Bacillus subtilis subso natto for producing natto kinase and application thereof

A technology of Bacillus subtilis and nattokinase, applied in the biological field, can solve the problems of low cost of health care products, high cost of clinical standard drugs for nattokinase, and high cost of nattokinase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

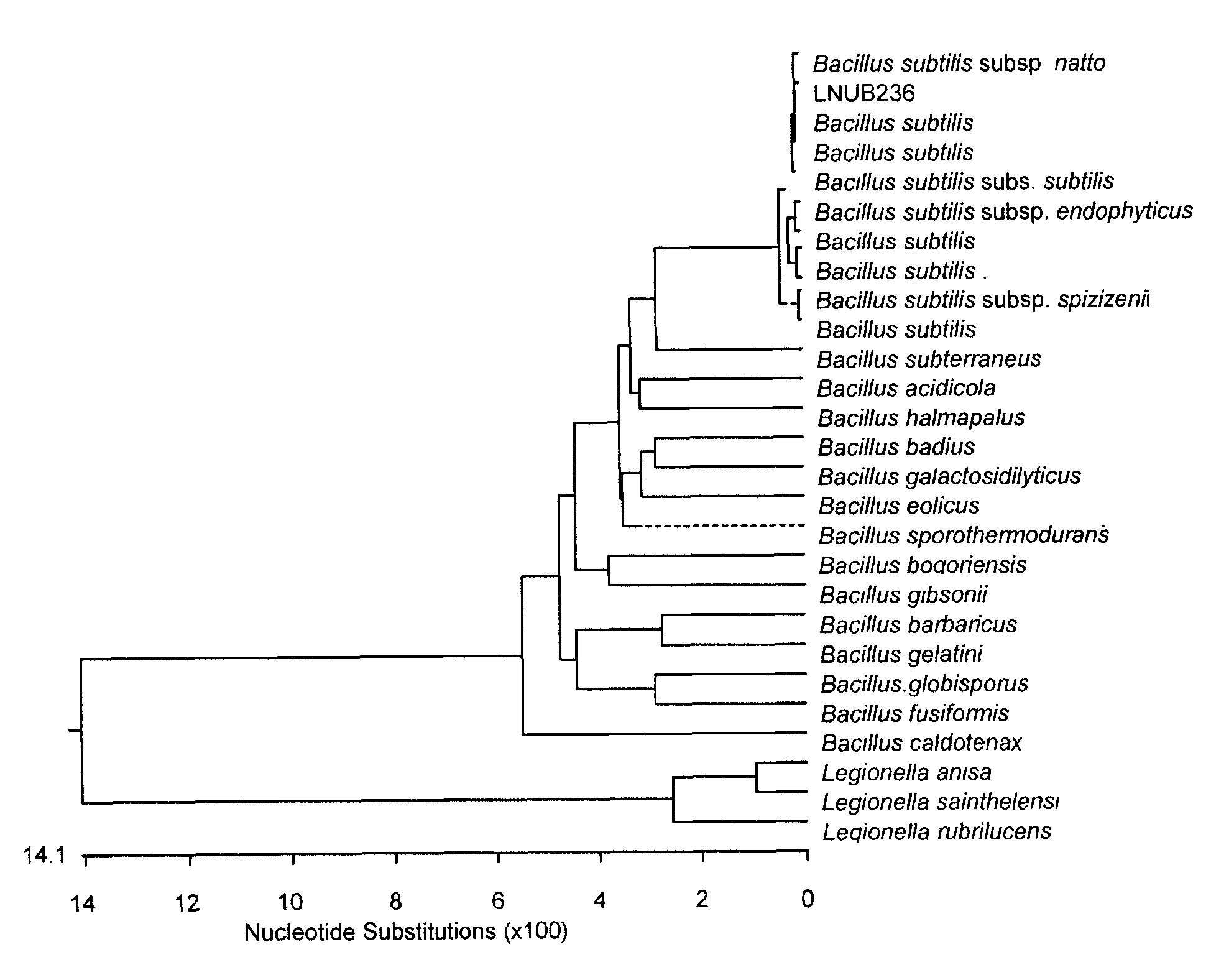

Image

Examples

Embodiment 1

[0044] Utilize bacillus subtilis natto subspecies LNUB236 to prepare nattokinase, its method is as follows:

[0045] 1) Strain activation: Bacillus subtilis subsp.natto LNUB236 was placed on LB slant medium, and cultured in a 37°C incubator for 24 hours;

[0046] The composition of LB slant medium is: tryptone 1g, sodium chloride 1g, yeast extract 0.5g, agar 1.5g, deionized water 100ml, pH 7.0;

[0047] 2) Seed liquid preparation: Pick the activated strains into two 500 ml Erlenmeyer flasks containing 200 ml LB liquid medium with an inoculation loop, and cultivate them at 37°C and 200 rpm for 18 hours;

[0048] LB liquid medium: 4 grams of tryptone, 4 grams of sodium chloride, 2 grams of yeast extract, 400 ml of deionized water, pH 7.0;

[0049] 3) Preparation of fermented liquid: Inoculate 2% seed liquid into the liquid comprehensive culture medium of fermenter, ferment temperature is 37°C, ferment time is 72 hours, pH is 7.0, ventilation rate is 0.5-1.0 cubic meters per hou...

Embodiment 2

[0055] A health product prepared by using nattokinase. The health product is proportioned by weight, natto freeze-dried powder:nattokinase:evening primrose oil=1:2.5:1.5.

[0056] Wherein, nattokinase is the nattokinase prepared in Example 1.

[0057] Preparation:

[0058] (1) Preparation of natto freeze-dried powder: soybeans were soaked in running water for 18 hours, then steamed in a pressure cooker at 121° C. for 90 minutes. After cooling, inoculate with an inoculum size of 40%, culture at 37°C for 1 day, and then culture at 4°C for 1 day, then mature natto, then add a small amount of distilled water to mash the mature natto with tissue crushed by a machine, and then freeze-dried in a vacuum to obtain freeze-dried natto powder.

[0059] (2) 15 grams of evening primrose oil is heated to remove oxygen therein and cooled to room temperature;

[0060] (3) Under aseptic conditions, 10 grams of natto freeze-dried powder, evening primrose oil and 25 grams of nattokinase were un...

Embodiment 3

[0062] A health product prepared by using nattokinase. The health product is proportioned by weight, natto freeze-dried powder:nattokinase:evening primrose oil=1:2.0:1.0.

[0063] Wherein, nattokinase is the nattokinase prepared in Example 1.

[0064] Preparation:

[0065] (1) Preparation of natto freeze-dried powder: soybeans were soaked in running water for 18 hours, then steamed in a pressure cooker at 121° C. for 90 minutes. After cooling, inoculate with an inoculum size of 40%, culture at 37°C for 1 day, and then culture at 4°C for 1 day, then mature natto, then add a small amount of distilled water to mash the mature natto with tissue crushed by machine, and then vacuum freeze-dried to obtain freeze-dried natto powder;

[0066] (2) 10 grams of evening primrose oil is heated to remove oxygen therein and cooled to room temperature;

[0067] (3) Under aseptic conditions, 10 grams of natto freeze-dried powder, evening primrose oil and 20 grams of nattokinase were uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com