Device and method for enriching oxygen from compressed air

A technology of compressing air and enriching oxygen, which is applied in separation methods, chemical instruments and methods, and dispersed particle filtration, etc., to achieve the effect of reducing the demand for separation area, reducing equipment cost, and reducing device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

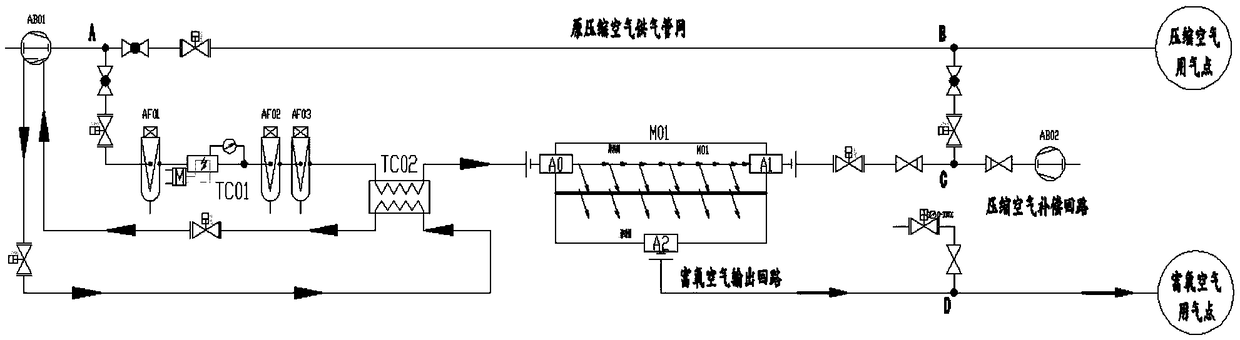

[0054] This embodiment provides a device for enriching oxygen from compressed air, the structural connection diagram of the device is as follows figure 1 As shown, it includes a gas compression device AB01, a heat exchange device TC02 and a membrane separation device M01. The gas compression device AB01 is connected to the heat source inlet and outlet of the heat exchange device TC02 to form a cycle. The gas compression device AB01 is also connected to the heat exchange device TC02 The cold source inlet of the heat exchange device TC02 is connected to the cold source outlet of the heat exchange device TC02 and the membrane separation device M01 is connected, and the outlet of the membrane separation device M01 obtains retentate gas and permeate gas.

[0055] Wherein, the gas compression device AB01 is divided into two parts, one part includes a first inlet and a first outlet, and the other part includes a second inlet and a second outlet, the first outlet of the gas compression...

Embodiment 2

[0065] This embodiment provides a method for enriching oxygen from compressed air, said method is carried out using the device in Embodiment 1, and its specific application environment is:

[0066] A cement plant, the supporting flow is about 340m 3 / min, the compressed air system with an outlet pressure of 1.0MPa is mainly used to supply compressed air for the needs of dust removal and blockage removal, and the normal operating pressure of the gas point is about 0.6MPa. Make the site supply compressed air and oxygen-enriched at the same time, the compressed air can meet the above-mentioned pressure requirement of 0.6MPa, there is no requirement for the components, and the oxygen is used for oxygen-enriched combustion in the cement plant.

[0067] The membrane separation device used in this example is produced by Shanghai Suishan Industrial Co., Ltd. Membrane separator, the oxygen and nitrogen separation membrane material used in it has a separation coefficient of 6.35 at 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com