High-performance reverse osmosis composite membrane and preparation method thereof

A reverse osmosis composite membrane, high-performance technology, applied in the field of high-performance reverse osmosis composite membrane and its preparation, can solve the problems of difficult synthesis process, complex chemical structure, difficult to obtain, etc., to reduce the probability of shedding, low membrane cost, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of polyvinyl alcohol grafted zwitterionic copolymer: in 100ml of 10% polyvinyl alcohol aqueous solution, add mass fraction and account for 1% tryptophan, under nitrogen protection conditions, add 0.05mol of DCC (dicyclohexylcarbodiethylene Amine) was used as a redox catalyst, reacted at a temperature of 40°C for 1h, the product was precipitated and washed with methanol, and the obtained solid was dried in an oven at 60°C for 1h to obtain a polyvinyl alcohol grafted zwitterionic copolymer.

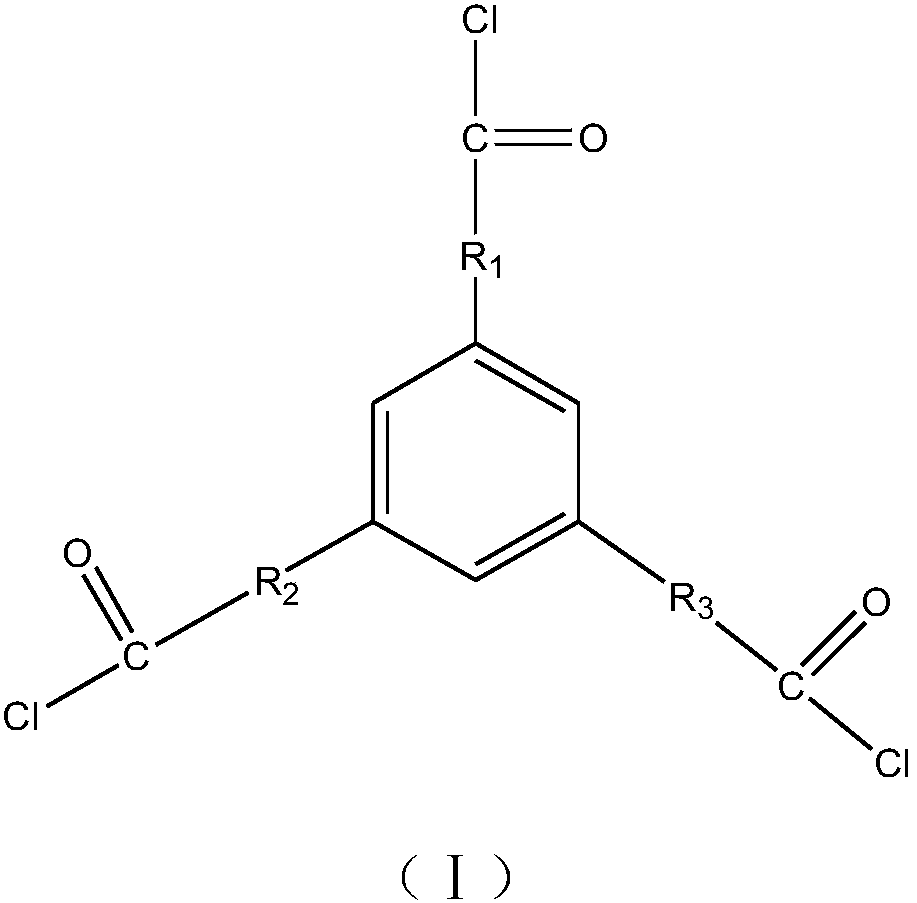

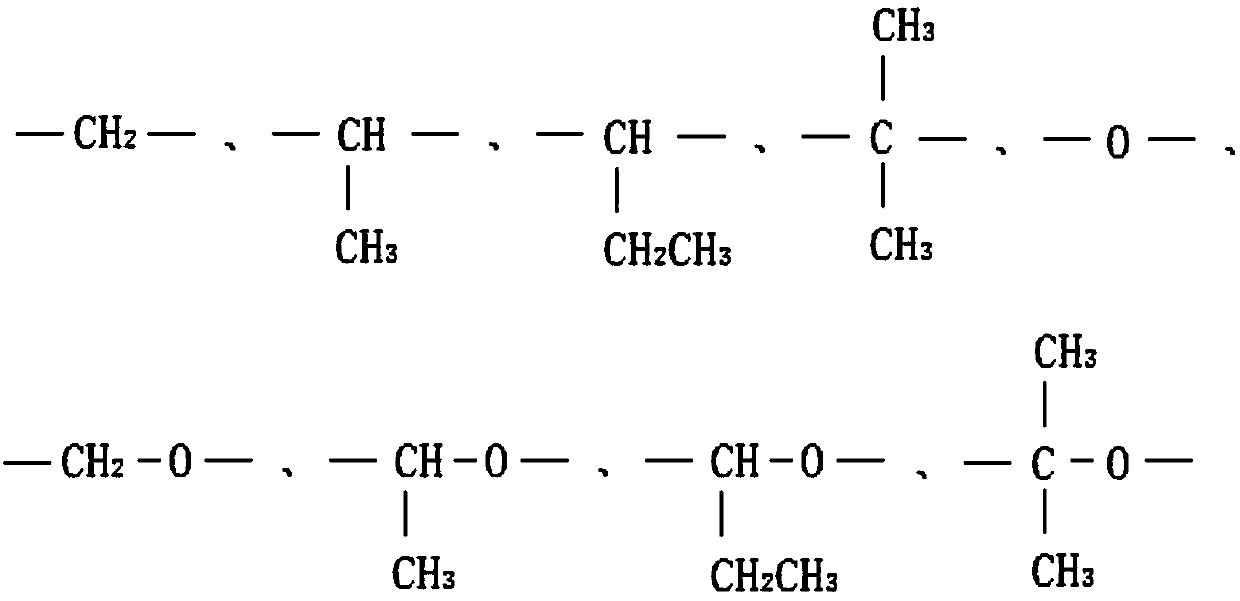

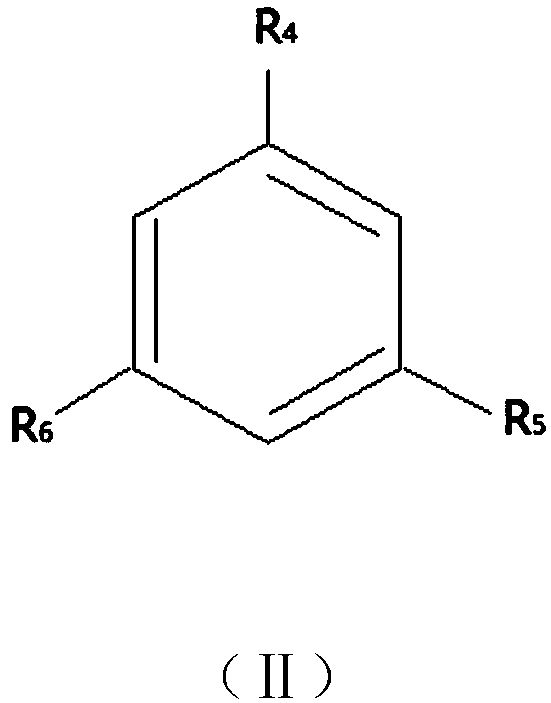

[0036] Preparation of polybasic acid chloride: 0.15mol of trichloromethyl carbonate and 0.15mol of Place in a four-necked bottle, add 150ml of ether and stir until dissolved. 1 g of sodium methoxide was added dropwise to the reaction system through a constant pressure separatory funnel, and reacted for 1 h at 0°C. After the reaction finished, the reactant was distilled to remove low-boiling substances; in the gained reactant, the DMF of 50ml and the normal hexane of 50m...

Embodiment 2

[0043] Preparation of polyvinyl alcohol grafted zwitterionic copolymer: in 100ml of 10% polyvinyl alcohol aqueous solution, add mass fraction and account for 20% glutamic acid, under nitrogen protection conditions, add 0.05mol of DCC (dicyclohexylcarbodiethylene Amine) was used as a redox catalyst, reacted at 40°C for 6h, the product was precipitated and washed with methanol, and the obtained solid was dried in an oven at 60°C for 12h to obtain a polyvinyl alcohol grafted zwitterionic copolymer.

[0044] Preparation of polybasic acid chloride: 0.23mol of trichloromethyl carbonate and 0.23mol of Place in a four-necked bottle, add 150ml of acetone and stir until dissolved. 3 g of diethylamine was added dropwise to the reaction system through a constant pressure separatory funnel, and reacted for 15 h at 10° C. After the reaction finished, the reactant was distilled to remove low-boiling substances; in the gained reactant, the DMF of 75ml and the normal hexane of 75ml were adde...

Embodiment 3

[0051] Preparation of polyvinyl alcohol graft zwitterionic copolymer: in the 10% polyvinyl alcohol aqueous solution of 100ml, add the glycine and 16% lysine that mass fraction accounts for 24%, under nitrogen protection condition, add the DCC of 0.05mol (bicyclic Hexylcarbodiimide) was used as a redox catalyst, reacted at a temperature of 40°C for 12h, the product was precipitated and washed with methanol, and the obtained solid was dried in an oven at 60°C for 24h to obtain polyvinyl alcohol grafted zwitterions copolymer.

[0052] Preparation of polybasic acid chloride: 0.3mol of trichloromethyl carbonate and 0.3mol of Place in a four-necked bottle, add 50ml of isopropanol and 100ml of dichloroethane and stir until dissolved. 5 g of 3-methylpyridine was added dropwise to the reaction system through a constant pressure separatory funnel, and reacted for 30 h at 20° C. After the reaction finished, the reactant was distilled to remove low-boiling substances; in the gained rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com