Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

517 results about "Nattokinase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nattokinase (pronounced nuh-TOH-kin-ayss) is an enzyme extracted and purified from a Japanese food called nattō. Nattō is produced by fermentation by adding the bacterium Bacillus natto, which also produces the enzyme, to boiled soybeans. While other soy foods contain enzymes, it is only the nattō preparation that contains the specific nattokinase enzyme.

Method for preparing natto

InactiveCN102008052AReduce generationDoes not affect kinase activityFood preparationBiotechnologyMicroorganism

The invention provides a method for preparing natto, belonging to the field of food microorganism and fermentation engineering. The natto prepared by the existing natto preparation method is bitter and has stink, thus influencing the natto taste. The method for preparing natto in the invention comprises the following steps: preprocessing, soaking, cooking at high temperature, cooling, inoculating, performing primary fermentation, performing secondary fermentation after auxiliary materials are added, and performing subpackage to obtain the finished product. The beneficial effects of the preparation method lie in that the fermentation substrate types and C / N ratio can be changed in the fermentation process by performing twice fermentations and adding auxiliary materials before the secondaryfermentation, thus reducing the generation of unpleasant flavor substances, acquiring natto with different flavors, further improving the natto taste while having no influence on natto kinase activity, greatly lightening the specific bitter and stink of the nano, being more suitable for taste of people in China and having more comprehensive nutrition.

Owner:SHENZHEN INST OF TECH

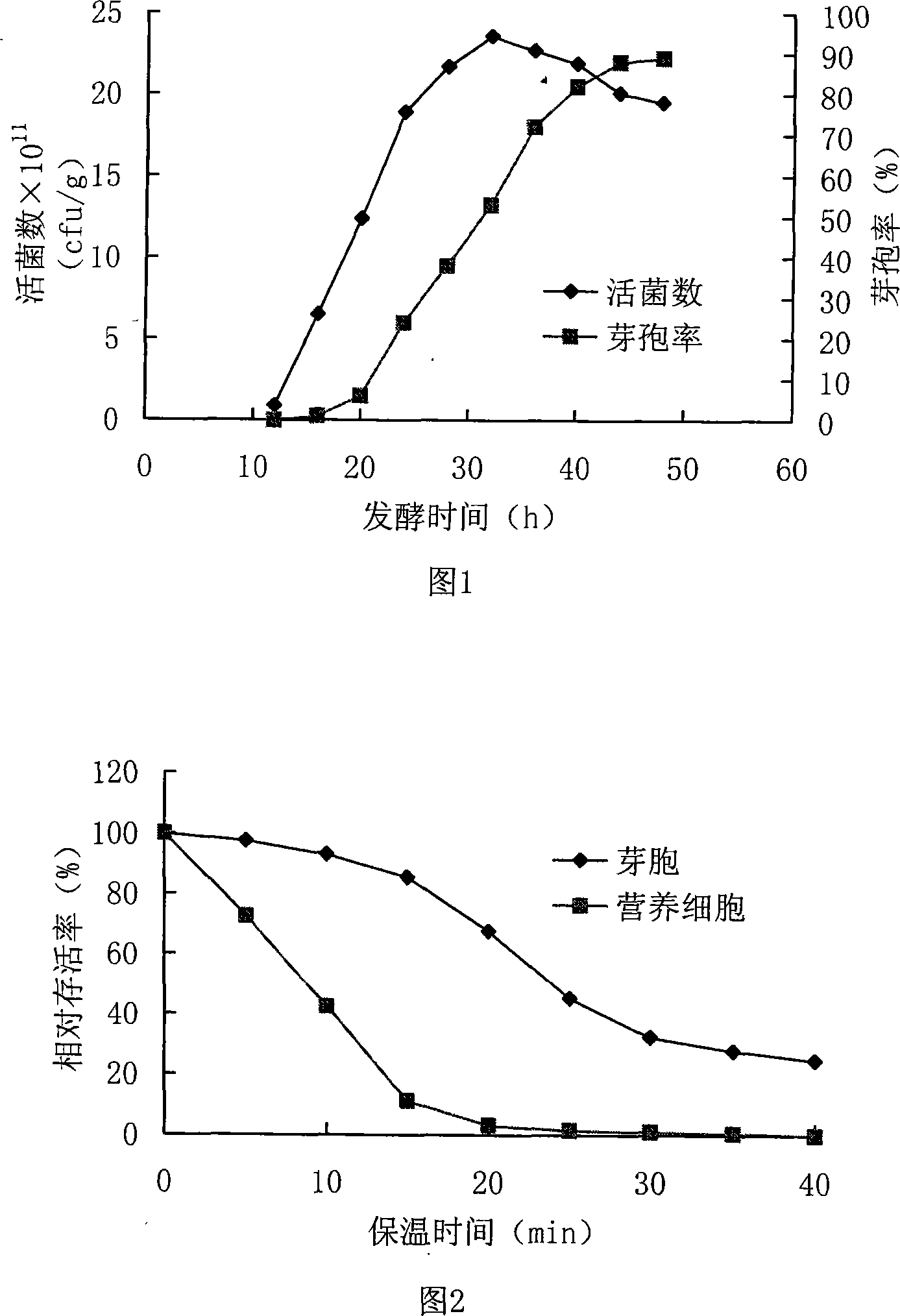

Solid fermentation process for preparing bacillus natto microecological preparation

InactiveCN101215535AIncrease productionRealize large-scale scale-up productionBacteriaAnimal feeding stuffDipotassium hydrogen phosphateFiber

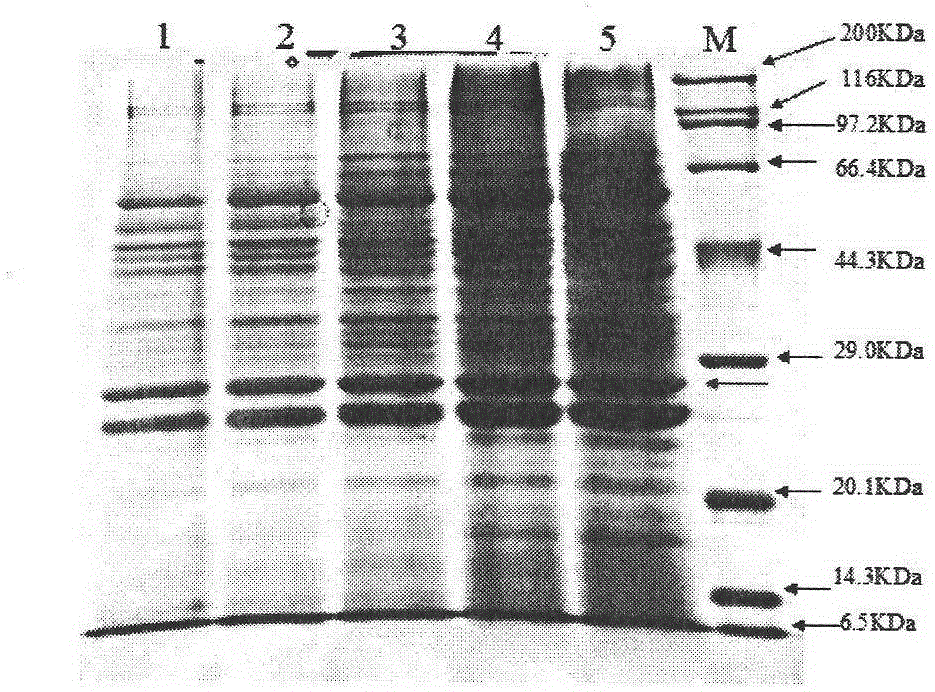

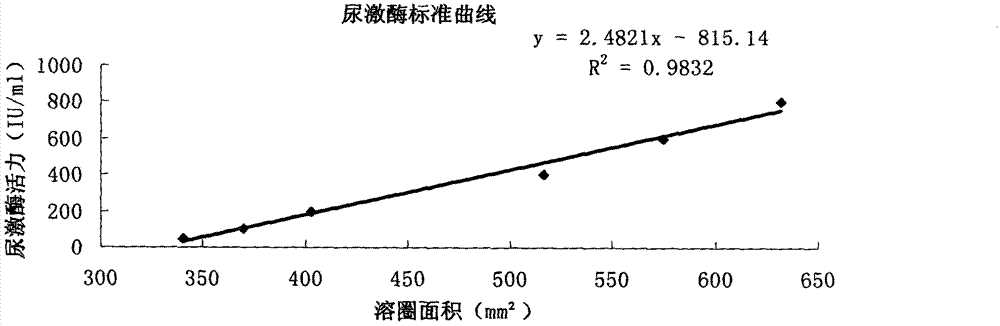

A method for preparing solid natto bacillus microecological agent by solid fermenting is disclosed, which belongs to the biological engineering technique field. The strain is separated from natto as natto bacillus which is named as Bacillus natto S703 and the preservation number of the strain is CCTCC M207147. The sieving method comprises the following steps: utilizing the character that the natto bacillus produces natto kinase to do dilute flat separation for natto leach, seeding the obtained single colony in the primary sieving culture medium of the flat which contains fiber, selecting single colony to purify and obtain the fitful natto bacillus according to the size of transparent coil diameter and colony diameter. The strain is inoculated in the solid ferment culture medium which comprises bran, soya bean waste, corn starch, dipotassium hydrogen phosphate and magnesium sulfate, which can produce the natto bacillus microecological agent by solid fermenting, drying and grinding. The prepared natto bacillus microecological agent can be chicken feed, which is provided with obvious modification for daily chicken weighing, feed coefficient and survival rate.

Owner:无锡市高宝特生物工程技术有限公司 +2

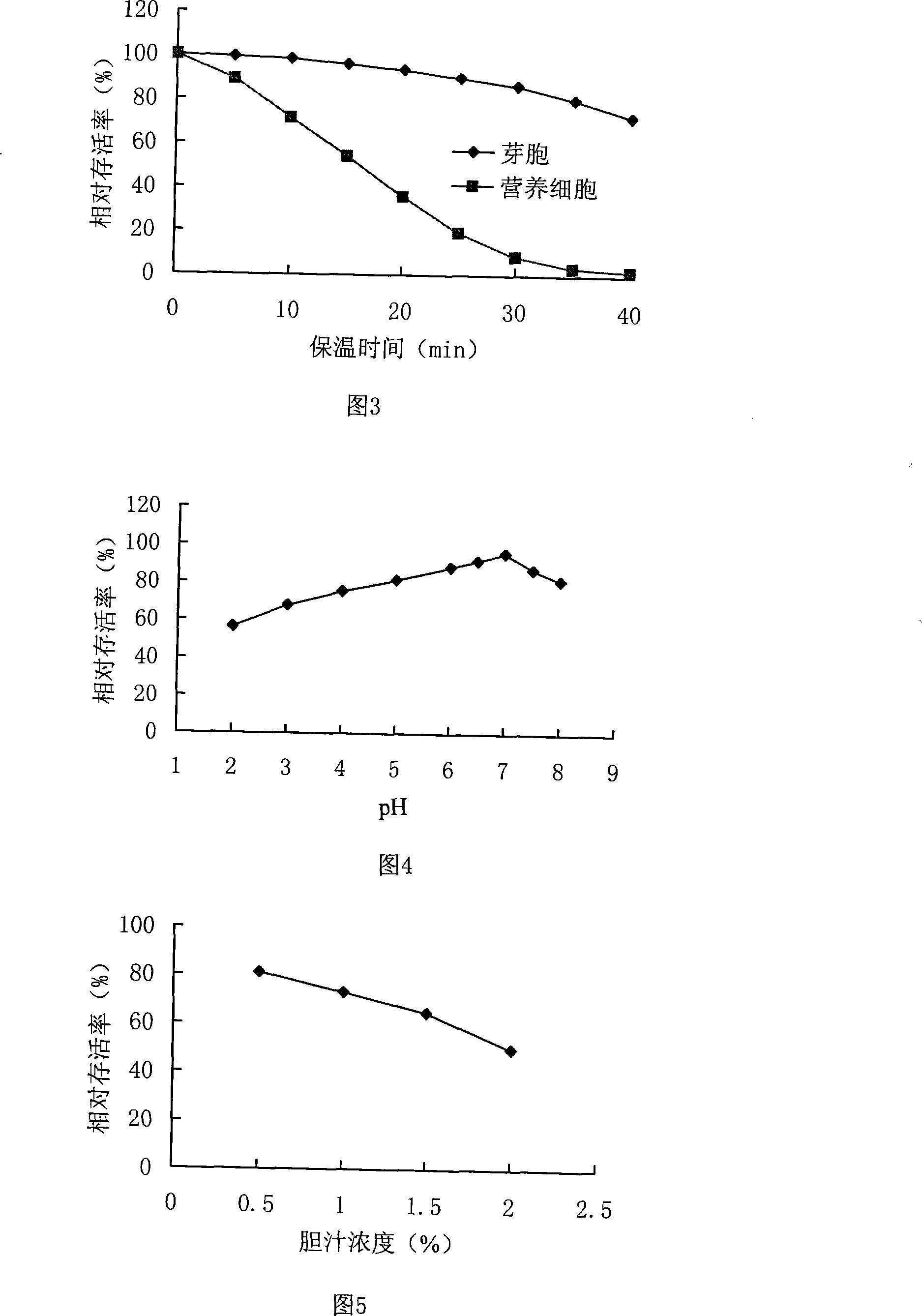

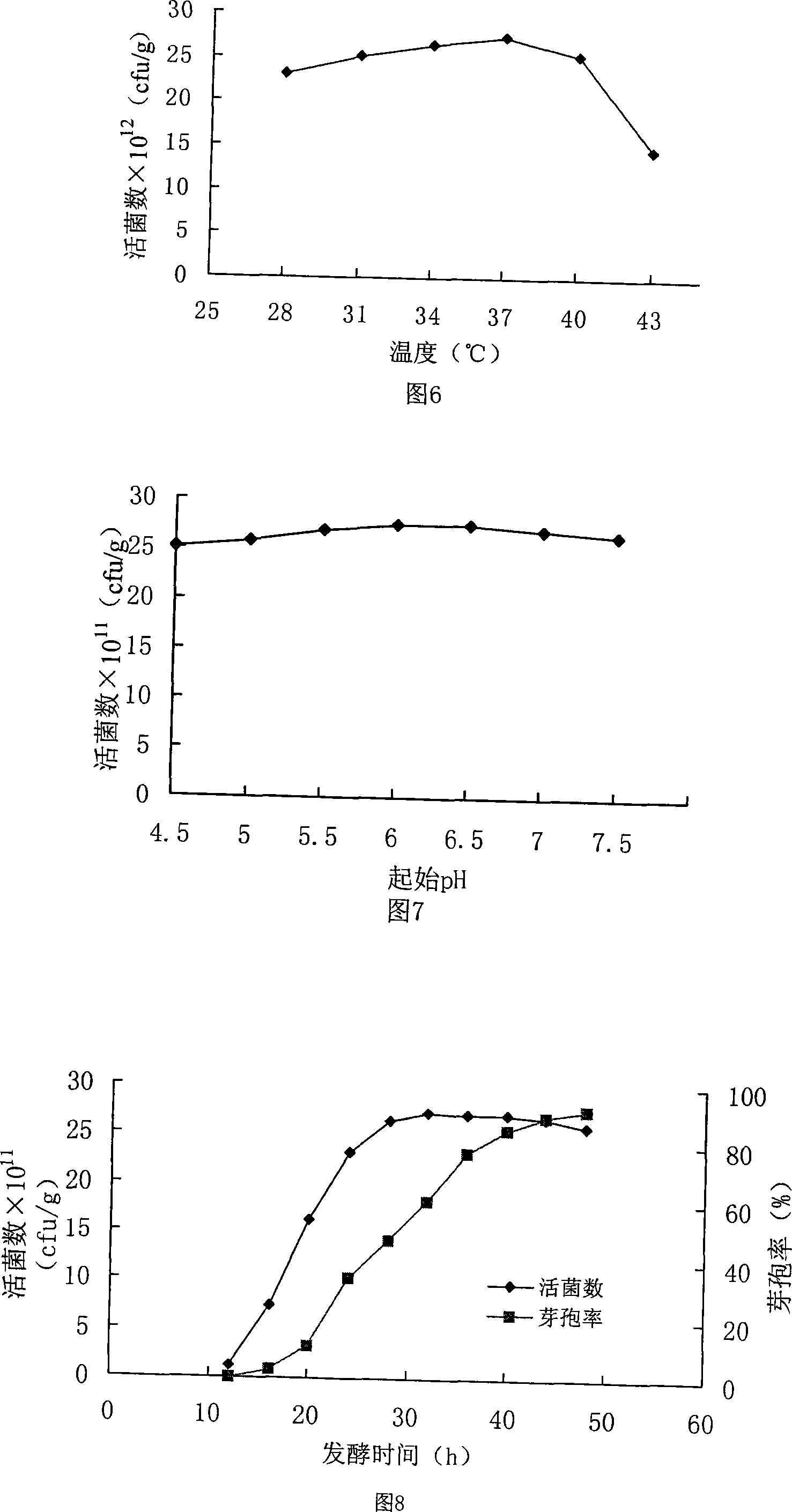

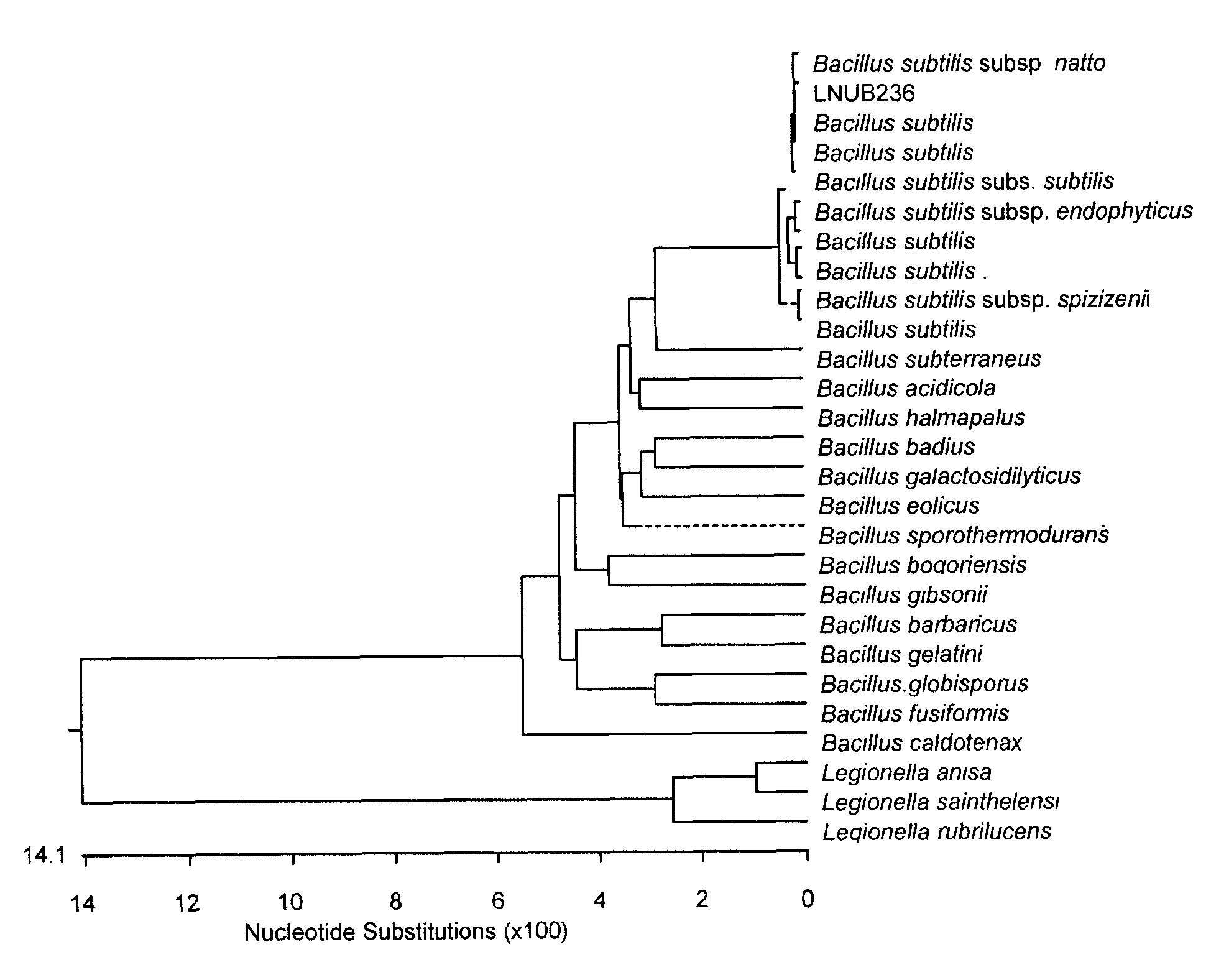

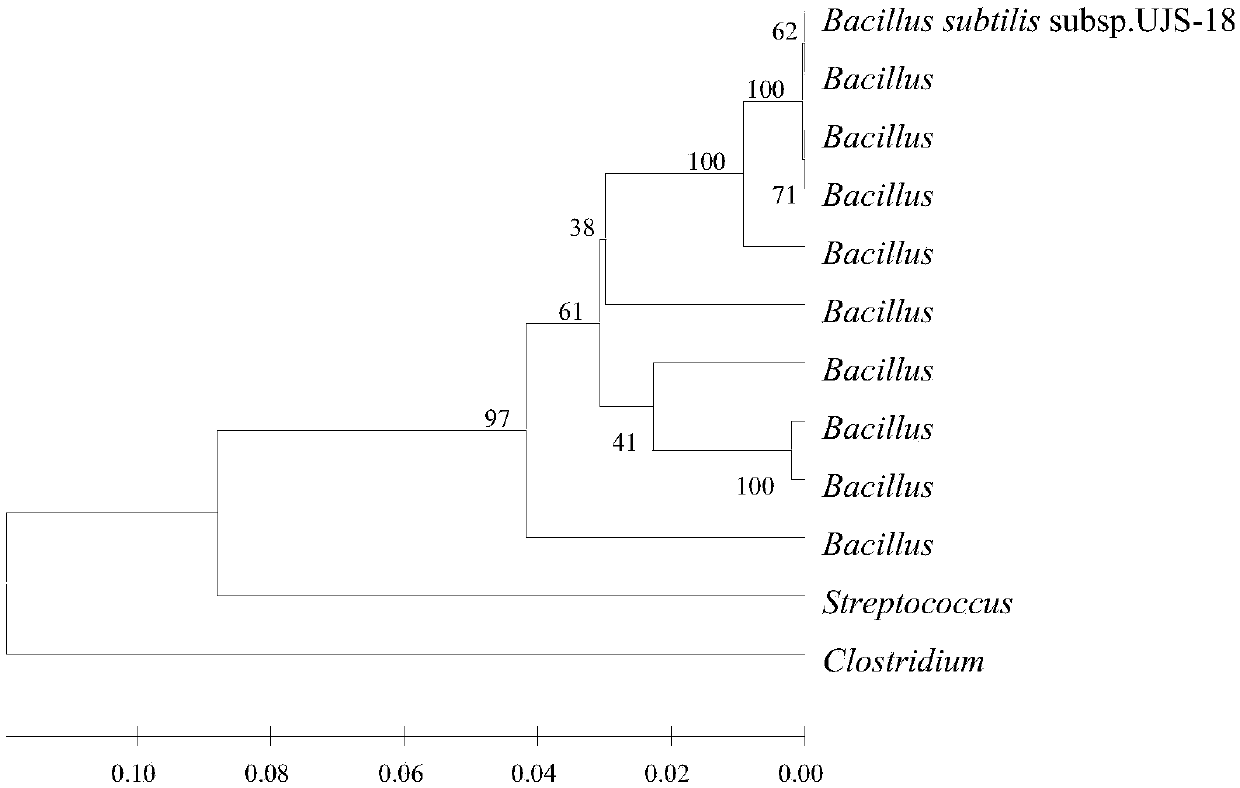

Bacillus subtilis subso natto for producing natto kinase and application thereof

InactiveCN101560478AIncrease enzyme activityGood effectBacteriaPeptide/protein ingredientsCerebral thrombosisSide effect

The invention relates to a bacillus subtilis subso natto for producing natto kinase and application thereof. The bacillus subtilis subso natto (bacillus subtilis subso natto LNUB236), CCTCC No.: M 208156. The bacillus subtilis subso natto is subject to activation of culture, seed liquid and fermentation liquor are prepared, and the natto kinase is extracted. The invention relates to application of the natto kinase to preparing a health product for preventing and treating cerebral thrombosis. Constituents of the health product are proportioned by weight: lyophilized natto powder : natto kinase : natto kinase : evening primrose oil=1:2.0-3.0:1.0-1.5. The bacillus subtilis subso natto LNUB236 has high natto kinase yield, the highest enzyme activity is 431.455IU / ml in the event of production in a 30l fermenter, and the prepared natto kinase-containing health product has the advantages of high enzyme activity, obvious effect and no side effect.

Owner:辽宁储阳生物科技开发有限公司

Bacillus adhaerens and its use in preparing health food having thrombolysis property

InactiveCN1464046AHigh activityStrong thrombolytic effectBacteriaBacteria material medical ingredientsAcid-fastSolubility

Bacilliis natto NLSSc with the preservation number CGMCC No. 0724 is Gram staining positive, non-acid fast, straight or near straight, (0.6-0.8)x(1.5-2.0) micron sized and aerobic; has mesial and un-swelled spore with the spore number inside one sporange cell not more than one, meso diamino heptane diacid and glycin contained in the cell wall, no characteristic saccharum and peripheral flagellum; and can be grown well in five kinds of natural organic culture medium and can form relatively thick mycoderm and butter fat colored colony with smooth edge in soybean cake powder culture medium. Bacilliis natto can be cultured in culture medium with nitrogen source to obtain thrombus dissolving matter natto kinase and the cultured matter may be extracted to obtain powdered matter as the additive for thrombolytic health food.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Fermentation process for natto flavoring paste

The invention discloses a method for processing natto flavoring paste which is suitable for Chinese. The method comprises the following steps of: soaking, cleaning and cooking soybean; performing pure culture of strains; inoculating; performing primary fermentation; performing secondary refrigerating fermentation; and seasoning to obtain the finished product. Due to a temperature shift fermentation mode, the activity of nattokinase is ensured after natto is fermented, lactobacillus acidophilus generates acid to neutralize partial fermentation ammoniacal odor, and the product does not have peculiar smell which is not liked by Chinese, and has special aroma, pleasant flavor and smooth mouthfeel. The method has the advantages of reasonable process, simple operation, short process period and good flavor of the natto, the natto flavoring paste meets the requirements of Chinese on mouthfeel and flavor, industrial production can be realized, the process is controllable, the quality is stable, the benefits of soybean product processing enterprisers can be improved, and lactic acid bacteria are added to further enhance the health-care effect of the natto product; and the invention provides a feasible method for promoting the natto product in China.

Owner:HUNAN AGRICULTURAL UNIV

Method for preparing freeze-dried powder containing bacillus natto and nattokinase

InactiveCN101214263AReduce purification costsKeep alivePowder deliveryPeptide/protein ingredientsSucroseFreeze-drying

The present invention relates to freeze-dried powder containing bacillus natto and nattokinase and a preparation method thereof, the process of which comprises that: firstly, culture medium is confected and sterilized, wherein, the culture medium components with the weight percentage are 8 percent to 15 percent of soybean flour, 1 percent to 5 percent of sucrose, 0.4 percent to 0.6 percent of NaCl and the water with the rest quantity, the pH value of which is 6.8 to 7.2; secondly, the bacillus natto is inoculated, and the inoculation quantity is 2 percent to 8 percent; thirdly, the bacillus natto after the inoculation is cultured and fermented for 20 to 28 hours under the temperature of 36 DEG C to 38 DEG C; fourthly, fermentation liquid is frozen and dried in vacuum, the glycerin with 1 percent to 7 percent of the weight of the fermentation liquid is used protecting agent to be added into the fermentation liquid, which is frozen under the temperature of subzero 18 DEG C in advance to be frozen and dried in vacuum for 12 to 20 hours and then is resolved under the temperature lower than 30 DEG C. The method has low cost and is in favor of the industrial production. Under the precondition of maintaining the nattokinase activity, the freeze-dried process also holds other nutrient component in the bacillus natto and the fermentation liquid, which reduces the nattokinase purification cost.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Fermented soybean milk, fruit juice soymilk and preparation method of fermented soybean milk and fruit juice soymilk

InactiveCN102630757AReduce fishy smellAdd flavorMilk preparationMilk substitutesFruit juiceLactarius

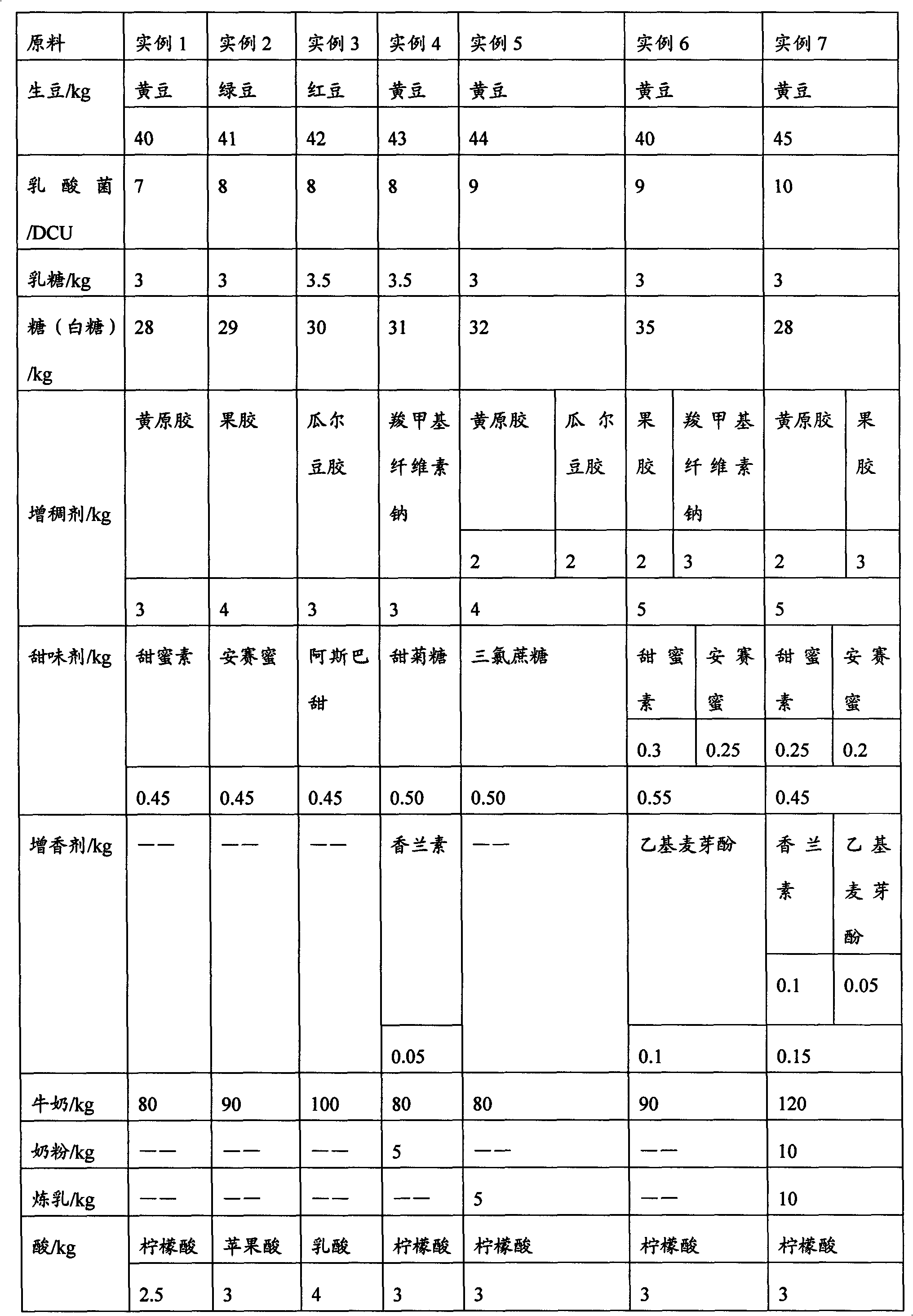

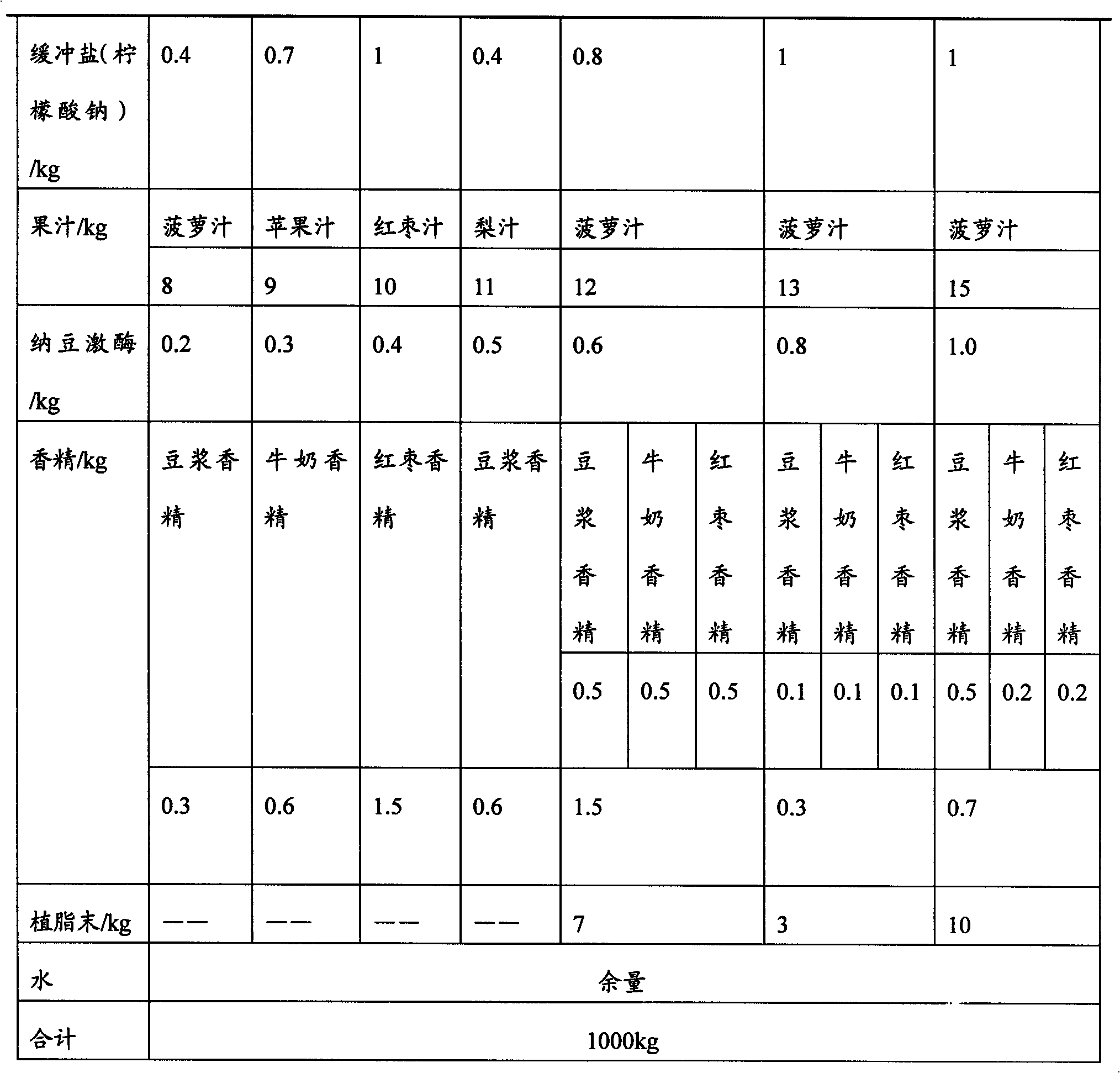

The invention belongs to the technical field of drinks and discloses fermented soybean milk, fruit juice soymilk and a preparation method of the fermented soybean milk and the fruit juice soymilk. The method comprises the following steps of: preparing raw soybeans, sequentially performing sorting, washing, soaking, cooking, beating, separating and filtering treatments on the raw soybeans, homogenizing, sterilizing, cooling to the temperature of 40-45 DEG C, and adding lactic acid bacteria and milk sugar for fermenting in 12-16 hours to obtain the fermented soybean milk; and on the basis of taking the raw soybeans, the lactic acid bacteria, the milk sugar, sugar, a thickening agent, a sweetener, milk, nattokinase, fruit juice, acid, buffer salt, essence and water as raw materials, preparing the fermented soybean milk, mixing, performing a constant volume process, blending, homogenizing, sterilizing and cooling to obtain the fermented soymilk. According to the invention, the amount of the soybean beany flavor in the product is reduced by 80-90%, the fruit juice is added to the soybeans so as to complement each other and enable the taste to be blander and delicate, in addition, the nattokinase is added to the soymilk, so that the nutrition of the product can be improved; the product can be placed at a room temperature for 6 months with stable state, no bleeding and a deposition rate of less than 1%.

Owner:HENAN SUNJOCK DAIRY

Frozen dried natto producing method

The present invention provides a manufacturing method of freeze-dried natto. The manufacturing method of the present invention comprises the steps of soybeans immersion, cooking, flavoring, fermentation, pre-cooling, and vacuum freeze drying and so on. The freeze-dried natto is dried under the conditions with low temperature and frost. The thrombolytic enzyme-natto kinase will not inactivate. The flavoring agents are added in the process of manufacturing, which can make the freeze-dried natto have a plurality of flavors like salt, delicious, sweet and so on, can improve the growth of bean bacteria, and can make the natto produce much more kinase. In addition, after the natto is frozen and dried, the natto has loosened texture, which can be eaten as food. The freeze-dried natto is also suitable for the old to eat conveniently. The freeze-dried natto is dry product, and can be packed with paper cup or paper wed without polluting the environment.

Owner:SHANGHAI NORMAL UNIVERSITY

Bacillus subtilis generating nattokinase and method for producing nattokinase by fermenting same

ActiveCN102220258ALow priceHigh in proteinBacteriaMicroorganism based processesMicrobiological cultureProtein content

The invention relates to bacillus subtilis generating nattokinase and a method for producing nattokinase by fermenting the same. The bacillus subtilis generating nattokinase is named as TK-1, the class name is bacillus subtilis, the collection number is CGMCC No.4731, the collection date is 4 / 2 / 2011, the collection address is: 3# yard, No.1 West Beichen Road, Chaoyang District, Beijing, and the collection organization is China General Microbiological Culture Collection Center. A fermentation medium contains bean pulp, and the fermentation method is mainly characterized in that the fermentation medium contains the bean pulp. According to the invention, the bacillus subtilis generates nattokinase through solid state fermentation of bean pulp serving as a raw material; the bean pulp is relatively cheap and has high protein content, thereby being favorable for the growth of thalli; the maximum enzymatic activity of the obtained nattokinase reaches 5,670 FU per gram of dry basis; and the maximum viable count can reach 7-109 cfu per gram of dry basis.

Owner:南京御匾国健生物科技有限公司

Functional lactobacillus plantarum and preparation method of compound bacterial powder of functional lactobacillus plantarum

The invention relates to a functional lactobacillus plantarum plant subspecies having a holesterol lowering function and a preparation method of a compound bacterial powder of the plant subspecies, and belongs to the application fields of functional food and microecologics. According to the preparation method, the lactobacillus plantarum plant subspecies Zhang-LL CGMCC No. 6936 is used for preparing Zhang-LL strain freeze-dried powder by virtue of culture activation, fermentation, bacterial sludge collection and freeze-drying, and the viable count of the freeze-dried powder is 3.50*10<11> CFU / g. Bacillus natto BNZ3 CGMCC No. 9146 is used for preparing bacillus natto power by virtue of culture activation, enlarged cultivation, fermentation and drying, and the activity of nattokinase in the bacillus natto power is 2000IU / g; monacus purpureus Zhang-MP CGMCC No. 9221 is used for preparing monacus purpureus powder by virtue of culture activation, enlarged cultivation, solid-state fermentation, drying and grinding; as being tested, the content of the active substance Monacolin K in the monacus purpureus powder is 4.98mg / g. The prepared lactobacillus plantarum plant subspecies powder is thoroughly mixed with the bacillus natto power and the monacus purpureus powder in the ratio of 1:1:1(w / w), thereby obtaining compound bacterial powder having the serum cholesterol lowering effect.

Owner:BEIJING UNIV OF AGRI

Bacillus subtilis mutant strain for highly producing NK (nattokinase) and application of Bacillus subtilis mutant strain

PendingCN107828685AImprove securityStrong ability to produce nattokinaseBacteriaMicroorganism based processesDiseaseSide effect

The invention discloses a Bacillus subtilis mutant strain for highly producing NK (nattokinase) and an application of the Bacillus subtilis mutant strain and belongs to the biotechnology field. The strain is collected in CGMCC (China General Microbiological Culture Collection Center) with the collection number of CGMCC No.14433 on July 17, 2017, with the suggested classification name Bacillus subtilis. The strain and a liquid fermentation medium are used for producing an NK-containing fermentation liquid with the enzyme activity up to 27,690 u / g, high-purity NK powder prepared from the fermentation liquid has the enzyme activity up to 497,280 u / g, and a healthcare capsule which is prepared from main materials including freeze-dried natto powder and the high-purity NK powder and has functions of reducing blood pressure and preventing cardiovascular-cerebral thrombosis diseases has the characteristics of being high in NK activity, good in food therapy and free of side effects.

Owner:JIANGSU UNIV

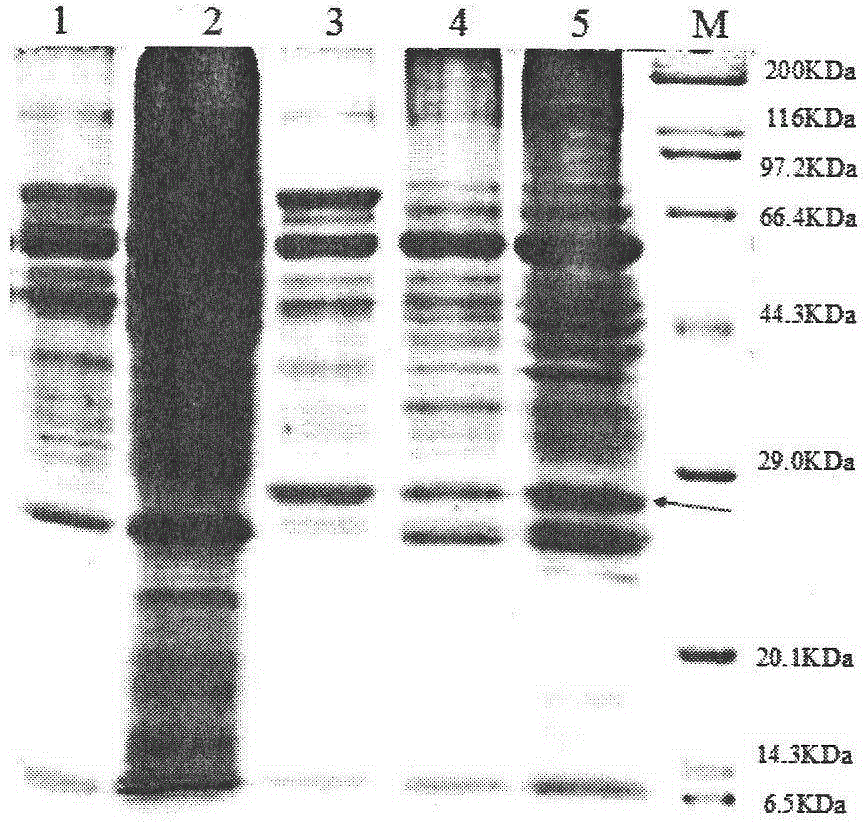

Bacillus licheniformis engineering bacteria for nattokinase production and method for producing nattokinase by using bacillus licheniformis engineering bacteria

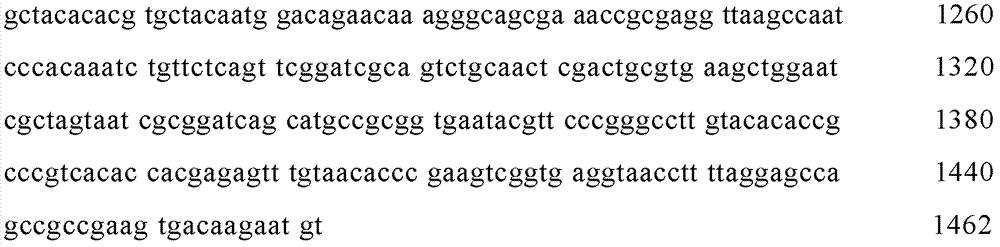

ActiveCN104630124AAchieve secretory expressionSecreted expression highly mediatedBacteriaMicroorganism based processesBacillus licheniformisShuttle vector

Disclosed are bacillus licheniformis engineering bacteria for nattokinase production and a method for producing nattokinase by using the bacillus licheniformis engineering bacteria, which belong to the technical fields of microorganism genetic engineering and enzyme engineering. According to the invention, a nattokinase gene of bacillus subtilis MBS04-6 is obtained through PCR technology augmentation. Bacillus licheniformis BL10 is utilized as an expression host; promoter P43 of bacillus subtilis 168 is taken as a promoter; a signal peptide of extracellular serine protease Vpr of bacillus licheniformis WX-02 is taken a signal peptide; and a terminator sequence of alpha-amylase of bacillus licheniformis WX-02 is taken as a terminator. The expression elements are connected to shuttle vector pHY300PLK to form an expression vector, and the expression vector is transformed into the bacillus licheniformis BL10 to obtain the bacillus licheniformis engineering bacteria BL10 (pP43SNT) for nattokinase production. The bacterial strain has been deposited with the China Center for Type Culture Collection (CCTCC) at September 10th, 2013, and the accession number is CCTCC NO:M2013401. The invention also provides a method of the bacterial strain for producing nattokinase, and the maximum enzyme activity can reach 11.37 FU / mL in a liquid fermentation medium.

Owner:HUAZHONG AGRI UNIV

Natto beverage and preparation method thereof

InactiveCN101731706AImprove product qualityIncrease biomassFood preparationBacillus subtilis var. nattoAdditive ingredient

The invention discloses a natto beverage and a preparation method thereof. The natto beverage contains a fermentation product obtained by deep fermenting beans with natto bacillus liquid, the used natto bacillus is a bacillus subtilis natto subspecies ODK-BN1 strain with the preservation number of CCTCC No. M207055; the preparation method of the natto beverage comprises the steps of: firstly deep fermenting beans with natto bacillus liquid to obtain a fermentation product, and then preparing the liquid fermentation product and edible auxiliaries into beverages according to a conventional method. By adopting the natto bacillus strain which is anoxia-tolerant, high-temperature resistant and has high yield of nattokinase, and adopting a liquid deep fermentation method to prepare the natto beverage, therefore, the invention has the advantages of simple method, low cost, a plurality of beneficial physiologically-active components in the product, attractive appearance and flavour, safe and non-toxic, good stability, long preservation time, easy acceptance by consumers and broad market prospects.

Owner:CHONGQING LIKE BIOTECH

Chickpea natto and making method and application of chickpea natto

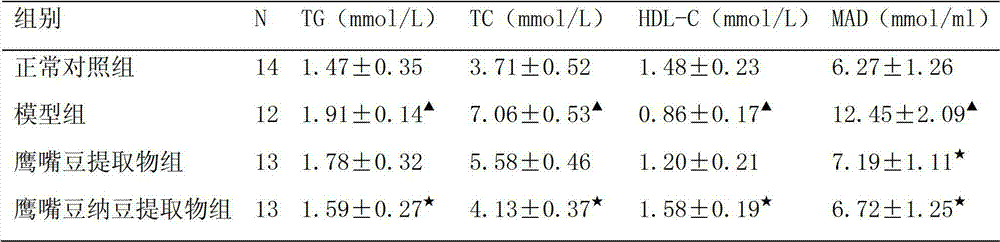

InactiveCN102763815AHigh in nutrientsPrevent or improve hyperlipidemiaFood preservationFood preparationAdditive ingredientFreeze-drying

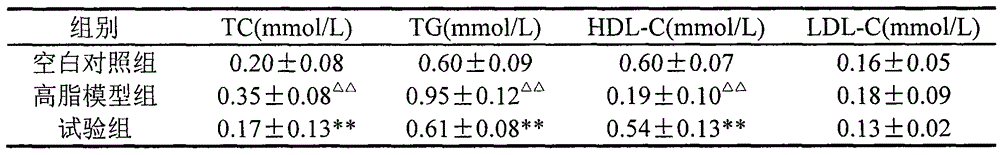

The invention discloses a making method of chickpea natto. The method comprises the following steps of: soaking the chickpea for sprouting, steaming and boiling, inoculating, fermenting, after-ripening, freeze-drying and the like. In the method, the chickpea biochanin isoflavone is generated by carrying out the sprouting pretreatment on the chickpea; the nutritional ingredients of the chickpea are enhanced; and subsequently the natto bacillus subtilis is inoculated for fermentation so as to make the chickpea natto which is rich in chickpea flavonoid, bacillus natto and nattokinase. In addition, the invention also discloses the chickpea natto made by using the method and the application of the chickpea natto for preparing health-care foods or medicines for preventing or improving hyperlipidemia and resisting thrombosis. The experiments show that the chickpea natto disclosed by the invention can reduce the contents of the TC (total cholesterol), the TG (total glycerin) and the MAD (monoamine oxidase) of the organism blood serum, has the significant blood-fat depression and thrombolytic functions, and can be used for preparing the health-care foods or medicines for preventing or improving hyperlipidemia and resisting thrombosis.

Owner:上海诺金科生物科技有限公司

Bacillus subtilis high in nattokinase secretion and application thereof

ActiveCN107099487AImprove metabolic activityHigh activityBacteriaMicroorganism based processesPollutionMicrobiological culture

The invention discloses Bacillus subtilis high in nattokinase secretion and application thereof. The strain is named as Bacillus subtilis gs-11061 and is preserved in China General Microbiological Culture Collection Center, and the collection number of the Bacillus subtilis gs-11061 is CGMCC No. 13932. The invention further discloses a method using the Bacillus subtilis high in nattokinase yield to produce nattokinase. Compared with other fermentation methods, the method has the advantages that the Bacillus subtilis can be fermented under high temperature, and the fermentation cycle is shortened evidently; in terms of a culture medium, a xylose mother liquor coarse raw material is used to lower cost, and low energy consumption and low pollution are achieved; compared with original bacteria, the secretion of the nattokinase is increased evidently, fermentation products can be processed easily, and few byproducts are produced.

Owner:NANJING UNIV OF TECH

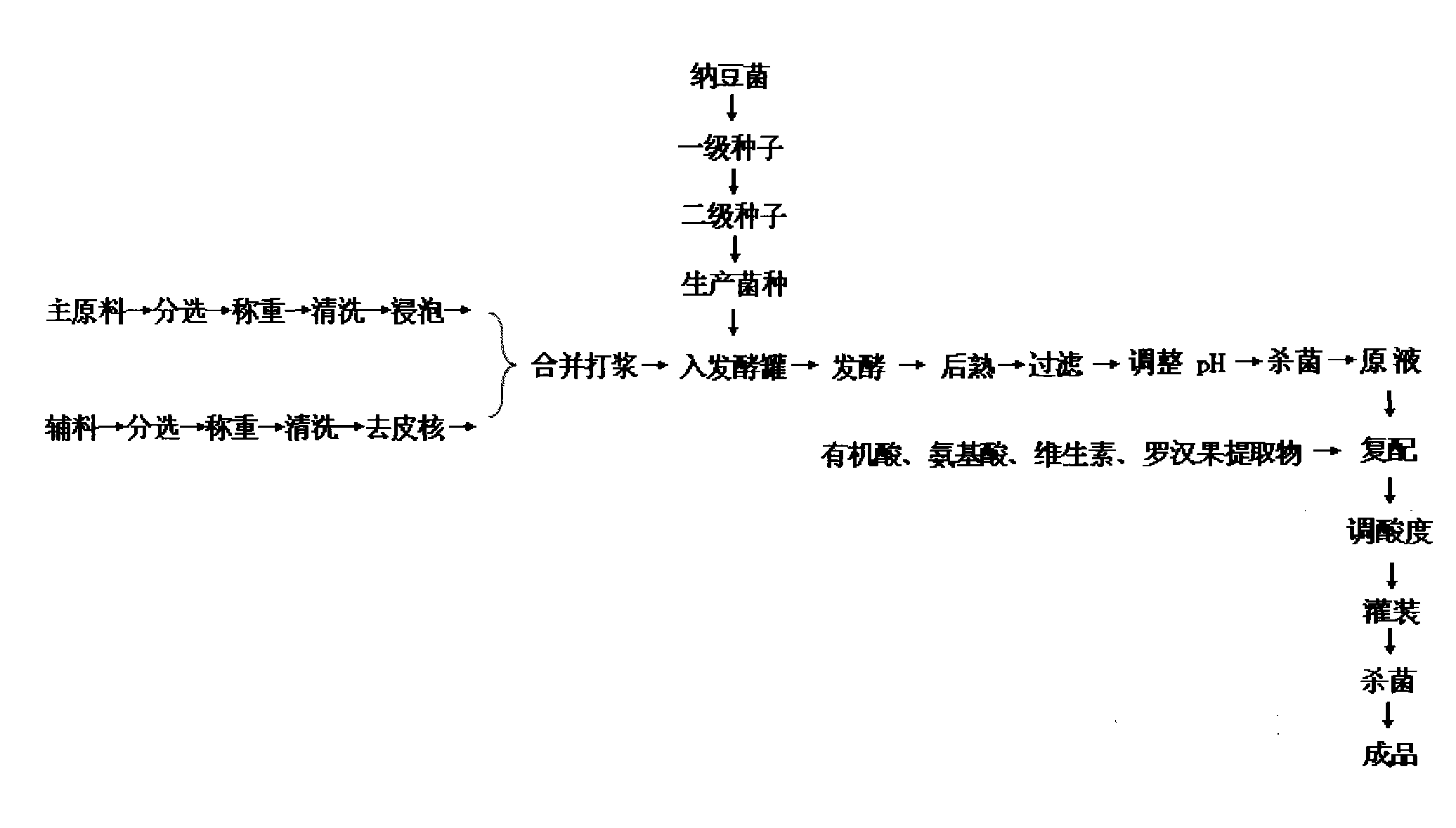

Method for producing bacillus natto comprehensive enzyme low-molecular beverage

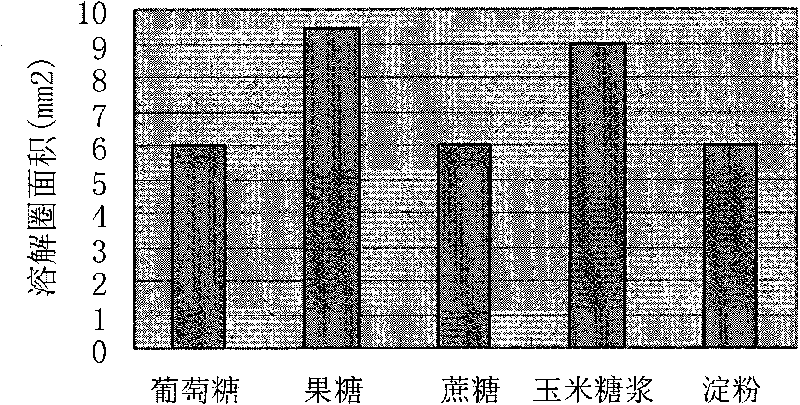

ActiveCN101803774AStrong environmental toleranceAchieve probiotic effectFood preparationAdditive ingredientThrombus

The invention discloses a method for producing bacillus natto comprehensive enzyme low-molecular beverage, which comprises the following steps: 1, pulping plant raw materials to form fermentation liquor; 2, inoculating bacillus natto into the fermentation liquor, and fermenting the mixture for 2 to 3 months at the temperature of between 30 and 37 DEG C; and 3, after-ripening the fermentation liquor for 4 to 5 months at the temperature of between 10 and 15 DEG C to form low-molecular enzyme liquor, wherein the plant raw materials comprise grains, fruits or vegetables. The method has the advantages that: the bacillus natto has strong environment tolerance and can restrain pathogenic bacteria; the fermentation of the bacillus natto does not produce acid, and the beverage does not need to adda sweetener, so the beverage is beneficial to health; natto kinase produced by the bacillus natto can dissolve thrombus, restrain the generation of angiotensin and reduce blood pressure; effective substances of the beverage are not living bacteria but stable low-molecular active components produced by the living bacteria such as low-molecular peptide, oligosaccharide, saponins, isoflavone and other active factors, so the beverage does not need low-temperature preservation and has preservation time; and the beverage adds amino acid and vitamin necessary for the human body, so the beverage is more nutrient and healthy.

Owner:全然之心(大连)商贸有限公司

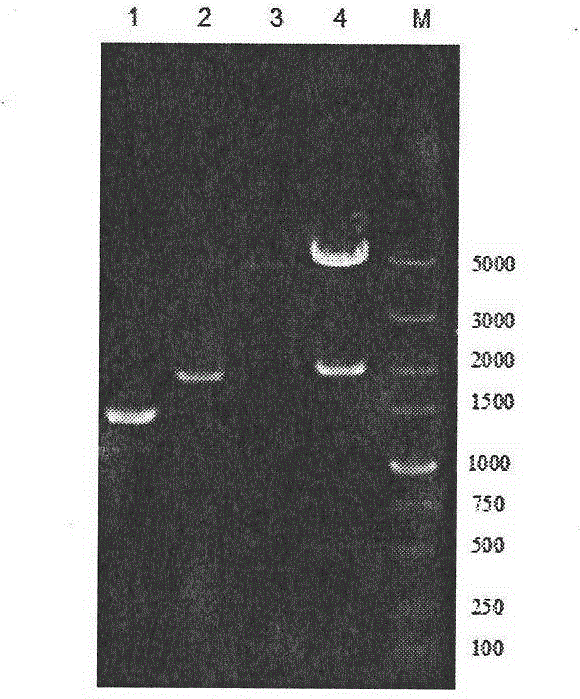

Bacillus subtilis strain for excreting nattokinase at high efficiency and preparation technology of high-purity nattokinase

InactiveCN107058204AIncrease enzyme activityBacteriaMicroorganism based processesRestriction enzyme digestionDigestion

The invention relates to a bacillus subtilis strain for excreting nattokinase at high efficiency. An aprN gene of bacillus subtilis NK is amplified by a PCR (polymerase chain reaction) technique; codons of initial thirty amino acids are optimized according to the codon preference of the bacillus subtilis, a recombination expression plasmid pHT01-aprN is established, and the correctness is verified through the restriction enzymes digestion, PCR amplification and sequencing. The recombination expression plasmid pHT01-aprN is imported into the bacillus subtilis 168 by an electric shocking method, and is performed with resistance screening by adopting chloramphenicol, so as to obtain engineering bacteria. After the fermenting condition is optimized, and the expression is induced by IPTG, the highest enzyme activity in a shake culture fermenting liquid is 289U / ml; the highest enzyme activity in a high-density fermenting liquid is 7778U / ml; the highest enzyme activity of a nattokinase preparation prepared by affinity column chromatography is 981731U / g.

Owner:上海诺金科生物科技有限公司

Preparation method for fibrinolytic fermented soya beans

InactiveCN103829166APromote growthProtease content has little effectFood preparationProduction linePlasmin

The invention provides a preparation method for fibrinolytic fermented soya beans. The preparation method comprises the steps of activating strains, preparing a mucor seed solution; preparing a bacillus natto seed solution; processing soya beans; inoculating; culturing and after-ripening. Under the conditions that mucor and bacillus natto produced protease and bacillus natto produced plasmin are used as evaluation indexes, the mucor grows well after bacillus natto is inoculated; influence to protease content is not large; nattokinase activity in the obtained fermented soya beans can reach 823.51 U / g; and protease activity reaches 1983.91 U / g. By seeking optimum conditions for fermentation of the fermented soya beans, the time required by a conventional fermentation process for the fermented soya beans is greatly shortened without influencing the flavor of the fermented soya beans. At the same time, during an operation process, condition control is convenient, thereby facilitating production operations. The preparation method can finish co-fermentation of the bacillus natto and the mucor to the soya beans only by using an original production line of the fermented bean curd blanks, without increasing any equipment, thereby greatly saving production cost.

Owner:CHONGQING NORMAL UNIVERSITY

Barley and yam Natto

InactiveUS6669971B1Promote absorptionAvoid accumulationTea extractionAnimal feeding stuffVitamin K2Disease

The present invention provides Natto manufactured by mixing steamed soybean, cooked barley and yam, inoculating Bacillus subtilis Natto to the mixture, and fermenting the mixture, which is almost odorless, soft, good taste, and viscous, and further, functional substances such as vitamin K2 and enzyme (Nattokinase and Protease) are remarkably increased. This product may extend the utilization as functional traditional foods relating to prevention of life-style related disease.

Owner:OOYAMA TOFU

Bacillus natto culture extract

InactiveUS7018630B2High activitySolve the real problemCosmetic preparationsBacteriaVitamin K2FP extract

A Bacillus natto culture is treated with chitosan, and then filtered, concentrated, and dried. According to this method, a Bacillus natto culture extract containing nattokinase and 1 μg or less of vitamin K2 / g dry weight is obtained.

Owner:JAPAN BIO SCI LAB

Method for simultaneously producing vitamin K2 and nattokinase through Bacillus natto fermentation

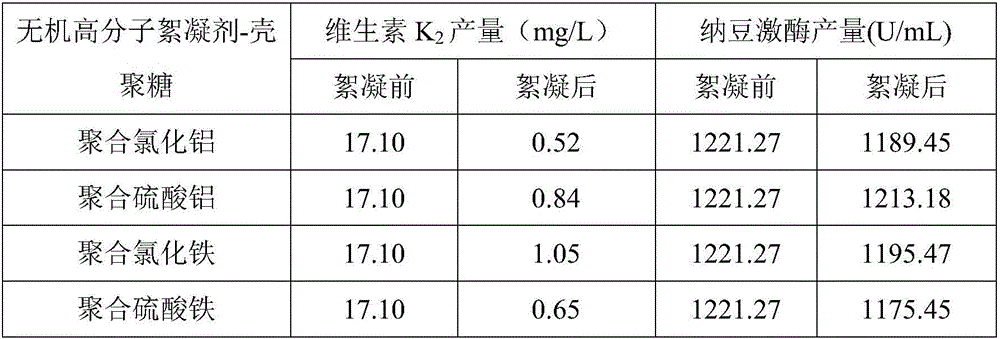

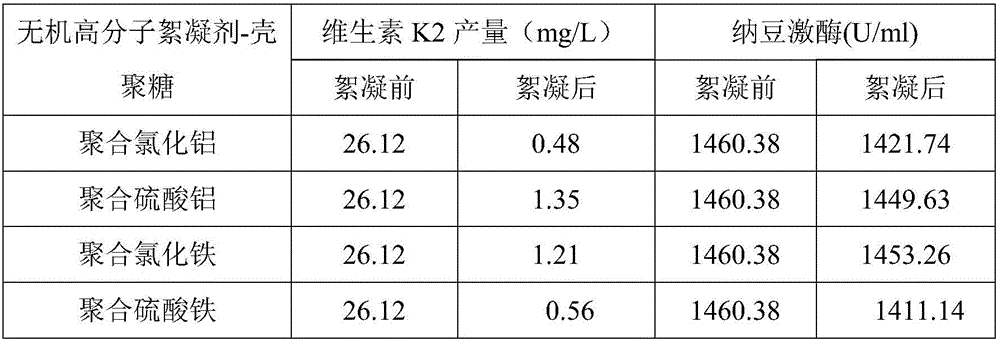

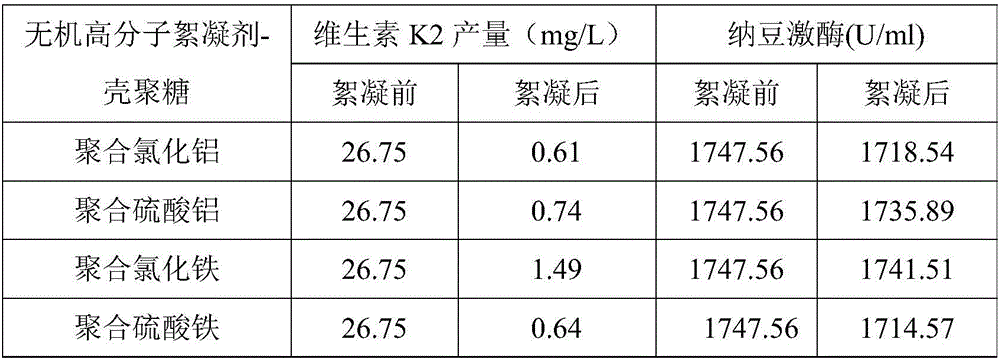

ActiveCN106701719ASolve the problem of high cost and low outputIncrease profitMicroorganism based processesFermentationVitamin K2Microbiology

The invention discloses a method for simultaneously producing vitamin K2 and nattokinase through Bacillus natto fermentation. The method comprises the following steps: strain activation: performing streak culture on Bacillus natto in a plating culture medium, and culturing a single colony in a test tube culture medium; seed preparation: inoculating the Bacillus natto in the test tube into a seed culture medium, and culturing; production of nattokinase and vitamin K2: preparing fermentation culture medium for simultaneous production, taking the prepared seed solution after the fermentation culture medium for simultaneous production is cooled, inoculating, and producing the nattokinase and vitamin K2 under optimal culture conditions for simultaneous production; and separation and extraction of the nattokinase and vitamin K2: centrifuging the fermentation solution, separating the supernatant from the precipitate, adding inorganic high polymer flocculant into the supernatant, and taking chitosan as coagulant aid to separate the vitamin K2 and nattokinase in the supernatant. The method has the advantages of improving the raw material utilization ratio and being suitable for industrial production.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Food-grade nattokinase expression bacterium

ActiveCN106085934AHigh purityHigh expressionBacteriaPeptide/protein ingredientsBacillus licheniformisBULK ACTIVE INGREDIENT

The invention discloses a food-grade nattokinase expression bacterium. The recombinant bacterium is bacillus licheniformis which is transformed so that the genome contains at least one copy nattokinase gene. Preferably, in the genome of the expression bacterium, the negative regulatory factor gene hrcA is inactivated. The production strain provided by the invention accords with the requirements of a food-grade expression system, multiple copy nattokinase genes are tracelessly integrated into the genome of the bacillus licheniformis to be expressed, the expression quantity is obviously improved compared with that in the prior art, through the inactivation of the negative regulatory factor gene hrcA, the enzyme activity and expression quantity are further improved, the enzyme activity achieves 1350FU / mL, and the protein content achieves 1.45g / L. The nattokinase prepared by the recombinant bacterium is high in purity, can be processed into a health product or can be taken as an active ingredient of a medicine for treating cerebral infarction.

Owner:WUHAN KANGFUDE BIOTECH CO LTD

Bacillus subtilis LSSE-22 and application thereof

ActiveCN103243040AHigh production activitySimple methodBacteriaMicroorganism based processesMicroorganismGallic acid ester

The invention relates to the field of microorganisms, and specifically relates to bacillus subtilis LSSE-22 and an application thereof. The invention provides the bacillus subtilis LSSE-22 with the preservation number of CGMCC No.4970. The invention also provides the application of the bacillus subtilis LSSE-22. The invention provides a natto food which is prepared by fermenting bean substrates through the bacillus subtilis LSSE-22. The bacillus subtilis LSSE-22 has higher natto kinase production activity, and when chick-peas are used as substrates, the highest activity of natto kinase reaches 356.25FU / g (the dry weight of the chick-peas). The natto kinase and an antioxidant active substance total phenol are prepared through simultaneous separation by using an ethanol separation method, the activity of the natto kinase reaches 2852.62FU / g (dry weight), the content of the total phenol reaches 14.78mg gallic acid / g (dry weight), and the method is simple and efficient.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Production method for bacillus natto and cordyceps fungus composite enzyme series of products

InactiveCN103371358AStrong environmental toleranceAchieve probiotic effectFood preparationBiotechnologyThrombus

Provided is a production method for bacillus natto and cordyceps fungus composite enzyme series of products. The main products comprise bacillus natto and cordyceps fungus composite low molecular weight enzyme beverage, composite enzyme capsules and composite enzyme tablets. The production method comprises a single-microorganism fermentation technology and a mixed-microorganism fermentation technology. The bacillus natto employs bacillus subtilis natto, and the cordyceps fungus employs cordyceps sinensis or cordyceps militaris. The bacillus natto can inhibit pathogenic bacteria. The generated nattokinase can dissolve thrombus, inhibit generation of angiotensin and reduce blood pressure. No acids are generated during fermentation of the bacillus natto, and no sweeteners need to be added into the products, which is beneficial to health. The cordyceps fungus has immune modulating functions, has anti-tumor, bacteriostasis and antiinflammation effects, and has some effects on nervous systems and livers. The effective substances of the products are stable active ingredients generated from the living microorganism, and with low molecular weight, such as peptides with low molecular weight, oligosaccharides, saponins, isoflavone, cordycepin, phosphatidylcholine, trace elements and the like. The products do not need to be stored at low temperature and has a long storage life. The products contain essential amino acids and vitamins of human body, and are nutritive and healthy.

Owner:DALIAN NUTRIZON BIOTECH

Nutrient black soya bean powder prepared by fermentation of bacillus natto and preparation method thereof

The invention discloses nutrient black soya bean powder prepared by fermentation of bacillus natto and a preparation method thereof. The preparation method comprises the following steps: (1) peeling black soya bean; (2) superfine grinding; (3) cooking for sterilizing; (4) fermenting by using bacillus natto, namely inoculating the amplified bacillus natto to the sterilized material and cultivating for 1-5 days under the conditions that the agitating speed of a rotary shaker is 160rpm and the temperature is 30 DEG C; (5) carrying out compound enzyme enzymolysis, namely adding deionized water to adjust pH after fermentation is finished, adding cellulose, papain and lysozyme to carry out enzymolysis for 0.5-6 hours; and (6) carrying out spray drying, so as to obtain nutrient powder. The product nutrient black soya bean powder disclosed by the invention is rich in nattokinase and polypeptide, and is reasonable in process, abundant in nutrients, fine in texture, good in solubility and long in storage period. The product, namely the nutrient black soya bean powder obtained by the method, can be prepared into capsules, tablets and granules by a conventional method, can be used as a health-care food, and has significant effects of helping to dissolve thrombus, reducing blood fat and preventing liver injury.

Owner:厦门元之道生物科技有限公司

Method for preparing high-activity nattokinase by taking black beans as raw material

ActiveCN103205409AIncrease enzyme activityGreat tasteMicroorganism based processesEnzymesFreeze-dryingNutrient solution

The invention discloses a method for preparing high-activity nattokinase by taking black beans as raw material, belonging to the technical field of biology. The method comprises the following steps: soaking the black beans by using a special nutrient solution, cooking the black beans after soaking and further inoculating bacillus natto to perform fermentation, wherein the special nutrient solution comprises the following components: lactose, tryptone, Na2HPO4, NaH2PO4, MgSO4 and CaCl2. The method further comprises the steps of performing extraction separation and freeze-drying on a fermentation product. The nattokinase obtained by adopting the method has high enzyme activity, which can achieve 42500IU / g, and the nattokinase has the advantages of high enzyme activity, low ammonia smell and good taste in comparison with the nattokinase produced by taking yellow beans as the raw material and performing a traditional fermentation method; and the content of nutritional components in obtained fermented black bean residue is also obviously improved. The method has the advantages of short fermentation period, simple preparation process and high bioavailability, and is conductive to industrial production.

Owner:湖北真福医药有限公司

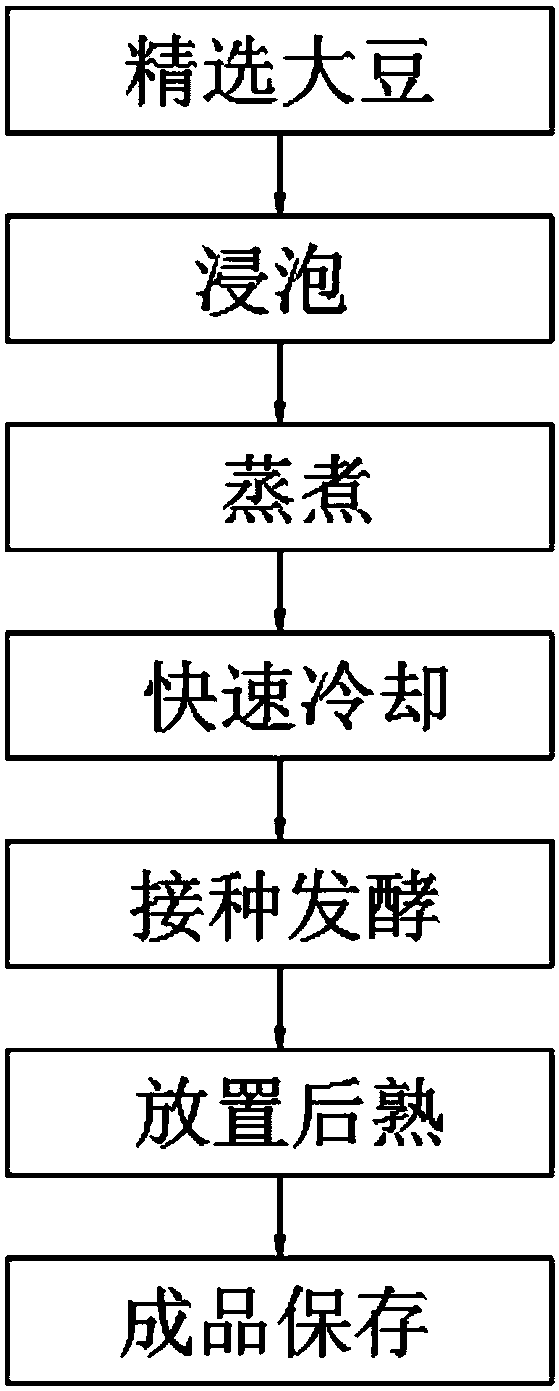

Preparation process of fermentation of non-ammonia-smell natto

InactiveCN108029972ASimplify the production processIncrease productivityBacteriaLactobacillusLactobacillus acidophilusBacillus natto

The invention discloses a preparation process of fermentation of non-ammonia-smell natto, which includes the steps of: 1) fine selection of soya beans; 2) soaking; 3) steaming; 4) quick cooling; 5) inoculation and fermentation; 6) standing post-maturation and storage of finish product. In the step 3), the soya beans are steamed without necessity of high temperature, so that loss on amino acids andsaccharides due to Maillard reaction is prevented and color deepening of the finish product is avoided. Generally, the steaming operation is carried out under 0.08-0.1 MPa for 30-40 min, and if the soya beans are crushed, the time only lasts for 7-8 min. The method simplifies the production route of the natto and improves production efficiency of enterprises, thus effectively improving convenience. Meanwhile, in the method, bacillus natto-lactobacillus acidophilus fusant strain is used instead of the bacillus natto strain, so that on the basis of maintaining the natto kinase activity to be not changed basically, content of amino acid nitrogen in the natto is increased. The natto is free of pungent ammonia smell, has a gentle mouth feel and reduced irritation, and has no difference from traditional natto in wire drawing.

Owner:SHANXI AGRI UNIV

Method for industrially producing nattokinase by using chickpea

InactiveCN102618522AImprove immunityIncrease profitMicroorganism based processesEnzymesBiotechnologyNutrient solution

The invention relates to a method for industrially producing nattokinase by using chickpea, which belongs to the biological field. The invention discloses the method for industrially producing nattokinase by using chickpea. According to the invention, high-yield strain fermented by a nattokinase solid is inoculated in the chickpea and a nutrient solution for fermenting and producing nattokinase, the method comprises the steps of crushing, immersing, disinfecting, inoculating, fermenting, ripening, extracting, separating, freeze-drying and the like. The method for producing nattokinase by fermenting chickpea, the enzyme activity of a crude enzyme liquid can reach 3270IU / g, the enzyme activity after extraction and separation is 35000IU / g, compared with the nattokinase produced by a traditional fermentation method which takes soybean as a raw material, the nattokinase produced by using chickpea has the advantages of high enzyme activity, short fermentation period, low ammoniacal smell and good mouthfeel. According to the invention, methods of cross flow nanofiltration and alcohol precipitation are used for extracting and separating nattokinase, the production technology is simple and is benefit for industrial production, simultaneously, advantages of more abundant nutrition and natural antioxidation of the chickpea are kept.

Owner:HUBEI GOLE BIO TECH DEV

Method for preparing nattokinase through solid-state fermentation

ActiveCN106085991AIncrease added valueReduce manufacturing costHydrolasesMicroorganism based processesSaline waterBiotechnology

The invention belongs to the technical field of microorganism fermentation engineering and relates to a method for preparing nattokinase through solid-state fermentation. The method includes: respectively preparing a bevel culture medium, a seed solution culture medium and a fermentation culture medium; inoculating bacillus natto onto the bevel culture medium for culture to obtain activated bacillus natto, picking and placing 1-2 rings into the seed solution culture medium for oscillation culture to serve as a fermentation seed solution; sterilizing and then naturally cooling the fermentation culture medium, spraying the fermentation seed solution into the fermentation culture medium, adding water, and stirring well; paving a thin layer in a beaker, using gauze to seal, sequentially performing fermentation and after-ripening for 24 h, and adding normal saline; performing extraction and centrifuging to obtain supernate rich in nattokinase. The method is simple in process and convenient to operate, raw materials are easy to get and low in cost, and nattokinase prepared by the method is high in activity and has obvious economic benefit.

Owner:烟台泰禾电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com