Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

768results about How to "Reduce purification costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

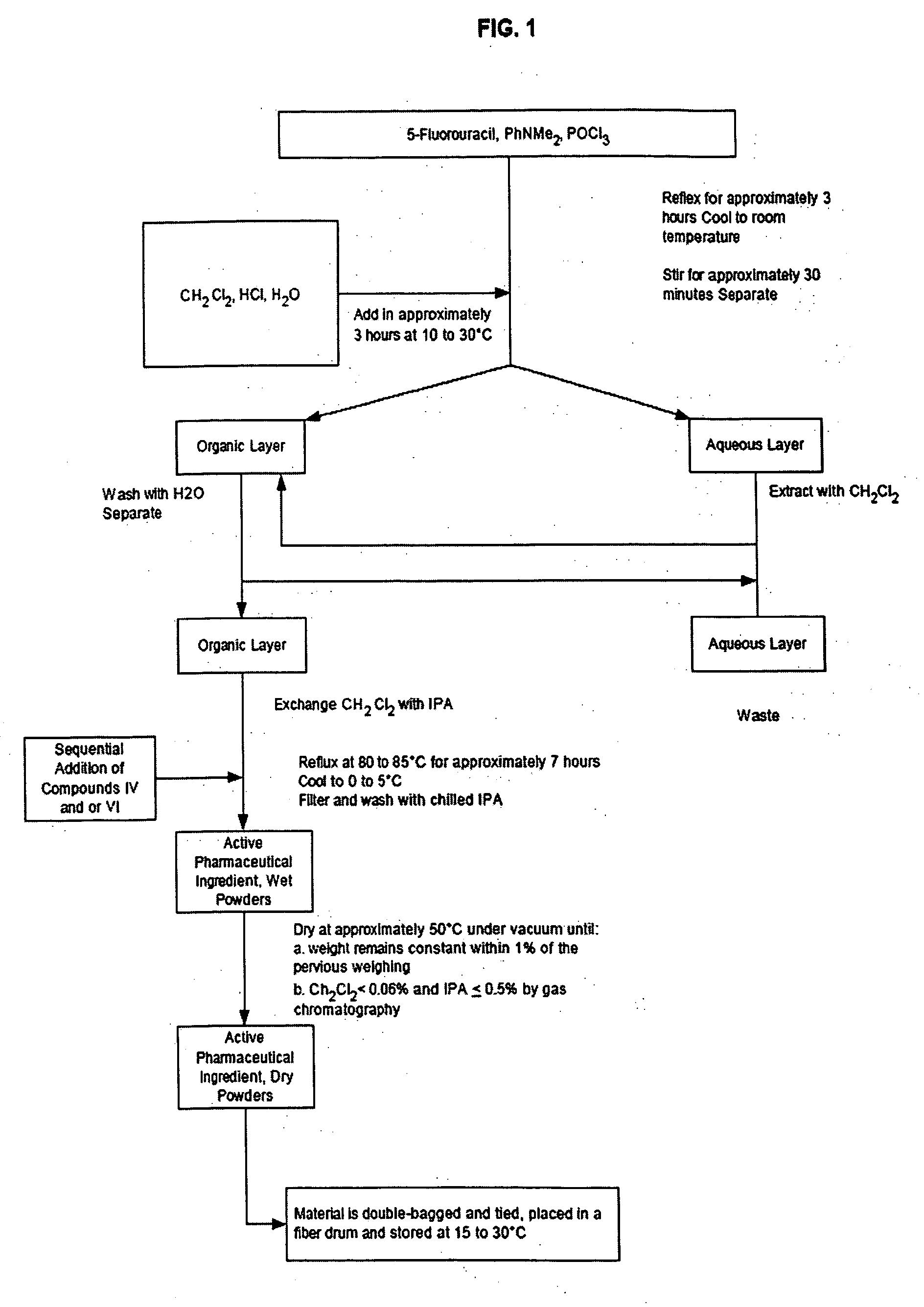

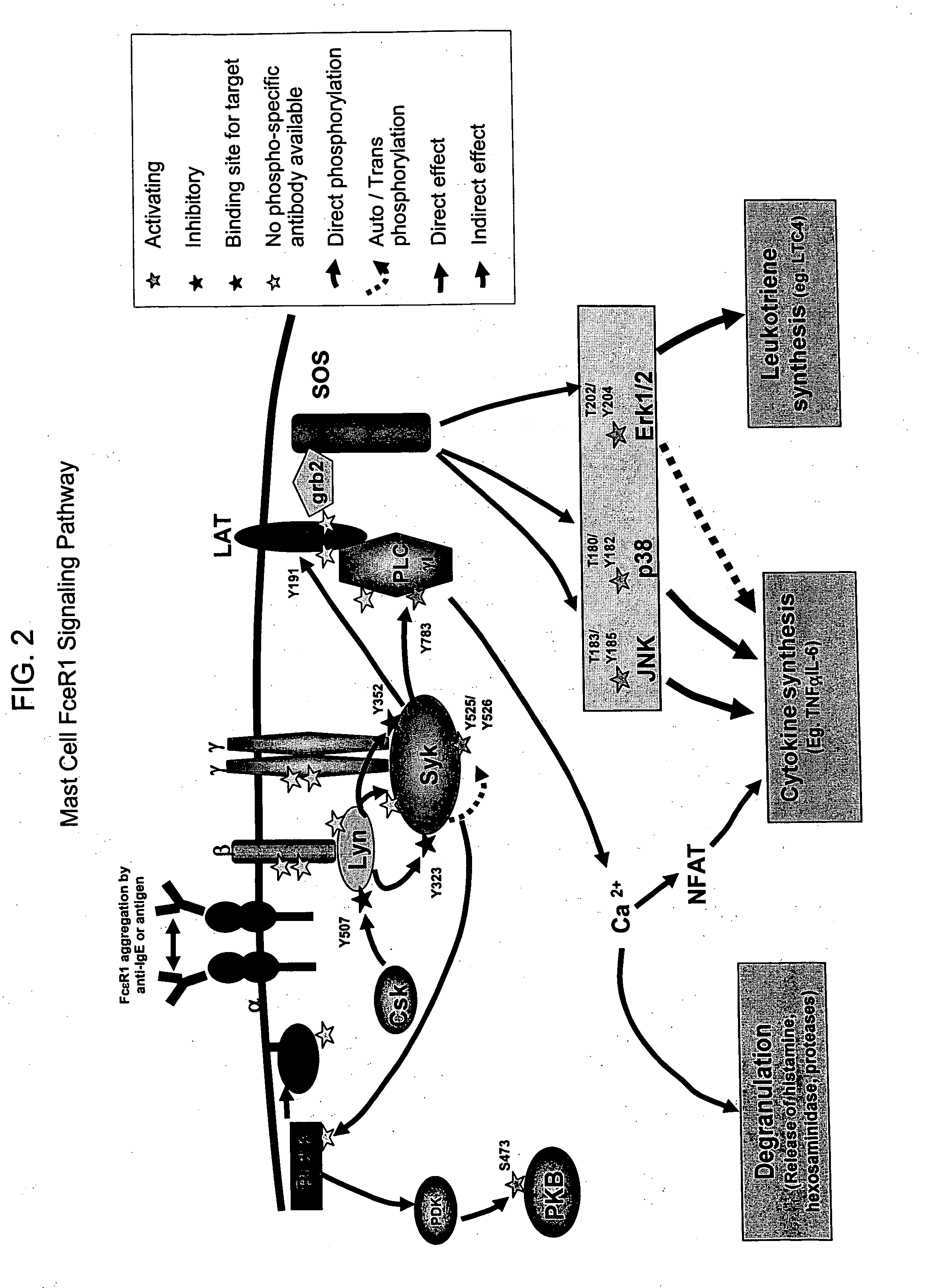

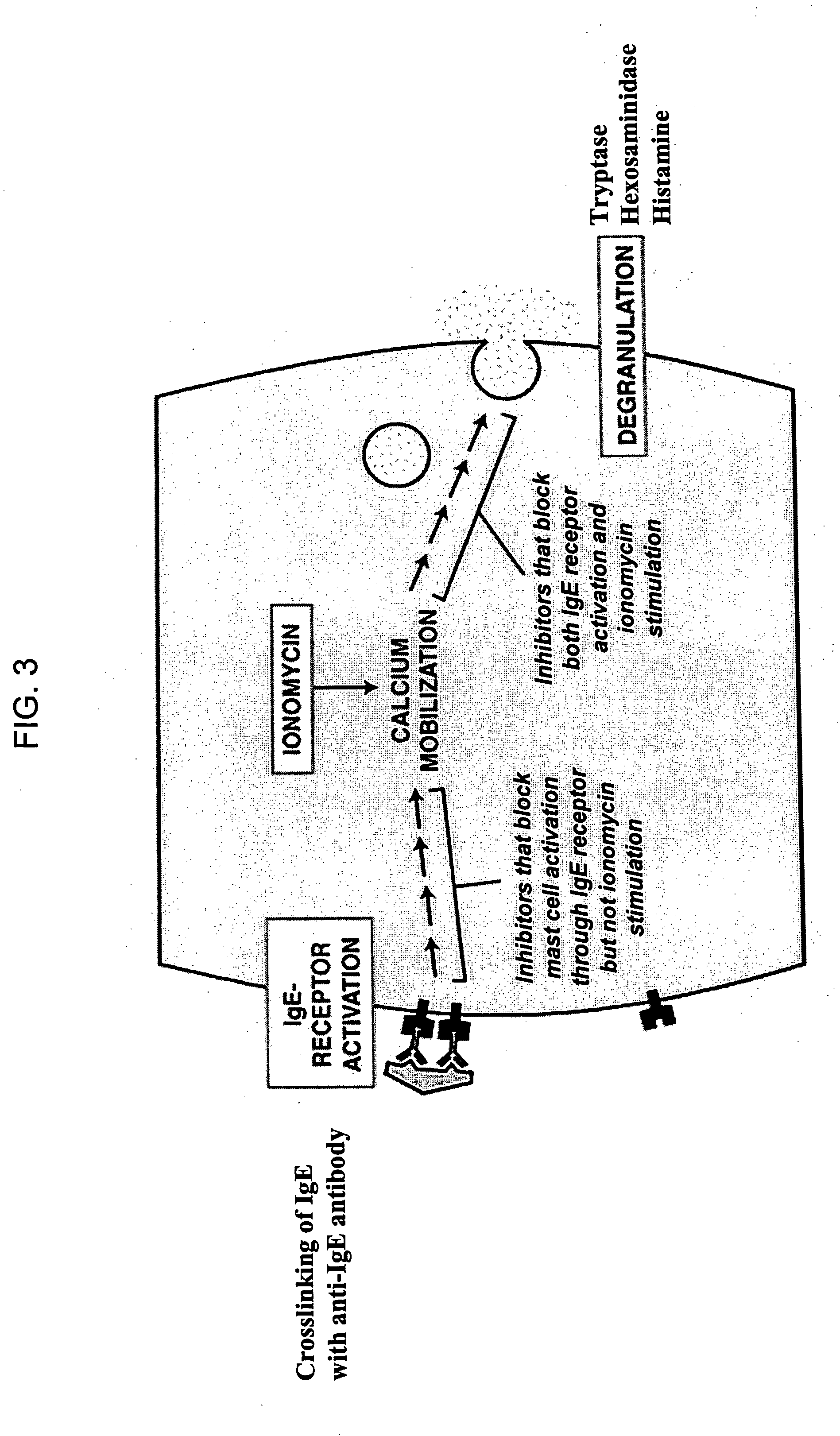

Synthesis of 2,4-pyrimidinediamine compounds

InactiveUS20060058525A1Reduce purification costsAvoids costly and inefficient purification procedureOrganic active ingredientsSenses disorderCombinatorial chemistry

Owner:RIGEL PHARMA

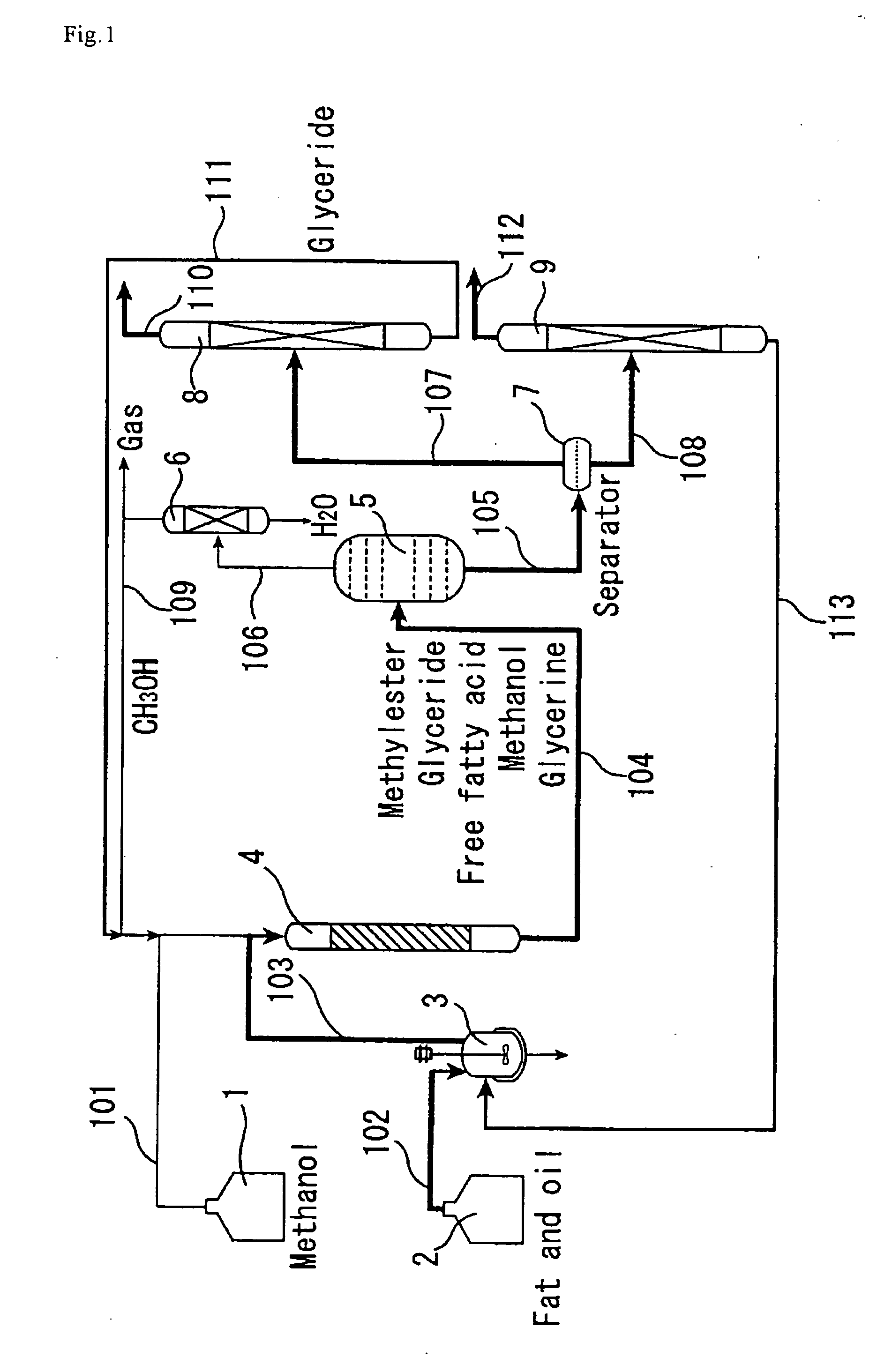

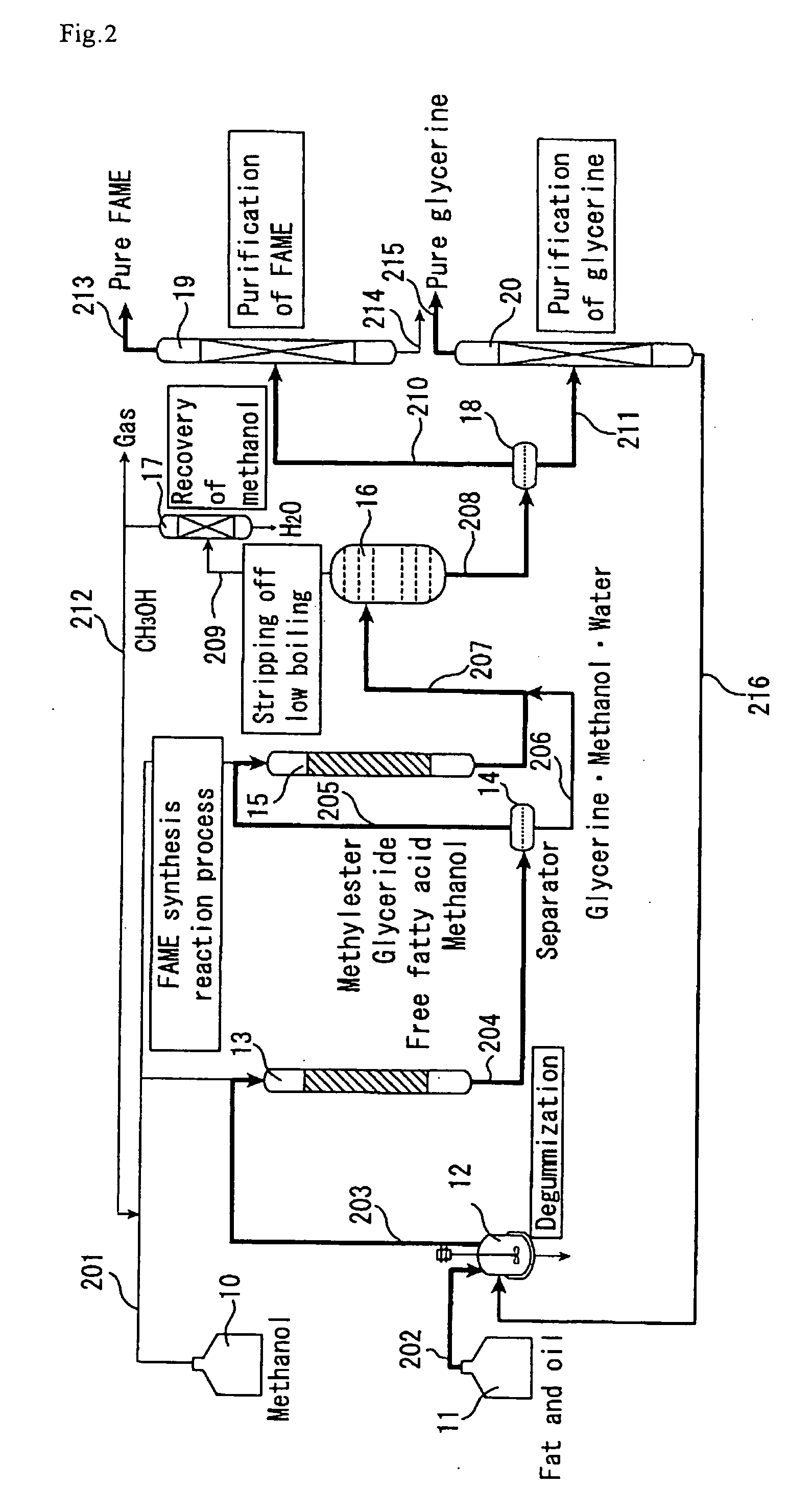

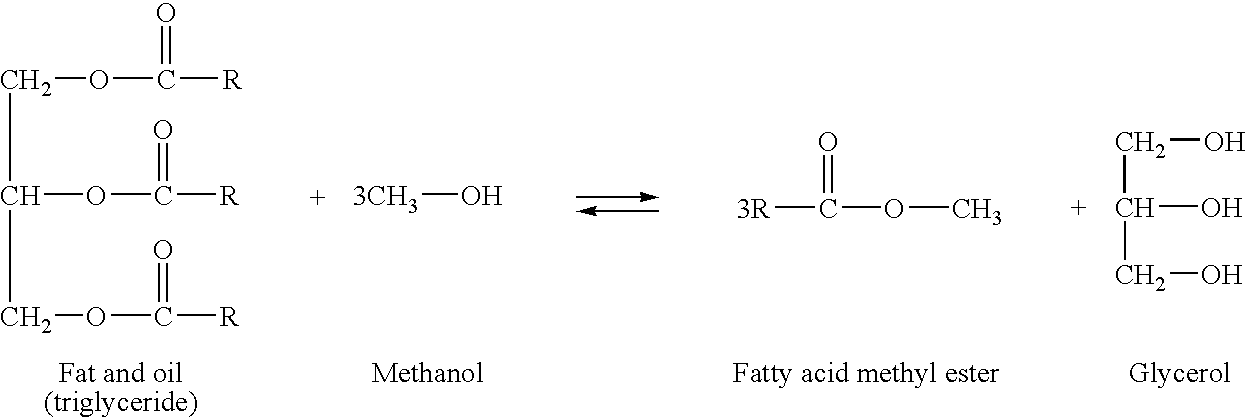

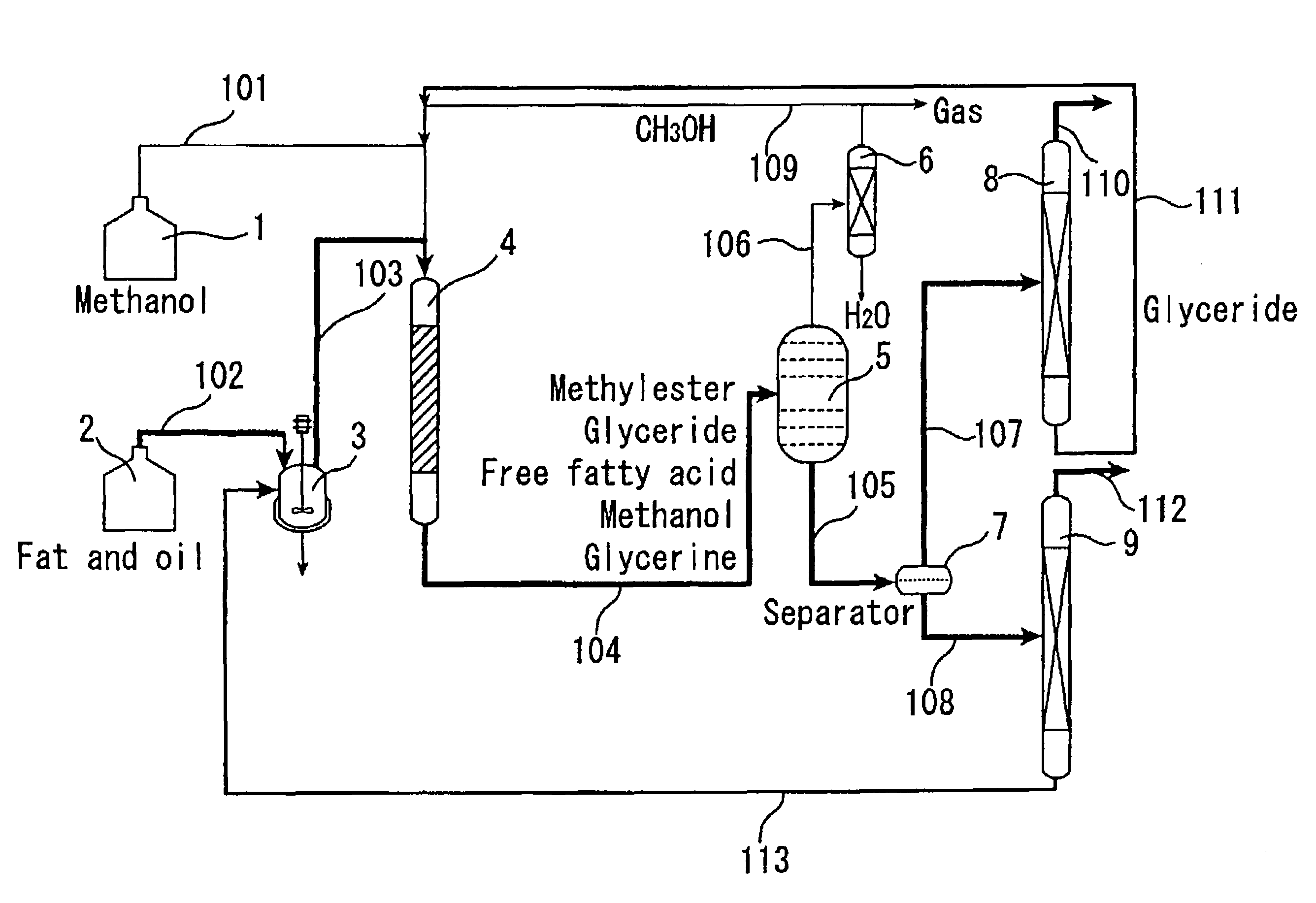

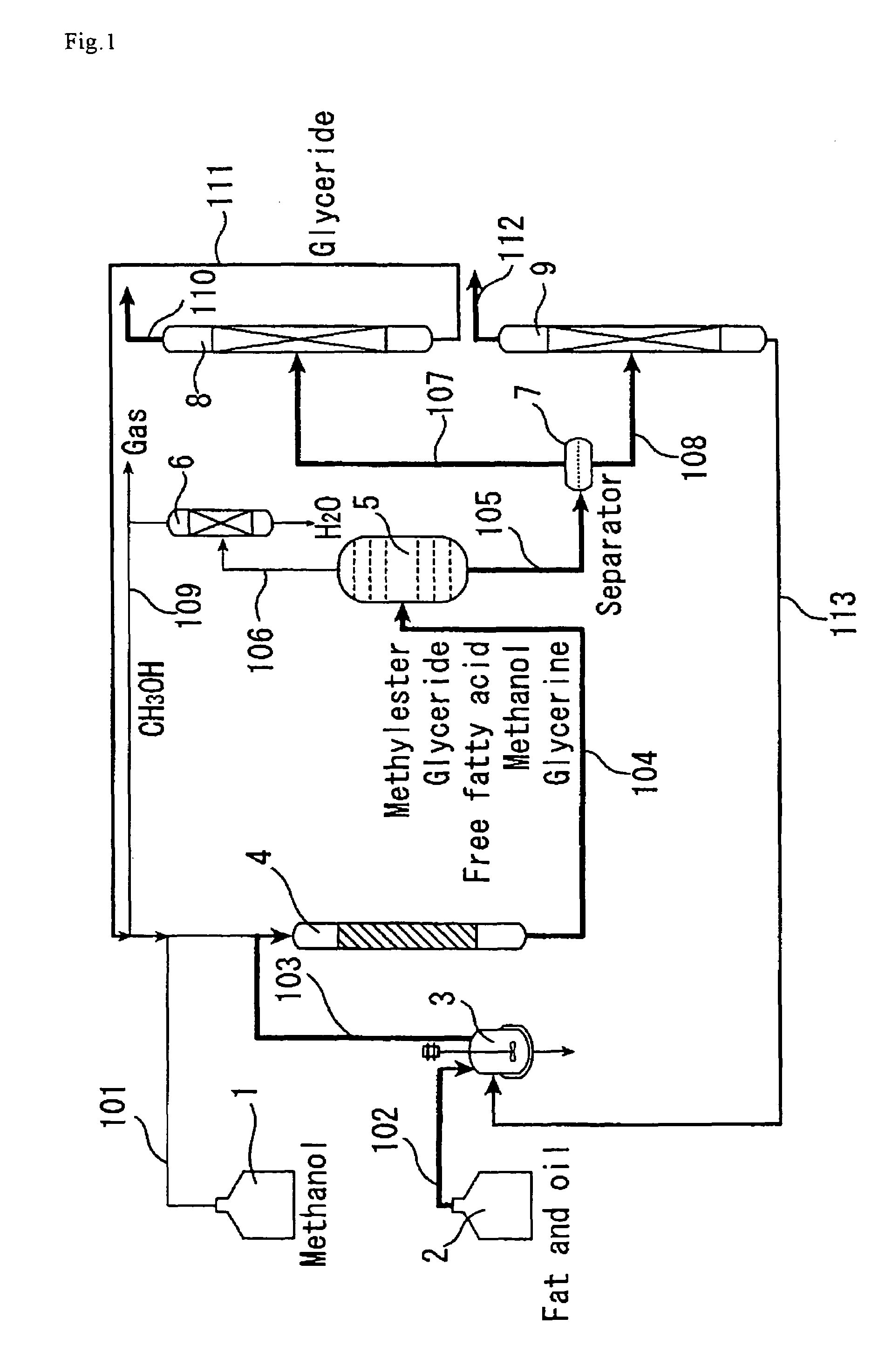

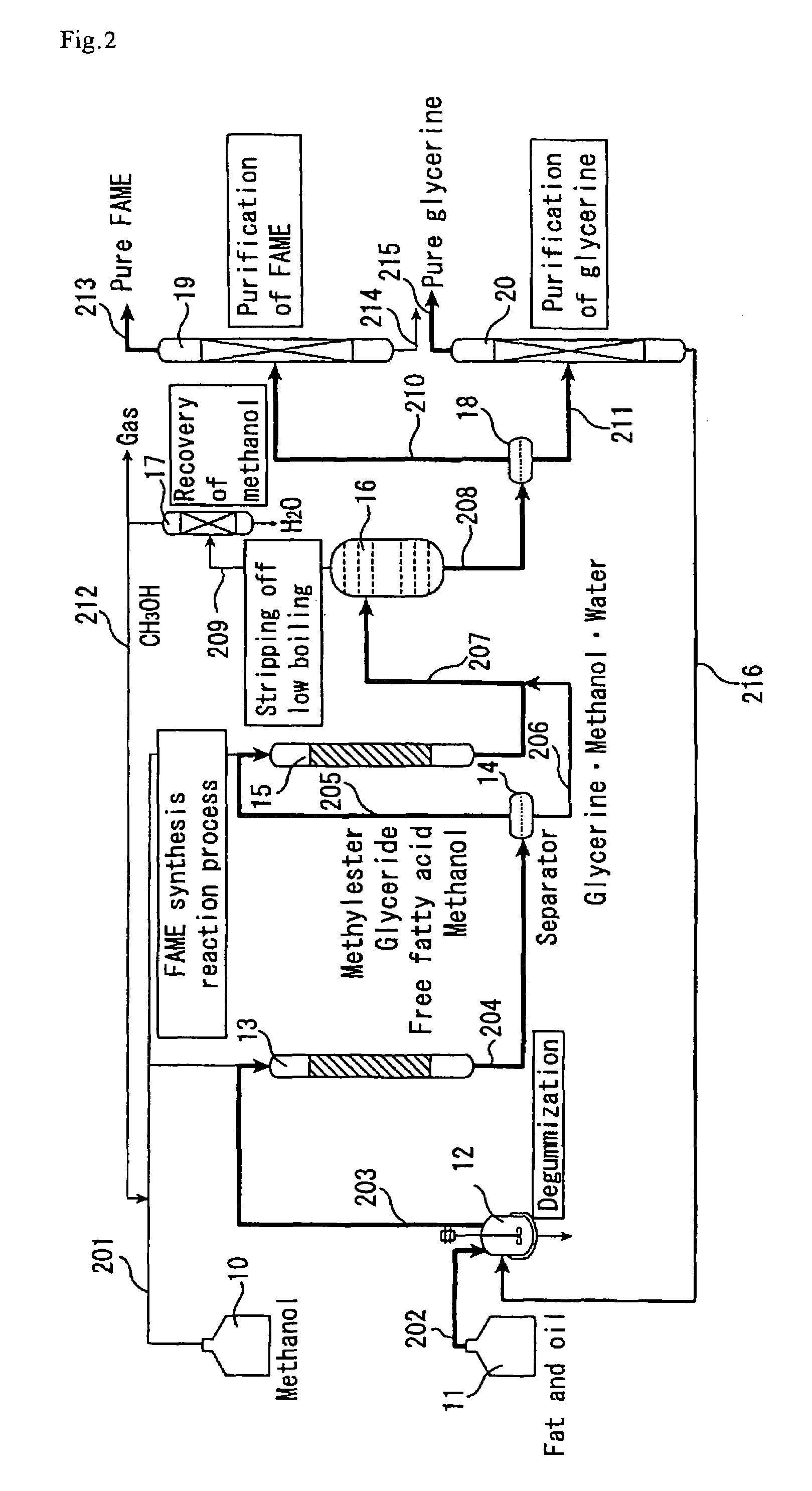

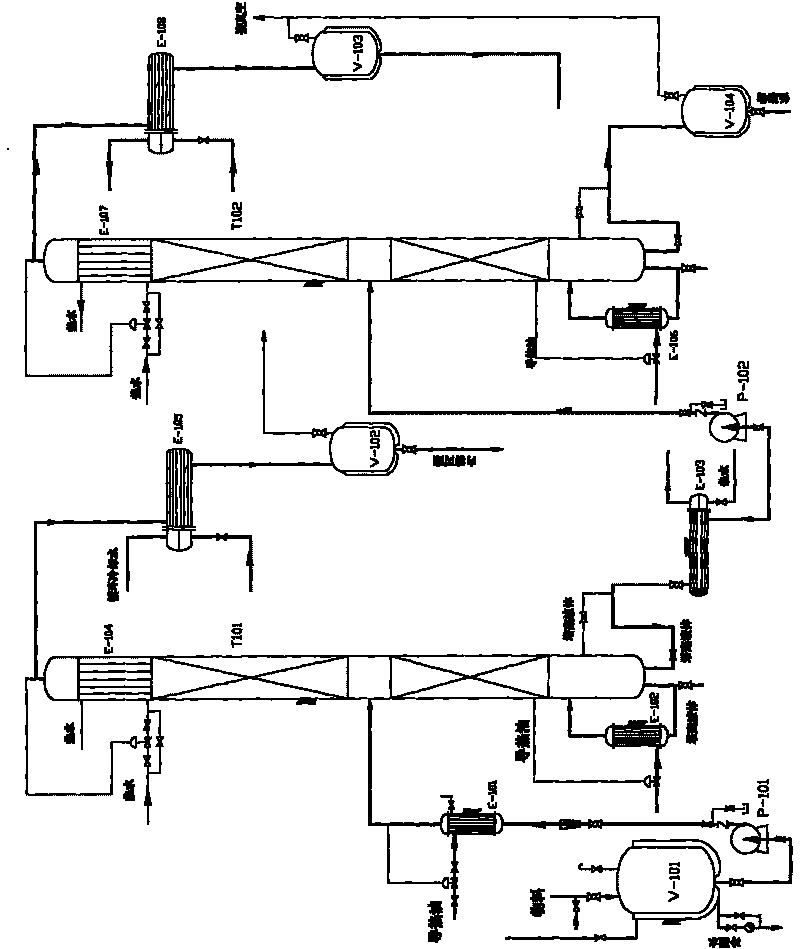

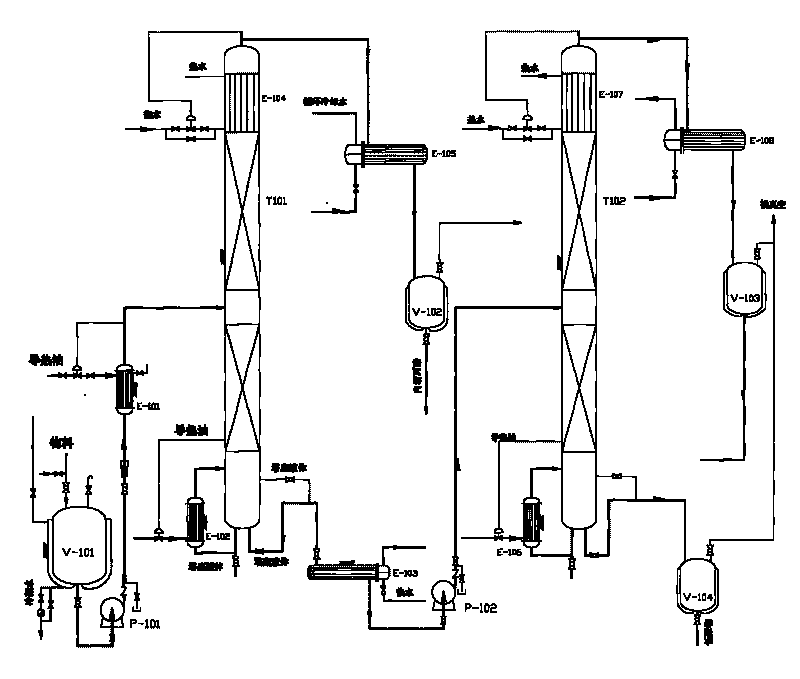

Method of production of fatty acid alkyl esters and/or glycerine and fatty acid alkyl ester-containing composition

InactiveUS20070167642A1Reduce energy consumptionIncrease contentFatty oils/acids recovery from wasteFatty acid esterificationBoiling pointGlycerol

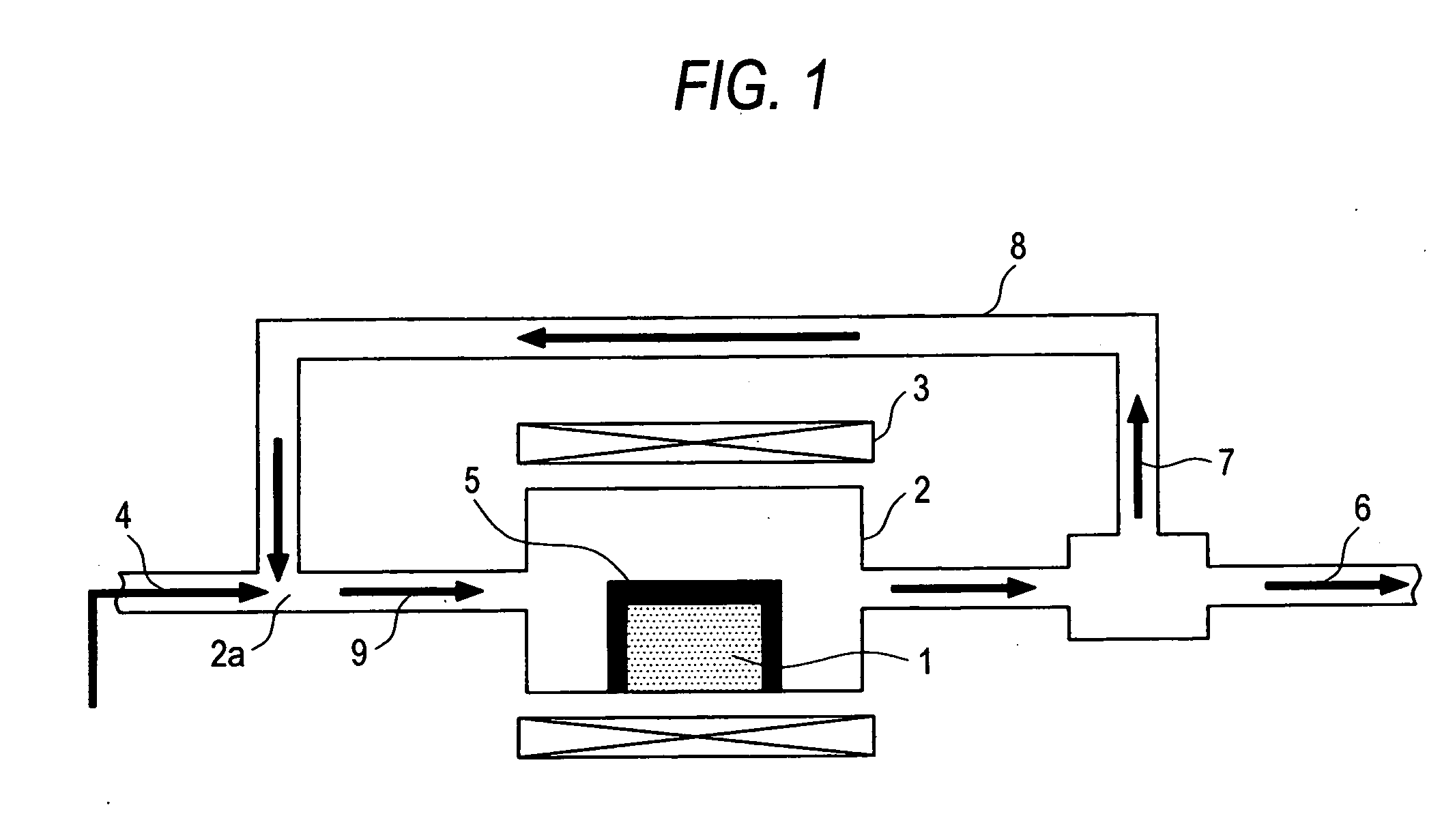

The method of producing fatty acid alkyl esters and / or glycerine of the present invention is a method of producing high-purity fatty acid alkyl esters and / or glycerine advantageously from the energy viewpoint while reducing the energy consumption of the production, and the products can be used in various fields of application, for example in biodiesel fuels, foods, cosmetics and pharmaceuticals. The above-mentioned method of producing fatty acid alkyl esters and / or glycerine by reacting a fat or oil with an alcohol using an insoluble solid catalyst in a reaction apparatus comprising at least one reactor, comprises (a) a step of obtaining low-boiling components removed liquid by removing low-boiling components or fraction from an effluent liquid of a reactor and (b) a step of separating the fatty acid alkyl esters and glycerine from the low-boiling components removed liquid, wherein an eluted active metal component of the insoluble solid catalyst in the effluent liquid of a reactor amounts to a level not higher than 1,000 ppm.

Owner:NIPPON SHOKUBAI CO LTD

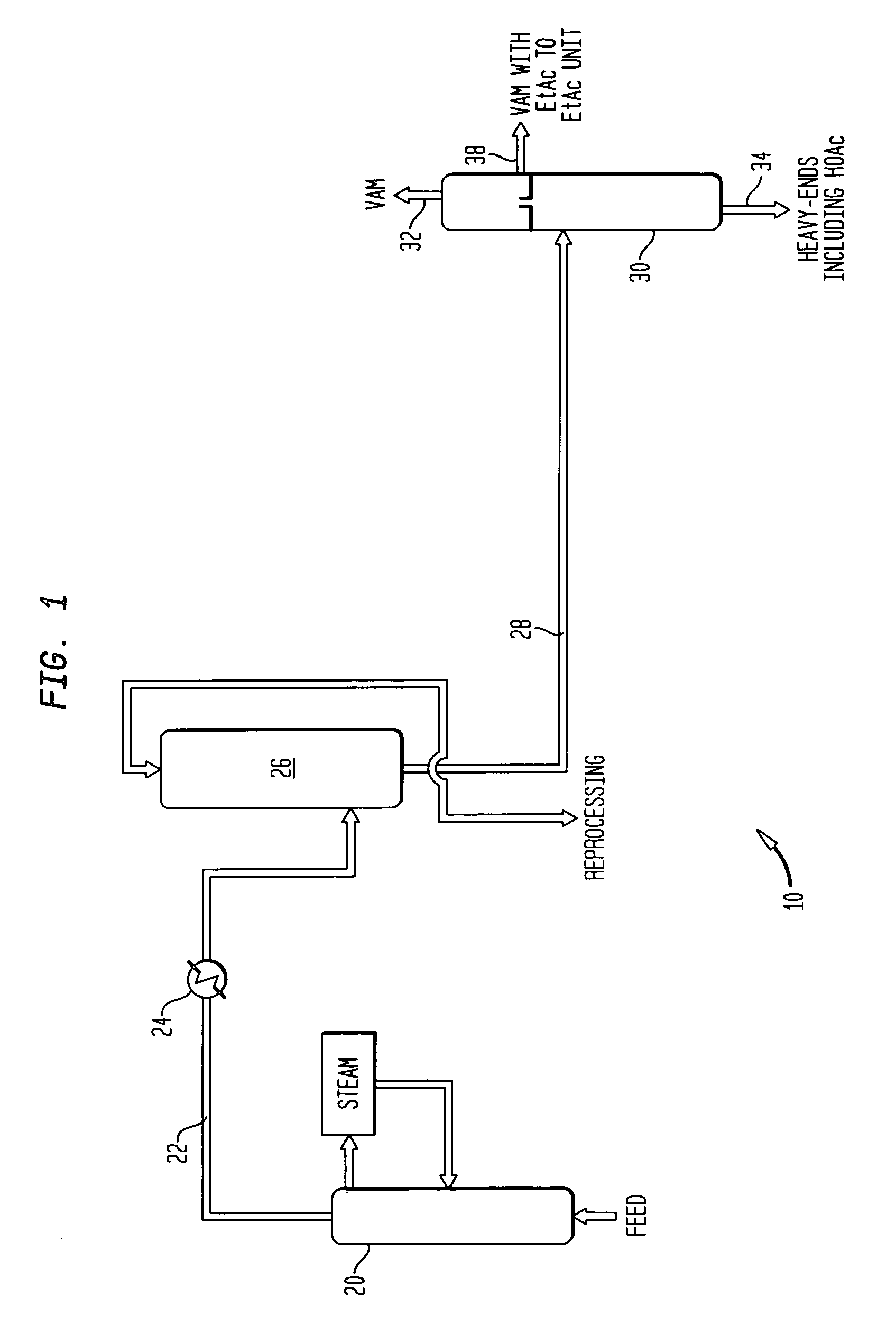

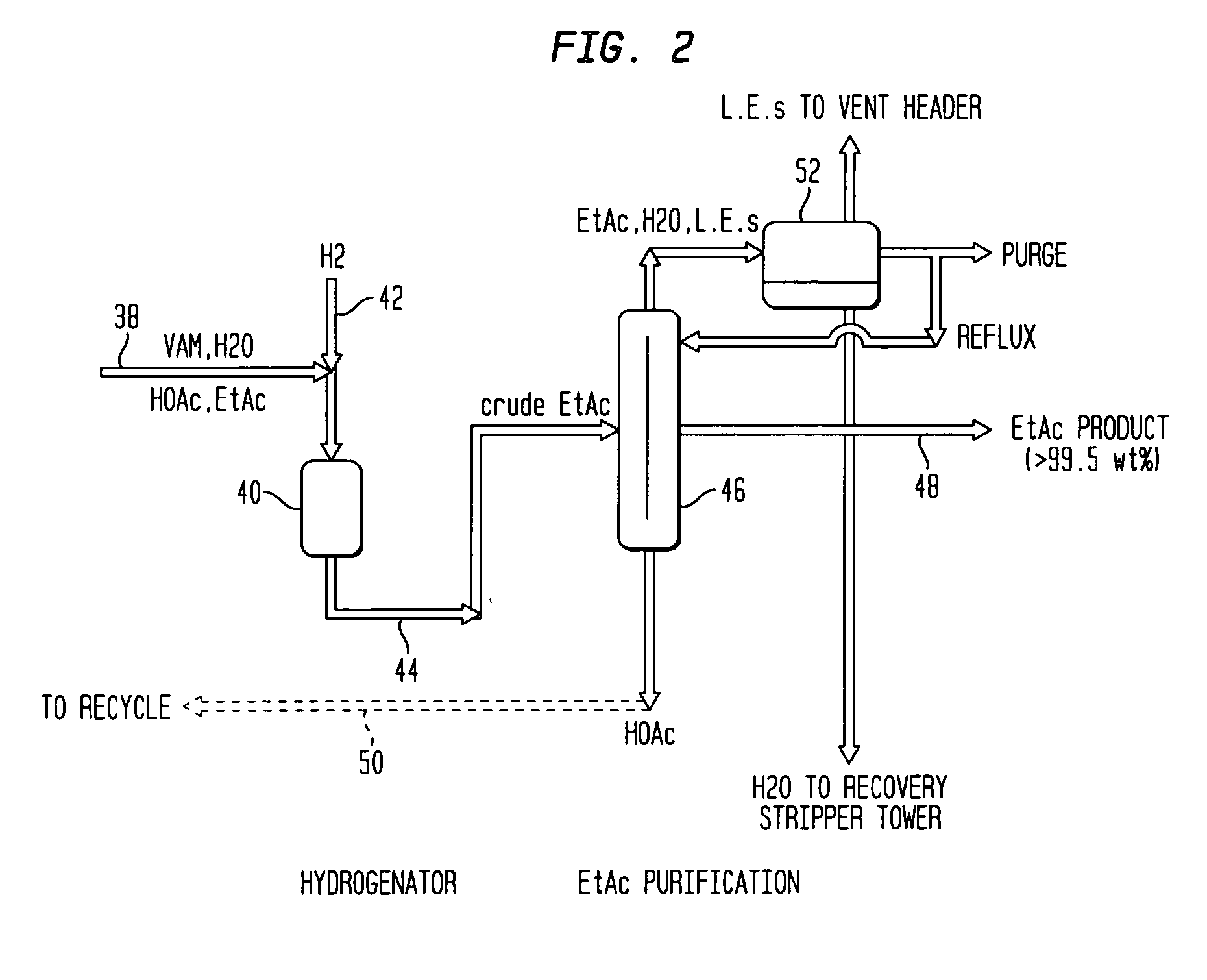

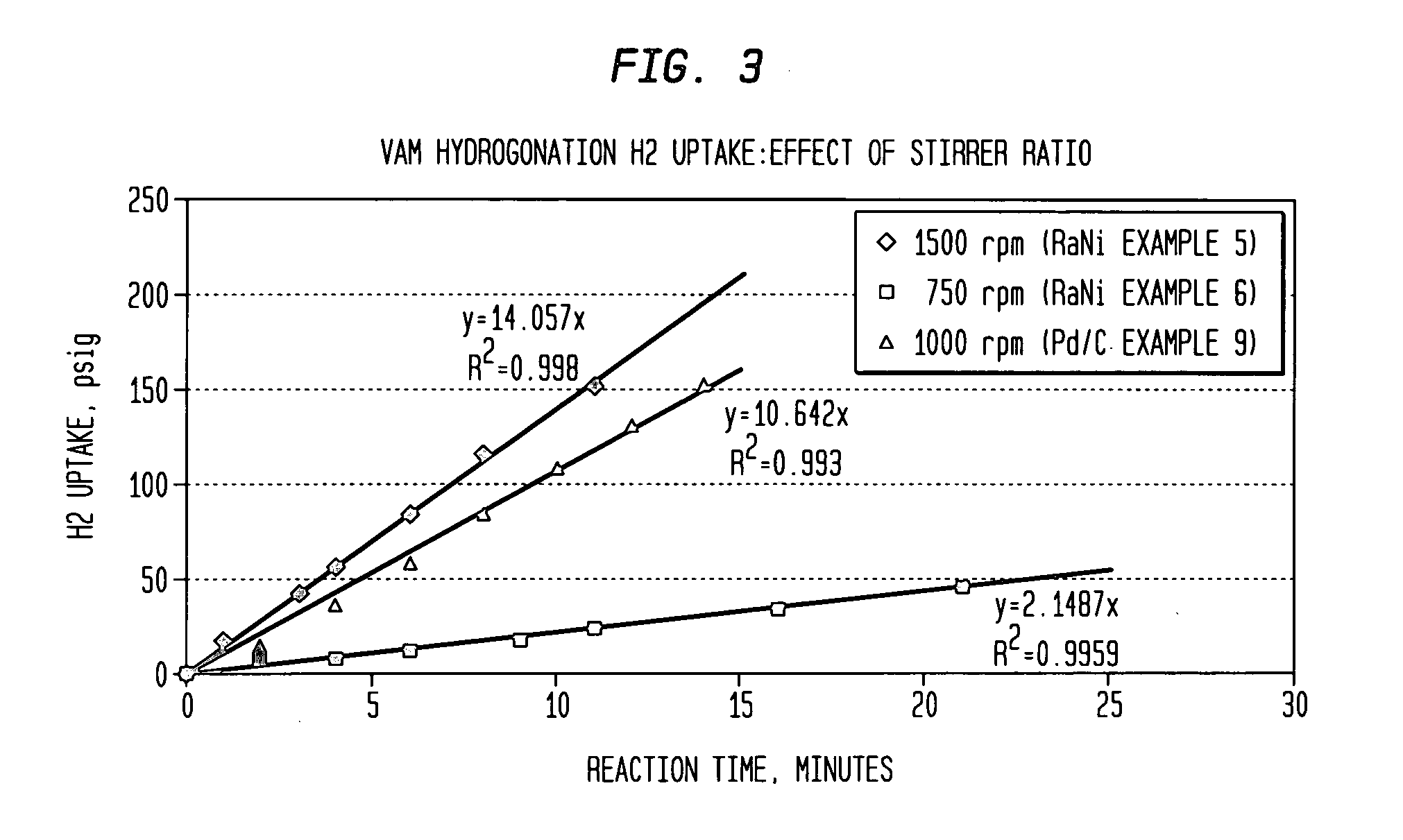

Co-production of vinyl acetate and ethyl acetate

InactiveUS20060106246A1Improve throughputReduce purification costsOrganic compound preparationCarboxylic acid esters preparationAcetic acidDistillation

A method of co-producing vinyl acetate and ethyl acetate includes: (a) reacting ethylene, acetic acid and oxygen to form vinyl acetate and at least a minor amount of ethyl acetate; (b) providing a crude product stream containing the vinyl acetate and ethyl acetate of step (a) and acetic acid to a distillation tower; (c) separating the crude product stream into: (i) a vinyl acetate product stream enriched in vinyl acetate with respect to the crude product stream; (ii) an acid recycle stream enriched in acetic acid with respect to the crude product stream; (iii) a mixed sidestream containing vinyl acetate and ethyl acetate, the mixed sidestream being enriched in ethyl acetate with respect to the vinyl acetate product stream; and (d) hydrogenating vinyl acetate in the mixed sidestream to provide an ethyl acetate product stream.

Owner:CELANESE INT CORP

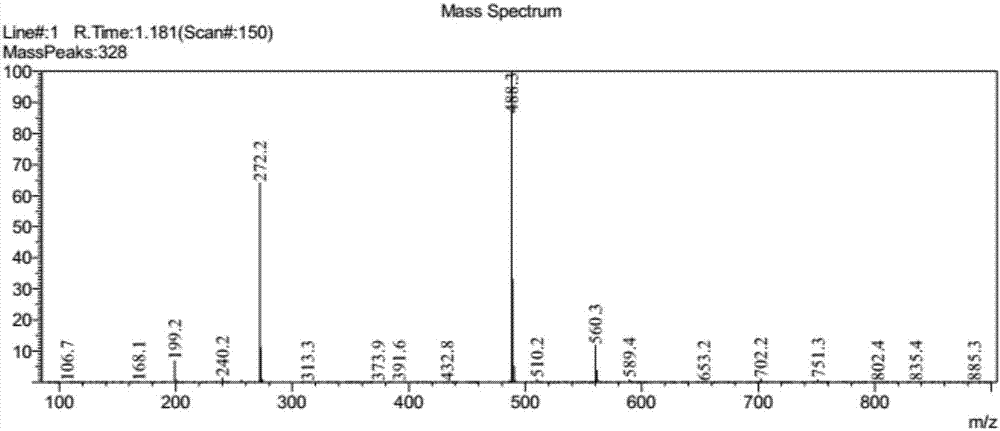

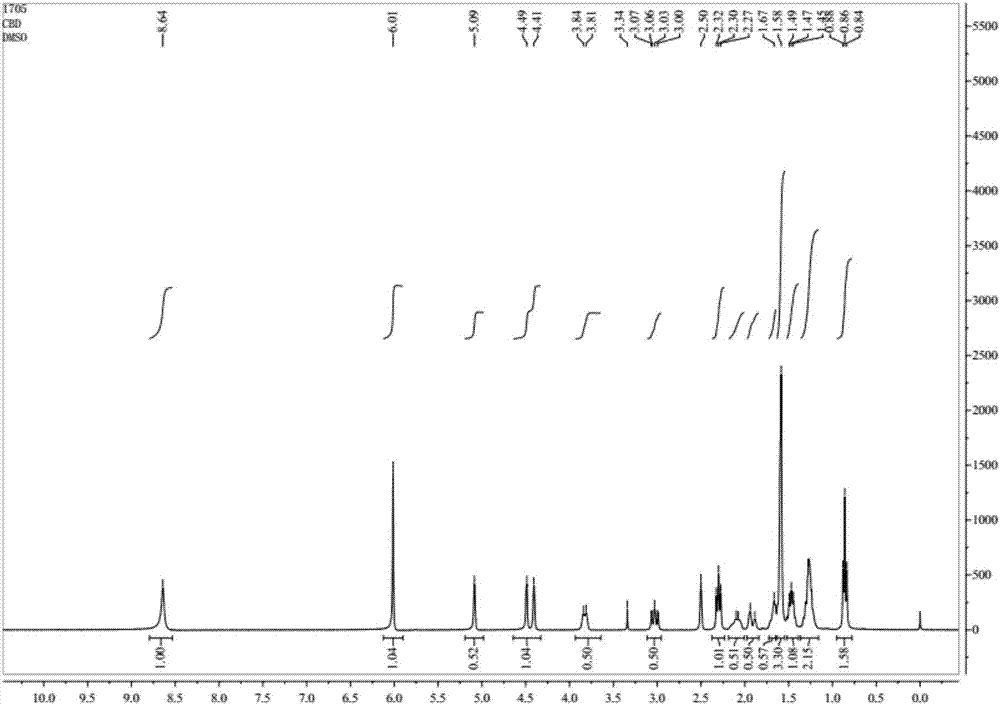

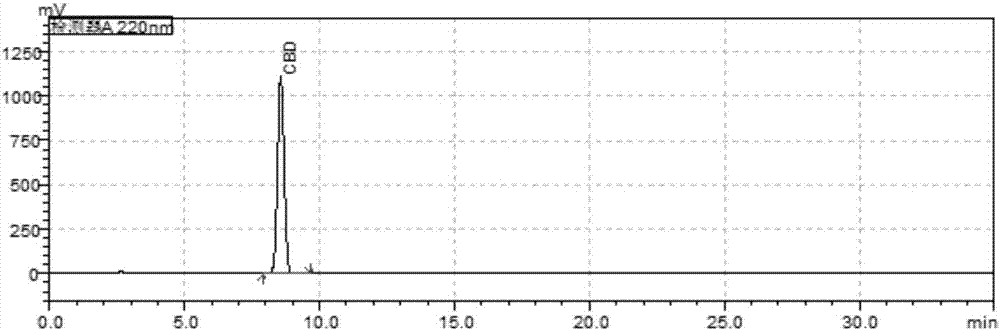

Method for extracting and purifying cannabidiol from China-hemp

ActiveCN107337586AImprove solubilityHigh extraction rateOrganic chemistryOrganic compound preparationOrganic solventElution

The invention belongs to the technical field of extraction and purification of plant ingredients and particularly relates to a method for extracting and purifying cannabidiol from China-hemp. In the method, an ingredient of cannabidiol is extracted from floral leaves in a mature period of the China-hemp according to a supercritical CO2 extraction technique, a cannabidiol extract is further purified by macroporous adsorbent resin and a rapid purification system, a cannabidiol content of an obtained product is 98% or higher, and the cannabidiol product does not contain a psychotoxic ingredient tetrahydrocannabinol. According to the method, a chemical organic solvent is not used in an extraction process, so that the method is environment-friendly and is low in toxicity and high in efficiency; the loss of cannabidiol in an adsorption elution process is reduced in a purification process, so that the impurity ingredients such as tetrahydrocannabinol and the like are effectively removed, and the use of an organic regent is decreased, so that the purification cost is lowered, and the environmental pollution is reduced. The product is high in yield and purity, and the requirement for development of a value-added product of the China-hemp, in particular to the market requirement of the active ingredient of the cannabidiol product in the China-hemp, can be met, and especially, the cannabidiol product has the great application advantage in the pharmaceutical field.

Owner:DAQING BRANCH OF HEILONGJIANG ACAD OF SCI

Method for preparing phosphoric acid and byproduct building brick by using phosphatic ore tailings after phosphate ore dressing

InactiveCN1837129AReduce consumptionReduce energy consumptionSolid waste managementPhosphoric acidBrickPhosphoric acid

The invention discloses a preparing phosphoric acid and by-product building brick method by debris with phosphor after phosphorus ore dressing ore, which comprises the following steps: adding in dinas rock powder, coking carbon powder (coal gangue powder), caoline to mix up; adding in water; ageing the mixture; modeling by vacuum extrusion machine or brick press; dipping after drying; putting mixture in kiln vehicle and entering tunnel oven; getting phosphor vapour and carbon monoxide after preheating and heating-up; getting concentrated phosphoric acid through hydrated tower; getting carrying brick production through heat transferring and cooling. The invention uses the mine and ore dressing fag-end to prepar acid and brick. We can use the ore when the P2O5 is not smaller than 6%.

Owner:HUBEI SANXIN PHOSPHORIC ACID

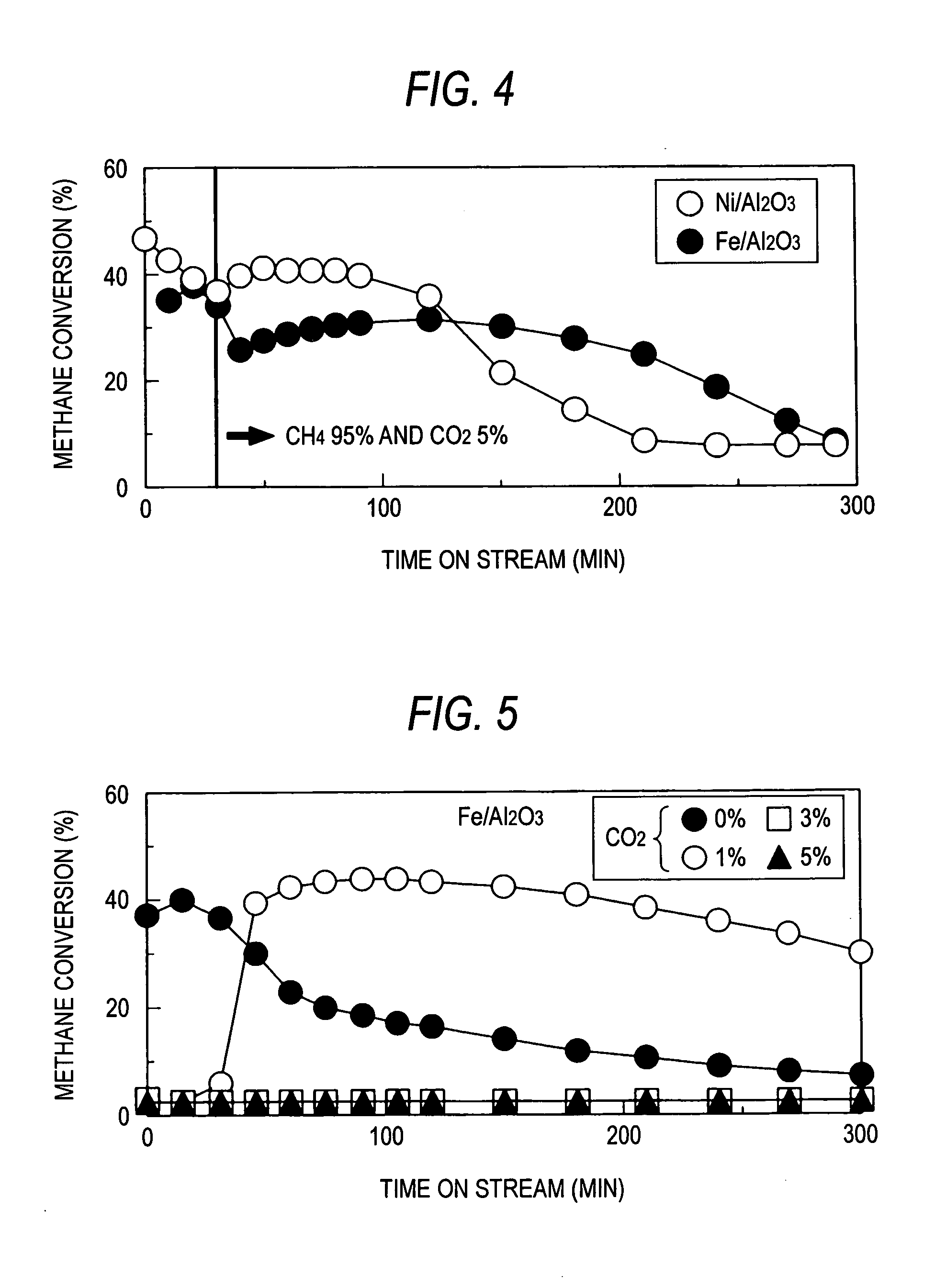

Method for producing functional nanocarbon and hydrogen by direct decomposition of lower hydrocarbon

ActiveUS20060257310A1Reduce conversionReduce purification costsMaterial nanotechnologyHydrogenHydrogenDecomposition

In a reaction where a lower hydrocarbon is subjected to direct decomposition by using a catalyst to produce a functional nanocarbon and hydrogen, the lower hydrocarbon is subjected to the reaction in an coexistent gas comprising low concentration of oxidizing gas, reducing gas or a mixture thereof. The precursor of functional nanocarbon produced on the catalyst and amorphous carbon secondarily produced on the catalyst react with the coexistent gas so that being removed from the catalyst, making it possible to prevent the drop of conversion with time on stream due to the inhibition of the reaction by the precursor and by-product. In the case where the raw material of lower hydrocarbon is biogas, the coexistent gas can be easily contained in methane by lowering purification degree of methane. Further, hydrogen can be obtained as one of decomposition products of lower hydrocarbon thus can be contained in methane during the reaction.

Owner:JAPAN STEEL WORKS LTD +1

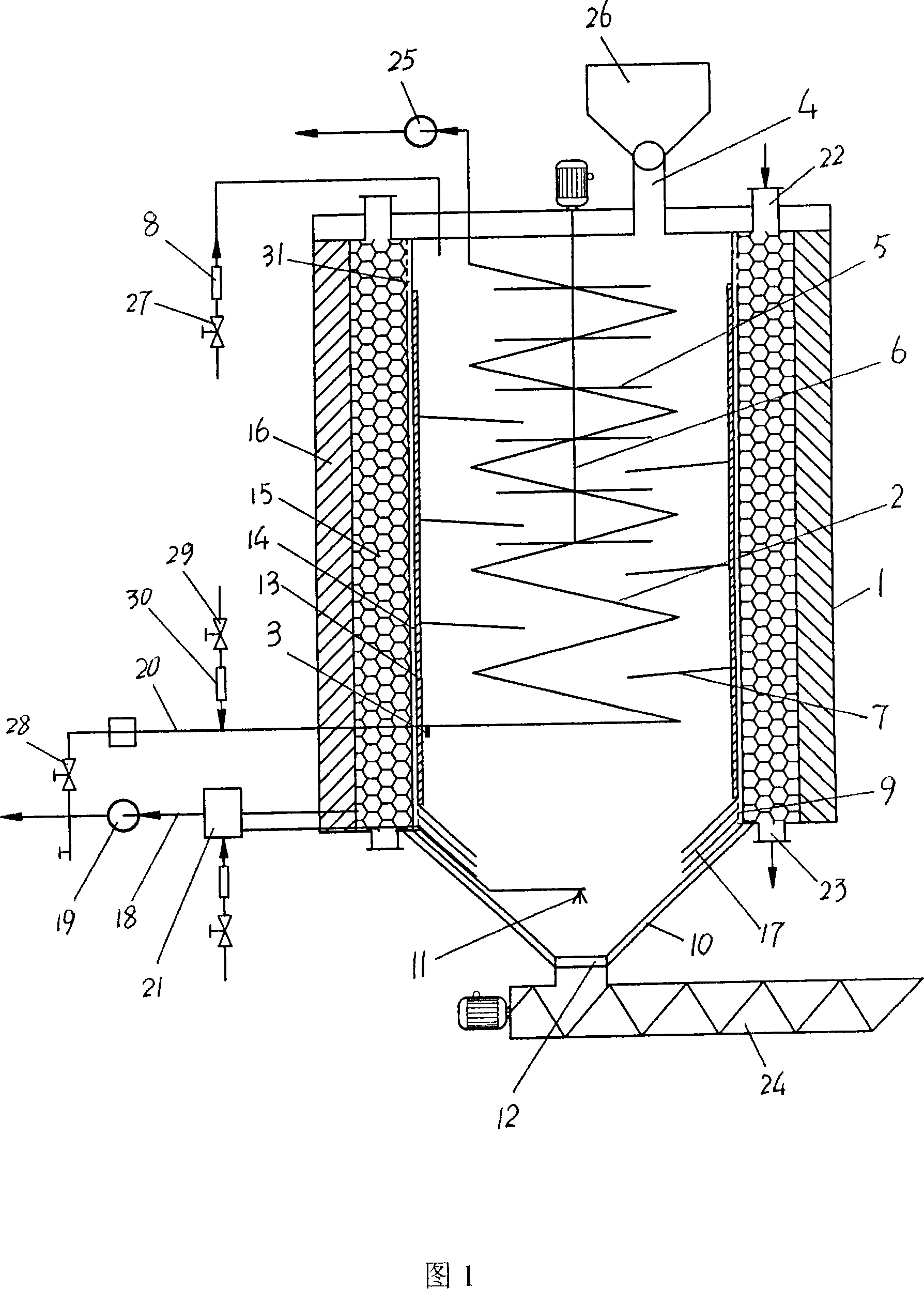

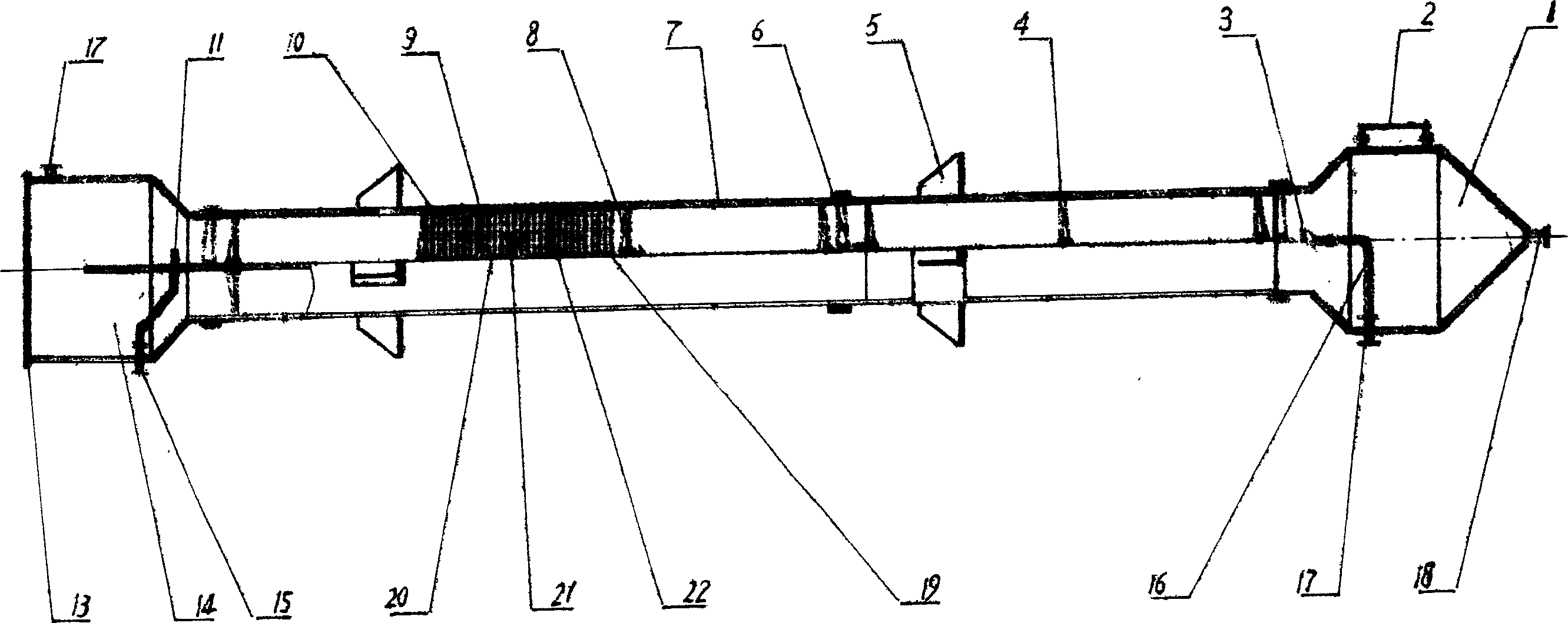

Internal-combustion heating type biomass gasification furnace

ActiveCN101021334AImprove biomass gasification rate and gas calorific valueImprove gasification efficiencyDomestic stoves or rangesLighting and heating apparatusNitrogen gasEngineering

The present invention relates to an internal combustion heated biomass gasification furnace. Its structure is characterized by that it adopts a cylindrical furnace body, in the furnace body interior a coiled internal combustion pipe is set, the internal combustion pipe inlet is positioned in the lower portion of said cylindrical furnace body, and its outlet is extended to the exterior of furnace body from the top portion of cylindrical furnace body, its igniter is positioned in the internal combustion pipe inlet; over the cylindrical furnace body a helical feeding mechanism is set, its helical feeding hole is positioned on the eccentric position of cylindrical furnace body top portion, on the centre axis position of said cylindrical furnace body a stirring shaft with stirring blades is set, on the inside wall of cylindrical furnace body several layers of baffle plates are set, the combustion-supporting air inlet is set in the top portion of said cylindrical furnace body, and the gas outlet in the furnace body is positioned in the lower portion of said furnace body.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

Method of production of fatty acid alkyl esters and/or glycerine and fatty acid alkyl ester-containing composition

InactiveUS7605281B2Reduce energy consumptionIncrease contentFatty oils/acids recovery from wasteFatty acid esterificationBiodieselAlcohol

The method of producing fatty acid alkyl esters and / or glycerine of the present invention is a method of producing high-purity fatty acid alkyl esters and / or glycerine advantageously from the energy viewpoint while reducing the energy consumption of the production, and the products can be used in various fields of application, for example in biodiesel fuels, foods, cosmetics and pharmaceuticals.The above-mentioned method of producing fatty acid alkyl esters and / or glycerine by reacting a fat or oil with an alcohol using an insoluble solid catalyst in a reaction apparatus comprising at least one reactor, comprises (a) a step of obtaining low-boiling components removed liquid by removing low-boiling components or fraction from an effluent liquid of a reactor and (b) a step of separating the fatty acid alkyl esters and glycerine from the low-boiling components removed liquid, wherein an eluted active metal component of the insoluble solid catalyst in the effluent liquid of a reactor amounts to a level not higher than 1,000 ppm.

Owner:NIPPON SHOKUBAI CO LTD

Method for industrial hydrochloric acid purification by liquid extraction

InactiveCN101041421AReduce pollutionRealize automatic controlChlorine/hydrogen-chloride purificationKeroseneDiluent

The invention discloses a method of extractive purifying industrial alcaine, which comprises the following steps: setting triallylamine as extractant, isooctanol as assisting solvent and coal oil as diluent; forming extract organic phase through kerosene; extracting industrial alcaine in the extract pot; washing through pure water; stripping; getting high-purity alcaine. The invention possesses steady quality and high-purity, which can realize continuous mass production.

Owner:广东省富远稀土有限公司

Culturing method of biological flocculation for aquiculture

ActiveCN102515339AReasonable nutritional composition of flocsSimple methodAnimal feeding stuffBiological water/sewage treatmentBiotechnologyFlocculation

The invention discloses a culturing method of a biological flocculation for aquiculture, comprising the following steps of: (1) extracting culturing water to a culturing unit; (2) additionally providing a carbon source or / and a nitrogen source for the culturing unit so that the total carbon content in water is 5.5-45mg / L, the total nitrogen content is 0.55-2.25mg / L and the ratio of carbon to nitrogen is (10-20):1; (3) placing cultured fishes into the culturing unit, wherein the released density is 5-30kg / m<3>; and (4) collecting flocculation when the total suspended solid (TSS) content of the water in the culturing unit is up to 100-500mg / L. The biological flocculation cultured by using the method provided by the invention is reasonable in nutritional composition, can be used as bait of aquatic animals and is simple in method, low in cost and suitable for popularization and use.

Owner:PEARL RIVER FISHERY RES INST CHINESE ACAD OF FISHERY SCI

High-efficiency composite desulphurization solvent and system and method for removing acidic gas and organic sulfur

InactiveCN105126576AHigh acid gas loadNon-corrosiveDispersed particle separationAir quality improvementSolventHeterocyclic amine

The invention discloses a high-efficiency composite desulphurization solvent and a system and method for removing acidic gas and organic sulfur. The high-efficiency composite desulphurization solvent comprises, by mass, 70-85% of compound amine, 10-20% of a desulfurization enhancer, 10-30% of a physical solvent, 0.01-0.1% of an antifoaming agent, 0.5-2% of a benzylamine anti-oxidant and 0.5-2% of a heterocyclic amine antiseptic. The high-efficiency composite desulphurization solvent has the advantages of large acidic gas load, low sulfur content of purified gas, stable solvent performances and no corrosion on equipment, and can remove most of H2S and a large part of organic mercaptan from mixed gas. The high-efficiency composite desulphurization solvent and the system and method can greatly reduce a gas purification cost and reduce total sulfur content of the purified gas. The high-efficiency composite desulphurization solvent and the system and method can be used for removing H2S, CO2 and organic mercaptan in natural gas, petroleum refinery gas and synthetic gas.

Owner:CHINA GASOLINEEUM ENG +1

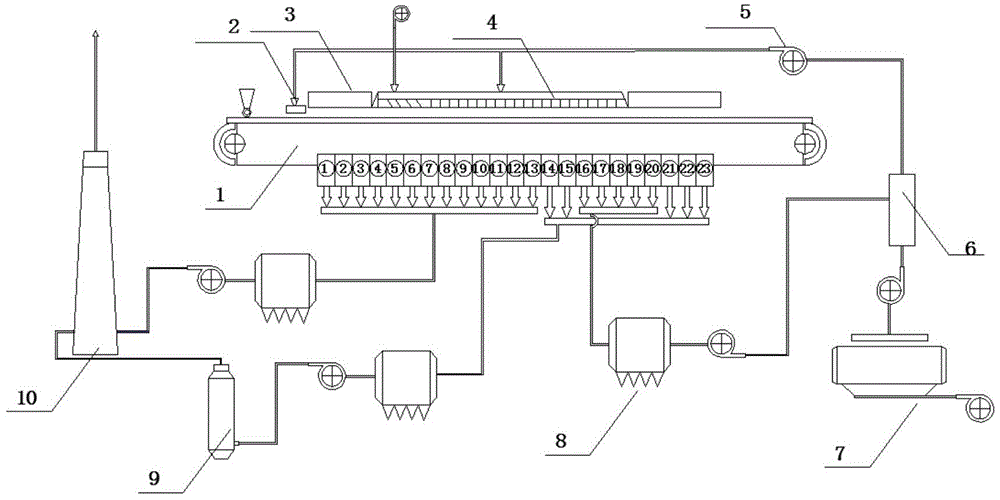

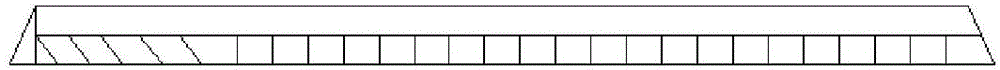

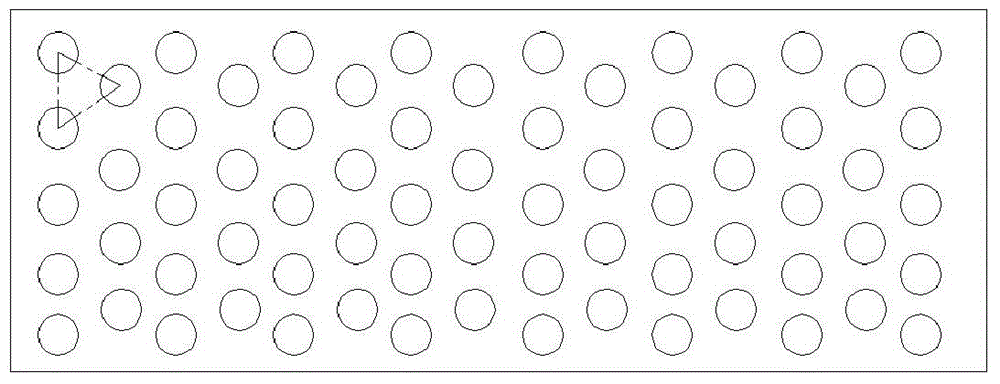

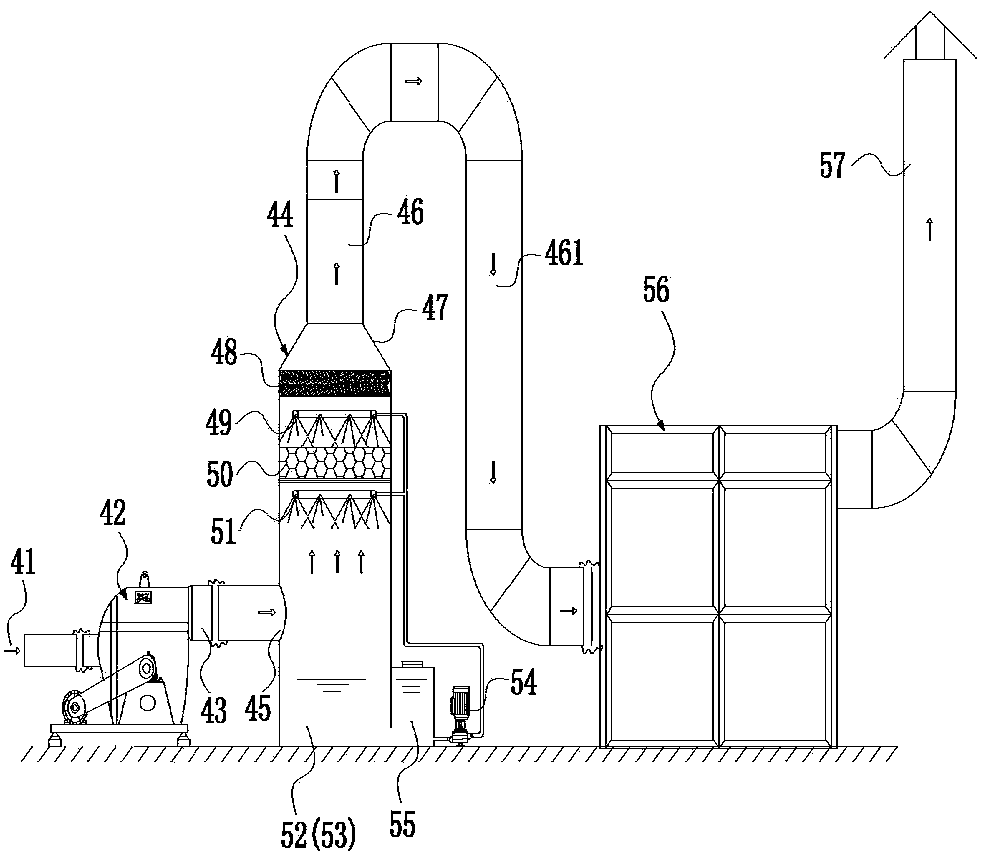

Energy-saving environment-friendly sintering waste gas waste-heat utilization and pollutant purification process and system

InactiveCN104132550AReduce purification costsEmission reductionCombustion technology mitigationWaste heat treatmentSulfurDecomposition

The invention relates to an energy-saving environment-friendly sintering waste gas waste-heat utilization and pollutant purification process and system. The energy-saving environment-friendly waste gas waste-heat utilization and pollutant purification process includes that sintering waste gas is divided into a low-temperature low-sulfur sintering waste gas, a middle-temperature high-sulfur sintering waste gas and a high-temperature middle-sulfur sintering waste gas according to waste gas temperature and pollutant discharge characteristics; content of sintering waste gas SO2 of the low-temperature low-sulfur is below the national discharge standard, and the SO2 can be directly discharged after dust removal; after the sintering waste gas in a middle-temperature high-sulfur section is subjected to dust removal and desulfurization processing, the SO2 meets the national discharge standard and can be discharged; the sintering waste gas in a high-temperature middle-sulfur section mixed with ring-cold waste gas is led into a sintering machine, and hot-wind igniting and hot-wind sintering are performed. The invention further provides a system for implementing the energy-saving environment-friendly sintering waste gas waste-heat utilization and pollutant purification process. Waste heat of the sintering waste gas can be recycled in classification and gradiently utilized, so that energy can be saved; the low-sulfur waste gas can be discharged directly, so that desulfurization cost of the waste gas is lowered; part of the high-sulfur waste gas participate in circulation, so that total discharge amount of pollutants is decreased, splitting decomposition of dioxin happens due to high temperature, and the purification function of the sintering waste gas is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

VOC (volatile organic compound) waste gas treatment system

ActiveCN104028086AEasy to handleImprove efficiencyCombination devicesUsing liquid separation agentActivated carbonEnvironmental engineering

The invention discloses a VOC (volatile organic compound) waste gas treatment system. The VOC waste gas treatment system sequentially comprises a fan, a padding spray tower device, an ultraviolet activated carbon integrated device and a purified gas discharge opening, wherein the fan is connected with a VOC waste gas source; the padding spray tower device is connected with an air outlet of the fan; the ultraviolet activated carbon integrated device is connected to an air outlet of the padding spray tower device; the purified gas discharge opening is connected to the ultraviolet activated carbon integrated device. Waste gas is treated efficiently by the design of combining the padding spray tower with the ultraviolet activated carbon integrated purifier. Firstly, the padding spray tower is used for spraying washing; organic waste gas is dissolved into a purifying liquid well by multi-surface hollow spheres; then air water of a defogging layer is matched to share efficiently, so that gas after primary treatment is obtained by the padding spray tower. The gas after primary treatment is treated by the ultraviolet activated carbon integrated purifier, and clean gas reaching the standard is discharged out. The size of the device is reduced; the waste gas treatment efficiency is high; the purification cost is reduced; the purification standard reaching effect is ensured.

Owner:DONGGUAN CITY HUANSHUN ENVIRONMENTAL PROTECTION EQUIP IND

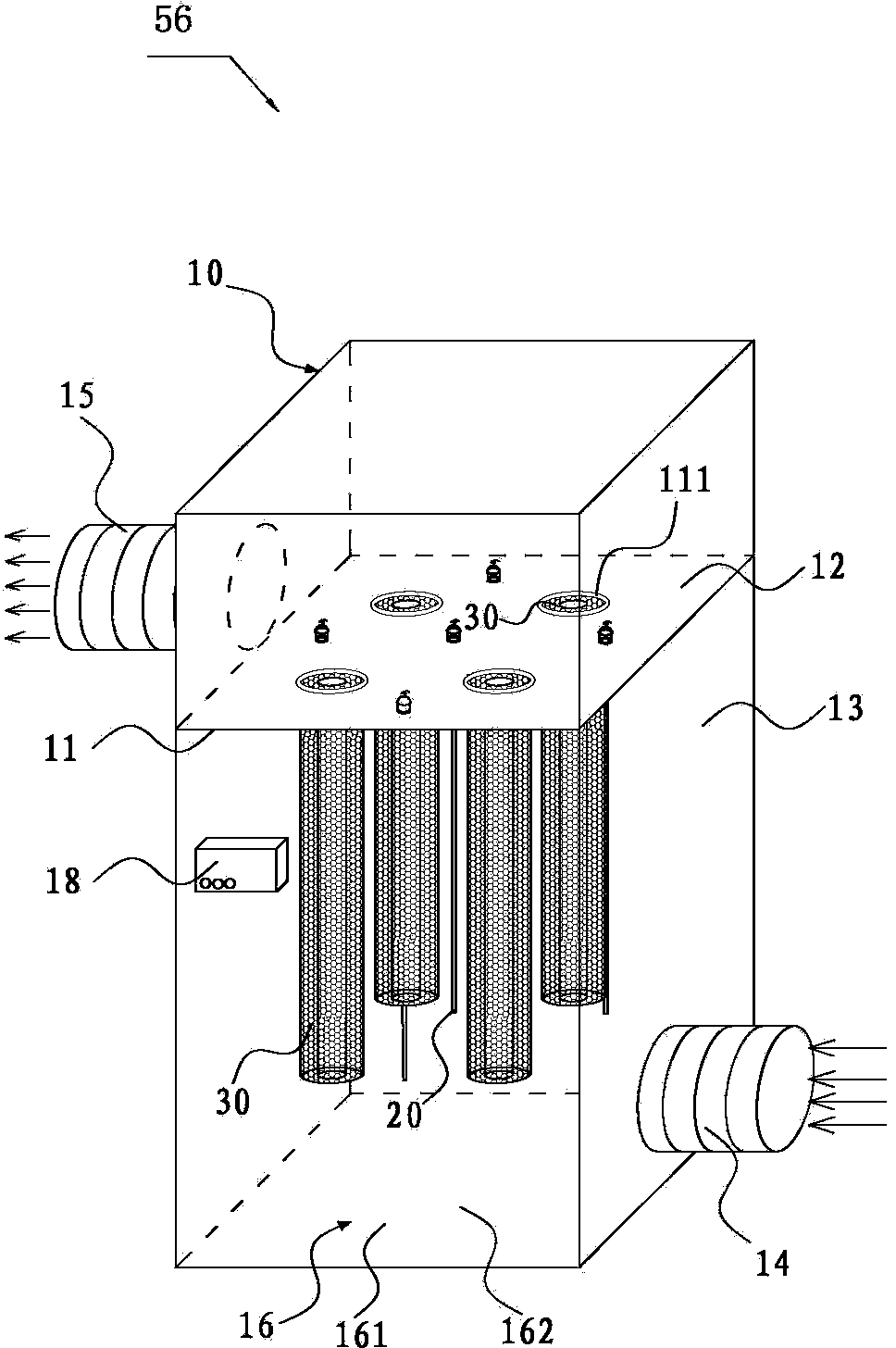

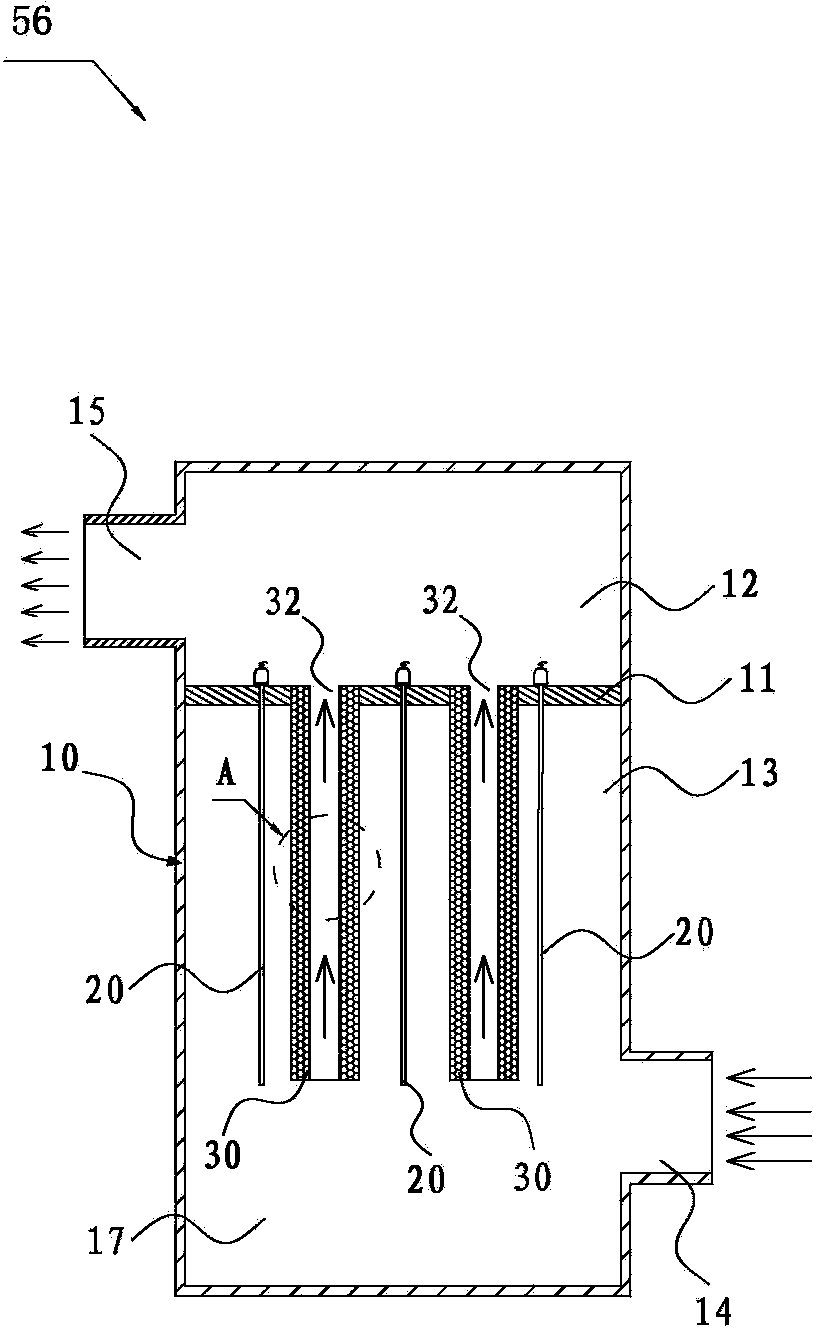

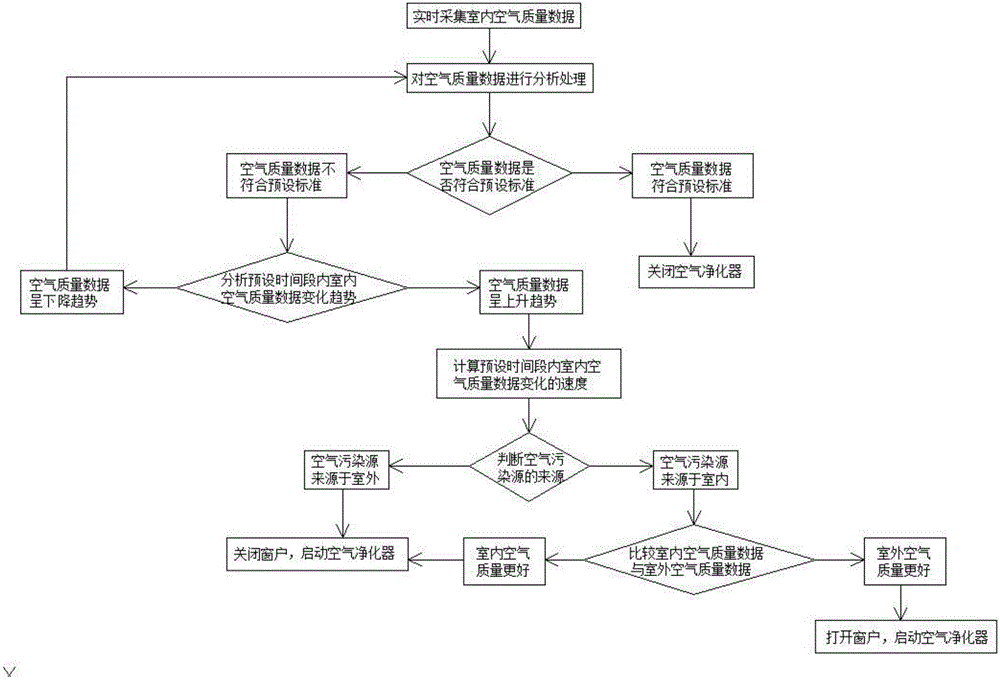

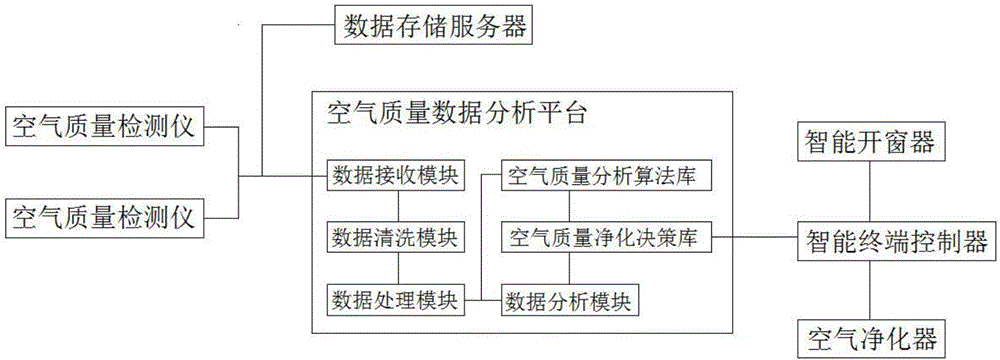

Indoor air quality purification method and system

InactiveCN106288195AImprove air qualityAccelerateSpace heating and ventilation safety systemsLighting and heating apparatusAir cleaningEngineering

The invention discloses indoor air quality purification method and system. The system comprises two mutually connected air quality detection instruments, an air quality data analysis platform, an intelligent terminal controller, an air purifier and an intelligent window opener. According to the method, whether the indoor air quality meets the standard or not is judged by collecting indoor and outdoor air quality data by the air quality detection instruments, and when the indoor air quality does not meet the standard, the air purifier is automatically started, and the air quality is improved; whether an air pollution source is located in or out of a room by calculating a variation speed of the indoor air quality data; and when the pollution source is from the interior of the room, whether the indoor and outdoor air quality is good or poor is judged by comparing the indoor and outdoor air quality qualities, and the window opener is automatically controlled to open or close a window, thus the speed of purifying air is accelerated, the working time of the air purifier is reduced, the air purifying efficiency is improved, and meanwhile, the air purifying cost is lowered.

Owner:安徽广行物联科技有限公司

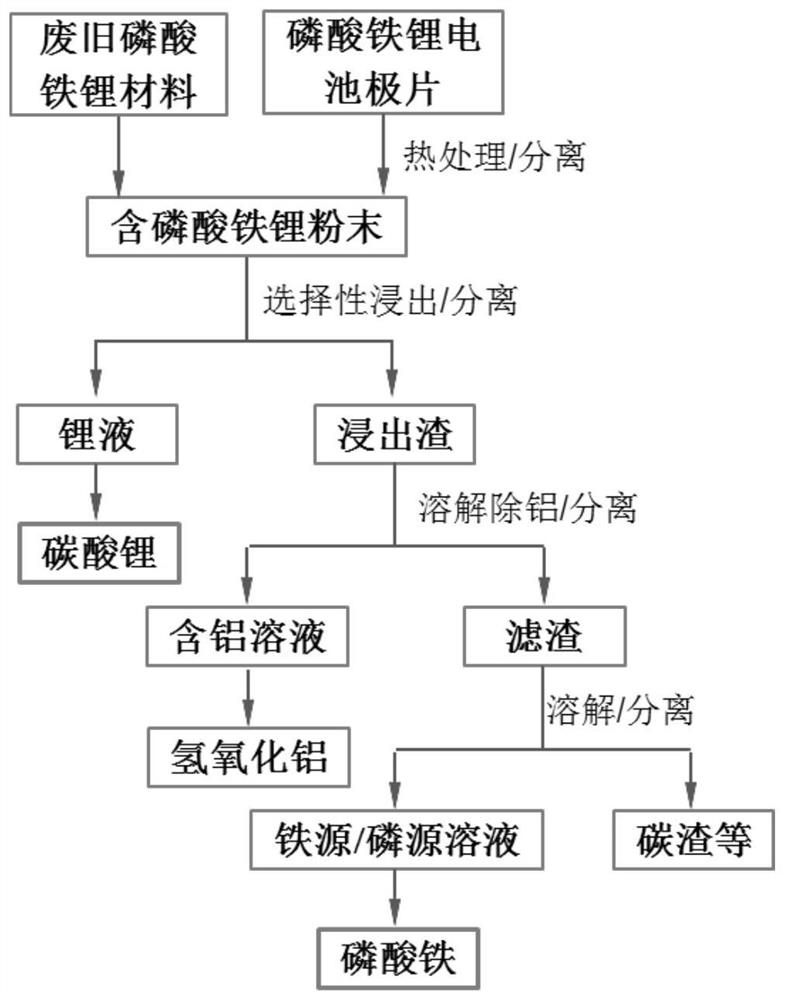

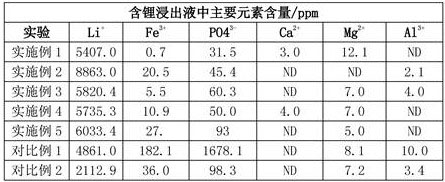

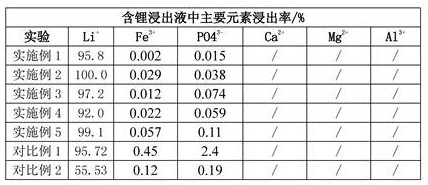

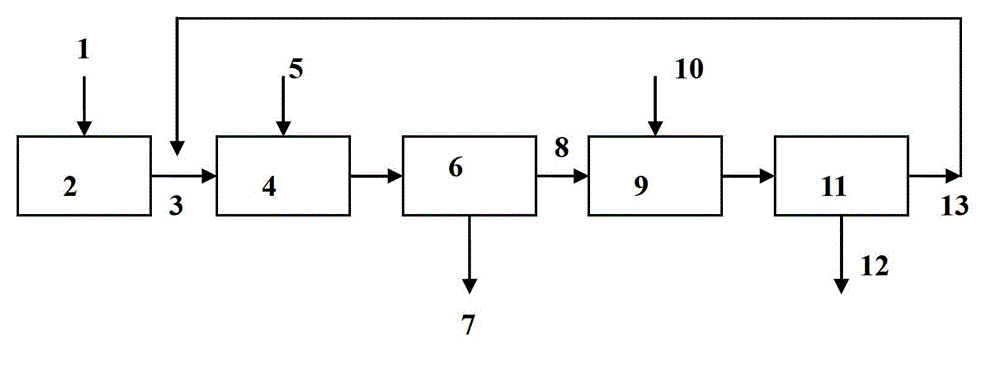

Recovery method of waste lithium iron phosphate positive electrode material

ActiveCN112441572AImprove leaching rateRealize full recyclingAluminium oxide/hydroxide preparationWaste accumulators reclaimingPregnant leach solutionO-Phosphoric Acid

The invention provides a recovery method of a waste lithium iron phosphate positive electrode material. The method comprises the following steps: S1, adding waste lithium iron phosphate powder to a leaching agent A, slowly adding a leaching agent B, adjusting the pH value to be more than or equal to 2, and carrying out solid-liquid separation to obtain a lithium-containing leaching agent and a leaching residue; S2, adding a precipitator into the lithium-containing leachate to obtain lithium carbonate; S3, adding a first alkaline solution into the leaching residues, and filtering to obtain an aluminum-containing solution and filter residues; S4, adjusting the pH value of the aluminum-containing solution to obtain an aluminum hydroxide precipitate; S5, adding the filter residue into a firstacidic solution, performing filtering, adding a second alkaline solution into the obtained filtrate, adjusting the pH value to 2.0-2.7 to obtain basic iron phosphate, and adding phosphoric acid to obtain iron phosphate. The leaching agent A comprises a mixed solution of at least one of a weak base solution or a weak acid solution and a first oxidizing agent; and the leaching agent B comprises a mixed solution of a second acidic solution and a second oxidant. By the adoption of the method, the leaching rate of lithium is high, impurities are few, the purification and wastewater treatment cost during lithium carbonate preparation is reduced, and meanwhile iron phosphate can be efficiently recycled.

Owner:BYD CO LTD +1

Mercury contaminated soil in-situ restoration method

ActiveCN102873086AImprove purification efficiencySave raw materialsContaminated soil reclamationRestoration methodWater soluble

The invention discloses a mercury contaminated soil in-situ restoration method. The method includes: preparation of extracting agent, namely dissolving water-soluble iodized salt, sulfate, nitrate and thiosulfate into water to prepare the extracting agent for restoration of mercury contaminated soil; and purification of mercury contaminated soil and regeneration of the extracting agent, namely subjecting the mercury contaminated soil and the extracting agent to mixing, stirring and centrifugal separation, wherein the centrifuged soil is clean soil; extracting 90% of mercury absorbable and usable for plants into supernatant, adding precipitating agent to recover mercuric sulfide and realize regeneration of the extracting agent, and reusing the regenerated extracting agent for the soil. Details are shown in the specification. The mercury contaminated soil in-situ restoration method has the advantages that mercury absorbable and usable for plants in soil is separated by extracting, and the purification efficiency is up to 90%; and materials of the extracting agent are low in cost and easy to obtain, the extracting agent preparation method is simple, feasible, recyclable and reusable, and thereby mercury contaminated soil purification cost is greatly reduced.

Owner:PEKING UNIV

Method for producing fatty acid by hydrolyzing lipid through three liquid-phase lipase catalytic systems

ActiveCN103184245AReduce manufacturing costSolve the problem of energy consumptionFermentationInorganic saltsAlcohol

The invention discloses a method for producing fatty acid by hydrolyzing lipid through three liquid-phase lipase catalytic systems. The method comprises the following steps: firstly, preparing enzyme solution with the lipase concentration of 5-20000 U / mL, and adding soluble inorganic salts, alcohol / ketonic hydrophilic fraction and lipid to the enzyme solution so as to form three liquid-phase systems; secondly, laying the prepared three liquid-phase systems into an agitated vessel for reaction, standing or centrifuging the systems after the reaction so as to divide the systems into an upper layer, a middle layer and a lower layer, and collecting products in the upper layer so as to obtain fatty acid phase. The method adopts the three liquid-phase systems to extract fatty acid in crude enzyme solution, performs direct hydrolyzing to produce fatty acid, can not only greatly reduce the production cost of enzyme, but also solve the problems of high energy consumption for glycerol and enzyme separation, high cost, high pollution and the like.

Owner:SOUTH CHINA UNIV OF TECH

Method for purifying in vivo heavy metal of bivalve shell

InactiveCN1736181AEasy to operateReduce purification costsClimate change adaptationPisciculture and aquariaMicrometerBivalve shell

The invention discloses a purity method for heavy metal in the bivalve shellfish. The purity method is: culturing the bivalve shellfish temporarily in the sand leach natural sea water that is 22 to 28 Deg.C of the water temperature, 12 to 32 per micrometer salinity, and continuous charge, releasing microalgae into the sand leach natural sea several times for purity treatment for 2 to 31 days. Purifying bivalve shellfish with the present invention, the heavy metal can be discharged 40 to 50 percents, which meets the edible hygienic standards.

Owner:JINAN UNIVERSITY

Method for enriching polyunsaturated fatty acids by virtue of enzyme method

The invention discloses a method for enriching polyunsaturated fatty acids by virtue of an enzyme method. The method comprises the following steps: (1) preparing an enzyme solution that lipase concentration is 5-20000U / mL, and adding soluble salt, a hydrophilic solvent and fish oil to the enzyme solution so as to prepare a three-liquid-phase system; (2) adding the prepared three-liquid-phase system to a stirring kettle and reacting, standing by or centrifuging until layering after reaction, and collecting a supernatant product so as to obtain a lipid product phase; and (3) adding alkaline liquor to the lipid product phase and adding a hydrophobic organic solvent, standing by and reserving a supernatant phase, recovering the hydrophobic organic solvent, reserving and extracting an upper phase which is an omega-3 enriched glyceride product and regulating pH value of a lower phase to be lower than 2 by virtue of acid; and then extracting by virtue of the hydrophobic organic solvent so as to obtain hydrolyzed fatty acid. The method disclosed by the invention has the advantages of low energy consumption, high raw material utilization rate, mild reaction conditions and the like; and the technical problem of an existing enzymatic hydrolysis method which is difficult to achieve industrialization in the production of fatty acid.

Owner:SOUTH CHINA UNIV OF TECH

Catalytic oxidation purification method for hydrogen cyanide in industrial waste gas

InactiveCN101269297AHigh catalytic activityImprove stabilityDispersed particle separationPurification methodsPhosphoric acid

The invention relates to a method of the catalytic oxidation and purification of tail gas containing hydrocyanic acid, in particular to a method for purifying the tail gas containing hydrocyanic acid by using a chemical method. The tail gas containing hydrocyanic acid is enabled to react with a prepared mixed catalyst solution containing palladium and copper under the temperature of 4 to 100 DEG C in a absorption tower, and the tail gas containing hydrocyanic acid is blown into the absorption tower in a gas-liquid negative-direction contact way, part of the hydrocyanic acid contacts and reacts with the palladium ions to form insoluble palladium simple substance, and part of the hydrocyanic acid reacts with the copper ions to form insoluble phosphor copper, part of the hydrocyanic acid is oxidized into phosphoric acid; all the generated substances enter into the liquid phase, and the mixed catalyst solution which absorbs the hydrocyanic acid and the purified and qualified tail gas not containing the hydrocyanic acid are acquired, the mixed hydrocyanic acid catalyst solution is oxidized into a by-product of the phosphoric acid to be used as resources again, the problems of hydrocyanic acid pollution is effectively eliminated, and the method provided by the invention provides a practical purifying method for the calcium carbide furnace gas and yellow phosphorus exhaust gas used as monocarbide chemical raw materials.

Owner:KUNMING UNIV OF SCI & TECH

Method for continuously refining L-lactide from crude L-lactide

The invention discloses a method for continuously refining L-lactide from crude L-lactide, which comprises the following steps of: firstly, performing at least once lightness removal to the crude L-lactide by using a lightness-removing column, sending melted crude L-lactide into the middle of the lightness-removing column, refluxing and separating as well as distilling the crude L-lactide in the lightness-removing column, condensing vapor distillate at the upper end of the lightness-removing column for removing water, L-lactate and meso-lactide; secondly, enabling column bottom liquid to enter a reboiler for vaporization and then enter into the column, performing at least once rectification to the left column bottom liquid through a treating column after cooling, wherein the lower end of the lightness-removing column mainly has high-boiling point distillate liquid comprising the L-lactide and lactate oligomer; and when in rectification, refluxing and separating the column bottom liquid of the lightness-removing column to obtain a refined L-lactide; refining column bottom flow to obtain concentrated lactate oligomer. The L-lactide purified by the method can be directly used in the polymerization of poly L-lactate, thereby lowering the purifying cost of the L-lactide, increasing the yield, and being environmental friendly without organic solvents.

Owner:南京冠创生物科技有限公司

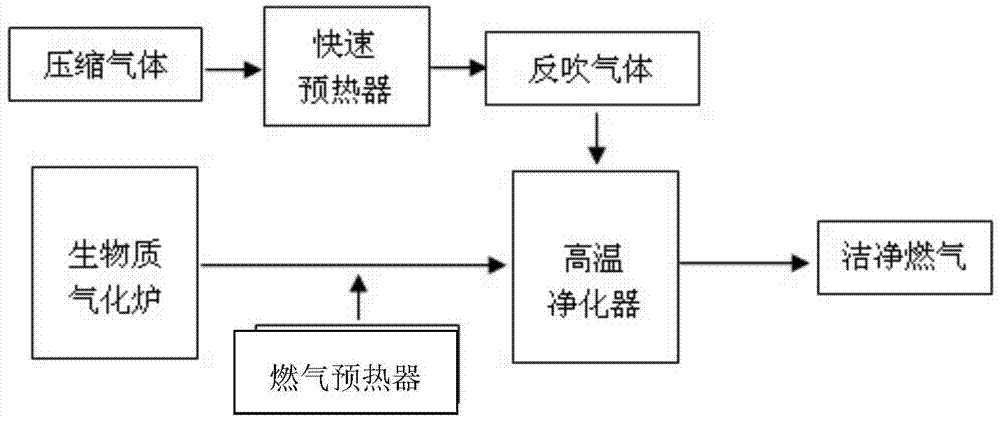

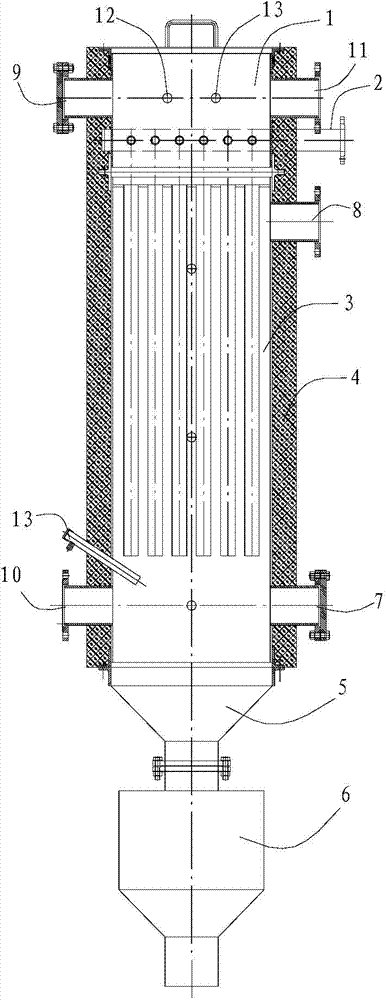

High-temperature dust-removing and coke-removing integrated purifying process of biomass crude gas

ActiveCN103614167AFully purifiedAvoid secondary pollutionGas purification by catalytic conversionGas dust removalInsulation systemIntegrated devices

The invention discloses a high-temperature dust-removing and coke-removing integrated purifying process of biomass crude gas and provides a new process for high-efficiency purification of biomass high-temperature gas at low cost. The process comprises a high-temperature gas heat exchanger (A), a high-temperature gas purifier (B), a Venturi pulse back-blowing system (C), a gas preheater (D) and an electric-heating insulation system (E), wherein the five sets of equipment operate cooperatively to form a set of complete high-temperature gas purifying integrated device; a filtering medium in the high-temperature gas purifier is a modified ceramic membrane dust-removing pipe. When filtering cakes on the outer surface of the modified dust-removing pipe are deposited to certain thickness, deposited ash can be back-blown into an ash discharging hopper box for collection by the Venturi pulse back-blowing system. The high-temperature dust-removing and coke-removing integrated purifying process disclosed by the invention has the advantages that high-efficiency separation and integrated treatment of ash and coke components in biomass gas are realized; the dust-removing temperature is low so as to be beneficial to reducing the manufacturing cost of the equipment and prolonging the service life; biomass ash side products with commercial value are produced while the high-efficiency purification of the biomass crude gas is realized; the process flow is simple and flexible, the operation is simple, the purification cost is low and the suitability for industrial production is achieved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

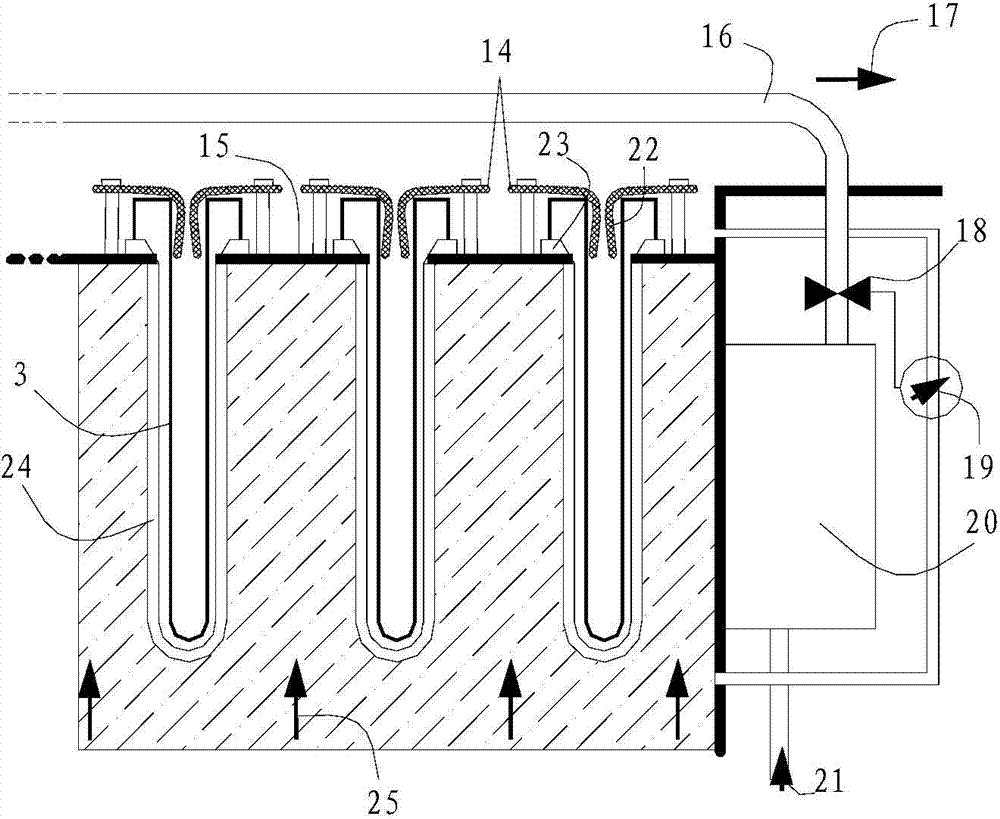

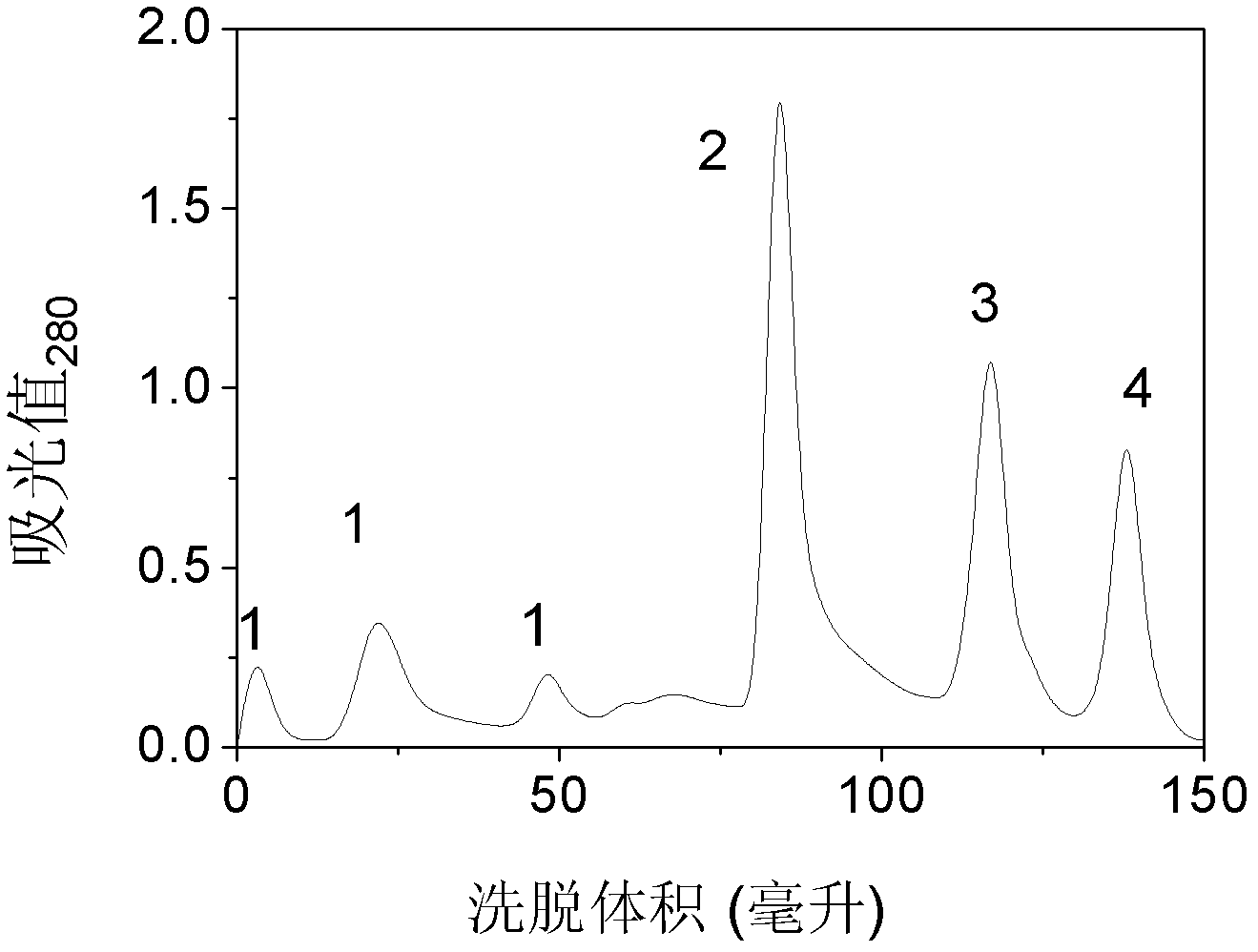

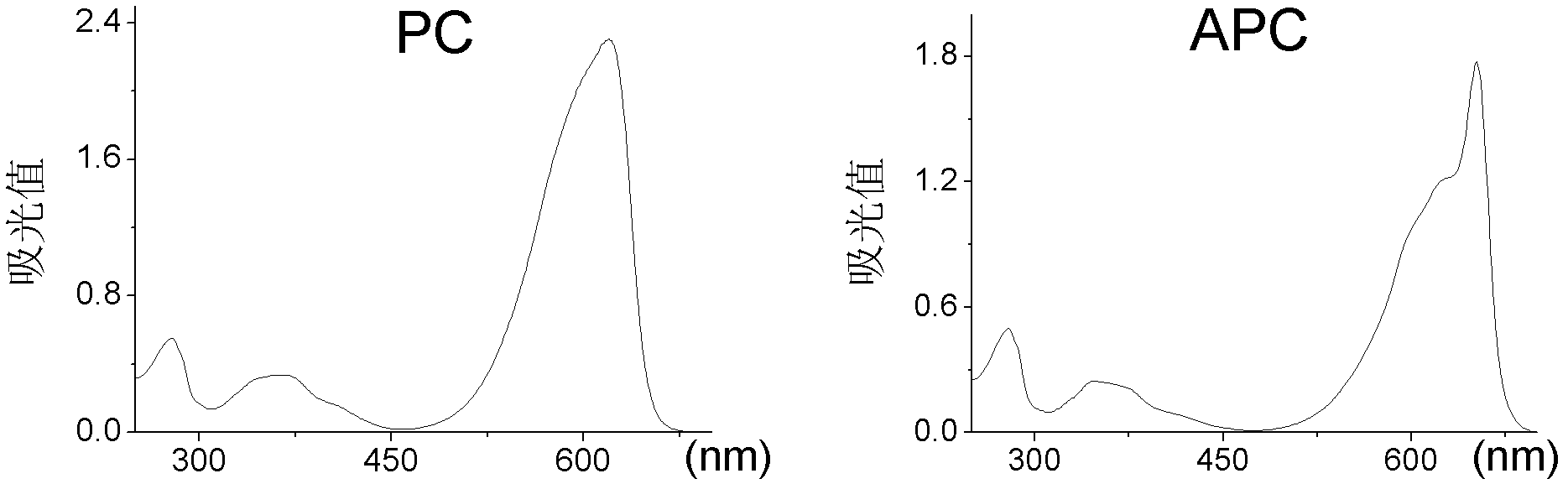

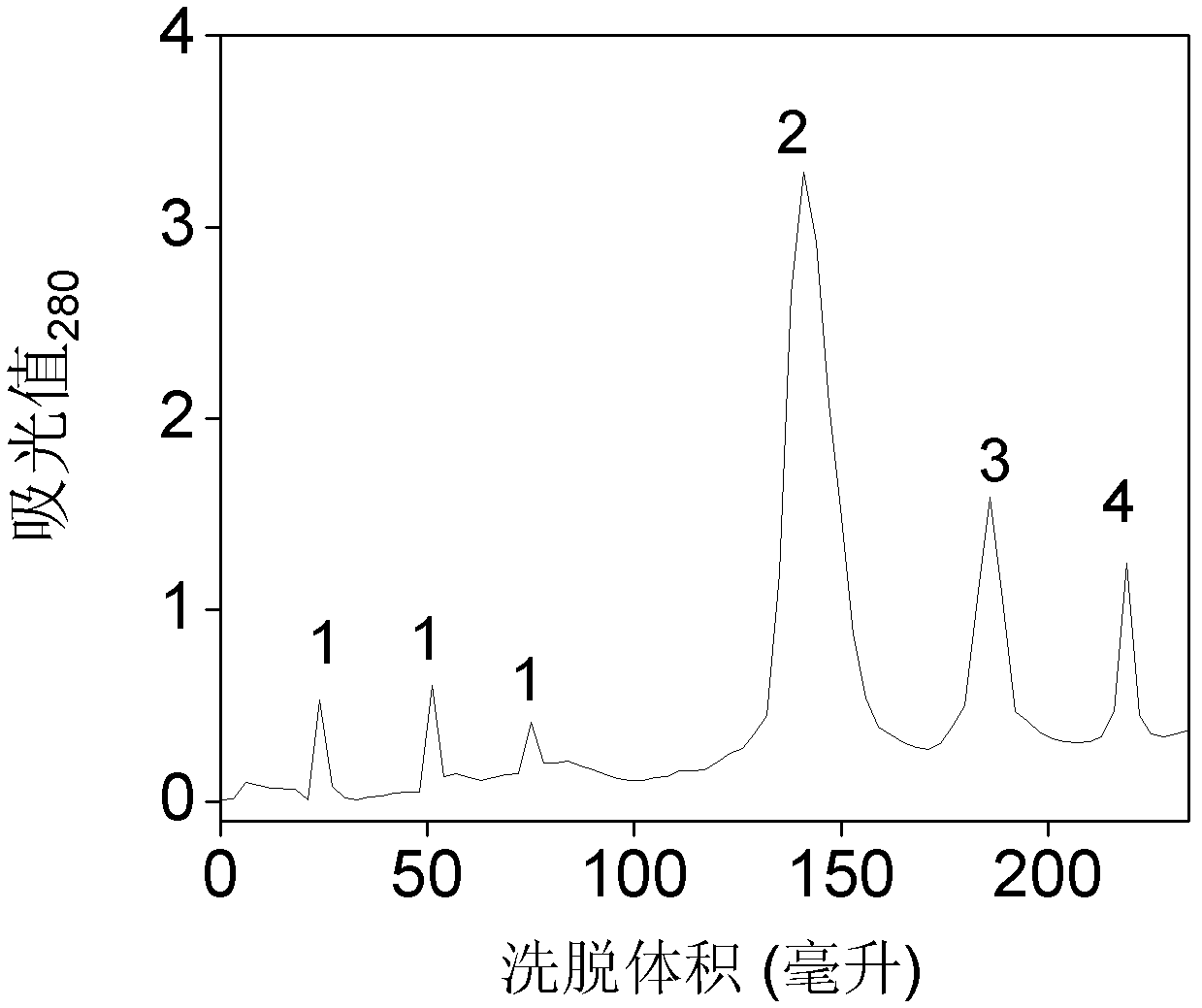

Method for simultaneously separating high-purity phycocyanin and allophycocyanin and application thereof

InactiveCN102329381AReduce purification costsLow costPeptide preparation methodsAlgae/lichens peptidesPhosphateAmmonium sulfate

The invention discloses a method for simultaneously separating high-purity phycocyanin and allophycocyanin and application thereof. The method comprises the following steps of: repeatedly freezing and thawing spirulina dry powder, ultrasonically crushing, and centrifuging, wherein supernate is a crude phycobiliprotein extracting solution; then adding ammonia sulfate, and taking out the supernate when the saturation degree is 25-35%; then, adding ammonia sulfate, taking out precipitates when the saturation degree is 60-70%, dialyzing for precipitation to obtain a primarily purified phycobiliprotein extracting solution, and loading the primarily purified phycobiliprotein extracting solution to a hydroxyapatite column; and collecting 0.02-0.03M phosphate buffered solution which contains 0.1-0.2M sodium chloride and has the pH value of 6.5-7.2, and 0.1-0.12M phosphate buffered solution which contains 0.1-0.2M sodium chloride and has the pH value of 6.5-7.2, wherein the 0.02-0.03M phosphate buffered solution is phycocyanin and the 0.1-0.12M phosphate buffered solution is allophycocyanin. The method disclosed by the invention can be used for simultaneously preparing phycocyanin with a purification factor reaching 4.5 and allophycocyanin with a purification factor reaching 3 as well as analogues containing selenium and tellurium, and the purification scale of the method is amplified so as to acquire high-purity protein of a gram level through primary chromatography, so that the purification cost is greatly reduced, and the method can be used for producing the phycocyanin and the allophycocyanin.

Owner:JINAN UNIVERSITY

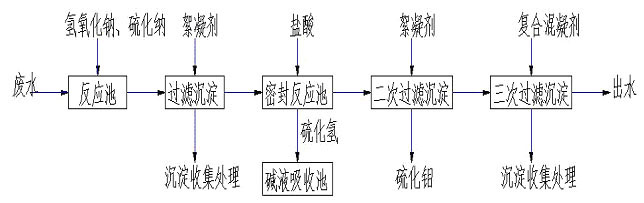

Method for purifying molybdenum sulfide in heavy metal waste water containing molybdenum, and the like

ActiveCN101973652AReduce purification costsReduce contentMultistage water/sewage treatmentWater/sewage treatment by neutralisationAluminium chlorideMolybdic acid

The invention belongs to the technical field of water treatment, in particular to a method for purifying molybdenum sulfide in heavy metal waste water containing molybdenum, and the like. The method comprises the following steps of: putting waste water containing the heavy metal molybdenum and other heavy metals to be purified in a reaction tank; regulating the waste water to alkalinity and adding sodium sulfide for reacting; filtering the waste water and putting filtered water in a sealing device; regulating the pH value of the waste water to 1-3 and reacting at normal temperature to guarantee that molybdenum acid radical ions are all converted into molybdenum sulfide to precipitate; absorbing gas generated by using an absorption tower, wherein sodium hydroxide is used as absorption liquid; adding polyacrylamide used as a flocculating agent to an obtained solution and quickly stirring for reacting; standing still; after the precipitate subsides, draining the supernate, filtering through a filtering device, and treating the precipitate for recycling; regulating the pH of the obtained acid solution to neutrality, adding a coagulant compounded by polymeric aluminum and ferrous sulphate and quickly stirring to remove redundant sulfur ions and further improve the quality of yield water; standing still; and after the precipitate subsides, filtering. The invention has the advantages of good treatment effect, simple and convenient treatment equipment, low treatment cost, higher purity of recovered molybdenum sulfide, and the like.

Owner:TONGJI UNIV

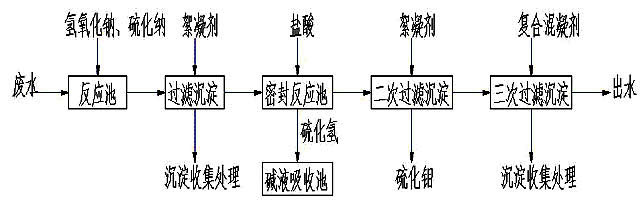

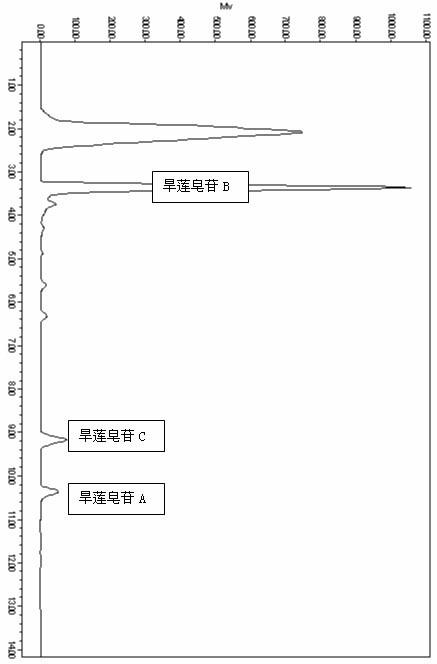

Preparation method and application of eclipta extract

InactiveCN102247420AReduce purification costsNo pollution to the environmentMetabolism disorderAntipyreticChemistryMedicinal herbs

The invention discloses a preparation method and application of eclipta extract. The preparation method comprises the following steps of: 1) selecting eclipta, soaking for 0.5 hour with ethanol water solution with the volume percent concentration of 5-95%, extracting for 1 hour when the weight of the ethanol water solution is 20 times of the weight of eclipta and extracting for 0.5 hour when the weight of the ethanol water solution is 16 times of the weight of the eclipta, mixing extracts together, concentrating the extract into 0.25-1.0g crude drug / ml, standing for 6 hours, and filtering to obtain the eclipta extract; and 2) adsorbing the eclipta extract by adopting pretreated macroporous resin, wherein the weight ratio of the eclipta extract to the macroporous resin is 1:1-1:5, feeding flow rate is 1-3BV / h and the diameter height ratio of the resin is 1:4- 1:7, washing for 3-6BV with water after adsorbing, wherein eluting flow rate is 2-4BV / h, throwing away eluent; eluting for 3-6BV with the ethanol water solution with the volume percent concentration of 20-90%, wherein the flow rate is 2-4BV / h, collecting the ethanol / water eluent, concentrating, and drying to obtain the eclipta extract. By adopting the preparation method disclosed by the invention, purification cost is reduced, industrial production is easy to realize, and no environment pollution is caused.

Owner:ZHEJIANG UNIV

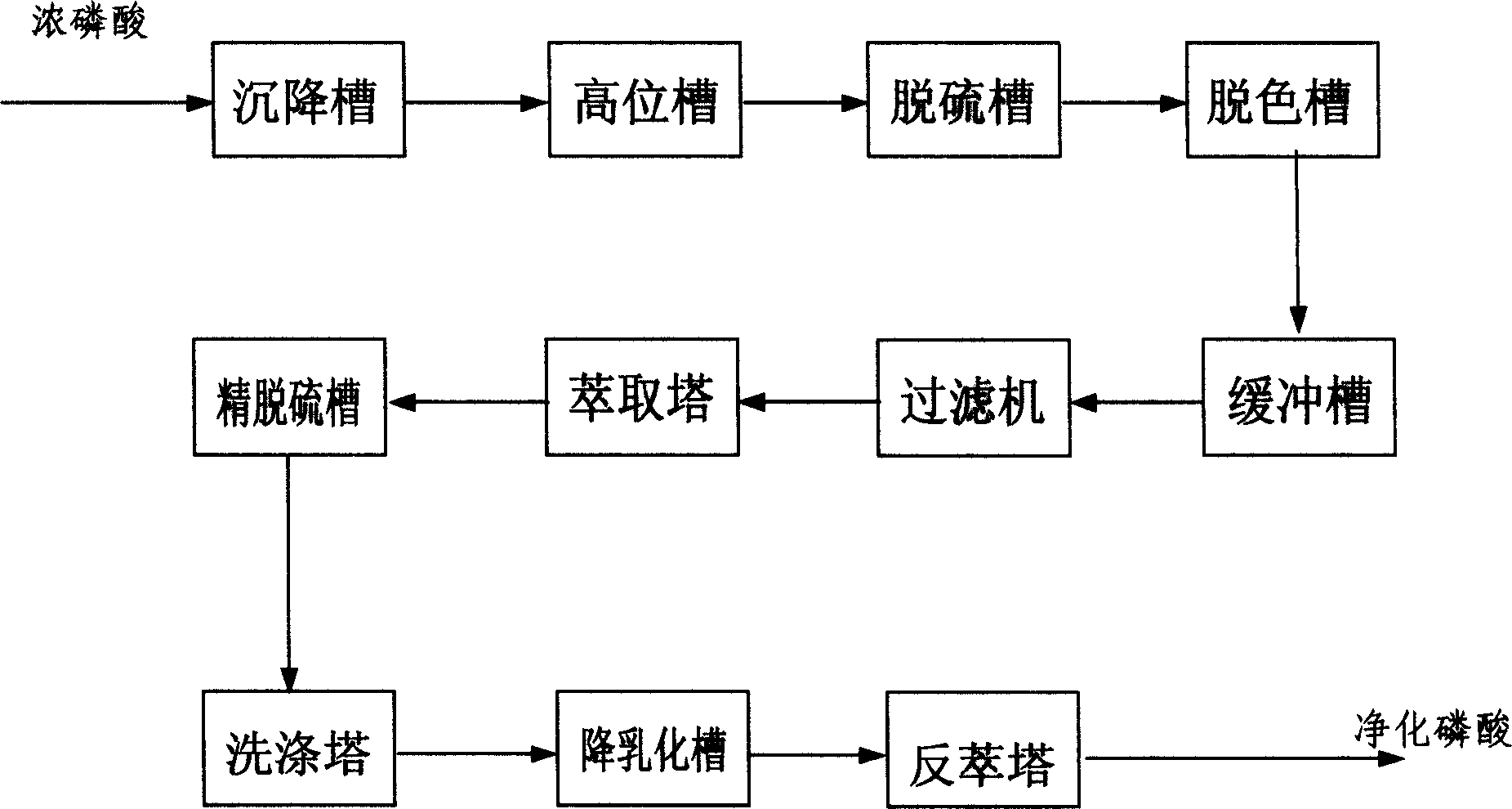

Purified wet-process technique for producing phosphoric acid and equipment thereof

InactiveCN1654317AAchieving stirringRealize reciprocating motionPhosphorus compoundsPhosphoric acidTower

The present invention relates to solvent extracting process as industrial wet process phosphoric acid purifying process. On the basis of technological process of preparing industrial phosphoric acid with wet process phosphoric acid, the present invention has the measures of: 1) setting desulfurizing and defluorinating buffer in the pre-treating section and setting one re-desulfurizing and deferrizing tank between the extracting tank and the washing tank for reinforced desulfurizing, defluorinating and deferrizing; 2) performing extraction, washing and reverse extraction in the rotary vibrating sieve-plate tower; and 3) setting one demulsifying tank between the washing tower and the reverse extracting tower. The present invention has one special rotary vibrating sieve-plate tower developed as the key apparatus. The present invention is used in the industrial production of purifying wet process phosphoric acid and has greatly reduced loss and low cost.

Owner:WENGFU (GRP) CO LTD

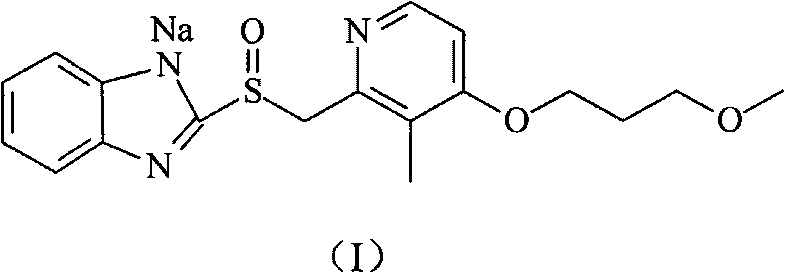

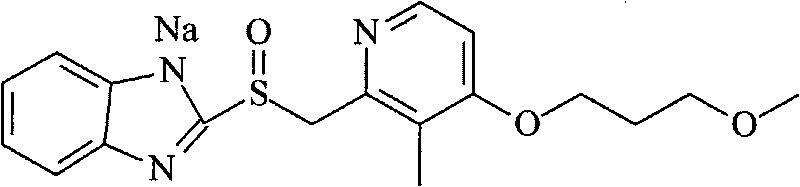

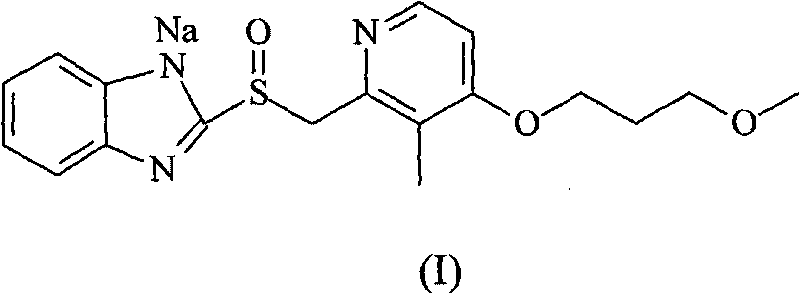

High-purity sodium rabeprazole compound

InactiveCN101704811AOvercome purityOvercome the disadvantages of difficult purificationOrganic chemistryOrganic solventRabeprazole

The invention relates to a high-purity sodium rabeprazole compound, belonging to the technical field of medicine. The method includes the following steps: dissolving crude sodium rabeprazole synthesized by the reaction of rabeprazole and sodium hydroxide in water, adjusting pH value to be faintly acid to neutral by using solid acid salt, and collecting precipitated solid; after dissolving the solid with organic solvent, conducting elution and purification by using eluting agent through macroporous adsorption resin, and collecting eluent; and adjusting the pH value of the eluent to be alkaline, and collecting the precipitated solid to obtain the pure sodium rabeprazole.

Owner:HAINAN MEILAN SMITH KLINE PHARMA

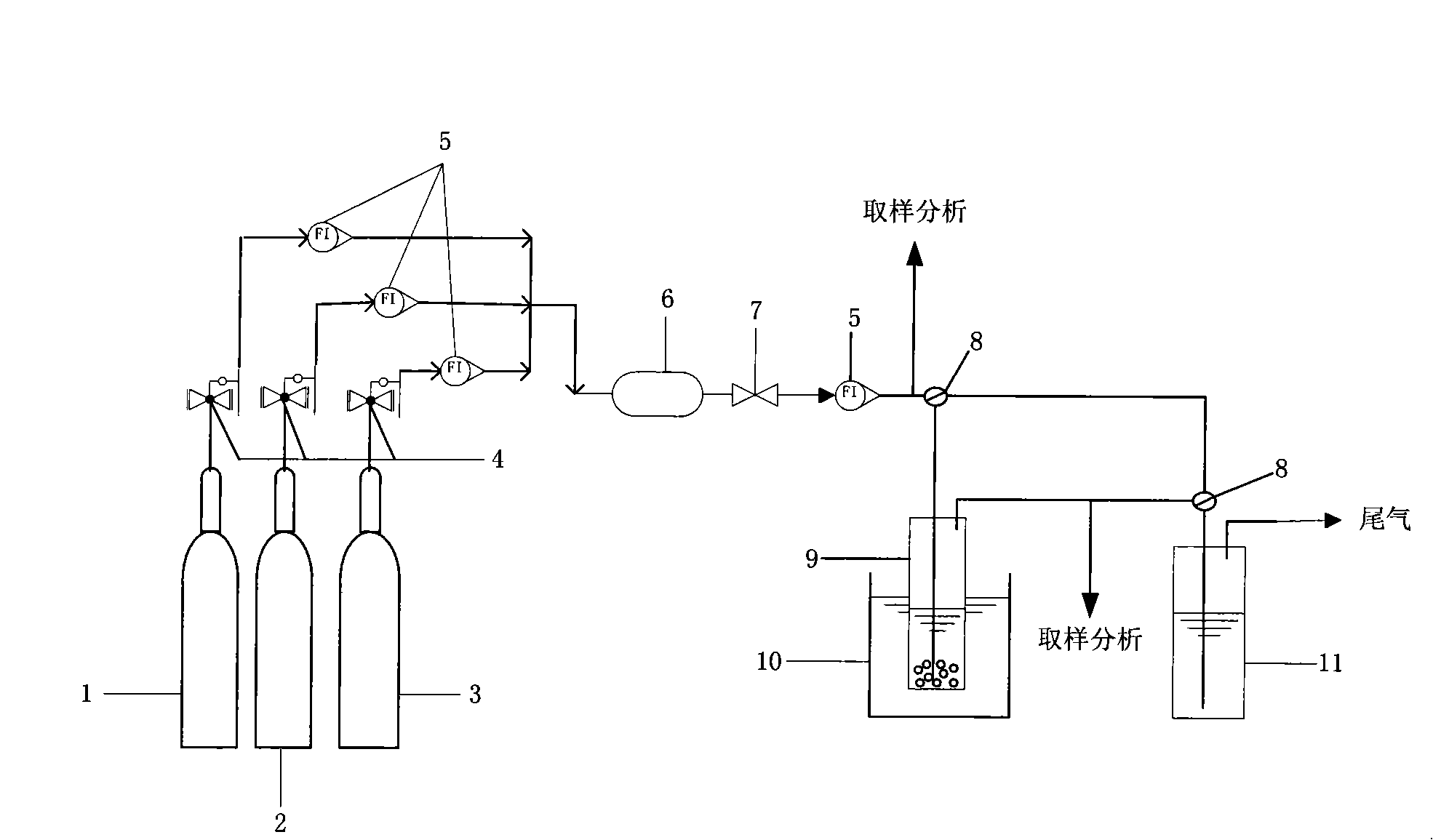

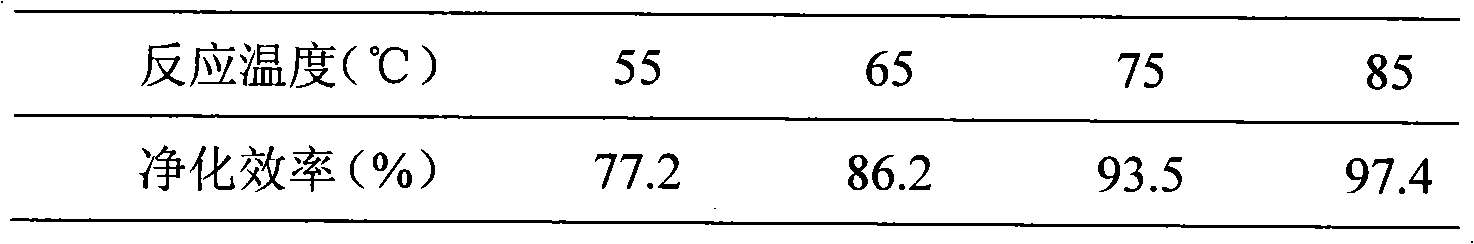

Purification method of low concentration phosphine waste gas

InactiveCN101337157ASimple methodEasy to operateDispersed particle separationCatalyst activation/preparationPurification methodsPhosphoric acid

The invention provides a method for purifying the exhaust gas with low concentration of phosphine. The method is characterized in that an absorption liquid and a solid catalyst are put into a bubbling reactor according to the ratio of 100 ml:1-3 g; the gas containing low-concentration phosphine is allowed to enter the reactor; the reaction temperature is controlled to be 40 DEG C to 80 DEG C; phosphine is purified in the bubbling reactor; and the tail gas after purification has the concentration of phosphine as low as 50 mg / m<3>. The method has the advantages as follows: (1) the method is simple, the operability is strong, the purification efficiency is improved, and the purification cost is reduced; (2) the catalyst is easy to separate, reclaim and reuse; (3) the bubbles in the bubbling reactor are tiny and uniform, thereby strengthening the dissolution of phosphine in the absorption liquid; (4) the reaction conditions are mild and easy to implement; and (5) phosphoric acid can be reclaimed for re-implement of changing waste into resource.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing xylo-oligosaccharide by corn husk enzymatic hydrolysis

The invention relates to a method for preparing xylo-oligosaccharide by corn husk enzymatic hydrolysis. In the method, corn husks are added with water to be in pulp conditioning; after high-temperature boiling for a short time, the mixture is pre-treated by diastasum diastace and protease and filtered; filter residues are added with water to be in pulp conditioning so as to be degraded by xylanase and Beta-glucanase; and after hydrolysate filters ions, xylo-oligosaccharide is obtained by separating a simulated moving bed (SMB). According to the material components, the invention adopts a corresponding compound enzyme targeted hydrolysis macromolecular compound method to produce xylo-oligosaccharide with high additional value; xylo-oligosaccharide liquid contains no furfural compound, improves the purity of hemicellulose, ensures the nutrient component of hydrolyzed substance, and reduces the generation of melanoidin pigment caused by Maillard reaction; in addition, the method of the invention avoids the disadvantages of high requirement for acid hydrolyzer, hard control of hydrolysis speed, mass harmful substance generation and complex refining technology, and conforms to the national requirements of resource saving, and energy saving and emission reduction.

Owner:TIANJIN UNIV OF SCI & TECH

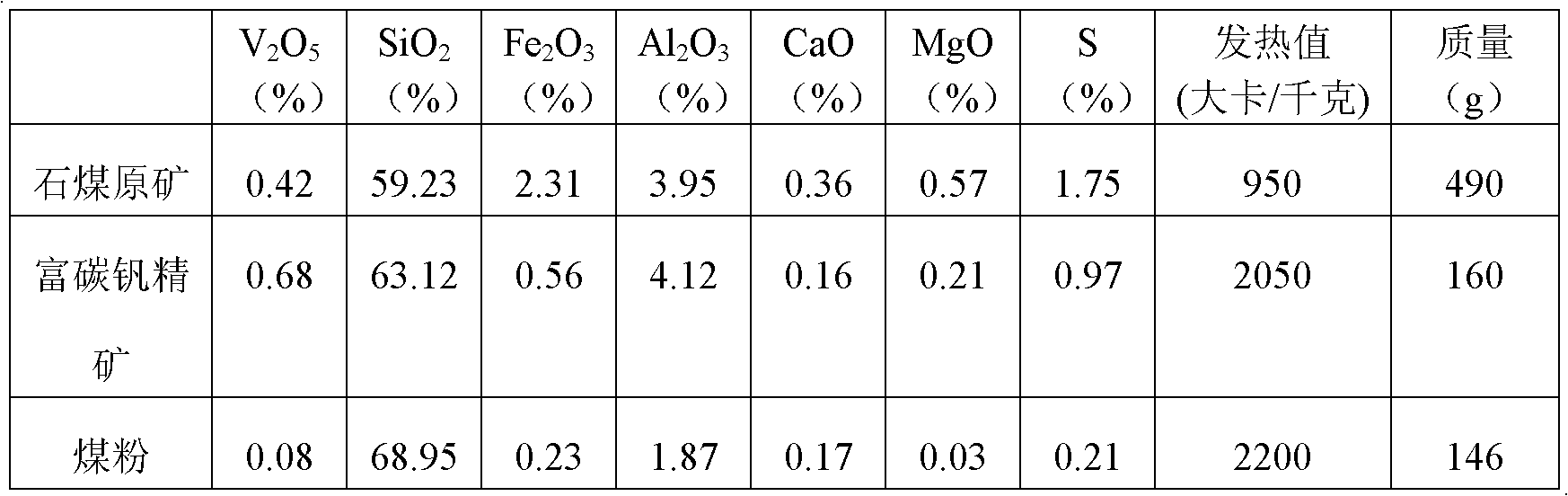

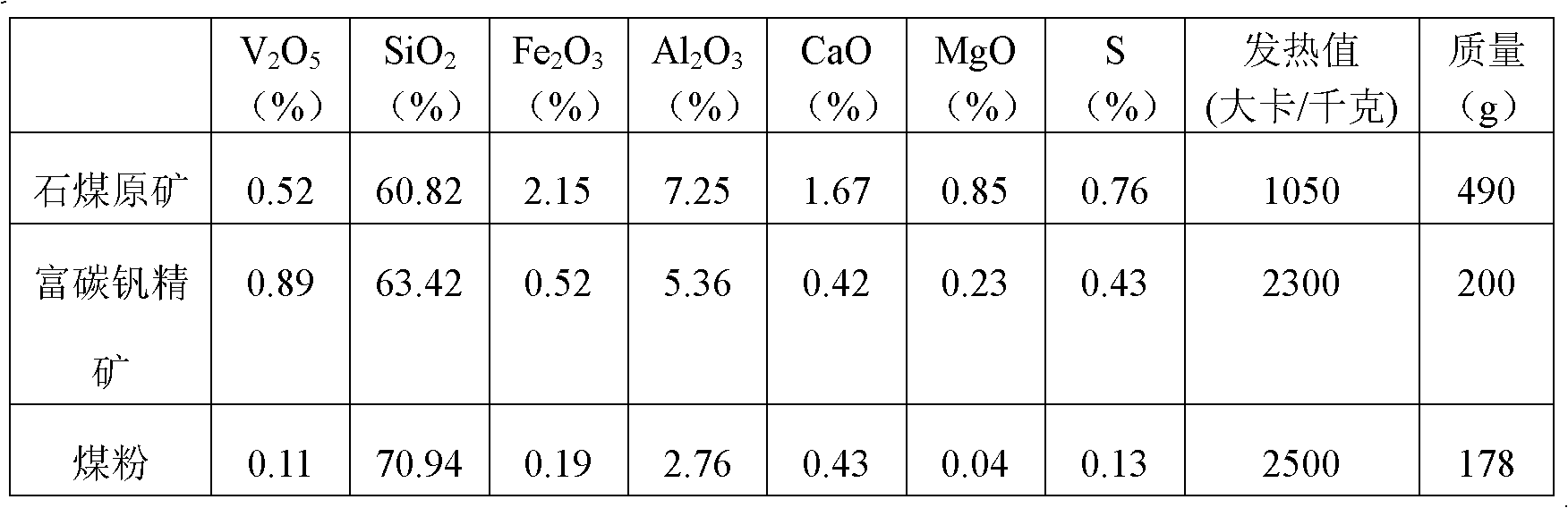

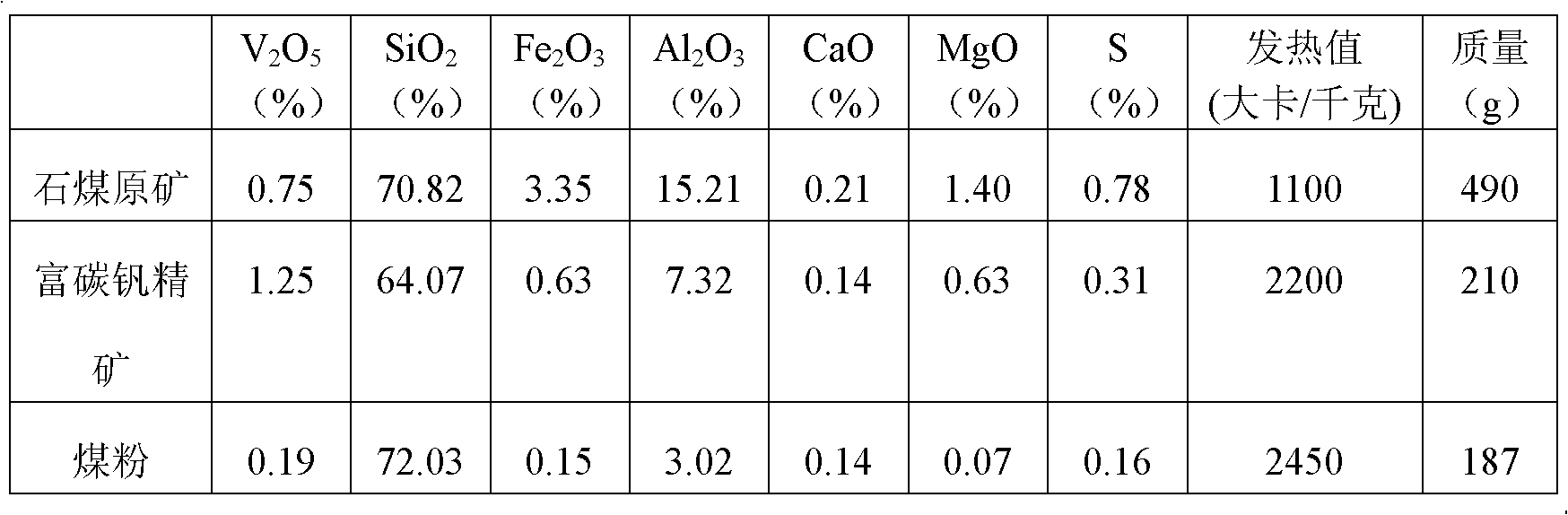

Method for comprehensively recovering carbon from extraction of vanadium from stone coal

The invention discloses a method for comprehensively recovering carbon from the extraction of vanadium from stone coal, which comprises: firstly, milling stone coal, adding water into the stone coal to prepare slurry, adding the inhibitor and flotation collector of gangue and pyrite, keeping the pH value of the slurry between 9 and 11.5, and floating to obtain carbon-enriched vanadium concentrate and tailings; and secondly, adding sulfuric acid in an amount which is 1.0 to 3.0 times the stoichiometric number of the acid soluble substance for reacting with the sulfuric acid in the carbon-enriched vanadium concentrate into the carbon-enriched vanadium concentrate for soaking the carbon-enriched vanadium concentrate in acid at normal pressure or reduced pressure or soaking the carbon-enriched vanadium concentrate in water after low-temperature sulfation and roasting, and filtering to obtain vanadium-containing leachate and vanadium extraction slag; using the vanadium-containing leachate for vanadium extraction; and selling the vanadium extraction slag, which is coal powder, as a fuel. The method can improve the comprehensive utilization rate of resources and the comprehensive economic benefit of vanadium extraction and reduce the industrial exploitation grade of the extraction of vanadium from stone coal. The method has high vanadium extraction rate and is environmentally-friendly. The coal powder, which is produced after the extraction of vanadium from the carbon-enriched vanadium concentrate obtained by stone coal flotation has low vanadium content and low sulfur content, so the corrosion to a burner and the wear caused by smelting slag to the burner when the stone coal is burnt are reduced effectively and the smoke desulfuration and purification cost are reduced at the same time. The method is suitable for industrial production.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com