Method for increasing methane production efficiency in organic waste anaerobic process

A technology of organic waste and methane, applied in the field of resource utilization, can solve problems such as low efficiency, high price, and slow methane speed, and achieve the effect of abundant natural resources, low price, and promoting hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 20g of medium (which contains 5g beef extract, 10g protein jelly and 5g sodium chloride to the 1000mL anaerobic digestion flask, and then add 0.102g industrial pure iron trioxide powder (Fe 2 O 3 98% by mass, containing Fe 2 O 3 0.1g, and the mass ratio of the culture medium is 0.5%), inoculate 5mL mixed anaerobic bacteria (bacteria concentration 10 10 Pieces / mL), mix well and seal. Regularly take the gas above the anaerobic digestion flask and measure the content of hydrogen sulfide, carbon dioxide and methane in the gas.

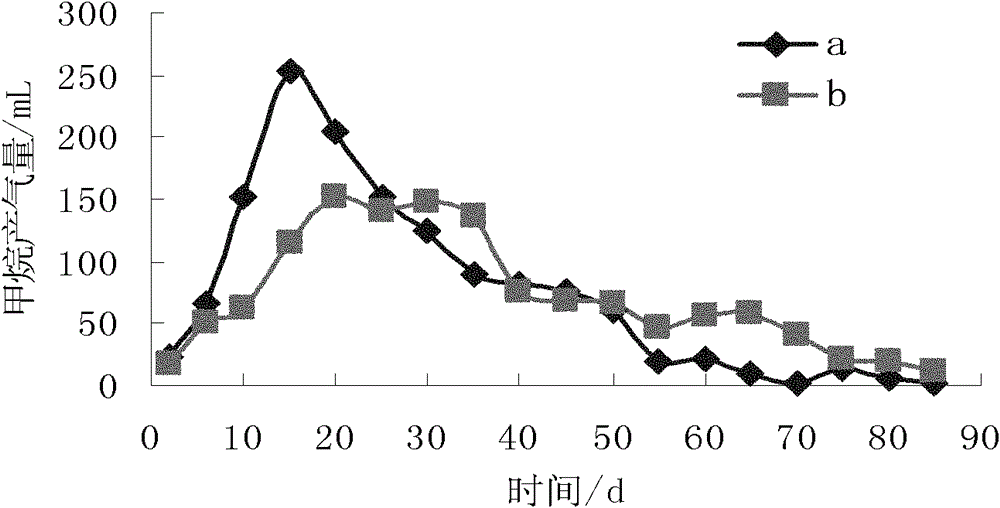

[0026] The methane production rate in this example is shown in figure 1 Middle curve a.

Embodiment 2

[0028] Add 20g of culture medium (containing 5g beef extract, 10g protein jelly and 5g sodium chloride) to a 1000mL anaerobic digestion flask, and then inoculate 5mL mixed anaerobic bacteria (bacteria concentration 10 10 Pieces / mL), mix well and seal. Regularly take the gas above the anaerobic digestion flask and measure the content of hydrogen sulfide, carbon dioxide and methane in the gas.

[0029] The methane production rate in this example is shown in figure 1 Middle curve b.

[0030] By right figure 1 The comparative analysis of middle curve a and b shows that adding Fe 2 O 3 The methane production rate in the anaerobic digestion flask of mineral powder (curve a) is much higher than that without Fe 2 O 3 The methane production rate of ore fines (curve b).

Embodiment 3

[0032] The limonite ore is crushed through a 200-mesh sieve to obtain limonite powder, of which free Fe 2 O 3 The mass percentage is 68%. Put 300g of pig manure into a 1000mL anaerobic digestion flask, add 2.21g of limonite powder (containing Fe 2 O 3 1.5g, and the mass ratio of organic waste is 0.5%), and inoculate 5mL mixed anaerobic bacteria solution (bacteria concentration 10 10 Pieces / mL), mix well and seal. Regularly take the gas above the anaerobic digestion flask and measure the methane content in the gas.

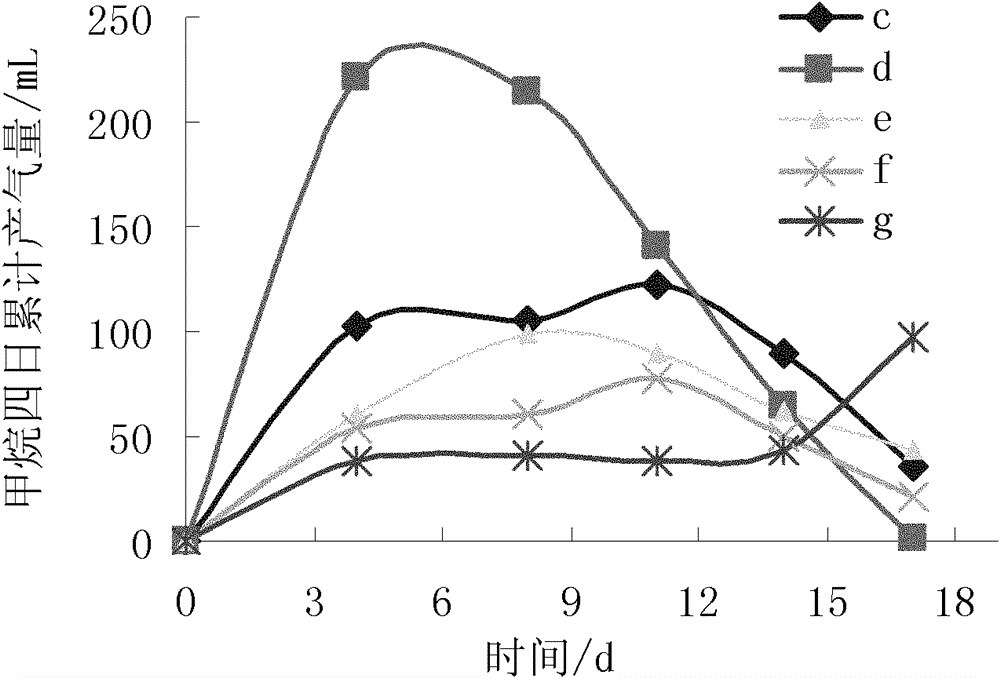

[0033] The methane production rate in this example is shown in figure 2 Middle curve c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com