Drill blade and drill

A drill bit and blade technology, applied in drilling/drilling equipment, drill repair, drilling tool accessories, etc., can solve the problems of reducing the service life of the drill piece, prolonging the cutting time, and increasing the load of the drill piece, so as to save material costs, The effect of reducing processing time and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

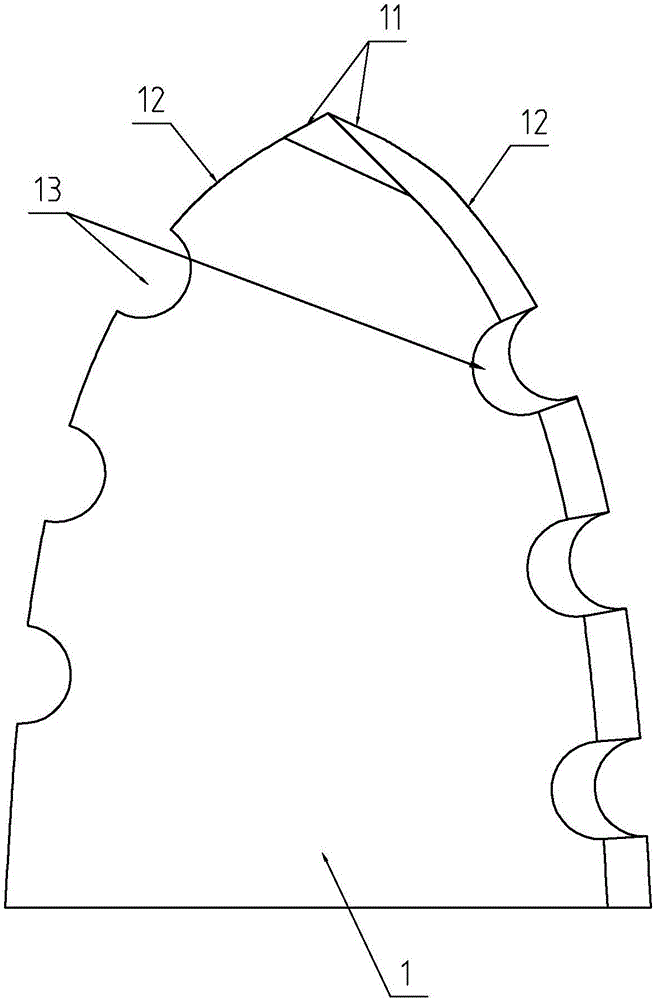

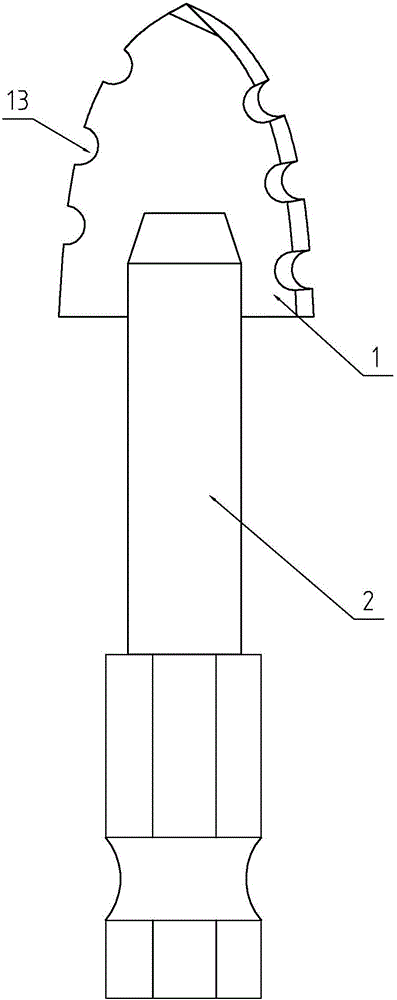

[0035] Embodiment one, with reference to figure 1 As shown, the outer contour of the cutter tooth 1 is arranged in a melon-shaped structure, and the number of secondary cutting edges 12 is two, and the arc-shaped structure of the two secondary cutting edges 12 increases the thickness dimension between the two secondary cutting edges 12, Thereby the structural strength of the secondary cutting edge 12 is enhanced; the two secondary cutting edges 12 are provided with a gap 13 to reduce the contact area of the secondary cutting edge 12 during cutting, and the gap 13 is placed on the two secondary cutting edges 12. There are two on each, and the gaps 13 are distributed on the secondary cutting edge 12 in a complementary manner, so that the cutter tooth 1 is always kept at any depth when drilling, and the secondary cutting edge 12 can guide the chips , so as not to affect the drilling of the main cutting edge 11, but also enable the adjacent minor cutting edge 12 to avoid contact...

Embodiment 2

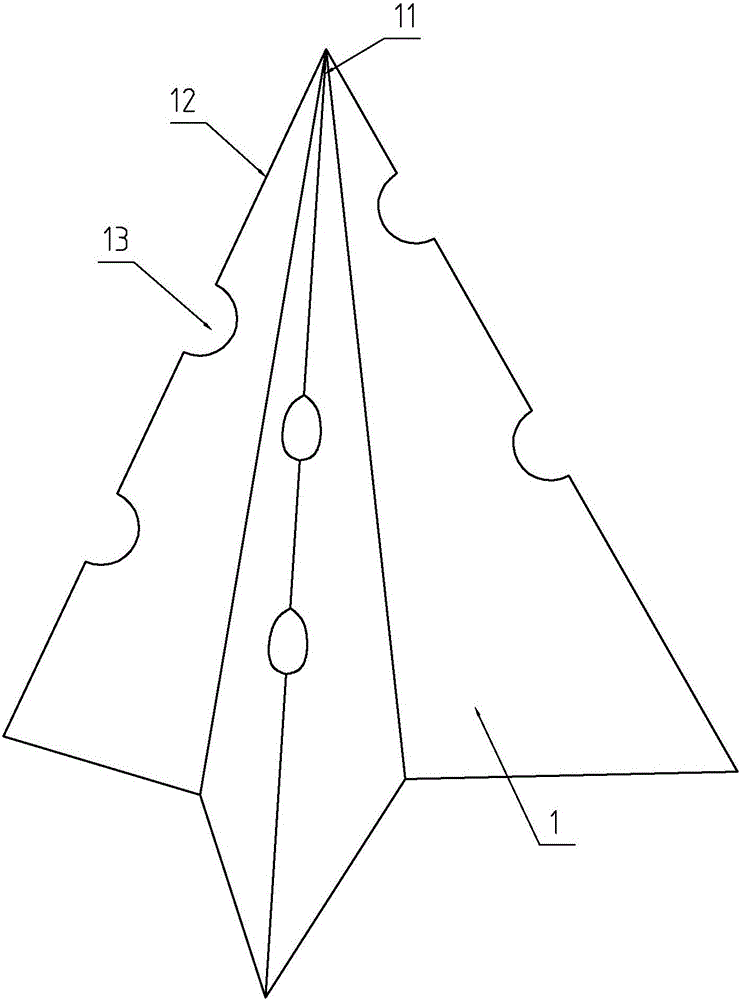

[0036] Embodiment two, refer to figure 2 As shown, the outer contour of the cutter tooth 1 can also be set in a triangular structure, and the number of minor cutting edges 12 is three, and the minor cutting edge 12 is also provided with a gap 13, and the setting of the gap 13 is the same as in the embodiment one by one. Sincerely. It can be seen that the profile of any cutter tooth 1 and the number of cutting edges will reduce the contact area of the cutting edge under the structure of this application, so the specific shape and structure of the cutter tooth 1 and the number of cutting edges do not involve this application the substance of the content.

[0037] In addition, it should be noted that the maximum inner diameter of the relief notch 13 is not less than the thickness of the cutter tooth 1. When the size of the relief notch 13 is properly maintained, it is avoided that the relief notch 13 is too small to easily generate stress concentration and cause the knife to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com