Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Does not affect use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dust collection and mercury removal integrated electric-bag composite dust collector

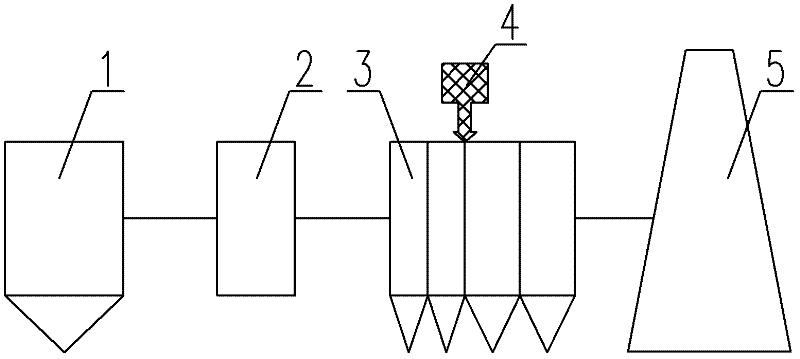

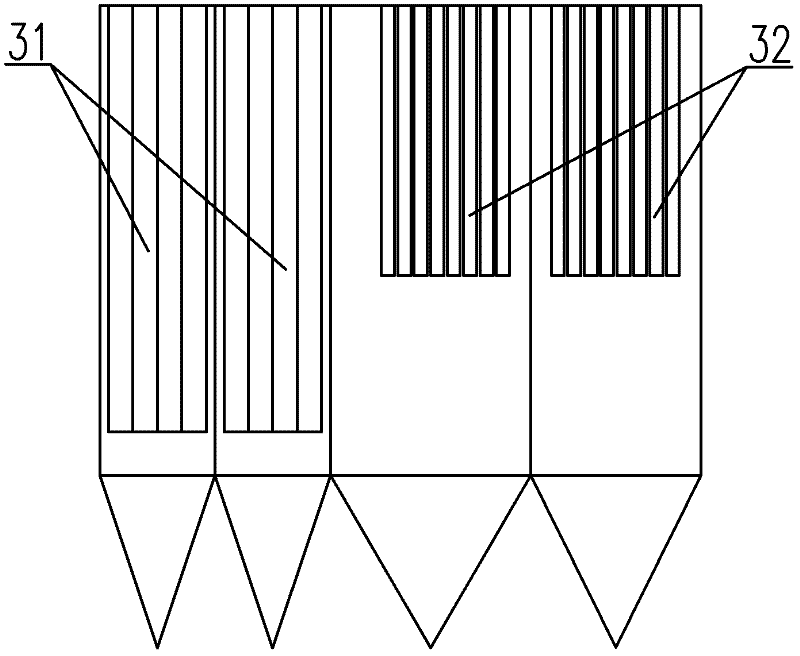

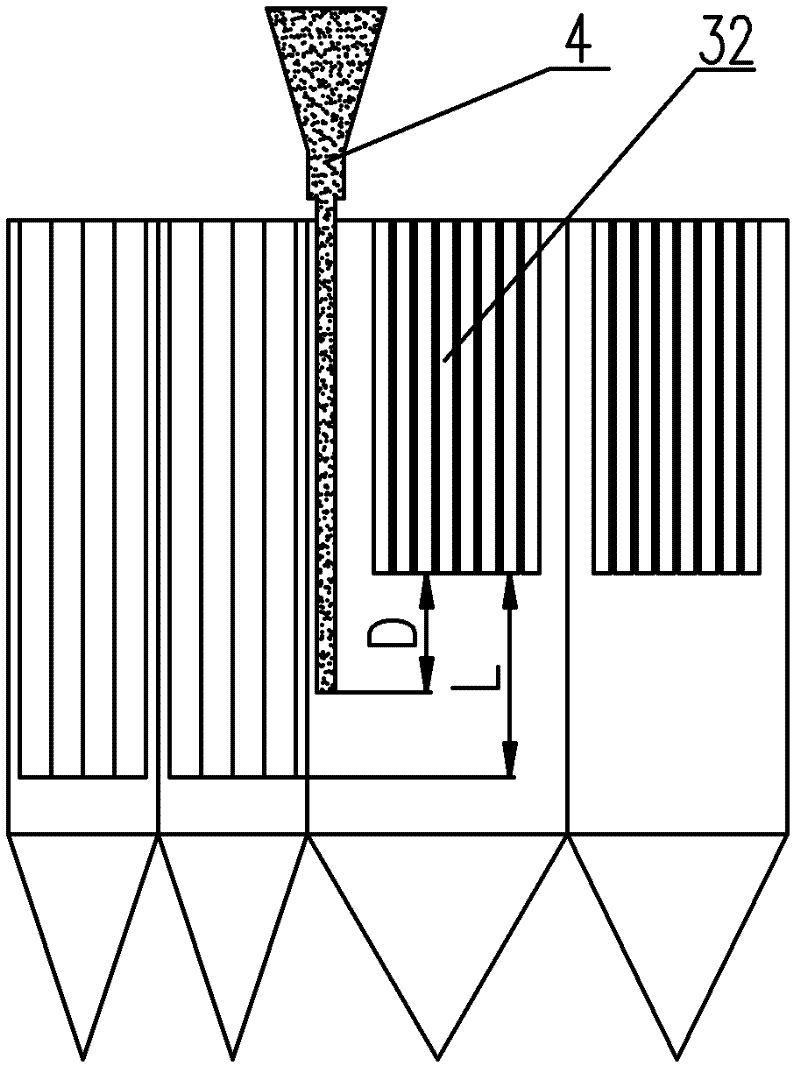

The invention discloses a dust collection and mercury removal integrated electric-bag composite dust collector, and relates to a dust collector. The dust collector comprises a preheater, an electric-bag composite dust collector and an active carbon adsorbent spraying device, wherein an air inlet of the preheater is connected with a smoke outlet of a boiler; the electric-bag composite dust collector consists of a pre-level electric field dust collection area and a post-level filter-bag filtering area; a smoke inlet of the pre-level electric field dust collection area is connected with a smoke outlet of the preheater; a smoke outlet of the pre-level electric field dust collection area is connected with a smoke inlet of the post-level filter-bag filtering area; the active carbon adsorbent spraying device is arranged between the pre-level electric field dust collection area and the post-level filter-bag filtering area; and the smoke flowing to the post-level filter-bag filtering area is discharged to the atmosphere through a chimney. The dust collector disclosed by the invention has higher efficiency in collecting fine dust PM2.5 than an electrostatic dust collector and bag-type dust collector, and also has a good effect in collecting tiny mercury particles. Due to the long ash removal period, the acting time of the adsorbent on mercury is prolonged, and the mercury collection efficiency is improved.

Owner:FUJIAN LONGKING

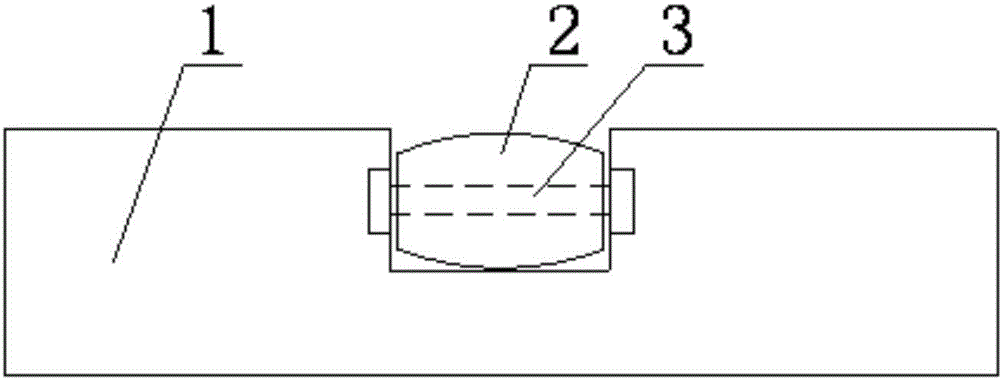

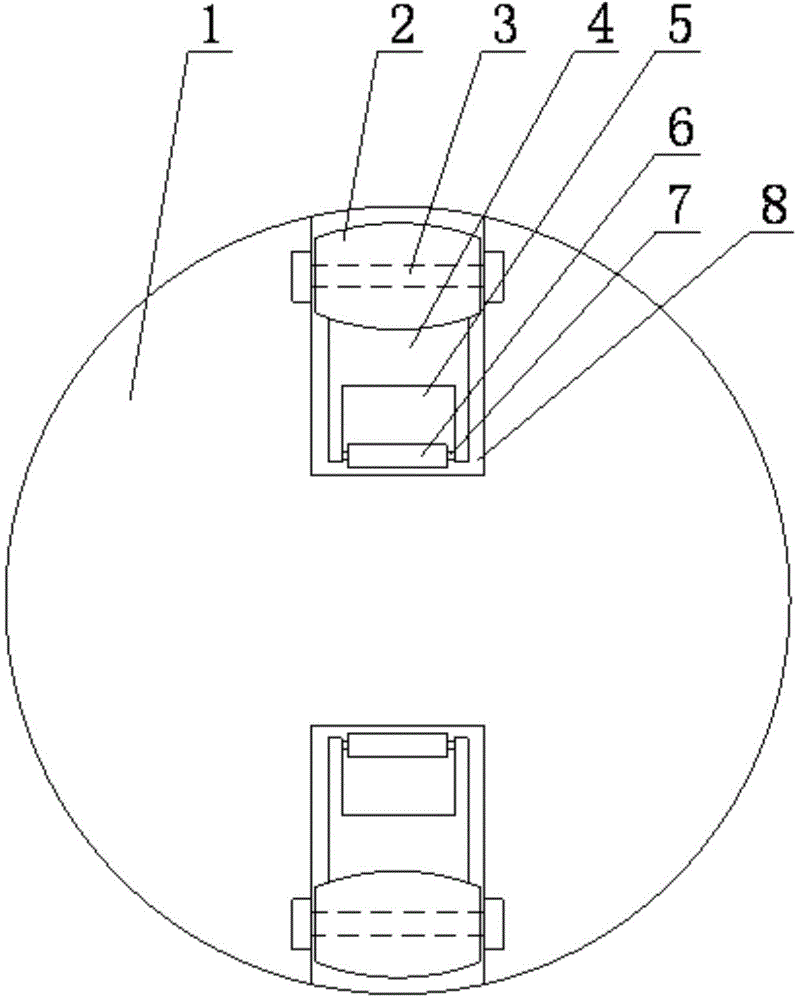

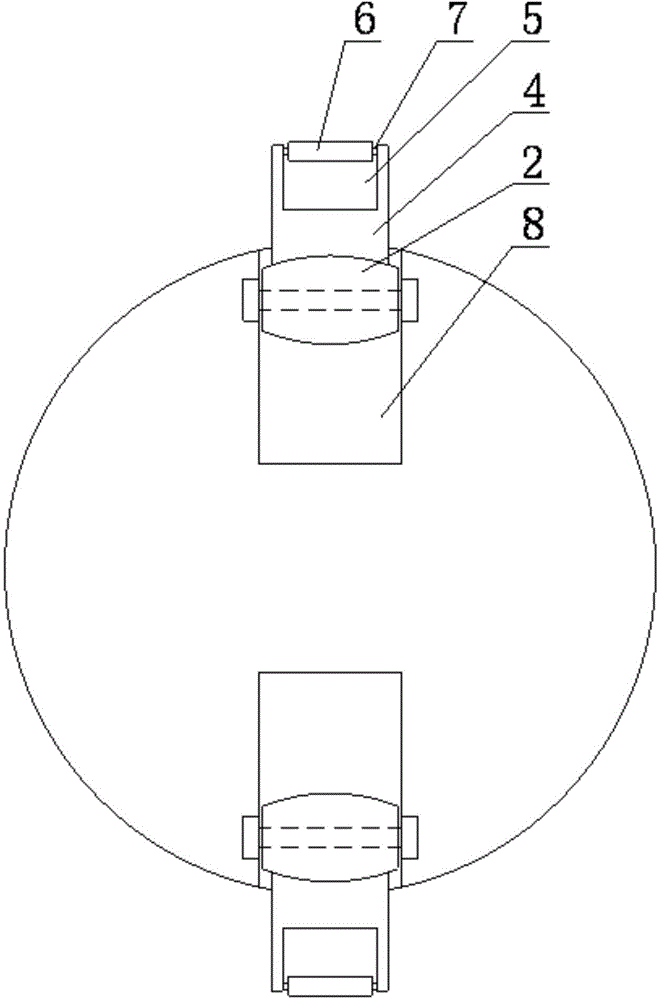

Deduster

InactiveCN102489099AReduce pollutionThe dust removal effect is achievedCombination devicesElectricityFlue gas

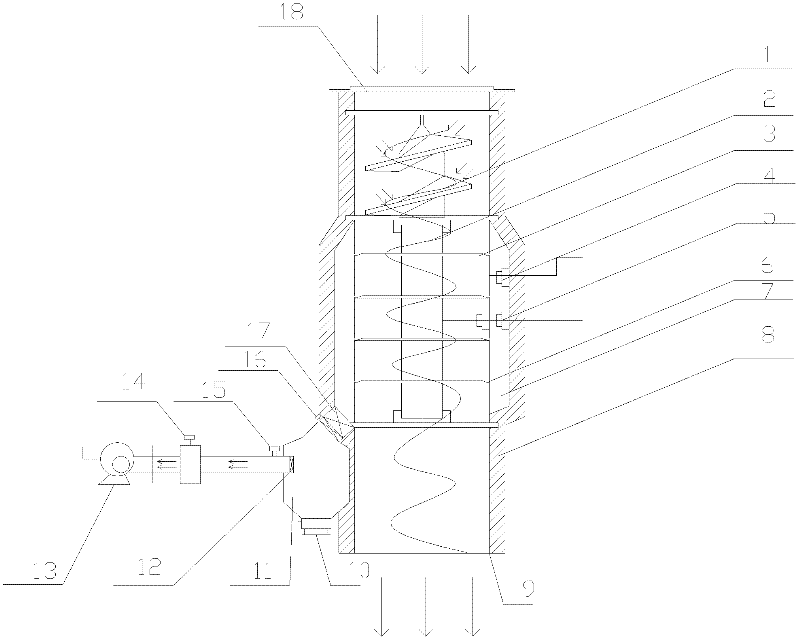

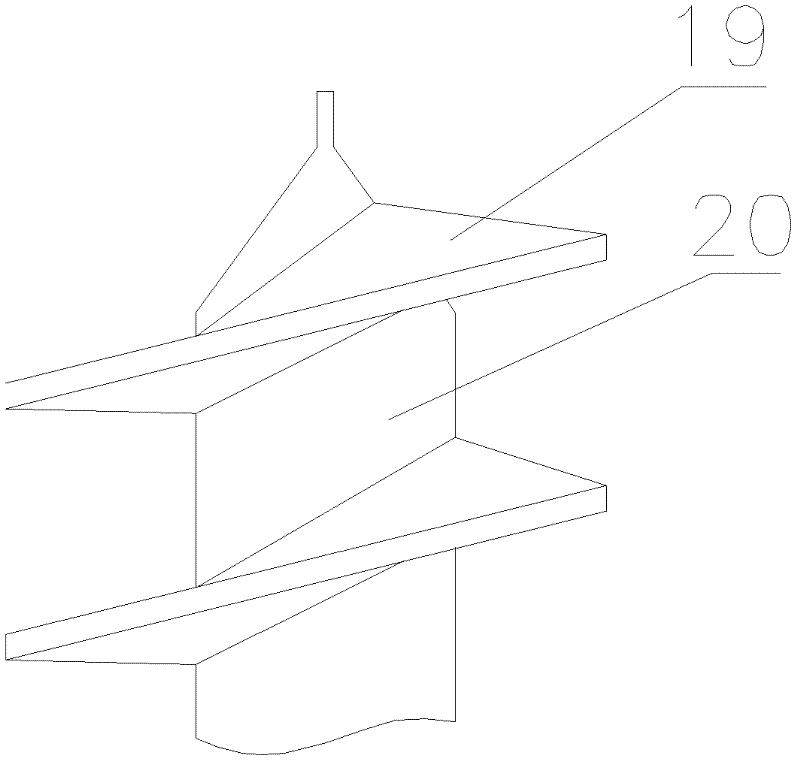

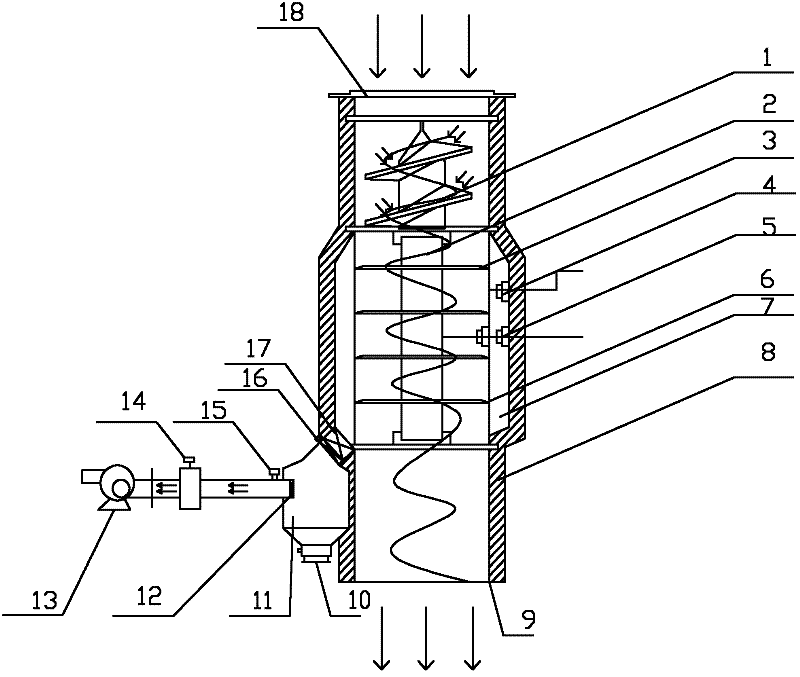

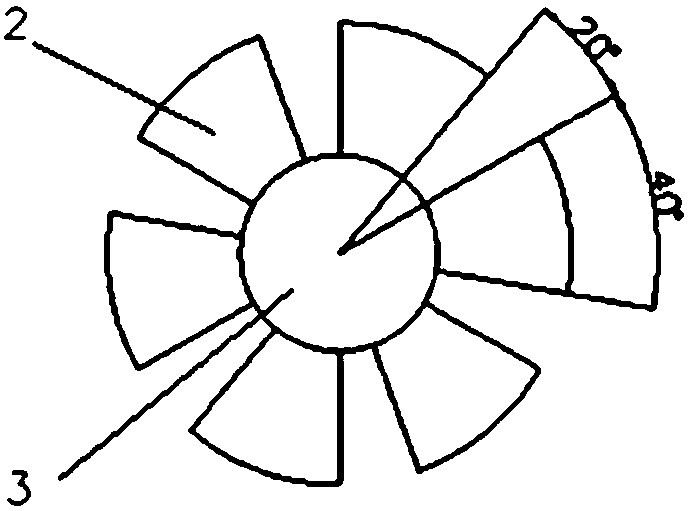

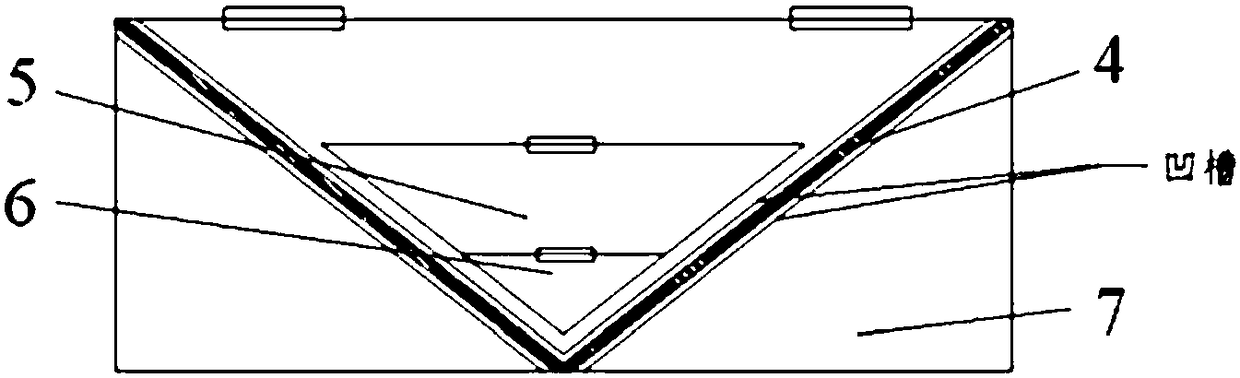

The invention provides a deduster composed of two components, which are a dust particle and flue gas separating apparatus and a dust discharging apparatus. The dust particle and flue gas separating apparatus comprises a cyclone generator 1 arranged above a built-in cylinder-shaped electrode. The middle part of the cyclone generator 1 is a support, and the peripheral of the cyclone generator 1 is fixed on the wall of an electric dedusting apparatus. A heat insulating layer 8 is arranged on the wall of the electric dedusting apparatus, wherein the heat insulating layer 8 is used for holding temperature. A space between a cylinder wall contacting an edge of a dust inhibitor 3 and a wall of the electric dedusting apparatus is provided with a jacket 7. The dust discharging apparatus is mainly composed of a dust collecting hopper 11, a dust filter 12, a back flushing apparatus 15, a water cooler 17, a dust discharging blower 13, and the like. The dust discharging apparatus is positioned at a lower part of the dust particle and flue gas separating apparatus, and is used for discharging separated dust. With the deduster with the structure, advantages of cyclone centrifugal dedusting and electric dedusting can be combined, and dust particles can be effectively separated from flue gas, such that a dedusting effect is reached. The pollution to the atmosphere is reduced, and the purified flue gas can be recycled. Therefore, an environment protection effect can be reached, electricity consumption can be reduced, and energy can be saved.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

Aluminum alloy tube for camping tent support and preparation method thereof

ActiveCN102839304ANo effect on product performanceDoes not affect useAluminium alloyUltimate tensile strength

The invention provides an aluminum alloy tube for a camping tent support and a preparation method thereof, relating to the aluminum alloy tube and the preparation method thereof. In order to solve the problem that the conventional camping tent support has poor mechanical properties and cannot meet the requirements of carrying more items in travel, the aluminum alloy tube for the camping tent support is prepared from the following components in percentage by mass: 0.05 to 0.30 percent of Si, 0.07 to 0.35 percent of Fe, 2.0 to 3.0 percent of Cu, 0.01 to 0.15 percent of Mn, 2.8 to 4.0 percent of Mg, 0.18 to 0.35 percent of Cr, 7.5 to 9.0 percent of Zn, 0.02 to 0.20 percent of Ti and 82.65 to 87.37 percent of Al. According to the preparation method, the content of other elements is controlled to form a novel aluminum alloy material by increasing the content of main reinforcement elements such as Zn and Cu, the mechanical properties are high, the tensile strength is greater than 700 MPa, and the non-proportional extension strength is greater than 600 MPa.

Owner:HARBIN ZHONGFEI NEW TECH CO LTD

Remediation method for heavy metal pollution of neutral soil

ActiveCN106001094ALong-term stability in captivityCaptivity" long-term stabilityContaminated soil reclamationAlcoholSoil heavy metals

The invention discloses a remediation method for heavy metal pollution of neutral soil. The remediation method comprises the steps of dissolving a siloxane substance of which the structural formula is Si(OR)4 into an acid solution of alcohol or ether as a remediation reagent; mixing the mixture of the siloxane substance and the acid solution of alcohol or ether with neutral soil for reaction; and then, adding an aqueous solution of inorganic strong base or inorganic weak base for further reaction, wherein the R refers to one or more of methyl, ethyl and propyl. The remediation method for heavy metal pollution of neutral soil is low in cost, and simple, convenient and efficient to implement, and restored heavy metals can be stably maintained in soil for a long time.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

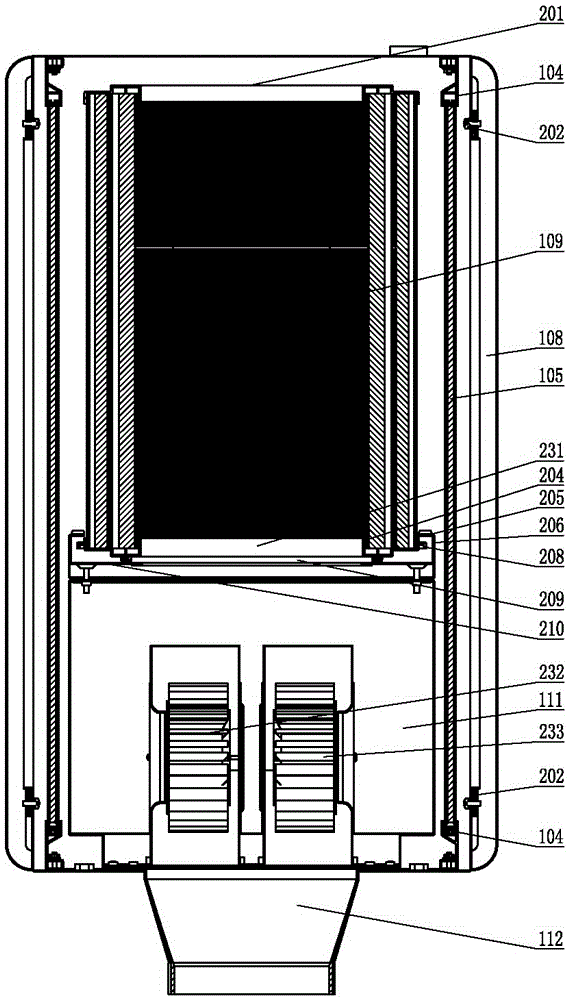

Outdoor air purifier

ActiveCN105605702AReasonable layoutCompact structureMechanical apparatusLighting and heating apparatusCentrifugal forceAir purifier

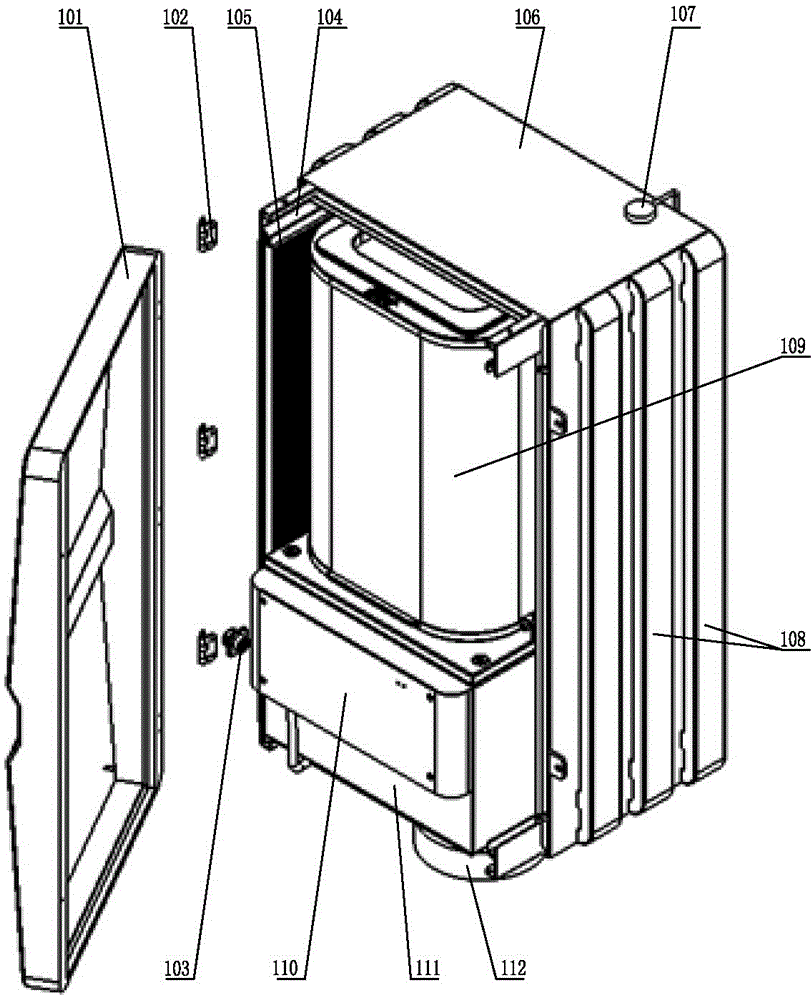

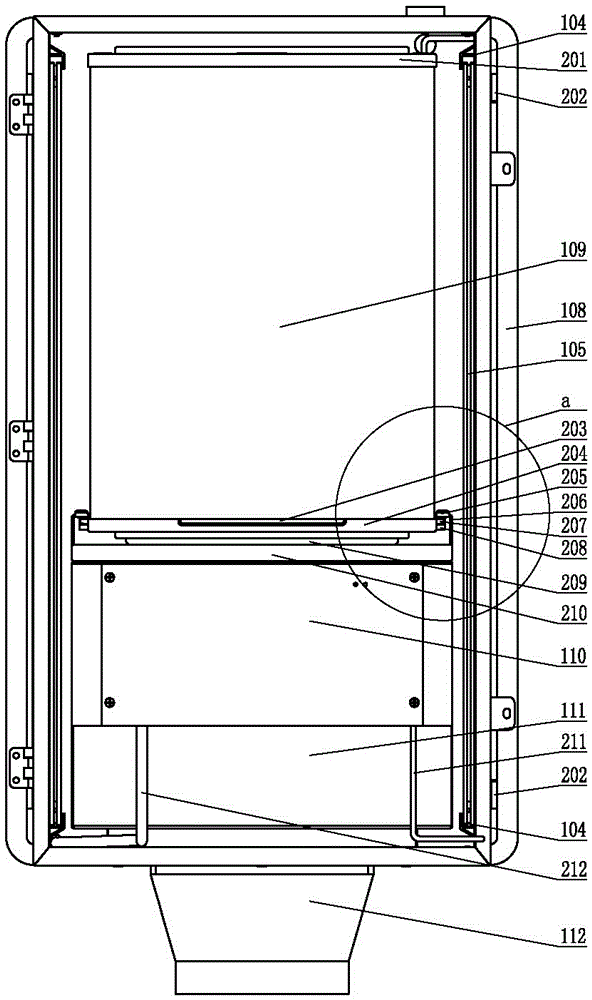

The invention belongs to the technical field of air purification, and discloses an outdoor air purifier. The outdoor air purifier comprises a case; a case door adopting the openable design is arranged at the front side of the case; air inlets are formed at both left and right sides of the case; rail-type clamping grooves are formed in the inner sides of the air inlets at both the left and right sides; filter screens are inserted in the clamping grooves; a filter cartridge is arranged at the upper part inside the case; a fan bin is formed at the lower part of the case; the top of the fan bin is open; the filter cartridge is mounted at the top of the fan bin; an opening of the filter cartridge is downward; an opening at the lower end of the filter cartridge is abutted with an opening at the top of the fan bin; an abutted face is sealed by a sealing cushion; two centrifugal fans with opposite rotating directions are symmetrically arranged side by side at the middles of the left and right parts in the fan bin; air inlets of the two centrifugal fans are on the contrary; air outlets of the two centrifugal fans pass downwards through the bottom of the fan bin to be communicated with an air outlet at the bottom of the case. The outdoor air purifier disclosed by the invention is reasonable in layout, compact in structure, small in integral size, large in effective filtering area, low in wind resistance and long in service life.

Owner:HANGZHOU FILTECH INTELLIGENT CO LTD

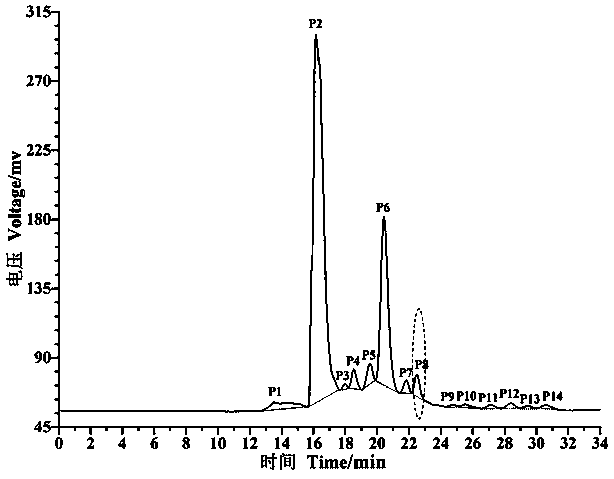

Method for extracting ceramide amphoteric lipid from agriculture-forestry byproducts

InactiveCN101591262ASimplified separation stepsDoes not affect useSugar derivativesCarboxylic acid amide separation/purificationChromatographic separationSolvent

The invention relates to a method for extracting ceramide amphoteric lipid from agriculture-forestry byproducts, which comprises the following steps: using waste materials of the processing of the agriculture-forestry byproducts of rice bran, wheat bran and corn as raw materials; adding protease which is 0.1 to 1.0 percent of the agriculture-forestry byproducts in weight and an amino acid chemical penetrating agent which is 0.01 to 0.1 percent of the agriculture-forestry byproducts in weight to the raw materials; extracting the raw materials for 3 times by using a mixed solvent of chloroform and methanol; performing column chromatographic separation; using a solvent to elute out lipid rich in ceramide; and after alkaline treatment, performing high-efficiency liquid phase chromatographic separation to obtain ceramide. The method has high extraction efficiency, simplifies the separation steps of other components, and obtains the ceramide lipid with different contents at the same time.

Owner:ZHEJIANG UNIV

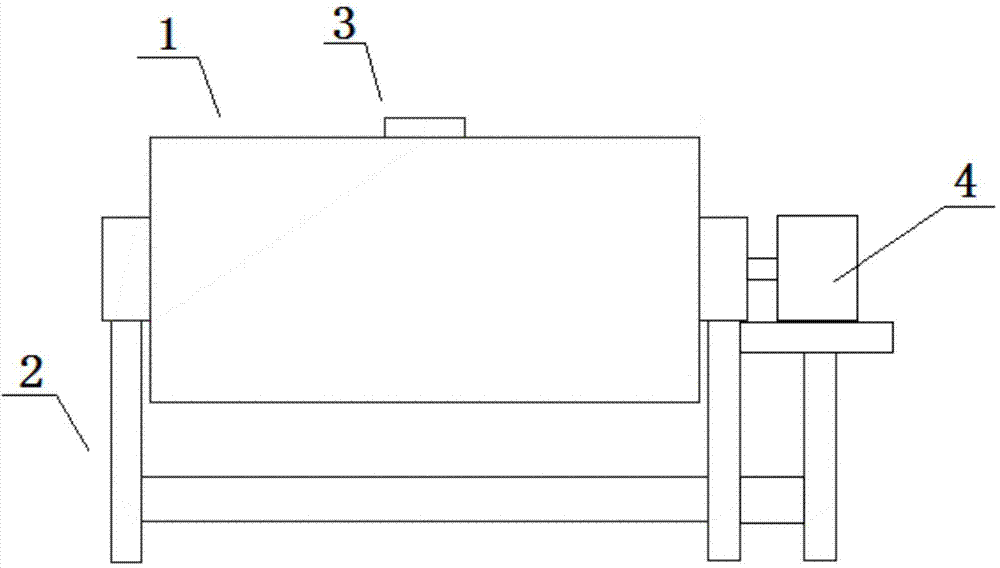

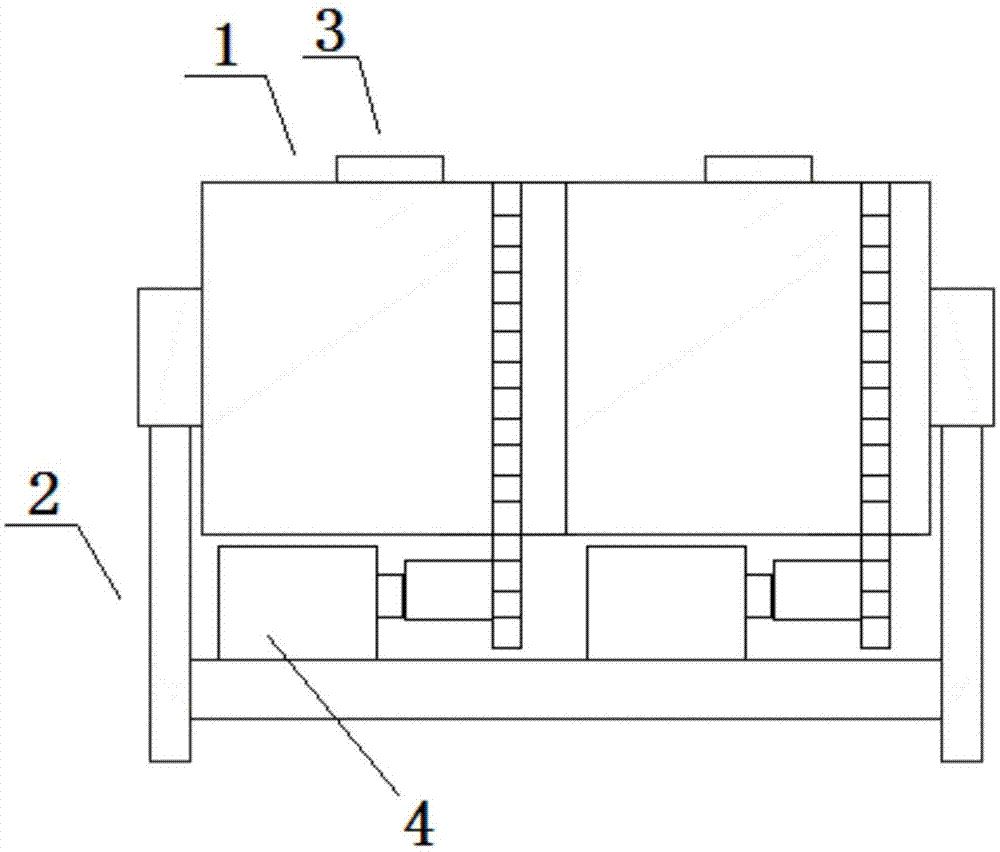

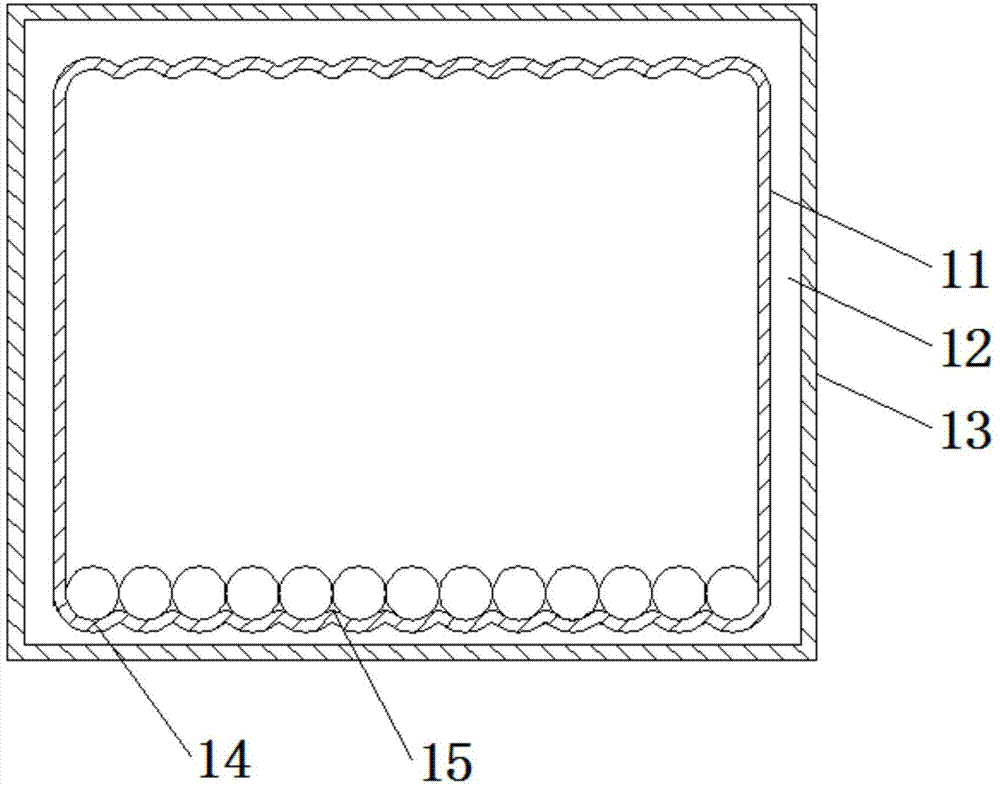

Application of ball milling immobilization method in treatment of heavy metal contaminated soil

ActiveCN104841690ADoes not affect useEffectively fixedContaminated soil reclamationGrain treatmentsEngineeringExcavator

The invention relates to a ball mill and discloses application of a ball milling immobilization method in treatment of heavy metal contaminated soil. The ball milling immobilization method is applied to restoration of heavy metal contaminated soil containing nickel, zinc, arsenic, lead and copper. The restoration comprises the following concrete steps: step 1, excavating the heavy metal contaminated soil with an excavator and screening and separating the excavated heavy metal contaminated soil according to particle sizes; step 2, screening and separating out heavy metal contaminated soil with a particle diameter of no more than 2 mm and grinding the separated heavy metal contaminated soil with a ball mill; step 3, adding a mixed reagent for immobilization into the ground heavy metal contaminated soil and carrying out uniform mixing under stirring; and step 4, sampling the restored heavy metal contaminated soil and detecting the obtained sample. With the ball milling immobilization method, heavy metals in the contaminated soil and heavy metal tailings are effectively immobilized, the physical and chemical properties of original soil are not influenced, and the purposes of the soil are not affected.

Owner:SHANGHAI JIANWEI ENVIRONMENTAL PROTECTION TECH CO LTD

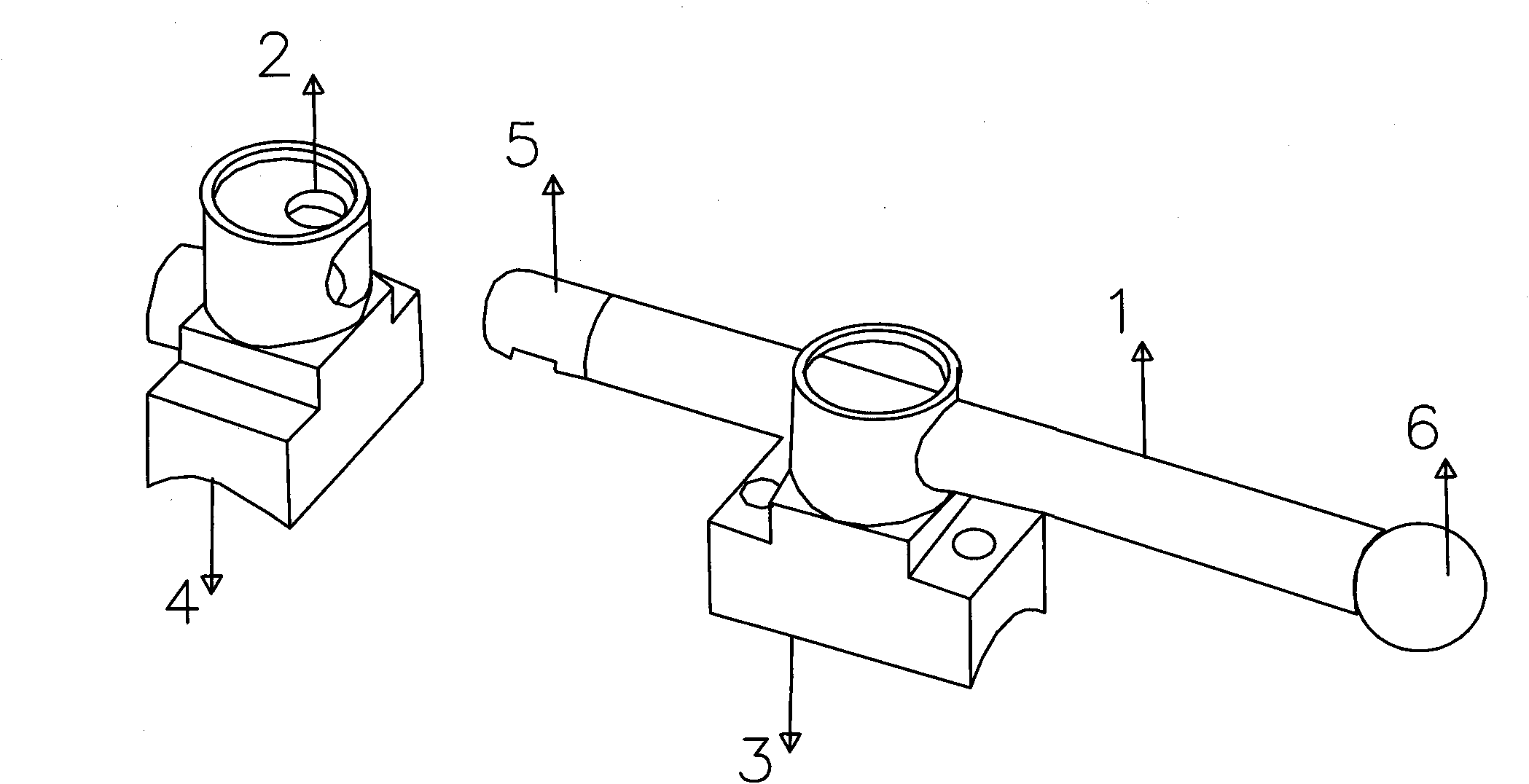

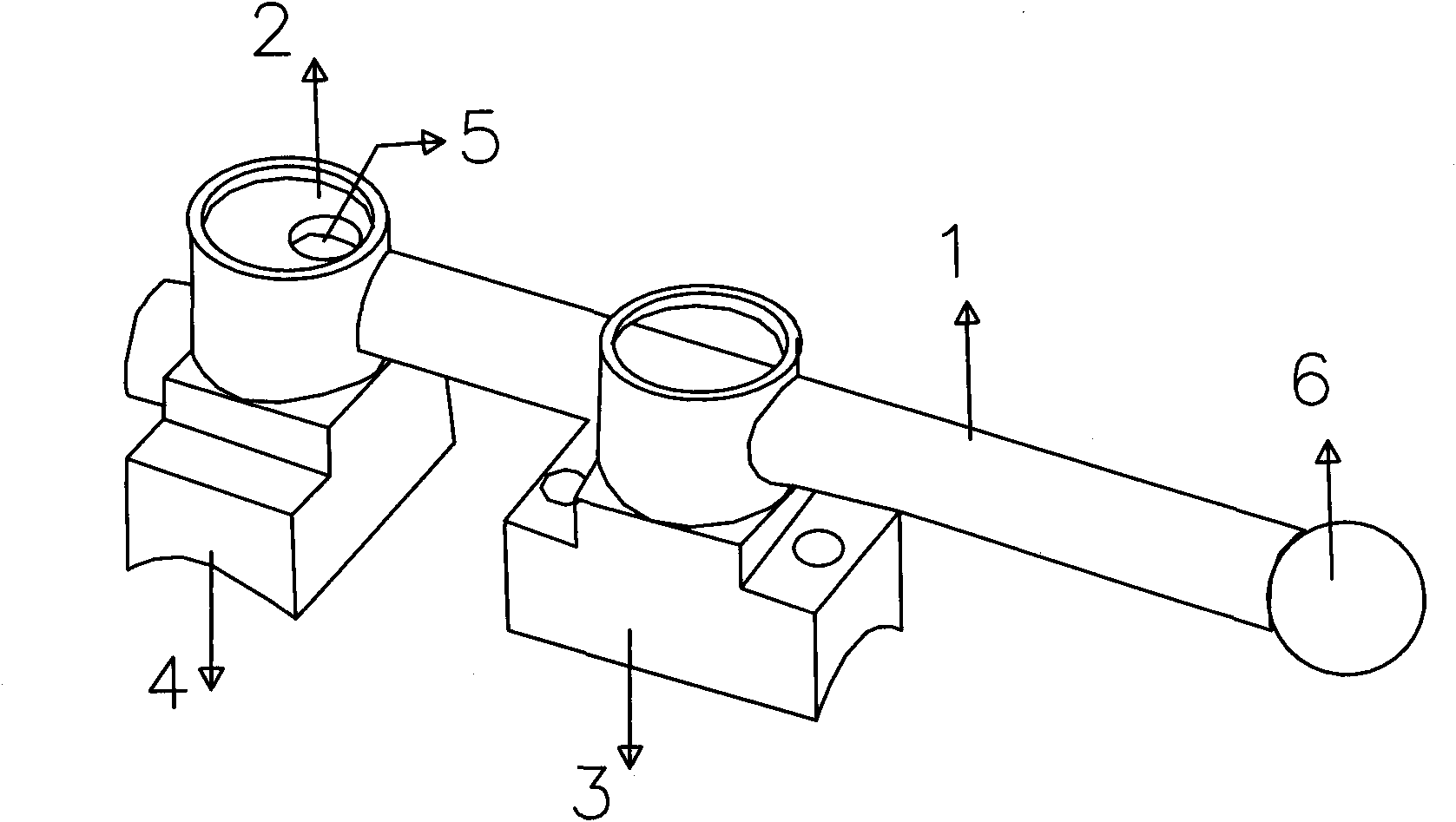

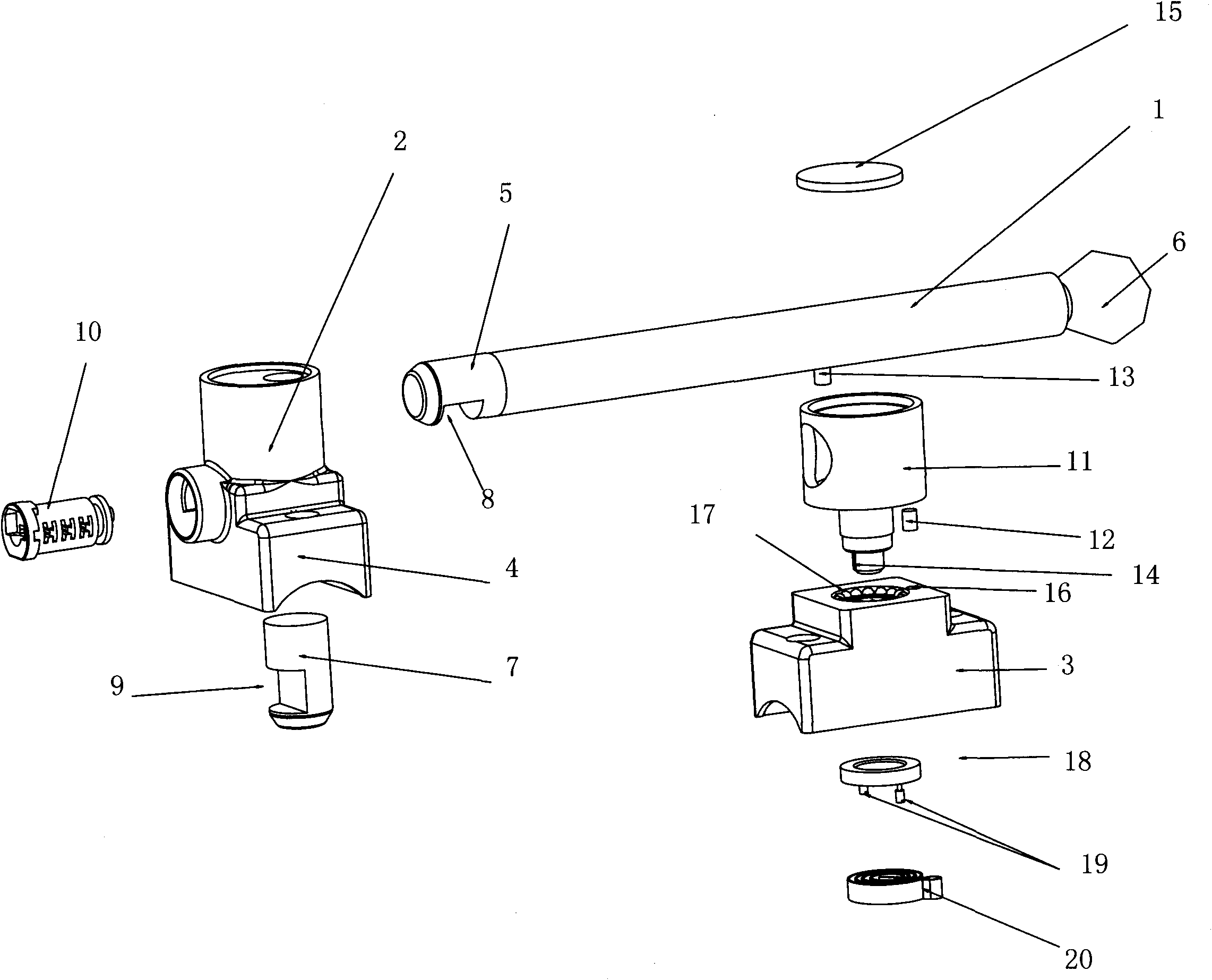

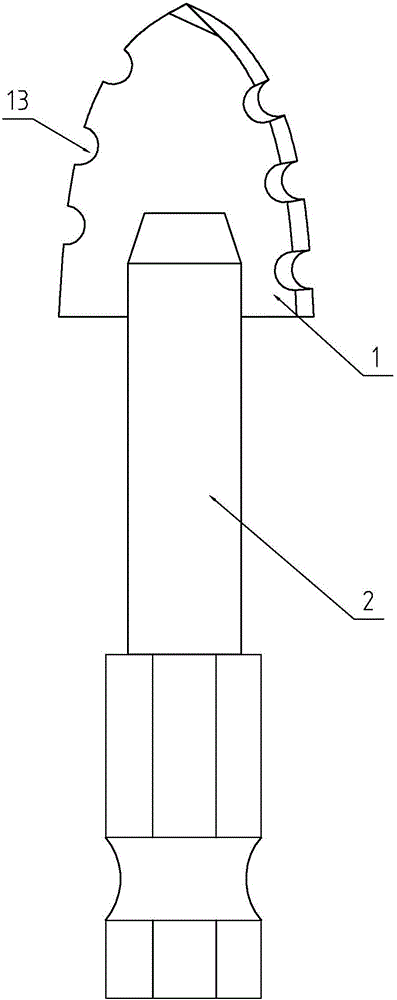

Front fork lock with automatic reset pin column

The invention discloses a front fork lock with an automatic reset pin column. The structure of the front fork lock mainly comprises a pin column part and a lock catch part, wherein an automatic reset device capable of automatically resetting the pin column is arranged in the pin column; the pin column slides in a pin column shell on a pin column base back and forth and is integrally designed with the pin column base; and an automatic reset device capable of automatically resetting the pin column shell with the pin column is arranged in the pin column base. The front fork lock has the advantages that the pin column and the pin column shell both have the function of automatic reset; when the front fork lock lock is unlocked, the pin column can eject automatically and the pin column shell drives the pin column to rotate and return by 90 degrees on the pin column base. When locking the front fork lock, a user only needs to push down a pin column handle to lock a pin column bolt and the pin column shell. Compared with a traditional design of separation of lock pin column and a lock shell, the front fork lock with the automatic reset pin column is more practical, convenient, stable and safer. A user can locks or unlocks the front fork lock more quickly and conveniently and time delaying is no longer caused by locking and unlocking.

Owner:李孝聪

Protein powder for children and teenagers and preparation method of protein powder

InactiveCN108926000ADoes not affect useDoes not affect metabolismVitamin food ingredientsFood ingredient functionsFruit juiceWhey protein powder

The invention discloses protein powder for children and teenagers and a preparation method of the protein powder. The protein powder comprises the following components in parts by weight: 25-35 partsof soy protein isolate powder, 15-25 parts of soyabean protein powder, 4-6 parts of whey protein powder, 1.2-1.8 parts of walnut powder, 1.5-1.7 parts of calcium carbonate, 0.8-1.2 parts of calcium citrate malate, 0.05-0.07 part of iron lactate, 0.08-0.10 part of zinc gluconate, 0.001-0.002 part of vitamin A, 30.06-30.08 parts of vitamin D, 32-34 parts of white granulated sugar, 0.10-0.12 part oftaurine, 1.1-1.2 parts of fruit juice powder, 1.1-1.2 parts of citric acid and 5-7 parts of vegetable fat powder. According to the protein powder disclosed by the invention, various substances which are beneficial to bodies of the children and the teenagers can be taken in, and the protein powder is easy to absorb and capable of promoting skeleton growth; and the preparation method is simple to operate and short in cycle and is uniformly mixed.

Owner:安徽合生堂药业有限公司

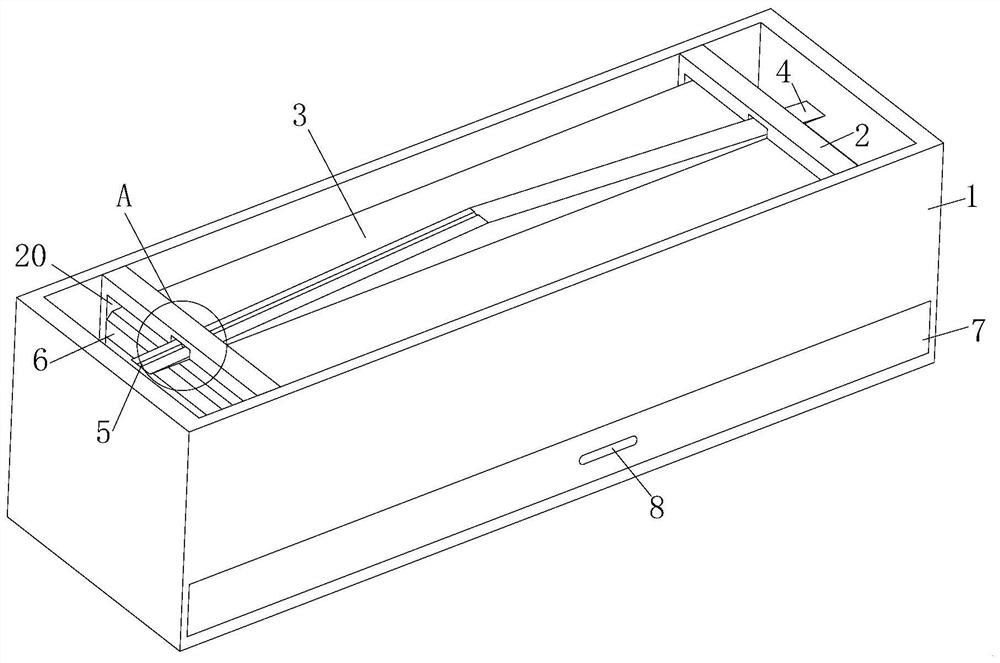

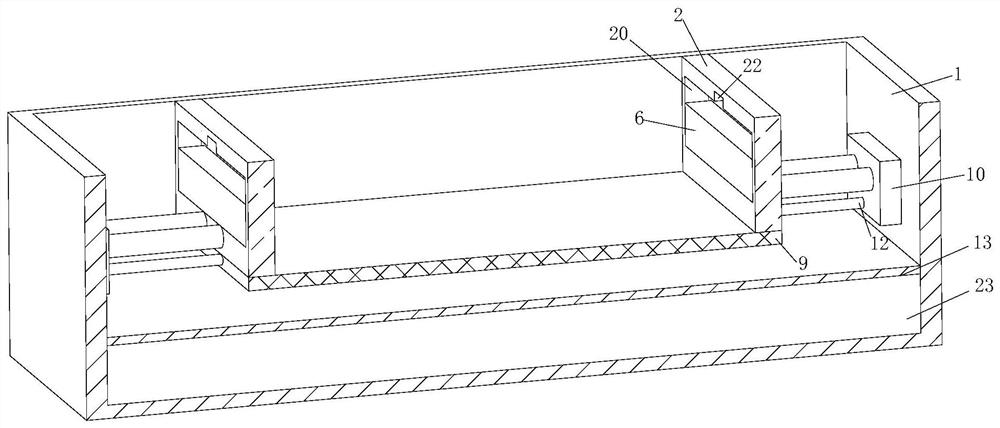

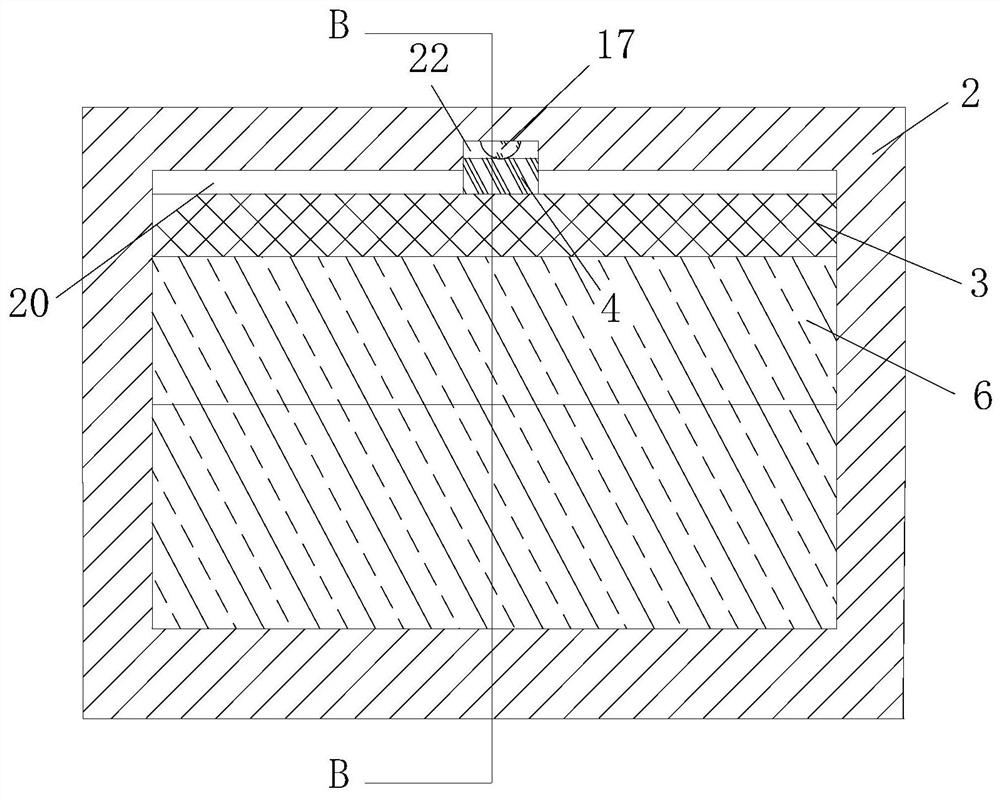

Sand box for copper furnace foundry casting

PendingCN113828738AGuaranteed tightnessFull compaction operationMould handling/dressing devicesMoulding machinesFoundryEngineering

The invention relates to the field of sand boxes, in particular to a sand box for copper furnace foundry casting. The sand box comprises a sand box body, wherein a filter screen is fixedly connected to the position, close to the lower end, in the sand box body through screws, the interior of the sand box body is divided into two parts by the filter screen, the part above the filter screen serves as a sand cavity, and the part below the filter screen serves as a collecting cavity; an opening is formed in the position, close to the bottom of the outer surface of the front end of the sand box body, below the filter screen, a collecting box is arranged in the opening, the collecting box is movably connected into the collecting cavity through the opening and is sealed with the periphery of the opening, and a grip is fixedly connected to the middle of the front end of the outer surface of the collecting box; and a bottom plate is arranged above the filter screen, and rotating shafts are fixedly connected to the left side and the right side of the bottom plate. According to the structure of the device, compaction of the left side and the right side of sand before casting can be achieved, and compaction can be conducted from top to bottom; automatic sand discharging can be conducted when movable plates reset, so that the recovery efficiency is greatly improved; and after casting is completed, caked sand can be smashed, so that the sand recovery benefit is improved.

Owner:徐永上

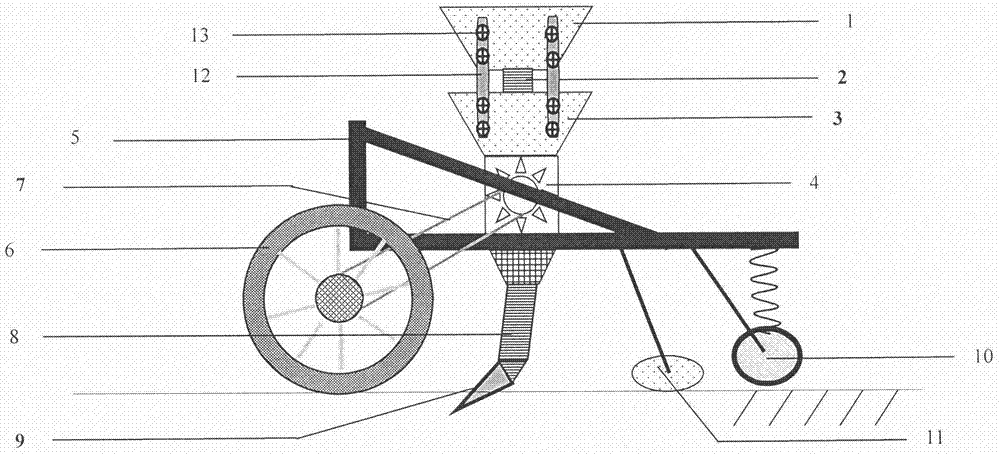

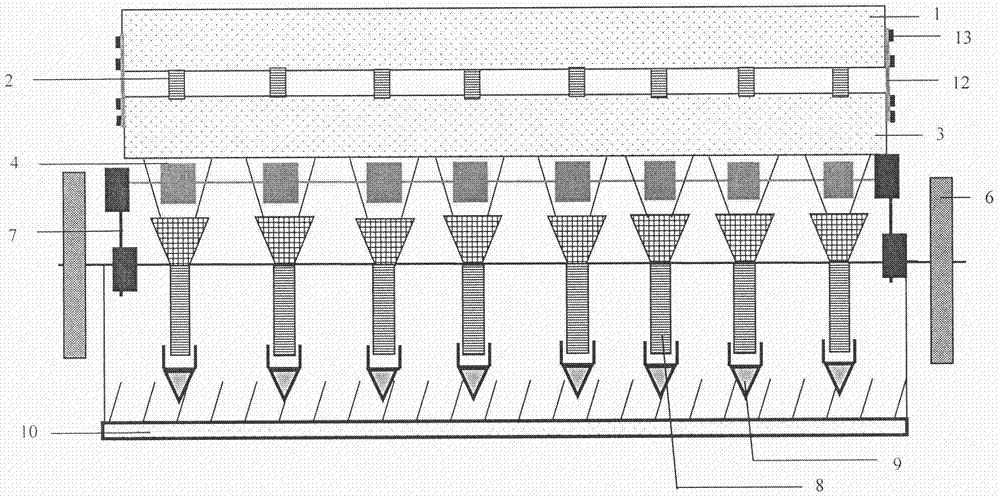

Intercropping seeding machine

PendingCN107258160ADoes not affect the original purposeDoes not affect usePlantingFurrow making/coveringAgricultural engineeringIntercropping

The invention discloses an intercropping seeding machine, which comprises a lower seed box, a seed meter, a frame, a traveling wheel, a transmission chain, a lower seed delivery pipe, a ditch opener, a pressing wheel, and a soil covering device, and is characterized in that it also includes an upper seed Box, upper seed tube, fixing bracket and fixing bolts. The upper seed box is fixed above the lower seed box by fixing brackets and fixing bolts on both sides, the lower part of the upper seed box is connected with the upper seed delivery pipe, and the upper seed delivery pipe passes downward through the lower seed box and is connected with the seed metering device. The seed meter is fixed below the lower seed box. The seed meter connected to the upper seed delivery pipe is arranged at intervals with the seed meter connected to the lower seed box. When sowing, put two different crop varieties or different varieties of the same crop into the upper seed box and the lower seed box respectively to realize mechanized intercropping. The invention can also be obtained by increasing the upper seed box, the upper seed delivery pipe, the fixed bracket and the fixed bolt on the basis of the existing single variety sowing machinery.

Owner:JIANGSU COASTAL AREA AGRI SCI RES INST +1

Restoration method for alkaline soil heavy metal pollution

ActiveCN106001093ALong-term stability in captivityCaptivity" long-term stabilityContaminated soil reclamationAlcoholRestoration method

The invention discloses a restoration method for alkaline soil heavy metal pollution. Siloxane substances with the structural formula of Si(OR)4 are dissolved in an alcohol or ether acid solution to serve as a restoration reagent and are mixed with alkaline soil to react; and then water is added for a further reaction, wherein R represents one or more of methyl, ethyl or propyl. The restoration method easily, conveniently and efficiently treats alkaline soil heavy metal pollution at low cost, and restored heavy metal can be steadily kept in soil for a long time.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

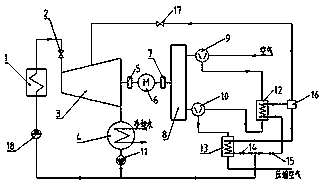

Organic Rankine circulatory system for recovering various residual heat through gas and electricity combined supply and using method

InactiveCN109667635AIncrease profitWays to expand waste heat utilizationSteam engine plantsClutchOrganic Rankine cycle

The invention discloses an organic Rankine circulatory system for recovering various residual heat through gas and electricity combined supply. The organic Rankine circulatory system is characterizedby comprising an ash residue residual heat recovering high-pressure circulation loop, an air compressor exhaust residual heat recovering low pressure circulation loop, a motor, a speed increasing box,a first clutch and a second clutch, wherein the air compressor exhaust residual heat recovering low pressure circulation loop comprises an expander, a condenser, a condensation pump, a first air heatexchanger, a second air heat exchanger, a first air compressor, a second air compressor and an air collecting bag, wherein the motor is also connected to the expander through the first clutch; the other side of the motor is connected with the speed increasing box through the second clutch; and the speed increasing box is connected with the first air compressor and the second air compressor. A lowboiling organic working substance namely Rankine for comprehensively cycling residual heat of ash residues and high pressure air, the expander is used for dragging the air compressor and the motor, and the motor is mainly used as a standby application power source of the air compressor. Under the premise that the dragging of the air compressor is met, the motor can also be used for power supply outwards.

Owner:JIN TONG LING TECH GRP CO LTD

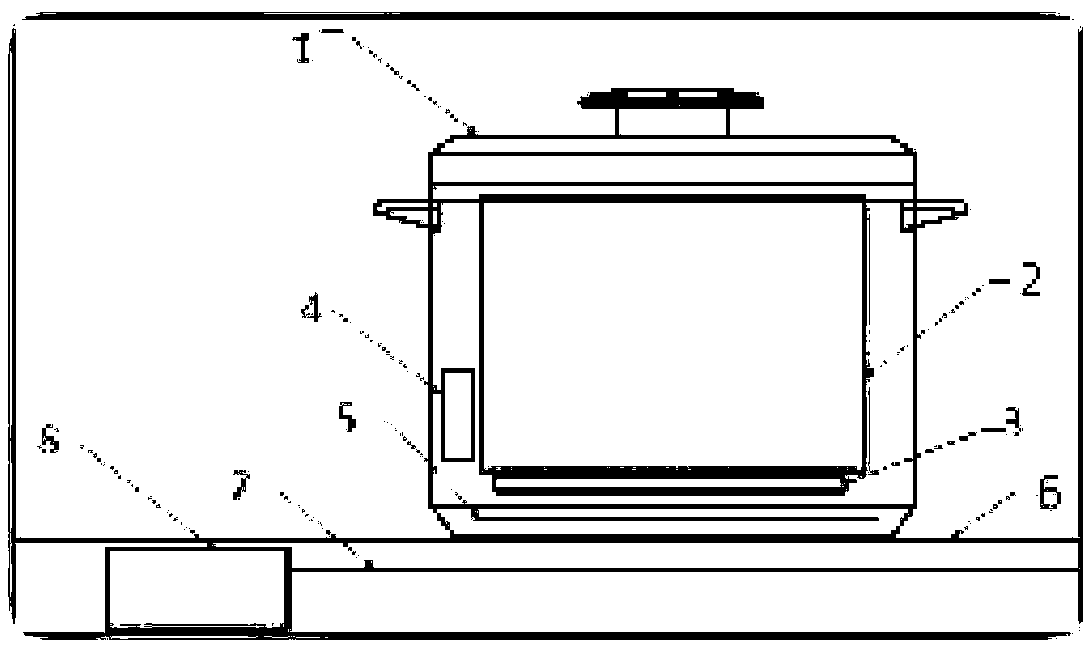

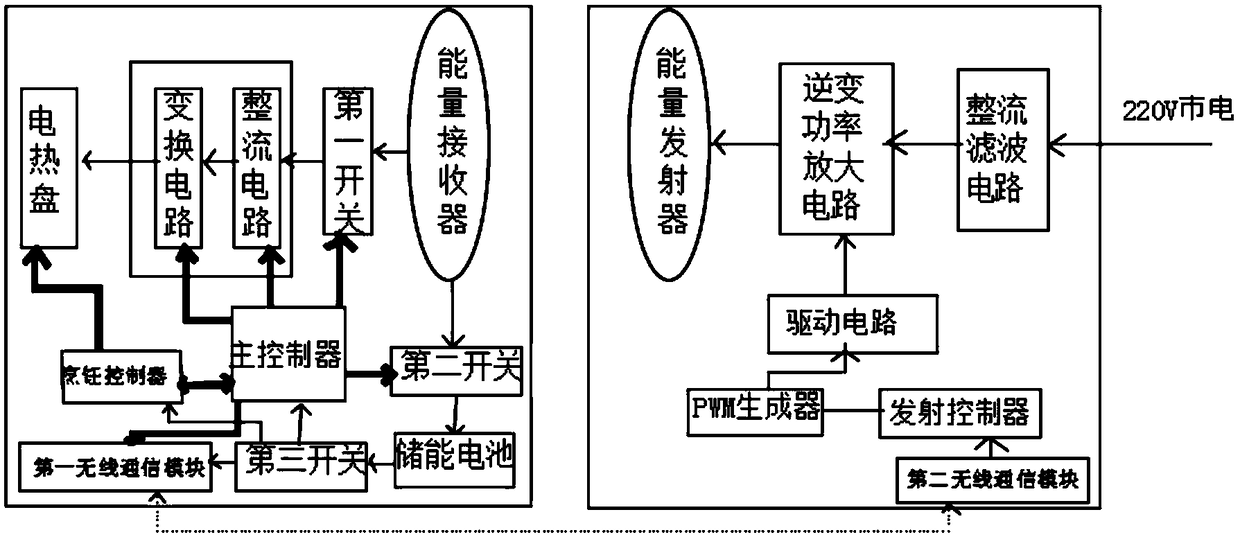

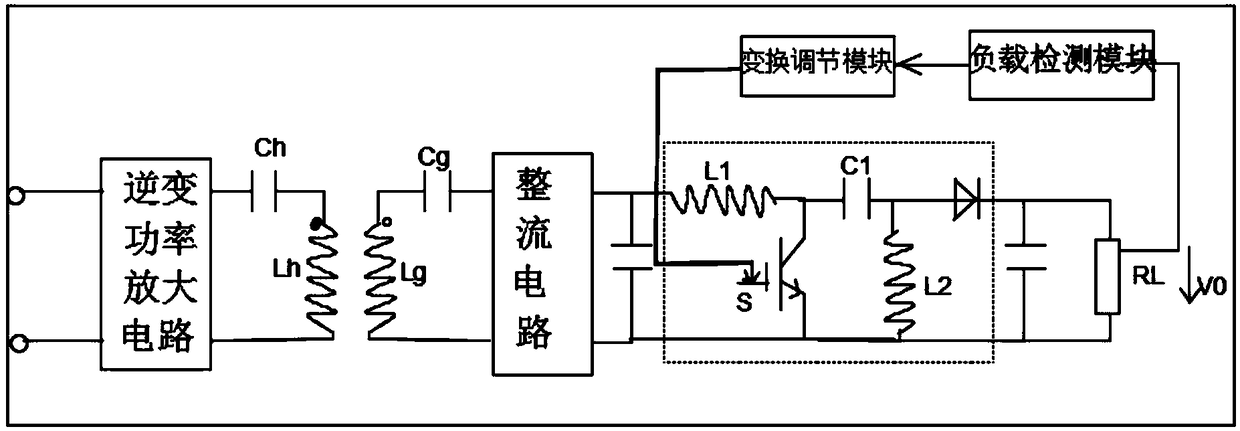

Wireless charging-based intelligent temperature control container

ActiveCN108736580AGuaranteed self-startImprove wireless energy transfer efficiencyElectric heatingCircuit arrangementsElectricityTemperature control

The invention provides a wireless charging-based intelligent temperature control container. The wireless charging-based intelligent temperature control container comprises a container body and a charging seat matched with the container body, wherein the container body comprises a shell, a liner, an electric heating tray, a wireless power supply receiving circuit, and an energy receiver, no external interface is arranged outside the shell, the liner is arranged in the shell, the energy receiver receives transmitted electromagnetic energy and is electrically connected with the wireless power supply receiving circuit generating electric energy demanded by the electric heating tray and the electric heating tray in sequence, the charging seat comprises a table top, an energy emitter and a wireless power supply emitter host, no electric equipment is connected between the table top and the shell, the energy emitter and the energy receiver are fitted with each other so as to transmit energy, and the wireless power supply emitter host and the energy emitter are electrically connected and are arranged in the table top. The temperature control container is not limited by length of a power line and heats up rapidly and controls temperature well when in use as a whole.

Owner:广州达通光电科技有限公司

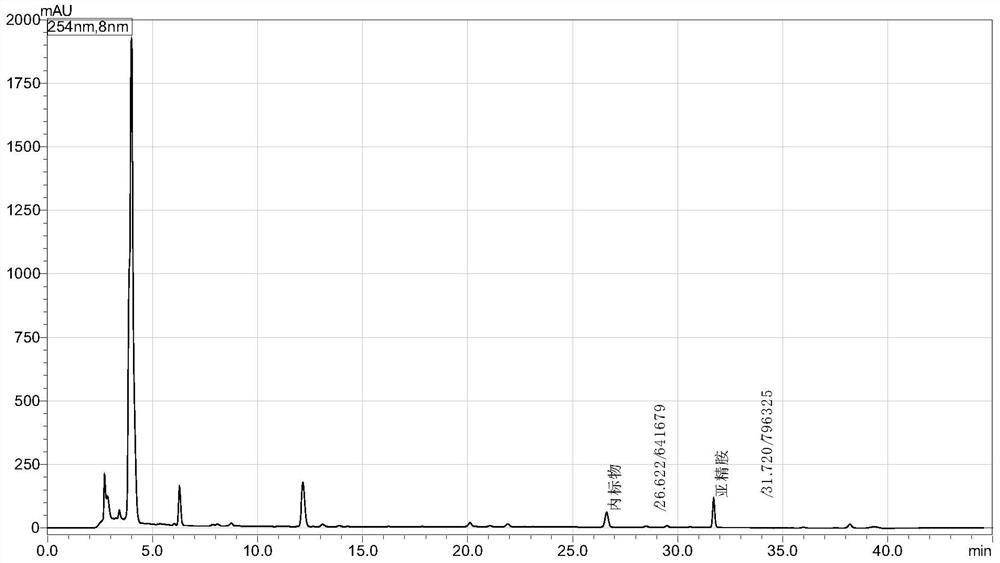

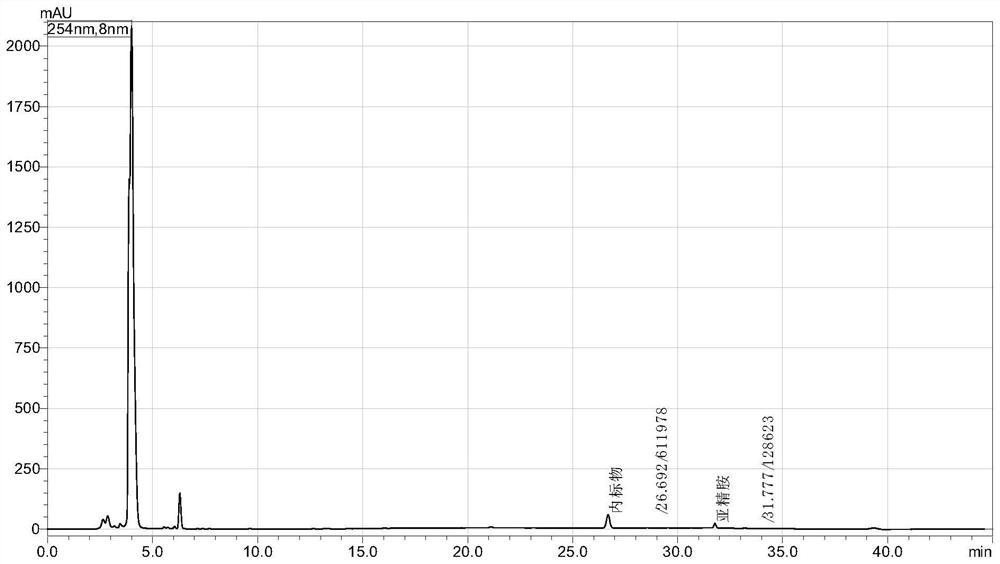

Preparation method of natto extract rich in spermidine

InactiveCN112544888ASimple and efficient operationShort preparation timeFood scienceNutritional compositionEngineering

The invention relates to a preparation method of a natto extract rich in spermidine. The preparation method is characterized in that the natto extract rich in spermidine is prepared from solid-state fermented natto by using a supercritical carbon dioxide fluid extraction technology. The method is simple in processing course, short in preparation time, high in extraction rate and low in extractiontemperature, and can effectively avoid thermal degradation of heat-sensitive components; the content of the spermidine in the obtained natto extract is 10-15 times that of natto. The natto extract does not contain thalli or spores, does not have unpleasant ammonia smell in fresh natto or natto freeze-dried powder, and can be accepted by more people. In the preparation process, waste residues, waste liquid and waste gas are not generated, nattokinase and other nutritional ingredients contained in the fresh natto are still retained in the extraction residues, further utilization is not affected,and the best use of the natto is achieved.

Owner:天津市尖峰天然产物研究开发有限公司

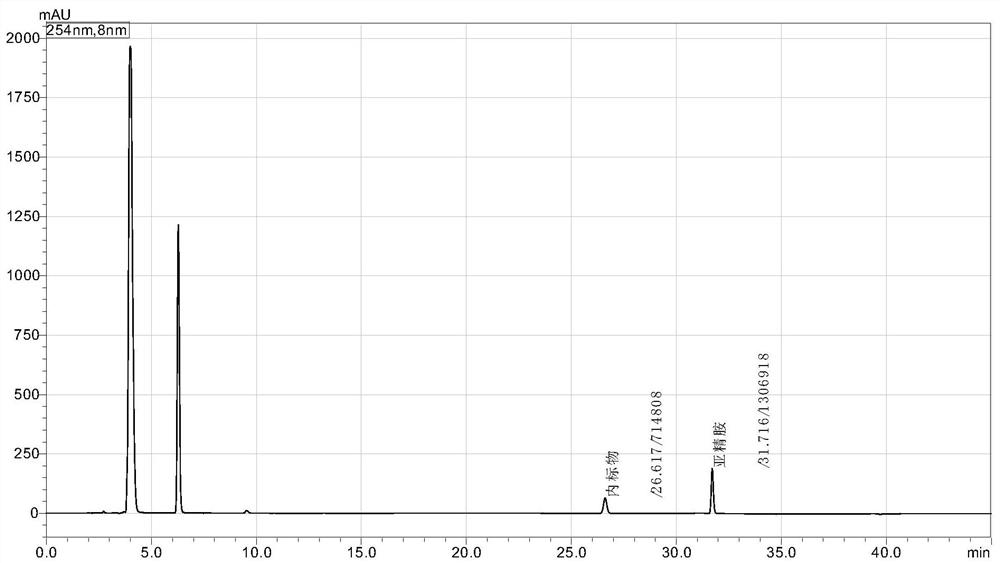

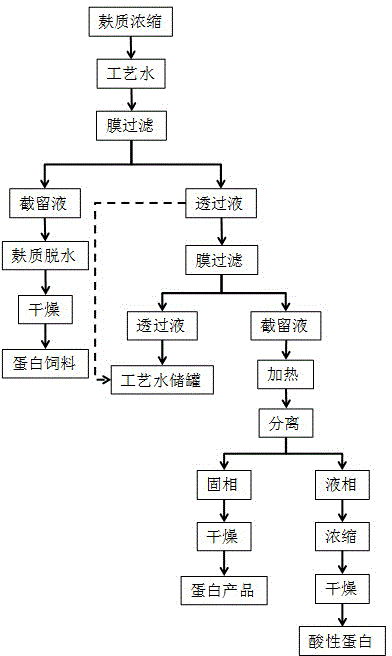

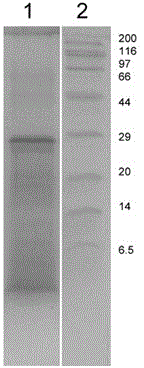

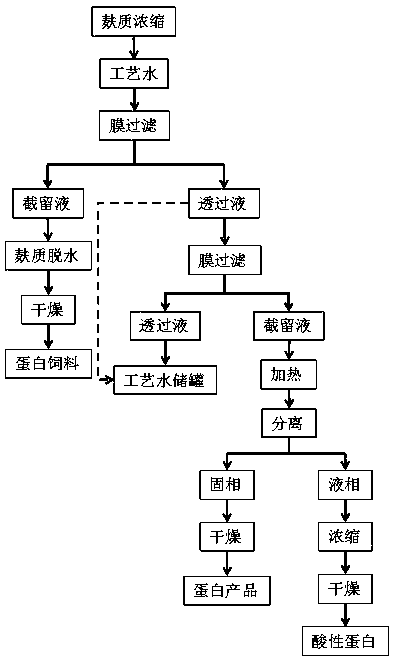

Corn starch process water protein recovery technique

ActiveCN104672299ALittle impact on utilizationGood dispersionPeptide preparation methodsEngineeringCorn starch

The invention provides a corn starch process water protein recovery technique which comprises the following steps: 1) treating process water, which is generated in the gluten concentration step in a wet-grinding technique for producing corn starch, to obtain a first permeation solution and a first trapped fluid containing rich com gluten meal; 2) filtering the first permeation solution through a hyperfiltration membrane with the molecular weight cut-off of 10-200 kDa under the conditions of 3-4 Bar and 35-45 DEG C to obtain a second permeation solution and a second trapped fluid containing rich soluble proteins; and 3) heating the second trapped fluid at 75-150 DEG C for 0.3 second-31 minutes, coagulating to precipitate a first protein product, separating to obtain a first protein product and a separation liquid, and concentrating and drying the separation liquid to obtain a second protein product. The recovery technique overcomes the defect that the traditional technique only treats the insoluble com gluten meal in the process water generated by the gluten concentration step, can obtain the two protein products, and can enhance the yield of the com gluten meal.

Owner:COFCO NUTRITION & HEALTH RES INST +1

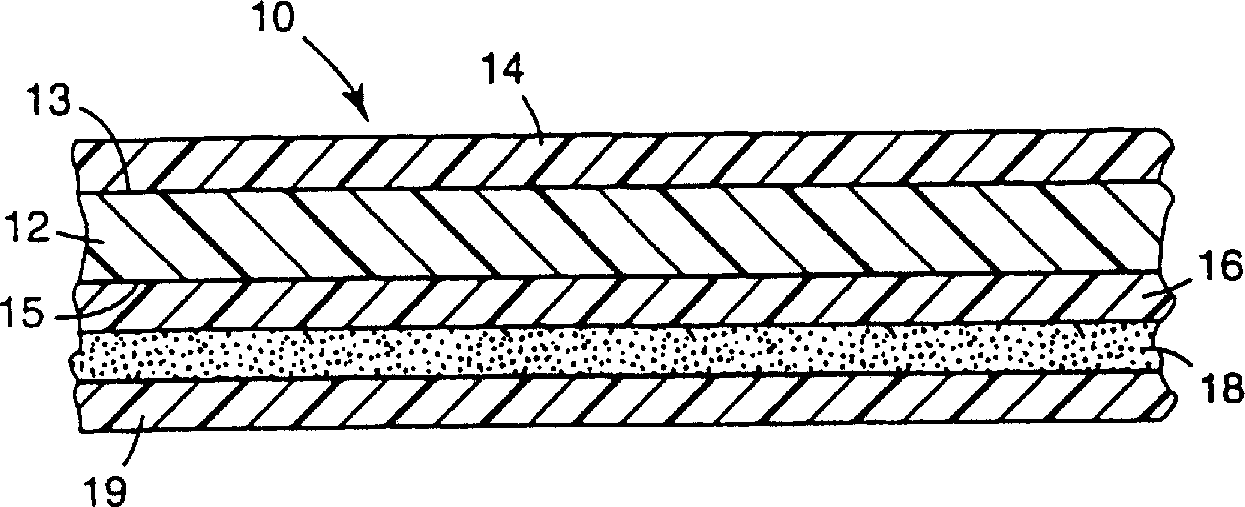

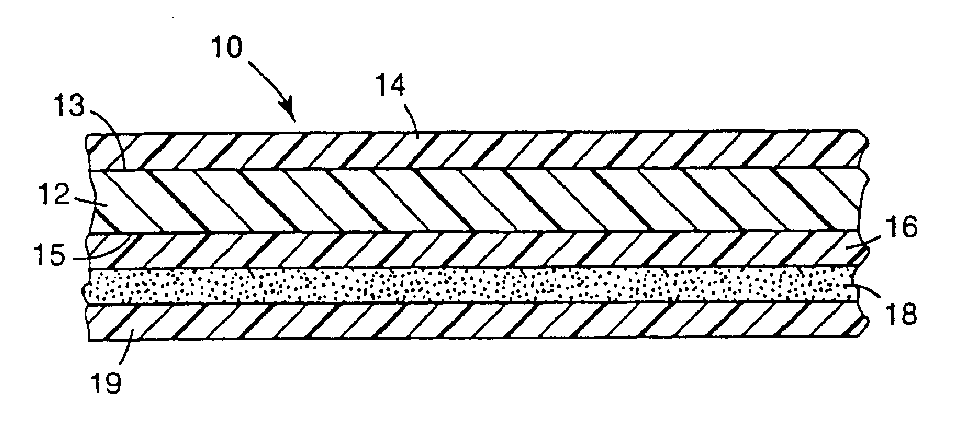

Multilayer electronic cutter film for image graphics

InactiveCN1254309AAffect cuttingLow costDecorative surface effectsSynthetic resin layered productsGraphicsPolyolefin

A multilayer polyolefin film for use as an electronic cutter film is disclosed. The film provides improved abrasion and graffiti resistance, and adhesive anchorage versus a comparable single layer film while still maintaining excellent cutting properties. The film also shows excellent resistance to ''surface impressions'', which are a major problem for traditional vinyl-containing electronic cutting films.

Owner:3M CO

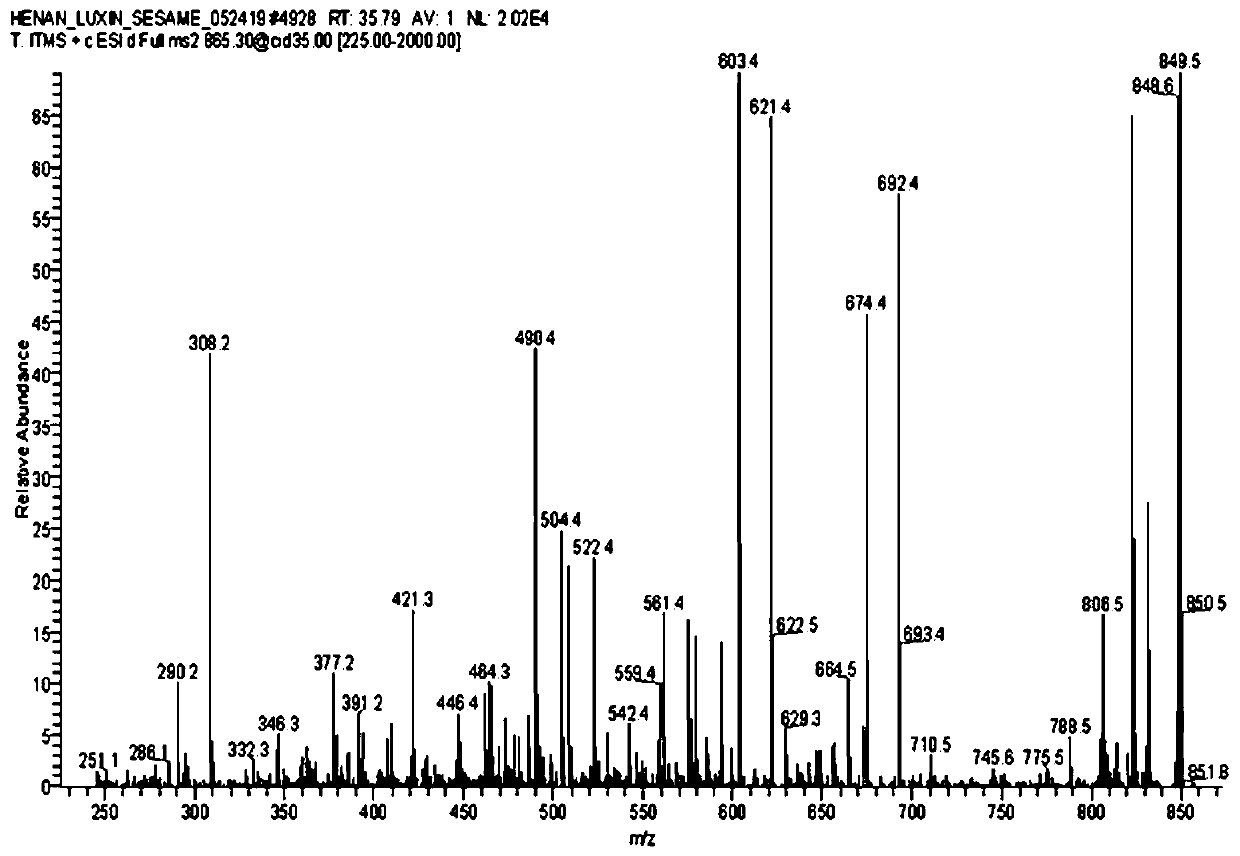

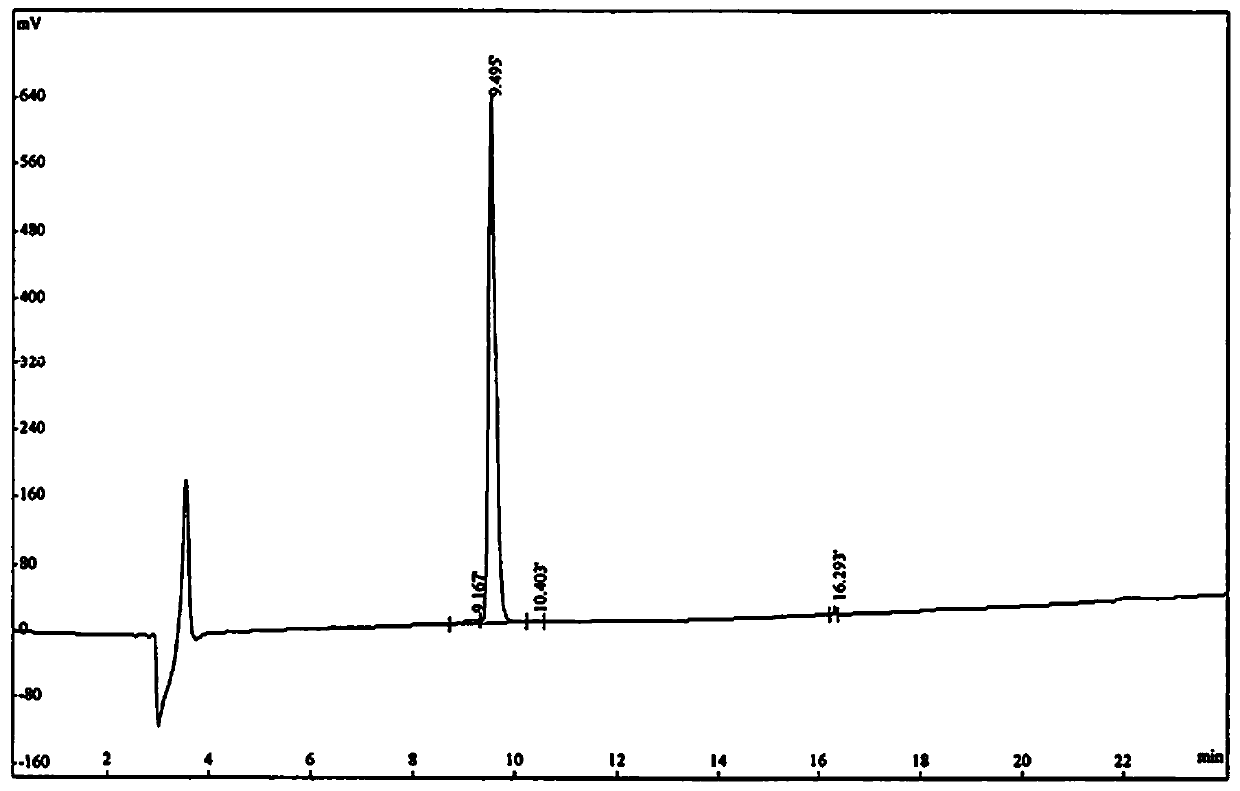

Sesame polypeptide and preparation method and application thereof

ActiveCN111471086AIncrease profitWide variety of sourcesPeptide preparation methodsFermentationAntioxidant capacityNutrition

The invention belongs to the technical field of food-borne protein deep processing, and particularly relates to a sesame polypeptide. The polypeptide is composed of eight amino acids of which the sequence is as follows: Glu-Ala-Cys-Ile-Gln-Ala-Cys-Lys (EACIQACK). The sesame polypeptide disclosed by the invention can be obtained by separating and purifying enzymolysis sesame protein, and can also be artificially synthesized by adopting a chemical solid-phase synthesis method. By determining the DPPH scavenging capability, the ABTS scavenging capability, the total antioxidant capacity (FRAP) andthe ACE inhibition capability, the invention finds that the polypeptide has strong antioxidant activity and strong antihypertensive activity, can be used as a functional active component in the fields of preparation of medicines, health care products, foods, nutrient supplements, feeds, cosmetics, daily chemical products and the like, and has a wide market prospect.

Owner:HENAN ACAD OF AGRI SCI

A kind of water protein recovery process of corn starch process

ActiveCN104672299BLittle impact on utilizationGood dispersionPeptide preparation methodsEngineeringCorn starch

The invention provides a corn starch process water protein recovery technique which comprises the following steps: 1) treating process water, which is generated in the gluten concentration step in a wet-grinding technique for producing corn starch, to obtain a first permeation solution and a first trapped fluid containing rich com gluten meal; 2) filtering the first permeation solution through a hyperfiltration membrane with the molecular weight cut-off of 10-200 kDa under the conditions of 3-4 Bar and 35-45 DEG C to obtain a second permeation solution and a second trapped fluid containing rich soluble proteins; and 3) heating the second trapped fluid at 75-150 DEG C for 0.3 second-31 minutes, coagulating to precipitate a first protein product, separating to obtain a first protein product and a separation liquid, and concentrating and drying the separation liquid to obtain a second protein product. The recovery technique overcomes the defect that the traditional technique only treats the insoluble com gluten meal in the process water generated by the gluten concentration step, can obtain the two protein products, and can enhance the yield of the com gluten meal.

Owner:COFCO NUTRITION & HEALTH RES INST +1

Plastic barrel cover

The invention relates to a plastic barrel cover. The plastic barrel cover comprises a barrel cover main body, a pair of mounting grooves are symmetrically arranged on the two ends of the upper surface of the barrel cover main body, one twisting mechanism is mounted in each mounting groove and comprises a movable head, a twisting handle and a pin axle, the movable head is fixedly mounted on one end of the twisting handle, an opening is formed on the other end of the twisting handle, a holding rod is mounted on the end of the opening, and the movable head is rotatably mounted in the mounting groove by a pin axle. The structure is scientifically and reasonably designed, the barrel cover can be conveniently opened and twisted on, the plastic barrel is convenient to transport, human saving is saved, the labor intensity is reduced, and the barrel cover is easy to implement, so that the plastic barrel cover has relatively high novelty.

Owner:天津市科润特包装有限公司

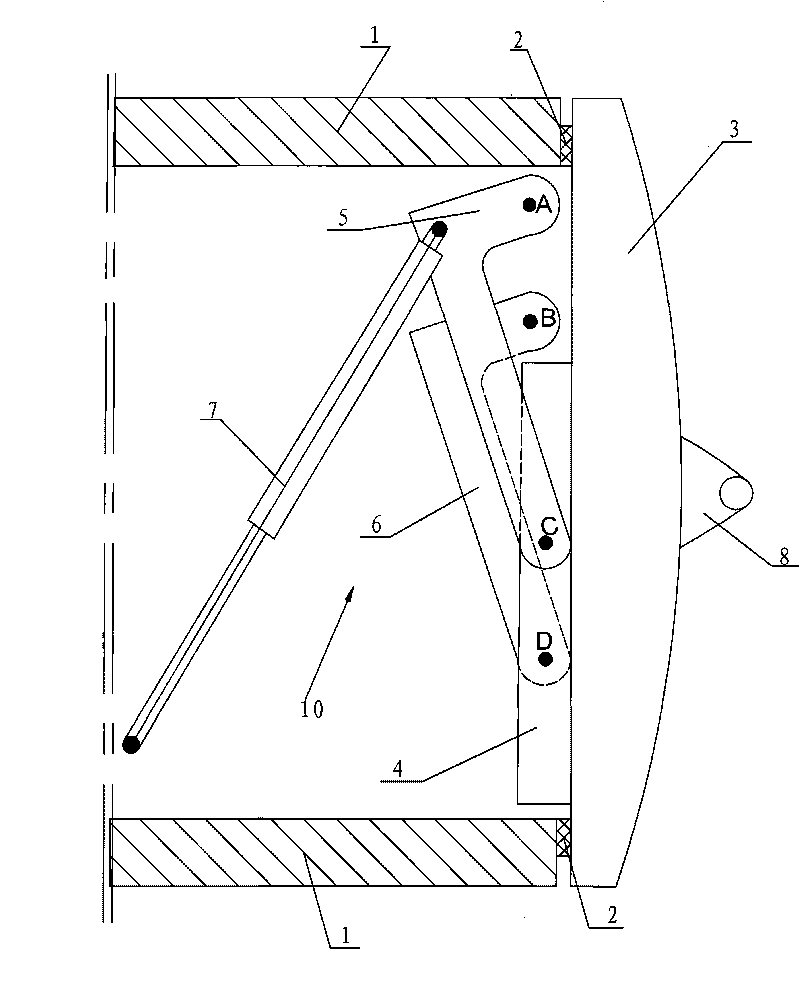

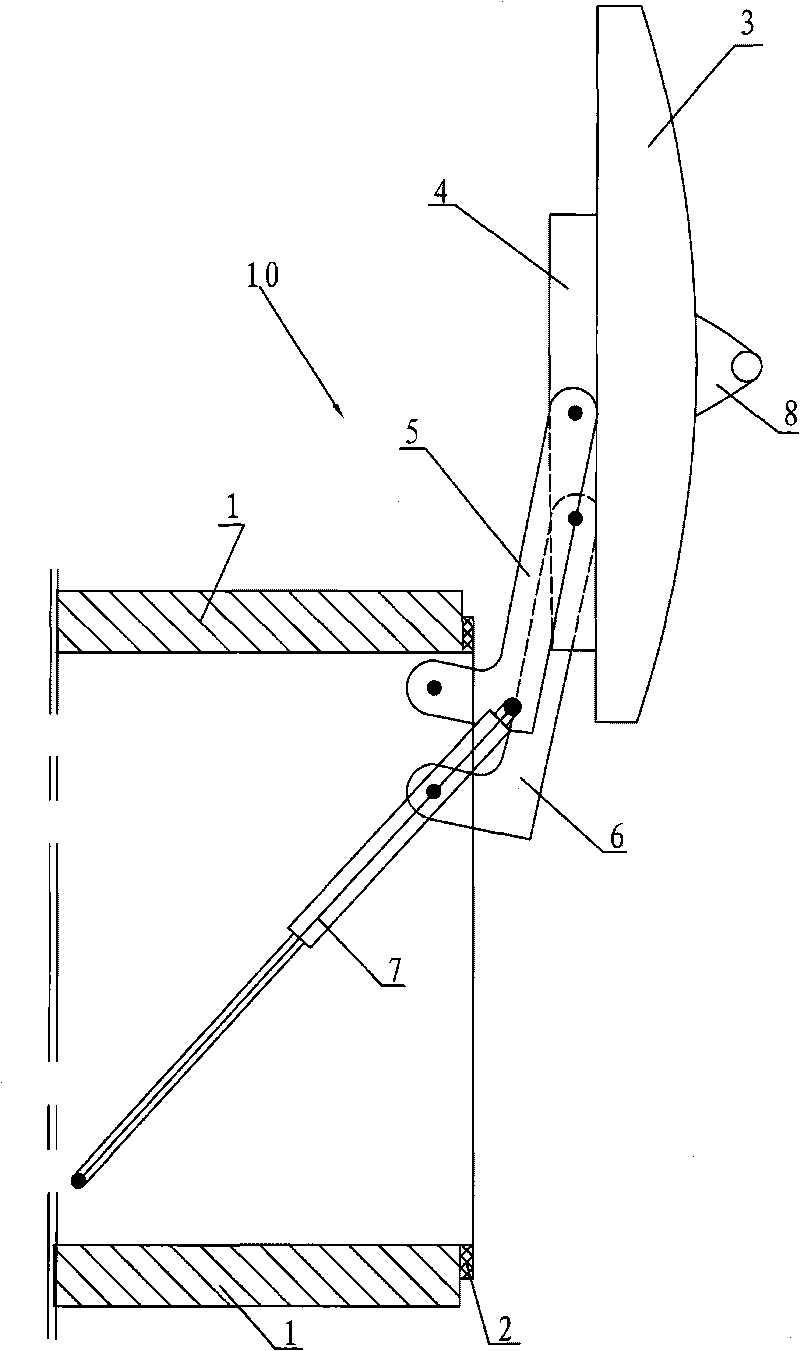

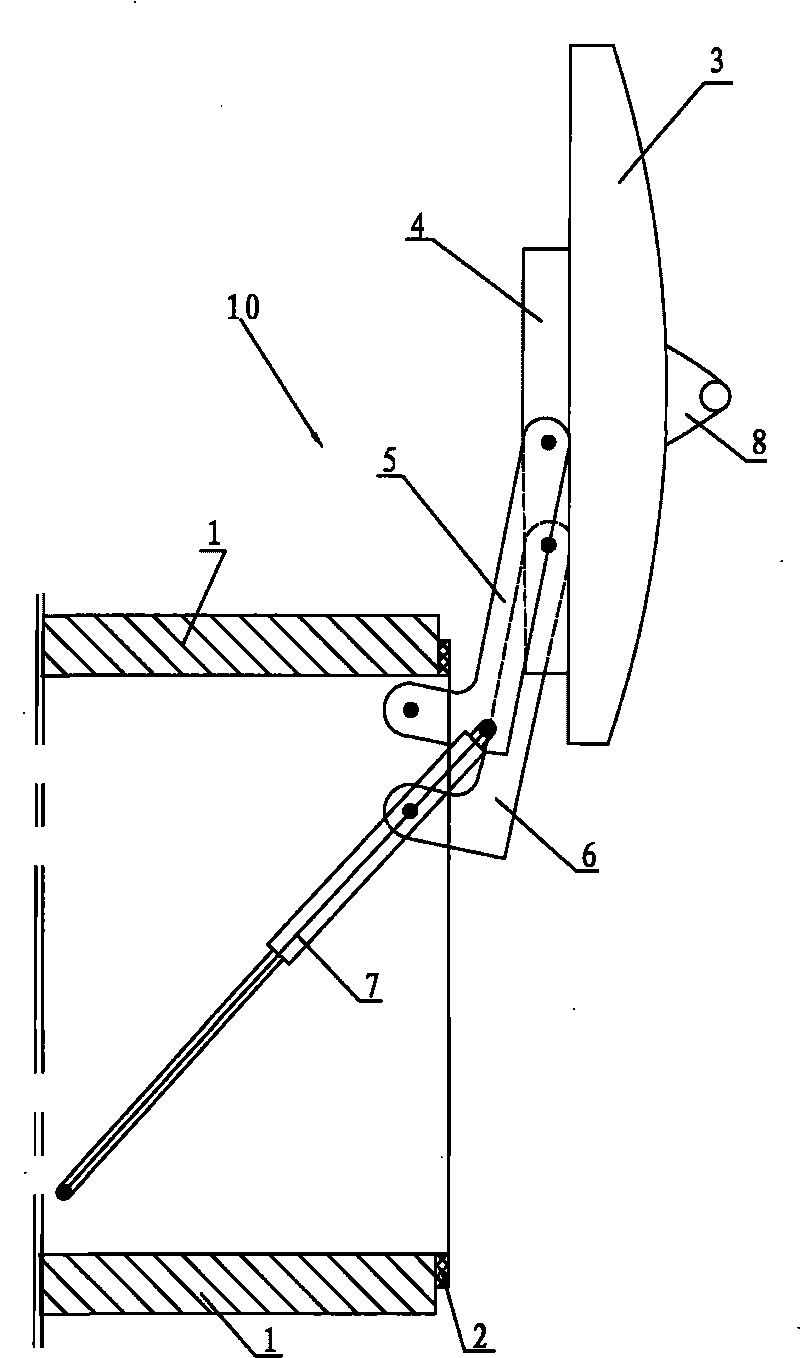

Door opening and closing mechanism for constant temperature vibrator

InactiveCN101735938ADoes not affect useSpatial location does not affectBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMechanical engineering

Owner:李雪兴

Method for extracting ceramide amphoteric lipid from agriculture-forestry byproducts

InactiveCN101591262BSimplified separation stepsDoes not affect useSugar derivativesCarboxylic acid amide separation/purificationChromatographic separationSolvent

The invention relates to a method for extracting ceramide amphoteric lipid from agriculture-forestry byproducts, which comprises the following steps: using waste materials of the processing of the agriculture-forestry byproducts of rice bran, wheat bran and corn as raw materials; adding protease which is 0.1 to 1.0 percent of the agriculture-forestry byproducts in weight and an amino acid chemical penetrating agent which is 0.01 to 0.1 percent of the agriculture-forestry byproducts in weight to the raw materials; extracting the raw materials for 3 times by using a mixed solvent of chloroform and methanol; performing column chromatographic separation; using a solvent to elute out lipid rich in ceramide; and after alkaline treatment, performing high-efficiency liquid phase chromatographic separation to obtain ceramide. The method has high extraction efficiency, simplifies the separation steps of other components, and obtains the ceramide lipid with different contents at the same time.

Owner:ZHEJIANG UNIV

Remediation method for heavy metal pollution of acid soil

ActiveCN106001095ALong-term stable captivityReduced ability to migrateContaminated soil reclamationAlcoholEther

The invention discloses a remediation method for heavy metal pollution of acid soil. The remediation method comprises the steps of dissolving a siloxane substance of which the structural formula is Si(OR)4 into an aqueous solution of alcohol or ether as a remediation reagent; mixing the mixture of the siloxane substance and the aqueous solution of alcohol or ether with acid soil for reaction; and then, adding an aqueous solution of inorganic strong base or inorganic weak base for further reaction, wherein the R refers to one or more of methyl, ethyl and propyl. The remediation method for heavy metal pollution of acid soil is low in cost, and simple, convenient and efficient to implement, and restored heavy metals can be stably maintained in soil for a long time.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

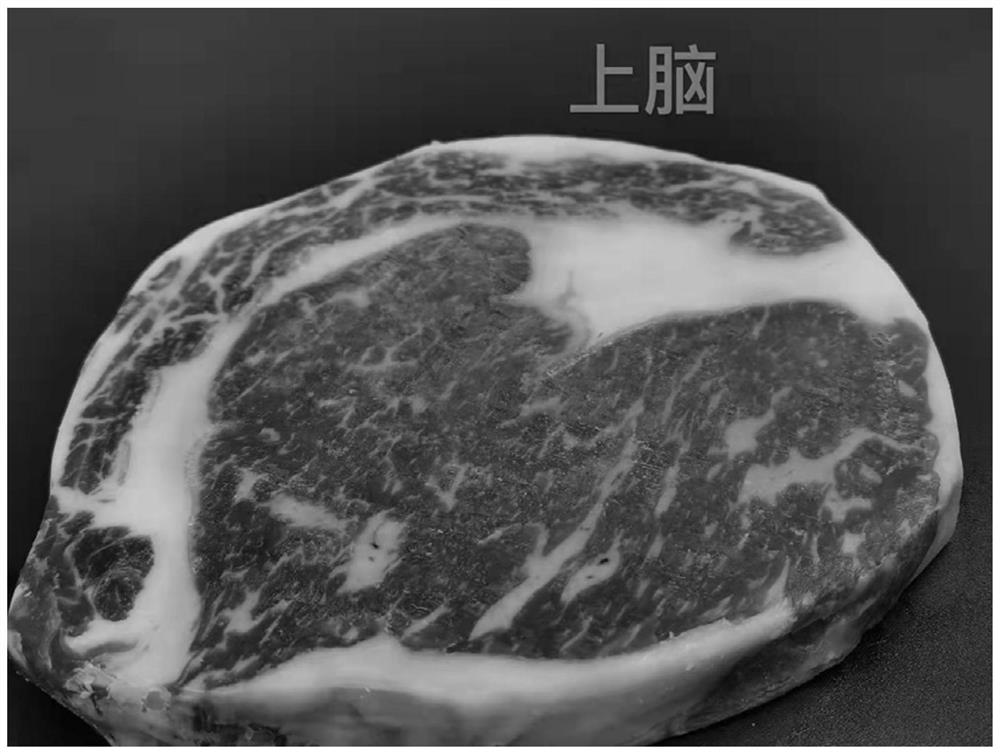

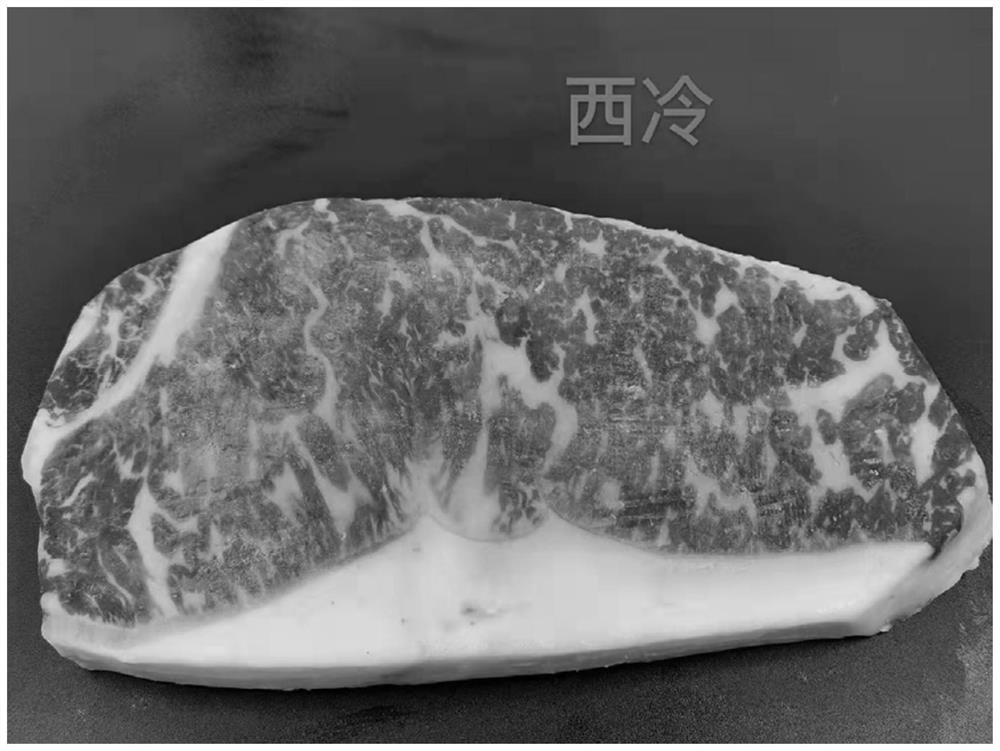

Unconventional feed capable of improving growth performance of beef cattle

PendingCN114451495AMetabolic function is normalMetabolism does not affectFood processingAnimal feeding stuffBiotechnologyAgricultural science

The invention discloses an unconventional feed capable of improving the growth performance of beef cattle, which is characterized in that palm meal, soybean hull, guniting corn bran and manioc waste are mixed to replace part of corn concentrate, and the influence on the growth performance, nutrient digestibility, rumen fermentation and blood biochemical indexes of the beef cattle is researched; results show that the growth performance of the beef cattle is improved and health of the beef cattle is not affected after the four commercial crop byproducts including the palm meal, the soybean hulls, the guniting corn bran and the manioc waste are used for partially replacing the corn concentrate, and the effect is the best by combining 30% of corn, 12.5% of the guniting corn bran, 12.5% of the soybean hulls, 12.5% of the manioc waste and 12.5% of the palm meal.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION INST OF ANIMAL HUSBANDRY +1

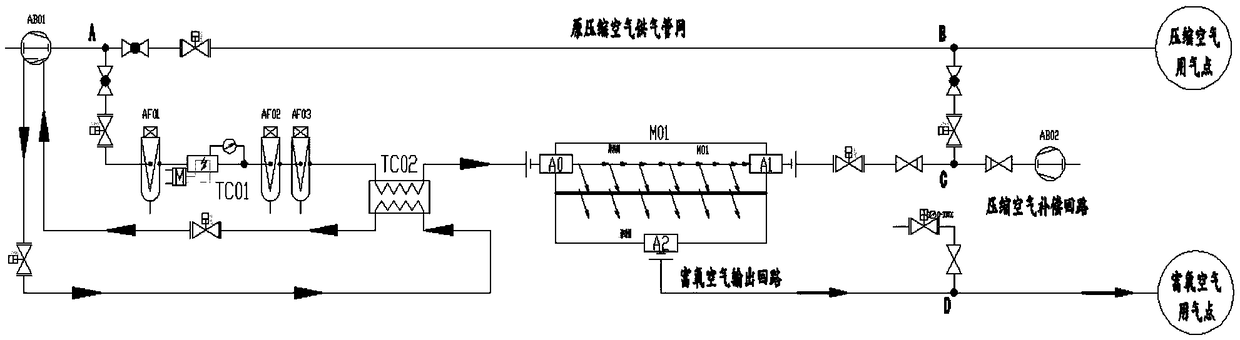

Device and method for enriching oxygen from compressed air

PendingCN109173619ADoes not affect useReduced separation area requirementsDispersed particle filtrationProduct gasOxygen enrichment

The invention provides a device and method for enriching oxygen from compressed air. The device comprises a gas compression device, a heat exchange device and a membrane separation device. The gas compression device is bidirectionally connected to a heat source inlet and outlet of the heat exchange device so that a cycle is formed. The gas compression device is connected to a cold source inlet ofthe heat exchange device. A cold source outlet of the heat exchange device is connected to the membrane separation device. Retentate gas and permeate gas are obtained from an outlet of the membrane separation device. The membrane separation device is coupled to the existing compressed air supplying device so that low cost oxygen enrichment is realized, oxygen and compressed air are simultaneouslyfed on situ without influencing the use of the existing compressed air, the heat energy of the compressed air is fully recovered and is used for preheating membrane separation gas, the separation arearequired by the membrane separation device is effectively reduced, the cost of the equipment is reduced and the application prospect is wide.

Owner:上海穗杉实业股份有限公司 +1

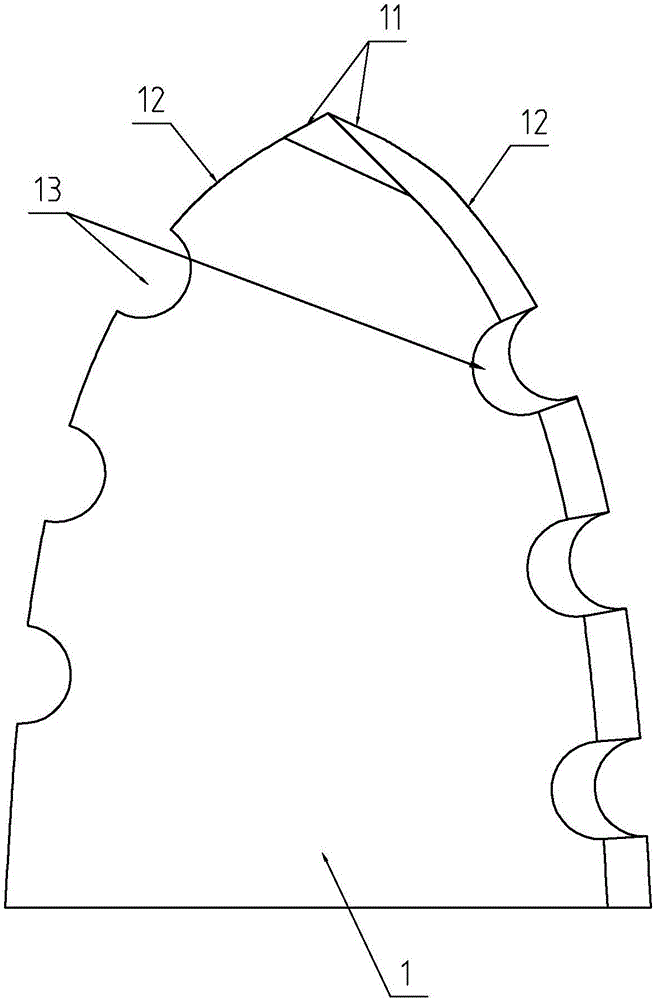

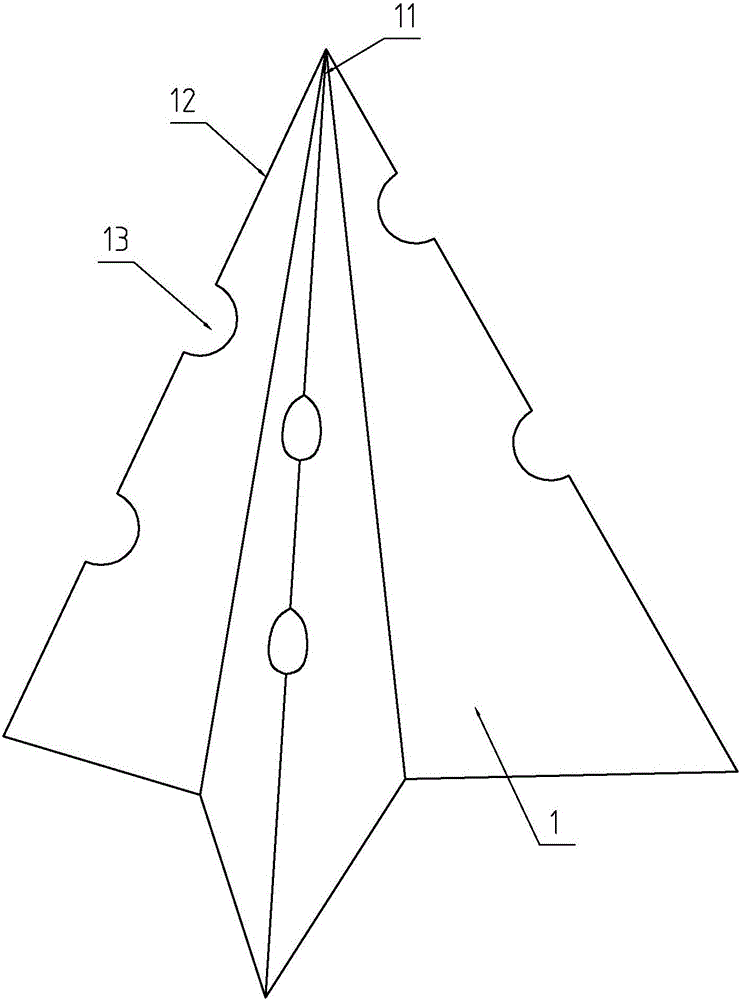

Drill blade and drill

InactiveCN106077766AReduce contact areaReduce frictionTransportation and packagingTrepanning drillsDrill bitEngineering

The invention discloses a drill blade and a drill. According to the technical scheme, the drill blade is characterized by comprising a blade tooth, wherein the cross section of the blade tooth is roughly of a triangular structure, a main cutting edge is arranged at the end of the blade tooth, the side edges of the blade tooth are provided with auxiliary cutting edges connected with the main cutting edges, and the side edges of the blade tooth are provided with receding notches relative to the auxiliary cutting edges. The contact area of the auxiliary cutting edges is effectively reduced during cutting, so that drilling resistance is greatly reduced, drilling is easier and faster, and the possibility that hard and brittle materials fracture when drilled is reduced. In addition, since the load on the drill is reduced, the number of times of friction between the drill and a workpiece when a hole is drilled is reduced, and the service life of the drill is remarkably prolonged.

Owner:乐清市一线天工具科技有限公司

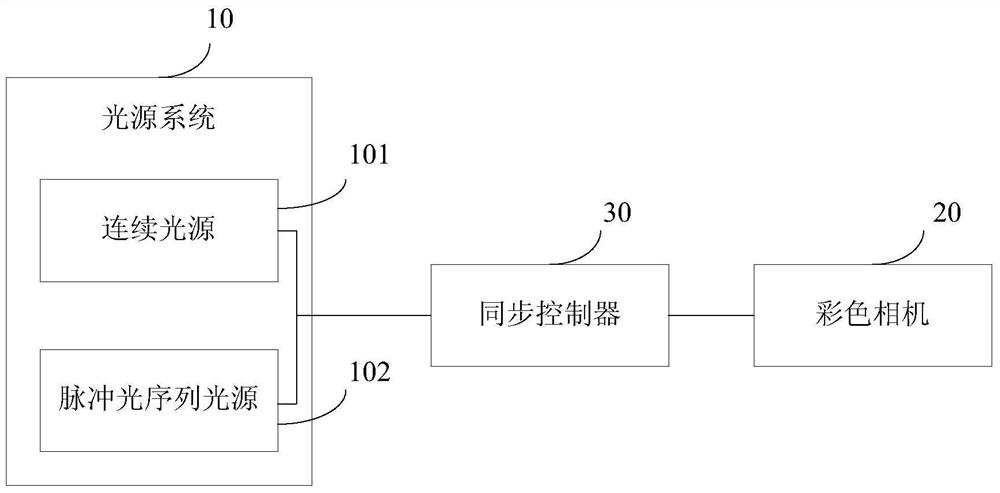

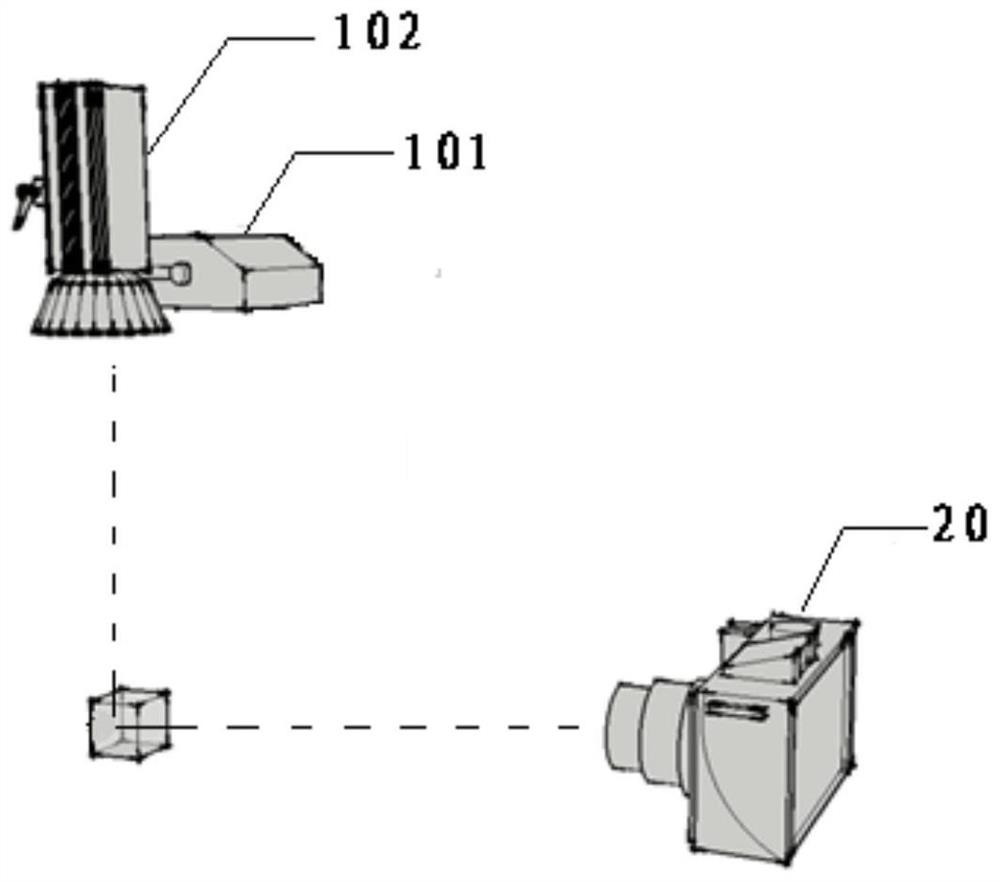

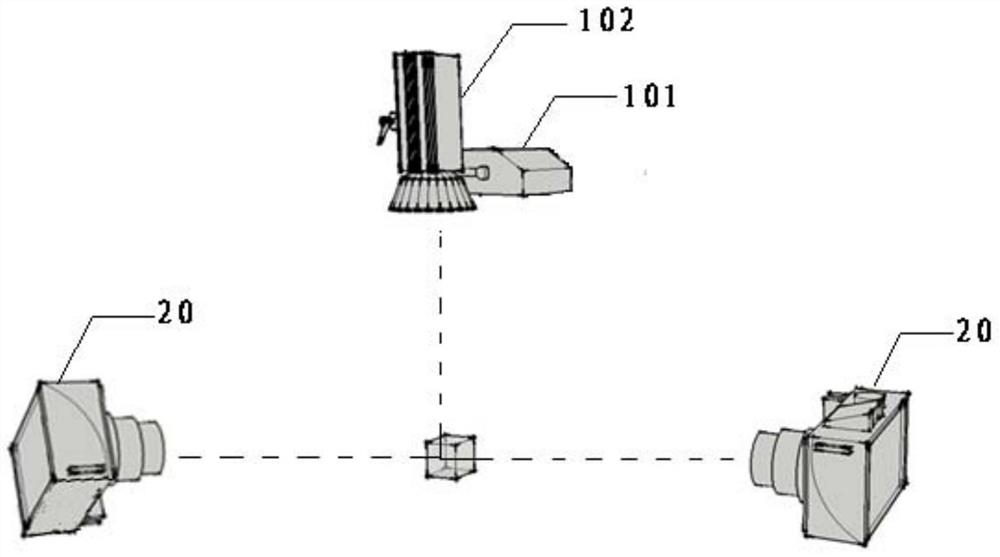

A device and method for recording object motion information

ActiveCN106713733BReduce synchronization errorReduce the impact of synchronization errorsTelevision system detailsPicture signal generatorsContinuous lightColor image

The invention provides a device and method for recording object motion information, the device includes: a light source system, a color camera and a synchronization controller; the light source system includes a continuous light source and a light source for irradiating according to a predetermined pulse flickering interval and pulse color change sequence Pulse light sequence light source; continuous light source is used to provide illumination for the test area; pulse light sequence light source is used to provide pulse light illumination for the test area; color camera is used to collect color images that record the motion trajectory of the moving object to be tested in the test area; The synchronization controller is used to control the pulsed light sequence light source and the color camera of the light source system to realize the synchronization of the pulsed light sequence light source and the color camera; wherein, the exposure time of the color camera is greater than the predetermined pulse flashing interval of the pulsed light sequence light source. The present invention can realize object motion information recording without the need for trajectory estimation and reconstruction, which saves the amount of calculation and makes the object tracking more accurate.

Owner:TSINGHUA UNIV

A kind of remediation method of alkaline soil heavy metal pollution

ActiveCN106001093BUnavailableDoes not affect useContaminated soil reclamationSoil scienceSoil heavy metals

The invention discloses a restoration method for alkaline soil heavy metal pollution. Siloxane substances with the structural formula of Si(OR)4 are dissolved in an alcohol or ether acid solution to serve as a restoration reagent and are mixed with alkaline soil to react; and then water is added for a further reaction, wherein R represents one or more of methyl, ethyl or propyl. The restoration method easily, conveniently and efficiently treats alkaline soil heavy metal pollution at low cost, and restored heavy metal can be steadily kept in soil for a long time.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

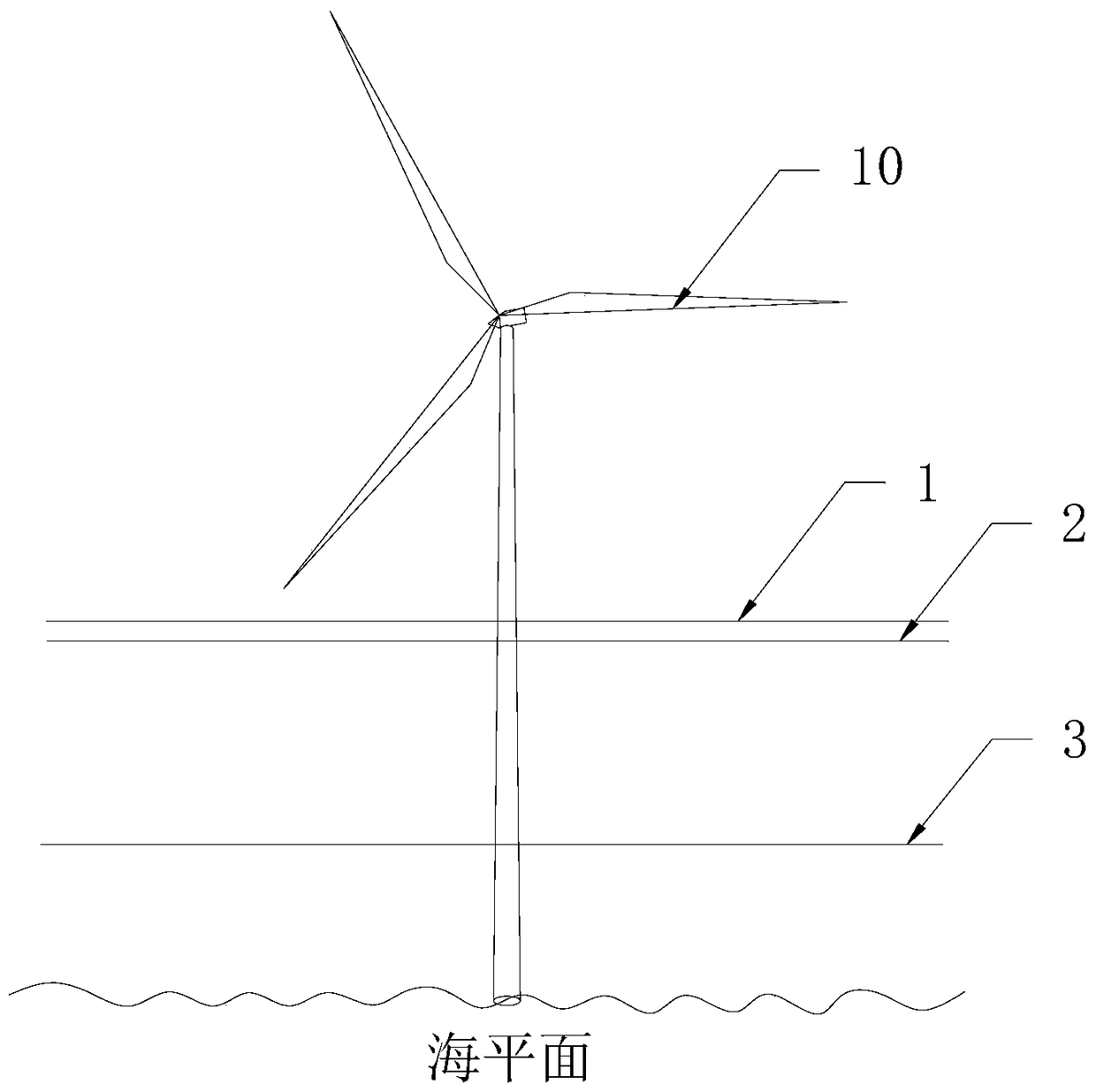

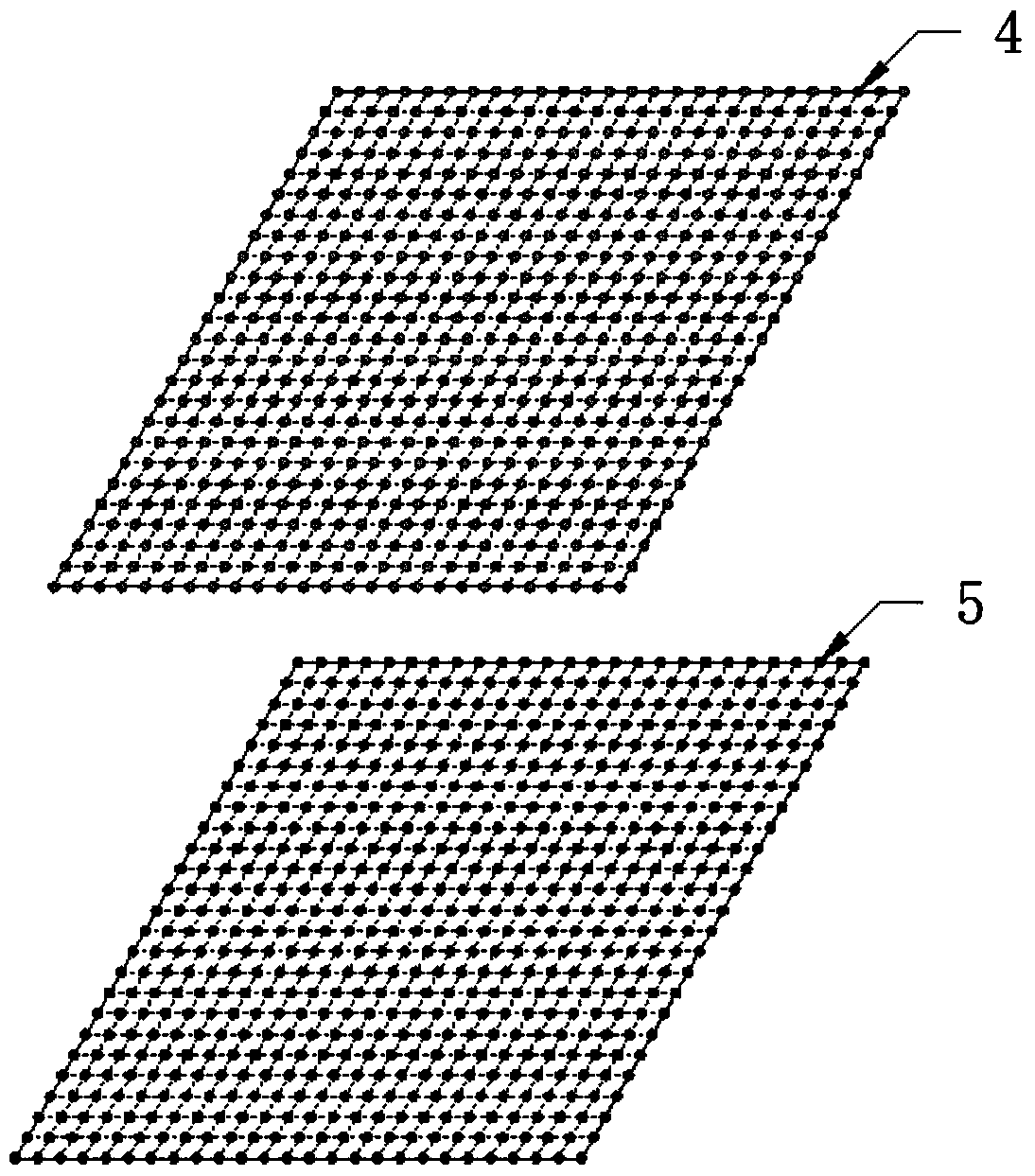

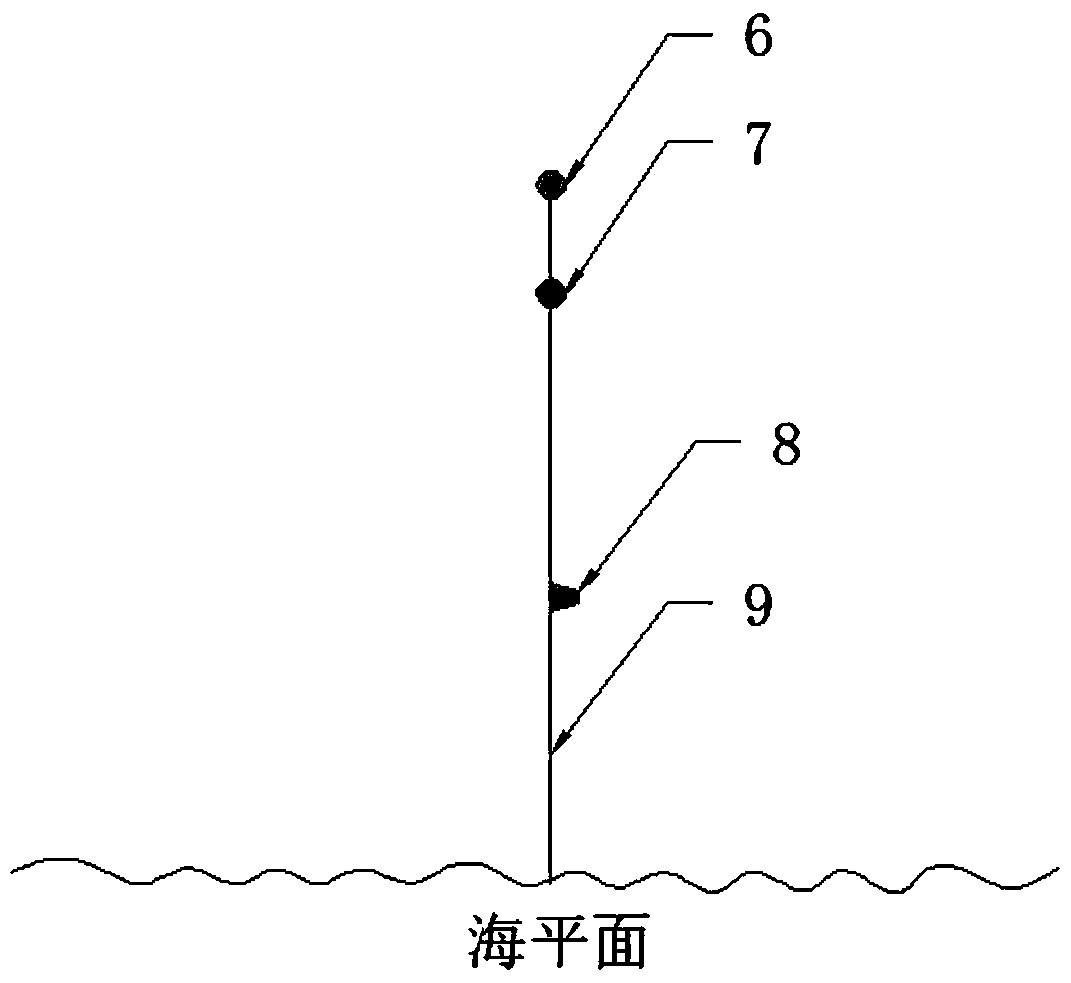

A method and device for effectively reducing the impact of offshore wind turbine infrasound on marine organisms

InactiveCN104992702BBreak through limitationsReduce noiseSound producing devicesSensor arrayElectricity

Owner:ZHEJIANG UNIV

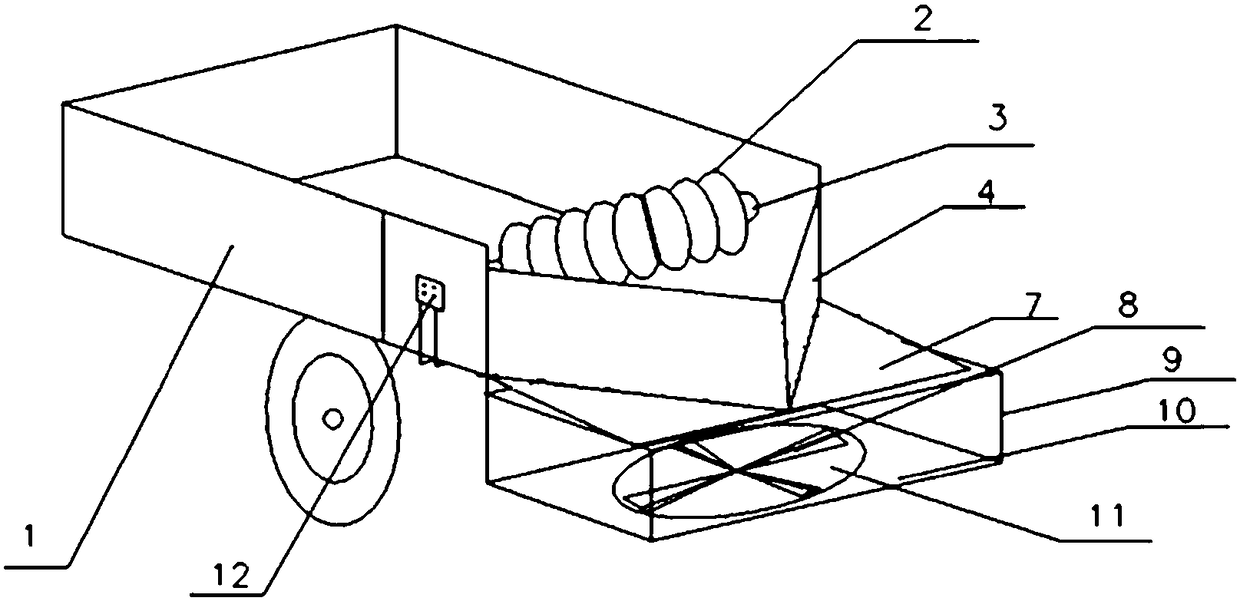

Agricultural tricycle-based dual-purpose fertilizer spreader for farmyard manure and chemical fertilizer, and operating method thereof

InactiveCN108432398ADoes not affect useGuaranteed fertilizer efficiencyFertiliser distributersCentrifugal wheel fertilisersAgricultural engineeringFarmyard manure

The invention discloses an agricultural tricycle-based dual-purpose fertilizer spreader for farmyard manure and a chemical fertilizer, and an operating method thereof. The fertilizer spreader comprises a fertilizer crushing and conveying device, a fertilizer baffle plate and a support; the back baffle plate of an agricultural tricycle is provided with a fertilizer outlet, the support is fixedly mounted at the lower rear part of the wagon box of the agricultural tricycle, and the support can support the rear baffle plate after the rear baffle plate is downwards overturned; the fertilizer baffleplate is detachably mounted at the rear end of the wagon box of the agricultural tricycle, the fertilizer baffle plate matches with the fertilizer outlet, and the fertilizer baffle plate makes the fertilizers sprinkled only from the fertilizer outlet; and the fertilizer crushing and conveying device is arranged in the wagon box of the agricultural tricycle, and is used for crushing the fertilizers and conveying the crushed fertilizers to the fertilizer outlet. The dual-purpose fertilizer spreader can complete the transportation, manure spreading and fertilizer spreading operations one time, so the working efficiency is high; and the dual-purpose fertilizer spreader makes farmyard manure produced from the animal husbandry directly applied without exposing the farmyard manure to sunlight, so the higher fertilizer efficiency of the farmyard manure is ensured.

Owner:张毅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com