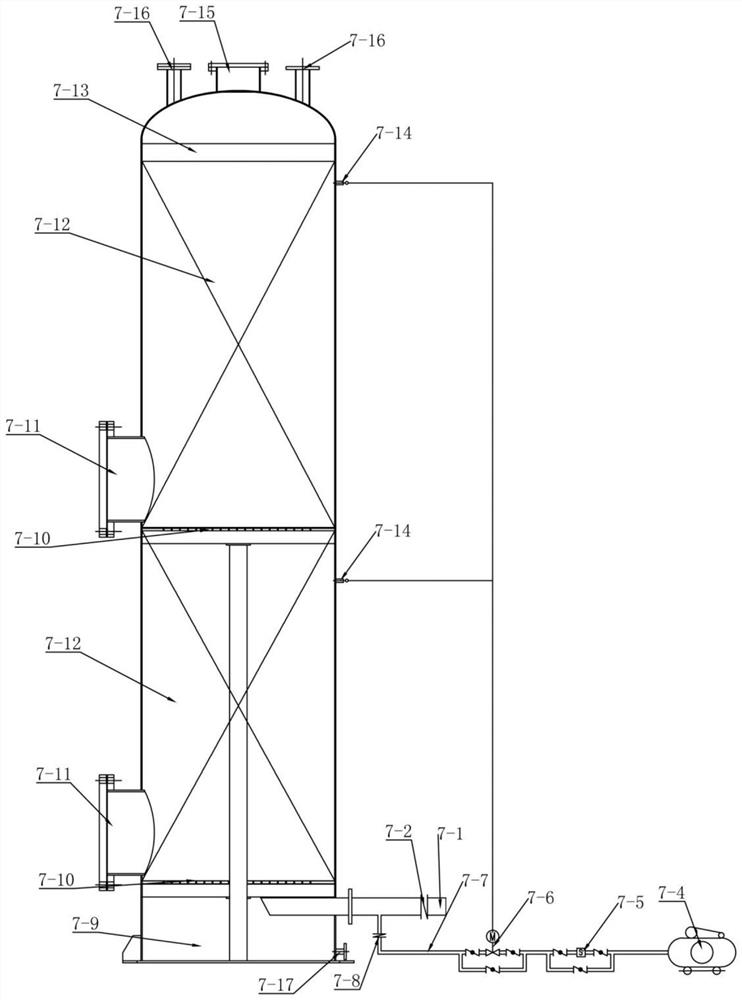

Desulfurizing system and method for biogas containing high-concentration hydrogen sulfide

ActiveCN108579373ASatisfy the utilizationReduce the concentration of hydrogen sulfideGas treatmentDispersed particle separationHigh concentrationGas detector

The invention relates to a desulfurizing system for biogas containing high-concentration hydrogen sulfide. The desulfurizing system comprises a biogas inlet, a biogas flowmeter, a biogas cabinet, a wet-process desulfurizing tower, a gas-water separator, a plurality of dry-process desulfurizing towers in serial connection or parallel connection, an outlet gas detector, a biogas fan and a biogas utilization pipeline which are sequentially communicated through biogas, and both spraying liquid after being treated by the wet-process desulfurizing tower and liquid of the gas-water separator enter adesulfurizing liquid regeneration and treatment device. The desulfurizing system combines wet-process desulfurizing with dry-process desulfurizing, and concentration of hydrogen sulfide can be loweredfrom higher than 20000ppm to below 100ppm to meet biogas energy utilization needs. the desulfurizing system is low in running cost, economic benefit can be generated utilizing biogas after being treated by the system, and generated byproducts can be sold as goods, so that many things are achieved at one stroke.

Owner:华夏碧水环保科技股份有限公司

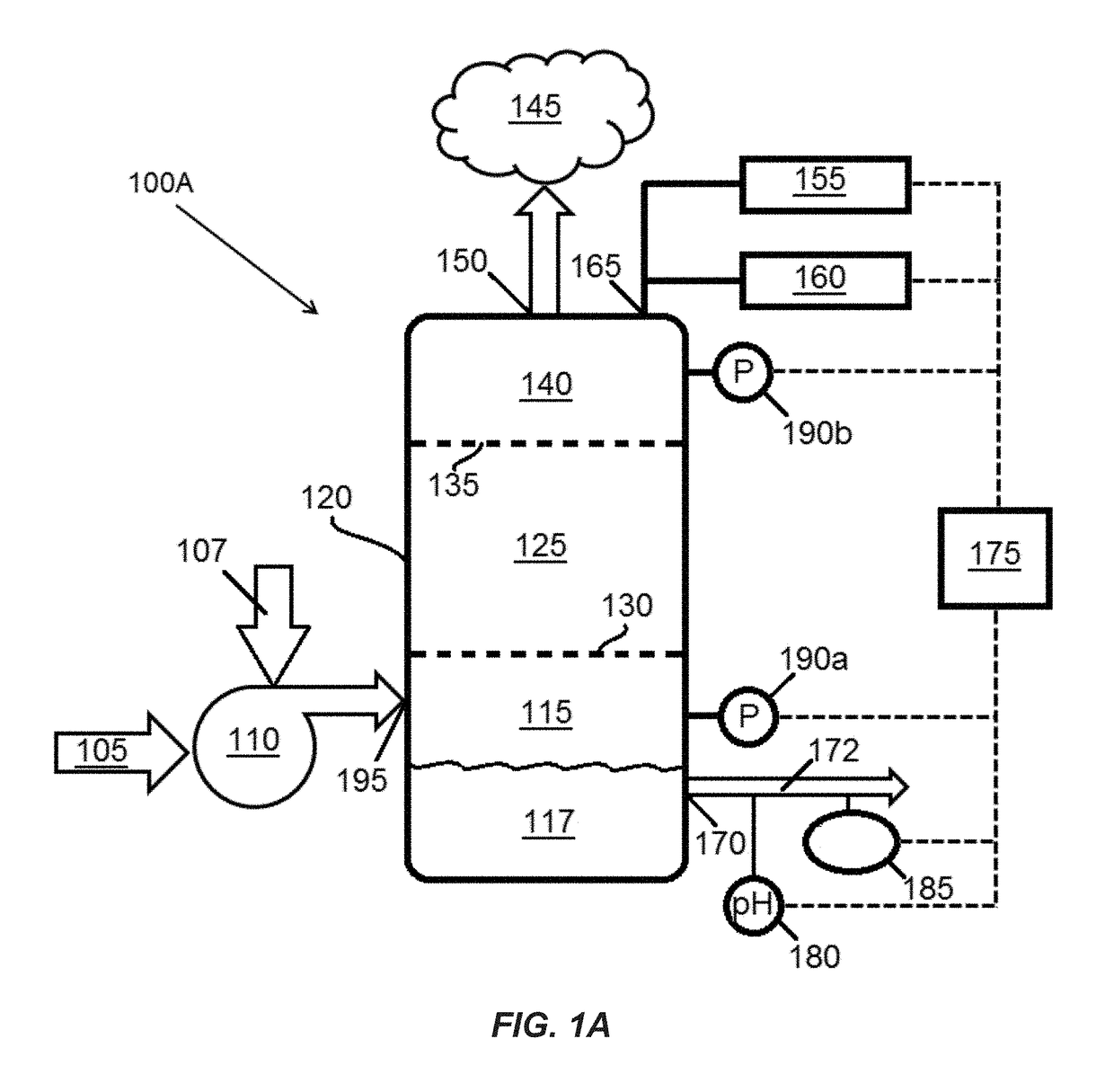

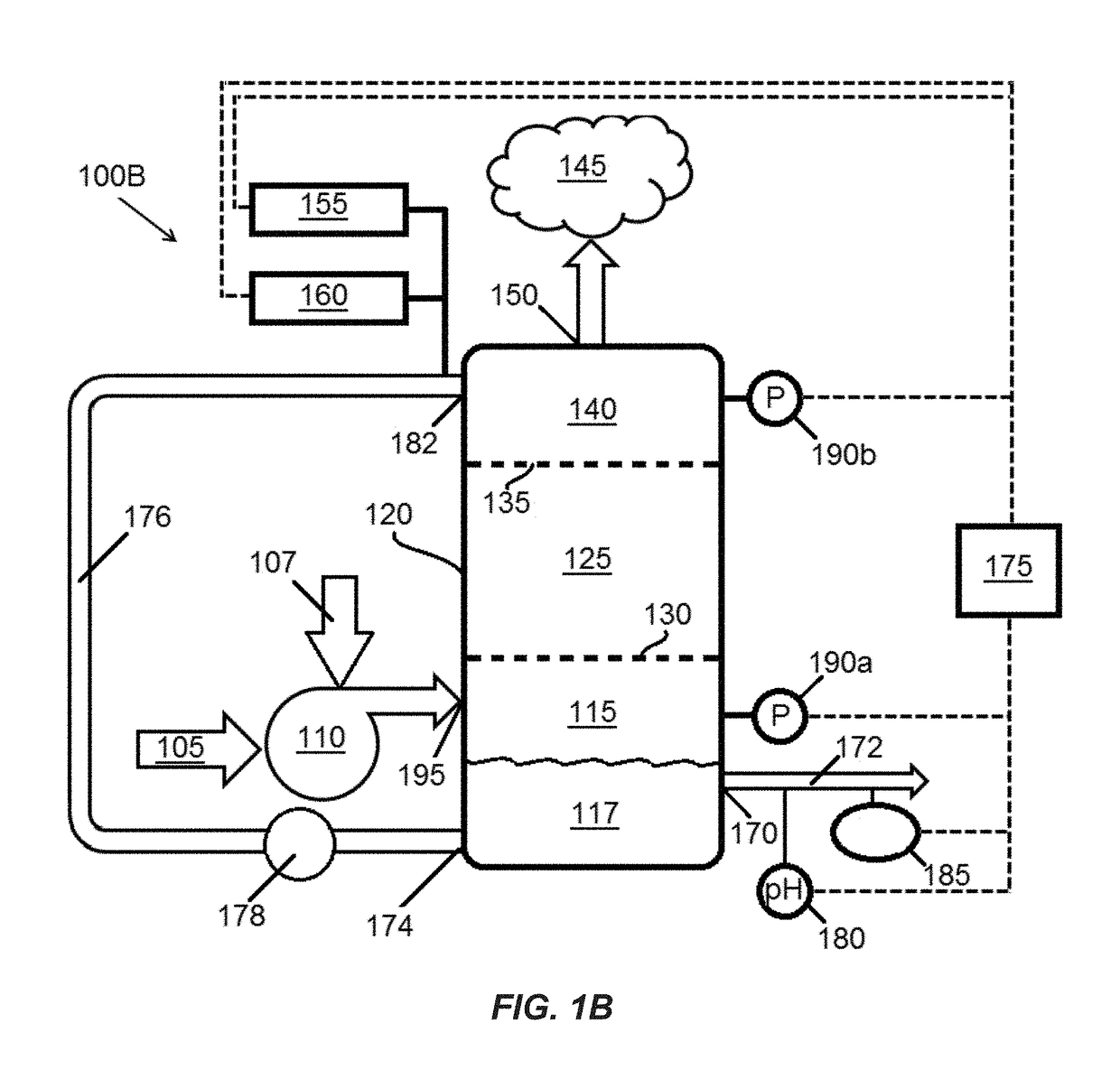

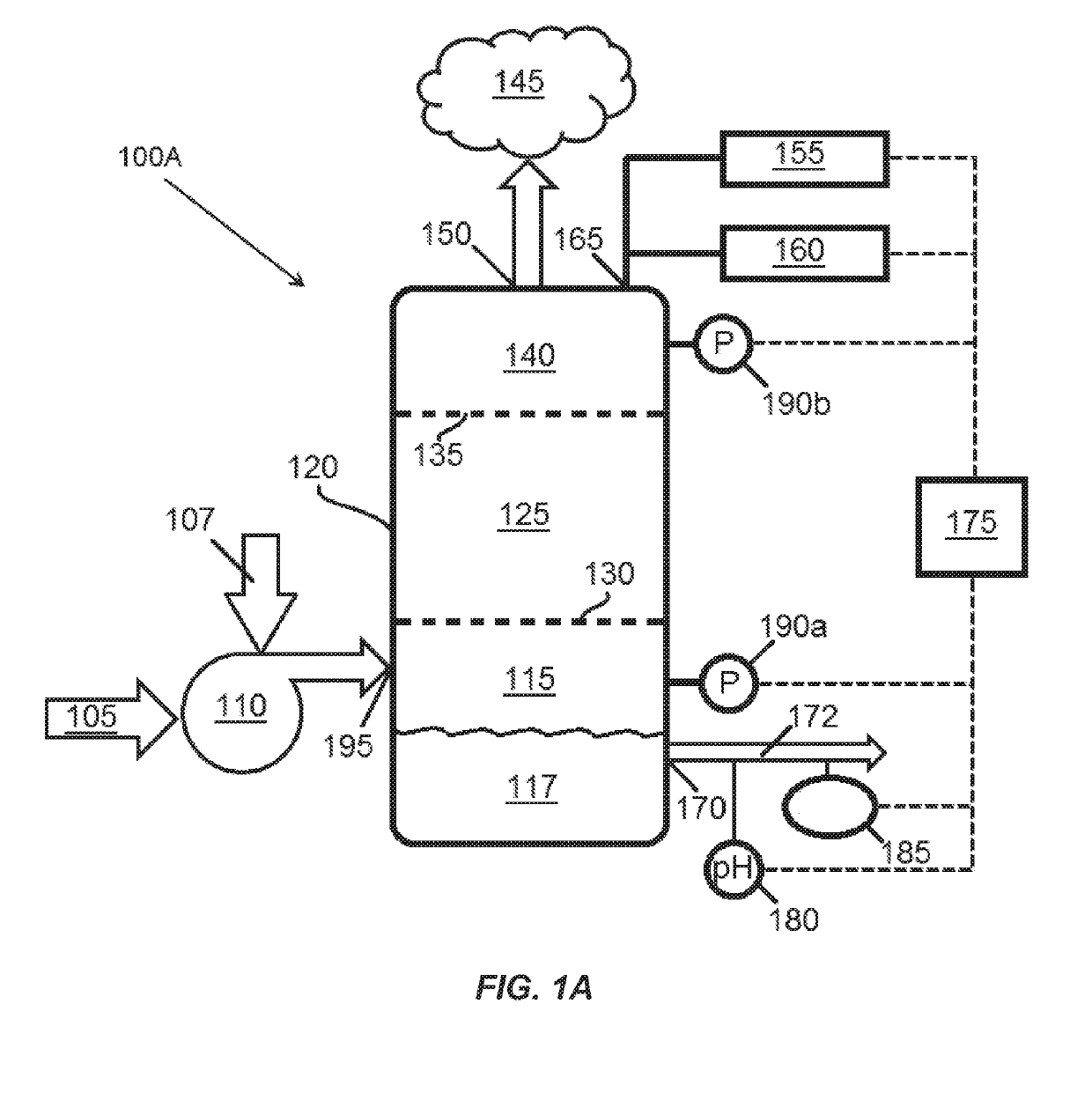

Odor abatement of organic waste

InactiveUS20110044927A1Reduce the concentration of hydrogen sulfideOffensive toxicGas treatmentSpecific water treatment objectivesOrganic matterCopper

The present invention relates to a system and a method of abating hydrogen sulfide gas emitted by or generated by organic matter. Certain embodiments of the present invention relate to contacting hydrogen sulfide gas with metals such as copper, iron, zinc, silver or mixtures thereof, and other components. Other embodiments of the present invention relate to contacting hydrogen sulfide gas with a solution of metals such as copper, iron, zinc or mixtures thereof, and other components.

Owner:ACETO CHEM

Combined method for sulfur production, hydrogen production and low-sulfur desorbed gas production by coal gas

InactiveCN102180444ASmall sizeMass transfer theory has few stagesHydrogen separation using solid contactChemical industryProcess integrationCombined method

A combined method for sulfur production, hydrogen production and low-sulfur desorbed gas production by coal gas. Raw coal gas and a semi-lean solvent are separated into cleaned coal gas and a rich solvent after completing counterflow contact for absorbing hydrogen sulfide in a first gas-liquid mass-transfer segment, and the hydrogen sulfide absorbed by the rich solvent is transformed into elemental sulfur in a solvent regeneration part; the cleaned coal gas serially passes through a carbon monoxide transformation hydrogen production process, a first pressure swing absorption part and a second pressure swing absorption part to obtain a first desorbed gas rich in hydrogen sulfide, a highly-pure hydrogen gas, and a second desorbed gas low in hydrogen sulfide; the first desorbed gas and a lean solvent from the solvent regeneration part are separated into a first desorbed gas cleaned gas and a recyclable semi-lean solvent after completing counterflow contact for absorbing hydrogen sulfide in a second gas-liquid mass-transfer segment. The invention belongs to a process integration method, has the advantages of simple process flow, high total sulfur removal rate, high-efficient operation of each step and the like, and is especially suitable for the process of producing crude gas by semi-coke units.

Owner:何巨堂

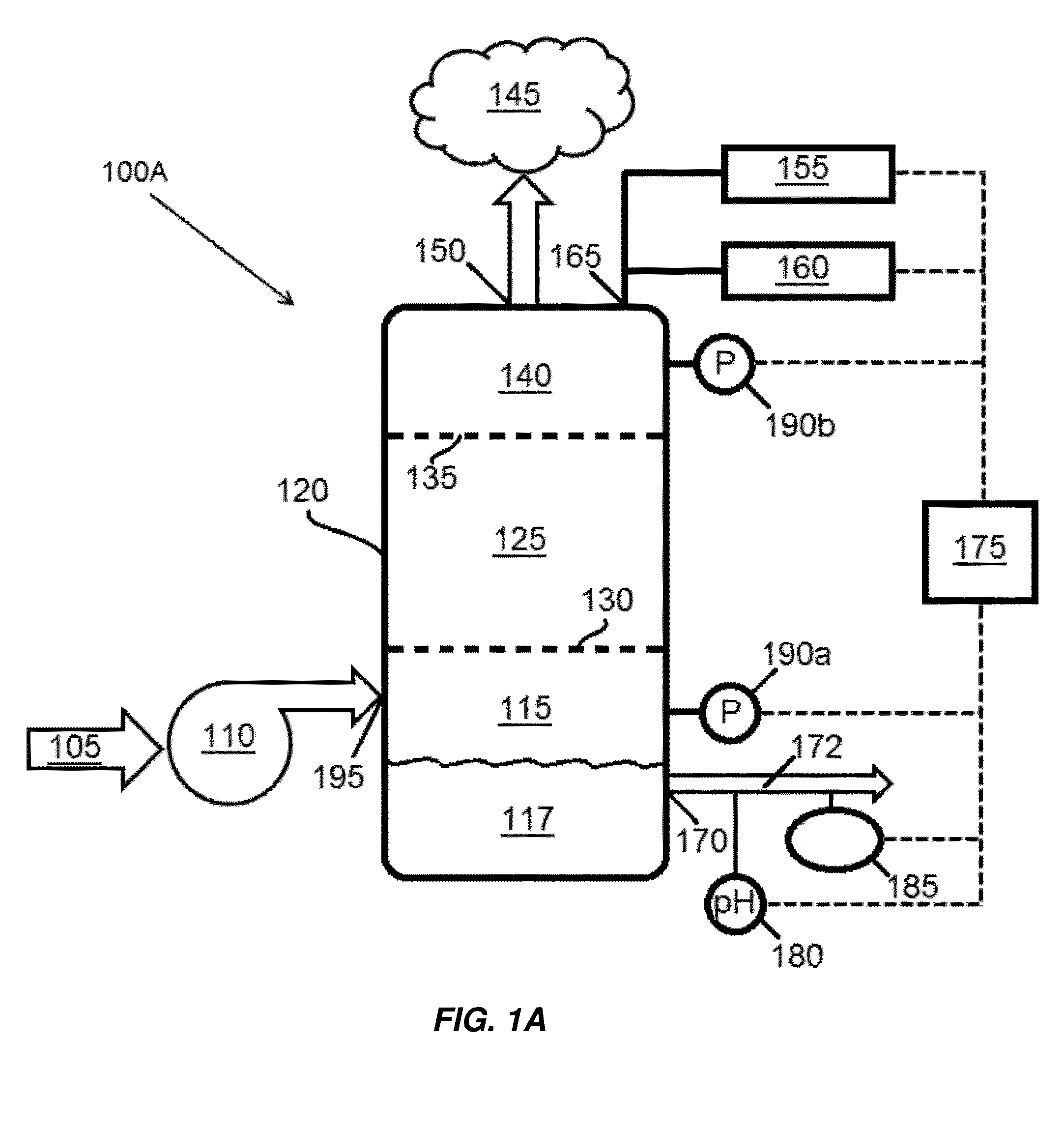

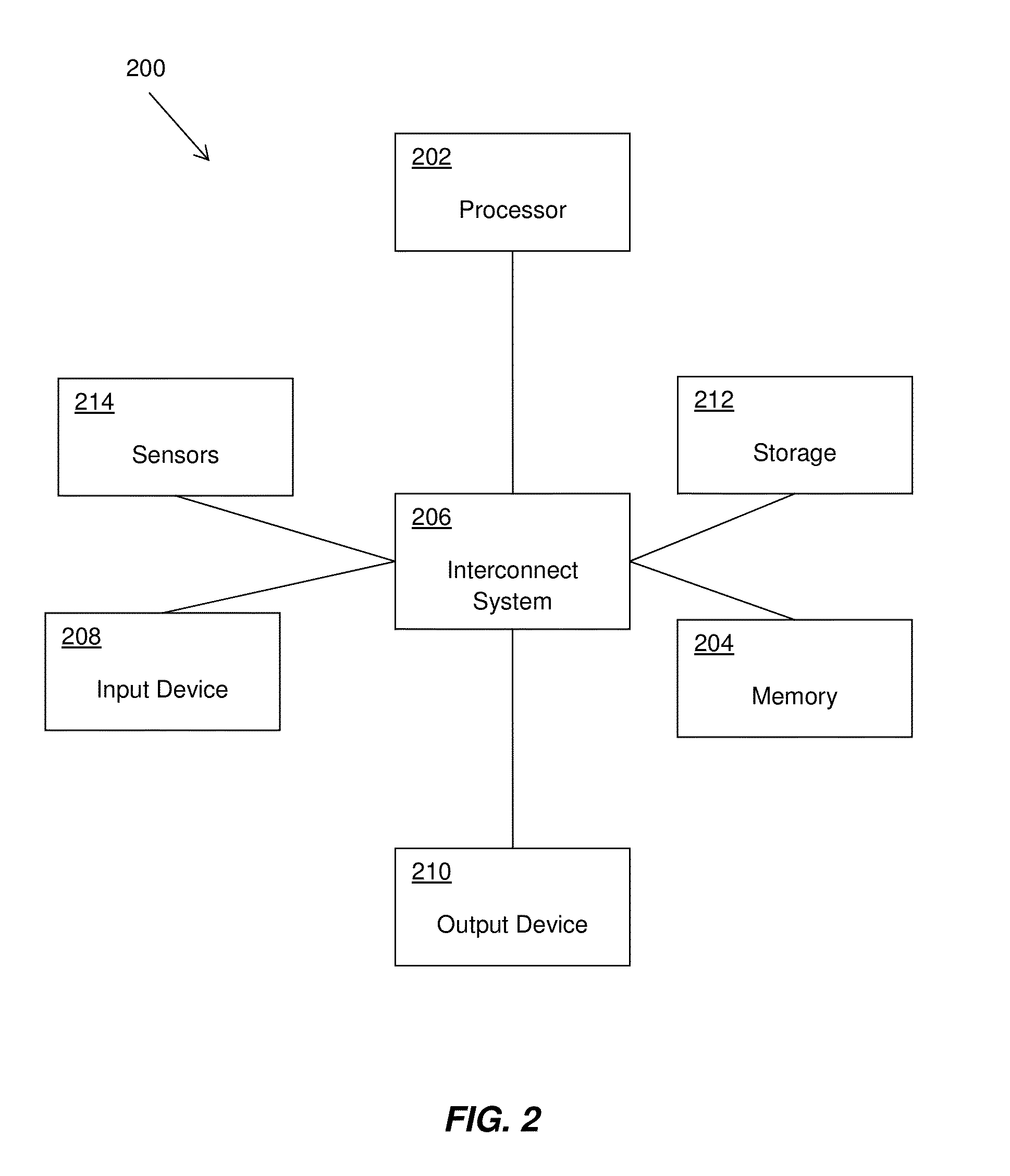

Use of porous glass media for a biofilter to remove odorous compounds from an air stream

ActiveUS10159932B2Reduce the concentration of hydrogen sulfideReduce concentrationGas treatmentDispersed particle separationPorous mediumBiological filter

A system for removing undesirable compounds from contaminated air includes a biofilter having porous glass media. Hydrogen sulfide is removed from contaminated air by passing the contaminated air through the biofilter.

Owner:EVOQUA WATER TECH LLC

A kind of kitchen garbage two-phase anaerobic fermentation method

ActiveCN103695472BReduce outputImprove organic degradation rateBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationSlurry

The invention relates to the kitchen waste treatment field, in particular to a two-phase anaerobic fermentation method for kitchen waste. The two-phase anaerobic fermentation method for kitchen waste includes the steps of: 1) sending leached oil water into a grease separation system to undergo grease separation, recovering the separated grease, and carrying the separated wastewater and the kitchen waste conveyed by a lifting screw conveyor to a crushing separation system; 2) carrying out crushing and separation; 3) conducting hydrolytic acidification; 4) inputting the waste slurry subjected to hydrolytic acidification in a hydrolysis tank into a heat exchanger, performing heating, then sending the waste slurry into a fermentation tank to undergo anaerobic fermentation; 5) conducting re-fermentation, and subjecting biogas to desulfurization treatment; and 6) recovering biogas residue and biogas. The method provided by the invention applies the two-phase anaerobic technology to the kitchen waste industry, and can effectively avoid the easy acidification phenomenon of high concentration organic waste anaerobic fermentation. The multifunctional tank integrating gas production, gas storage and desulfurization is adopted in the invention, and the gas production efficiency is improved.

Owner:北京时代桃源环境科技股份有限公司

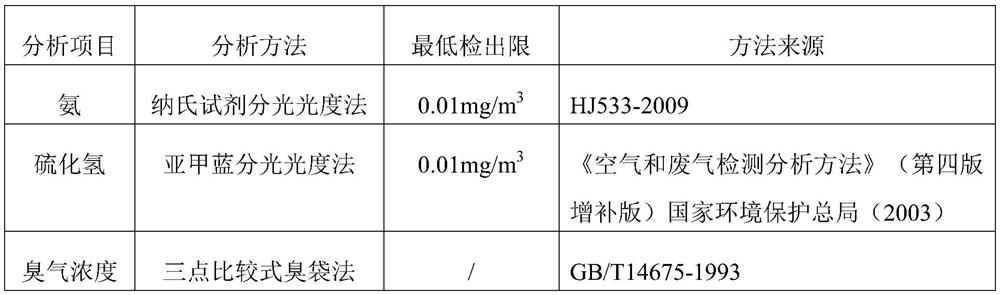

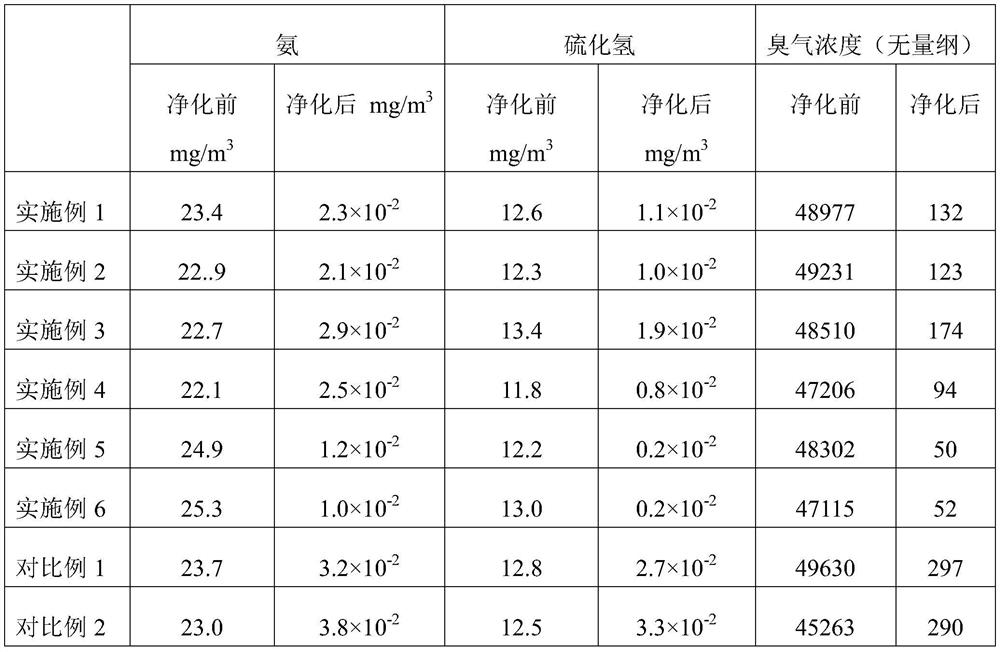

A kind of nano air deodorizing purification liquid and preparation method thereof

ActiveCN111203087BReduce ammonia concentrationEasy to deodorizeGas treatmentDispersed particle separationAir decontaminationAmmonia

The invention provides a nanometer air deodorizing and purifying liquid and a preparation method thereof. The nanometer air deodorizing and purifying liquid comprises, by weight, 25-35 parts of nanometer titanium dioxide, 23-28 parts of corn polypeptide, 8-12 parts of nanometer calcium peroxide, 8-12 parts of a dispersant and 13-36 parts of water. According to the nanometer air deodorizing and purifying liquid, the size effect, the quantum effect, the interface effect and the tunnel effect among different components are reasonably applied, and the remarkable deodorization effect is achieved. After ammonia is treated by the air purifying liquid, the ammonia concentration is as low as 0.01 mg / m<3>, the hydrogen sulfide concentration is as low as 0.002 mg / m<3>, and the odor concentration is as low as 118. The raw materials are easy to obtain, the cost is low, the deodorization effect is remarkable, the preparation method is simple and convenient, and industrial application and promotion are facilitated.

Owner:海南保斯绿环保科技有限公司

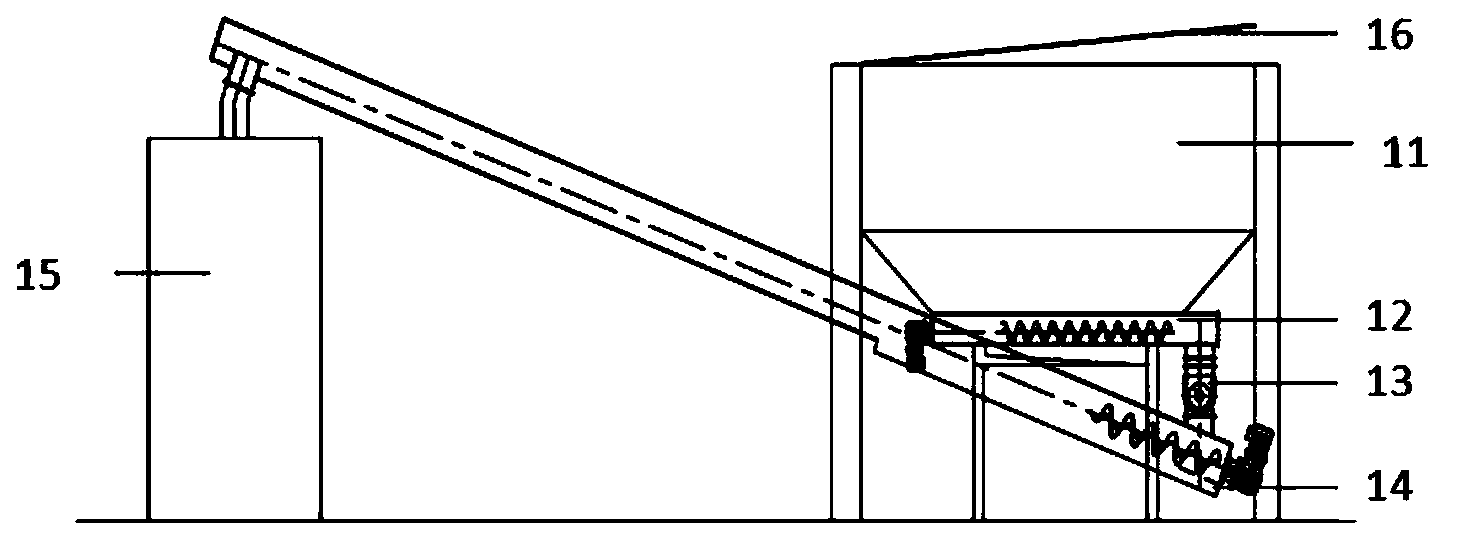

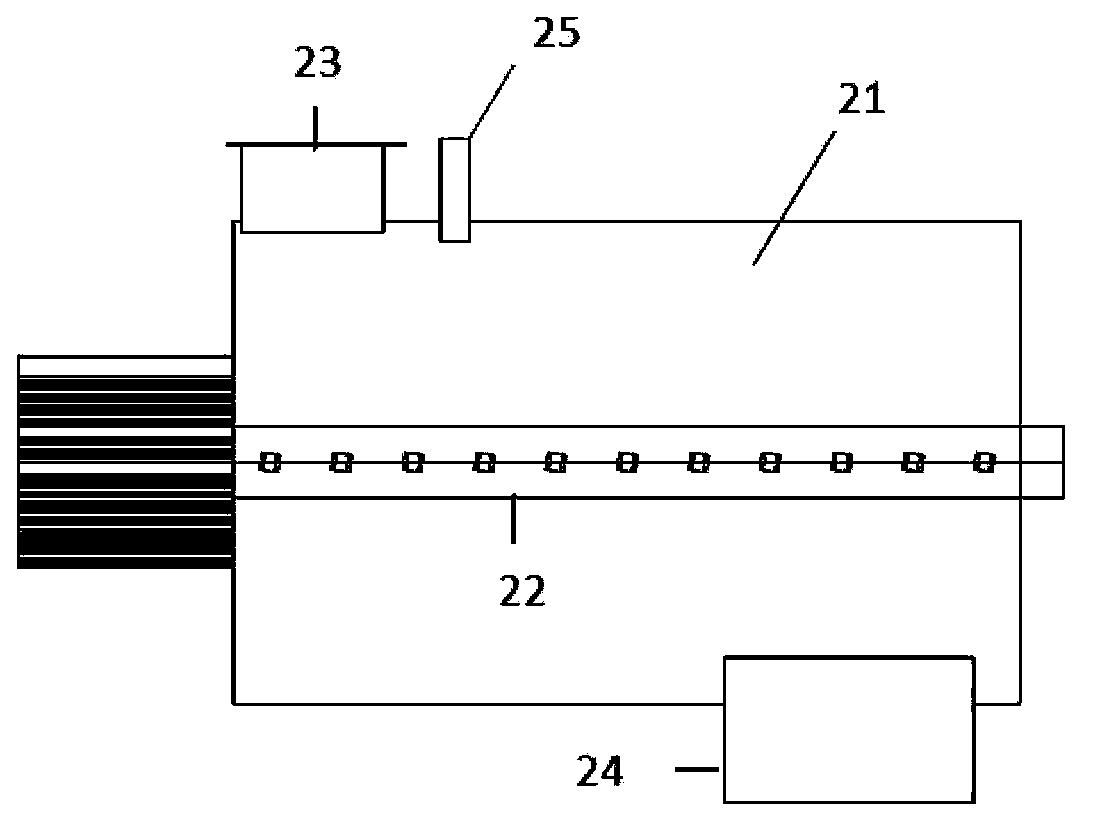

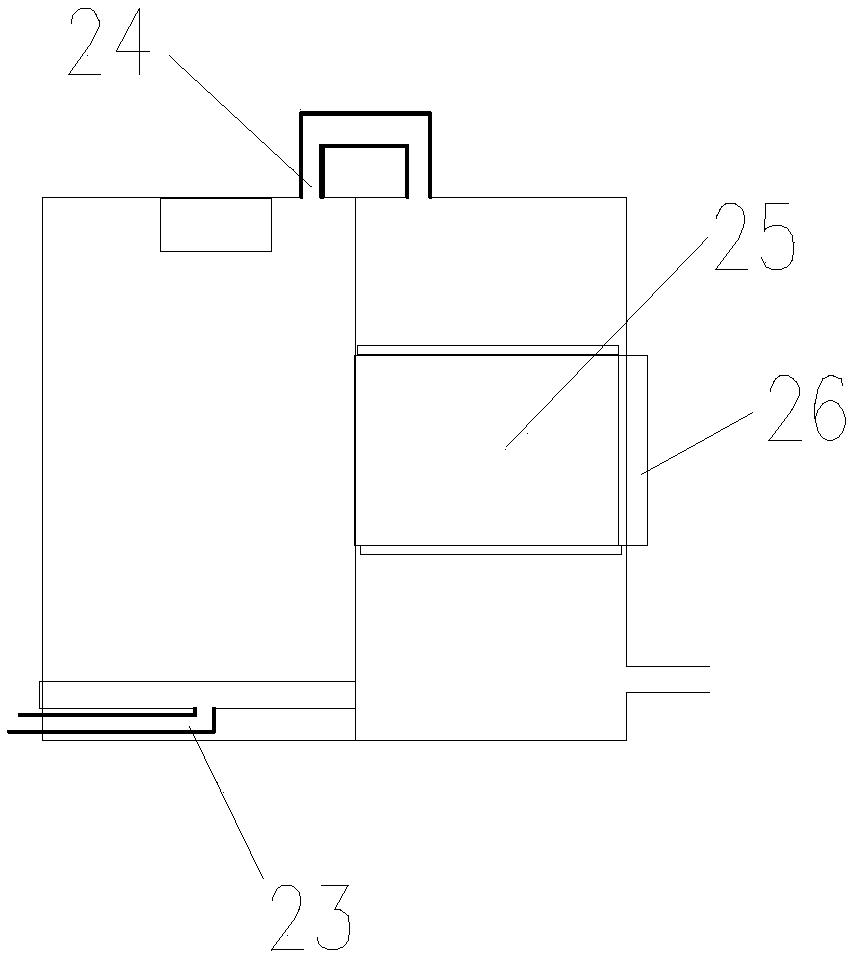

Sieving precipitation method for hydrogen sulfide gas in sulfur-containing drilling fluid

InactiveCN104653132AReduce the concentration of hydrogen sulfideReduce poisoning incidentsFlushingInert gas productionScrapProcess engineering

The invention discloses a sieving precipitation method for hydrogen sulfide gas in a sulfur-containing drilling fluid. The sieving precipitation method comprises the following steps: (1) enabling slurry to enter a closed tank through a feeding hole, and sieving the slurry into a recycling serous fluid and waste particles through a sieving net in the closed tank; enabling the sieved recycling serous fluid to enter a collection pool, and discharging the waste particles out of the closed tank through a screw chip conveyor; (2) stirring the recycling serous fluid flowing into the collection pool by a stirring device, and during the stirring process, conveying gas into the collection pool through a gas inlet passage on the stirring device, wherein the inflated gas is used for replacing the hydrogen sulfide gas in the recycling serous fluid, and the gas mixed with hydrogen sulfide flows out through a gas outlet pipe at the top end of the closed tank; (3) discharging the flowing gas into the atmosphere or returning the flowing gas into the collection pool through the gas inlet passage on the stirring device after the hydrogen sulfide gas in the gas is removed. The sieving precipitation method has the advantages of safe operation, environmental protection, cost reduction, good sulfur removal effect and the like.

Owner:SICHUAN XILIN OIL SUPPLIES EQUIP

Use of porous glass media for a biofilter to remove odorous compounds from an air stream

ActiveUS20190134562A1Reduce the concentration of hydrogen sulfideReduce concentrationGas treatmentDispersed particle separationBiological filterBiofilter

A system for removing undesirable compounds from contaminated air includes a biofilter having porous glass media. Hydrogen sulfide is removed from contaminated air by passing the contaminated air through the biofilter.

Owner:EVOQUA WATER TECH LLC

Biogas production device and method

PendingCN108795714AHigh outputHigh activityBioreactor/fermenter combinationsBiological substance pretreatmentsBiogas productionTower

The invention discloses a biogas production device and method. The biogas production device comprises a biogas fermentation device, a desulfurization device, a decarbonation device and a dehydration device, wherein the biogas fermentation device is communicated with a primary inlet separator, a primary compressor is communicated with the primary inlet separator, a secondary compressor is communicated with the primary compressor, a secondary inlet separator is communicated with the secondary compressor, and the desulfurization device is communicated with the secondary inlet separator; the desulfurization device, the dehydration device and the decarbonation device are sequentially communicated; the biogas fermentation device is composed of a preprocessing heating tank, a primary anaerobic fermentation gas production tank and a secondary anaerobic fermentation gas production tank to enhance activity of anaerobic bacteria and uniformly mix the raw materials and the anaerobic bacteria, thereby increasing the biogas yield; the desulfurization device performs dry and wet combined desulfurization, and desulfurizer is connected with a desulfurization tower through a storage bucket and is convenient to replace; two-stage dehydration modules are applied to achieve more thorough dehydration.

Owner:扬州永清新能源发展有限公司

Preparation method of sulfurized gasoline hydro-upgrading catalyst

ActiveCN107185597BImplementation importAchieve selective passivationMolecular sieve catalystsCatalyst activation/preparationVulcanizationRare earth

The invention relates to a method for preparing a gasoline hydrogenation modification catalyst, which uses a polysulfide ion sulfurizing agent containing an organic nitrogen compound as a passivating agent to treat the gasoline hydrogenation catalyst at low temperature, wherein the active component in the gasoline hydrogenation catalyst is the third One or more of Group VIB Mo, W or Group VIIIB Co, Ni, the stabilizer is one or more of Group IIB Zn, Cd or Group IA Na, K or rare earth metal La, Ce, This achieves stepwise complete sulfidation of metal oxides or their precursors and selective passivation of strongly acidic sites in the ZSM-5 molecular sieve composite carrier. The sulfurized gasoline hydrogenation modification catalyst prepared by the invention has the advantages of short start-up time, high hydrogenation olefin modification activity and selectivity, strong carbon deposition resistance, small octane number loss and high liquid yield, and It is especially suitable for low-cost hydrogenation and olefin reduction modification of inferior catalytic cracking gasoline to produce clean gasoline components.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A kind of multifunctional base modifier and preparation method thereof

ActiveCN104891669BNo drug resistanceImprove the ecological environmentClimate change adaptationPisciculture and aquariaWater transparencyAmmonium nitrate

The invention discloses a multifunctional base modifier and a preparation method thereof. The multifunctional bottom modifier includes: peanut shell powder, peanut antimicrobial peptide, peanut water-soluble dietary fiber, tea polysaccharide, diatomaceous earth, xanthan gum, cerium ammonium nitrate, zeolite powder, Bacillus pumilus, Bacillus subtilis, swamp red Pseudomonas, Lactobacillus plantarum, Saccharomyces cerevisiae. Preparation method: cerium ammonium nitrate and xanthan gum are catalyzed by microwaves to make xanthan gum polysaccharide-cerium complex; mix it with diatomite, Bacillus pumilus, Bacillus subtilis, Rhodopseudomonas palustris, Lactobacillus plantarum , beer yeast to make microcapsule preparation; peanut shell powder, peanut antibacterial peptide, peanut water-soluble dietary fiber, tea polysaccharide, microcapsule preparation and zeolite powder are mixed and granulated. The multi-functional bottom modifier has the functions of adsorbing heavy metals, degrading pesticide residues and drug residues, resisting harmful bacteria and viruses, degrading organic matter, reducing the concentration of ammonia nitrogen, nitrite, and hydrogen sulfide in water and bottom, improving bottom quality, and improving water transparency. Function.

Owner:沧州旺发生物技术研究所有限公司

Desulfurization and decarburization integrated absorption process for polyglycol dimethyl ether

InactiveCN101492616BLess investmentSimple processDispersed particle separationCombustible gas purificationPoly(ethylene glycol) dimethyl etherTower

The invention discloses an NHD desulphurization-decarbonization absorption process. The invention is characterized in that the NHD desulphurization and decarbonization are finished in one absorption tower, systemic circulation is low, running equipment is less, and hydrogen sulphide at the outlet of the absorption tower is not more than or equal to 2ppm and CO2 index can be less than or equal to 5% according to follow-up product requirement. The concentration of the hydrogen sulphide in regenerated acid gas is over 70%, and the hydrogen sulphide can be directly used by downstream products. The invention has the advantages of simple process, reasonable energy utilization, convenient operation, low investment and small occupied space, and is suitable for the purification system for producing methanol, synthetic ammonia or other gases.

Owner:YANKUANG LUNAN CHEM FERTILIZER PLANT

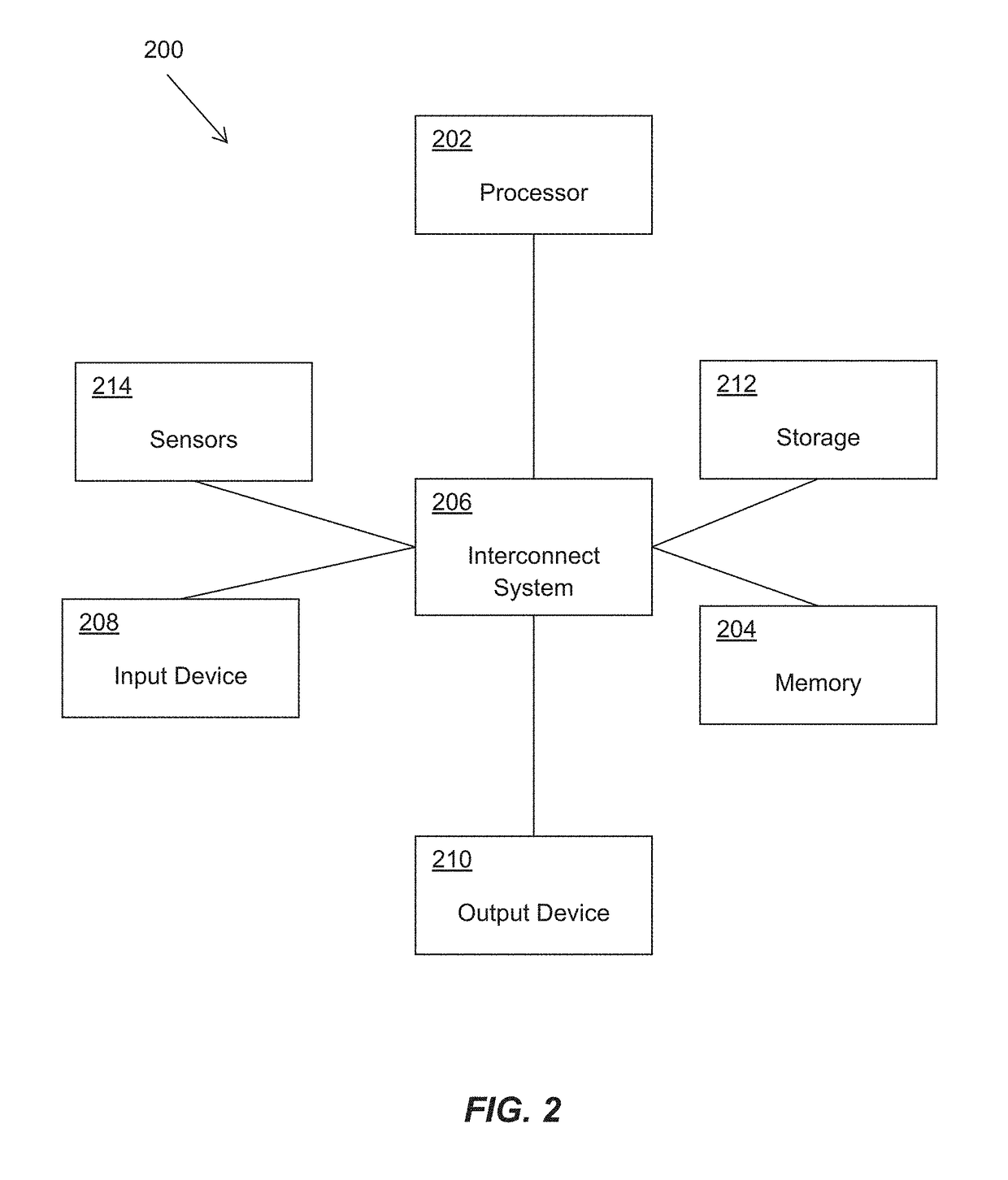

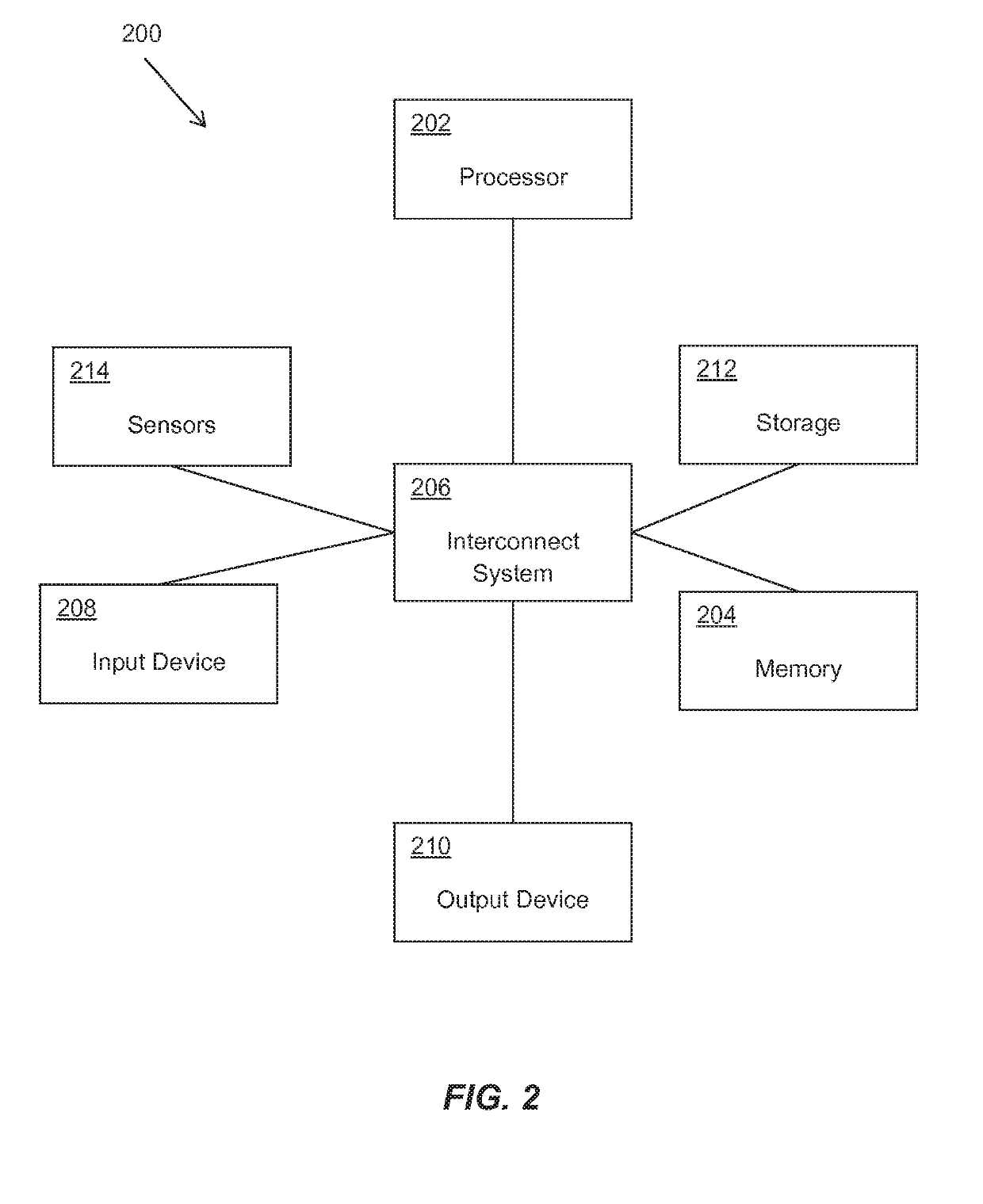

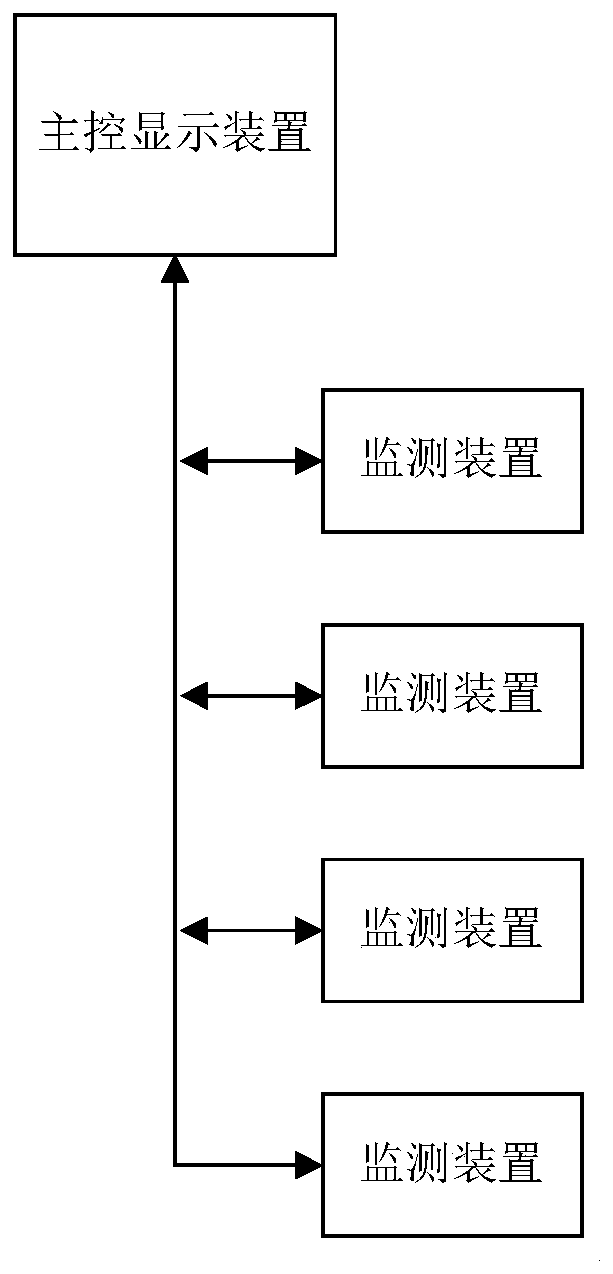

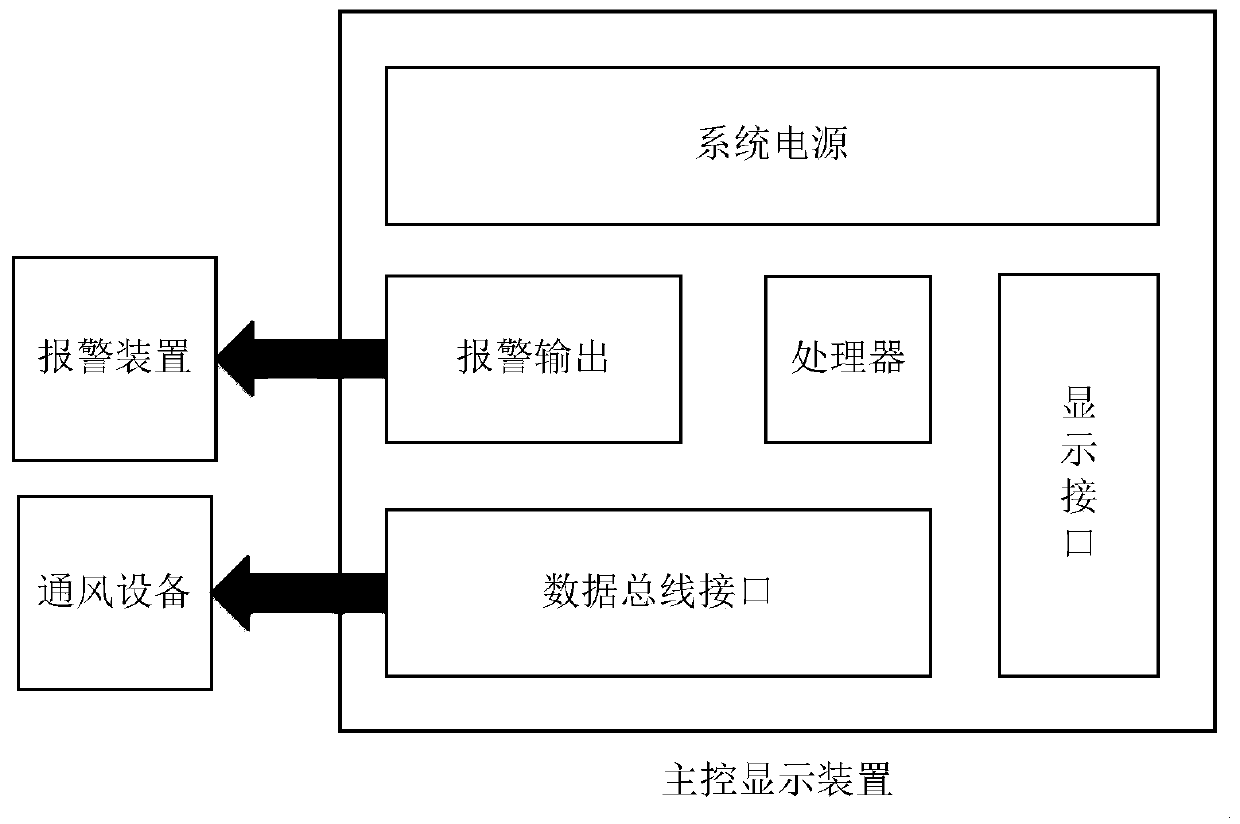

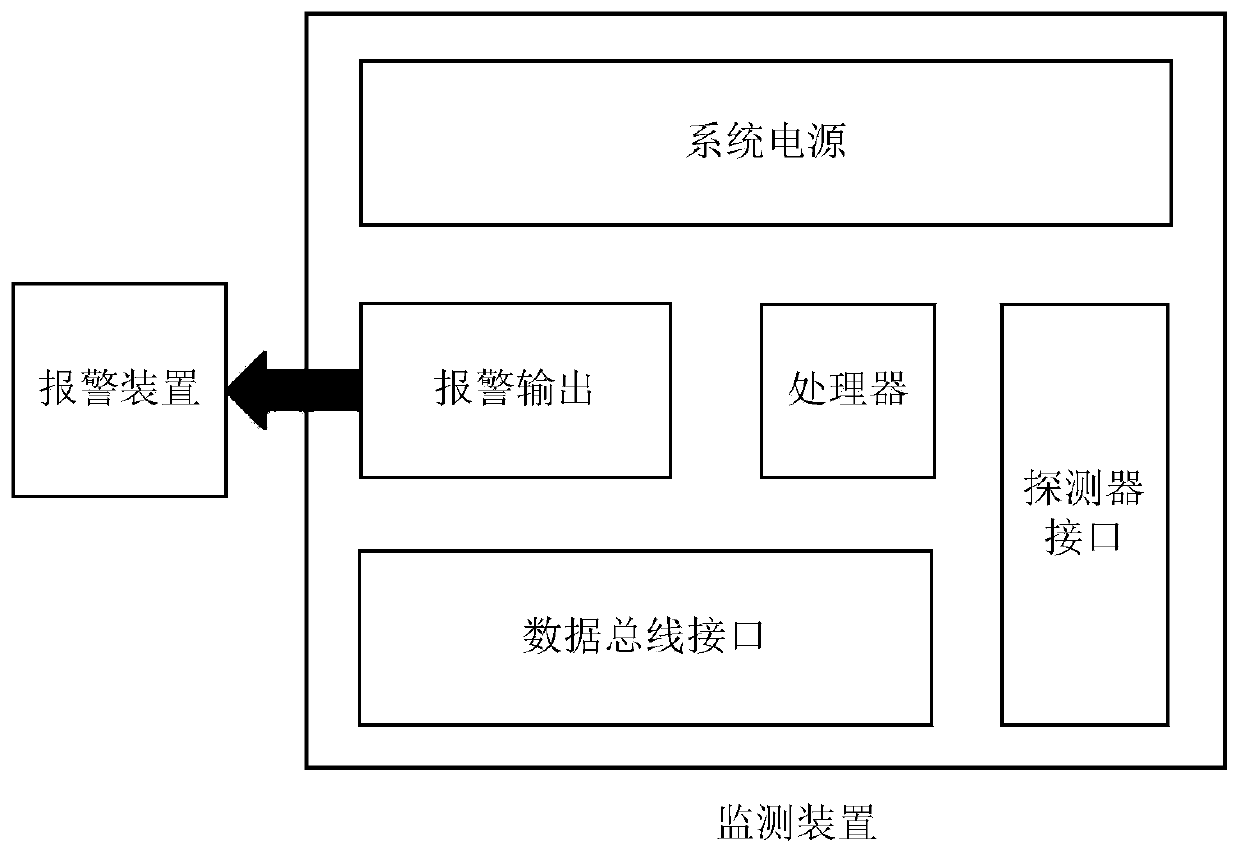

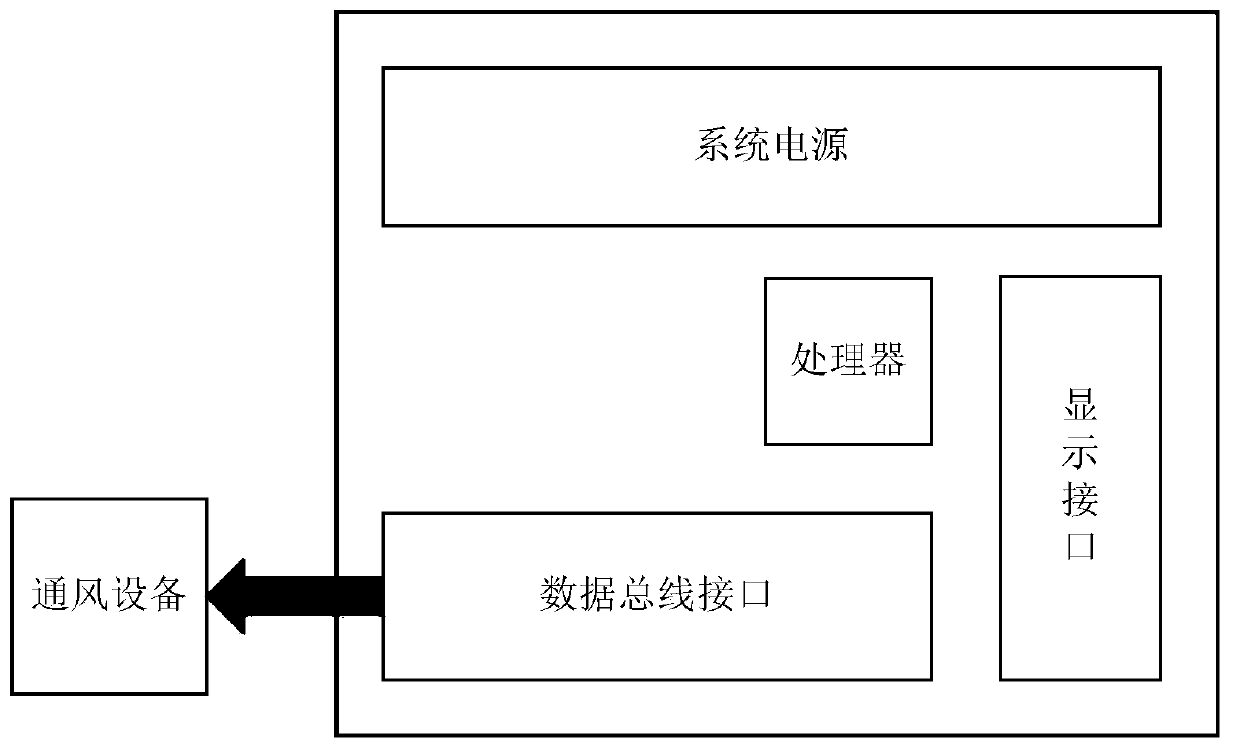

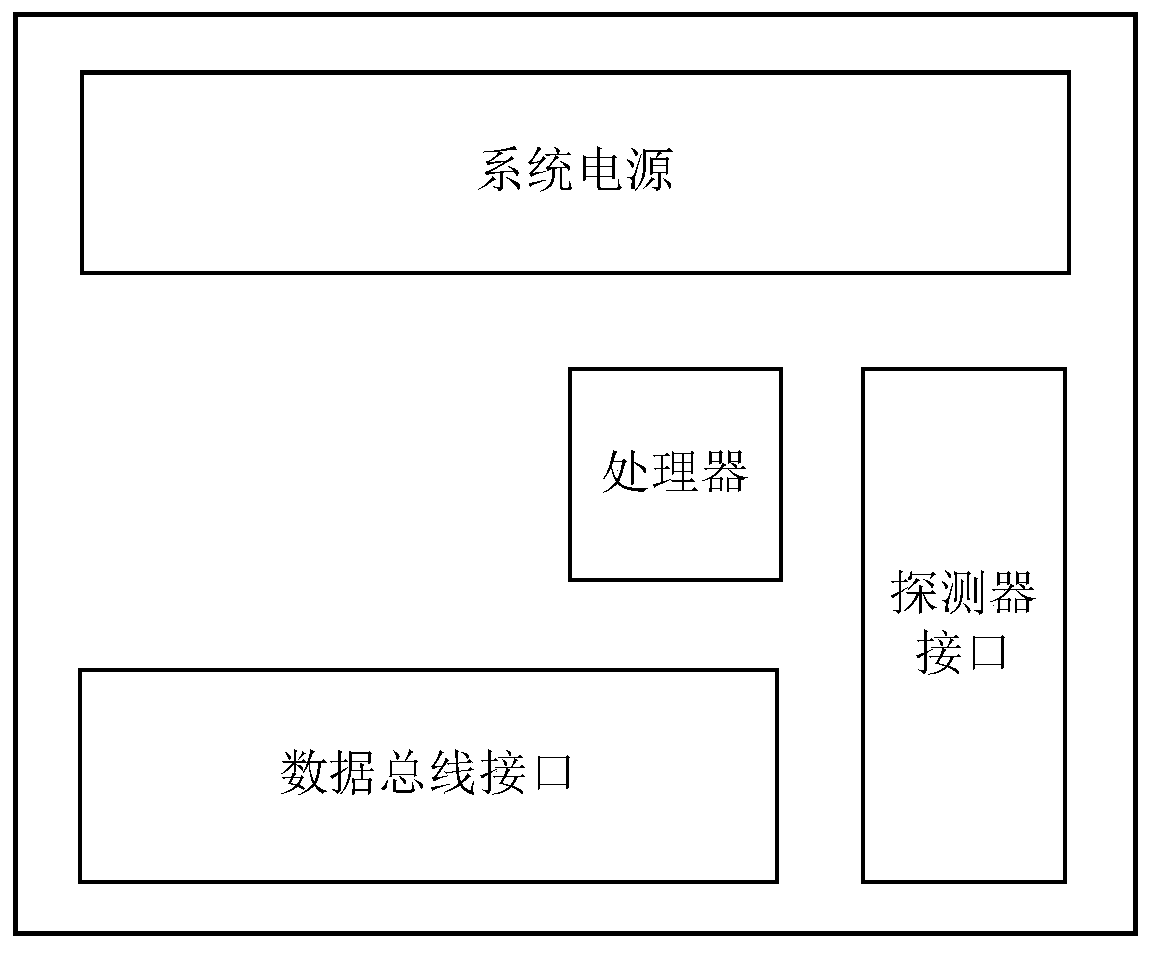

Main control display device for monitoring hydrogen sulfide in fishing boat cabin and system constructed by same

PendingCN111007769APrevention of poisoning incidentsReduce the concentration of hydrogen sulfideProgramme controlComputer controlAutomotive engineeringPower management

A fishing boat cabin hydrogen sulfide monitoring and control system comprises a main control display device and at least one monitoring device; the main control display device comprises a power supplymanagement module, a main control board, a display screen and an alarm; the power supply management module converts alternating current into direct current and provides stable power supply for the system; the main control board calculates and converts data detected by the monitoring devices to obtain a digital result, sends the digital result to the display screen for display, and judges the data; the alarm is used for sending an alarm signal when the main control board judges that the concentration of the H2S gas exceeds the standard; each monitoring device is composed of an H2S detector, analarm and a monitoring main board; and the monitoring main board receives the electric signal from the detector, sends the electric signal to the display main control terminal for display, judges whether the H2S gas exceeds the standard or not, and gives an alarm if the H2S gas exceeds the standard. The system can detect and control the concentration of hydrogen sulfide in the cabin of the fishing boat, and safety accidents caused by over-high concentration of hydrogen sulfide are avoided.

Owner:宁波象研科技服务发展有限公司

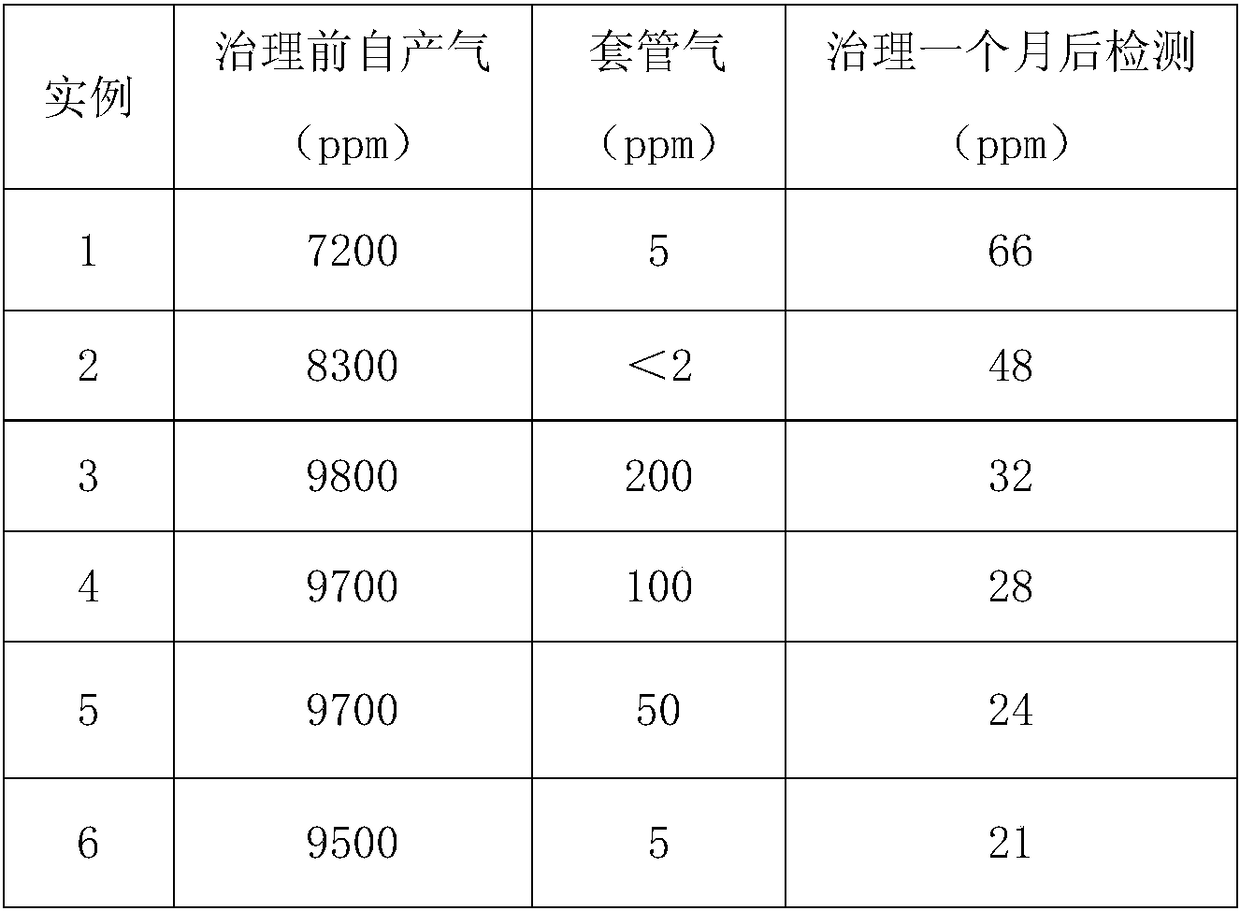

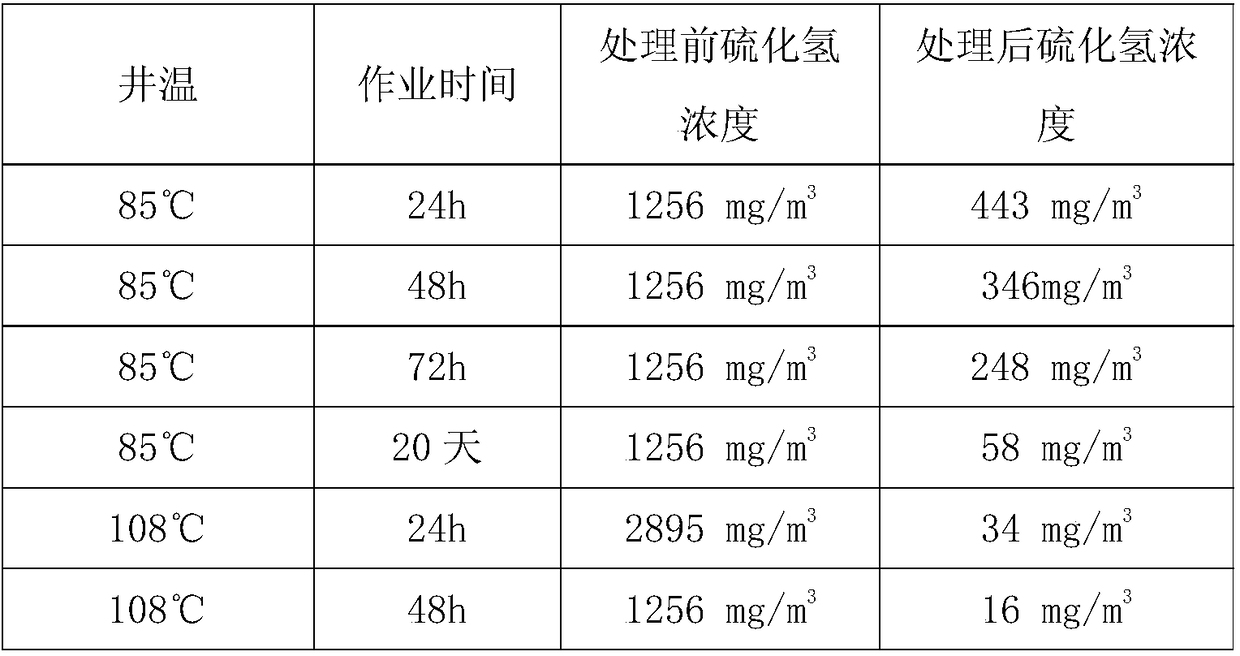

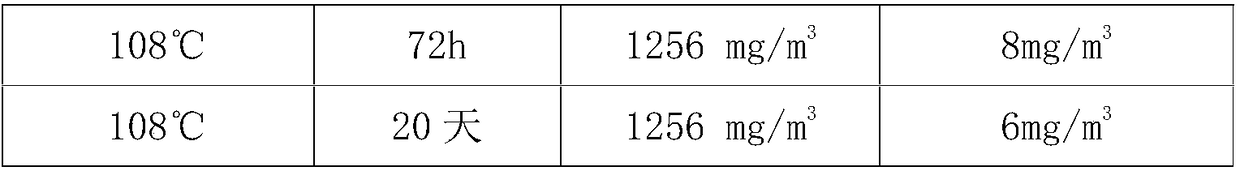

A method for eliminating and suppressing hydrogen sulfide in oil well production process

InactiveCN106150436BElimination of inhibitionInhibitionBorehole/well accessoriesEnvironmental effectWater well

The invention discloses a method for elimination and inhibition of hydrogen sulfide in oil well production. The method comprises a measure for processing a water well tube pillar and a water injection near-well zone, as well as a measure for processing an oil well tube pillar and a near-well zone of oil well tube pillar. The method disclosed by the invention has the advantages that generation of the hydrogen sulfide during the oil well production can be eliminated and inhibited efficiently and safely; the method has good effects and a long-term measure validity period especially for the inhibition of hydrogen sulfide which is generated from bacteria breeding; the maximum decrease rate of the hydrogen sulfide concentration reaches 99.68%; the method disclosed by the invention can obviously reduce the hydrogen sulfide concentration at different well temperatures; and a green and environment-friendly bactericide can be selected during biologic inhibitor selection of the method disclosed by the invention, so that fewer influences are brought to environments. The method is an economic, practical and environment-friendly technological measure for controlling the hydrogen sulfide generation.

Owner:CHINA PETROLEUM & CHEM CORP +1

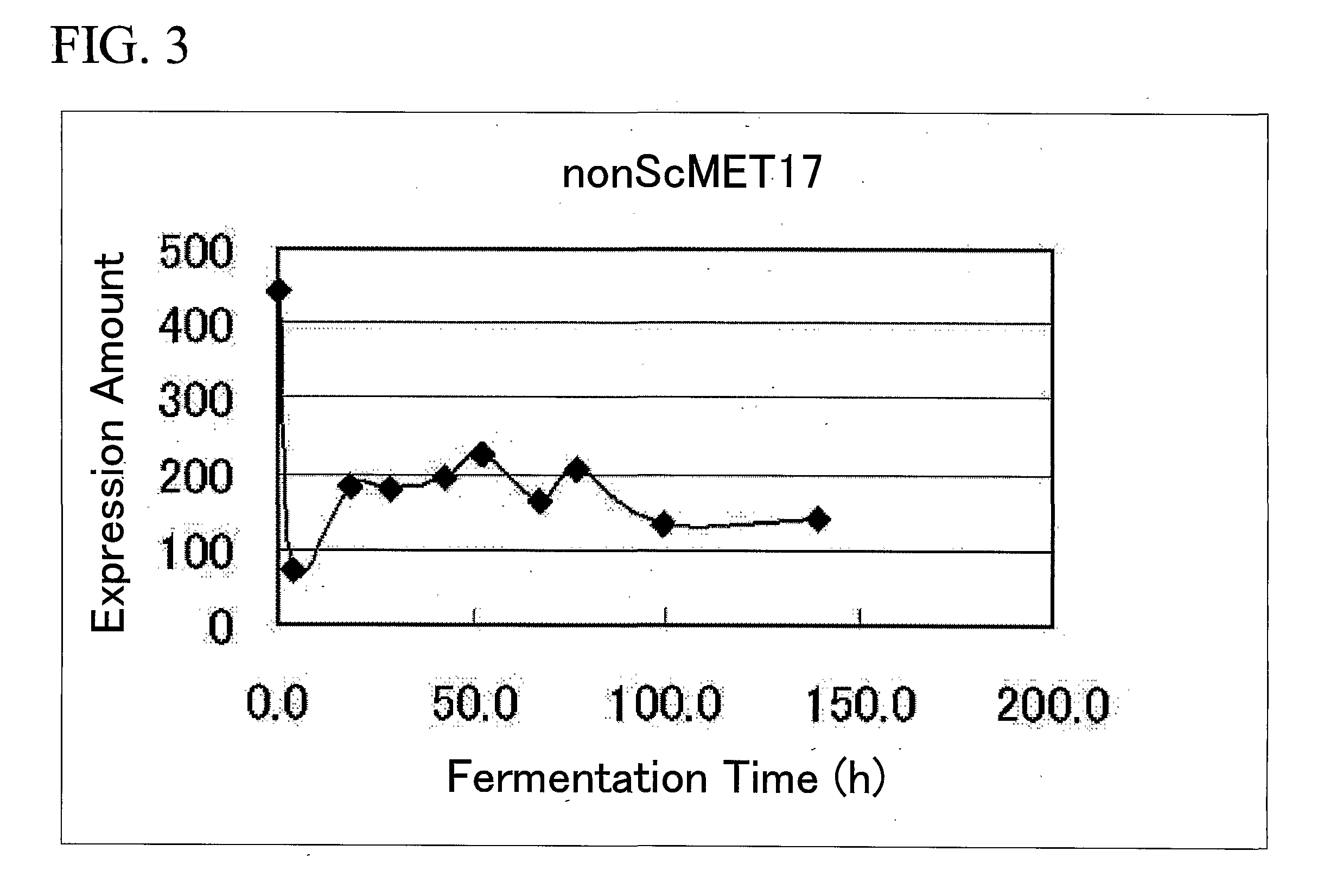

O-acetylhomoserinesulfhydorelace gene and use thereof

The present invention relates to a brewery yeast having controlled hydrogen sulfide-producing capability, a process for producing alcoholic beverages with controlled hydrogen sulfide amount. More particularly, the present invention relates to a yeast whose hydrogen sulfide-producing capability that increases the product flavor is controlled by enhancing the expression level of MET17 gene encoding brewery yeast O-acetylhomoserinesulfhydorelace Met17p, particularly non-ScMET17 gene specific to lager brewing yeast, and to a method for producing alcoholic beverages with said yeast.

Owner:SUNTORY HLDG LTD

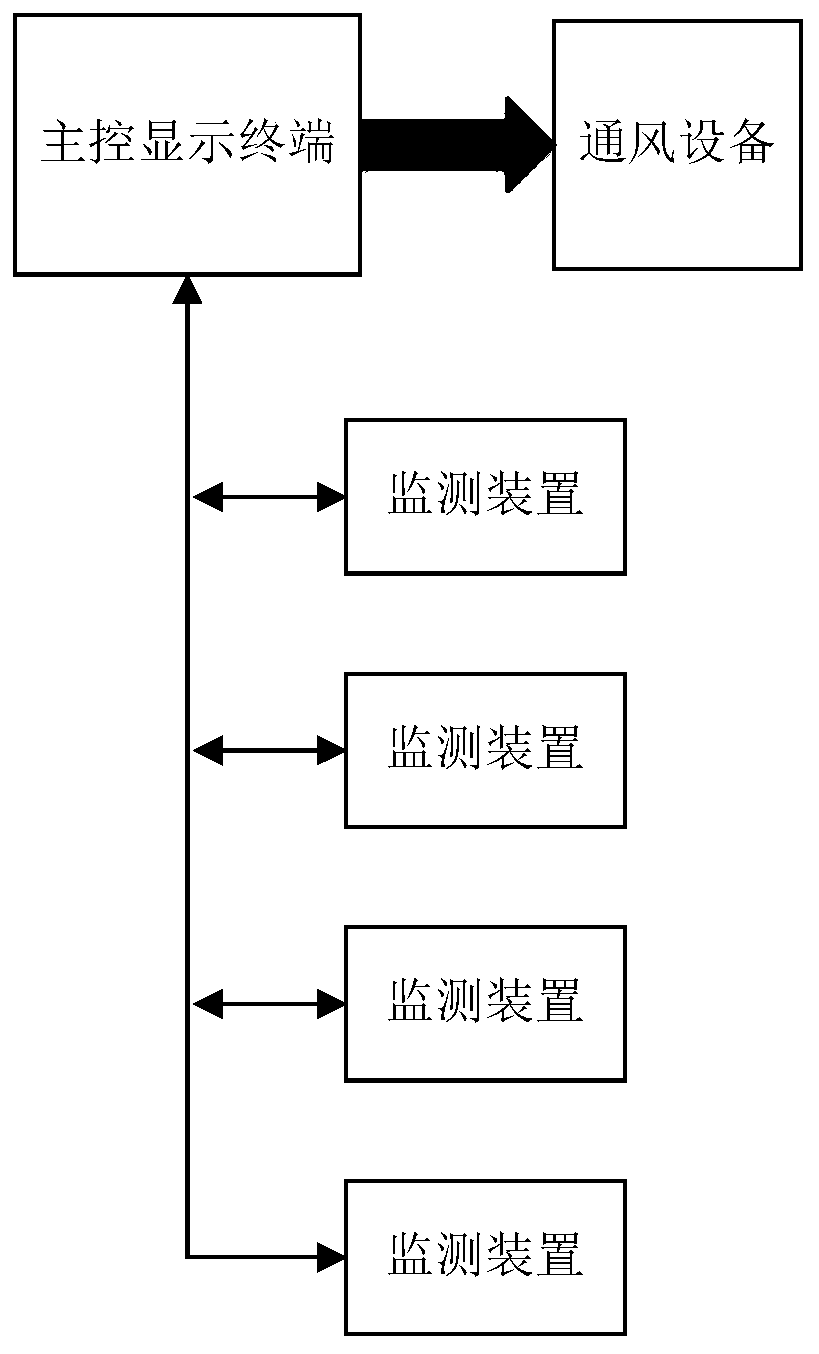

Control system of fishing boat cabin ventilation equipment

PendingCN110888375AReduce the concentration of hydrogen sulfideThe display effect is intuitiveProgramme controlComputer controlPower managementEnvironmental geology

A control system of fishing boat cabin ventilation equipment comprises a main control display terminal and at least one monitoring device. The main control display terminal comprises a power supply management module, a main control board and a display screen. The main control display terminal is provided with a ventilation signal control interface, which is used for being connected with ventilation equipment. The power supply management module converts alternating current into direct current and provides a stable power supply for the system. The main control board is used for calculating and converting the data detected by each monitoring device to obtain a digitized result, sending the digitized result to the display screen for display, judging the data and starting the ventilation equipment when the concentration of hydrogen sulfide exceeds the standard. The monitoring device is composed of an H2S detector and a monitoring main board. The monitoring main board receives electric signals from the detector, converts the electric signals into a digital signal, and sends the digital signal to the main control display terminal for display. The system can detect and control the concentration of hydrogen sulfide in the cabin of the fishing boat, and thus safety accidents caused by over-high concentration of hydrogen sulfide are avoided.

Owner:宁波象研科技服务发展有限公司

Apparatus and Method for Sintered Glass Media Biofilter

InactiveUS20150321132A1Reduce concentrationReduce the concentration of hydrogen sulfideBioreactor/fermenter combinationsGas treatmentFritted glassHydrogen sulfide

A system for removing undesirable compounds from contaminated air includes a biofilter having sintered glass media. Hydrogen sulfide is removed from contaminated air by passing the contaminated air through the biofilter.

Owner:EVOQUA WATER TECH LLC

Swirl flow strengthening method and device for purification of sulfur tail gas by Claus process

ActiveCN103170223BReduce sulfur contentProblems with increased energy loadDispersed particle separationIncinerator apparatusSulfurAtmospheric air

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

A desulfurization system and desulfurization method for biogas containing high concentration hydrogen sulfide

ActiveCN108579373BSatisfy the utilizationReduce the concentration of hydrogen sulfideGas treatmentDispersed particle separationThermodynamicsProcess engineering

The invention relates to a desulfurizing system for biogas containing high-concentration hydrogen sulfide. The desulfurizing system comprises a biogas inlet, a biogas flowmeter, a biogas cabinet, a wet-process desulfurizing tower, a gas-water separator, a plurality of dry-process desulfurizing towers in serial connection or parallel connection, an outlet gas detector, a biogas fan and a biogas utilization pipeline which are sequentially communicated through biogas, and both spraying liquid after being treated by the wet-process desulfurizing tower and liquid of the gas-water separator enter adesulfurizing liquid regeneration and treatment device. The desulfurizing system combines wet-process desulfurizing with dry-process desulfurizing, and concentration of hydrogen sulfide can be loweredfrom higher than 20000ppm to below 100ppm to meet biogas energy utilization needs. the desulfurizing system is low in running cost, economic benefit can be generated utilizing biogas after being treated by the system, and generated byproducts can be sold as goods, so that many things are achieved at one stroke.

Owner:华夏碧水环保科技股份有限公司

Method and device for removing hydrogen sulfide in gas phase through oxidation

InactiveCN103111177BShort regeneration timeAvoid cloggingDispersed particle separationGas phaseProcess engineering

The invention discloses a method and a device for removing hydrogen sulfide in a gas phase through oxidation. The device comprises a settling tank, an extracting pump, a filtering membrane, an ultra gravity rotary packed bed, a separator, a balanced tank and a regeneration ultra gravity machine, wherein the extracting pump and the filtering membrane are sequentially connected between the settling tank and the ultra gravity rotary packed bed; the balanced tank is connected between the settling tank and the separator; the ultra gravity rotary packed bed is communicated with the balanced tank; the settling tank and the separator are sequentially connected with the extracting pump and the filtering membrane; and the extraction pump and the filtering membrane are sequentially connected between the settling tank and the regeneration ultra gravity machine. A technology flow of pre-oxidation sweetening, ultra oxidation sweetening, sulfur settlement, and regeneration is adopted for the method. According to the method and the device, the ultra gravity machine is adopted to replace the traditional low-mass-transfer-efficiency reactor, and the ultra gravity rotary packed bed reactor is adopted both in hydrogen sulfide oxidation and catalyst regeneration, the process mass transfer efficiency is intensified greatly, and the regeneration time oxidation sulfur removing time and the desulfurizing agent regenerating time are shortened.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD

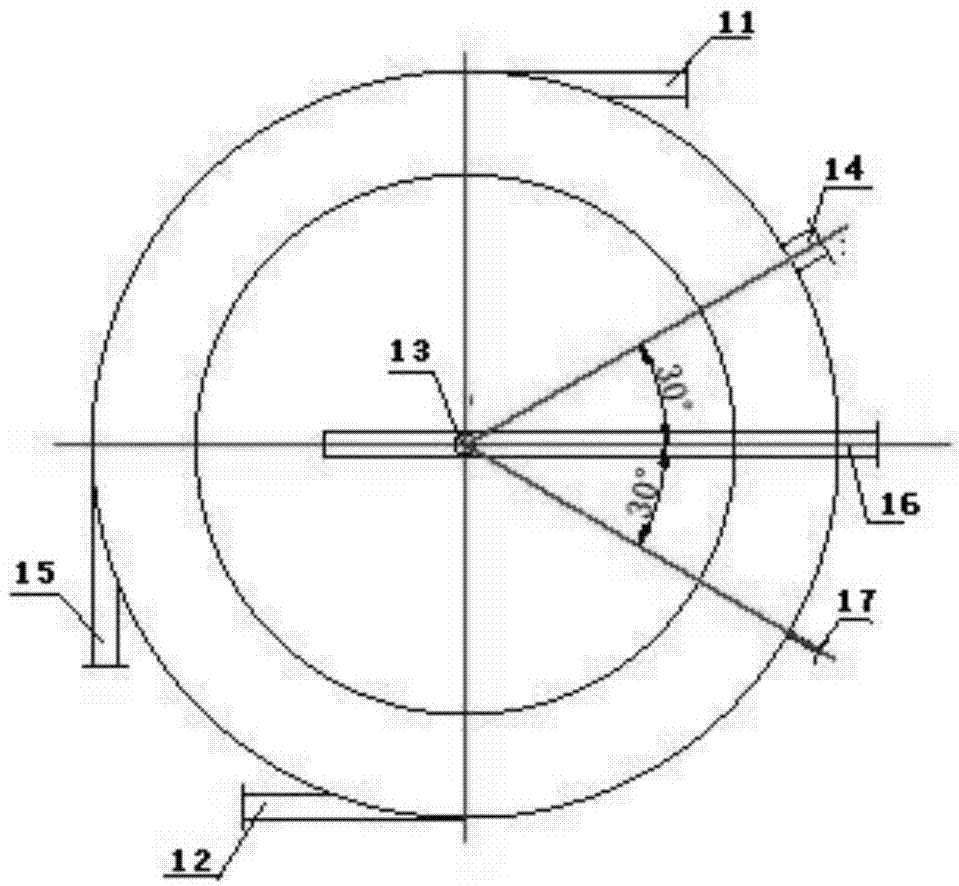

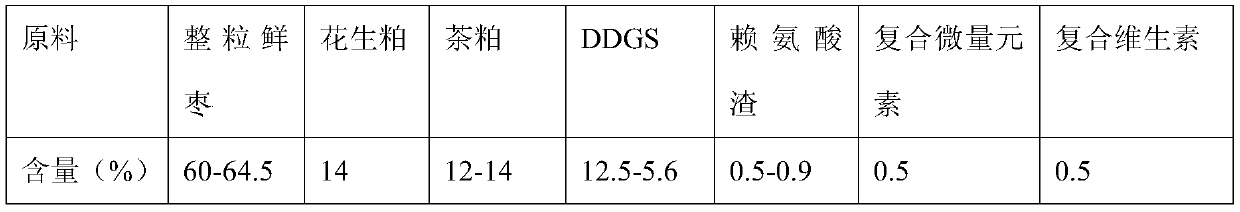

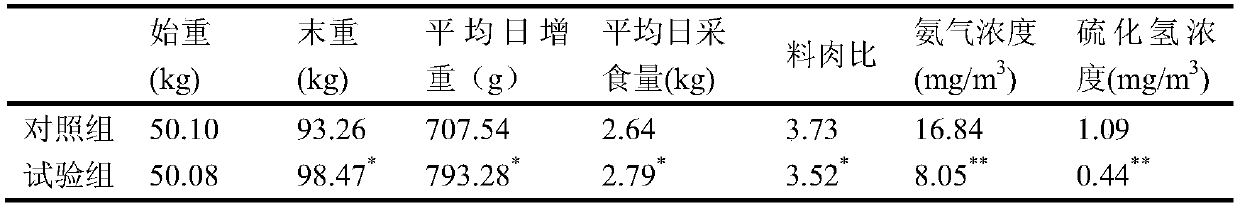

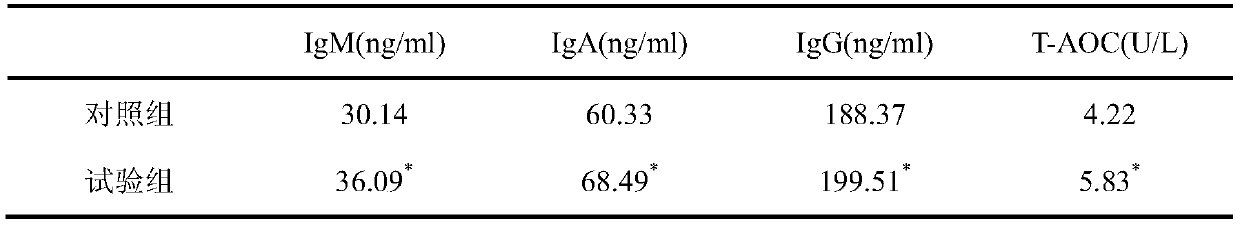

A method for preparing pig feed by fermenting fresh jujube

InactiveCN106333109BLow costIncrease profitFood processingAnimal feeding stuffBiotechnology[Candida] apicola

The invention discloses a method for utilizing fresh jujube fermentation to prepare a pig feed. According to the method, whole fresh jujubes are used as main raw materials and are compounded with peanut meal, tea meal, DDGS, lysine residues, composite trace elements and compound vitamins; the microbial additive prepared from enterococcus faecium, bacillus natto, candida utilis and trichoderma longibrachiatum are added, and sealed anaerobic fermentation is performed at the temperature of 16-23 DEG C for 5 days, and then fermentation succeeds; it is detected that the flavonoid content in the feed after fermentation is greater than 2000 mg / kg, and the cyclic adenosine monophosphate content is greater than 7.0 mg / kg. The fermented feed can be used for feeding pigs, improves the production performance and immune functions of pigs and reduces the influence of the concentration of ammonia and hydrogen sulfide in a piggery and the mineral element content in pig manure content, and the feed cost is reduced.

Owner:盛清凯

Method for increasing methane production efficiency in organic waste anaerobic process

ActiveCN102140001BPromote hydrolysisImprove metabolic activityGas production bioreactorsWaste based fuelGeneration rateFeces

The invention discloses a method for increasing methane production efficiency in organic waste anaerobic process. The method is characterized in that powder containing no less than 15% of free ferric iron oxides is added into an anaerobic biochemical system to be uniformly blended, wherein the anaerobic biochemical system produces methane by utilizing organic wastes; and ferric ions released when microbes reduce the ferric iron oxides in the anaerobic process can promote the activity of anaerobic bacteria such as methane bacteria and the like, thus increasing the production rate and yield of methane by utilizing organic wastes. The method can be widely used for increasing the methane production rate and yield of an energy utilization system for biogas production of municipal domestic waste, agriculture product processing wastes, excess sludge of sewage treatment plants, feces of intensifying raising farms and the like and improves the utilization rate of renewable energy sources of organic wastes.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com