Preparation method of organosilicon sol-gel coating for magnesium alloy substrate surface corrosion resistance

An organosilicon sol, magnesium alloy technology, applied in anti-corrosion coatings, metal material coating processes, coatings, etc., can solve problems affecting the corrosion resistance of organosilicon sol-gel coatings, and achieve high catalytic hydrolysis capacity, Good anti-corrosion effect and improved anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

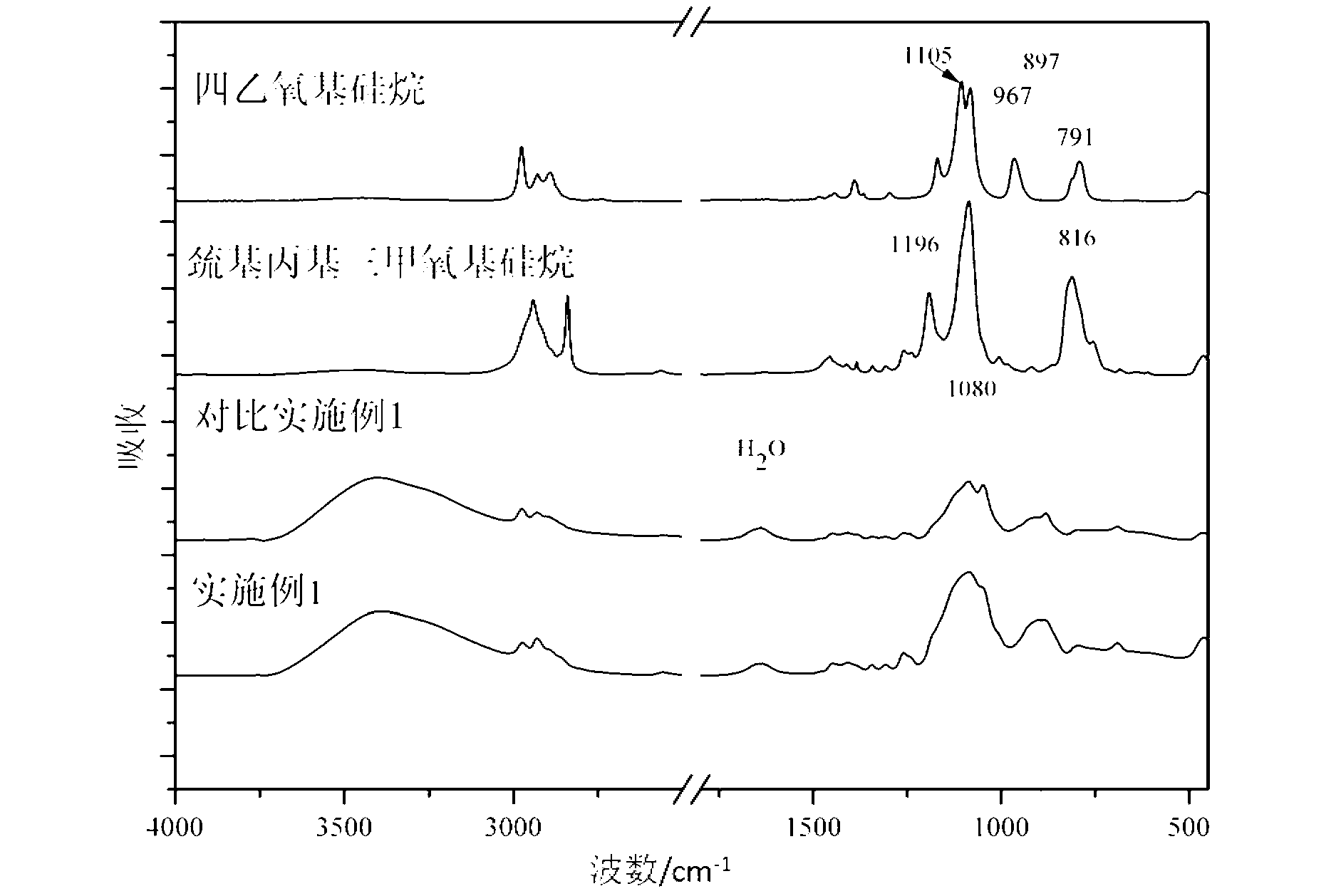

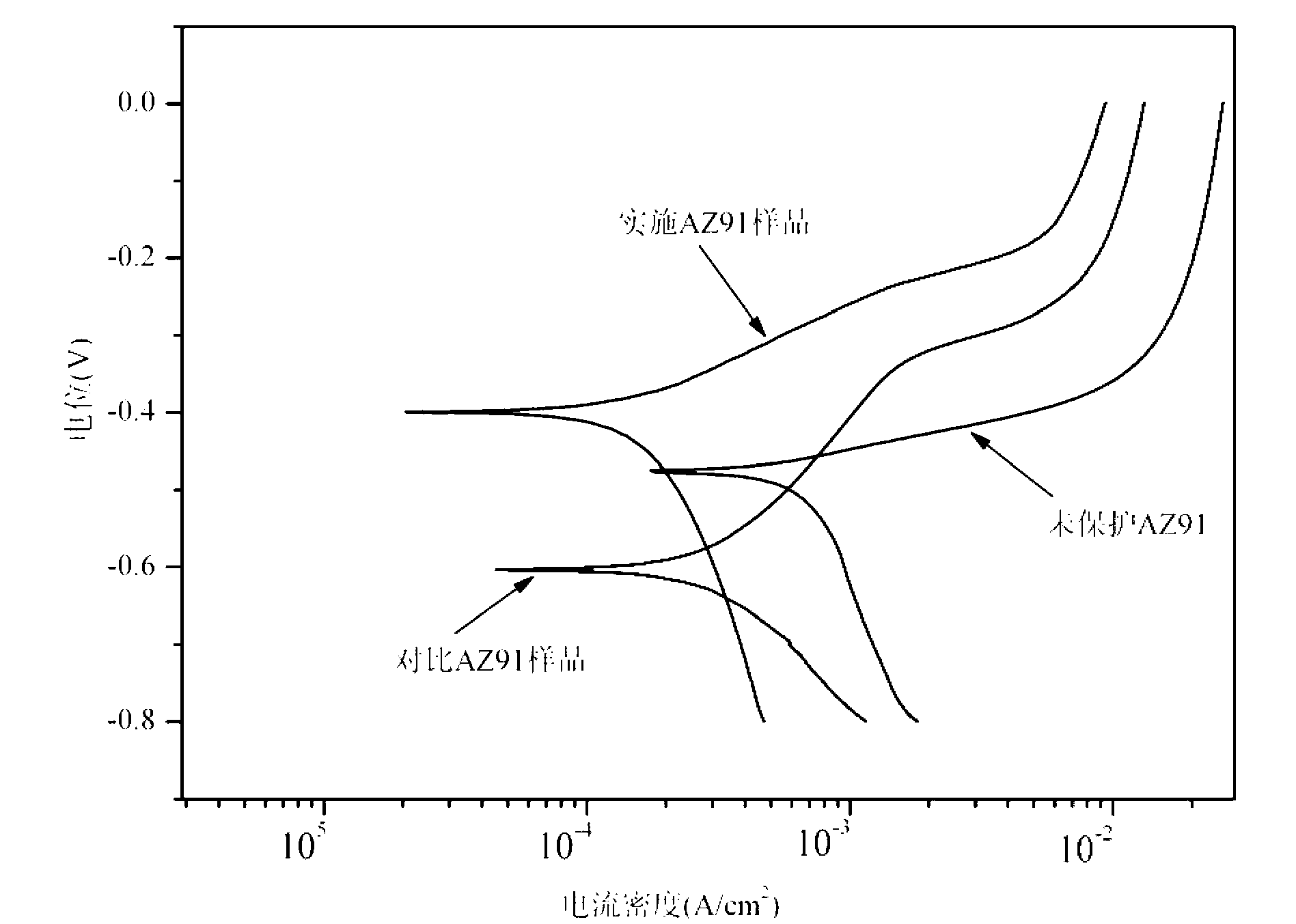

[0033] In this embodiment, the magnesium alloy substrate is exactly the same as the above-mentioned Comparative Example 1, and an anti-corrosion organic silicon sol-gel coating is prepared on the surface of the magnesium alloy substrate. base silane as precursor, using Ce(NO 3 ) 3 It is obtained by carrying out a hydrolysis-condensation reaction with a catalyst, and the specific steps are as follows:

[0034] (1) Mix 3.75g of mercaptopropyltrimethoxysilane, 1.25g of tetraethoxysilane, 20g of ethanol, and 5g of 0.1% Ce (NO 3 ) 3The solution was mixed evenly, and stirred at room temperature for 12 hours to obtain an alkoxysilane hydrolyzate;

[0035] (2) After the magnesium alloy AZ91 is mechanically polished and ultrasonically cleaned, it is soaked in the above-mentioned alkoxysilane hydrolyzate for 1 minute. After taking it out, it is heat-treated at 120°C for 30 minutes. After drying, the surface is covered with organic silicon sol-gel Coating implemented on AZ91 samples....

Embodiment 2

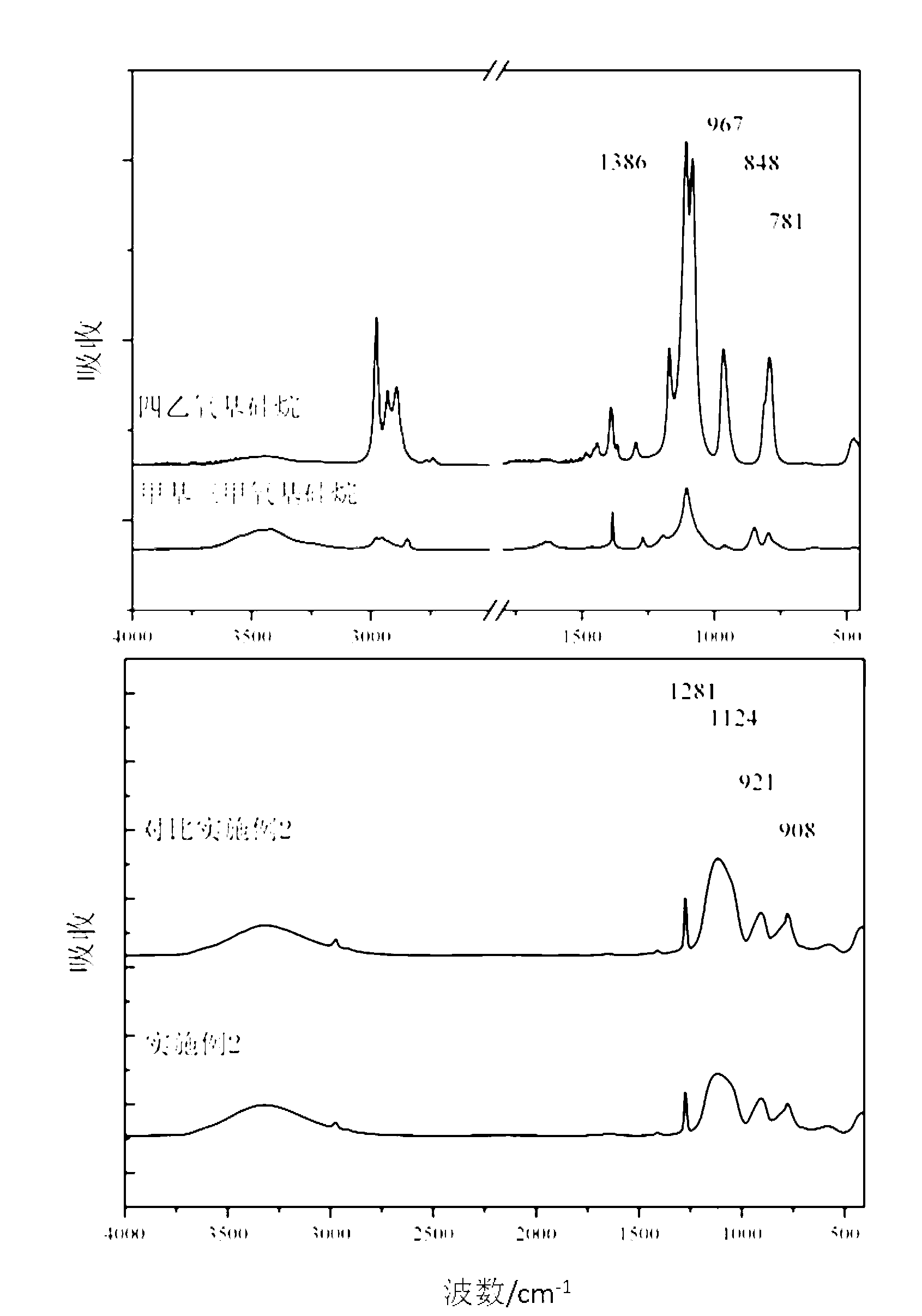

[0053] In this embodiment, the magnesium alloy substrate is exactly the same as the above-mentioned comparative example 2, and an anti-corrosion organic silicon sol-gel coating is prepared on the surface of the magnesium alloy substrate, and the coating is made of methyltrimethoxysilane and tetraethoxysilane Silane as the precursor, using La(NO 3 ) 3 It is obtained as a hydrolysis reaction catalyst for hydrolysis-condensation reaction, and the specific steps are as follows:

[0054] (1) Mix 8.16g methyltrimethoxysilane, 4.16g tetraethoxysilane, 7.02g ethanol, and 7.02g0.1%La (NO 3 ) 3 The solution was mixed evenly, and stirred at 40° C. for 6 hours to obtain an alkoxysilane hydrolyzate;

[0055] (2) After the AZ31 magnesium alloy is mechanically polished and ultrasonically cleaned, it is soaked in alkoxysilane hydrolyzate for 1 minute, and after taking it out, it is heat treated at 100 ° C for 1 hour. After drying, the surface is covered with organic silicon sol-gel coating...

Embodiment 3

[0072] In this embodiment, the magnesium alloy substrate is exactly the same as the above-mentioned comparative example 3, and an anti-corrosion organic silicon sol-gel coating is prepared on the surface of the magnesium alloy substrate. The coating uses methyltrimethoxysilane as a precursor, and adopts Ce (NO 3 ) 3 It is obtained as a hydrolysis reaction catalyst for hydrolysis-condensation reaction, and the specific steps are as follows:

[0073] (1) Add 6g of methyltrimethoxysilane, 21g of ethanol, and 3g of 0.1% La (NO 3 ) 3 The solution was mixed evenly, and stirred at 60°C for 2 hours to obtain an alkoxysilane hydrolyzate;

[0074] (2) After the JDM2 magnesium alloy is mechanically polished and ultrasonically cleaned, it is soaked in alkoxysilane hydrolyzate for 1 minute. After taking it out, it is heat treated at 80°C for 90 minutes. After drying, the surface is covered with organic silicon sol-gel coating. Layer implementation of the JDM2 sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com