Organic Rankine circulatory system for recovering various residual heat through gas and electricity combined supply and using method

A waste heat recovery and circulation system technology, which is applied in mechanical equipment, steam engine devices, machines/engines, etc., can solve the problems of single application mode of endothermic power generation of organic Rankine cycle, low utilization efficiency, insufficient utilization of domestic water and heating, etc. , to achieve the effect of flexible and convenient use of waste heat, increase utilization rate, and expand the way of waste heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

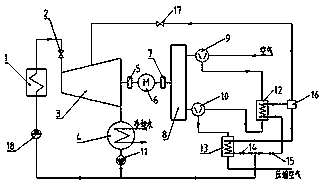

[0034] A variety of waste heat recovery organic Rankine cycle systems and usage methods of the gas-power cogeneration of the present invention, such as figure 1 As shown, it includes a high-pressure circulation circuit for recovery of waste heat from ash and slag, a low-pressure circulation circuit for recovery of waste heat from air compressor exhaust, a motor 6 , a gearbox 8 , a first clutch 5 and a second clutch 7 .

[0035] In the present invention, the high-pressure circulation circuit of waste heat recovery from ash and slag includes a slag cooler 1, an expander 3, a condenser 4, a condensation pump 11 and a booster pump 18; figure 1As shown, the outlet of the slag cooler 1 is connected to the inlet of the expander 3 through a high-pressure steam pipeline, and the high-temperature and high-pressure gaseous organic working fluid formed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com