Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73 results about "Benzotrichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Benzotrichloride, also known as trichlorotoluene is an organic compound with the formula C₆H₅CCl₃. It is principally used as an intermediate in the preparation of other chemical products such as dyes.

Preparation process of benzoyl chloride

ActiveCN103787874AReduce pollutionSave resourcesPreparation from carboxylic acid halideOrganic compound preparationBenzoic acidPtru catalyst

The invention discloses a preparation process of benzoyl chloride. The preparation process comprises the following steps of synthesis of benzotrichloride: carrying out temperature reaction on methylbenzene and chlorine under the catalytic action of a catalyst to synthetize a crude benzotrichloride product; synthesis of the benzoyl chloride: continuously stirring and heating the crude benzotrichloride product and benzoic acid to prepare a crude benzoyl chloride product after adding the catalyst; refining of the benzoyl chloride: carrying out reduced pressure distillation on the crude benzoyl chloride product to prepare a refined benzoyl chloride product; recovering benzoyl chloride raffinate, adding water to the benzoyl chloride raffinate which is subjected to the reduced pressure distillation, heating and stirring to transform the benzoyl chloride contained in the raffinate into the benzoic acid, cooling, then separating out benzoic acid. The preparation process disclosed by the invention is easy to safe to operate, effectively shortens the reaction time, achieves the purity of the prepared benzoyl chloride by 99.5%, reduces the environmental pollution by recycling residues, saves the resources, reduces the cost, meets the requirements of pharmaceutical chemicals and can carry out massive industrial production.

Owner:YIDU YOUYUAN IND CO LTD

Synthesis method of 5-bromo-2-chloro benzoic acid

ActiveCN105622382AEasy to operateHigh purityOrganic compound preparationCarboxylic compound preparationBenzoic acidChlorobenzilate

The invention provides a synthesis method of 5-bromo-2-chloro benzoic acid.The method includes the following steps of A, making 2-chlorine benzotrichloride and bromide reagents react under the effect of a catalyst to obtain 2-chloro-5-bromine benzotrichloride, wherein bromide reagents include one or more of bromine, N-bromosuccinimide, dibromohydantoin and hydrobromic acid; B, conducting hydrolysis reaction on 2-chloro-5-bromine benzotrichloride in the step A under the acid condition to obtain 5-bromo-2-chloro benzoic acid.According to the method, 2-chlorine benzotrichloride which is low in price and easy to obtain is adopted as the raw material, operation is easy, intermediates do not need to be purified, 5-bromo-2-chloro benzoic acid is synthesized through a one-pot method, purity is high, yield is high, three-waste emission is little, and production cost is low.It is shown through experiment results that 2-chloro-5-benzoic acid obtained according to the synthesis method has yield larger than 95% and purity of 80-92%.

Owner:苏州正济药业有限公司

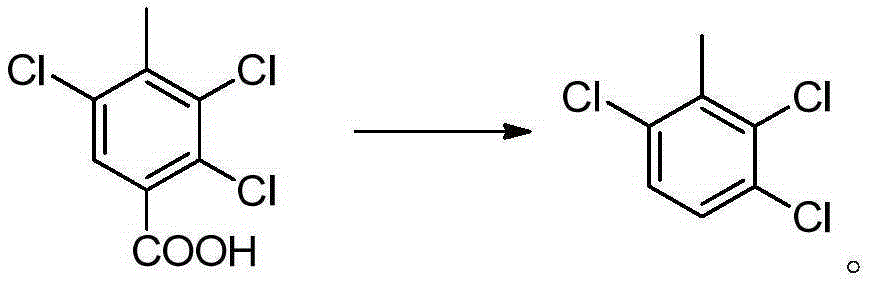

Synthesis methods of 3, 6-dichloro-2-methoxybenzoic acid and its intermediate

InactiveCN105294419AWide variety of sourcesSimple processOrganic compound preparationCarboxylic preparation by ozone oxidationSynthesis methods2-methoxybenzoic acid

The invention discloses synthesis methods of 3, 6-dichloro-2-methoxybenzoic acid and its intermediate. The invention provides the synthesis method of 2, 3, 6-trichlorobenzoic acid. The synthesis method comprises that in the presence of a catalyst, 2, 3, 6-benzotrichloride and an oxidation reagent undergo an oxidation reaction to produce 2, 3, 6-trichlorobenzoic acid. The synthesis methods have simple processes, a high conversion rate, a high yield, high product purity, a low production cost and environmental friendliness and are suitable for industrial production.

Owner:JIANGSU LIANHE CHEM TECH +1

Composite catalyst and application

InactiveCN101947468AQuality improvementHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsHalogenated hydrocarbon preparationAlcoholOrganic synthesis

The invention belongs to the field of organic synthesis, in particular to a composite catalyst and an application thereof in synthesizing benzo-trichloride. The method for preparing the composite catalyst comprises the following steps: adding 1 to 4 parts of initiators into 100 parts of chlorinated raw materials or chlorinated products so as to obtain a mixture A after the initiators are dissolved; adding alcohol-amine compounds into the mixture A, wherein the addition of the alcohol-amine compounds accounts for 0.02 to 0.05% of the mixture A; evenly mixing the alcohol-amine compounds and the mixture A, and standing so as to separate a water layer from an organic layer, then obtaining the organic layer, namely, the composite catalyst. The composite catalyst can be used for generating bis(trichloromethyl) benzene or 2-(trichloromethyl) benzene by catalyzing xylene or chlorotoluene, and solves the problems of long synthesis time, low yield, difficult reaction and a large amount of impurities for the bis(trichloromethyl) benzene in existing catalytic / chlorinated technology.

Owner:ZHEJIANG KANGFENG CHEM

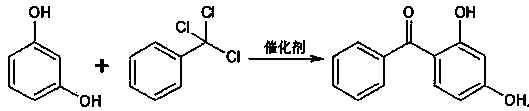

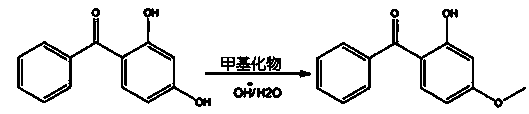

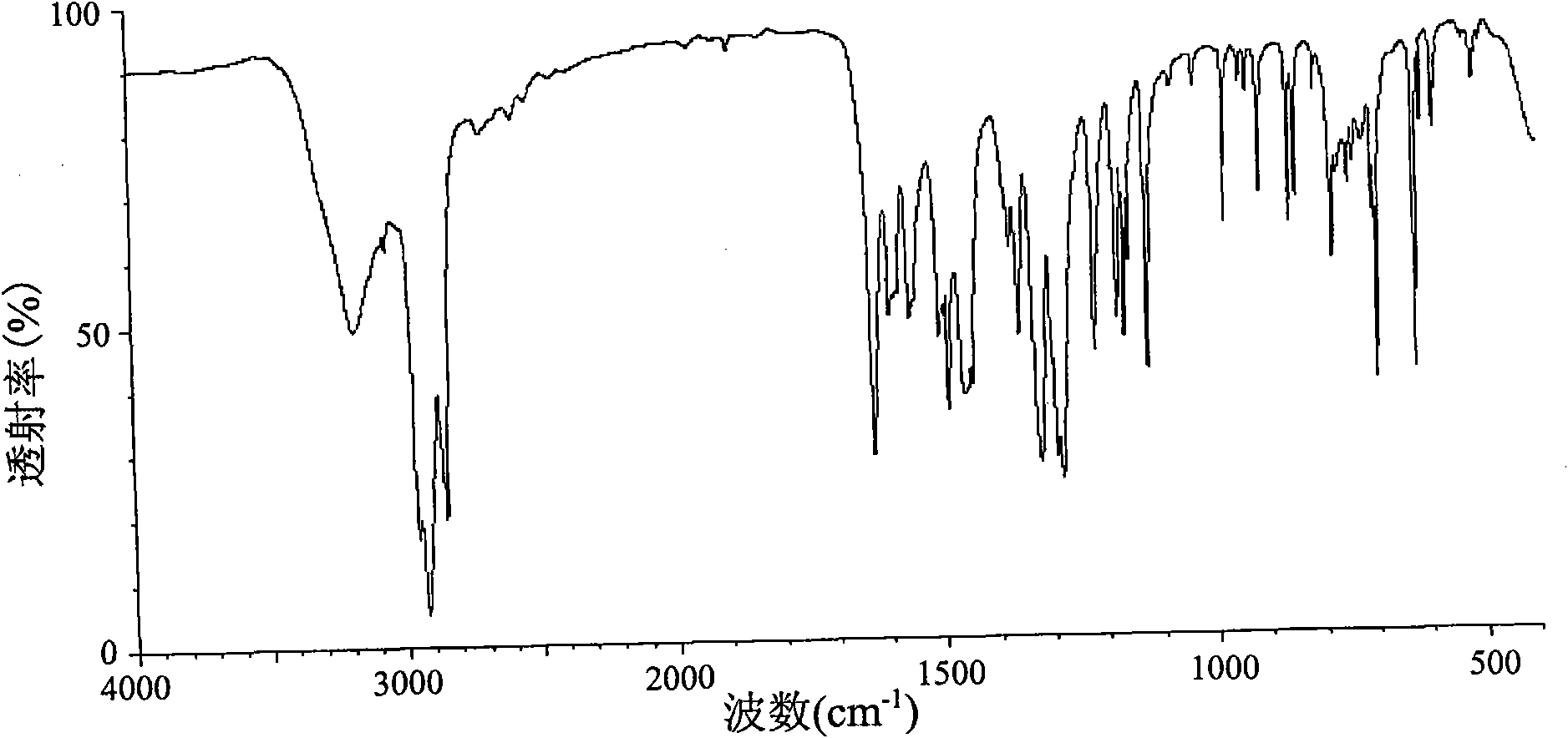

Synthetic method of 2-hydroxy-4-methoxybenzophenone

InactiveCN104163756AThe reaction process is simpleEasy to operateOrganic compound preparationCarbonyl compound preparation by condensationBiochemical engineeringCombinatorial chemistry

The invention discloses a synthetic method of 2-hydroxy-4-methoxybenzophenone. The method comprises the following steps: condensing main raw materials comprising benzenyltrichloride and resorcinol, methylating, and purifying to obtain a final product. Compared with traditional synthetic methods, the synthetic method of 2-hydroxy-4-methoxybenzophenone has the advantages of reduction of Friedel-Crafts and hydrolysis reaction steps through primarily carrying out condensation, simple reaction technology and easy operation; the set of a feed ratio makes the reaction full and complete, so a largest yield is guaranteed; and the final product is obtained through filtering, re-crystallizing and purifying, the purity of the product can reach 95-98%, and the yield of the product can reach above 90%.

Owner:江苏德峰药业有限公司

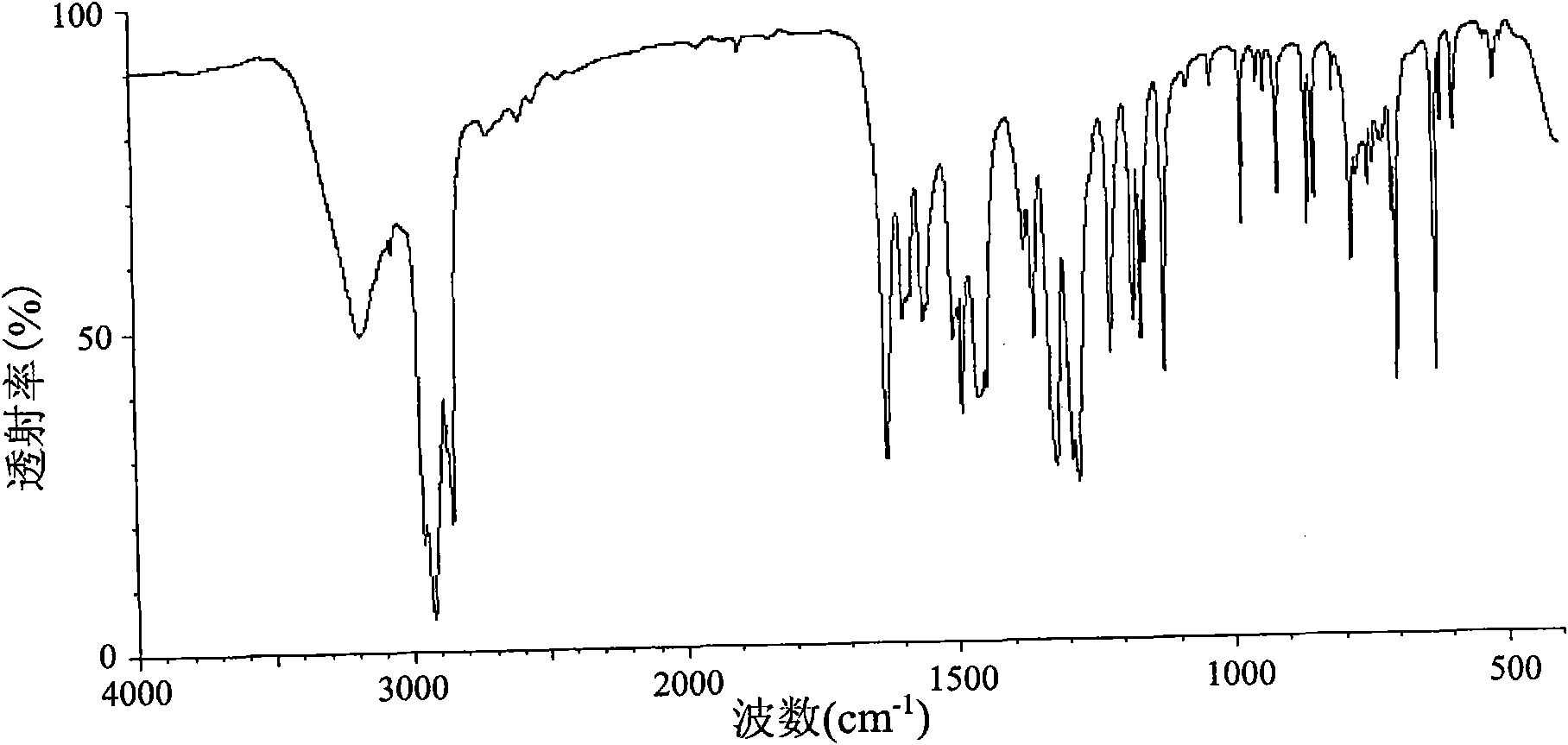

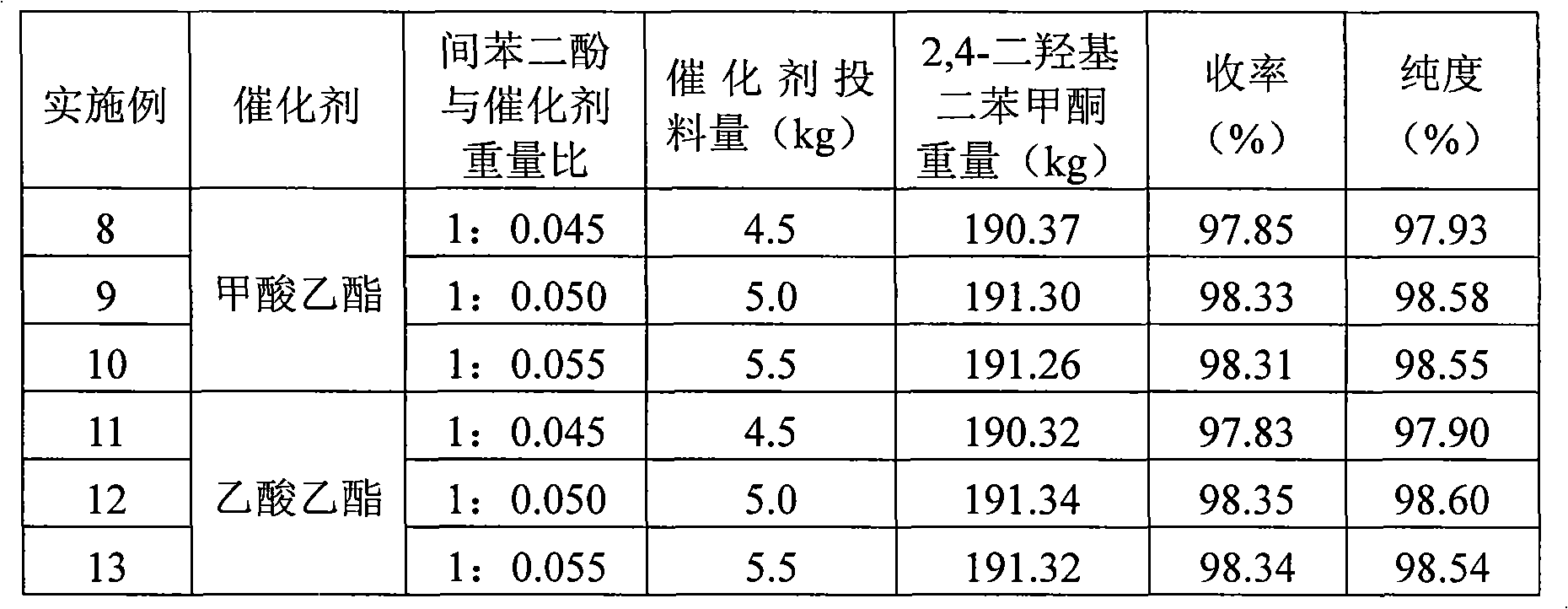

Preparation method of 2,4-dyhydroxyl benzophenone

ActiveCN101830791AReduce the risk of contaminationReduce dosageCarbonyl compound preparation by hydrolysisBenzophenoneResorcinol

The invention relates to a preparation method of 2,4-dyhydroxyl benzophenone, which comprises the steps of: adding resorcinol, water and a catalyst in a reaction container, wherein the catalyst is an ester compound; dripping benzotrichloride under the stirring condition at the temperature of 38-45 DEG C according to a certain proportion at a certain dropping speed, and fully reacting by preserving the temperature at 42-45 DEG C; washing a reactant until the pH value is 6.0-7.0; and centrifuging and drying to obtain the 2,4-dyhydroxyl benzophenone. The method has simple process, safe and convenient operation, less environment pollution, low cost and high product yield and purity.

Owner:HUBEI MEIKAI CHEM

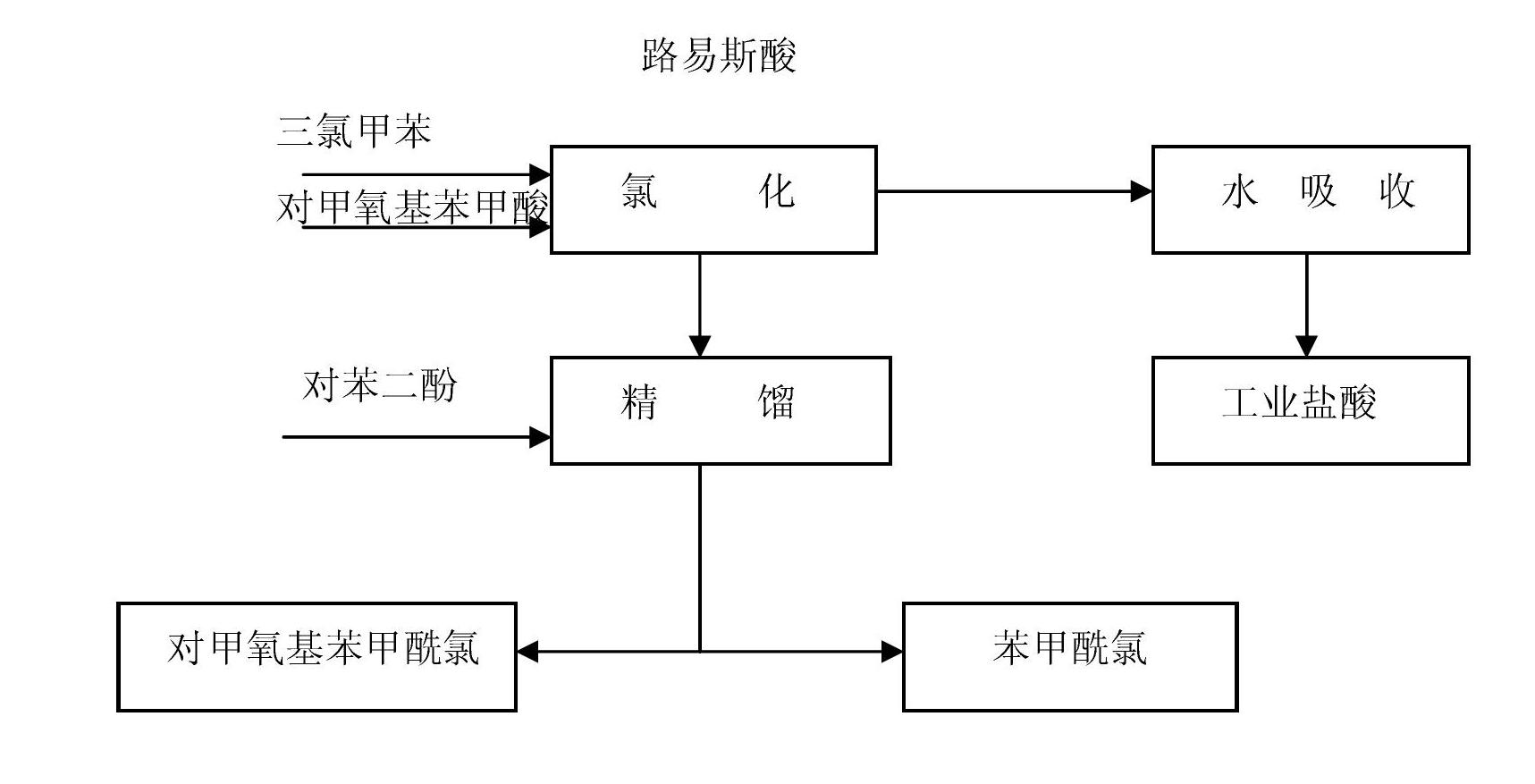

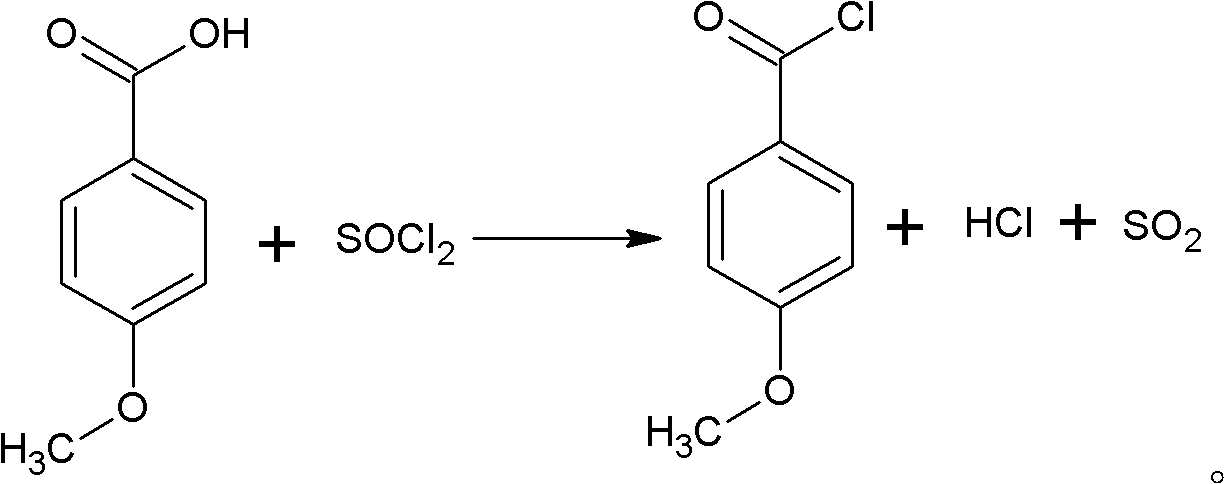

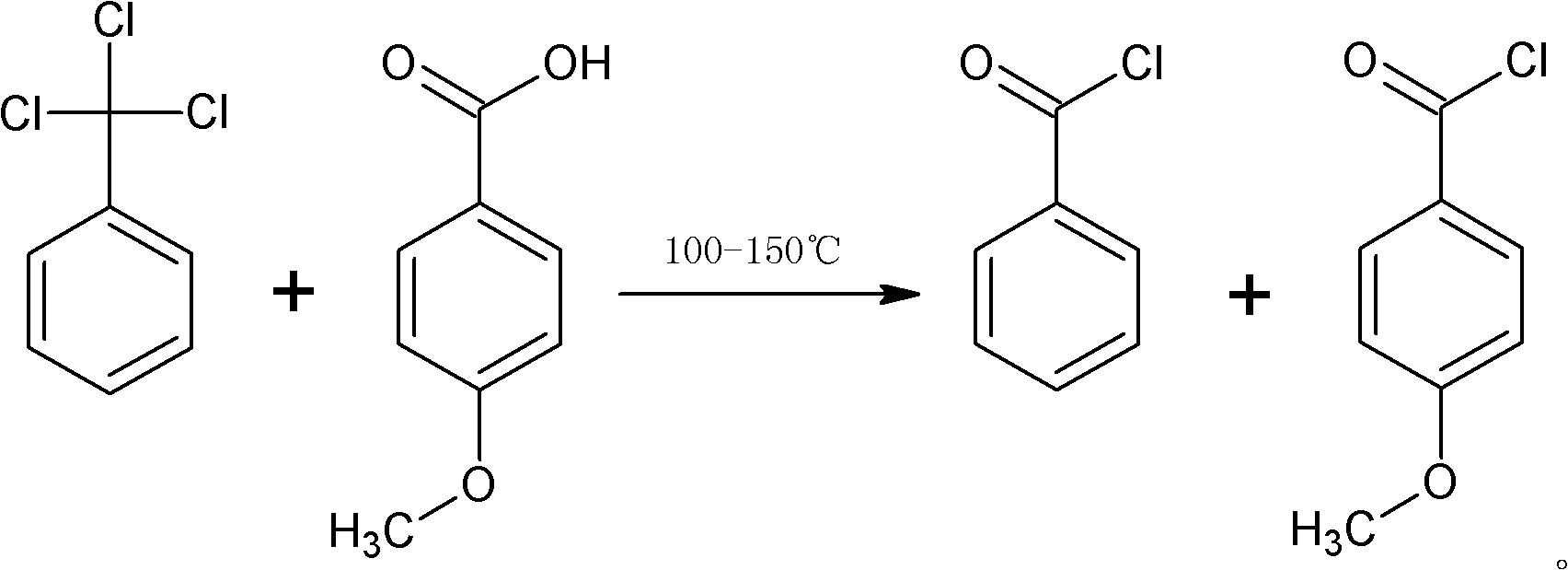

Preparation method of p-anisoyl chloride

ActiveCN102627555AHigh yieldReduce pollutionOrganic compound preparationCarboxylic compound preparationAnisoyl chlorideLewis acid catalysis

The invention relates to a preparation method of p-anisoyl chloride and belongs to the technical field of carbocyclic compounds. The preparation method comprises the following steps that raw materials of benzotrichloride and p-methoxybenzoic acid are mixed by stirring according to a mole ratio of 1: 1; the mixture undergoes an acyl chlonnation reaction in the presence of a lewis acid catalyst at a temperature of 100 to 150 DEG C for 5 to 10 hours; acyl chlonnation reaction products are cooled to a temperature of 20+ / -5 DEG C; the cooled acyl chlonnation reaction products are added with hydroquinone and then are purified so that p-anisoyl chloride and a by-product are obtained. Through the preparation method, low-cost, low-pollution and high-yield p-anisoyl chloride can be synthesized directly and simultaneously, the by-product of benzoyl chloride is obtained. In addition, the preparation method has the advantages that 1, tail gas produced by the preparation method can be absorbed by water and then is prepared into hydrochloric acid for recycle so that environmental pollution is reduced; and 2, the raw materials adopted by the preparation method do not corrode equipment so that an equipment loss is reduced.

Owner:江苏万隆化学有限公司

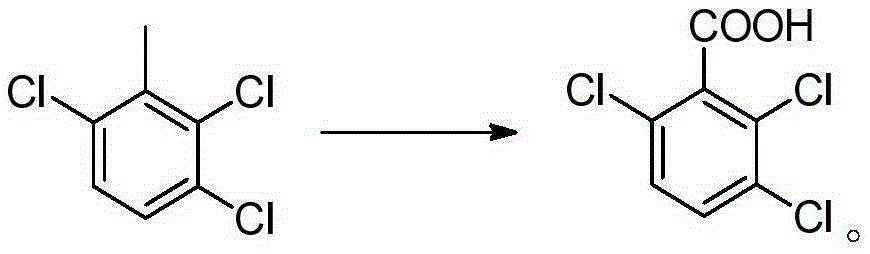

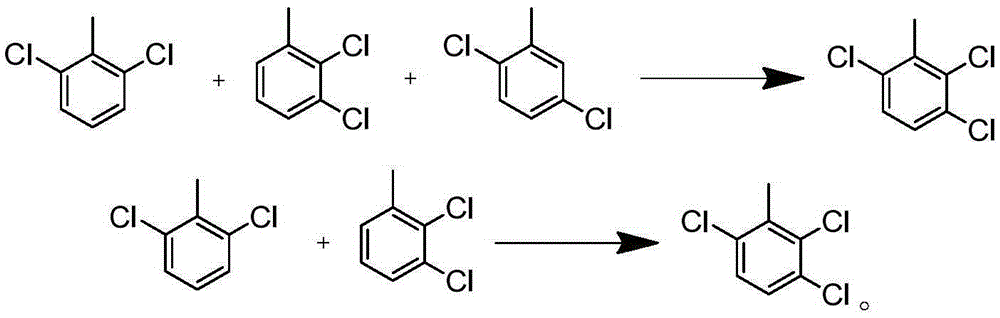

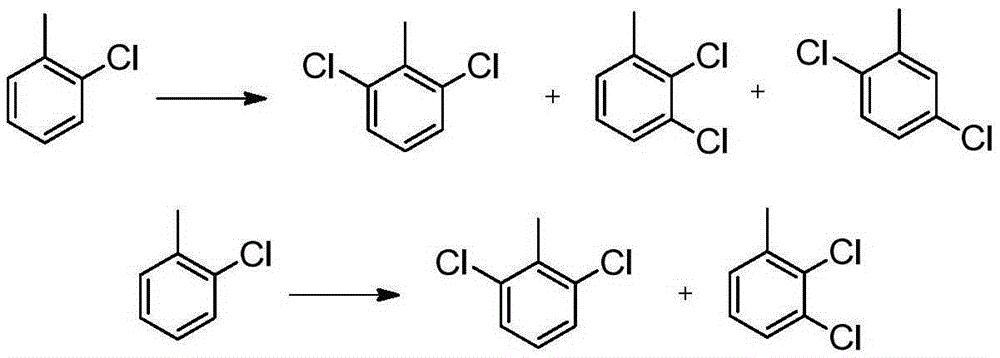

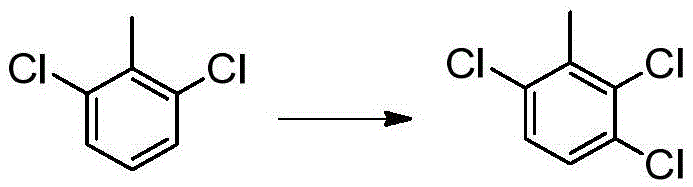

Synthesizing method for 2,3,6-trichlorobenzoic acid and intermediate of 2,3,6-trichlorobenzoic acid

ActiveCN105237330AHigh reaction yieldHigh selectivityOrganic compound preparationHalogenated hydrocarbon preparationMetal halidesTrichlorobenzoic acid

The invention discloses a synthesizing method for 2,3,6-trichlorobenzoic acid and intermediate of the 2,3,6-trichlorobenzoic acid, and provides a preparation method for 2,3,6-trichlorotoluene. The preparation method for the 2,3,6-trichlorotoluene comprises the following steps that on the condition that a catalyst exists, a chlorination reaction is performed on a mixture of dichlorotoluene and a chlorination agent to obtain the 2,3,6-trichlorotoluene; metal and / or metal halide are / is adopted as the catalyst, and a mixture of 2,6-dichlorotoluene and 2,3-dichlorotoluene or a mixture of 2,6-dichlorotoluene, 2,3-dichlorotoluene and 2,5-dichlorotoluene is adopted as the mixture of the 2,6-dichlorotoluene. The synthesizing method is high in reaction yield, selectivity and purity of the prepared product, low in production cost, easy to operate, mild in reaction condition and suitable for industrialize production.

Owner:JIANGSU LIANHE CHEM TECH +2

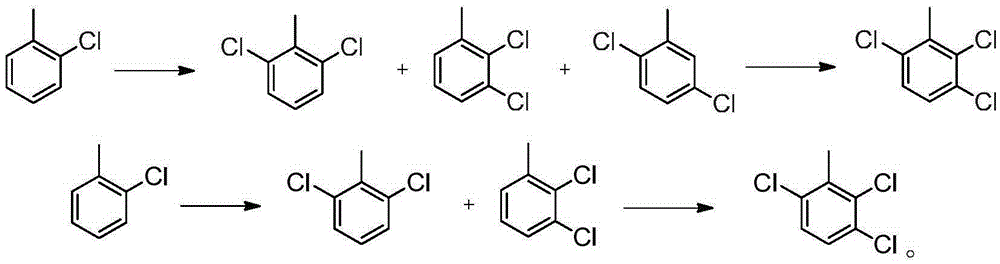

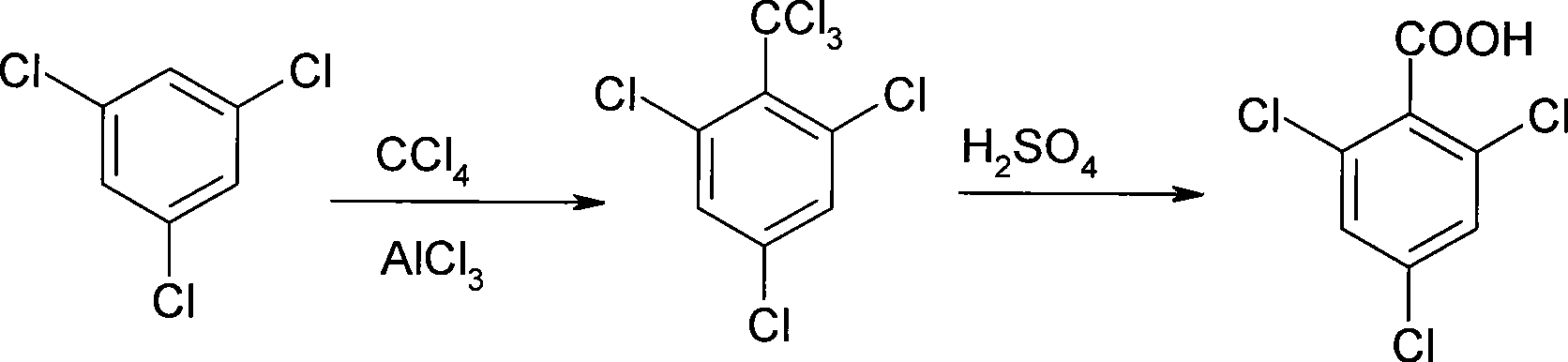

Process for producing 2, 4, 6-trichlorobenzoic acid

InactiveCN101429117ASimple preparation stepsReaction conditions are easy to controlOrganic compound preparationCarboxylic compound preparationBenzenePhenylacetic acid

The invention relates to a method for preparing 2, 4, 6-trichloro-phenylacetic acid. Specifically, 1,3,5-trichloro-benzene and carbon tetrachloride react to generate 2,4,6-trichloro-benzotrichloride; the 2,4,6-trichloro-benzotrichloride and concentrated sulfuric acid react to prepare the 2,4,6-trichloro-phenylacetic acid; and finally, the 2,4,6-trichloro-phenylacetic acid is formed by refining and crystallization. The preparation method has the advantages of low cost, simple reaction steps, easy control of reaction conditions and the like.

Owner:BEIJING ODYSSEY CHEM

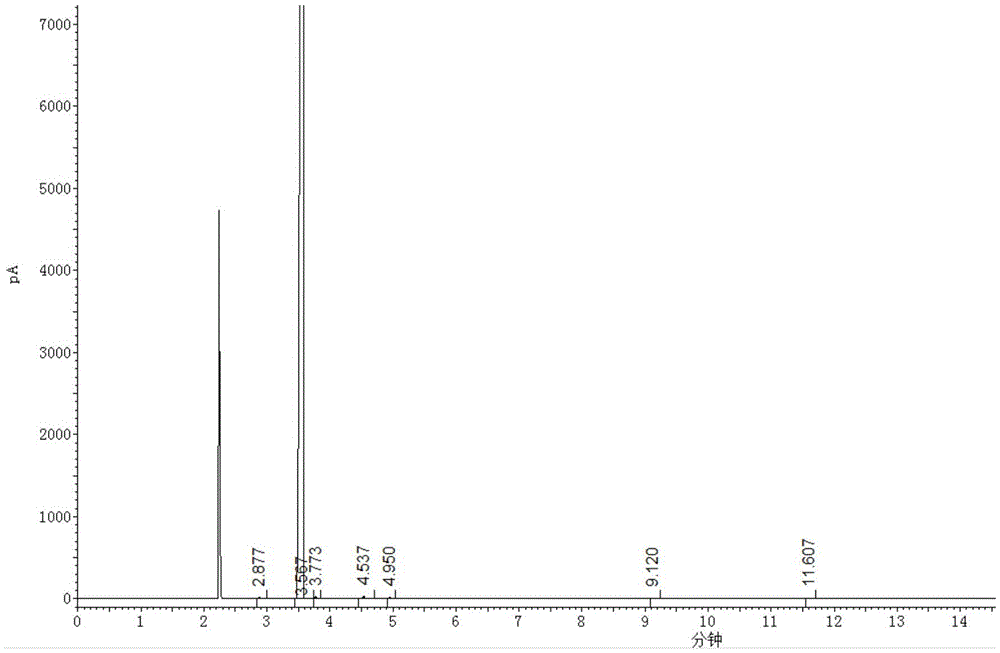

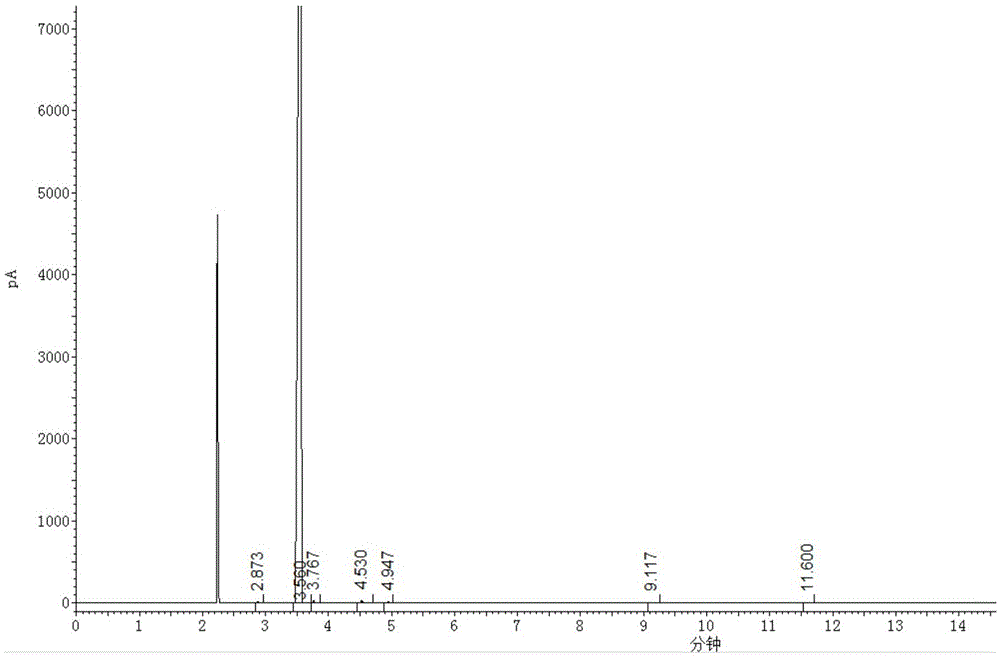

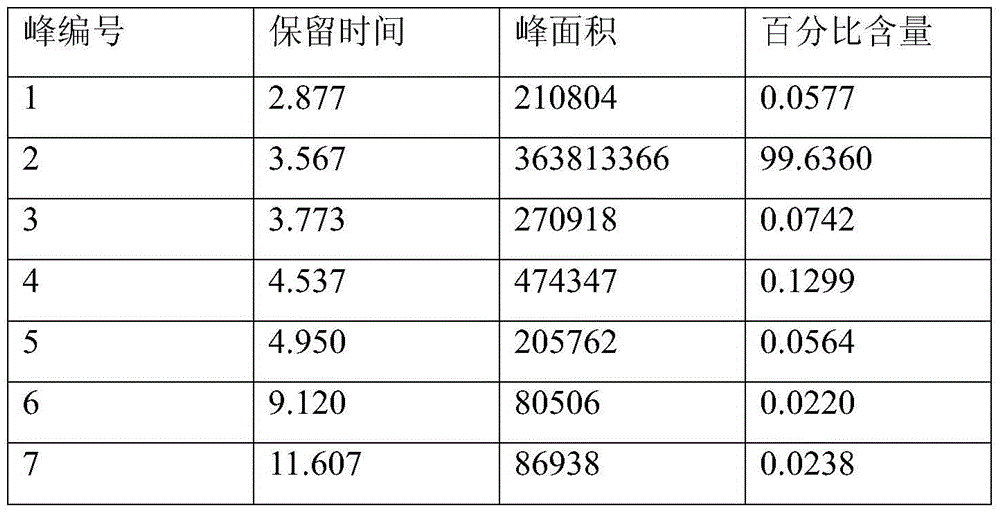

Gas chromatography detection method for benzotrichloride

The invention belongs to the technical of analysis, and particularly relates to a gas chromatography detection method for benzotrichloride. The detection method comprises the steps that 1, a sample to be detected is dissolved with a solvent; 2, working conditions of a gas chromatograph are set, wherein an Agilent DB-5 capillary column is adopted as a chromatographic column, the column box temperature is 150-240 DEG C, the sample inlet temperature is 280 DEG C, the temperature of a detector is 300 DEG C, the flow rate of carrier gas of the chromatographic column is 1 mL / min, the air flow speed is 300 mL / min, the hydrogen flow speed is 30 mL / min, and the split ratio is 100:1; 3, an automatic sampler is used for sampling, and a chromatogram starts to be detected and recorded; 4, an area normalization method is used for calculating out the content of benzotrichloride. The gas chromatography detection method has the advantages of being high in analysis speed, accurate in result, low in analysis cost, capable of effectively and rapidly guiding production arrangement, and capable of accurately measuring the content of a benzotrichloride product.

Owner:SHANDONG KAISHENG NEW MATERIALS

Benzoyl chloride and paraphthaloyl chloride co-production method

InactiveCN105001077ARealize deliveryMeet production requirementsOrganic compound preparationCarboxylic compound preparationReaction temperatureLewis acid catalysis

The invention discloses a benzoyl chloride and paraphthaloyl chloride co-production method. An acylating chlorination reaction is conducted under the action of a lewis acid catalyst with terephthalic acid and trichlorotoluene as raw materials, and paraphthaloyl chloride and benzoyl chloride are generated, wherein the catalyst is one or more of FeCl3, AlCl3, TiCl4 and tetrabutyl titanate, and the amount of the catalyst is 0.1-0.5% of the total mass of reactants; the molar ratio of the trichlorotoluene to the terephthalic acid is 2-3 to 1, the reaction temperature of the acylating chlorination reaction is 70-140 DEG C, and the reaction time is 2-6 hours. The benzoyl chloride is produced while the paraphthaloyl chloride is produced; the benzoyl chloride and paraphthaloyl chloride co-production method has the advantages that the raw materials are obtained easily, the reaction conditions are mild, safety is good, and the comprehensive production cost is low; the sulfur-containing raw material is not used in the new technology, micro sulphur does not exist in the paraphthaloyl chloride product, the inherent quality is high, and the para-aramid fiber production requirement can be met better.

Owner:NANJING FORESTRY UNIV +1

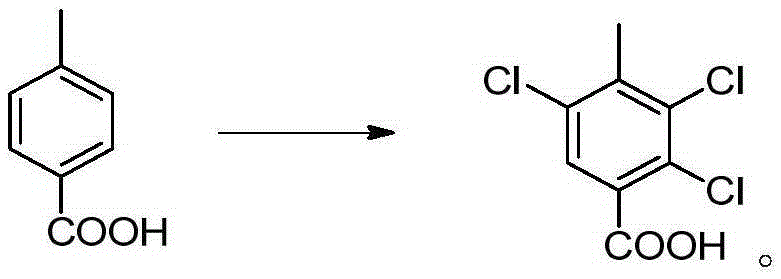

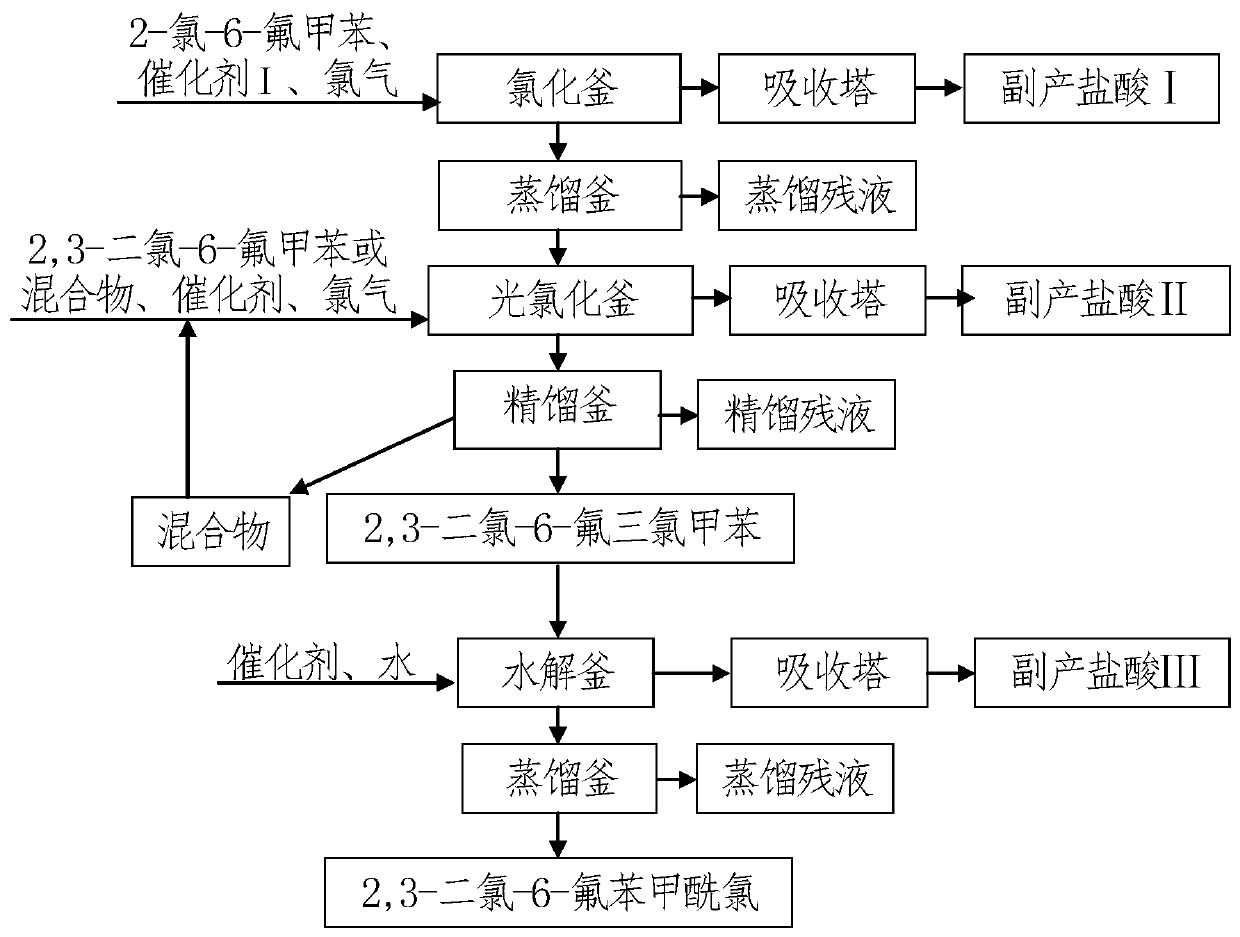

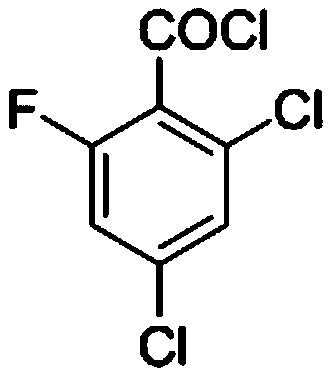

Method for synthesizing 2, 4-dichloro-6-fluorobenzoyl chloride by adopting two-step chlorination process

ActiveCN110937994APrecise location of chlorinationReasonable temperature controlHalogenated hydrocarbon preparationCarboxylic acid halides preparationHydroxylaminePtru catalyst

The invention discloses a method for synthesizing 2, 4-dichloro-6-fluorobenzoyl chloride by adopting a two-step chlorination process. The method comprises the steps of: introducing chlorine into 2-chloro-6-fluorotoluene under the action of a catalyst I to synthesize 2, 4-dichloro-6-fluorotoluene; introducing gas into the 2, 4-dichloro-6-fluorotoluene under the conditions of a catalyst II and illumination, carrying out side chain photochlorination to obtain a chlorination product II, and rectifying the chlorination product II to obtain 2, 4-dichloro-6-fluorotrichlorotoluene; hydrolyzing 2, 4-dichloro-6-fluorotrichlorotoluene under the action of a catalyst III, and distilling a hydrolysate to obtain a finished product 2, 4-dichloro-6-fluorobenzoyl chloride. In the whole reaction process, only one by-product hydrogen chloride is subjected to water spraying absorption, resin adsorption purification and hydroxylamine hydrochloride reduction, and is sold as commercial hydrochloric acid. Themethod has the advantages of a simple route, the excellent product quality, few side reactions, simple byproduct recycling and the like.

Owner:ZHEJIANG DAYANG BIOTECH GROUP

Method for recycling trichlorotoluene and/or benzoyl chloride waste slag

ActiveCN105175242AReduce pollutionReduce manufacturing costPreparation from carboxylic acid halideOrganic compound preparationBenzoic acidSlag

The invention discloses a method for recycling trichlorotoluene and / or benzoyl chloride waste slag, which comprises the following steps: melting the waste slag by heating, distilling the obtained liquid material by vacuum heating to recycle trichlorotoluene and / or benzoyl chloride, absorbing the generated exhaust gas by a falling film absorption tower, and continuing heating the completely distilled material to perform coking, thereby obtaining the coked material with the carbon content of 98% or above; and adding water into the recycled trichlorotoluene and / or benzoyl chloride, heating while stirring, regulating the pH value to 7 or above with a sodium hydroxide solution, separating the solution, adding a hydrochloric acid solution into the supernate to regulate the pH value to 4.8-5.2, cooling to room temperature, and carrying out centrifugal separation to obtain benzoic acid. The method provided by the invention can effectively treat the waste slag and recycle the effective components in the waste slag, thereby enhancing the added value of the product and reducing the environmental pollution.

Owner:YIDU YOUYUAN IND CO LTD

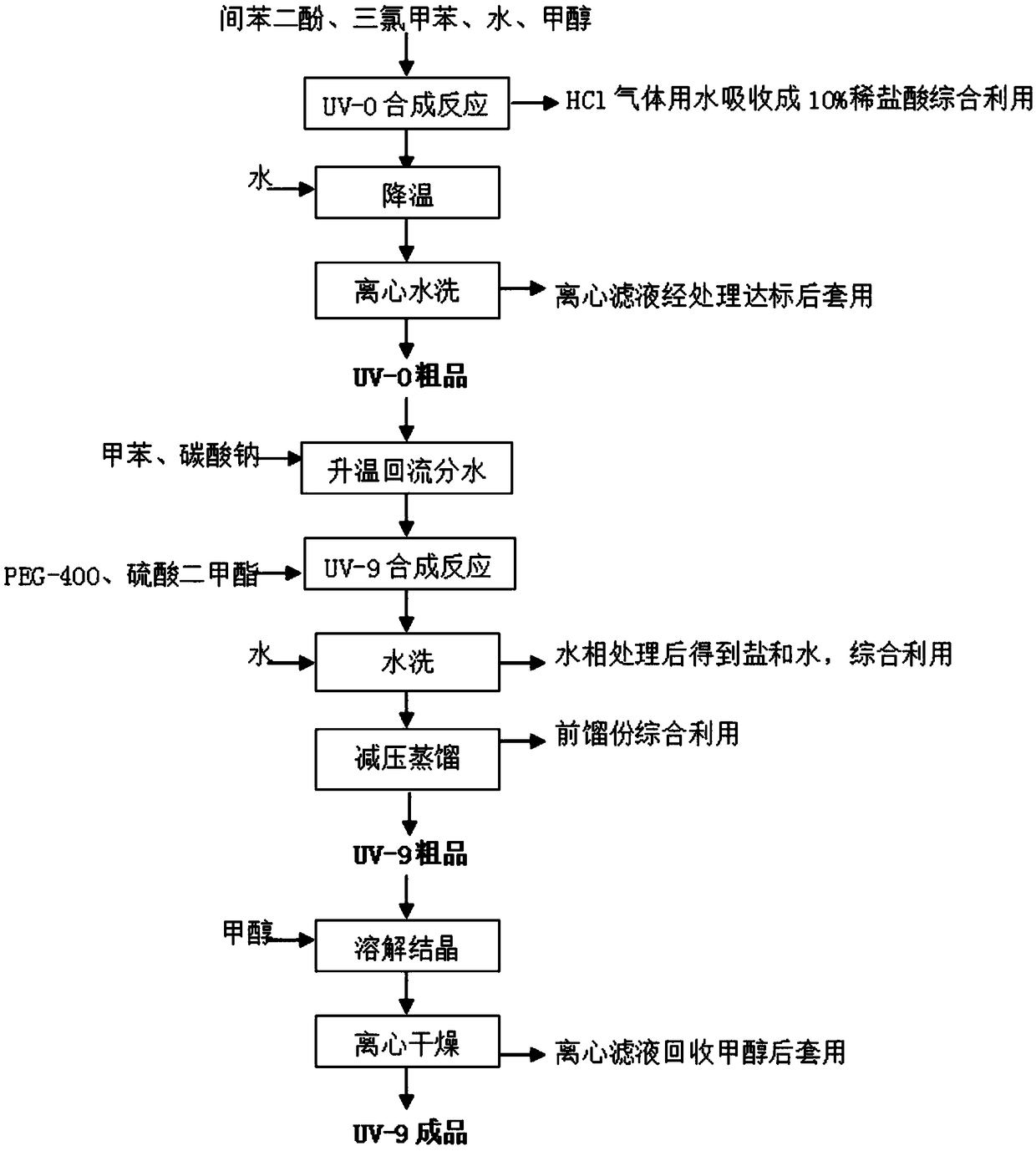

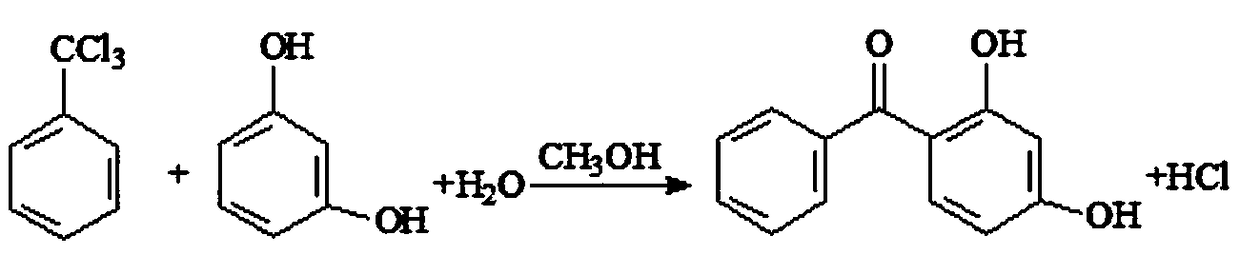

Preparation method of ultraviolet absorbent UV-9

InactiveCN109336754AAvoid uneven colorHigh yieldOrganic compound preparationCarbonyl compound preparationRefluxOrganic solvent

The invention provides a preparation method of an ultraviolet absorbent UV-9. The preparation method comprises following steps: step 1, water and methanol are added to a reaction kettle firstly, stirring is started, resorcinol is added, heating is performed, then benzotrichloride is dropwise added to the reaction kettle until the reaction is completed, mother liquor is subjected to centrifugal spin-drying, washing is performed until pH is neutral, and a UV-0 crude product is obtained; step 2, the UV-0 crude product, toluene and an acid-binding agent sodium carbonate are added to another reaction kettle, heating reflux is performed until no water drops appear, after cooling is performed, a catalyst PEG-400 is added, dimethyl sulfate is dropwise added, a mixture is heated after addition andsubjected to thermal insulation reaction until the components are reacted completely, water is added for washing, a product is left to stand for layering, organic phase is distilled under reduced pressure to remove an organic solvent methylbenzene, and a UV-9 crude product is obtained; step 3, the organic solvent is added to the UV-9 crude product for recrystallization, and a UV-9 finished productis obtained after centrifugation and drying. The problem of non-uniform color of the UV-9 product is solved, the product yield is increased, and the product cost is reduced.

Owner:XIANGYANG JINDACHENG FINE CHEM

A kind of synthetic method of 5-bromo-2-chlorobenzoic acid

ActiveCN105622382BEasy to operateHigh purityOrganic compound preparationCarboxylic compound preparationBenzoic acidSynthesis methods

The invention provides a synthesis method of 5-bromo-2-chloro benzoic acid.The method includes the following steps of A, making 2-chlorine benzotrichloride and bromide reagents react under the effect of a catalyst to obtain 2-chloro-5-bromine benzotrichloride, wherein bromide reagents include one or more of bromine, N-bromosuccinimide, dibromohydantoin and hydrobromic acid; B, conducting hydrolysis reaction on 2-chloro-5-bromine benzotrichloride in the step A under the acid condition to obtain 5-bromo-2-chloro benzoic acid.According to the method, 2-chlorine benzotrichloride which is low in price and easy to obtain is adopted as the raw material, operation is easy, intermediates do not need to be purified, 5-bromo-2-chloro benzoic acid is synthesized through a one-pot method, purity is high, yield is high, three-waste emission is little, and production cost is low.It is shown through experiment results that 2-chloro-5-benzoic acid obtained according to the synthesis method has yield larger than 95% and purity of 80-92%.

Owner:苏州正济药业有限公司

Synthesizing method of chloride

InactiveCN101037386ATimely distillateImprove working environmentChemical recyclingCarboxylic acid halides preparationCarbonyl chlorideBoiling point

A synthetic method of acyl chloride belongs to the synthetic technical field of the intermediate for the chemical products, consisting of two steps firstly catalyzing the halogenated trichlorotoluene compound and the carboxylic anhydride to produce a single or complex acyl chloride in the effect of the catalyzer, and secondly getting corresponding acyl chloride after rectification. The inventive synthetic method of the acyl chloride can improve the working environment because there provides no excitant gas chlorine hydride. The catalyzer can be recycled. The yield is high in unit period because the produced carbonyl chloride with the low boiling point can be drived off in time.

Owner:江苏强盛功能化学股份有限公司

Method for purifying benzoyl chloride reaction terminating solution

InactiveCN102557923ASimple operation processNo "three wastes"Organic compound preparationCarboxylic compound preparationBenzoic acidGreen environment

The invention discloses a method for purifying a benzoyl chloride reaction terminating solution. The method comprises the following steps of: reacting benzotrichloride serving as a main raw material with benzoic acid or water in the presence of a ferric trichloride catalyst to prepare a benzoyl chloride reaction terminating solution, performing precision filtration through active carbon in a metal filter at a certain temperature to obtain a benzoyl chloride finished product, regenerating the active carbon, and collecting a ferric trichloride solution and a benzoic acid solid for recycling. The method is simple in operation process, 'three wastes' are nearly not produced in the whole production process, the yield and the quality of the product are high, and the method is an ideal green environment-friendly process.

Owner:JIANGSU YUANYANG PHARMA

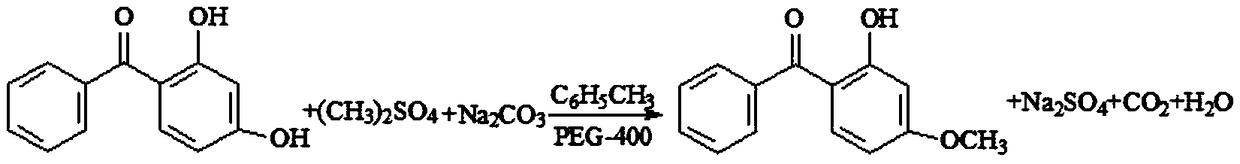

Method for preparing p-chlorodiphenyl ketone

InactiveCN104610036AFew reaction stepsLess investmentCarbonyl compound preparation by condensationBenzoic acidMeth-

The invention discloses a method for preparing p-chlorodiphenyl ketone. According to the method, p-chlorotrichloromethyl benzene, p-chlorobenzoic acid and benzene are subjected to Friedel-Crafts reaction in the presence of a catalytic amount of Lewis acid, such as FeCl3 to prepare p-chlorodiphenyl ketone. The method is performed under the conditions of a heating temperature of 150 DEG C-180 DEG C and a pressure of 0.5-0.8MPa, the molar ratio of p-chlorotrichloromethyl benzene to benzene is 1: (2-5), the molar ratio of p-chlorobenzoic acid to p-chlorotrichloromethyl benzene is 1: 1, the yield of p-chlorodiphenyl ketone is 90%, the disadvantage of aluminum-salt-containing wastewater pollution caused by catalysis of equimolar anhydrous AlCl3 used in the conventional acylation method is eliminated, the multi-step reaction of firstly preparing acyl chloride and then carrying out acylation in the traditional method is avoided, no isomer is generated and the product is high in quality.

Owner:JIANGSU MARINE RESOURCES DEV RES INST LIAN YUNGANG +1

Preparation method of o-chlorobenzonitrile

InactiveCN101941923AImprove securityHigh yieldCarboxylic acid nitrile preparationOrganic compound preparationDistillationNormal case

The invention discloses a preparation method of o-chlorobenzonitrile, which comprises the following steps: 1. weighing 3000kg of o-chlorobenzotrichloride prepared by chlorination, and sucking the o-chlorobenzotrichloride into a cyanation kettle; 2. adding 765kg of ammonia salt to the kettle with 3000kg of o-chlorobenzotrichloride while stirring, finishing the charging, starting a hydrochloric acid absorption system, and starting a heating valve for warming; 3. when the temperature of the kettle rises to 150 DEG C, adding 1kg of catalyst to the kettle, heating while stirring, keeping the inside of the kettle under negative micro-pressure all the time, and absorbing chlorine hydride produced by reaction of materials to obtain the byproduct hydrochloric acid; 4. when the temperature of the kettle reaches 195 DEG C, keeping the temperature for reaction, and carrying out chromatographic tracking detection, wherein the reaction finishes when the content of benzotrichloride is lower than and equal to 0.02%, and the reaction time is about 30 hours in normal cases; 5. and sucking the material which is subject to cyanation into a distillation kettle, and carrying out reduced pressure distillation to obtain the finished product o-chlorobenzonitrile of which the content is greater than and equal to 99%.

Owner:冯振灿

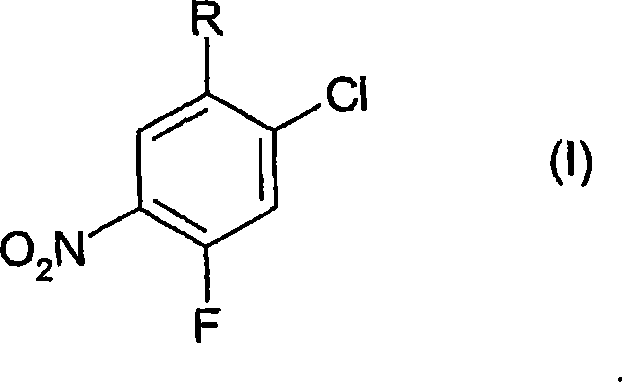

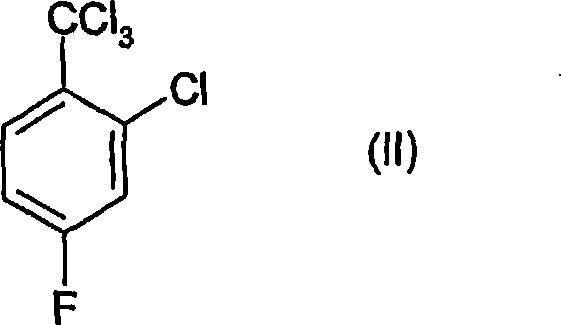

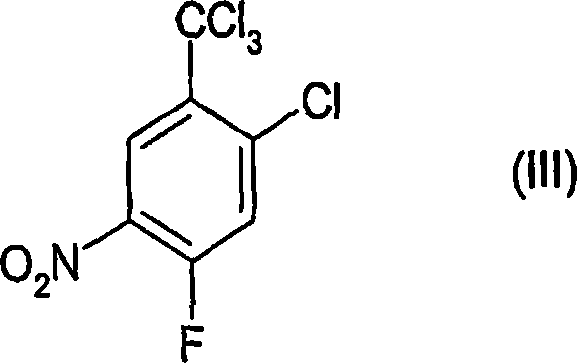

Process for the preparation of benzoic acid derivatives via a new intermediate of synthesis

The object of the invention is the preparation of 2-chloro-4-fluoro-5-nitrobenzoic acid and derivatives thereof, by nitration of 2-chloro-4-fuorobenzotrichloride and the conversion of the novel synthetic intermediate thus obtained into its acid form or derivatives thereof; a further object of the invention is the conversion of benzotrichloride synthetic intermediates into the corresponding benzotrifluoride derivatives.

Owner:BASF AG

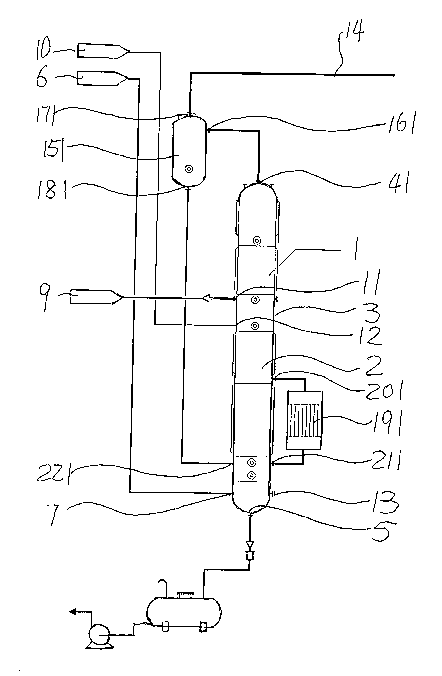

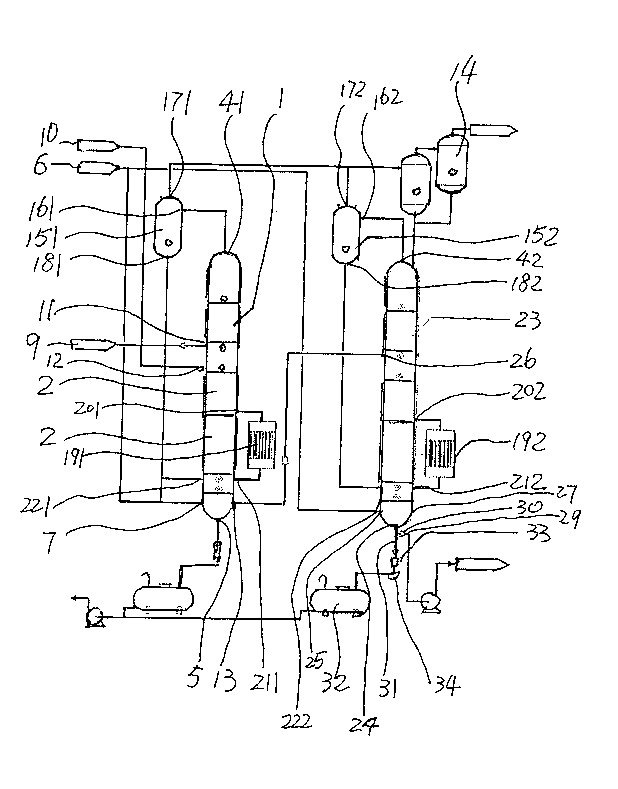

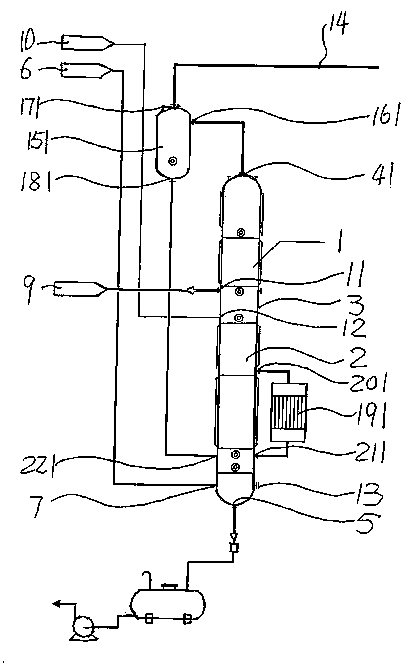

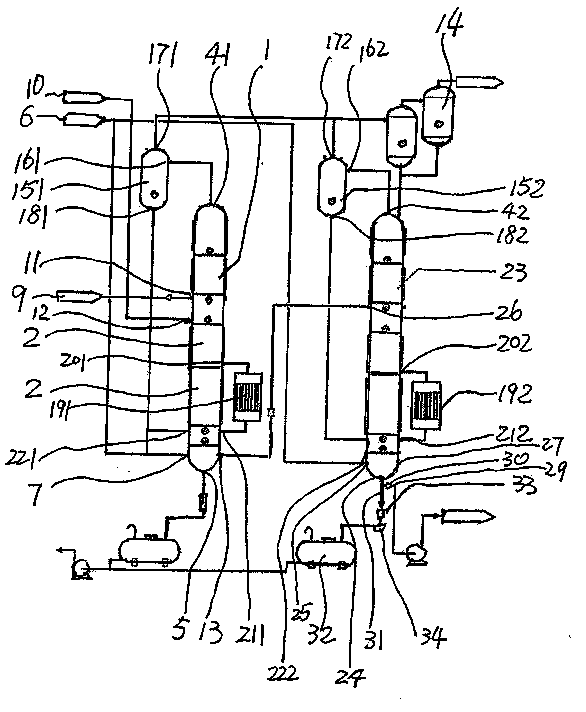

Technique and device for continuously refining heavy liquid paraffin

ActiveCN103289744AImprove qualityEfficient separationPetroleum wax refiningParaffin waxChemical reaction

The invention belongs to the technical field of refinement of heavy liquid paraffin, and particularly discloses a technique and device for continuously refining heavy liquid paraffin. The main technical scheme is as follows: liquid paraffin, hydrogen chloride gas and softened water simultaneously and continuously enter a first-stage reaction tower, of which the height is 10 meters or so, to react; the softened water absorbs hydrogen chloride to be converted into hydrochloric acid; the hydrochloric acid is further subjected to chemical reaction with aromatic hydrocarbons, basic nitrogen and iron ions in the liquid paraffin to generate benzyl chloride, toluene dichloride, benzotrichloride, benzotrichloride, iron chloride, pyridinium, quinoline salt and the like with the specific gravity of greater than 1 g / ml, which are dissolved or mixed in the hydrochloric acid with the specific gravity of 1.16 g / ml; and thus, the substances with the specific gravity of greater than 1 g / ml can be separated from the clean liquid paraffin with the specific gravity of 0.8 g / ml. The device and method disclosed by the invention can be used for completely separating the impurities from the liquid paraffin, and more importantly, the closed circulating device has the characteristic of environmental protection.

Owner:河北大景大搪化工设备有限公司

Synthetic method of 2,3,6-trichlorotoluene

The invention discloses a synthetic method of 2,3,6-trichlorotoluene. The invention provides the synthetic method of 2,3,6-trichlorotoluene, wherein the synthetic method includes the following steps: in the presence of a catalyst, 2,6-dichlorotoluene and a chlorination reagent are subjected to a chlorination reaction to obtain 2,3,6-trichlorotoluene, wherein the catalyst is a metal and / or a metal halide. The synthetic method has the advantages of simple preparation method, high yield, high selectivity, high purity of the prepared product, cheap and easy obtained raw materials and low production cost, and is suitable for industrialized production.

Owner:JIANGSU LIANHE CHEM TECH

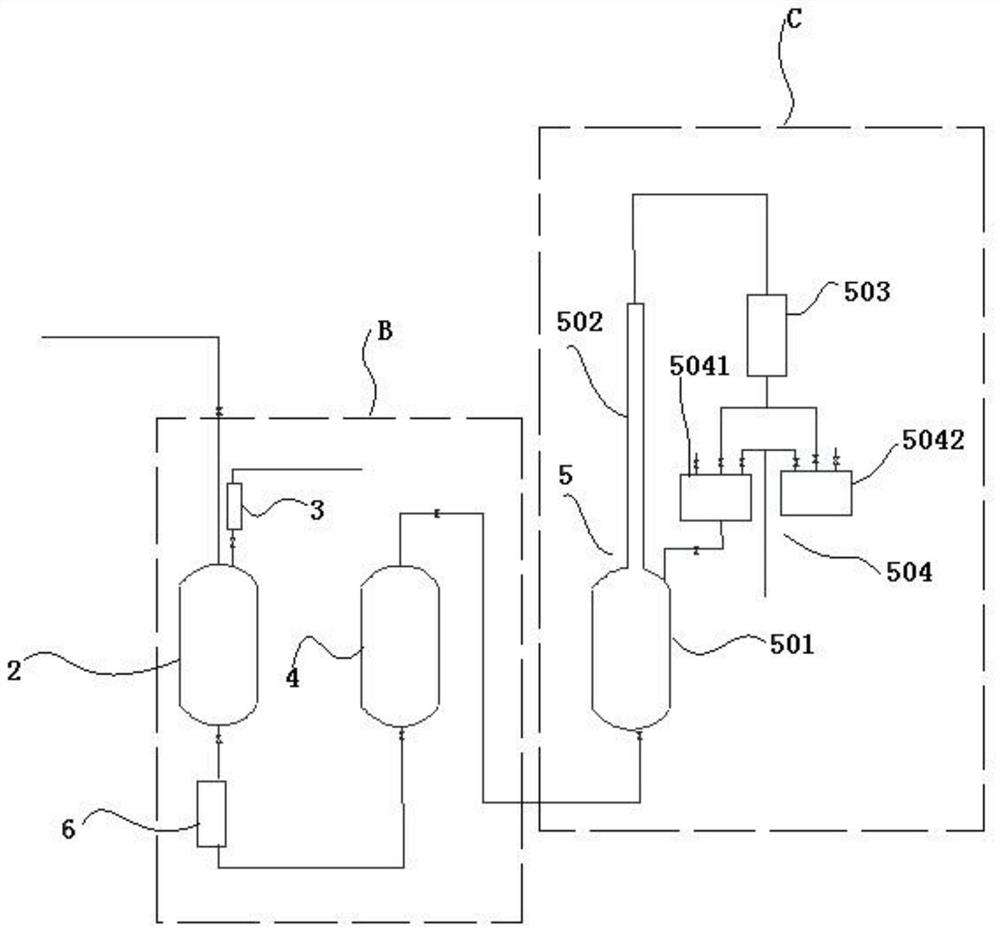

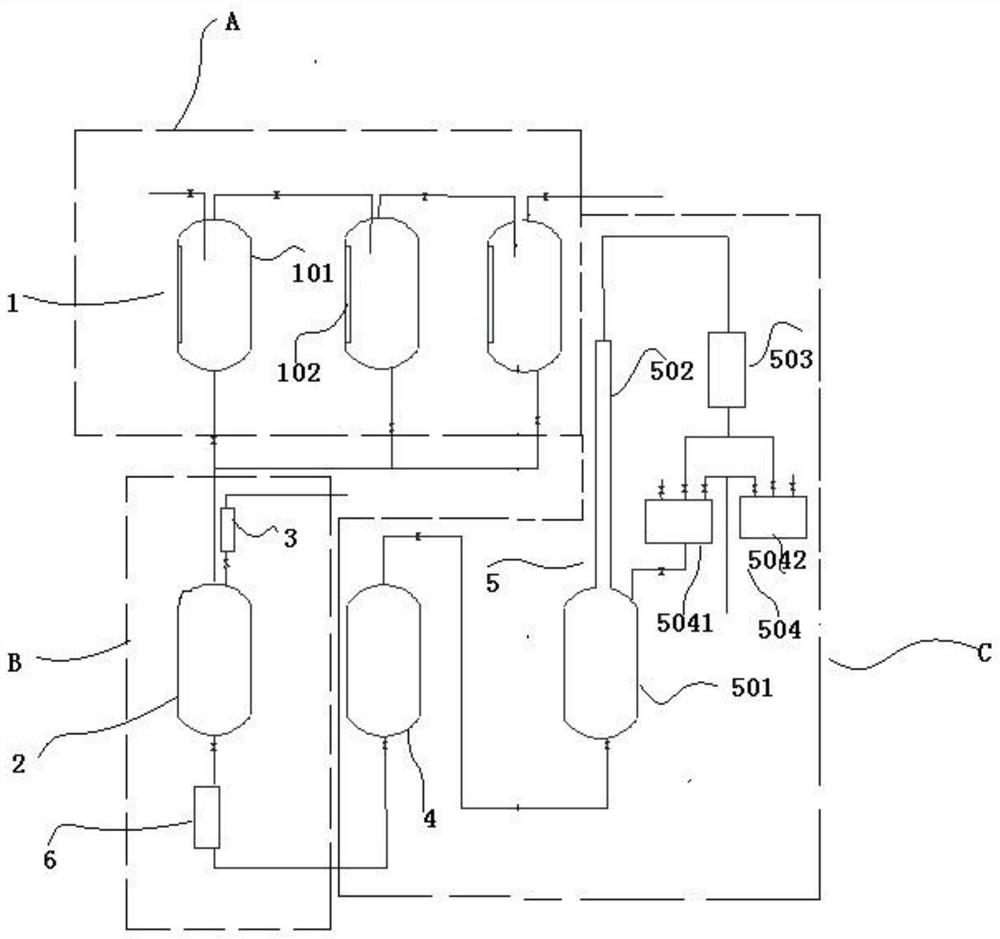

Preparation process and system of o-chlorobenzonitrile

InactiveCN112194597AAvoid dangerHigh yieldPreparation by hydrocarbon ammoxidationHalogenated hydrocarbon preparationChlorobenzenePtru catalyst

The invention provides a preparation process and system of o-chlorobenzonitrile. The preparation process of o-chlorobenzonitrile comprises the steps: mixing o-chlorobenzotrichloride and ammonium chloride, and carrying out ammoniation reaction under the catalysis of copper oxide to obtain o-chlorobenzonitrile. Compared with the prior art, the method has the beneficial effects that copper oxide is used as a catalyst, so that the whole reaction process can be in a stable state, and dangers caused by violent temperature rise are avoided.

Owner:HUBEI SHANSHUI CHEM

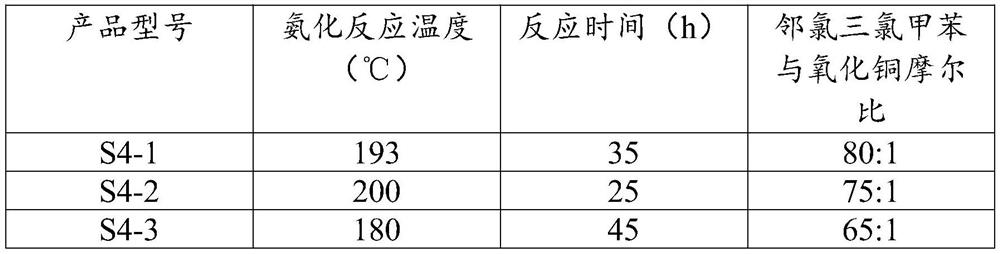

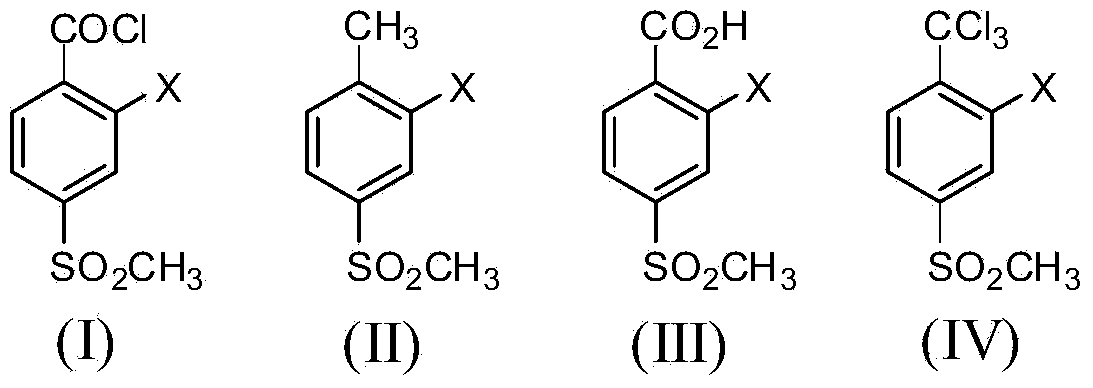

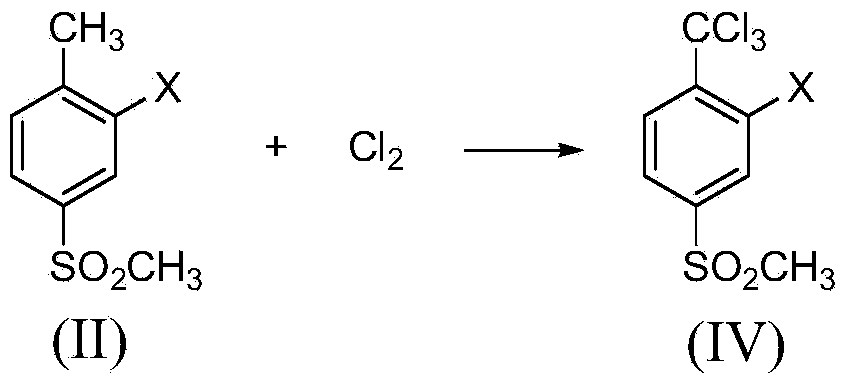

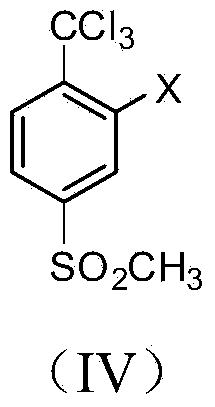

2-substituent-4-methylsulfonyl-alpha,alpha,alpha-trichlorotoluene, and preparation method and application thereof

ActiveCN103664714AShort process routeLow costOrganic chemistryOrganic compound preparationOrganic solventSynthesis methods

The invention discloses 2-substituent-4-methylsulfonyl-alpha,alpha,alpha-trichlorotoluene having a structure represented by formula (IV), and a preparation method and an application thereof. The preparation method comprises the following steps: adding 2-substituent-4-methylsulfonyltoluene having a structure represented by formula (II), an inert organic solvent and an acid binding agent into an autoclave, introducing chlorine, closing the autoclave, heating to 20-150DEG C for a reaction at 0.1-2MPa for 4-40h, and post-processing the obtained reaction solution after the reaction to obtain the above product (IV). The above compound (IV) can be used for synthesizing a triketone herbicide key intermediate 2-substituent-4-methylsulfonylbenzoyl chloride represented by formula (I). Compared with present 2-substituent-4-methylsulfonylbenzoyl chloride synthesis methods, the method has the advantages of short process route, few three wastes, low cost and the like.

Owner:ZHEJIANG UNIV OF TECH

A process and device for continuous refining of heavy liquid paraffin

ActiveCN103289744BImprove qualityEfficient separationPetroleum wax refiningParaffin waxChemical reaction

Owner:河北大景大搪化工设备有限公司

Preparation method of 5-bromo-2-chlorobenzoic acid

PendingCN111620778AHigh purityImprove responseOrganic compound preparationCatalystsBenzoic acidCupric bromide

The invention relates to a preparation method of 5-bromo-2-chlorobenzoic acid, which is characterized by comprising the following steps: reacting 2-chlorobenzotrichloride used as a raw material with abromination reagent under the catalytic action of a first catalyst to generate 2-chloro-5-bromobenzotrichloride, adding water and a hydrolysis catalyst into the 2-chloro-5-bromobenzotrichloride, andcarrying out after-treatment and purification to obtain 5-bromo-2-chlorobenzoic acid, wherein the first catalyst is prepared by compounding iron bromide, ferrous bromide, copper bromide, (ferrocene methyl) trimethyl ammonium bromide and brominated ferrocene. The invention further discloses the 5-bromine-2-chlorobenzoic acid prepared according to the preparation method of the 5-bromine-2-chlorobenzoic acid. According to the preparation method of 5-bromine-2-chlorobenzoic acid disclosed by the invention, the traditional preparation process conditions are optimized and innovated, so that the product purity, the reaction conversion rate and the production efficiency are effectively improved, the preparation cost is low, the environmental pressure is low, the synthesis route is short, the operation is simple and feasible, the emission of three wastes is reduced, and the reaction yield is high.

Owner:吴赣药业(苏州)有限公司

Method for preparing 2,4-dichlorotoluene by using parachlorotoluene

InactiveCN105367380ASuppress generationHigh selectivityHeterogenous catalyst chemical elementsHalogenated hydrocarbon preparationReaction temperatureChloride

The invention discloses a method for preparing 2,4-dichlorotoluene by using parachlorotoluene. The method comprises the steps of (a) adding a chlorination catalyst; (b) chlorinating the parachlorotoluene; and (c) separating components. According to the method, a mixture of aluminum oxide, ferric chloride, aluminum trichloride and silicon dioxide is taken as the catalyst for a chlorination reaction, so that the selectivity for 2,4-dichlorotoluene is effectively promoted. The production of poly-chlorotoluene such as benzotrichloride and tetrachlorotoluene is effectively inhibited due to a low reaction temperature, and the yield of 2,4-dichlorotoluene is improved. Moreover, the method is simple and convenient; the operation is easy; the effects are good; and the product yield is high.

Owner:NANJING ZHONGTENG CHEM

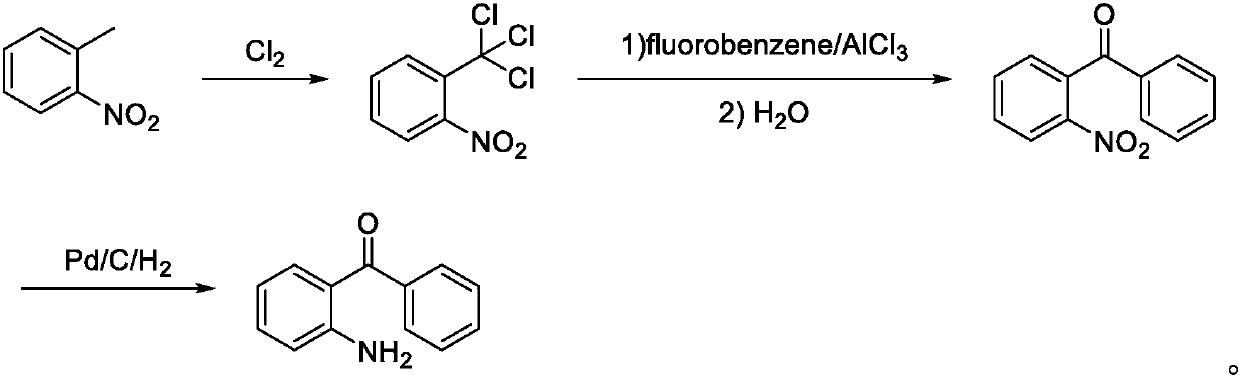

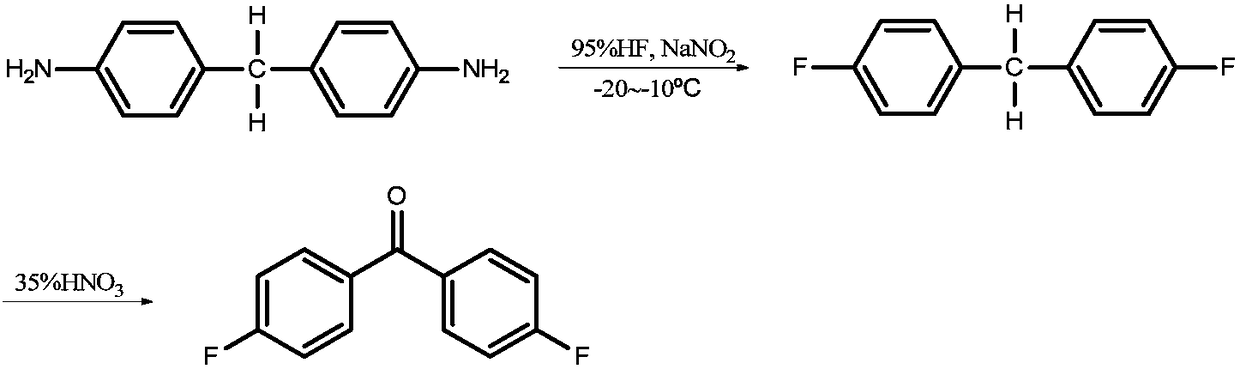

Preparation method of 2-amino-4'-fluoro-diphenyl ketone

ActiveCN107673982AHigh yieldHigh purityOrganic chemistryOrganic compound preparationTolueneFluorobenzene

The invention discloses a preparation method of 2-amino-4'-fluoro-diphenyl ketone. The preparation method comprises the following steps that ortho-nitrotoluene is chloridized by chlorine gas to obtainO-nitrotrichlorotoluene; then the O-nitrotrichlorotoluene performs Fridel-Crafts hydrolysis reaction with fluorobenzene to obtain 2-nitryl-4'-fluoro-diphenyl ketone; the 2-amino-4'-fluoro-diphenyl ketone is obtained through reduction. The synthetic route of the method is green and friend to the environment, the yield is high, the prepared 2-amino-4'-fluoro-diphenyl ketone is high in purity, the starting raw materials are cheap and easy to obtain, and the method is low in cost, easy to operate and suitable for industrial production.

Owner:ANHUI QINGYUN PHARMA & CHEM

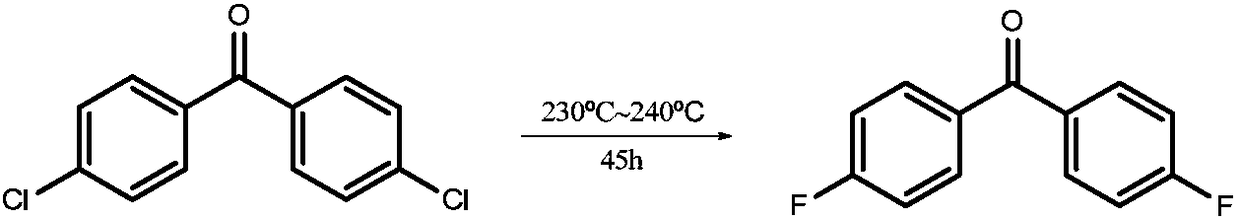

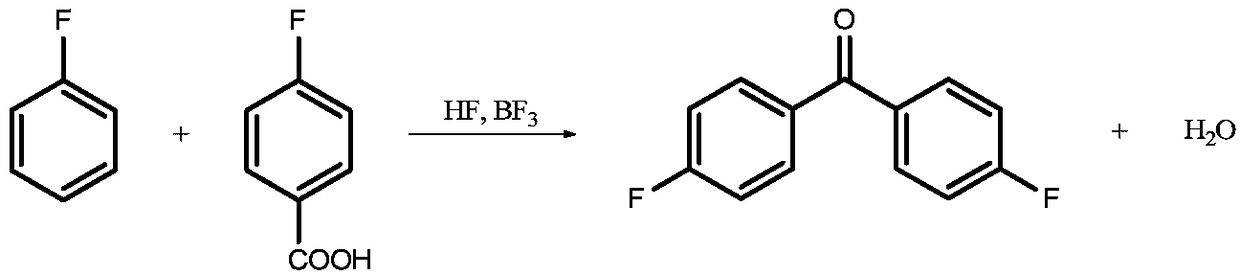

A kind of preparation method of 4,4'-difluorobenzophenone

ActiveCN106045828BSimple processHigh yieldCarbonyl compound preparation by hydrolysisChemical synthesisHydrolysis

The invention relates to a preparation method of 4,4'-difluorobenzophenone, belonging to the field of chemical synthesis. The preparation method comprises the steps of carrying out acylation reaction on fluorine benzotrichloride and fluorobenzene under the catalysis of aluminum trichloride, and carrying out hydrolysis reaction, so as to obtain 4,4'-difluorobenzophenone. The preparation method of 4,4'-difluorobenzophenone has the beneficial effects of simple process, high yield, good selectivity and low cost.

Owner:大连鼎燕医药化工有限公司

High-toughness antistatic foamed polypropylene and preparation method thereof

The invention discloses high-toughness antistatic foamed polypropylene and a preparation method of the high-toughness antistatic foamed polypropylene. The high-toughness antistatic foamed polypropylene comprises the following components in parts by weight: 20-25 parts of colorless polypropylene particles, 10-15 parts of colored polypropylene particles, 2-4 parts of carbon black, 5-10 parts of an antistatic agent, 2-3 parts of a bacteriostatic agent, 3-5 parts of an anti-aging agent, 2-5 parts of a lubricant, 8-10 parts of cyclic fatty acid methyl ester, 4-8 parts of methyl phosphate and 3-5 parts of sodium dodecyl benzene sulfonate. The preparation method has the advantages of light weight and heat insulation, twice screening is carried out in the preparation process, particles with uniform sizes can be screened out each time, and uniform sizes of foamed polypropylene particles are guaranteed; added phenol can be mixed with trichlorotoluene and N-N '-diphenyl-p-phenylenediamine for use, the ageing resistance of the product is improved, bromine water is added in the preparation process, inert gas can be emitted in the combustion process, then the oxygen content is reduced, the certain flame retardant purpose is achieved, and the flame retardant property is improved.

Owner:JIANGSU HAOSHENG PLASTIC IND TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com