Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "No "three wastes"" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon-based compound fertilizer containing probiotic organisms and preparation method of carbon-based compound fertilizer

ActiveCN102649655AReduced chances of reproductionReduce crop diseasesFertilizer mixturesFertilizerDecomposition

The invention discloses a carbon-based compound fertilizer containing probiotic organisms. The carbon-based compound fertilizer comprises biomass carbon black and probiotics, wherein the biomass carbon black is prepared by the following method: carrying out low-temperature carbonization on agricultural wastes as biomass raw materials to form porous biomass carbon black. The probiotics are prepared by the following method: carrying out amplification culture on beneficial microorganisms and fermenting to form probiotic liquid; and mixing and then carrying out solid-liquid separation and expansion drying to form the probiotics, wherein the beneficial microorganisms are selected from one or more of peanibacillus ploymyxa, trichoderma, nitrogen-fixing bacteria, root nodule bacteria, phosphate-solubilizing bacteria, potassium bacteria, cellulose decomposition bacteria, antibiotic-producing strain and photosynthetic bacteria. The carbon-based compound fertilizer disclosed by the invention is made of microporous biomass carbon, and thus the carbon-based compound fertilizer has extremely-strong adsorption capacity and favorable light absorbing and temperature increasing effects; in addition, the probiotics of the carbon-based compound fertilizer are high in cell viability; and the carbon-based compound fertilizer can be preserved at normal temperature for a long time, can be mixed, granulated and dried with other organic and inorganic fertilizers without being influenced and is remarkable in synergistic action.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +2

Biochar base soil modifier and preparation method thereof

ActiveCN102660291AReduce leaching wasteGood sustained release effectAgriculture tools and machinesOrganic fertilisersDecompositionCarbonization

The invention discloses a biochar base soil modifier and a preparation method thereof. The biochar base soil modifier comprises the following components in percentage by weight: 95.5-98.5% of biomass carbon black and 1.5-4.5% of probiotics agent. Agricultural waste serves as a biomass raw material to carry out low-temperature carbonization to form the porous biomass carbon black; beneficial microorganism is enlarged and cultivated and is fermented into probiotics liquid; after mixing, solid and liquid separation, flash evaporation and drying are carried out to obtain the probiotics agent; the beneficial microorganism is selected from one or more of paenibacillus polymyxa, trichoderma strains, nitrogen-fixing bacteria, rhizobium, phosphate solubilizing bacteria, potassium bacteria, cellulose decomposition bacteria, antibiotic generation bacteria and photosynthetic bacteria. The biochar base soil modifier disclosed by the invention adopts the microporous biomass carbon which has strong adsorption capability and good light absorption and temperature-increasing effect. The probiotics agent has a high survival rate and can be stored for a long time at the normal temperature, the fertilizer synergy action is obvious, and the soil borne disease can be effectively prevented and cured.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +2

Biological carbon base compound fertilizer and preparing method thereof

InactiveCN102659474AImprove soil physical propertiesIncrease the granular structureFertilizer mixturesInorganic fertilizerFertilizer

The invention discloses a biological carbon base compound fertilizer which is mainly composed of biomass carbon black and a compound fertilizer. The preparing method of the biomass carbon black includes subjecting agricultural wastes which serve as biomass raw materials to a low-temperature carbonization so as to form the porous biomass carbon black. The invention also discloses a preparing method of the biological carbon base compound fertilizer. The biological carbon base compound fertilizer adopts microporous biomass carbon, has high adsorptive capacity, good light absorption, temperature increasing and sustained release effects, is capable of reducing leaching loss waste of the fertilizer effectively, can be stored for a long time at a normal temperature and subjected to mixing granulation and drying with other organic and inorganic fertilizers without being influenced, and has an obvious synergistic function.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +2

Biomass charcoal based probiotic preparation and preparation method thereof

InactiveCN102701834AReduce leaching wasteGood sustained release effectClimate change adaptationAgriculture gas emission reductionAbsorption capacityDecomposition

The invention discloses a biomass charcoal based probiotic preparation, which is composed of biomass carbon black and concentrated probiotic preparation based on a weight ratio of (8.85-9.15): (0.85-1.15). The preparation is prepared by using agricultural wastes as biomass raw materials, conducting low-temperature carbonization to form porous biomass carbon black; conducting amplification culture to beneficial microorganism, and fermenting to produce probiotic solution; mixing above materials and separating solid from liquid; and drying by flash evaporation to obtain concentrated probiotic preparation, wherein the beneficial microorganism is one or more of paenibacillus polymyxa, trichoderma, nitrogen-fixing bacteria, rhizobium, phosphate dissolving bacteria, potassium dissolving bacteria, cellulose decomposition bacteria, antibiotic producing bacteria, and photosynthetic bacteria. In addition, the invention also discloses a preparation method for the biomass charcoal based probiotic preparation. The biomass charcoal based probiotic preparation provided by the invention uses microporous biomass charcoal, which has very strong absorption capacity and very good light absorption and warming effect. The probiotic preparation is high in survival rate of live bacteria, can be preserved for a long time at normal temperature and has evident synegistic effect for fertilizer.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +2

Radiation polymerization method for aqueous polyurethane-fluorine containing acrylic ester emulsion

InactiveCN101230120AMeet environmental protection requirementsReduce dependenceDyeing processReaction rateAlkylphenol

The invention relates to a preparation method for a textile dyed and printed product, namely, aqueous polyurethane-fluoride bearing acrylic ester textile emulsion, and solves the problems of the prior product that the reaction rate of the manufacturing technique is difficult to control, and the dependence on the temperature is large, etc. The technique of the invention comprises three major steps: firstly, various raw materials are adopted for preparing vinyl-terminated polyurethane prepolymer, neutralizer, namely, spasmolytol is added, and vinyl-terminated polyurethane emulsion is prepared through water; secondly, the vinyl-terminated polyurethane emulsion is uniformly mixed with pre-emulsion of acrylic ester and an organic fluorine monomer, to prepare the organic fluorine monomer water dispersion solution of vinyl-terminated polyurethane acrylic ester; thirdly, cobalt 60-Gamma radiation and polymerization are then performed, to prepare aqueous polyurethane-fluoride bearing acrylic ester emulsion. The product obtained through the technique of the invention is used for ensuring no formaldehyde release of finish fabrics, and does not contain alkylphenol polyoxyethylene (APEO), thereby meeting the environmental protection requirement. The polyreaction speed of the technique is easy to be controlled, the dependence on the temperature is small, the reaction can be performed at normal temperature, the three wastes (waste gas, waste water and industrial residue) can not be generated during the production process, the product quality is high, and the production cost is low.

Owner:ANHUI UNIVERSITY

Special charcoal-base slow release fertilizer for peanut and preparation method thereof

InactiveCN101121619AHigh porosityPoor adsorption capacityAgriculture gas emission reductionAmmonium salt fertilisersPotassiumBorax

The present invention relates to a special fertilizer for a charry releasing earthpea, which is characterized in that: the fertilizer comprises earthpea core grain carbon grain, ammonium sulphate, ammonium phosphate, zinc sulfate, kalium sulphate, potassium chlordide and borax. The present invention also relates to the produce method for the special fertilizer for a charry releasing earthpea. The method is to use the character of the earthpea core grain carbon grain with multi-micro hole and strong absorbing ability combined with nitrogen, phosphor, kalium and the other nutrition components required by the growth of the earthpea, and then uses a moist soil or clay as the cement compound to prepare the grain-shaped special fertilizer for a charry releasing earthpea. The preparation process for the fertilizer is simple, economical and environment-protective with one-off use; the fertilizer can satisfy the requirement of the nutrient for the whole growth period for the earthpea effectively; the utilization ratio of the fertilizer is higher with saving the energy and the cost; the fertilizer is adaptable to be widely popularized in the large-scale production for the earthpea.

Owner:辽宁金和福农业科技股份有限公司

Biomass charcoal based urea and preparation method for biomass charcoal based urea

InactiveCN102701833AReduce leaching wasteGood sustained release effectFertilizer mixturesBiomass carbonCarbonization

The invention discloses a biomass charcoal based urea which mainly comprises of biomass carbon black and urea. The biomass carbon black is prepared by using agricultural wastes as a biomass material for low-temperature carbonization to form porous biomass carbon black. By using microporous biomass carbon, the biomass carbon based urea has strong adsorption capacity and pretty good light absorbance and warming effects. The biomass carbon based urea has very good slow release ability to effectively reduce leaching loss and waste of the fertilizer, can be preserved for a long time at the normal temperature, and can also be mixed with other organic or inorganic fertilizers for granulating and drying without being affected but with remarkably increased fertilizer effect.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +2

Method for preparing super absorbent resin

The invention relates to the field of polymerization water-soluble high molecular auxiliary chemicals, in particular to a method for preparing super absorbent resin. The super absorbent resin comprises the following raw materials in parts by weight: 100 to 300 parts of acrylic acid, 100 to 300 parts of caustic soda solution with the mass concentration of 25 to 50 percent, 50 to 100 parts of cross linking agent, 100 to 300 parts of deionized water, 20 to 100 parts of reinforcing agent and 0.5 to 2 parts of redox initiator. The preparation method comprises the following steps of: after adding the acrylic acid into a reactor, adding the caustic soda solution to neutralize; then adding the cross linking agent and the reinforcing agent and filling nitrogen to remove oxygen; adding the initiator to carry out polymerization at a temperature of 30 to 80 DEG C; and after the reaction is completed, obtaining colloid and pelleting, drying and crushing the colloid to obtain the super absorbent resin. The super absorbent resin prepared by the method has higher water adsorption speed and larger water adsorption times. Compared with the existing super absorbent resin, the super absorbent resin prepared by the method can have better water adsorption and water retention effects under the condition of small using amount.

Owner:SHANDONG NUOER BIOLOGICAL TECH

Special charcoal-base slow release fertilizer for soybean and preparation method thereof

ActiveCN101121620ASimple preparation processImprove fertilizer use efficiencyAgriculture gas emission reductionAmmonium salt fertilisersAmmonium sulfateNutrient

The present invention relates to a special fertilizer for a charry releasing soybean, which is characterized in that: the fertilizer comprises earthpea core grain carbon grain, ammonium phosphate, zinc sulfate, kalium sulphate as well as one or more than one types amongcarbamide, ammonium sulphate, borax and molybdenum. The present invention also relates to the produce method for the special fertilizer for a charry releasing soybean. The method is to use the character of the earthpea core grain carbon grain with multi-micro hole and strong absorbing ability combined with nitrogen, phosphor, kalium and the other nutrition components required by the growth of the soybean, and then uses a moist soil or clay as the cement compound to prepare the grain-shaped special fertilizer for a charry releasing soybean. The preparation process for the fertilizer is simple, economical and environment-protective with one-off use; the fertilizer can satisfy the requirement of the nutrient for the whole growth period for the soybean effectively; the utilization ratio of the fertilizer is higher with saving the energy and the cost; the fertilizer is adaptable to be widely popularized in the large-scale production for the soybean.

Owner:沈阳隆泰生物工程有限公司

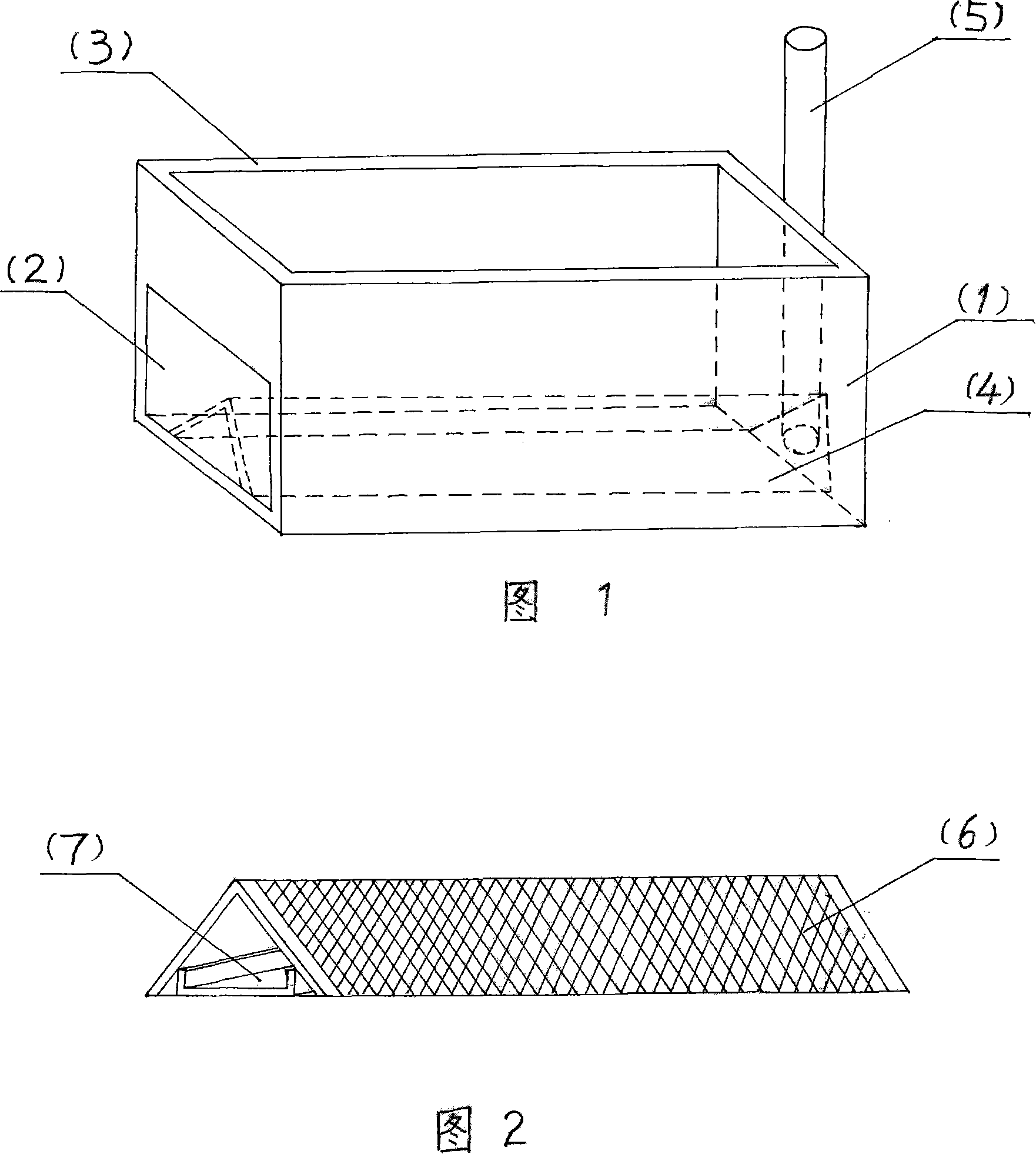

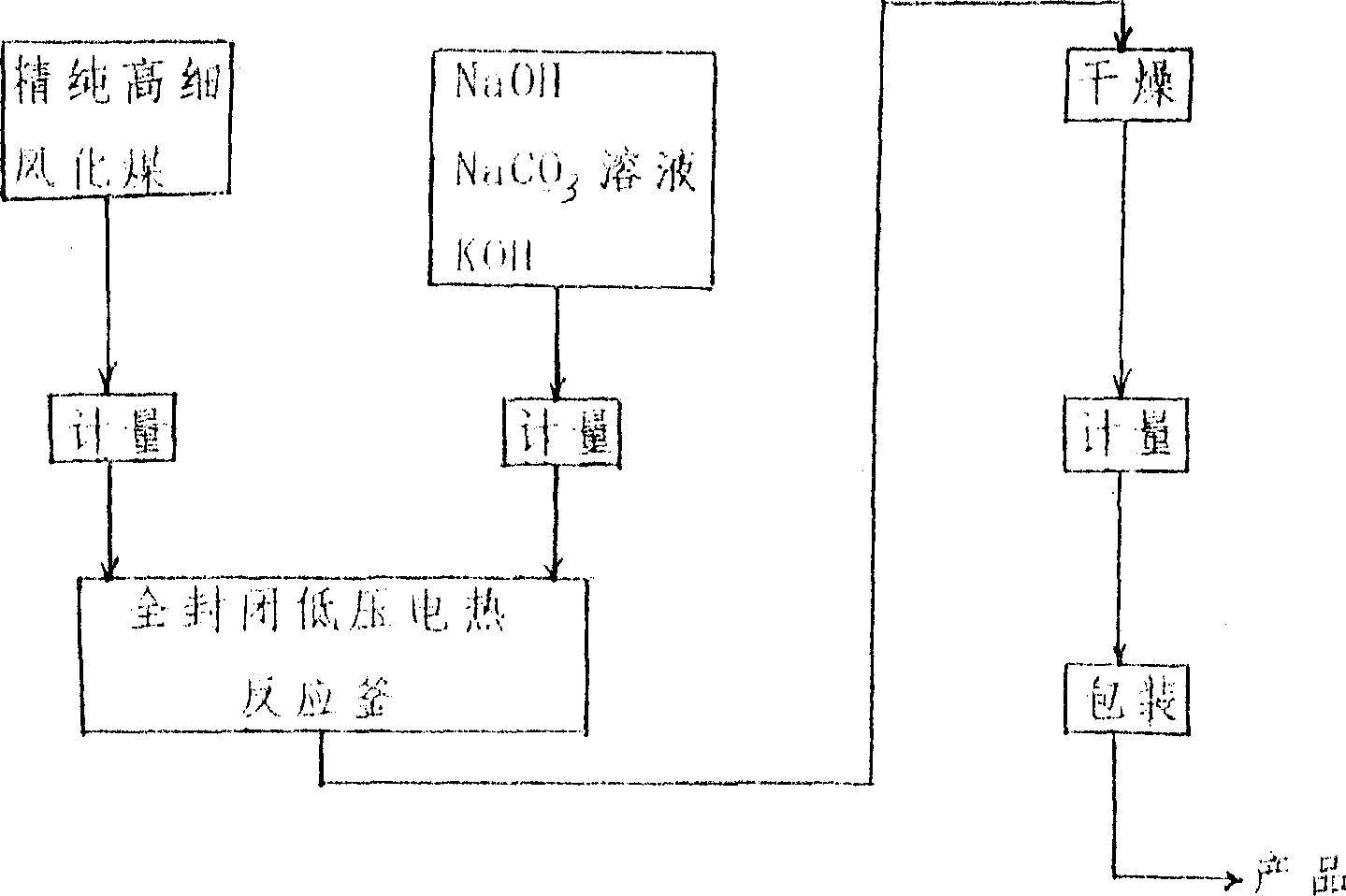

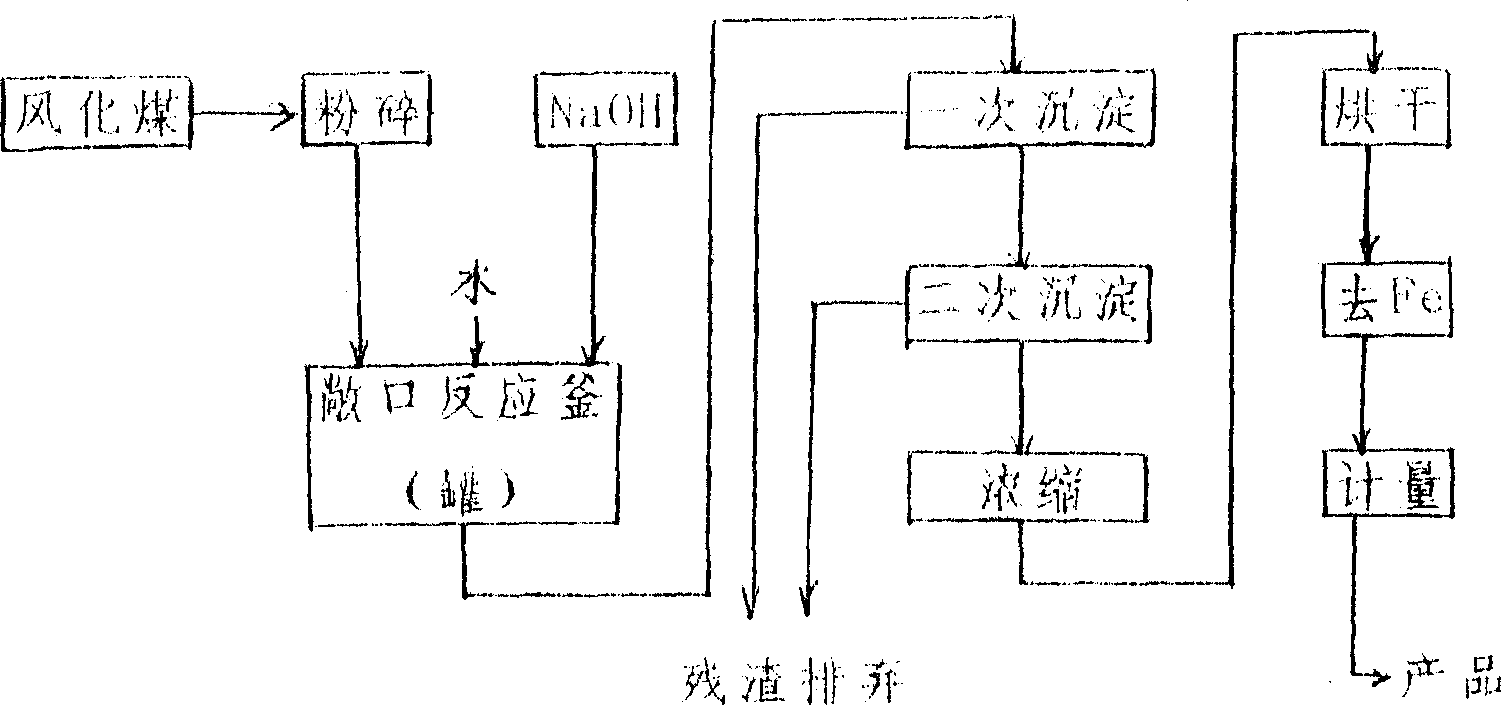

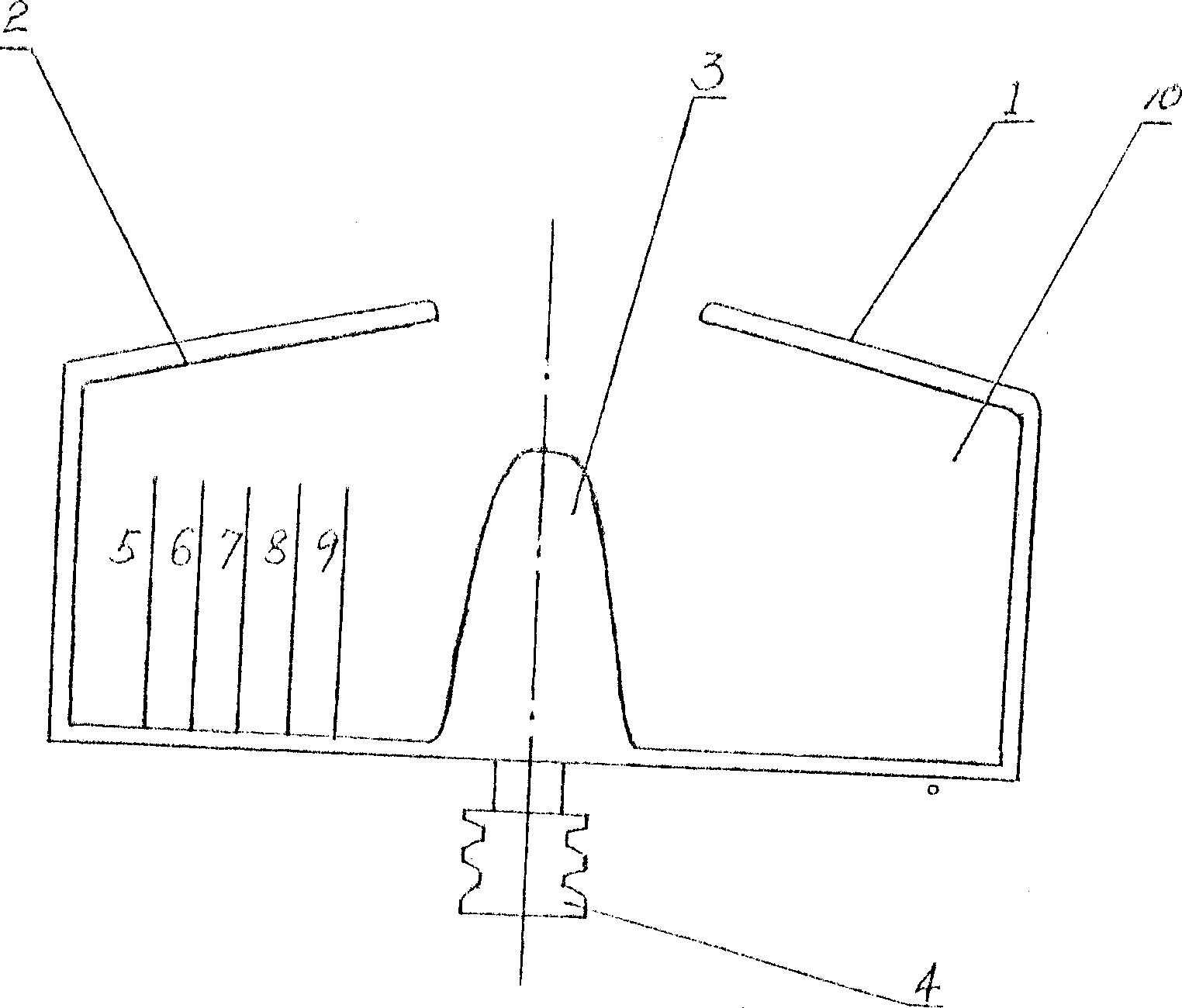

Production method of humic acid

InactiveCN1412223ANo pollution in the processNo "three wastes"Lignin derivativesHeat energyRaw material

On the basis of original wet production process said invention adopts full-sealed electric heat energy temp.-controlled reaction still and makes the leonardite undergo the processes of selection, purification, colloid milling and ultrasonic treatment, and adds the related chemical raw material to make reaction so as to obtain the invented product humic acid.

Owner:石历勤

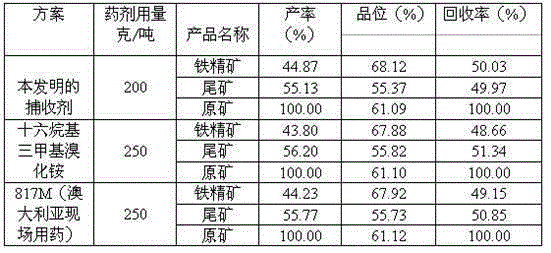

Compound type quaternary ammonium salt cation silicate mineral collecting agent and preparation method thereof

ActiveCN105396698AHigh selectivityPromote environmental protectionFlotationBenzoyl bromideActive agent

The invention discloses a compound type quaternary ammonium salt cation silicate mineral collecting agent and a preparation method thereof. According to the technology, the method comprises the following steps that 1, any one of alkyl tertiary amine containing carbon 14 to carbon 17 reacts with benzyl chloride or benzyl bromide accounting for, by mass, 45%-55% of the alkyl tertiary amine for 90-150 min under the condition of 90 DEG C-100 DEG C, then is cooled to 40 DEG C-50 DEG C and becomes to light yellow paste; 2, fatty alcohol-polyoxyethylene ether nonionic surfactant containing, by mass, 3%-8% of the alkyl tertiary amine is added; and 3, diesel oil accounting for, by mass, 2%-5% of the alkyl tertiary amine is added and uniformly stirred for 5-20 min at the temperature of 35 DEG C-50 DEG C, and the collecting agent is obtained. The compound type quaternary ammonium salt cation silicate mineral collecting agent has high collecting capacity and excellent selectivity on silicate minerals contained in micro-fine particle iron ore, floatation can be conducted normally within the ore pulp temperature of 5 DEG C-40 DEG C, the pH adaptive range of ore pulp is wide, and the floatation can be conducted normally within the pH range of 5-11.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Preparation method for micro-fine particle iron ore reverse flotation collector

The invention discloses a preparation method for a micro-fine particle iron ore reverse flotation collector. The adopted process steps include that any one of alkyl tertiary amine containing carbon 14 to carbon 18 reacts with benzyl chloride or benzyl bromide accounting for 45%-55% of the mass of the alkyl tertiary amine for 90-150 min under the condition of 90-100 DEG C, cooling is performed till the temperature is 40-50 DEG C, and the alkyl tertiary amine is made to become light-yellow paste; a fatty alcohol polyoxyethylene ether non-ionic surface active agent accounting for 2%-10% of the mass of the alkyl tertiary amine is added in; and finally, diesel oil accounting for 2%-5% of the mass of the alkyl tertiary amine is added in, uniform stirring is performed under the temperature of 35-50 DEG C, cooling is performed till room temperature is achieved, and the collector is obtained. The collector has high collecting force and excellent selectivity on silicate minerals contained in micro-fine particle iron ore, normal floatation can be performed within the temperature of ore pulp ranging from 5 DEG C to 40 DEG C, the adaptive ore pulp acidity and alkalinity range is wide, and normal flotation can be performed while pH ranges from 5 to 11.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Treatment method for industrial wastewater generated by copper wet-process smelting

InactiveCN103011360ASimple processLow costWaste water treatment from metallurgical processWater/sewage treatment by flocculation/precipitationThree levelChemical oxygen demand

The invention discloses a treatment method for industrial wastewater generated by copper wet-process smelting. The method comprises the following steps of: adjusting the pH value of the copper-containing industrial wastewater added with sodium hydroxide solution to be 7.5-8.5, and then performing flocculating-settling treatment; then adding sodium sulphide, and performing precipitation pre-treatment on copper ions; charging ammonia after the pre-treatment, adjusting the pH value to 8.5-9.5, adding propenol and EDTA (ethylene diamine tetraacetic acid) organic substance simultaneously, and stirring for completely reacting; and finally adding a polymeric ferric sulphate flocculant and performing flocculating treatment to obtain the effluent, namely, the copper-containing wastewater after the treatment. The treatment method disclosed by the invention is low in operating cost, low in slag amount, and simple and convenient to recover copper; and heavy metal ions, petroleum substances, suspended matters and COD (chemical oxygen demand) value achieve the three-level drainage standards of industrial wastewater.

Owner:CHANGZHOU UNIV

Production process for straw coal

InactiveCN102031175AImprove the environmentGood qualityBiofuelsSolid fuelsRural environmentParaffin wax

The invention relates to a production process for straw coal. The adopted technical scheme comprises the following steps of: crushing straw; adding the crushed straw into a charring furnace, and charring at the temperature of 800 and 1,200 DEG C for 30 to 50 minutes under the anaerobic state; cooling to the temperature of 200 and 250 DEG C, adding 20 to 30 weight parts of loess, 20 to 30 weight parts of coal slime, 0.1 to 0.7 weight part of sulphur-fixing agent and 0.1 to 0.7 weight part of paraffins into 100 weight parts of charred straw, and mixing the mixture uniformly; and conveying to an extruder, forming and drying. The straw coal produced by the invention is newly developed energy, and the straw of crops is utilized fully, so that waste materials are turned into wealth, the rural environment is improved, and the produced straw coal has high quality and heat value of up to about 5,000 kilocalories, and is safe, pollution-free, energy-saving and environmentally-friendly.

Owner:黄恩东

Method for extracting ceramide amphoteric lipid from agriculture-forestry byproducts

InactiveCN101591262ASimplified separation stepsDoes not affect useSugar derivativesCarboxylic acid amide separation/purificationChromatographic separationSolvent

The invention relates to a method for extracting ceramide amphoteric lipid from agriculture-forestry byproducts, which comprises the following steps: using waste materials of the processing of the agriculture-forestry byproducts of rice bran, wheat bran and corn as raw materials; adding protease which is 0.1 to 1.0 percent of the agriculture-forestry byproducts in weight and an amino acid chemical penetrating agent which is 0.01 to 0.1 percent of the agriculture-forestry byproducts in weight to the raw materials; extracting the raw materials for 3 times by using a mixed solvent of chloroform and methanol; performing column chromatographic separation; using a solvent to elute out lipid rich in ceramide; and after alkaline treatment, performing high-efficiency liquid phase chromatographic separation to obtain ceramide. The method has high extraction efficiency, simplifies the separation steps of other components, and obtains the ceramide lipid with different contents at the same time.

Owner:ZHEJIANG UNIV

Method for producing protein feed by utilizing bagasse

The invention discloses a method for producing a protein feed by utilizing bagasse. The protein feed is prepared from bagasse, molasses, corn flour, soybean meal, bran, rice bran, Chinese medicinal materials and a composite fermentation bacterial agent. The domestication bacteria used in the method for producing the protein feed by utilizing bagasse are from nature and obtained through enrichment,screening and domestication, have super strong cellulose decomposition capability. The prepared composite fermentation bacterial agent has high fermentation efficiency and good stability, can effectively reduce the crude fiber content of raw materials such as bagasse, rice bran and the like, so the high molecular carbohydrate which is difficult to be fully digested and absorbed by animals such ascrude fiber, lignin and the like is converted into low molecular substances which can be absorbed and utilized, the digestion and utilization rate of the animals is improved, the prepared fermented feed is more comprehensive in nutrition and higher in feed conversion rate, meanwhile, the content of crude protein in the fermented feed is improved, the nutrition and palatability of the feed are improved, the use of antibiotics can be avoided in the fermentation process, and the feed is safe and environment-friendly.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Preparation of antifalse pesticide and its use method

InactiveCN1623402AStrong anti-counterfeiting featuresNo drug resistanceBiocideAnimal repellantsSophora RootForsythia

An antiforge agricultural chemical for killing pests and treating ulcer, putrescence, rice blast, etc is prepared from coptis root, forsythia fruit and flavescent sophora root through slicing or pulverizing, immersing them in methanol, extracting, decocting, filtering, concentrating and adding B, Mn and Zn. It features that after it is loaded in bottle and the bottle is opened for 1-2 hr, the snow-like crystals are grown on the bottle mouth, so having antiforge function.

Owner:刘起麟

Method for producing -5 DEG C biodiesel by using drainage oil or waste cooking oil

InactiveCN103146488AHigh catalytic activityHigh yieldFatty acid esterificationBiofuelsDistillationPre treatment

The invention discloses a method for producing -5 DEG C biodiesel by using drainage oil. The method comprises the following steps of: 1, pretreatment; 2, esterification; 3, ester exchange; and 4, dealcoholization and simple distillation. According to the method, the IVB group and IIIA group metal-organic compounds serving as efficient environment-friendly economic catalysts are adopted, and are mainly characterized by high catalytic activity, neutrality and no corrosion on reaction equipment, the usage amount of the metal-organic compounds only accounts for 0.05-0.5% of the mass of the drainage oil or waste cooking oil, few side reactions happen, the yield of fatty acid methyl ester is high (above 92%), the methanol consumption is low (below 12%), no residues are generated, the product has light color and luster and good quality, no 'three wastes' (waste gas, waste water and industrial residual) are generated, and pollution is avoided. Compared with a conventional acid catalyst method, the method has the advantages that the yield of the product is increased by 5-7%, the condensation point is reduced by above 10 DEG C, and the color and luster of the product are light yellow and bright.

Owner:姬大菊

Nature-identical 2,3-butanedione flavor and preparation method thereof

InactiveCN101885673AImprove conversion rateHigh degree of naturalnessCarbonyl compound preparation by condensationCarbonyl compound separation/purificationFood flavorAcetaldehyde

The invention relates to a nature-identical 2,3-butanedione flavor and a preparation method thereof. The nature-identical 2,3-butanedione flavor contains the following components in parts by weight: 1000 parts of acetaldehyde and 1-10 parts of composite catalyst. By adopting the technology of the invention, the raw materials are accessible, the conversion rate of the raw materials is high, the conditions of the two-step reaction are mild, the content of 2,3-butanedione in the product is high, the natural degree is high, the production technology is clean, mass production can be realized, the production cost is low, and three wastes can not be generated.

Owner:HENAN HUALONG SPICE

Method for purifying benzoyl chloride reaction terminating solution

InactiveCN102557923ASimple operation processNo "three wastes"Organic compound preparationCarboxylic compound preparationBenzoic acidGreen environment

The invention discloses a method for purifying a benzoyl chloride reaction terminating solution. The method comprises the following steps of: reacting benzotrichloride serving as a main raw material with benzoic acid or water in the presence of a ferric trichloride catalyst to prepare a benzoyl chloride reaction terminating solution, performing precision filtration through active carbon in a metal filter at a certain temperature to obtain a benzoyl chloride finished product, regenerating the active carbon, and collecting a ferric trichloride solution and a benzoic acid solid for recycling. The method is simple in operation process, 'three wastes' are nearly not produced in the whole production process, the yield and the quality of the product are high, and the method is an ideal green environment-friendly process.

Owner:JIANGSU YUANYANG PHARMA

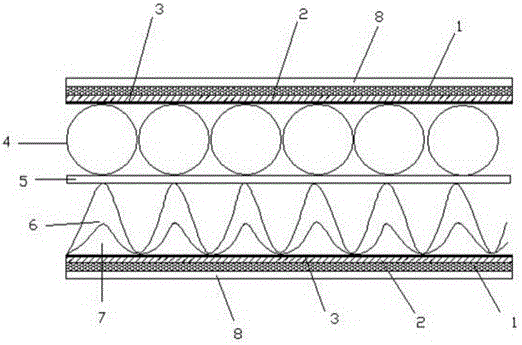

Environment-friendly fireproof corrugated board

InactiveCN105774066ALow costImprove buffering effectPaper/cardboard layered productsBoxesCardboardPulp and paper industry

The invention relates to an environment-friendly fireproof corrugated board.The environment-friendly fireproof corrugated board comprises two surface paper layers and a core paper layer arranged between the surface paper layers.The core paper layer mainly comprises an outer layer, an adhesion layer and an inner layer.Each surface paper layer comprises a waterproof layer and a buffer layer which are sequentially arranged in an attached mode, wherein a fireproof layer is attached to the surface of the waterproof layer made of kraft paper, and the buffer layer is a sponge layer pasted on the outer side of the surface paper layer.The outer layer is composed of round arrayed paperboards.The inner layer comprises a first U-shaped core paper interlayer and a second U-shaped core paper interlayer, transverse coordinate positions of crests and troughs of the first U-shaped core paper interlayer and the second U-shaped core paper interlayer are the same, and the crests of the first U-shaped core paper interlayer and the second U-shaped core paper interlayer make contact with each other.The adhesion layer is arranged between the outer layer and the inner layer.When the environment-friendly fireproof corrugated board is used for packaging fragile objects, the use amount of white foam can be reduced, so that pollution is reduced, and higher environmental friendliness is achieved; meanwhile, the fireproof and flame-retardant effect is achieved.

Owner:BAOYI NEW MATERIAL CO LTD

Cordyceps militaris fermented drink and production method thereof

InactiveCN106036281AGreat tasteHigh nutritional valuePolysaccharide/gum food ingredientsPhosphateAdditive ingredient

The invention discloses Cordyceps militaris fermented drink and a production method thereof. The method includes: crushing wolfberry fruit mixture, adding deionized water, boiling and extracting, filtering, collecting filtrate to obtain polysaccharide extract; using the polysaccharide extract as a solvent, adding glucose, soybean isolate protein, magnesium sulfate, potassium dihydrogen phosphate and vitamin B1, at pH 6-7, acquiring a fermentation medium; inoculating sterile suspension of spores of the Cordyceps militaris to the fermentation medium, fermenting at 20-30 DEG C, culturing, suction filtering, collecting filtrate, and adding erythritol to obtain the Cordyceps militaris fermented drink. The process used herein enables further fermentation and formation, the medium formula helps Cordyceps militaris to comprehensively utilize nutrients, and metabolism can be promoted to produce flavoring matters and effective ingredients. HPLC detection shows that Cordycepin content in the drink is up to greater than 0.16mg / mL and higher than 0.18 mg / mL in cordycepic acid content.

Owner:杭州彧弋科技有限公司

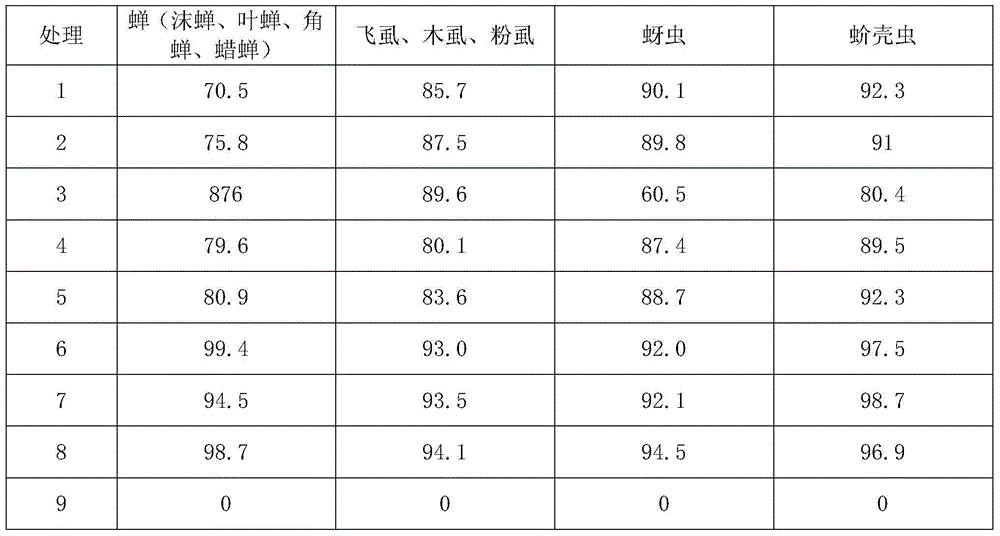

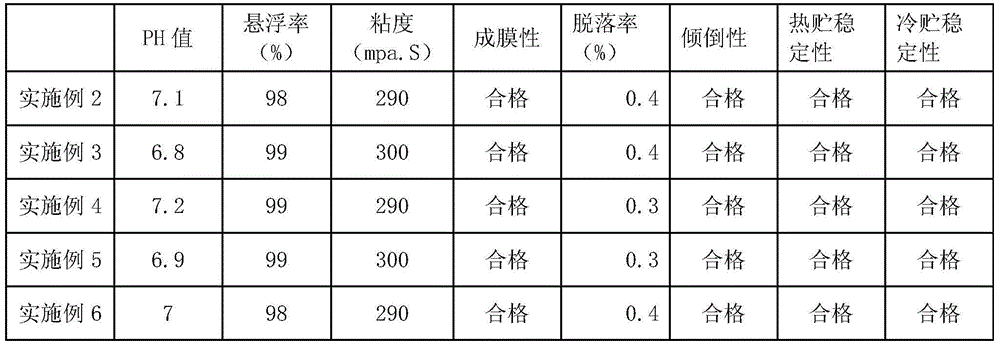

Novel suspended seed coating

InactiveCN104970036AGuaranteed germination rateGood effectPlant growth regulatorsBiocideAdjuvantFipronil

The invention discloses a novel suspended seed coating. The novel suspended seed coating comprises the following main ingredients in percentage by mass: 10-30% of imidacloprid, 10-30% of fipronil, 1-10% of pyraclostrobin, a proper amount of adjuvant and the balance of distilled water. The novel suspended seed coating disclosed by the invention is good in drug effect, long in effect duration and high in effect, is economical and safe and can be used for reducing the pollution to environment, increasing the utilization ratio of pesticides, lowering the consumption of the pesticides, thereby being worthy of widespread popularization and use.

Owner:山东罗邦生物农药有限公司

Carbon-based compound fertilizer containing probiotic organisms and preparation method of carbon-based compound fertilizer

ActiveCN102649655BReduce leaching wasteGood sustained release effectFertilizer mixturesDecompositionCarbonization

The invention discloses a carbon-based compound fertilizer containing probiotic organisms. The carbon-based compound fertilizer comprises biomass carbon black and probiotics, wherein the biomass carbon black is prepared by the following method: carrying out low-temperature carbonization on agricultural wastes as biomass raw materials to form porous biomass carbon black. The probiotics are prepared by the following method: carrying out amplification culture on beneficial microorganisms and fermenting to form probiotic liquid; and mixing and then carrying out solid-liquid separation and expansion drying to form the probiotics, wherein the beneficial microorganisms are selected from one or more of peanibacillus ploymyxa, trichoderma, nitrogen-fixing bacteria, root nodule bacteria, phosphate-solubilizing bacteria, potassium bacteria, cellulose decomposition bacteria, antibiotic-producing strain and photosynthetic bacteria. The carbon-based compound fertilizer disclosed by the invention is made of microporous biomass carbon, and thus the carbon-based compound fertilizer has extremely-strong adsorption capacity and favorable light absorbing and temperature increasing effects; in addition, the probiotics of the carbon-based compound fertilizer are high in cell viability; and the carbon-based compound fertilizer can be preserved at normal temperature for a long time, can be mixed, granulated and dried with other organic and inorganic fertilizers without being influenced and is remarkable in synergistic action.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +2

Preparation technology for catalytically synthetizing L-(+)-diethyl tartrate by using strong acid cation exchange resin as catalyst

InactiveCN104926658AHigh reaction yieldIncrease switching capacityOrganic compound preparationCarboxylic acid esters preparationPtru catalystStrong acids

The invention relates to the technical field of spices, and relates to a preparation technology for catalytically synthetizing L-(+)-diethyl tartrate by using strong acid cation exchange resin as a catalyst. The preparation technology comprises the following steps: adding L-(+)-tartaric acid, absolute ethyl alcohol and a catalyst to a reaction container, and performing a stirring and heating reaction; after the reaction is completed, cooling the reagent to room temperature, and then filtering the reagent to recycle the catalyst, wherein the catalyst is the strong acid cation exchange resin; and directly distilling a filter liquor to obtain the colorless clear liquid L-(+)-diethyl tartrate. According to the preparation technology, the yield of the L-(+)-diethyl tartrate can be improved, the technology is simple, the operation is convenient, the problems of catalysis and recycling by using a strong acid liquid and a solvent are avoided, the whole technological process is clean and environment-friendly, waste acid, waste water and waste gas cannot be generated, the environment is rarely polluted, and recycled ethyl alcohol and catalyst can be repeatedly used.

Owner:DONGGUAN BOTON FLAVORS & FRAGRANCES

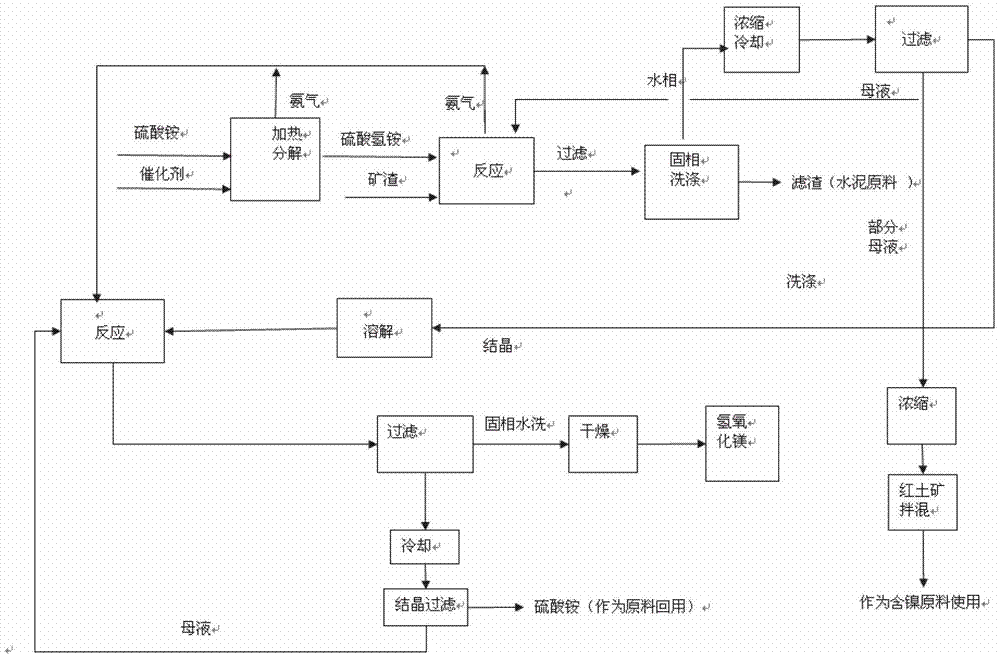

Recycling method of ferronickel slag

The invention relates to a recycling method of slag generated in the production of ferronickel from laterite ore, belonging to the technical field of smelting cleaning production. The method forms a complete recycling process by three main chemical reactions so as to economically, reasonably and comprehensively utilize the slag, and comprises: preparing ammonium bisulfate and ammonia gas through a thermal decomposition of ammonium sulfate, reacting the ammonium bisulfate and the slag to generate the ammonia gas and soluble sulfate salt such as nickel sulfate, magnesium sulfate, etc., and reacting the above ammonia gas and the magnesium sulfate to generate the ammonium sulfate and hydroxide, wherein the ammonium sulfate is repeatedly used in the thermal decomposition. The method effectively utilizes the slag, uses a clean production technology, eliminates influence of the slag on the environment, and basically does not generate "three wastes (waste gas,waste water and industrial residue)" during the recycling process.

Owner:NINGBO WANXIANG HLDG GRP CO LTD

Purification method and application of secondary zinc oxide

InactiveCN110016569ASimple and fast operationLow costZinc oxides/hydroxidesProcess efficiency improvementElectrolytic agentPhysical chemistry

The invention relates to a purification method of secondary zinc oxide. The purification method comprises the following specific steps of adding industrial sulphuric acid in soot containing secondaryzinc oxide, conducting granulating by a granulating device, and roasting particles in a rotary kiln for 3-5h at 600-800 DEG C. The application of secondary zinc oxide comprises the following specificsteps of adding 3-5 times of volume of electrolyte residue into the purified secondary zinc oxide for leaching, controlling the pH of a leaching terminal point at 3.3-4.1 by supplementing industrial sulphuric acid, conducting leaching for 4-5h, and conducting filtering separation to obtain leach liquor; adding hydrogen peroxide and lime milk in the leach liquor, controlling the pH at 5.0 and the temperature at 45-65 DEG C, and maintaining for 1-2h, and conducting filtering; and adding CuOH and Ni(OH)2 in the leach liquor, controlling the pH at 2.5-4.8 and the temperature at 35-50 DEG C, maintaining for 1h, conducting filtering, and thus obtaining pure electrolyte. The purification method has the advantages of unobstructed process, less consumption, low cost, no three wastes and environment-friendly property.

Owner:徐州市正峰锌业有限公司

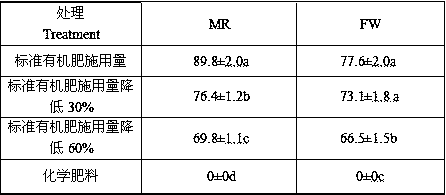

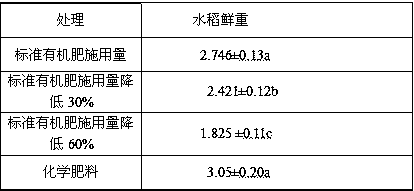

Efficient weeding medical fertilizer

InactiveCN107857634AGood broad-spectrum herbicideEfficient control effectBiocideAlkali orthophosphate fertiliserWater dispersiblePhosphate

The invention relates to an efficient weeding medical fertilizer. Active ingredients consist of urea, monoamine phosphate, potassium chloride, sodium selenate and 50% cyhalofop-butyl-sclerotium rolfsii water dispersible granules. The efficient weeding medical fertilizer has a good weeding effect: the 50% cyhalofop-butyl-sclerotium rolfsii water dispersible granules have an efficient broad-spectrumweeding effect, have an excellent control effect on various broadleaf weeds, sedge and weeds from places which are invaded by foreign weeds in dry direct seeding rice, and exceed the use of two single-dose varieties of sclerotium rolfsii and quinclorac. The efficient weeding medical fertilizer has the advantages of safety to crops, low cost and good control effect. Tests show that the 50% cyhalofop-butyl-sclerotium rolfsii water dispersible granules have stable chemical properties, efficient broad spectrum, and an obvious synergistic effect on controlled objects.

Owner:JIANGSU DONGBAO FERTILIZER CO LTD

Method for extracting ceramide amphoteric lipid from agriculture-forestry byproducts

InactiveCN101591262BSimplified separation stepsDoes not affect useSugar derivativesCarboxylic acid amide separation/purificationChromatographic separationSolvent

The invention relates to a method for extracting ceramide amphoteric lipid from agriculture-forestry byproducts, which comprises the following steps: using waste materials of the processing of the agriculture-forestry byproducts of rice bran, wheat bran and corn as raw materials; adding protease which is 0.1 to 1.0 percent of the agriculture-forestry byproducts in weight and an amino acid chemical penetrating agent which is 0.01 to 0.1 percent of the agriculture-forestry byproducts in weight to the raw materials; extracting the raw materials for 3 times by using a mixed solvent of chloroform and methanol; performing column chromatographic separation; using a solvent to elute out lipid rich in ceramide; and after alkaline treatment, performing high-efficiency liquid phase chromatographic separation to obtain ceramide. The method has high extraction efficiency, simplifies the separation steps of other components, and obtains the ceramide lipid with different contents at the same time.

Owner:ZHEJIANG UNIV

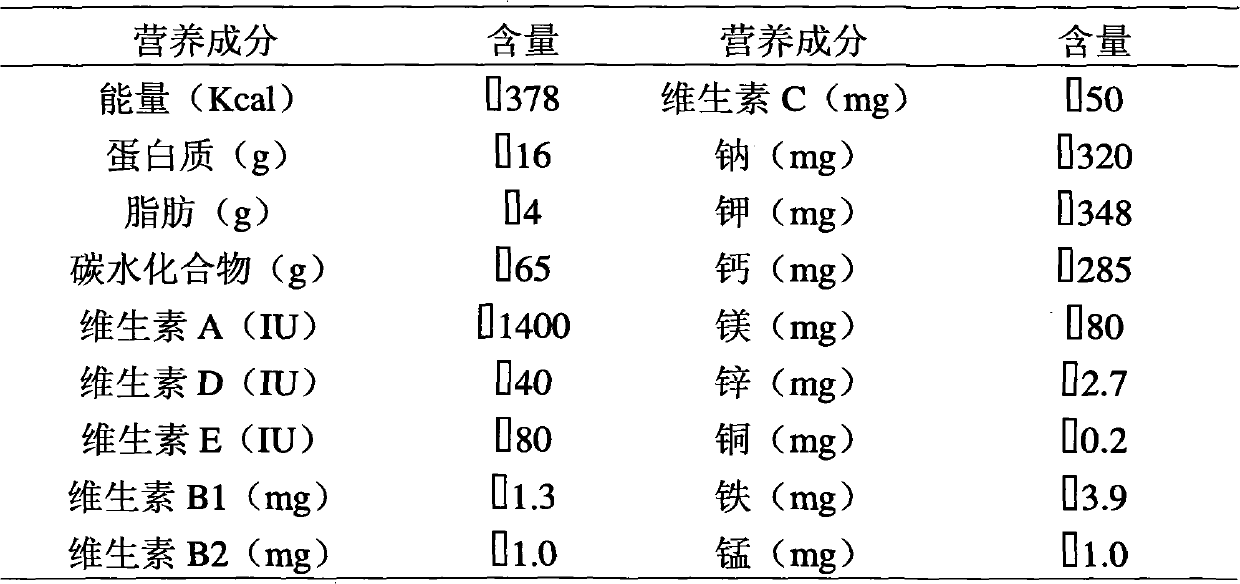

Enteral nutrition preparation, and preparation method and applications thereof

ActiveCN101785560BRich in nutrientsMaintain normal physiological functionFood preparationAdditive ingredientEnteral Nutrition Preparation

The invention discloses an enteral nutrition preparation, and a preparation method and applications thereof. The enteral nutrition preparation according to the invention contains the following ingredients by mass percent: 3-20% of marine life protein peptide powder, 1-3% of seawater spirulina powder, 3-5% of fruit and vegetable powder, 3-15% of soybean peptide powder, 2-3% of corn oil, 1-2% of fish oil and 55-75% of maltodextrin. The enteral nutrition preparation according to the invention has good dissolubility as homogeneous solid powder and is homogeneous suspension after being dissolved, and the enteral nutrition preparation also has complete nutrients, easy for digestion, high in content of minerals and vitamins and rich in unsaturated fatty acids such as EPA and DHA, etc., can be used as nutritive support for patients suffering from gastrointestinal dysfunction, is significant to the recovery of body and gastrointestinal functions of the patients suffering from gastrointestinal dysfunction, and can also promote digestion and prominently enhance immunity. The enteral nutrition preparation according to the invention has the advantages of low production cost and being capable of saving energy and enhancing the utilization rate of raw material obviously.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com