Multilayer electronic cutter film for image graphics

A technology for cutting films, thin films, applied in the direction of processes for producing decorative surface effects, layered products, synthetic resin layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0111] Examples 1-3, Cutting and Removal Tests

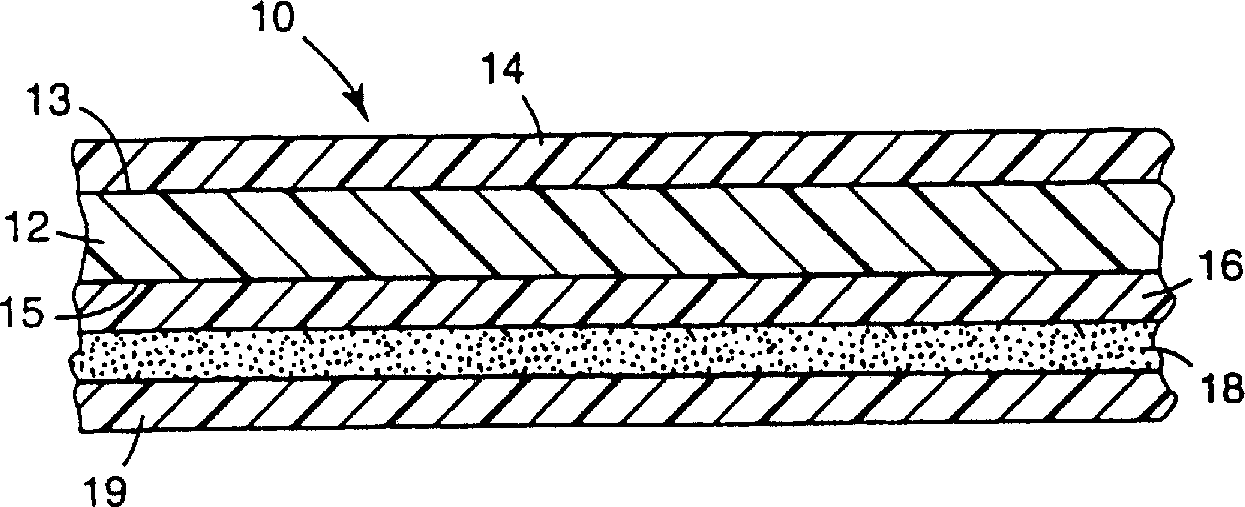

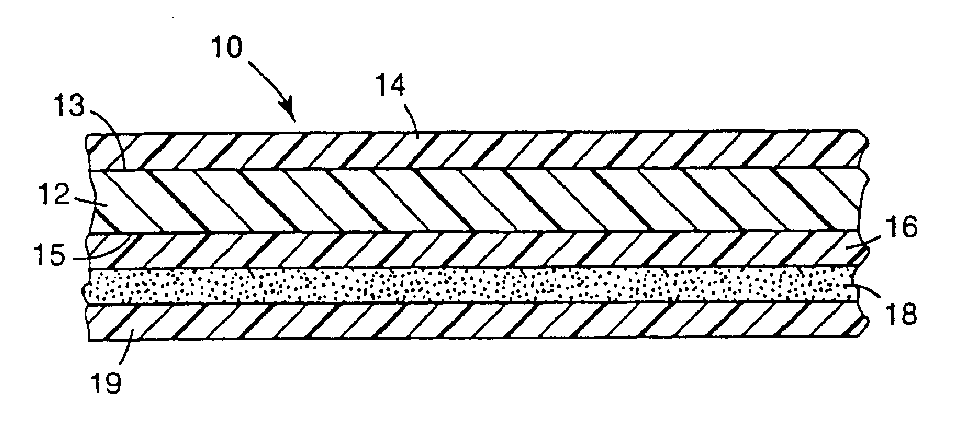

[0112] Formulations A-C were each made into a multilayer film of the present invention using conventional blown film coextrusion methods. Each of the three extruders (corresponding to the respective layers 12, 14 and 16) feeds the melt formulation to an annular die where it is melt bonded into a layer consisting of three distinct layers. A single melt stream in the form of a sleeve. For each example, the melt from the "top" extruder formed the wear layer, the melt from the "middle" extruder formed the core layer, and the melt from the "bottom" extruder formed the adhesive primer layer. The molten polymer sleeve is blown to its final diameter and thickness by introducing air into the sleeve and clamping it between the die and nip rolls at the top of the blown film tower. The film sleeve is then cut into two flat film rolls, the adhesive base coat of each film is corona treated and wound onto a core. The resulting specimens wer...

Embodiment 4 and comparative example 5

[0117] Embodiment 4 and comparative example 5, adhesive primer test

[0118] Films 60 microns (0.0024") thick were produced using Formulation A and Comparative Formulation B, corona treated non-Surlyn TM on one side and laminated to the acrylate copolymer adhesive and release liner as described above. The film was then cut into 25 mm (1") strips and attached to an aluminum panel. After 24 hours, the film / adhesive tape was removed from the aluminum panel by pulling the film 180° from the aluminum panel. Implementation The film / adhesive laminate of Example 4 could be removed cleanly with no adhesive remaining on the aluminum plate, while the adhesive layer of the film / adhesive laminate of Comparative Example 5 debonded from the film and bonded A layer of the agent remains on the aluminum panel. This is called 100% adhesive transfer and indicates poor adhesion of the adhesive to the film. This test shows that the primer contained in Formulation A The layer can provide improved ...

Embodiment 9

[0127] Example 9: Formulation A was processed into a 90 micron (0.0035") thick and corona treated film using the blown film process, which was laminated to an acrylate copolymer adhesive and silicone coated as described above. When the film was rubbed with a 3M PA-1 plastic applicator, very few scratches were visible to the naked eye, and the film was considered acceptable for image graphics applications.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com