Method for extracting and purifying cannabidiol from China-hemp

A technology of cannabidiol and hemp, which is applied in the field of plant component extraction and purification, can solve the problems of damaging the environment, affecting product safety, and low extraction yield of cannabidiol, so as to improve the extraction rate, reduce the cost of separation and purification, and purify short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

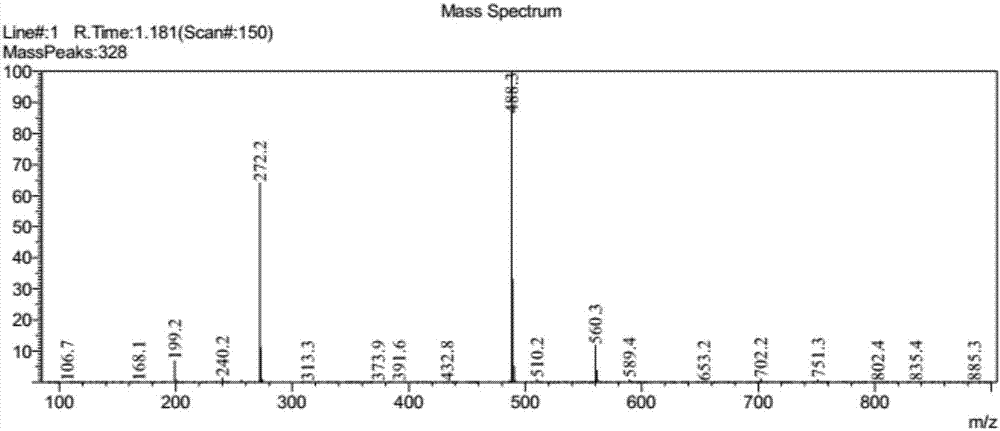

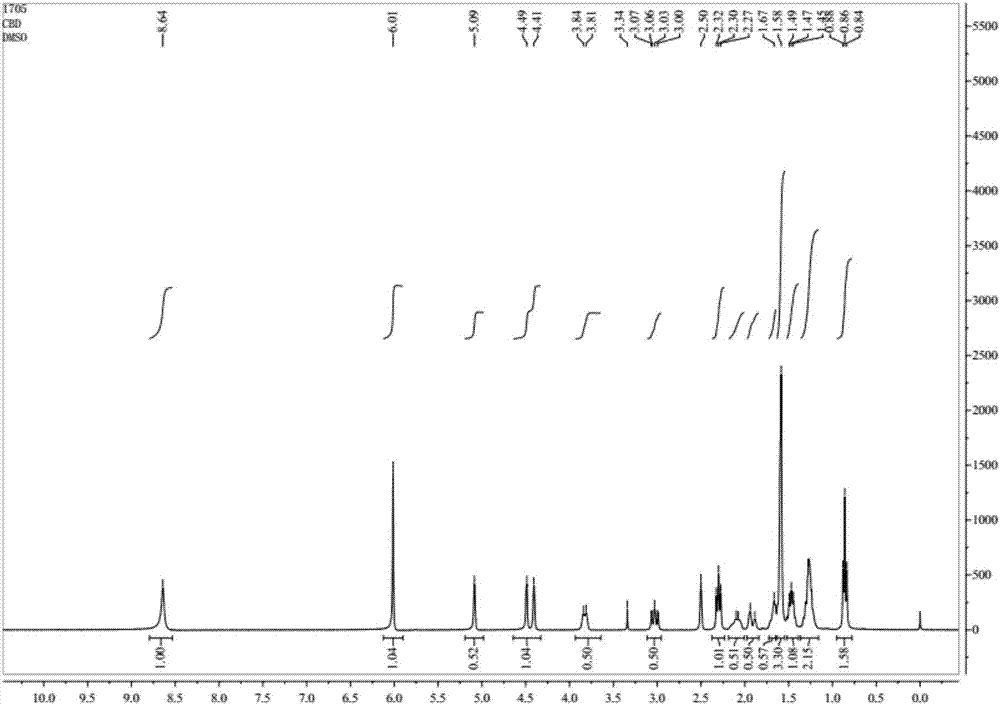

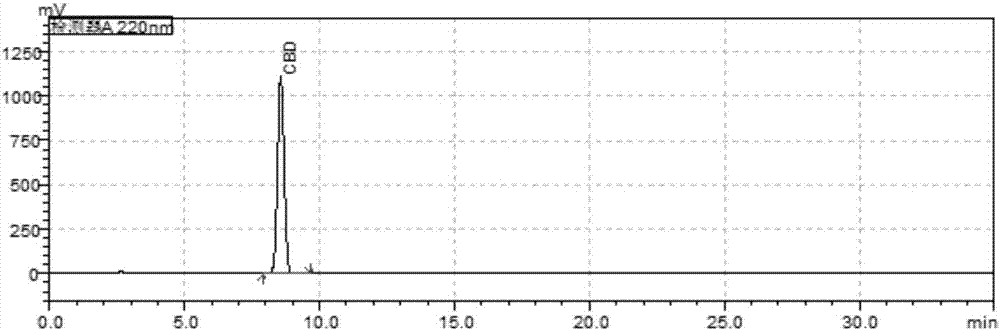

Examples

Embodiment 1

[0032] Embodiment 1: In this embodiment, the steps of extracting and purifying cannabidiol from hemp are as follows:

[0033] Step 1: Harvest hemp flowers and leaves at the mature stage, dry the hemp flowers and leaves at 40° C. for 3 hours to make the water content less than 5%, and crush the hemp flowers and leaves after removing the moisture for use.

[0034] Step 2: Put 100g of crushed hemp flower leaves into a 1L extraction kettle for extraction, supercritical CO 2 The fluid extraction operation process is liquid CO 2 →High pressure pump→extraction kettle (entering supercritical state)→separation kettle Ⅰ→separation kettle Ⅱ→circulation. CO during extraction 2 The fluid flow rate is 20L / h, the temperature of the extraction kettle is 45°C, the extraction pressure is 30MPa, the pressure of the separation kettle Ⅰ and the separation kettle Ⅱ are both 6MPa, and the separation temperature is room temperature. During the extraction process, absolute ethanol is used as the ent...

Embodiment 2

[0048] Example 2: In this example, the steps of extracting and purifying cannabidiol from hemp are as follows:

[0049] Step 1: Harvest hemp flowers and leaves at the mature stage, dry the hemp flowers and leaves at 50° C. for 2 hours to make the water content less than 5%, and crush the hemp flowers and leaves after removing the moisture for use.

[0050] Step 2: Put 100g of crushed hemp flower leaves into a 1L extraction kettle for extraction. During the extraction process, CO 2 The fluid flow rate is 20L / h, the temperature of the extraction kettle is 45°C, the extraction pressure is 30MPa, the pressure of the separation kettle Ⅰ and the separation kettle Ⅱ are both 6MPa, and the separation temperature is room temperature. During the extraction process, absolute ethanol is used as the entrainer. The amount of water and ethanol is 500mL, and the extraction time is 3h to obtain cannabidiol extract.

[0051] Dissolving the cannabidiol extract in absolute ethanol to obtain a ca...

Embodiment 3

[0055] Embodiment 3: The steps of the method for extracting and purifying cannabidiol from hemp in this embodiment are as follows:

[0056] Step 1: Harvest hemp flowers and leaves at the mature stage, dry the hemp flowers and leaves at 30° C. for 4 hours to make the water content less than 5%, and crush the hemp flowers and leaves after removing the moisture for use.

[0057] Step 2: Put 100g of crushed hemp flower leaves into a 1L extraction kettle for extraction. During the extraction process, CO 2 The fluid flow rate is 20L / h, the temperature of the extraction kettle is 45°C, the extraction pressure is 30MPa, the pressure of the separation kettle Ⅰ and the separation kettle Ⅱ are both 6MPa, and the separation temperature is room temperature. During the extraction process, absolute ethanol is used as the entrainer. The amount of water and ethanol is 500mL, and the extraction time is 3h to obtain cannabidiol extract.

[0058] Dissolving the cannabidiol extract in absolute et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com