Straw-containing composite material and preparation equipment thereof

A composite material and straw technology, applied in the field of plastic composite materials, can solve the problems of affecting the cutting accuracy, polluting the environment, and being unable to adjust the distance between the rotary knife roller and the auxiliary roller, etc., to achieve the effect of ensuring the cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A composite material containing straw, comprising the following raw materials in parts by weight: 8 parts of straw, 50 parts of polylactide, 3 parts of calcium powder, 1 part of titanium dioxide, 0.5 part of vegetable oil, 0.1 part of adhesive and a toughening agent 0.2 parts, and the adhesive is epoxy resin adhesive, and the toughening agent is barium sulfate.

Embodiment 2

[0040] A composite material containing straw, comprising the following raw materials in parts by weight: 20 parts of straw, 50 parts of polylactide, 8 parts of calcium powder, 5 parts of titanium dioxide, 1.4 parts of vegetable oil, 0.3 parts of adhesive and a toughening agent 0.6 parts, and the adhesive is epoxy resin adhesive, and the toughening agent is barium sulfate.

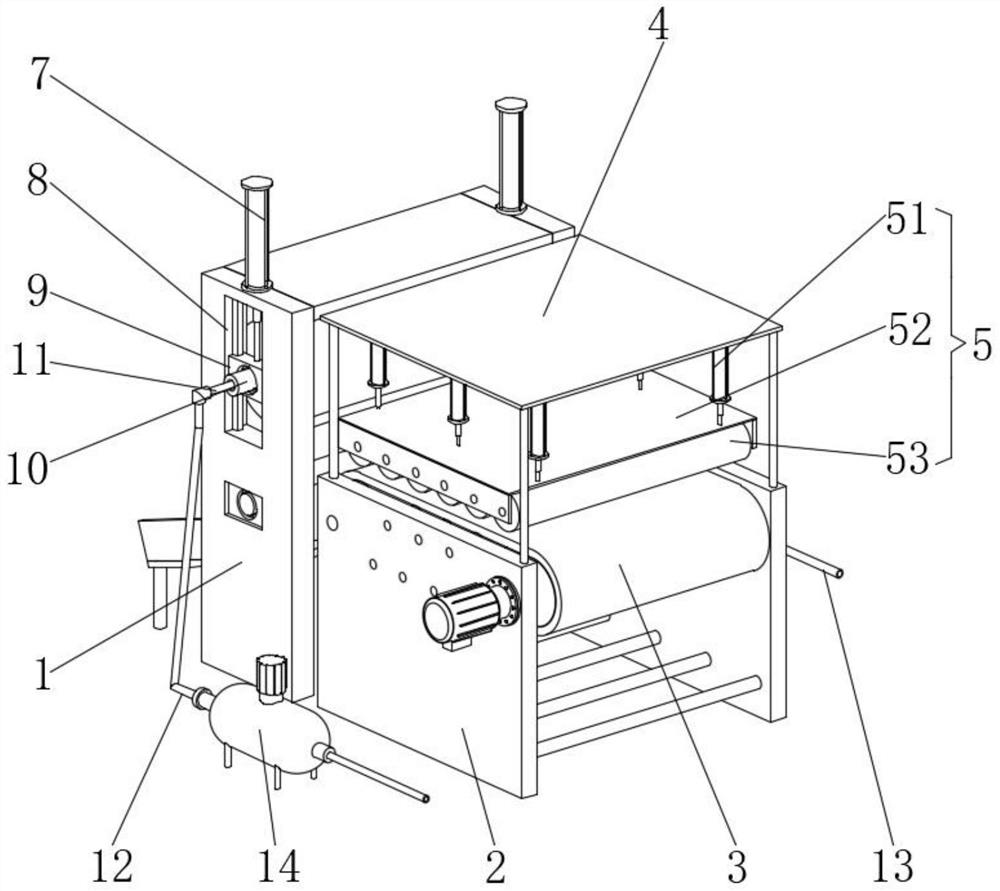

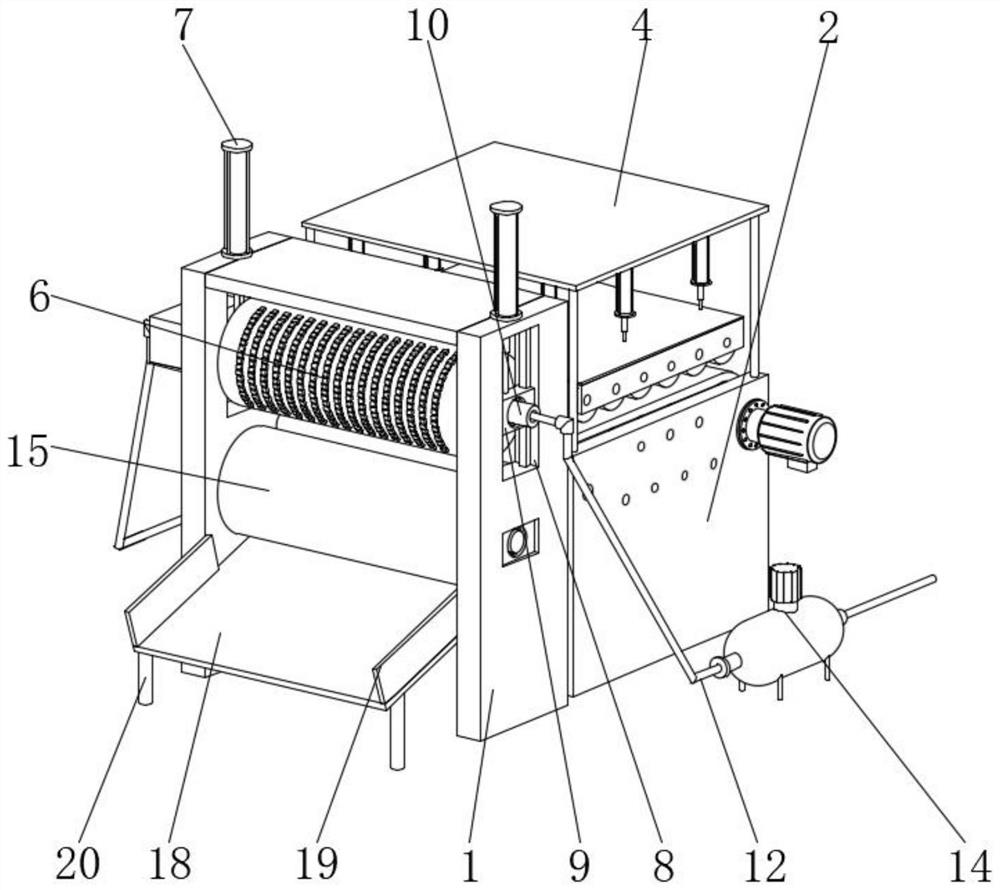

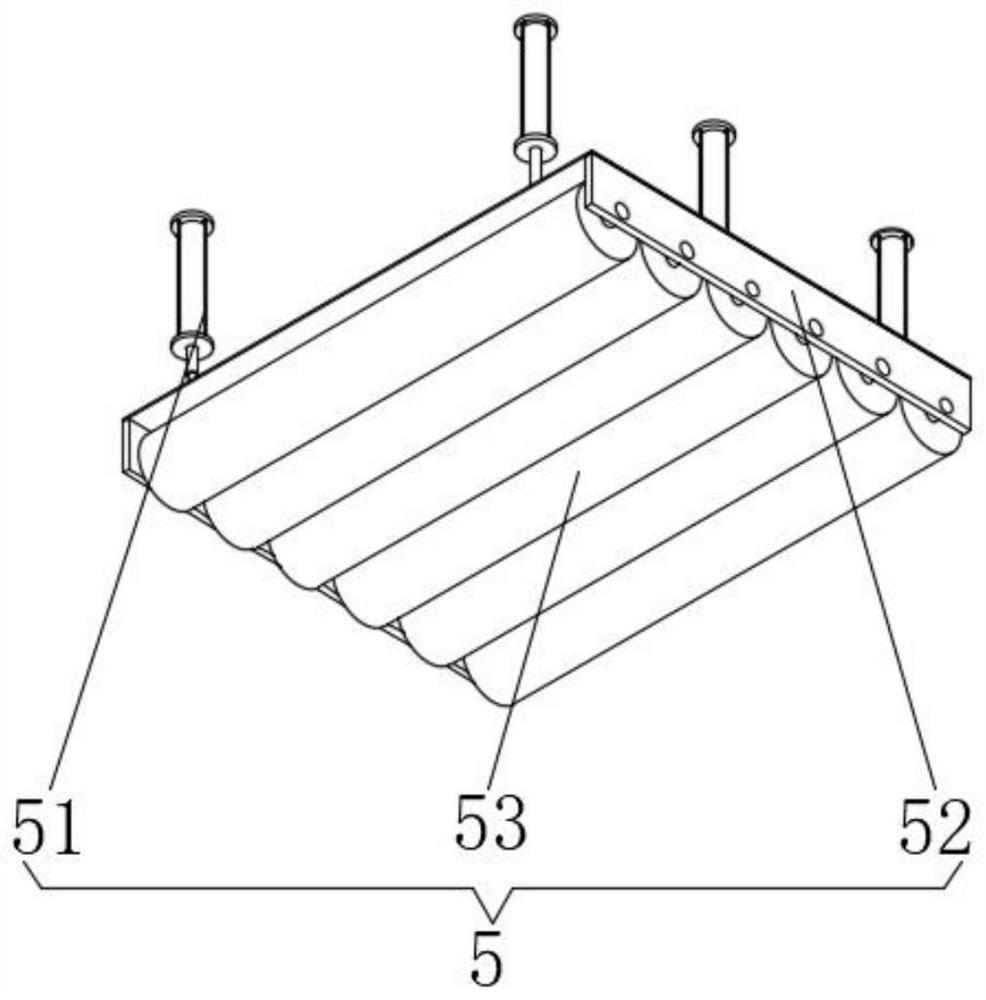

[0041] Such as Figure 1-Figure 6As shown, the preparation equipment for the straw-containing composite material includes a vertical frame 1, a support frame 2, a conveyor belt 3, an upper plate 4, a knife roller body 6, an auxiliary roller body 15 and a driving mechanism 16, and the support frame 2 is fixed by The column is bolted above the support frame 2, the auxiliary roller body 15 is rotationally connected with the vertical frame 1 through bearings, a leveling mechanism 5 is provided below the upper plate 4, and a second hydraulic rod 7 is bolted to the top of the vertical frame 1 , the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com