Fermented soybean milk, fruit juice soymilk and preparation method of fermented soybean milk and fruit juice soymilk

A fermented, soybean milk technology, applied in the field of beverages, to achieve the effects of improving fibrinolytic activity, improving nutritional efficacy and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

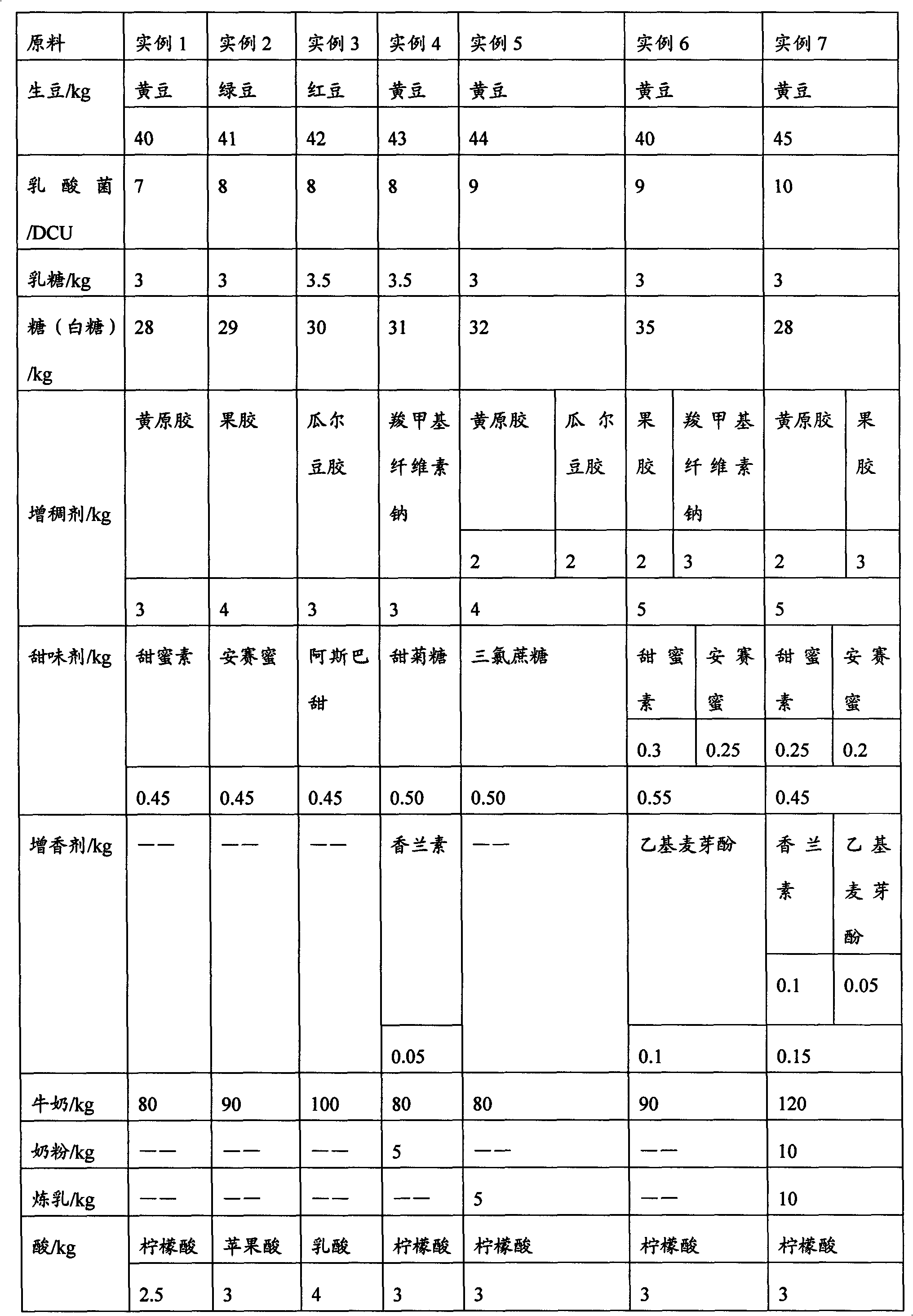

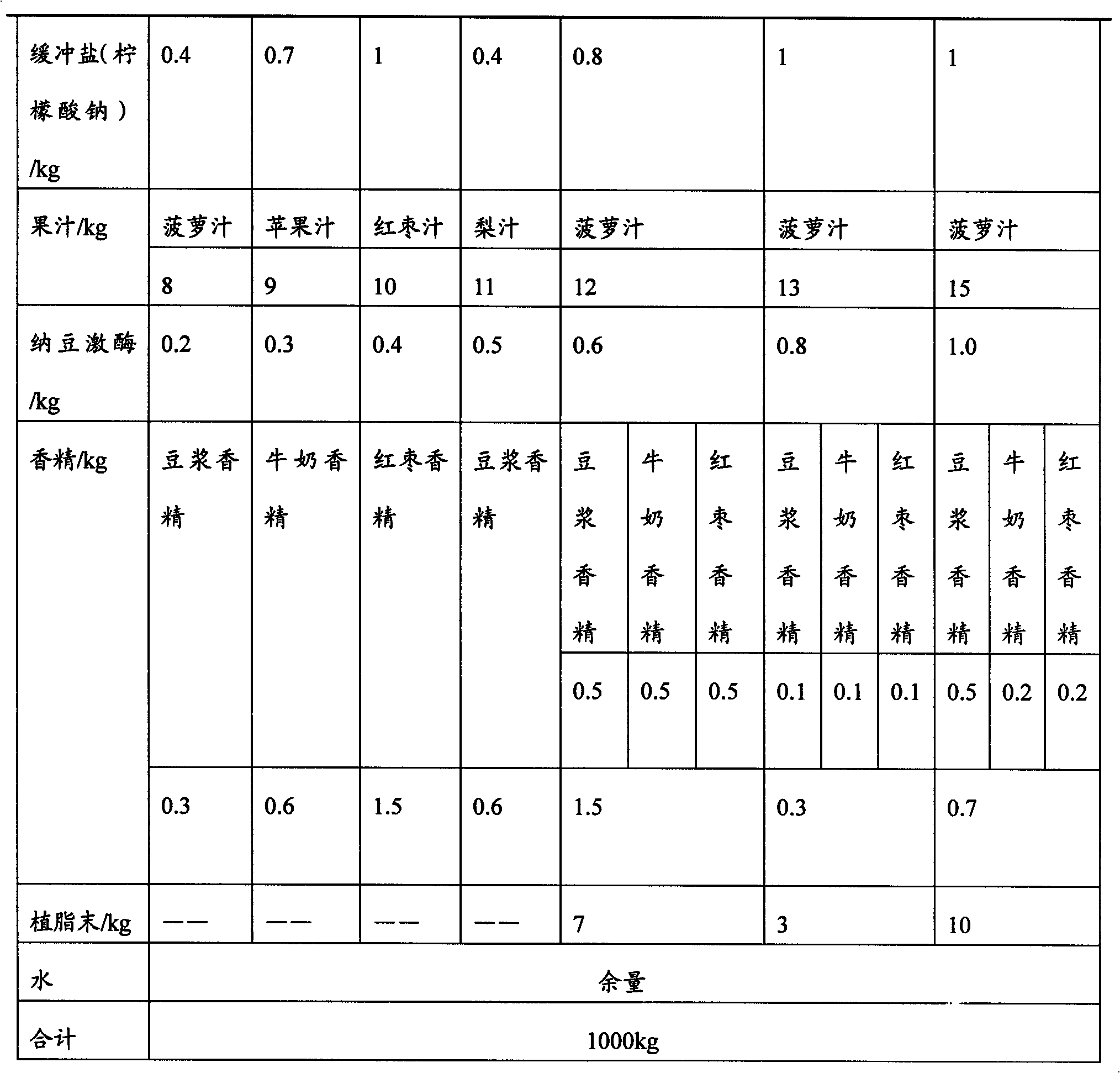

Examples

example 1

[0067] When preparing fermented soybean milk: when cooking, add 0.5g of sodium tripolyphosphate per kg of raw beans; soak for 8 hours; when beating, the temperature is 80°C, and the soybean-water ratio is 1:3; when homogenizing, the temperature is 20°C, The pressure is 15Mpa; when sterilizing, the temperature is 94°C, and the time is 10min; when fermenting, the temperature is lowered to 40°C, and the fermentation time is 12h.

[0068] When preparing fermented soybean milk: in the second step (2), the hot water temperature is 65°C; in the second step (3), hydration is 20min, the homogenization temperature is 60°C, and the homogenization pressure is 18Mpa; in the second step (5), Hot water temperature 30°C; in the fourth step, the total mass concentration of acid and buffer salt is 3%, pH 3.8; in the sixth step, homogeneous: preheat to 60°C, pressure 15Mpa, in the seventh step, pre-bar Sterilization: temperature 85°C, time 20s; in the ninth step, homogenization: preheat to 65°C,...

example 2

[0070] When preparing fermented soybean milk: when cooking, add 0.8g of sodium tripolyphosphate per kg of raw beans; soak for 10 hours; when beating, the temperature is 85°C, and the soybean-water ratio is 1:4; when homogenizing, the temperature is 23°C, The pressure is 20Mpa; when sterilizing, the temperature is 95°C and the time is 13min; when fermenting, the temperature is lowered to 43°C and the fermentation time is 14h.

[0071] When preparing fermented soybean milk: in the second step (2), the hot water temperature is 70°C; in the second step (3), hydration is 40min, the homogenization temperature is 63°C, and the homogenization pressure is 20Mpa; in the second step (5), Hot water temperature 35°C; in the fourth step, the total mass concentration of acid and buffer salt is 4%, pH 4.0; in the sixth step, homogenization: preheat to 63°C, pressure 20Mpa, in the seventh step, pre-bar Sterilization: temperature 85°C, time 15s; in the ninth step, homogenization: preheat to 70°...

example 3

[0073] When preparing fermented soybean milk: when cooking, add 1g of sodium tripolyphosphate per kg of raw beans; soak for 12 hours; 25Mpa; when sterilizing, the temperature is 96°C, and the time is 15min; when fermenting, the temperature is lowered to 45°C, and the fermentation time is 16h.

[0074] When preparing fermented soybean milk: in the second step (2), the hot water temperature is 75°C; in the second step (3), hydration is 60min, the homogenization temperature is 65°C, and the homogenization pressure is 22Mpa; in the second step (5), The temperature of hot water is 40°C; in the fourth step, the total mass concentration of acid and buffer salt is 5%, pH 4.5; in the sixth step, homogenization: preheating to 65°C, pressure 25Mpa, in the seventh step, pre-bar Sterilization: temperature 86°C, time 10s; in the ninth step, homogenization: preheat to 75°C, 25Mpa; in the tenth step, ultra-high temperature instantaneous sterilization: temperature 141°C, time 3s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com