Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1507results about "Gas dust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

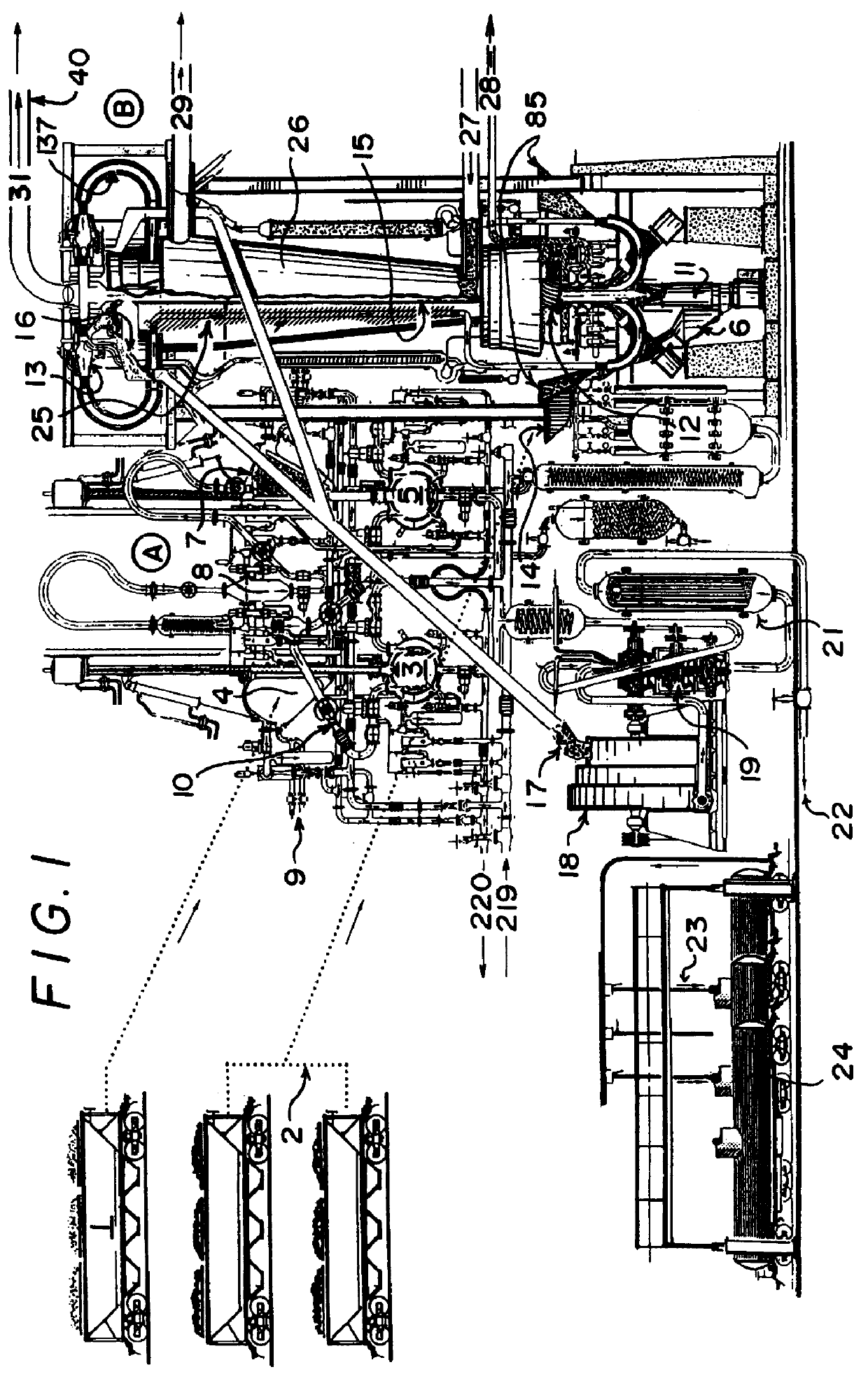

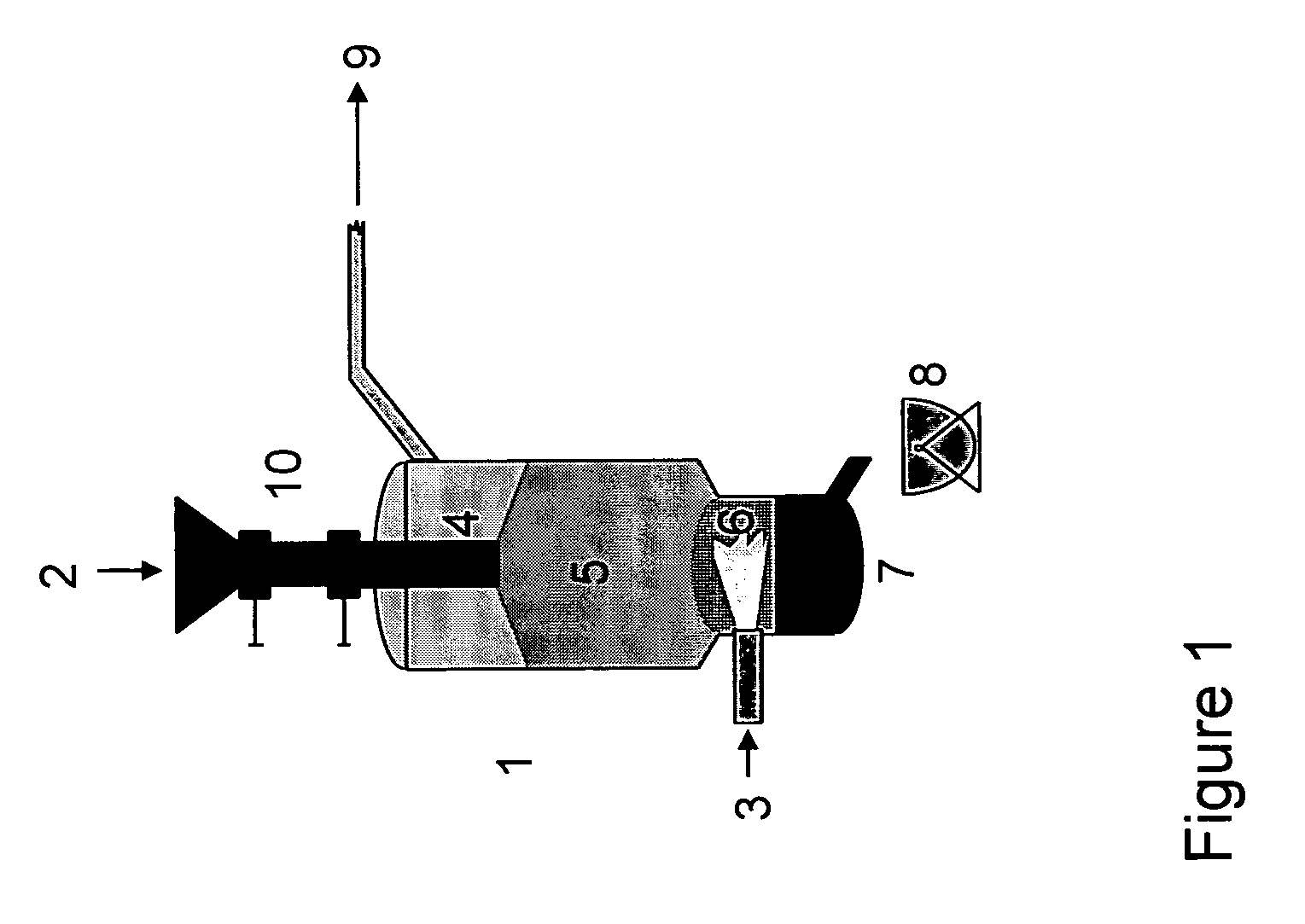

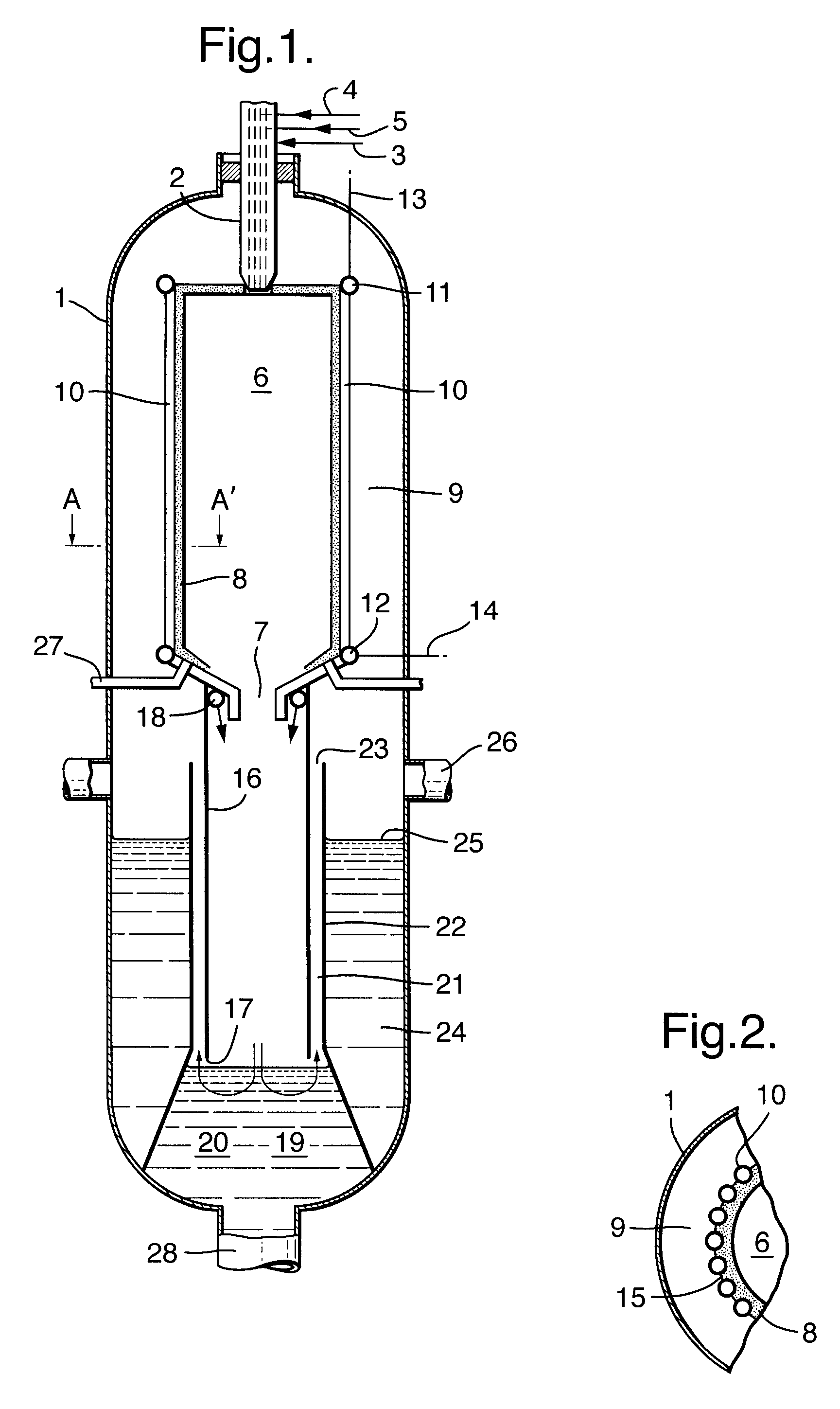

Apparatus for converting coal to hydrocarbons

InactiveUS6013158ALess producedLow costCombustible gas coke oven heatingDirect heating destructive distillationParticulatesSuspended particles

An apparatus for forming liquid hydrocarbons from solid coal. The coal is pulverized to provide a particulate coal feed, which is then extruded to provide a hollow tube of compressed coal supported inside of a support tube. A clay feed is extruded to provide a hollow tube of compressed clay supported inside of the coal tube and a combustible fuel is burned inside of the clay tube. The temperature of combustion is sufficient to fire the extruded clay and pyrolyze the extruded coal to produce hydrocarbon gases and coal char. The support tube has holes for releasing the hydrocarbon gases, which contain suspended particles formed during combustion. The suspended particles are removed from the hydrocarbon gases to provide clean gases, which are passed through an ionizing chamber to ionize at least a portion thereof. The ionized gases are then passed through a magnetic field to separate them from each other according to their molecular weight. Selected portions of at least some of the separated gases are mixed, and the mixed gases are cooled to provide at least one liquid hydrocarbon product of predetermined composition. Portions of the separated gases may also be mixed with the coal char and other input streams, such as waste plastics, and further treated to provide other hydrocarbon products.

Owner:WOOTTEN WILLIAM A

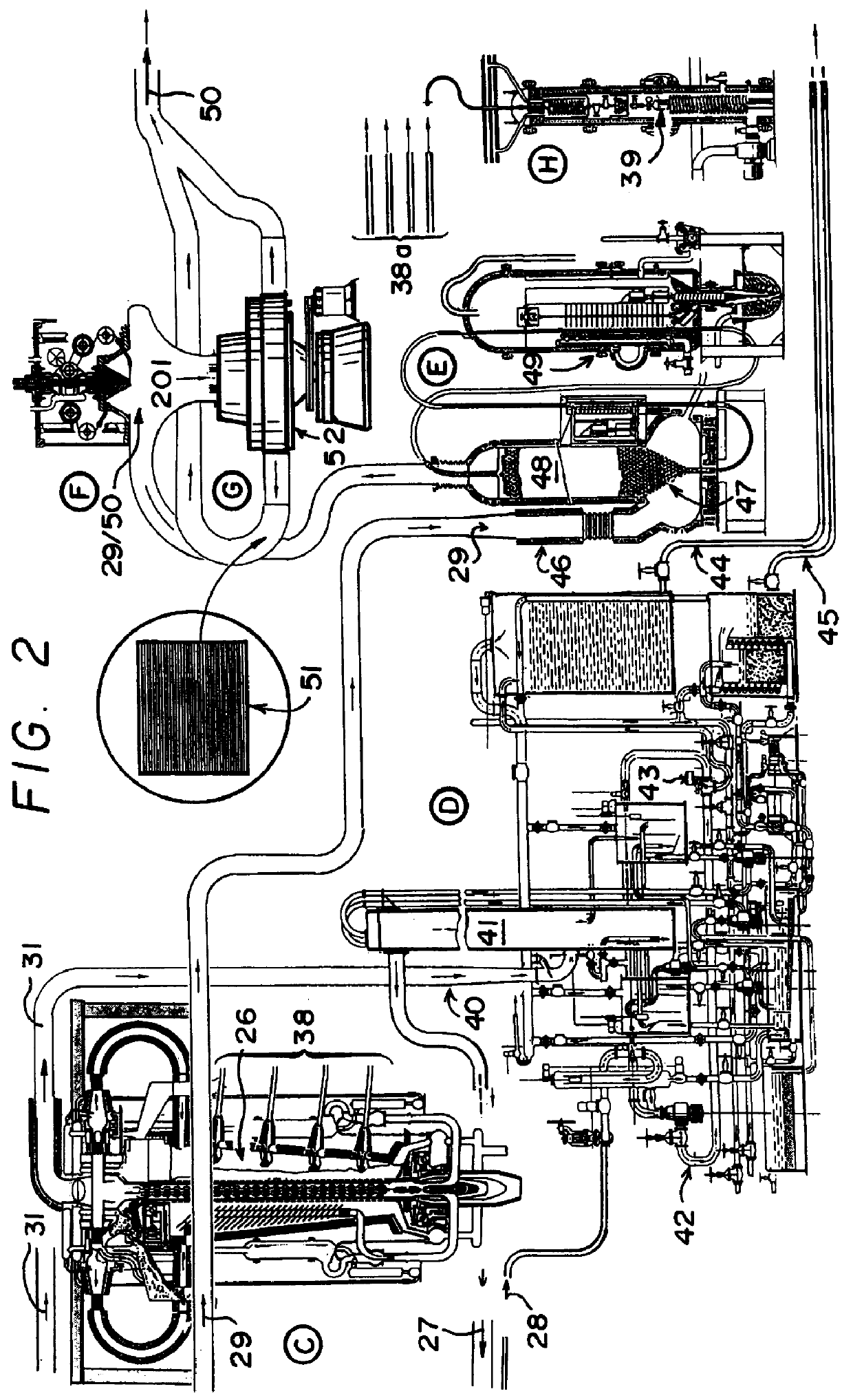

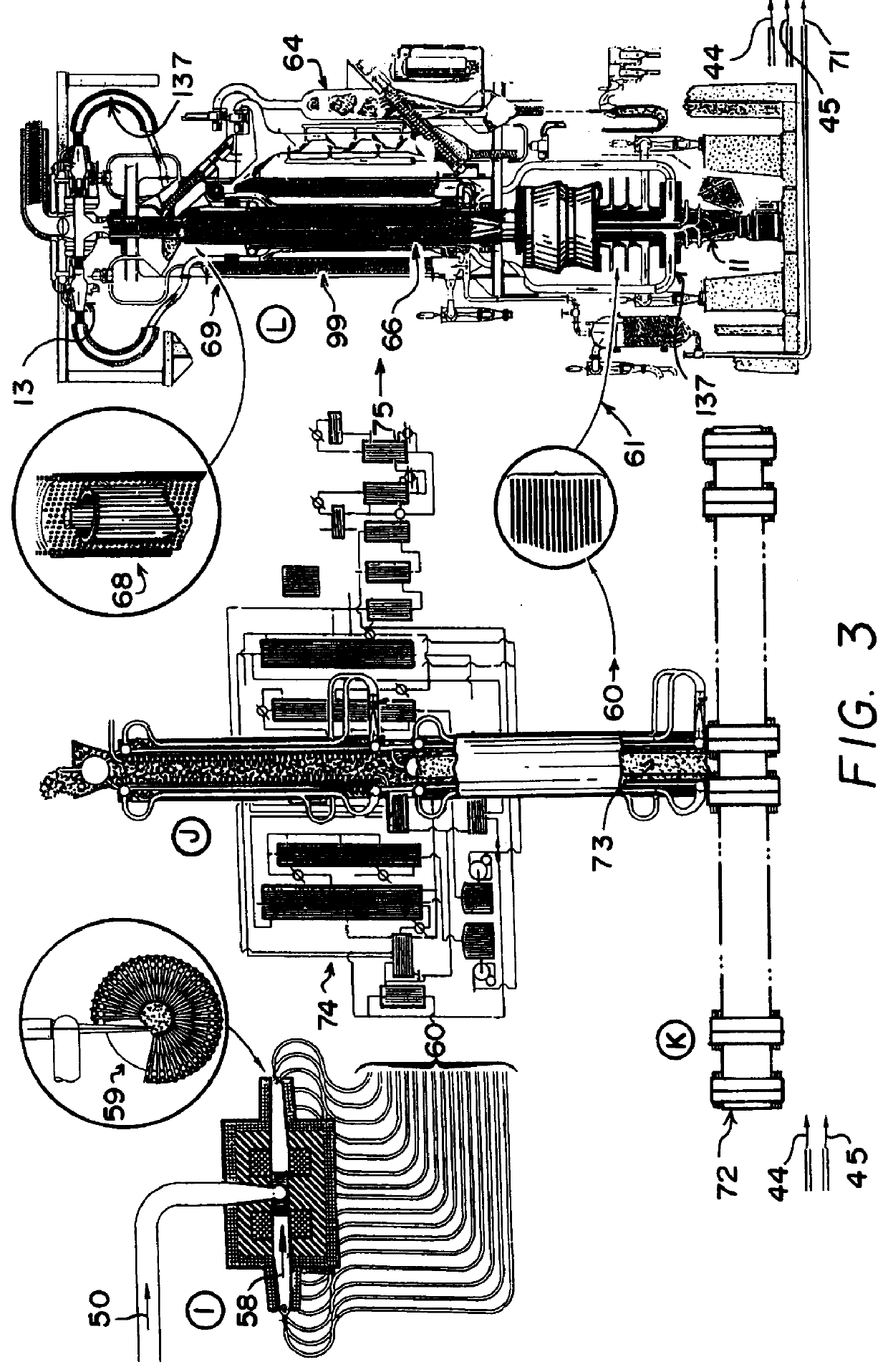

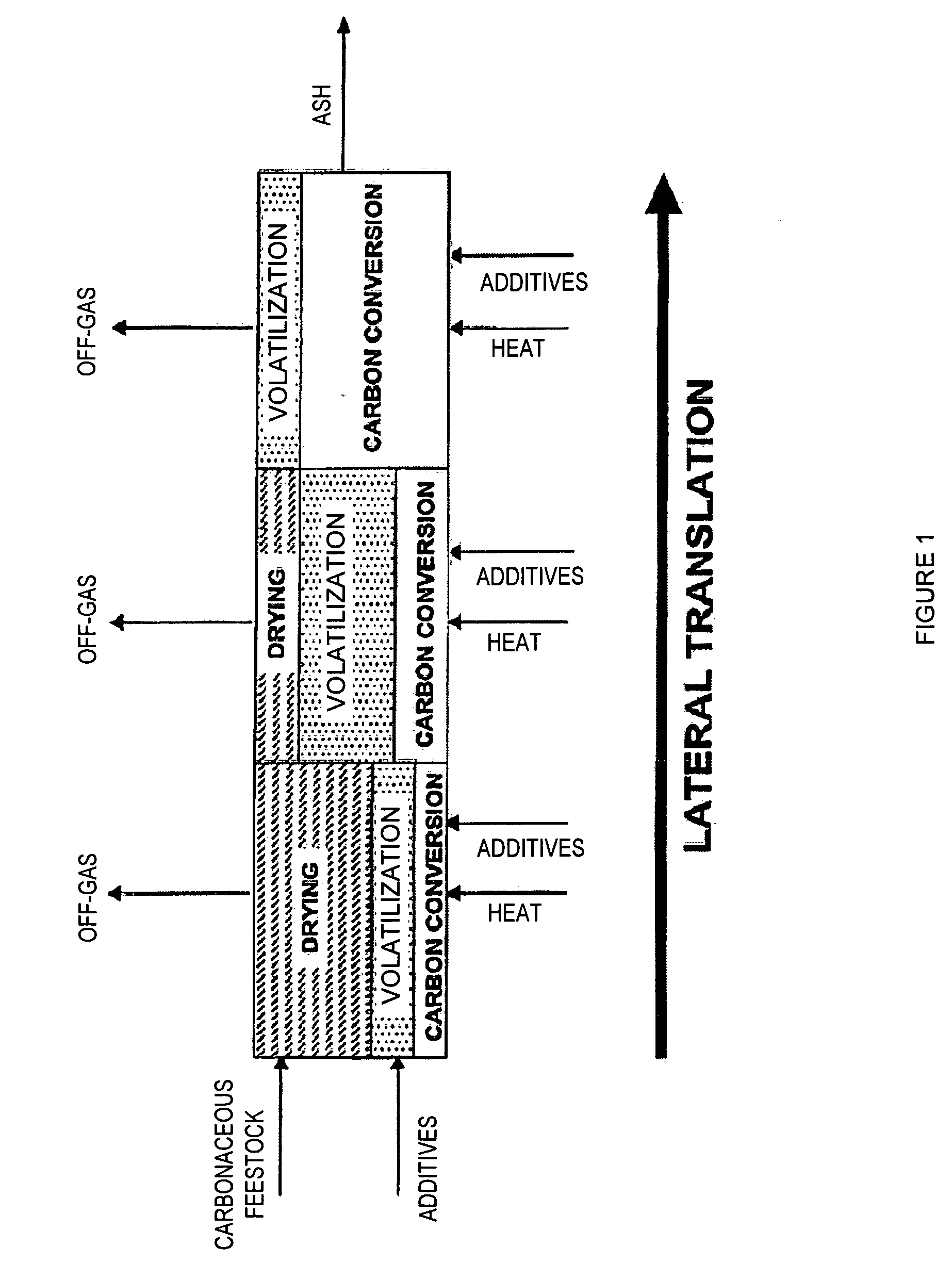

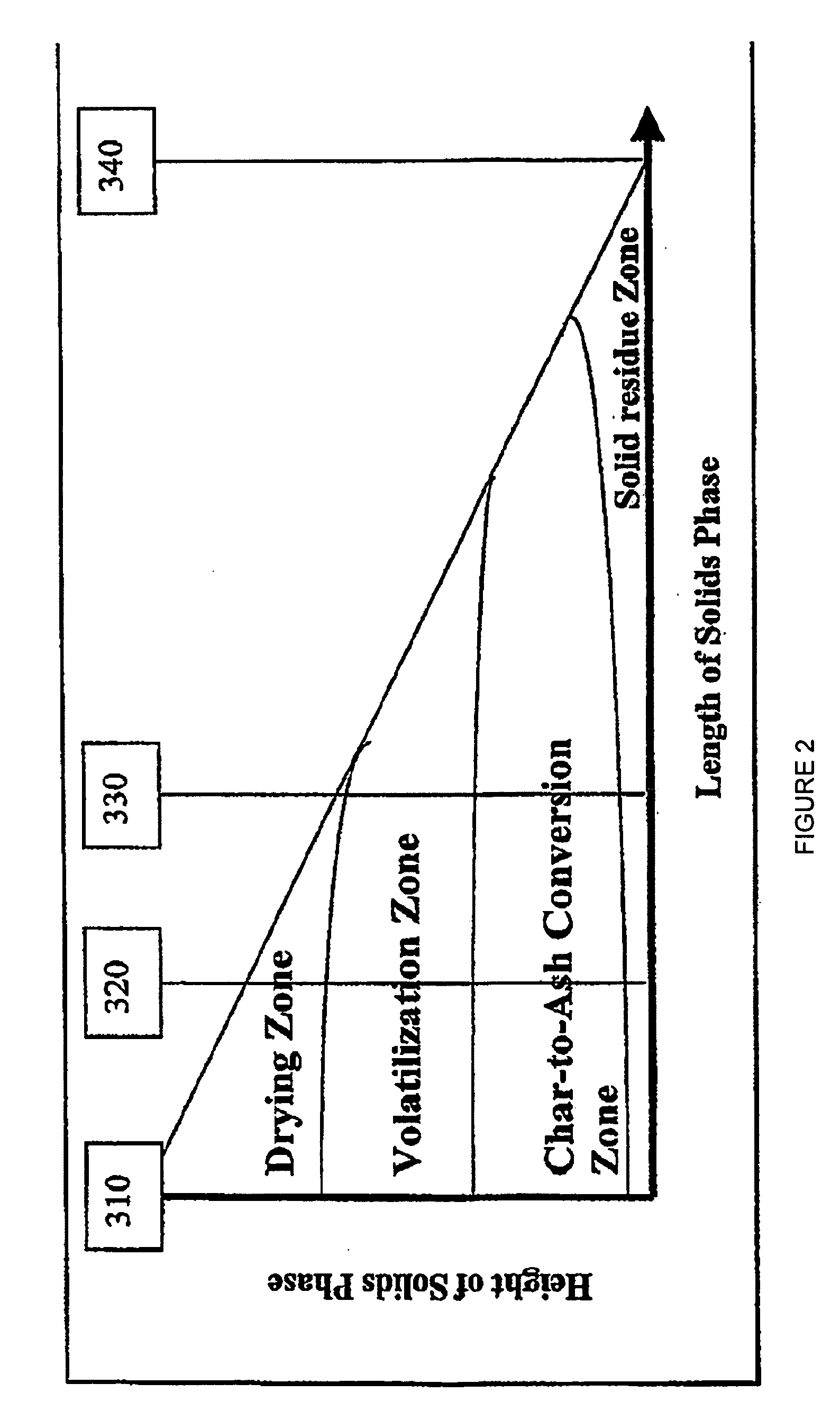

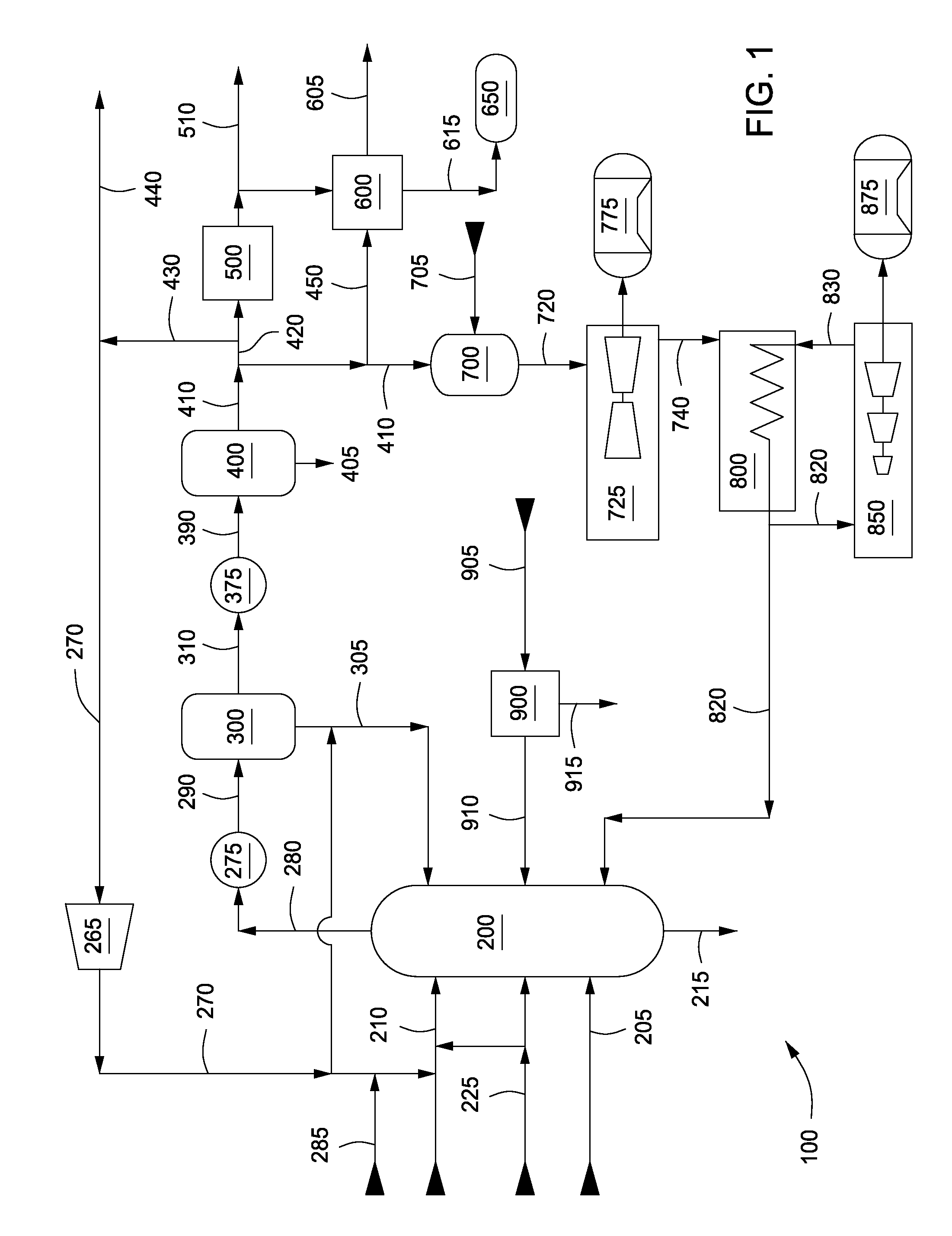

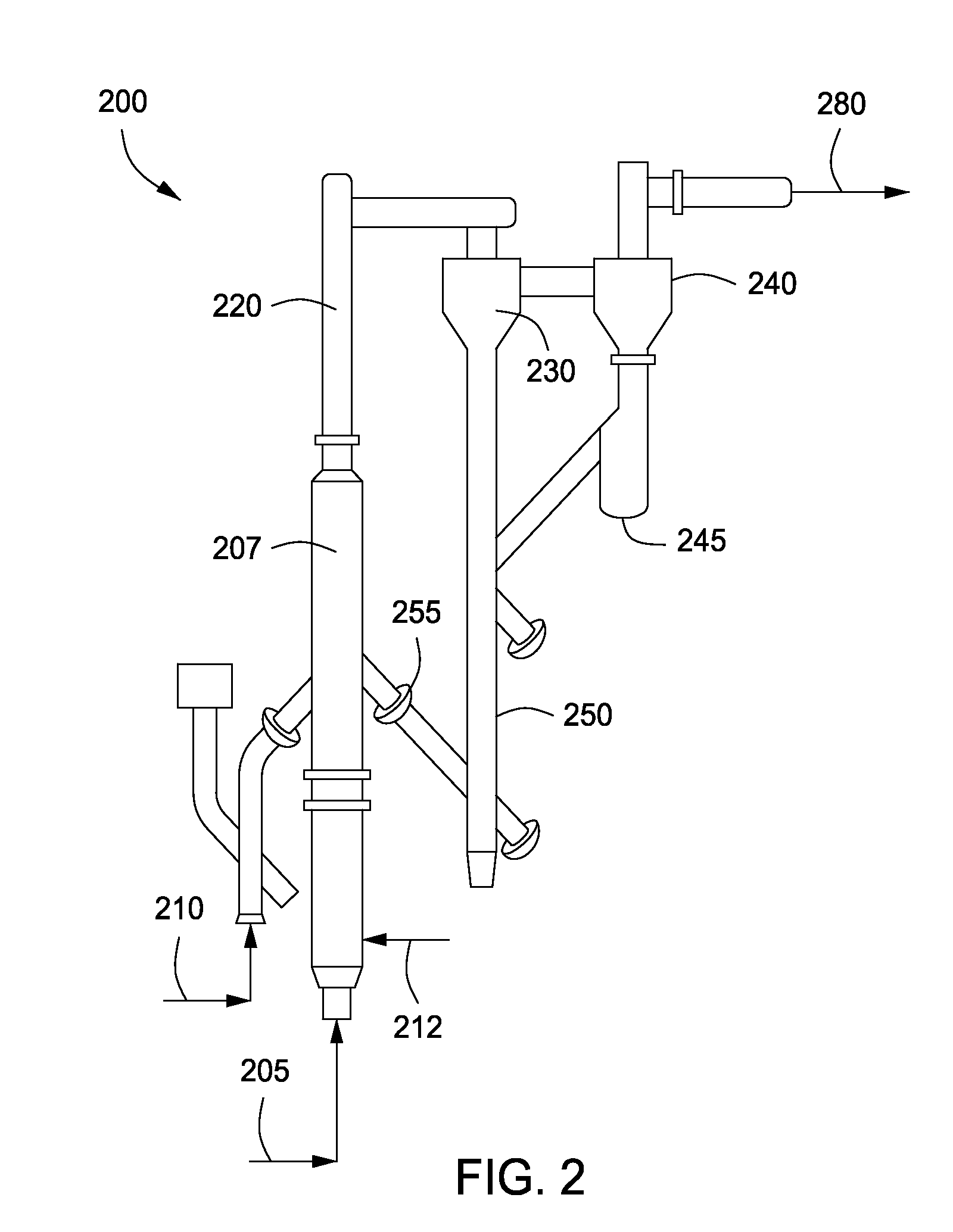

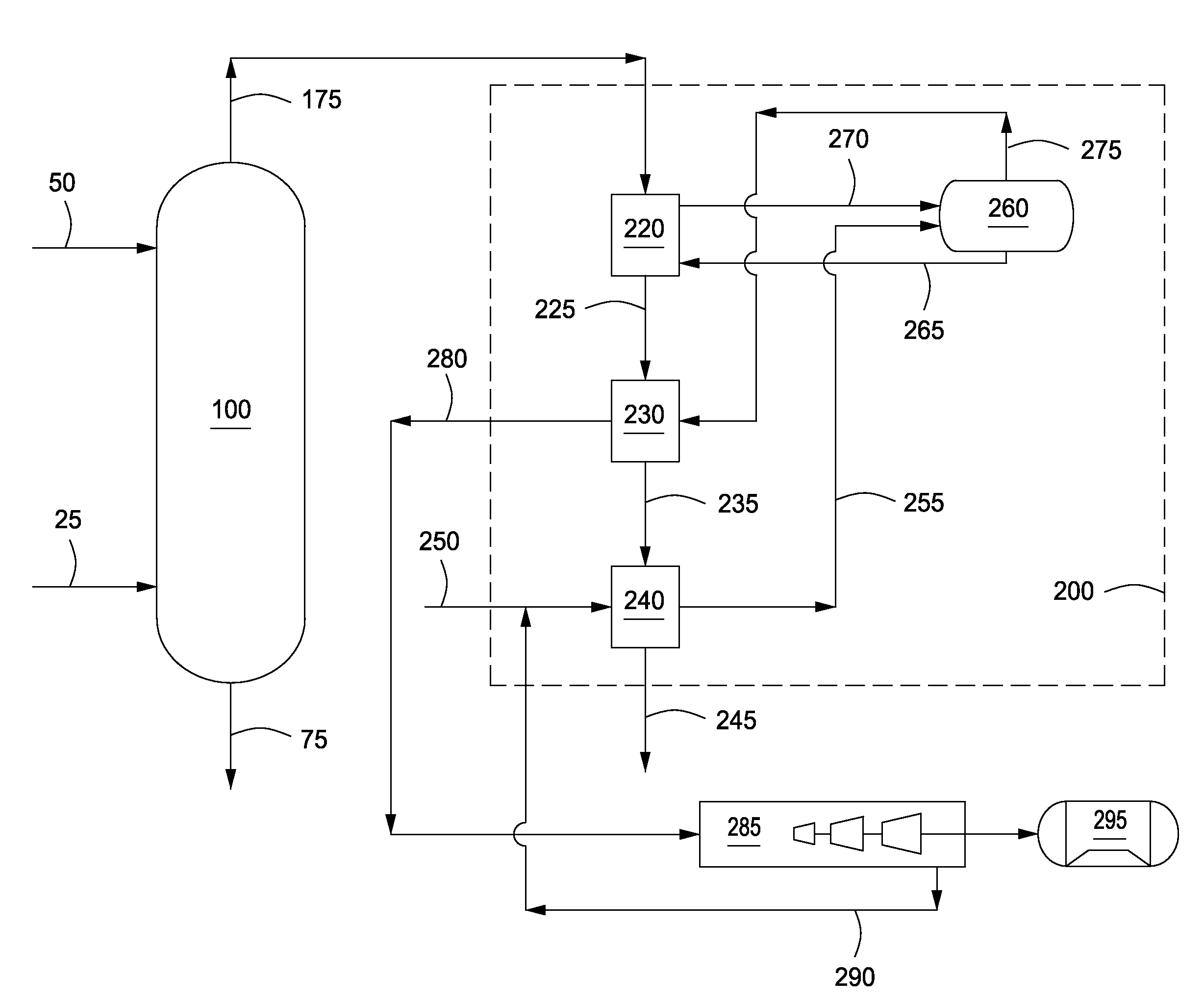

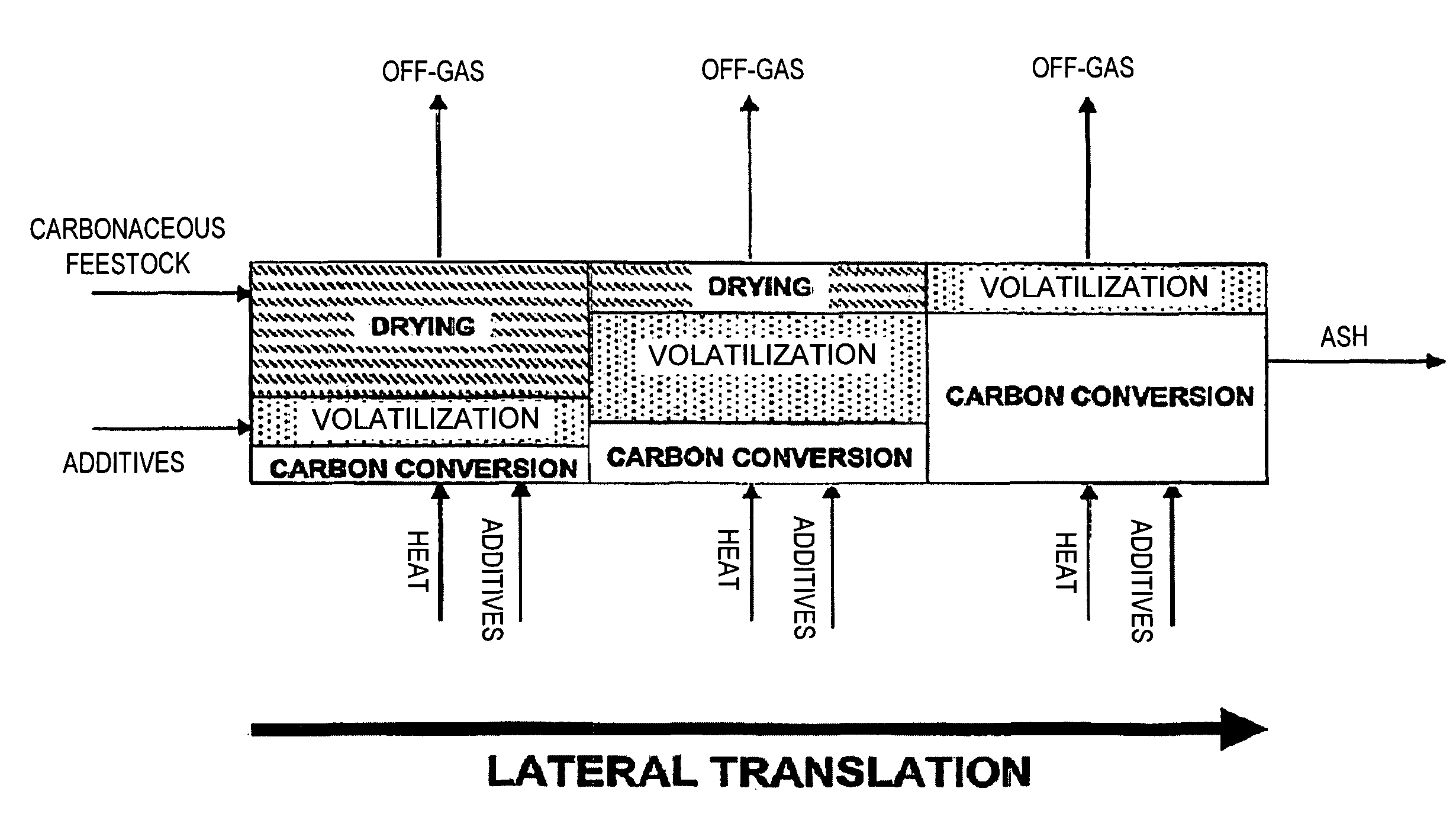

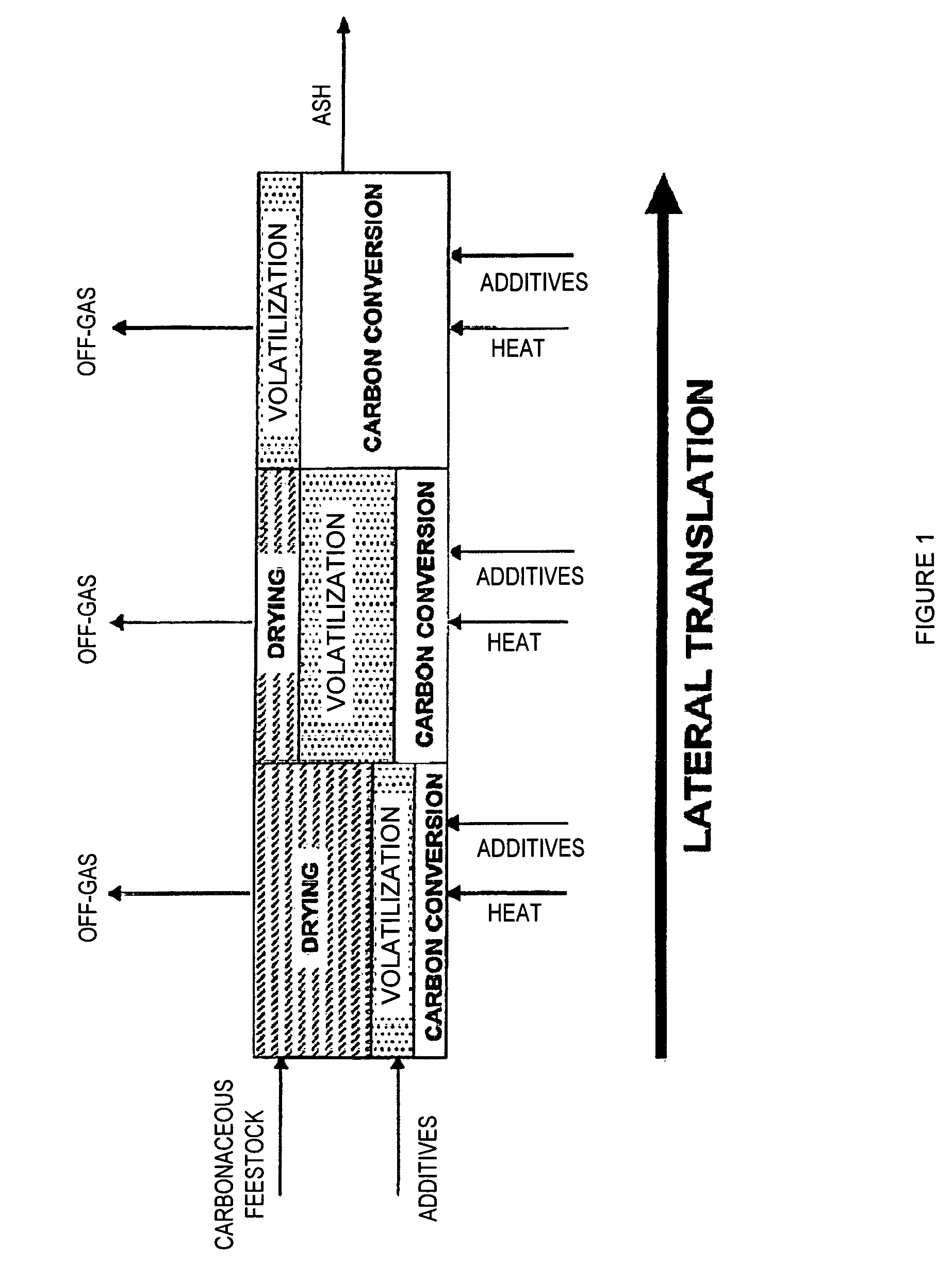

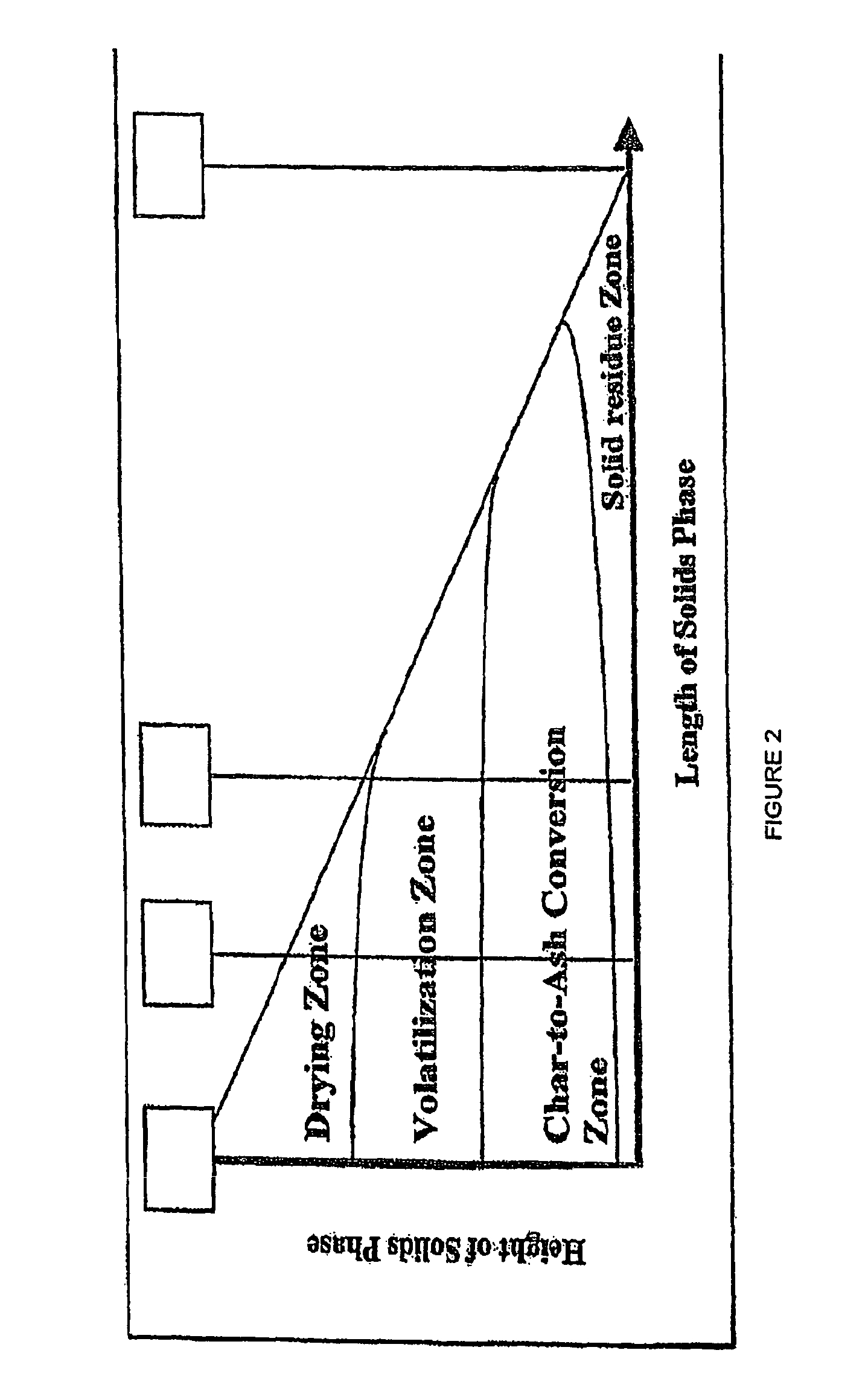

Low Temperature Gasification Facility with a Horizontally Oriented Gasifier

A low-temperature gasification system comprising a horizontally oriented gasifier is provided that optimizes the extraction of gaseous molecules from carbonaceous feedstock while minimizing waste heat. The system comprises a plurality of integrated subsystems that work together to convert municipal solid waste (MSW) into electricity. The subsystems comprised by the low-temperature gasification system are: a Municipal Solid Waste Handling System; a Plastics Handling System; a Horizontally Oriented Gasifier with Lateral Transfer Units System; a Gas Reformulating System; a Heat Recycling System; a Gas Conditioning System; a Residue Conditioning System; a Gas Homogenization System and a Control System.

Owner:PLASCO CONVERSION TECH INC

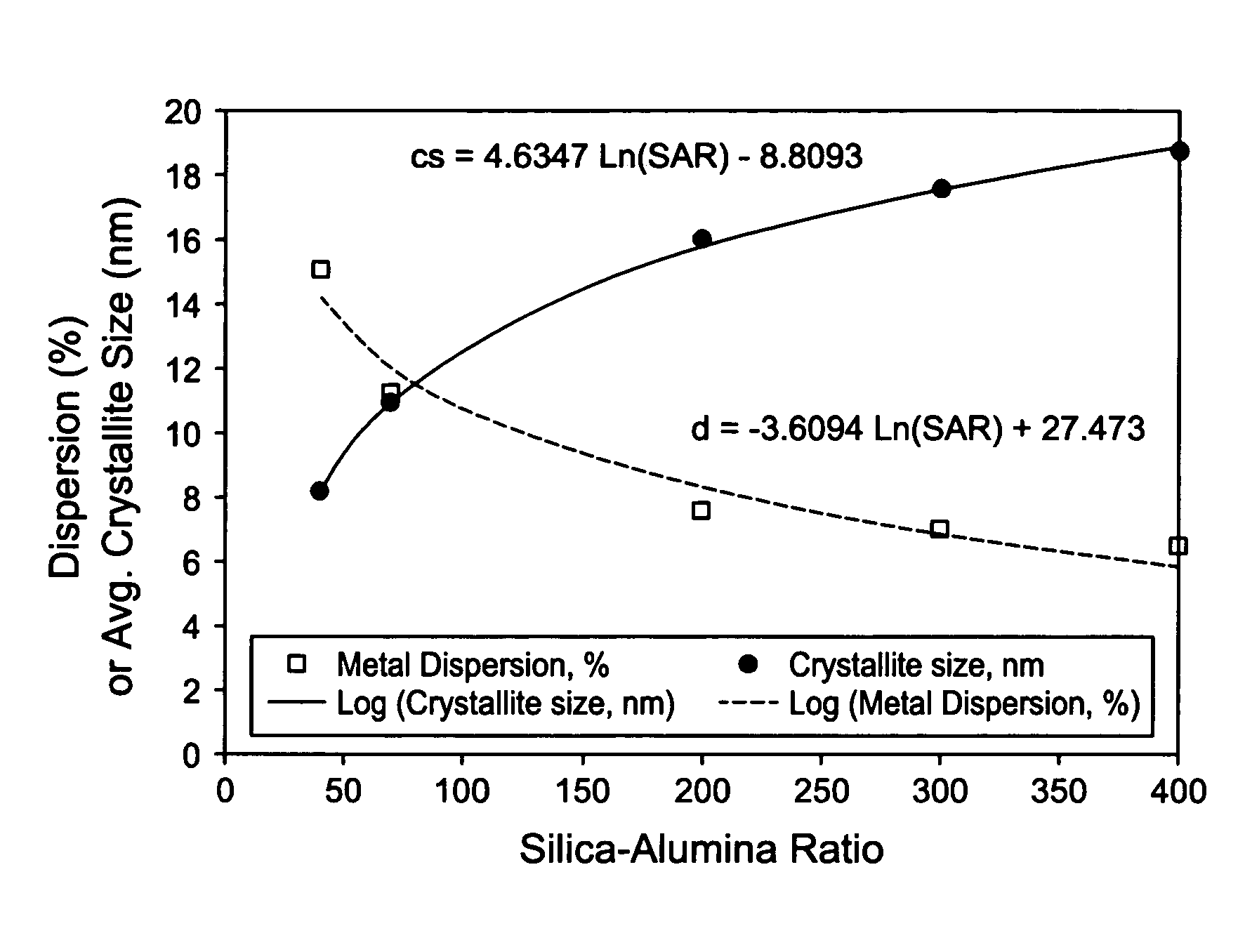

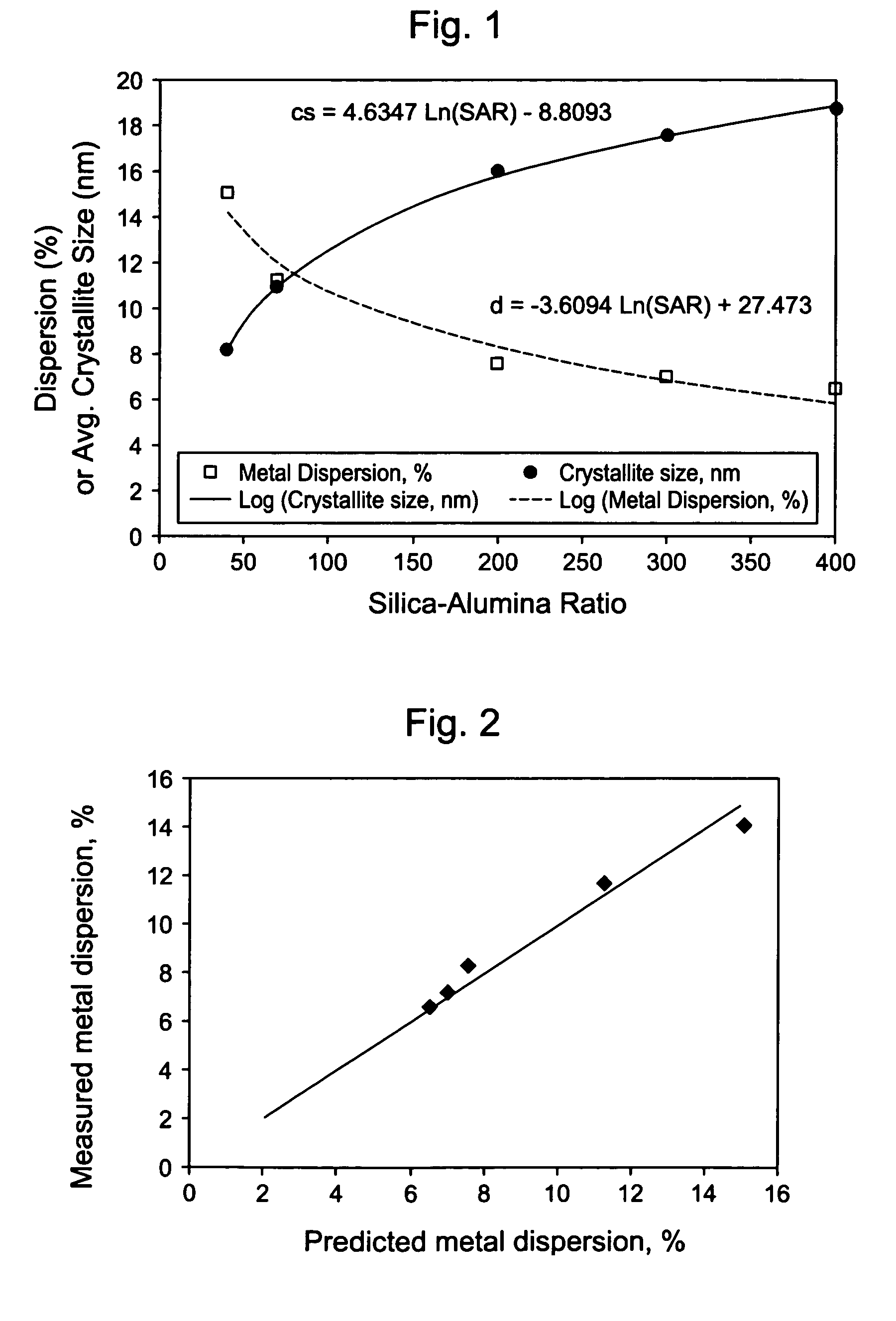

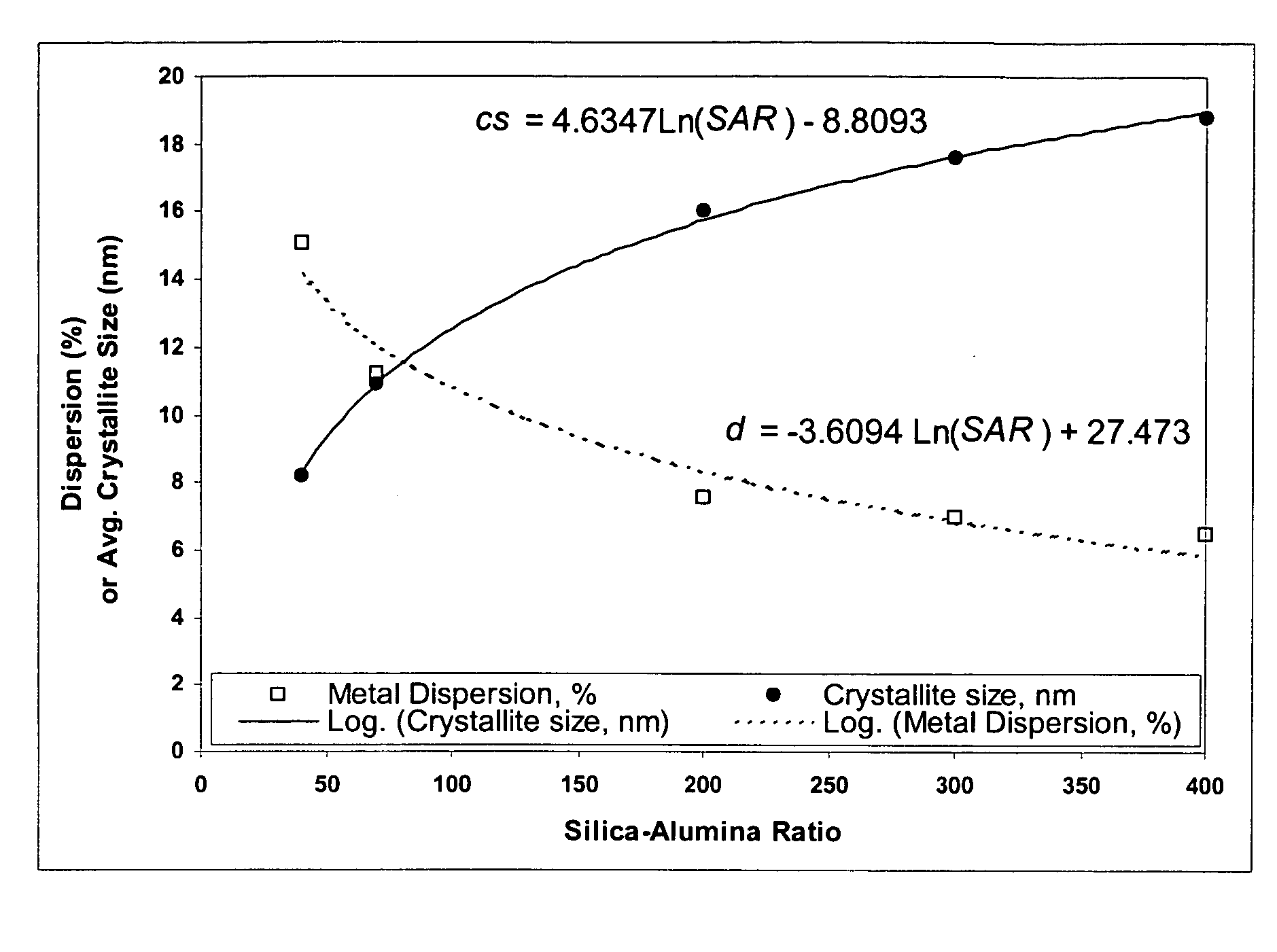

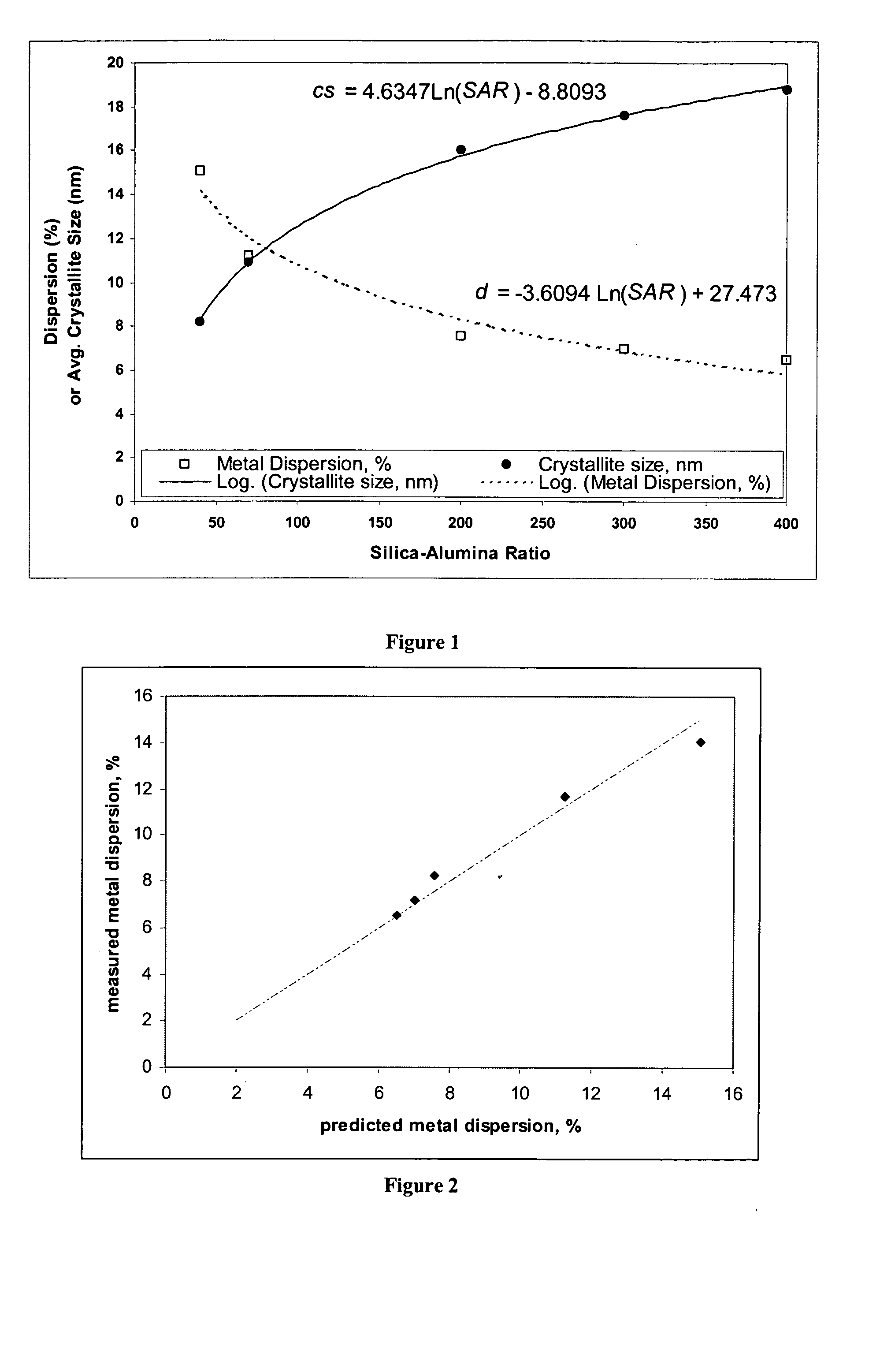

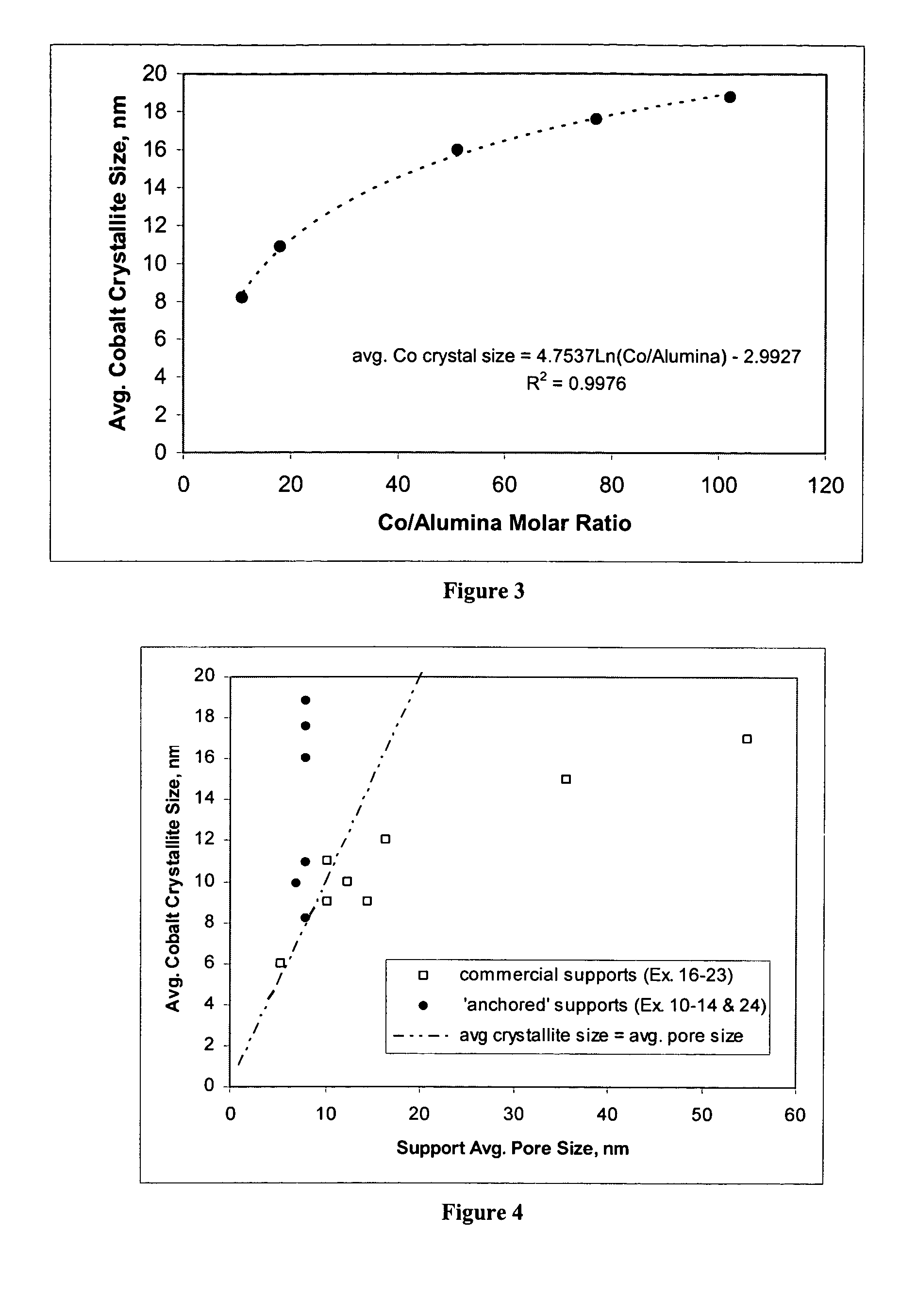

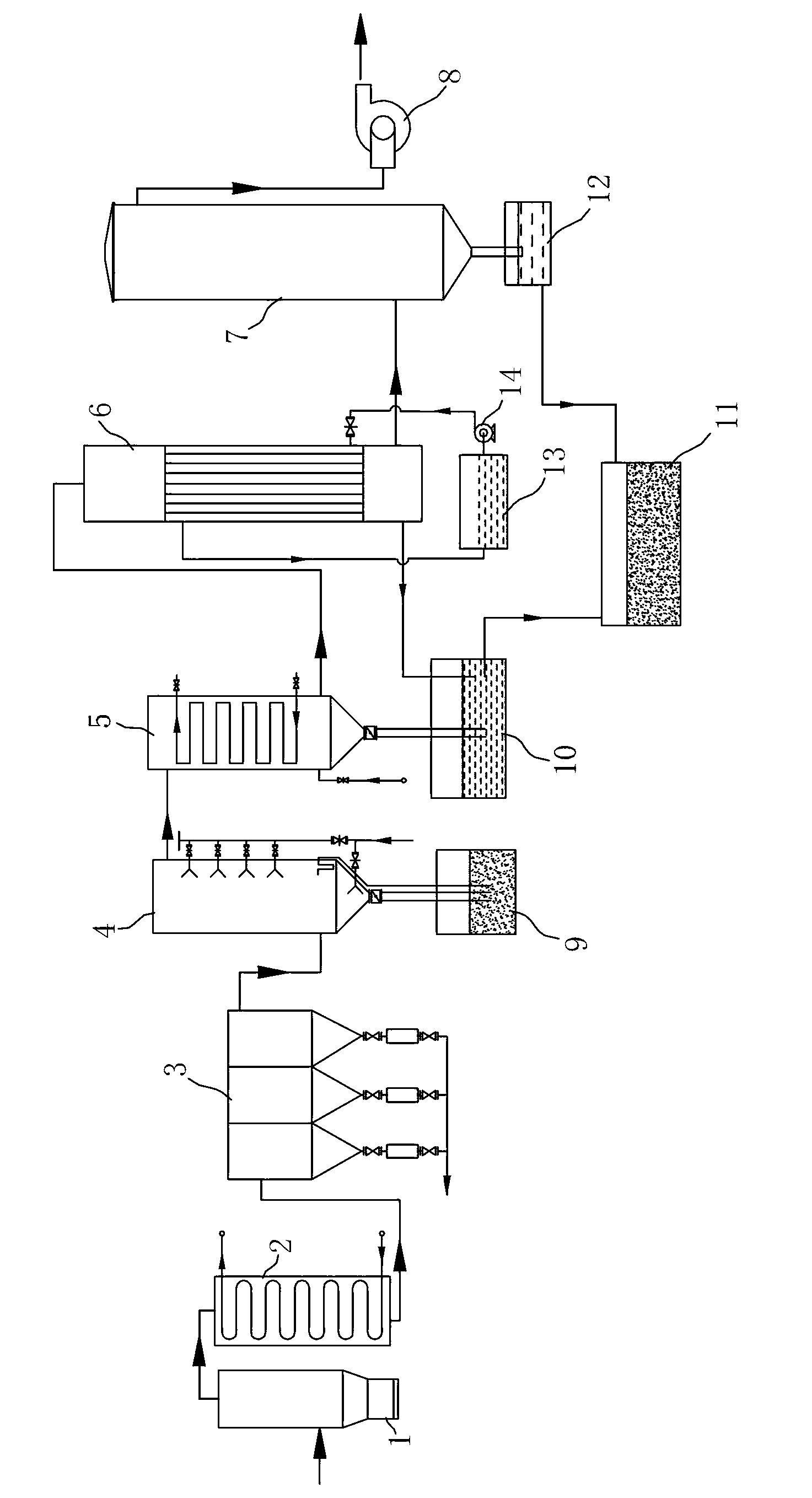

Silica-alumina catalyst support, catalysts made therefrom and methods of making and using same

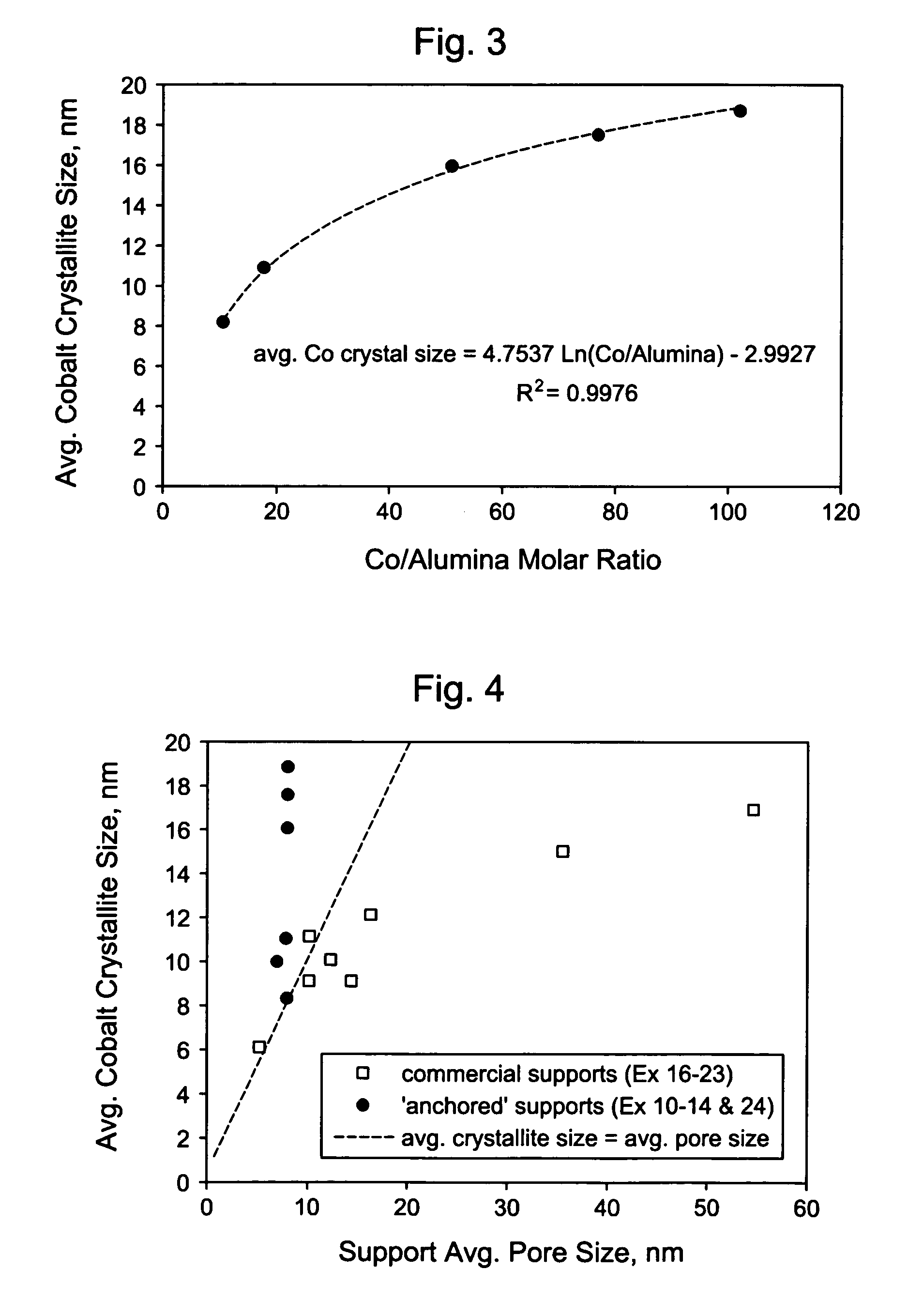

ActiveUS7541310B2High activityHydrocarbon from carbon oxidesMolecular sieve catalystsCompound (substance)Catalytic metal

This invention relates to catalysts comprising a catalytic metal deposited on a composite support with well-dispersed chemical “anchor” species acting as nucleation centers for catalytic metal crystallites growth. The catalysts have the advantage that the average catalytic metal crystallite size can be controlled by the molar ratio of catalytic metal to chemical “anchor,” and is not limited by the porous structure of the support. A preferred embodiment comprises a cobalt-based catalyst on a silica-alumina support made by a co-gel method, wherein its average pore size can be controlled by the pH. The alumina species in the support most likely serve as chemical “anchors” to control the dispersion of cobalt species, such that the average cobalt crystallite size can be greater than the average pore size.

Owner:CLARIANT INT LTD

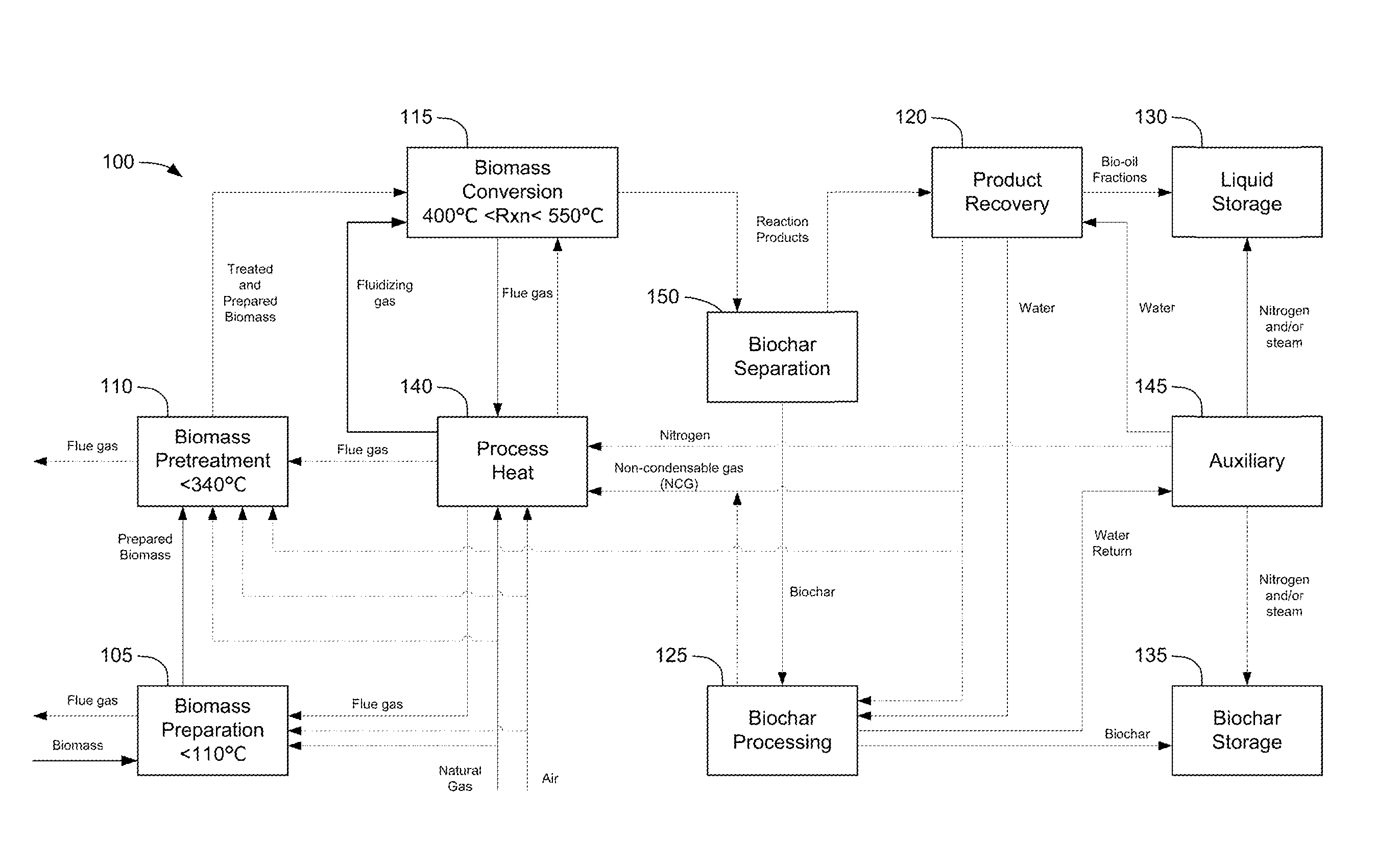

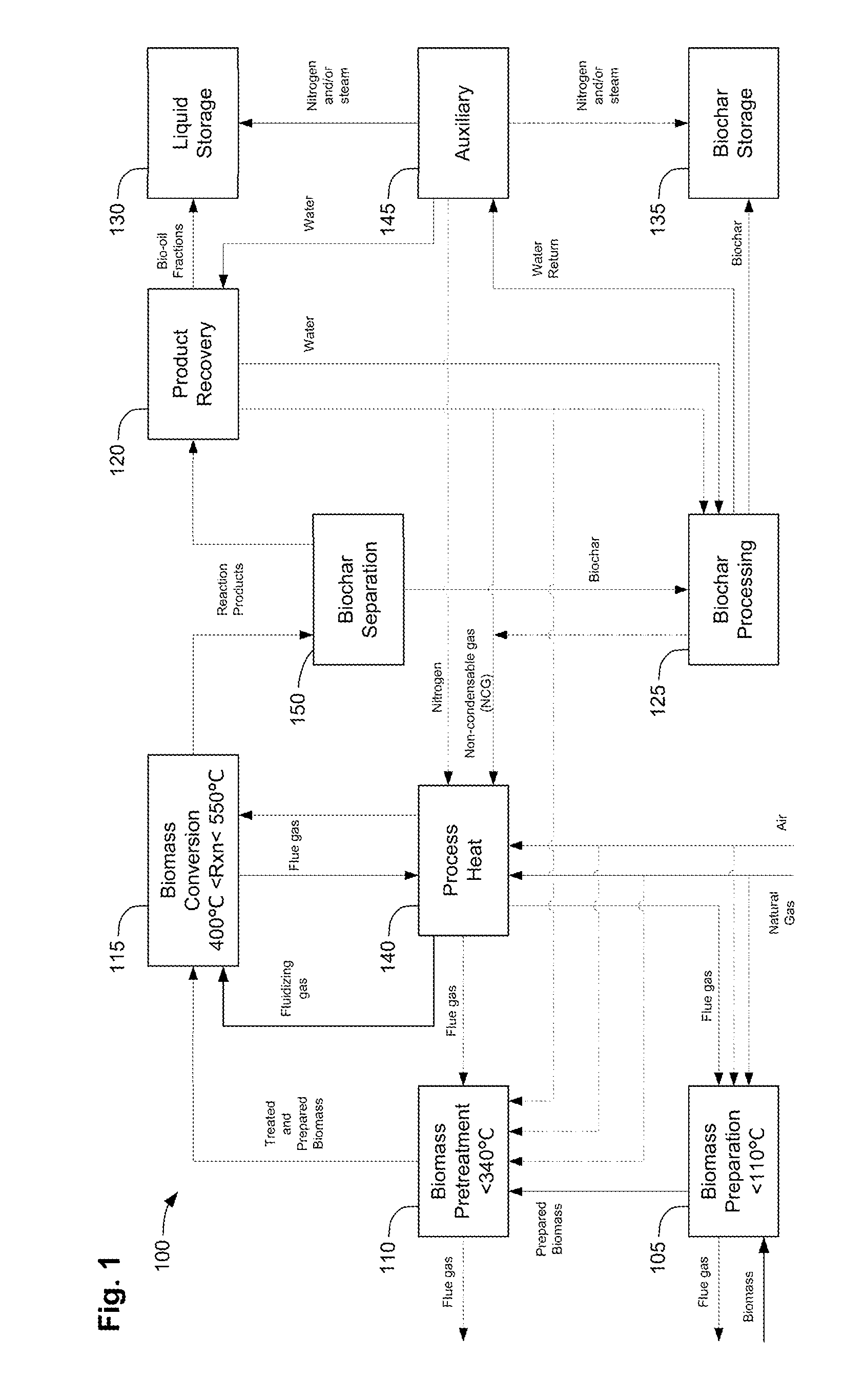

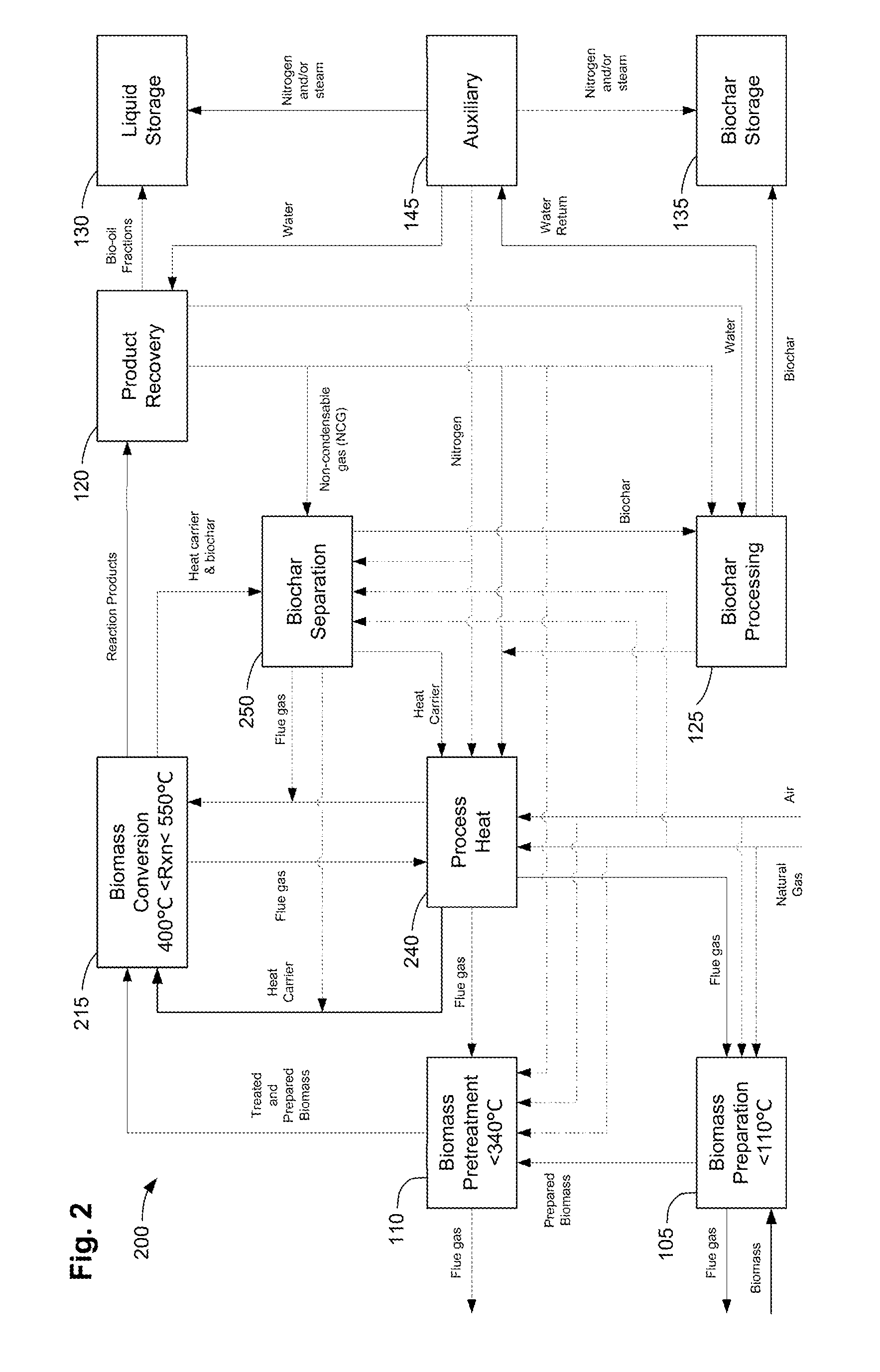

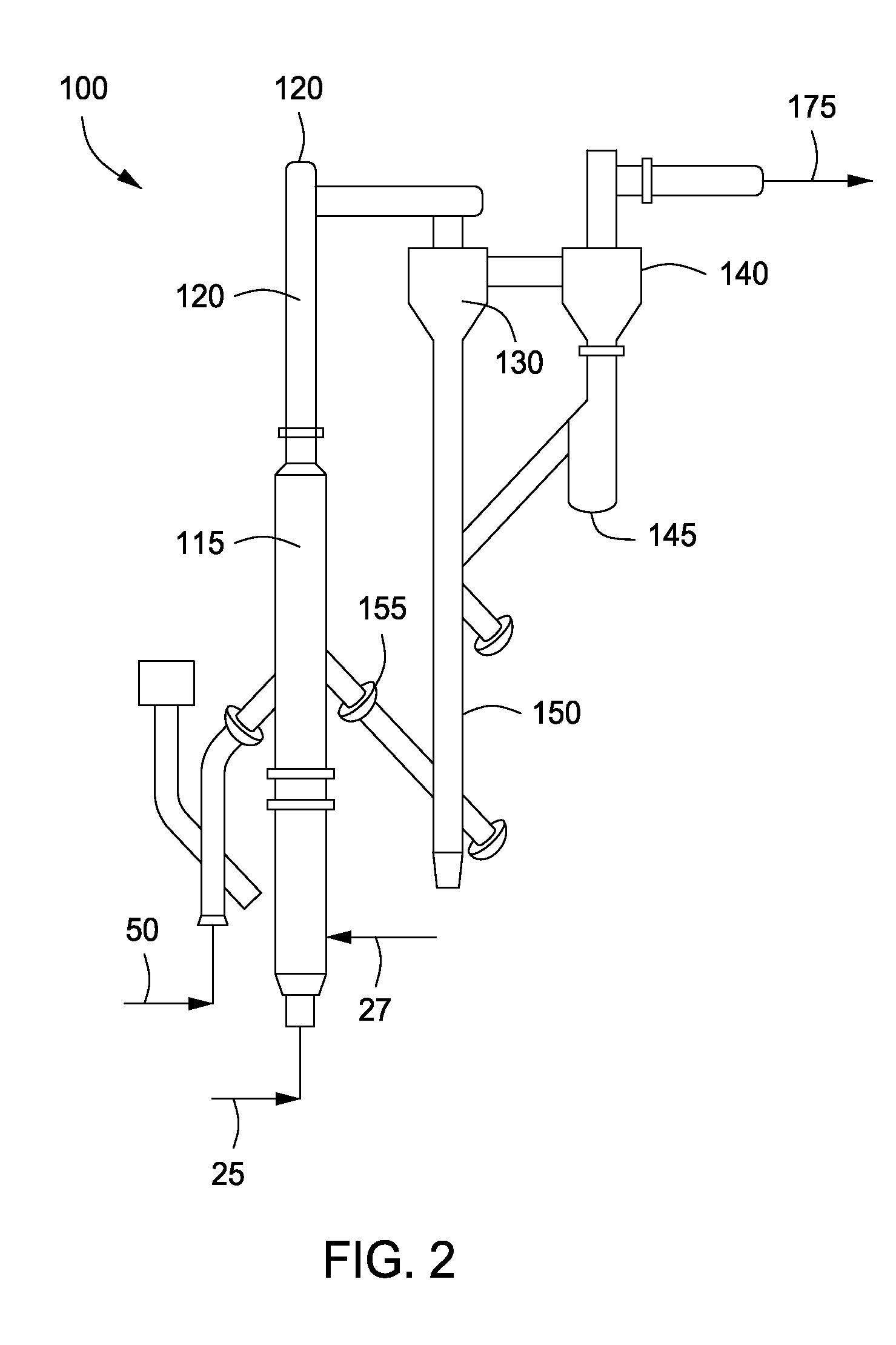

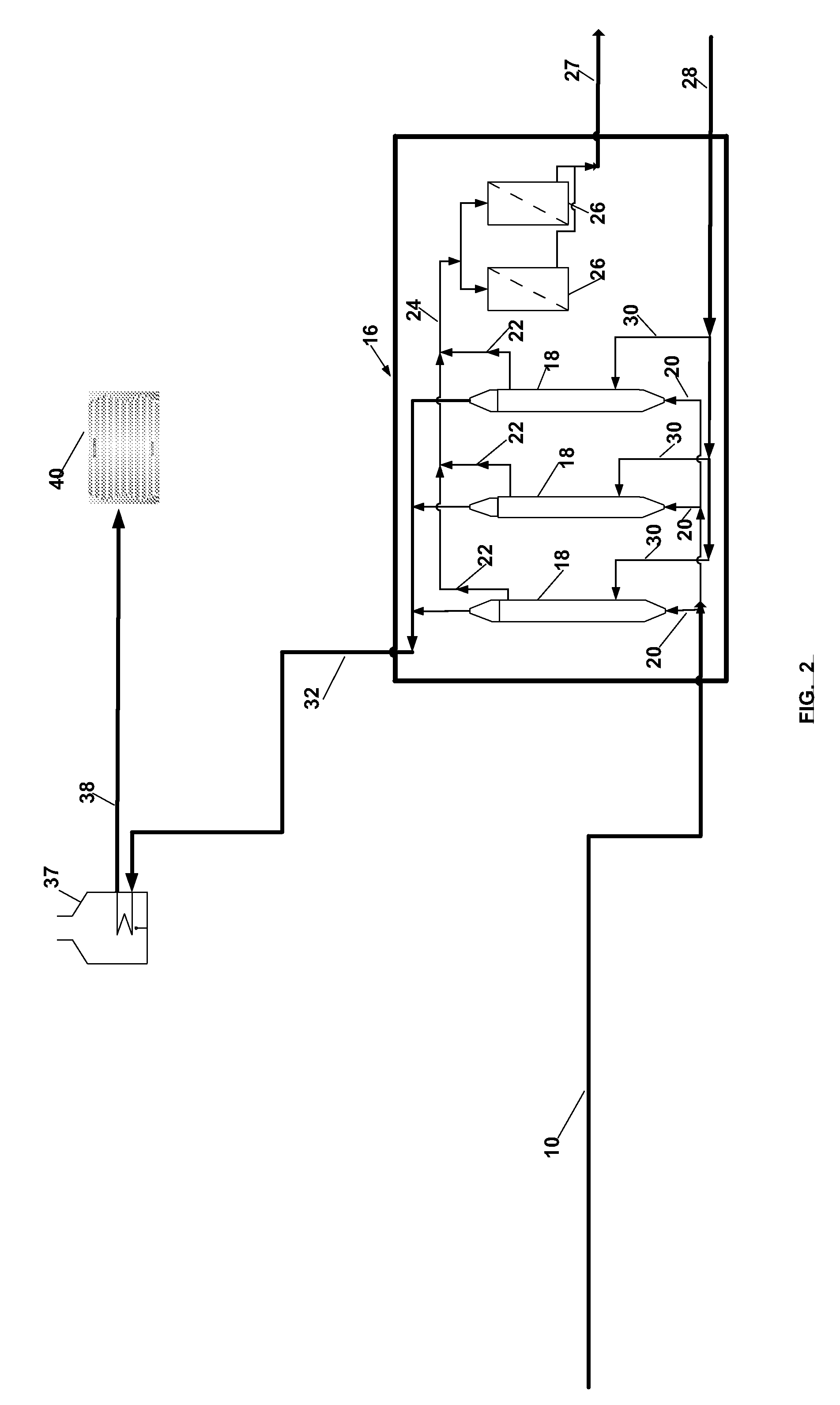

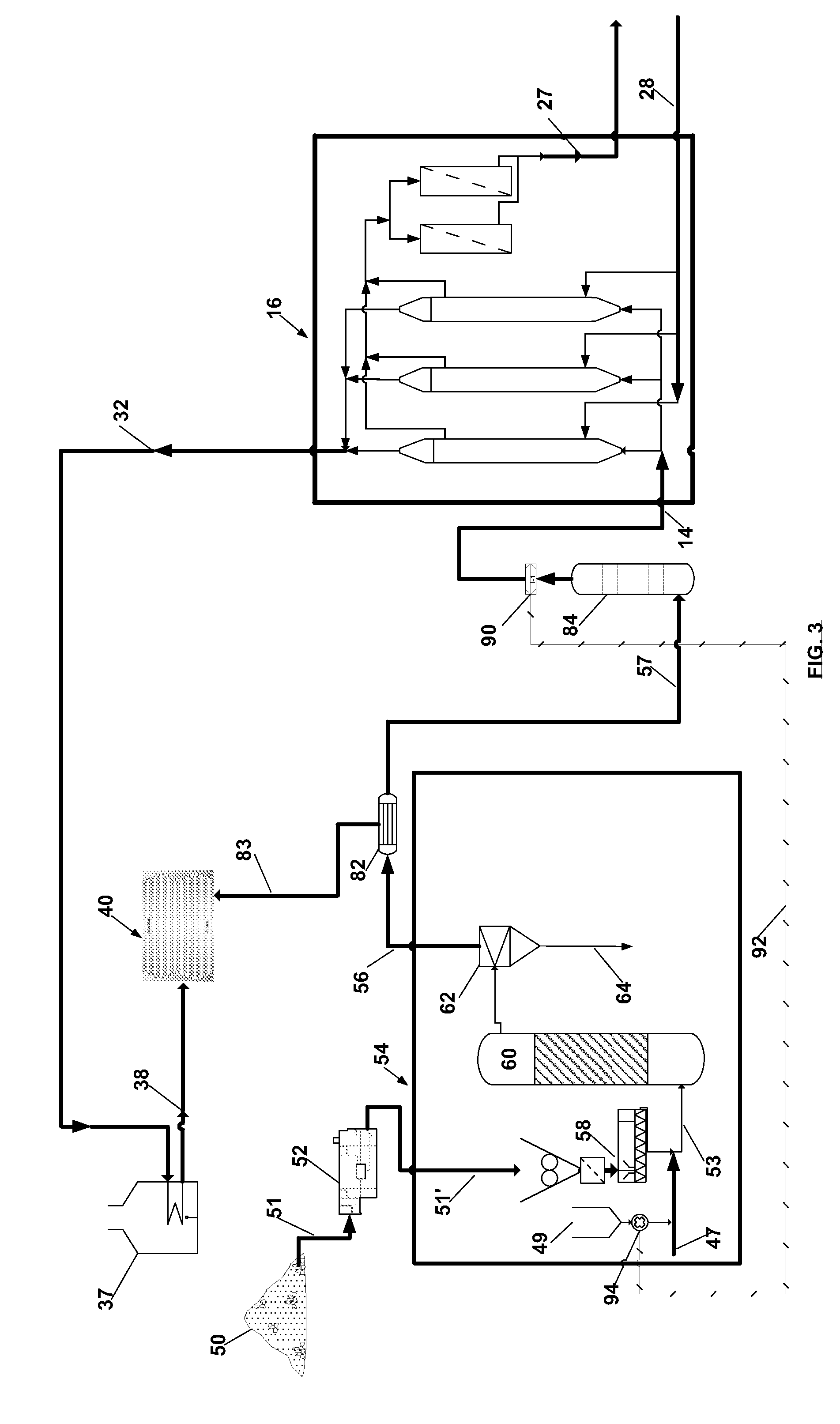

Methods for integrated fast pyrolysis processing of biomass

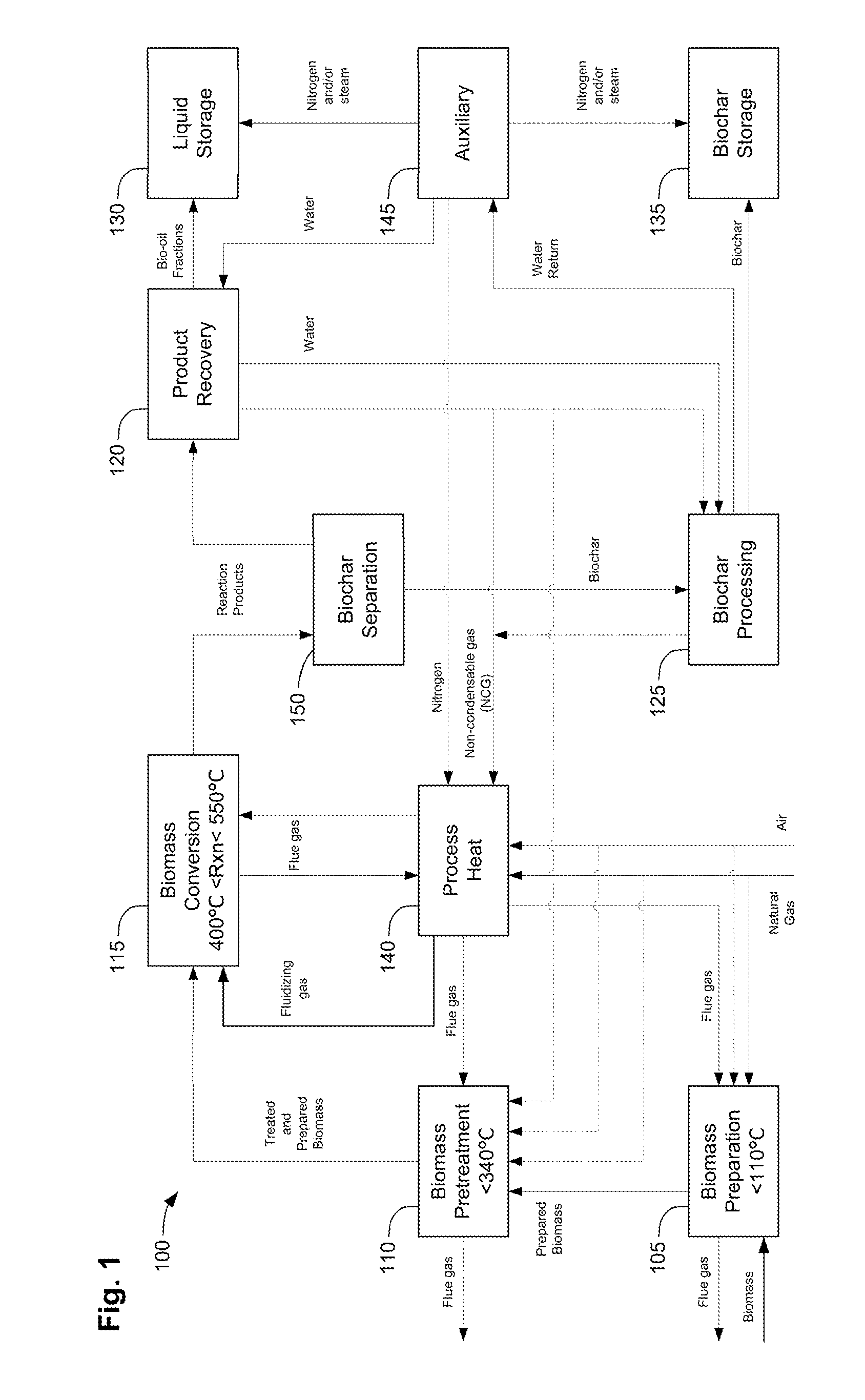

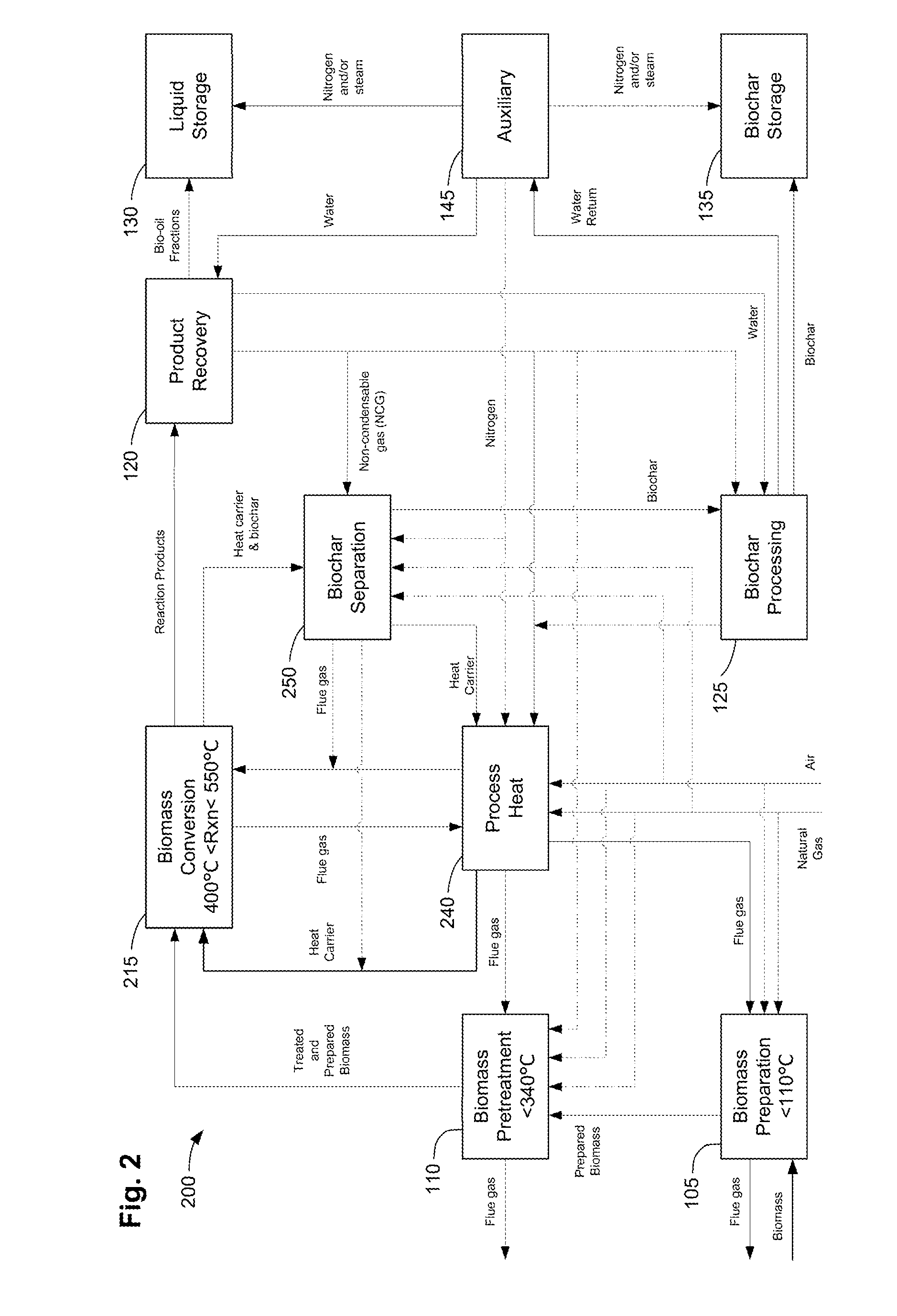

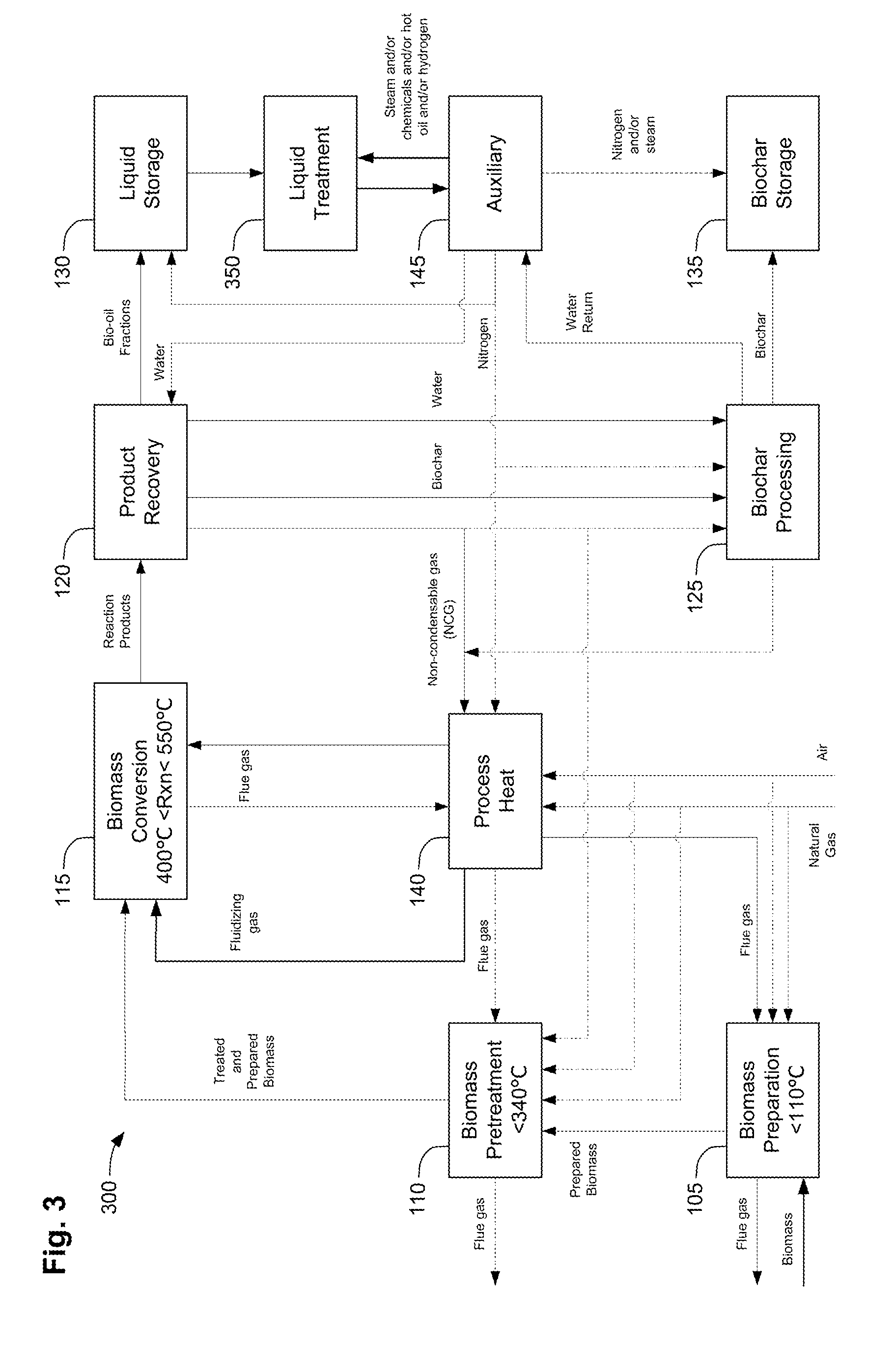

ActiveUS20110258914A1Improve collection efficiencyMinimizes water contentDirect heating destructive distillationBiofuelsPre treatmentSafe handling

Methods, process, apparatus, equipment, and systems are disclosed for converting biomass into bio-oil fractions for chemicals, materials, feedstocks and fuels using a low-cost, integrated fast pyrolysis system. The system improves upon prior art by creating stable, bio-oil fractions which have unique properties that make them individually superior to conventional bio-oil. The invention enables water and low-molecular weight compounds to be separated into a final value-added fraction suitable for upgrading or extracting into value-added chemicals, fuels and water. Initial bio-oil fractions from the process are chemically distinct, have low-water content and acidity which reduces processing costs normally associated with conventional bio-oil post-production upgrading since fewer separation steps, milder processing conditions and lower auxiliary inputs are required. Biochar is stabilized so that it can be handled safely. The integrated fast pyrolysis process includes biomass storage, preparation, pretreatment, and conversion, product recovery and processing to create and store stable biochar and bio-oil fractions.

Owner:AVELLO BIOENERGY

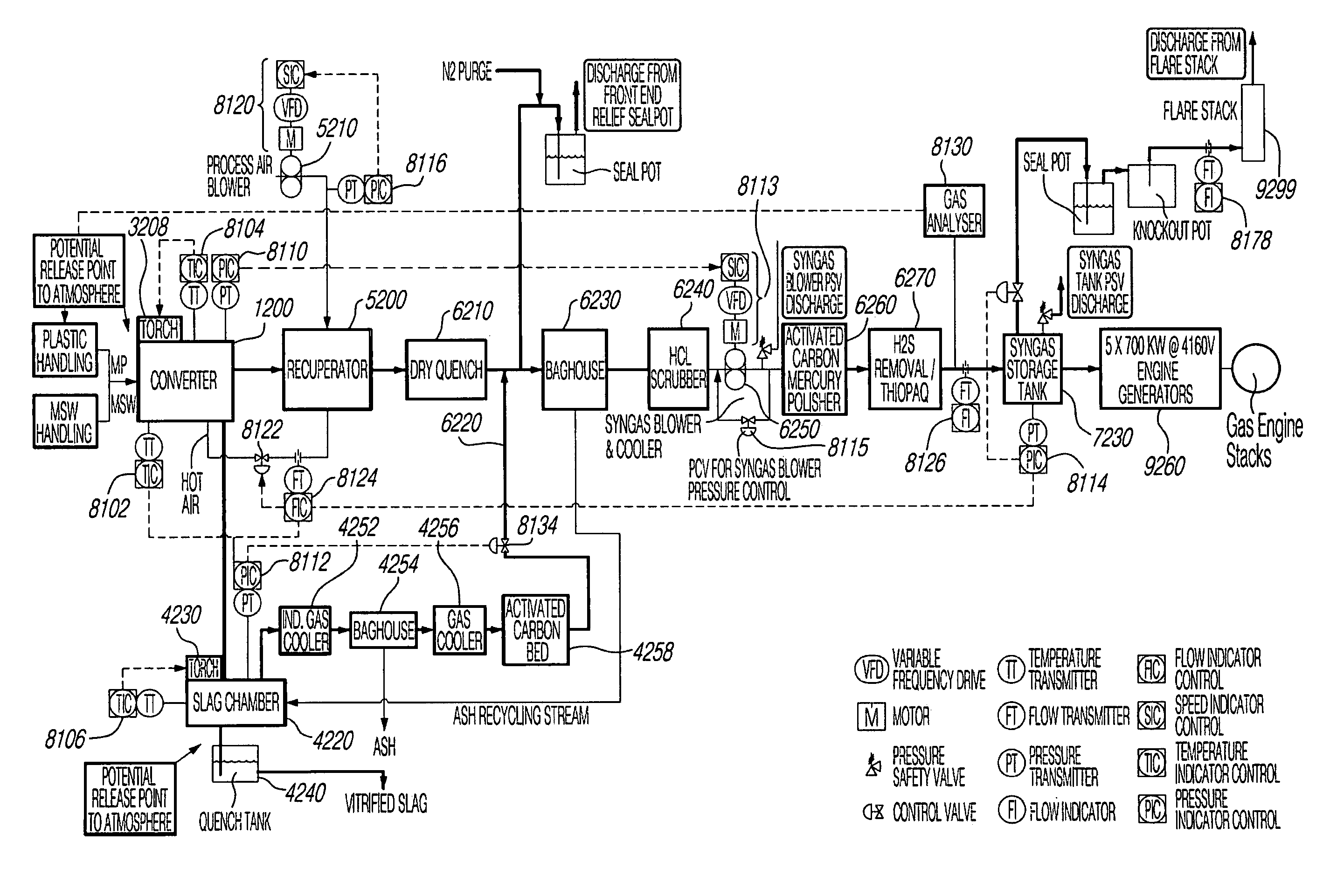

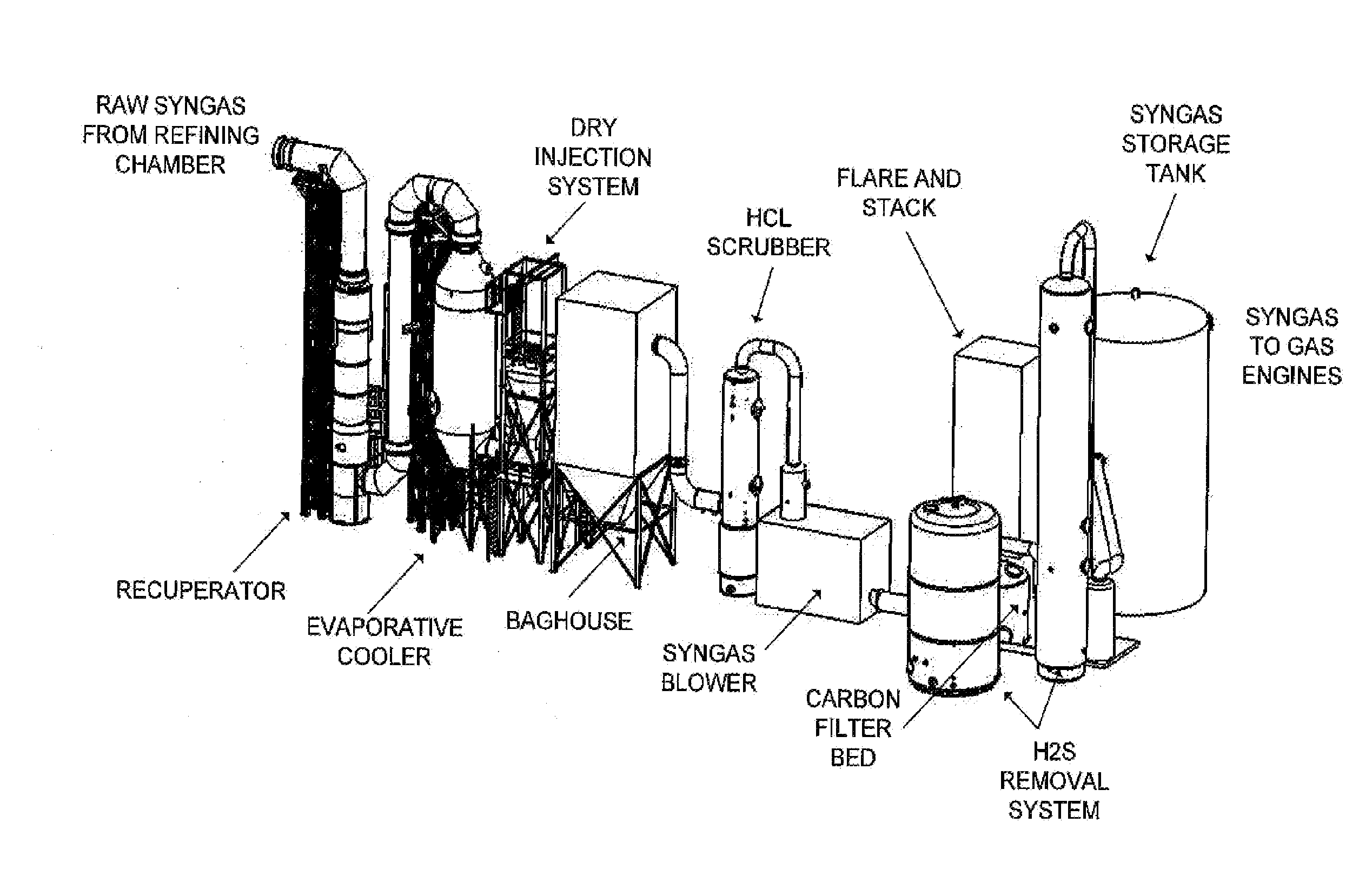

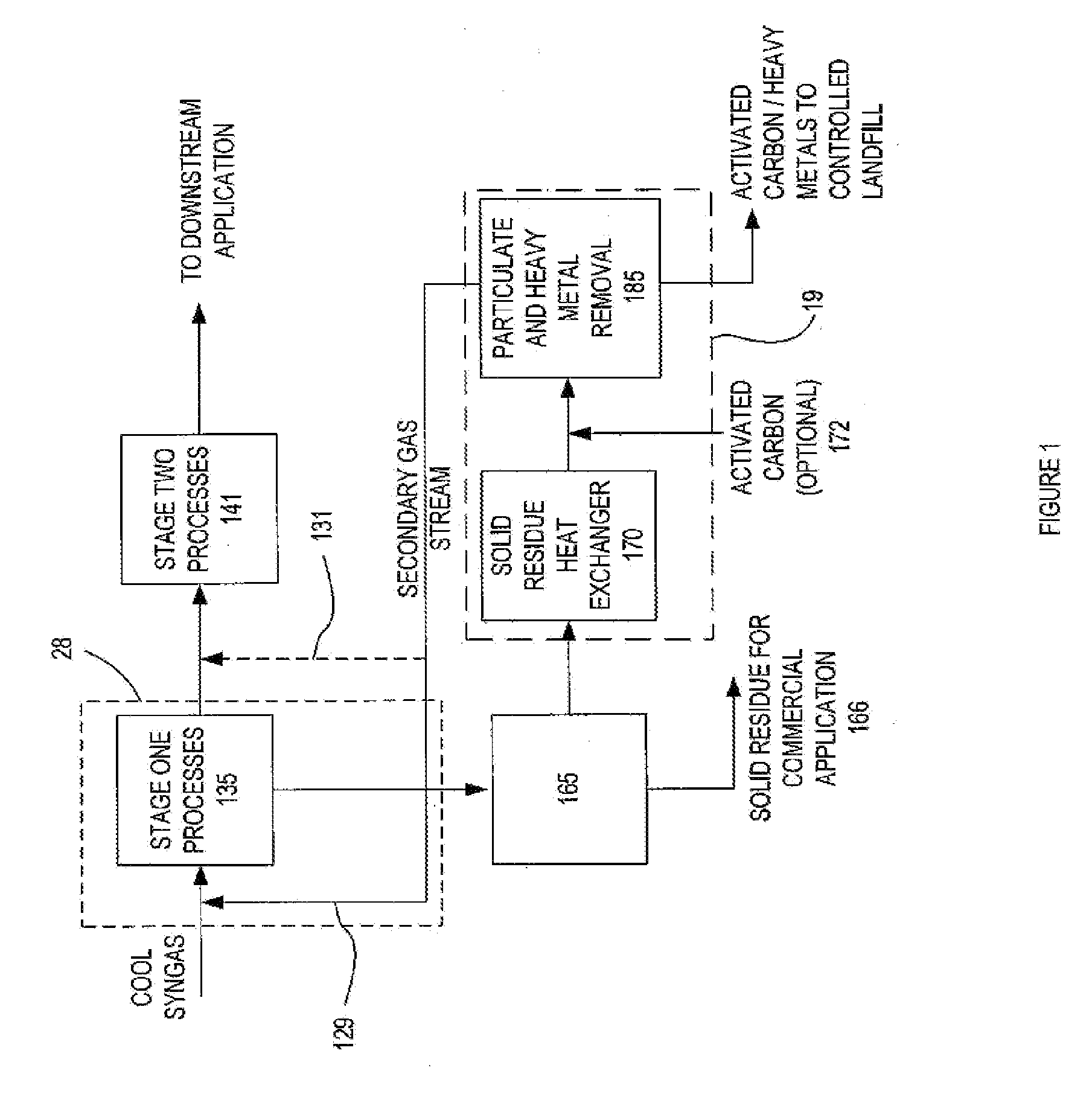

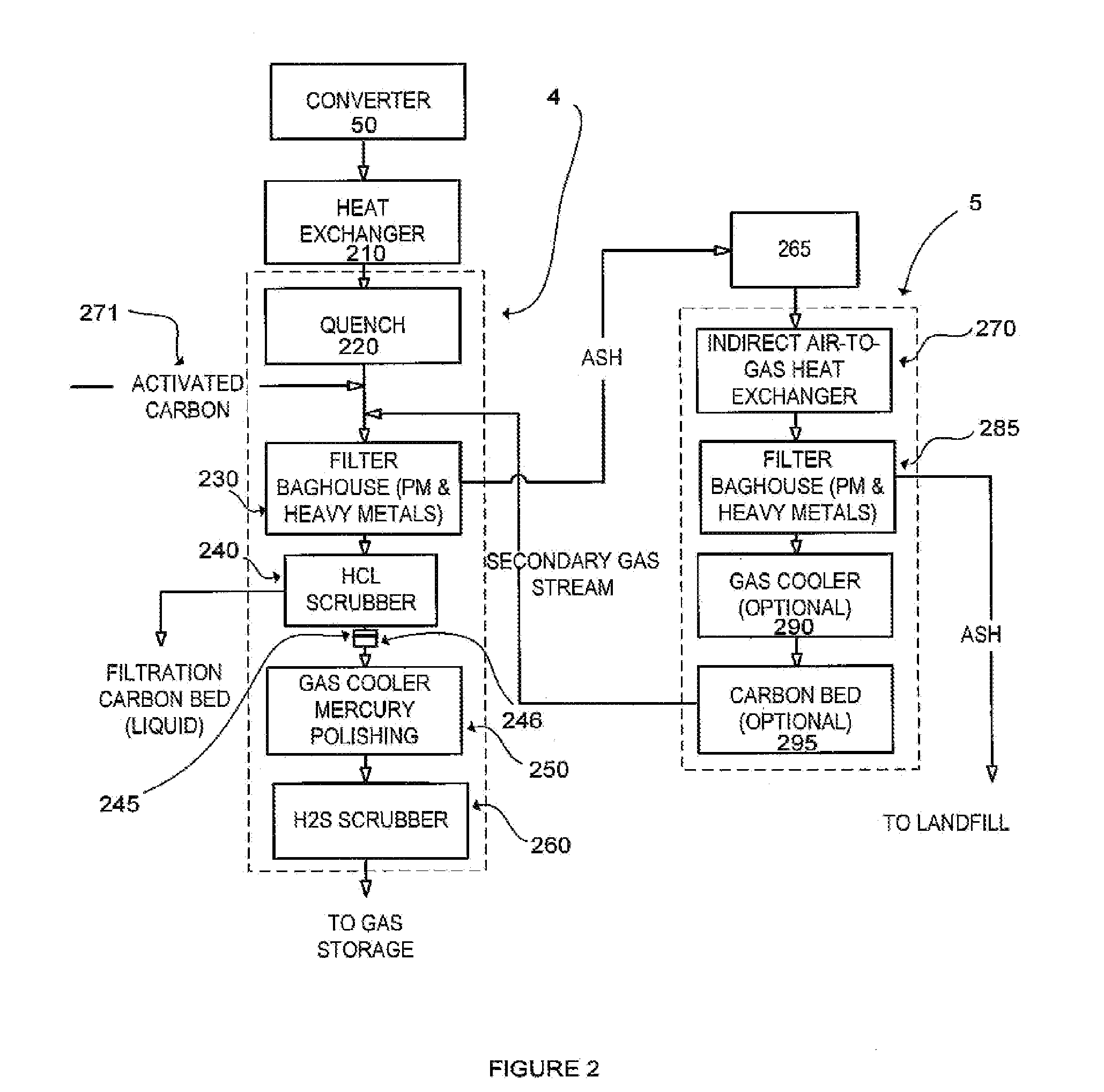

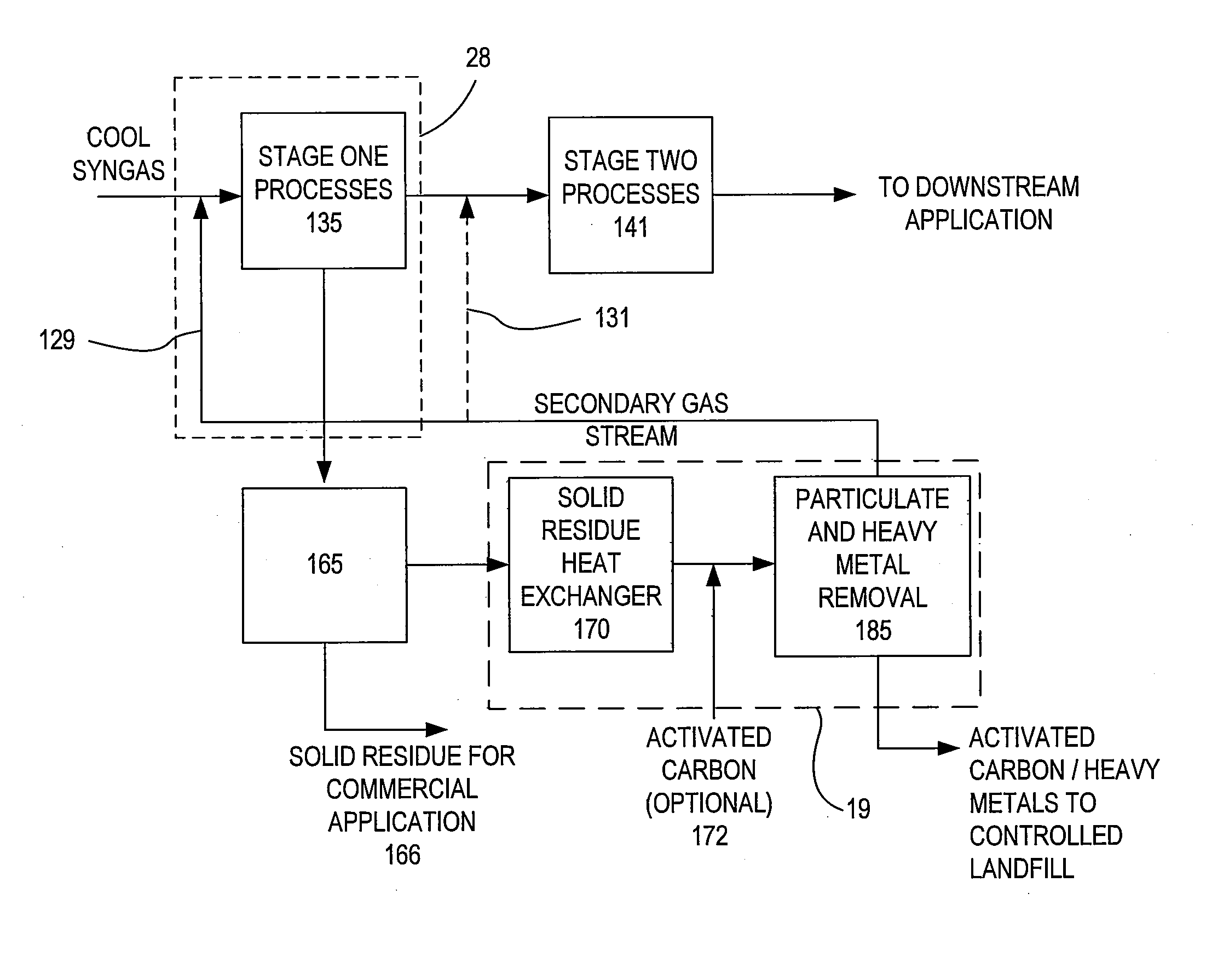

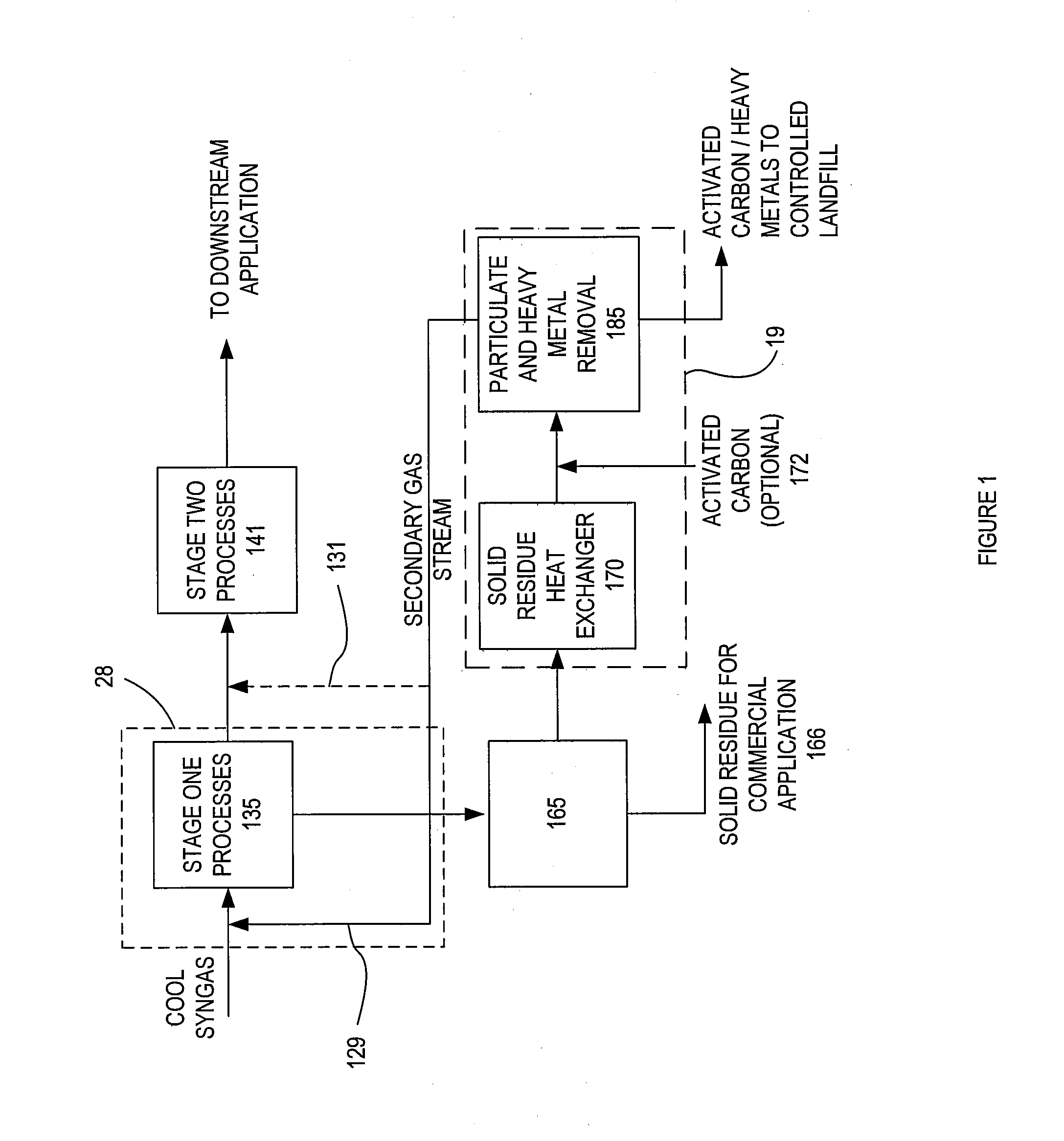

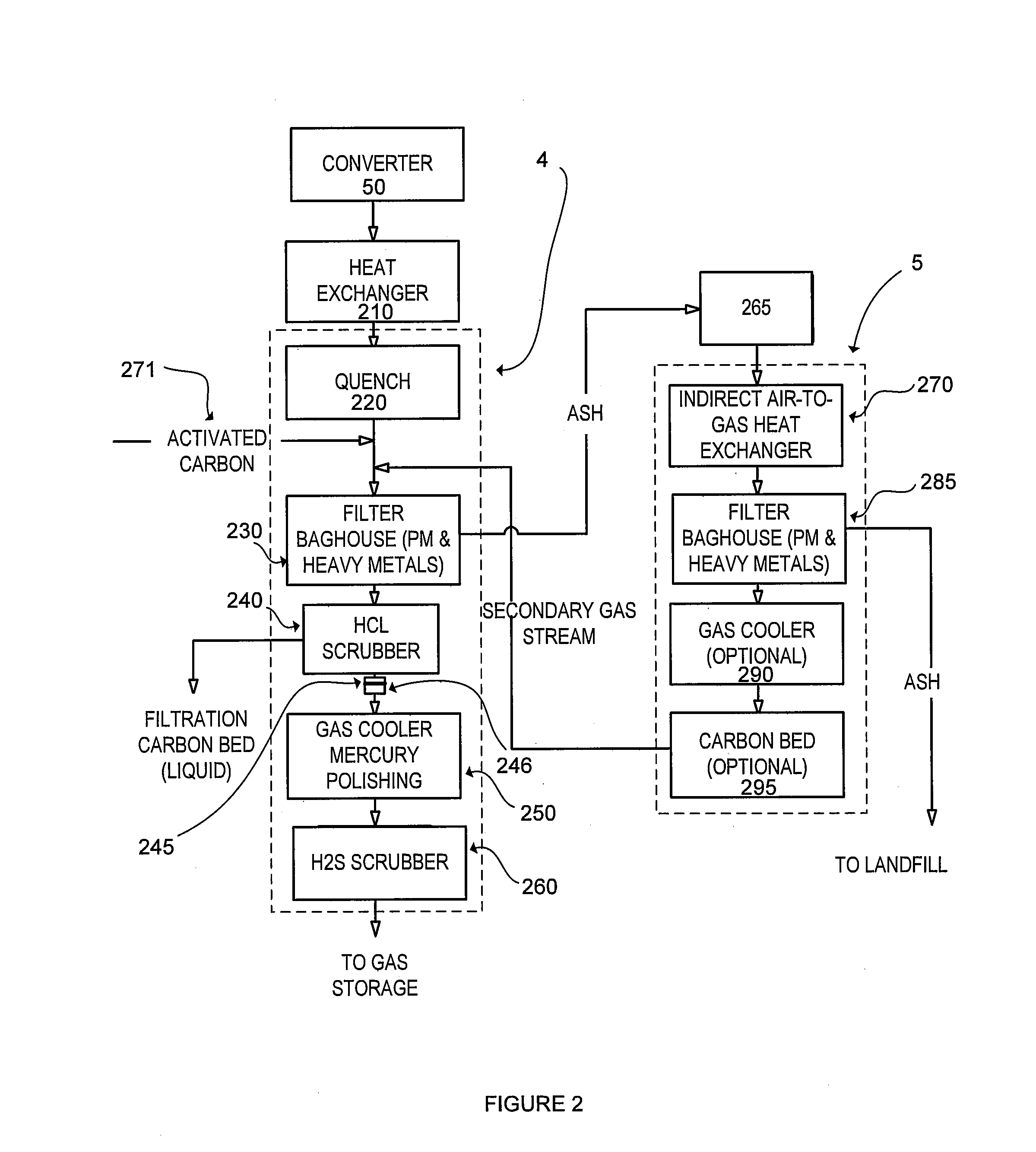

Gas conditioning system

The present invention provides a gas conditioning system for processing an input gas from a low temperature gasification system to an output gas of desired characteristics. The system comprises a two-stage process, the first stage separating heavy metals and particulate matter in a dry phase, and the second stage including further processing steps of removing acid gases, and / or other contaminants. Optional processes include adjusting the humidity and temperature of the input gas as it passes through the gas conditioning system. The presence and sequence of processing steps is determined by the composition of the input gas, the desired composition of output gas for downstream applications, and by efficiency and waste minimization.

Owner:PLASCO ENERGY GROUP INC

Gas Conditioning System

The present invention provides a gas conditioning system for processing an input gas from a low temperature gasification system to an output gas of desired characteristics. The system comprises a two-stage process, the first stage separating heavy metals and particulate matter in a dry phase, and the second stage including further processing steps of removing acid gases, and / or other contaminants. Optional processes include adjusting the humidity and temperature of the input gas as it passes through the gas conditioning system. The presence and sequence of processing steps is determined by the composition of the input gas, the desired composition of output gas for downstream applications, and by efficiency and waste minimization.

Owner:PLASCO ENERGY GROUP INC

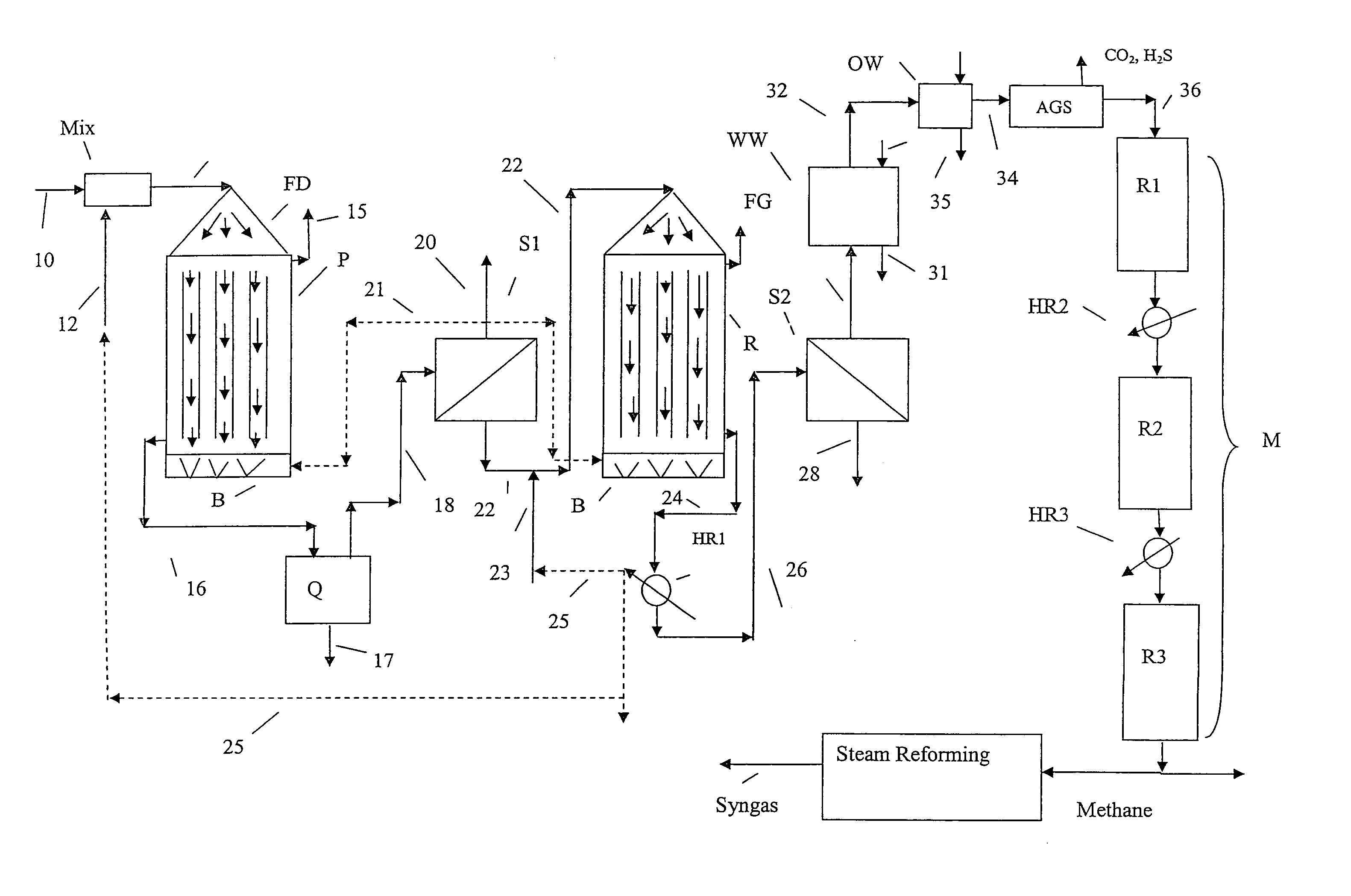

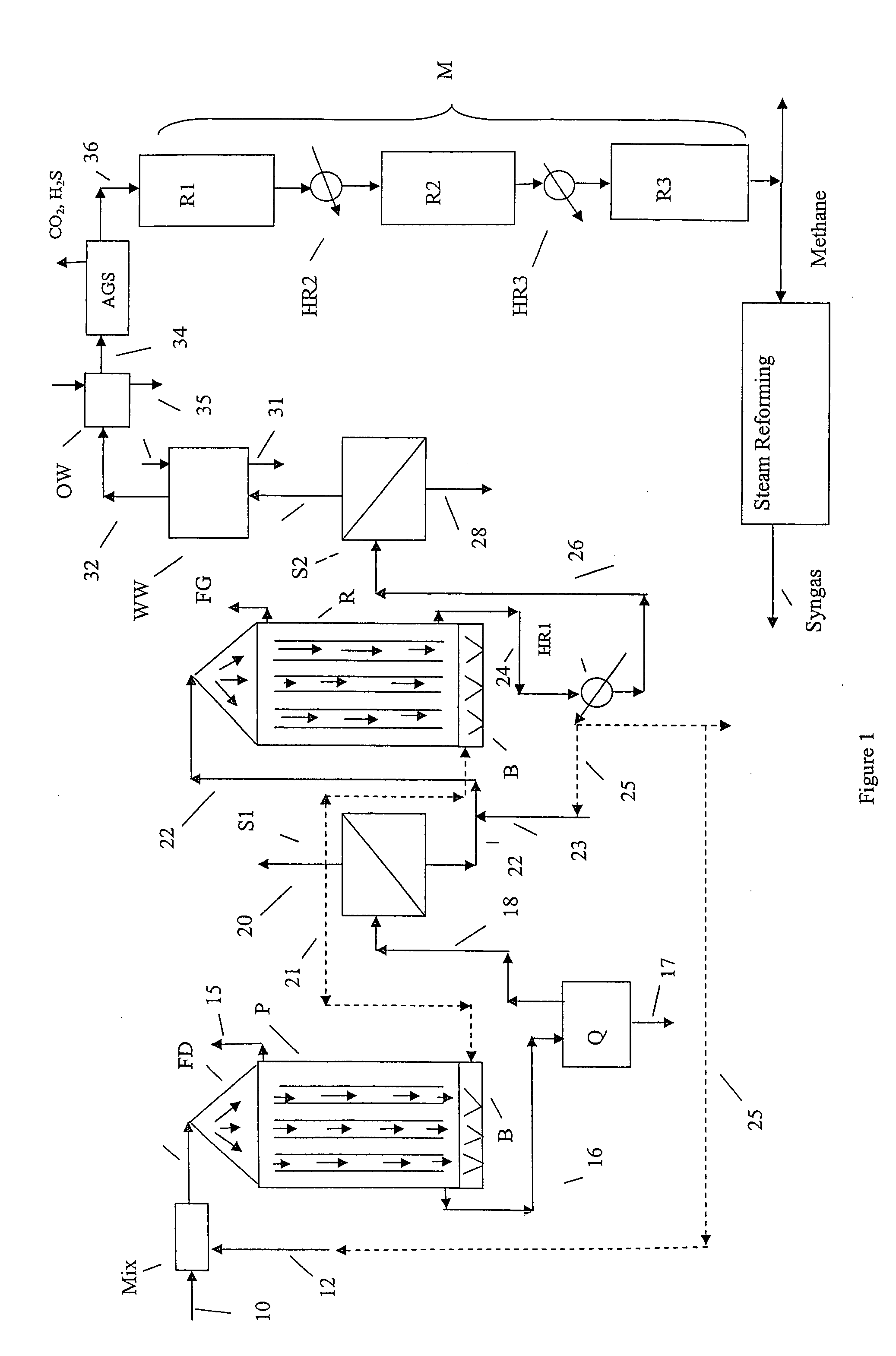

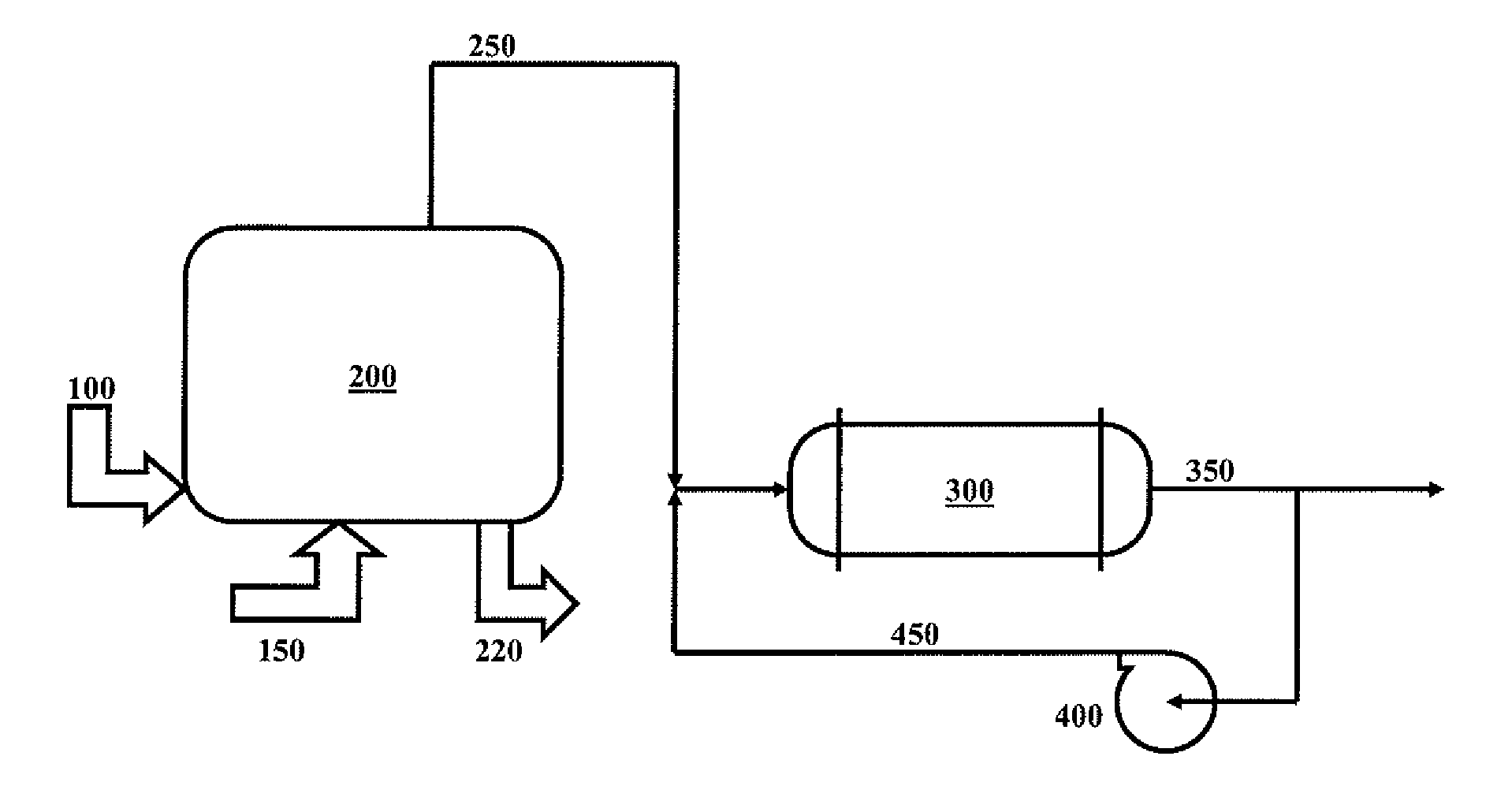

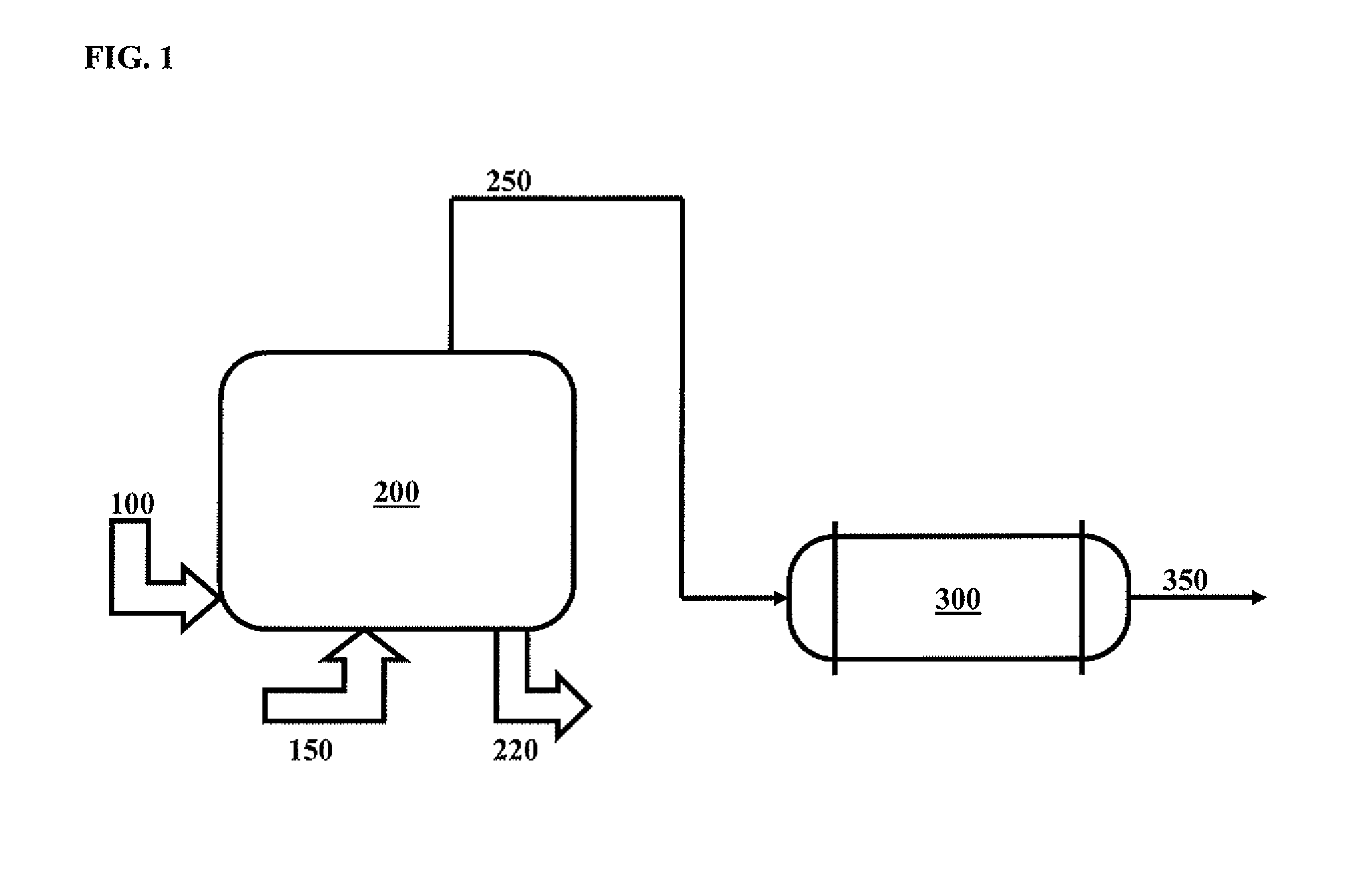

Conversion of carbonaceous materials to synthetic natural gas by pyrolysis, reforming, and methanation

InactiveUS20080016769A1Reduce the temperatureCombustible gas chemical modificationProductsSyngasSteam reforming

The production of synthetic natural gas from a carbonaceous material, preferably a biomass material, such as wood. The carbonaceous material is first pyrolyzed, then subjected to steam reforming to produce a syngas, which is then passed to several clean-up steps then to a methanation zone to produce synthetic natural gas.

Owner:CLEAN ENERGY LLC

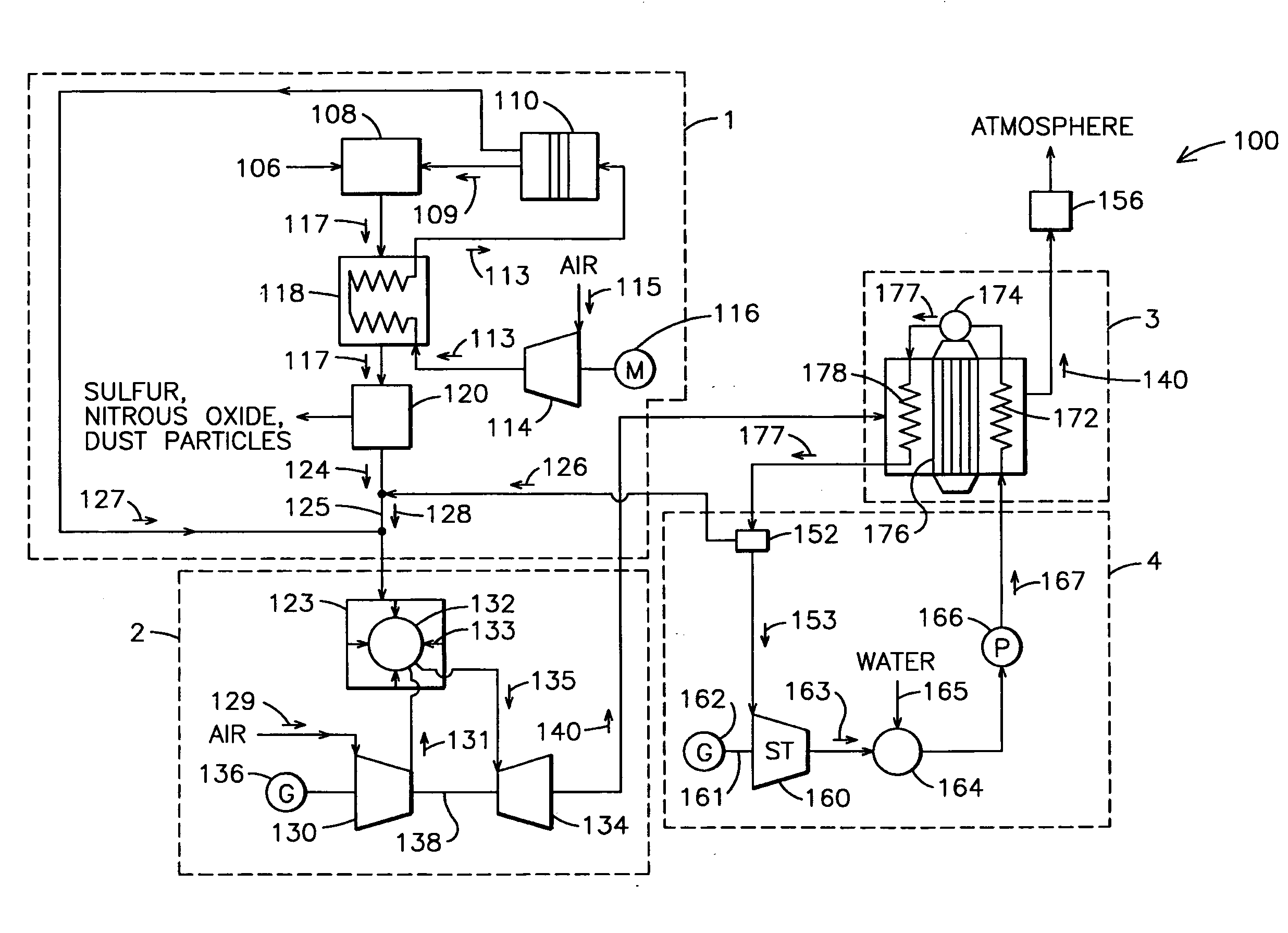

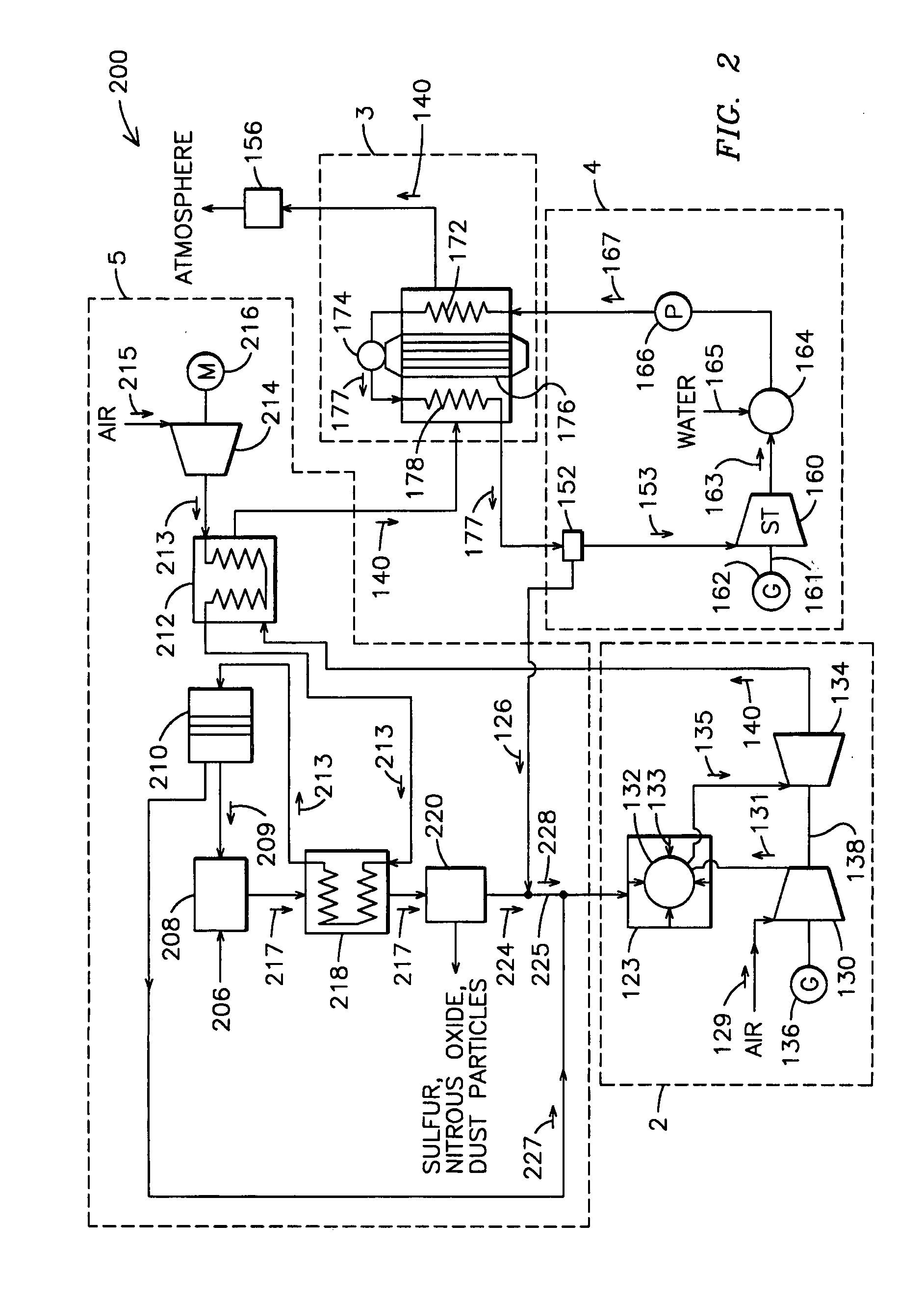

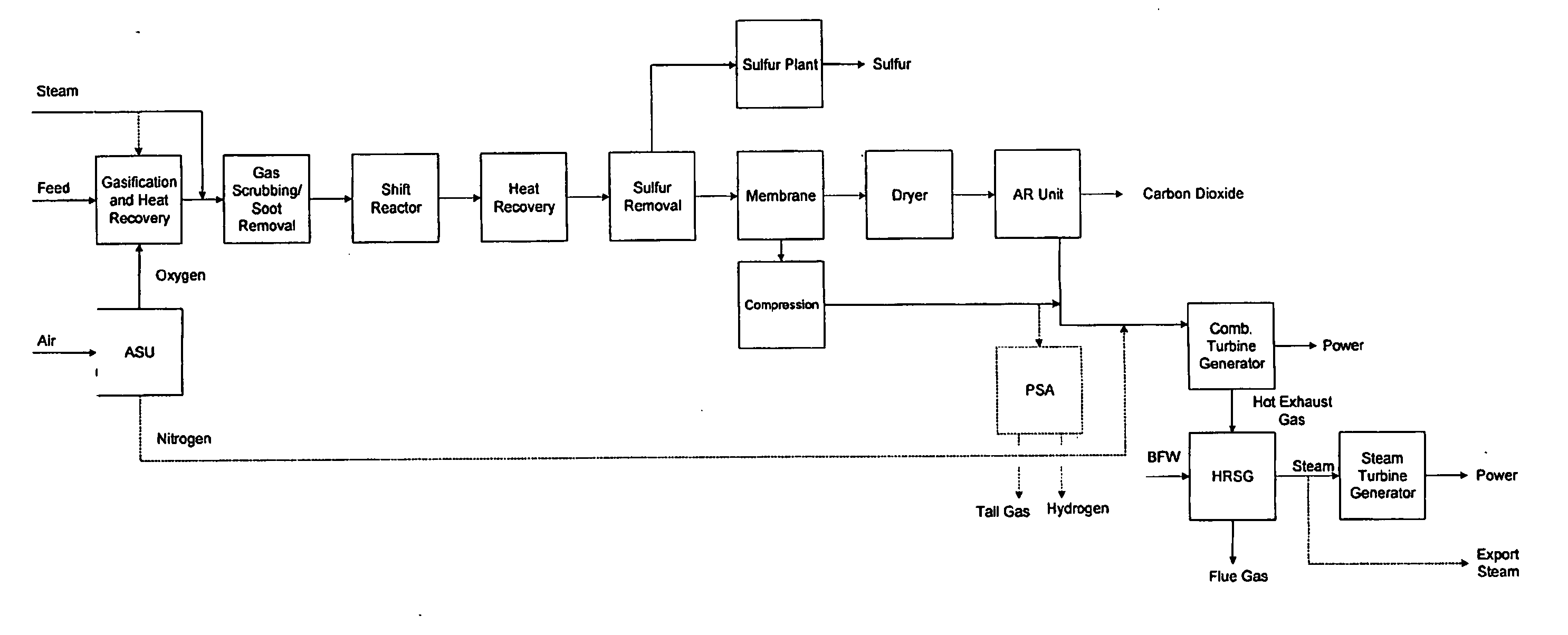

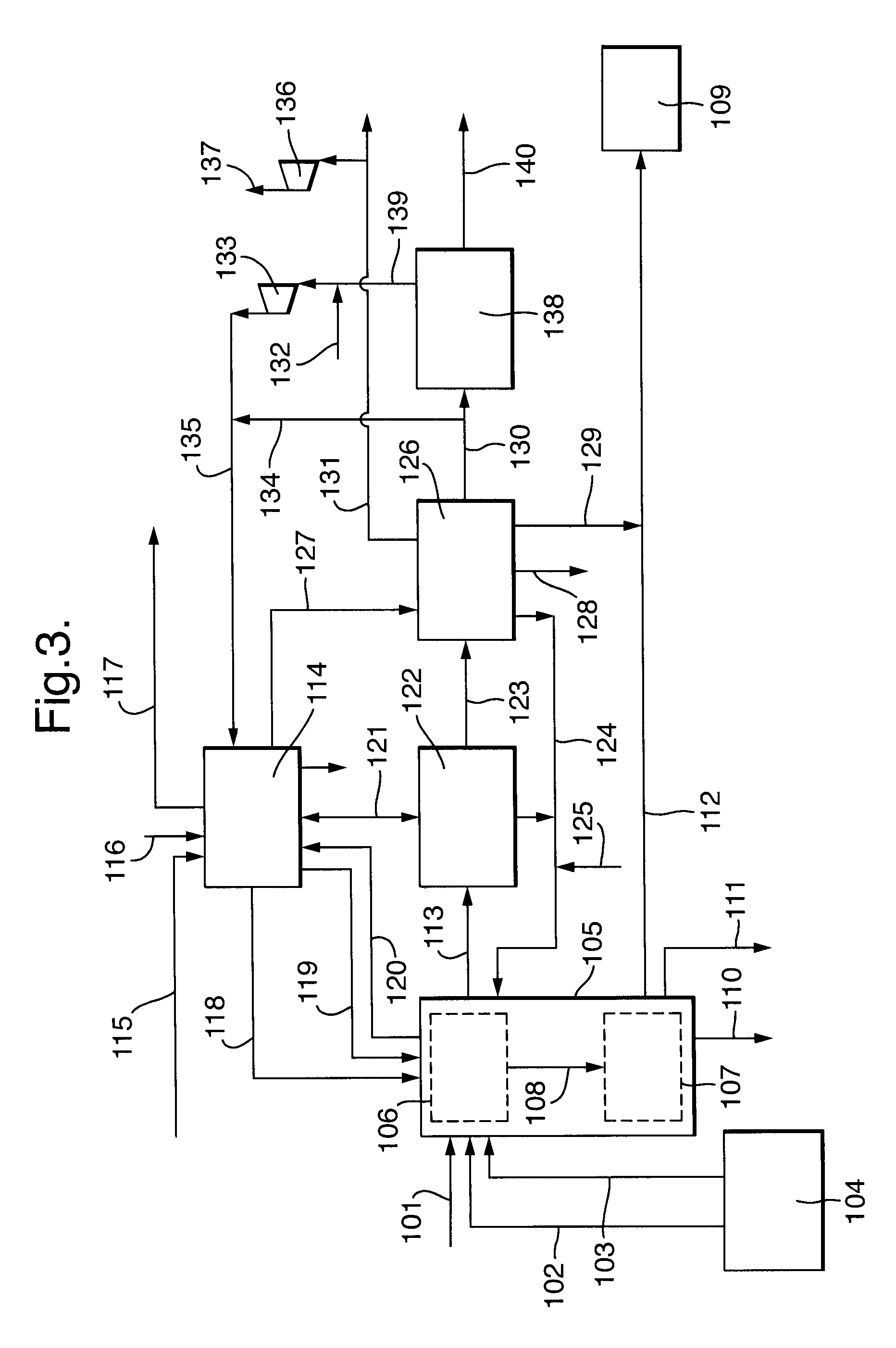

System and method for oxygen separation in an integrated gasification combined cycle system

An integrated gasification combined cycle power generation system (100). In one embodiment, shown in FIG. 1, a gasifier (108) is configured to generate synthetic gas (117) from a carbonaceous material (106) and an oxygen supply (109) with a cleaning stage (120) positioned to receive synthetic gas (117) from the gasifier (108) and remove impurities therefrom. A gas turbine combustion system (2) including a turbine (123) is configured to receive fuel (128) from the gasifier (108) and a first air supply (131) from a first air compressor (130). A steam turbine system (4) is configured to generate power with heat recovered from exhaust (140) generated by the gas turbine system (2) and an ion transport membrane air separation unit (110) includes a second air compressor (114) for generating a second air supply (113). A first heat exchanger (118) is configured to cool the synthetic gas (117) prior to removal of impurities in the cleaning stage (120) by flowing the second air supply (113) through the first heat exchanger (118) so that the second air supply (113) receives heat from the synthetic gas (117).

Owner:SIEMENS ENERGY INC

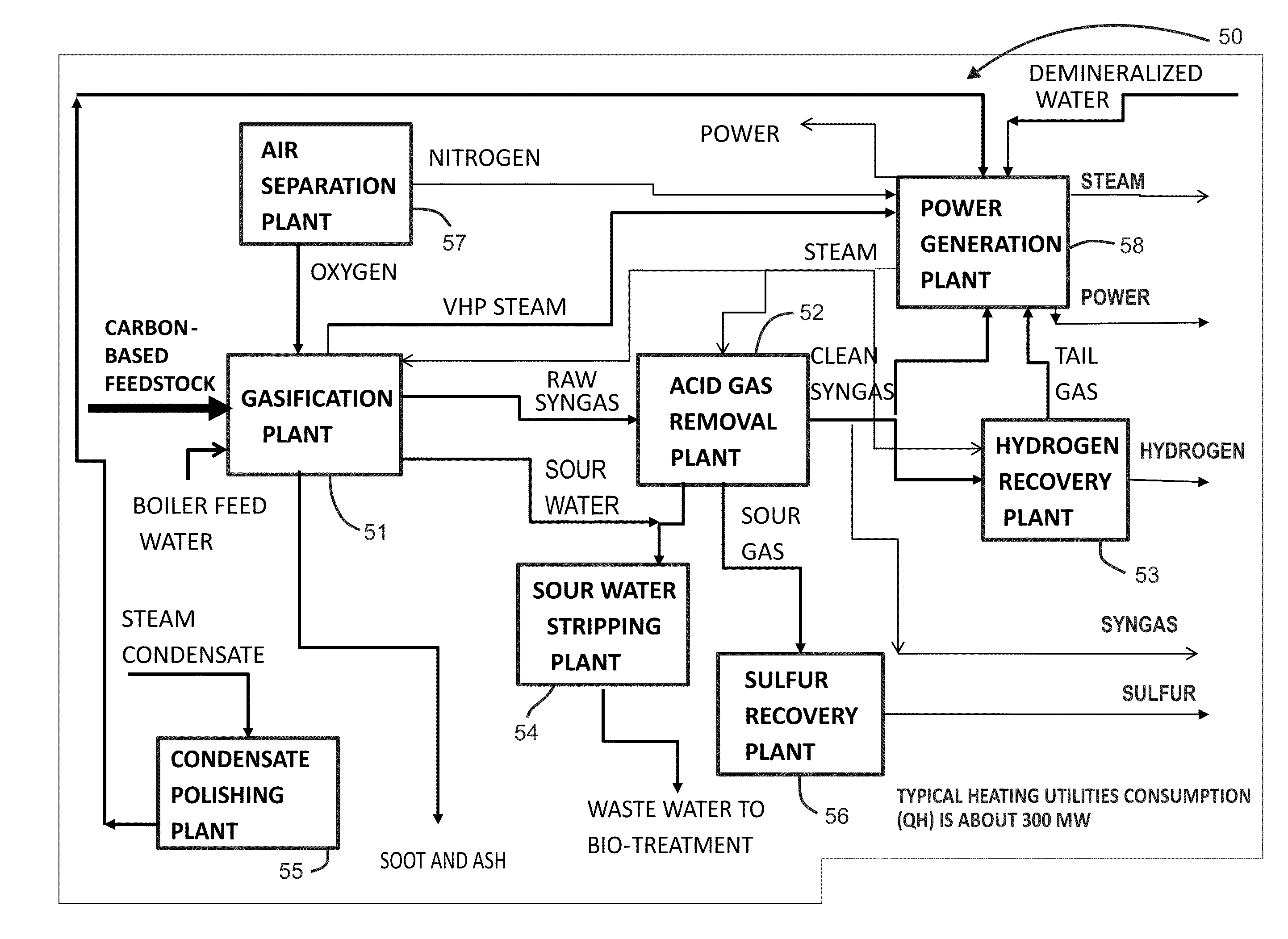

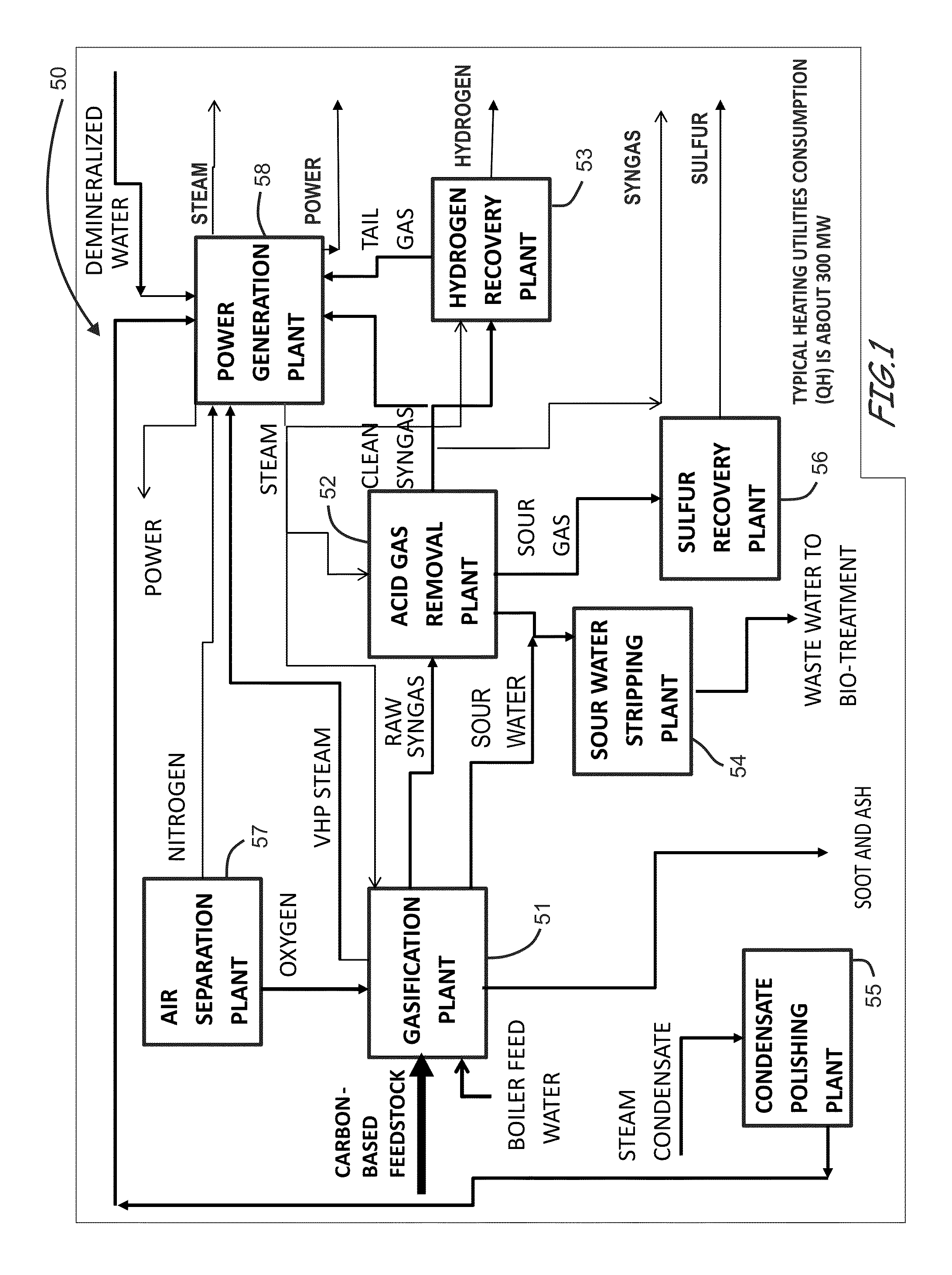

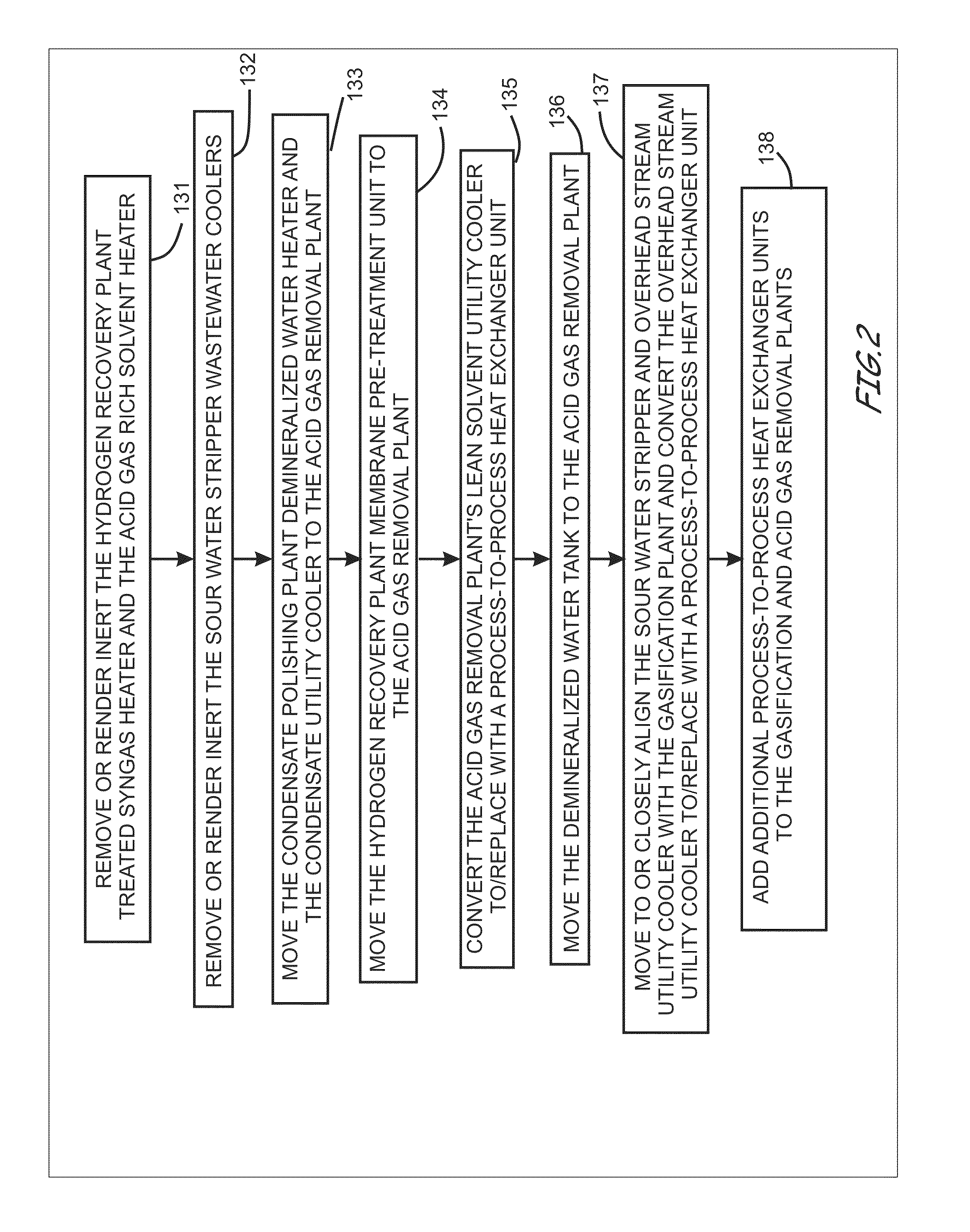

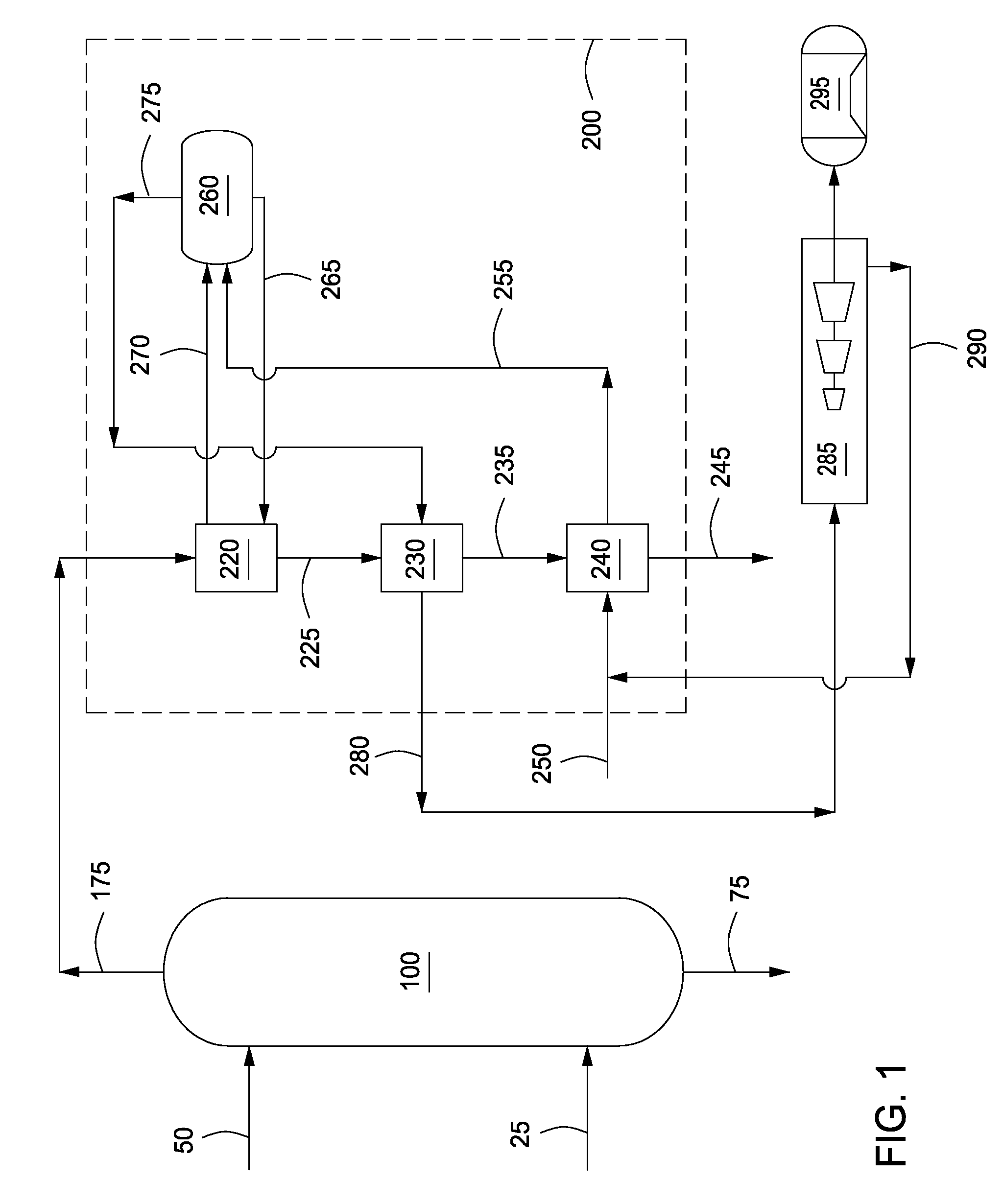

Energy efficient apparatus employing energy efficient process schemes providing enhanced integration of gasification-based multi-generation and hydrocarbon refining facilities and related methods

ActiveUS20150377079A1Less pollutionEasy to modifyProcess control/regulationGasifier mechanical detailsSolventMulti generation

Energy-efficient gasification-based multi-generation apparatus, facilities, or systems, and methods of modifying existing gasification-based multi-generation apparatus and the various conventional thermal coupling arrangements, are provided. Apparatus for managing waste heat recovery through integration of a gasification-based multi-generation facility or other multi-generation system with a hydrocarbon refining facility or other hydrocarbon refining system and methods of providing the respective integration are also provided. An exemplary apparatus includes an integrated site energy management system configured according to one or more process-based thermal coupling schemes comprising one or more thermal coupling arrangements between a gasification-based multi-generation system or facility and a hydrocarbon refining system or facility. The gasification-based multi-generation system or facility can include an acid gas removal system or plant configured to remove acidic contaminants from a raw syngas feed to thereby provide a treated syngas feed, the acid gas removal system or plant containing a separation section including a solvent regenerator, and a gasification system configured to generate the raw syngas feed from a carbon-based feedstock. The hydrocarbon refining system or facility can include an aromatics system or plant containing a xylene products separation section including one or more of the following: an Extract column and a Raffinate column. The integrated site energy management system can include a hot-water system extending between the separation section of the acid gas removal system or plant and the xylene products separation section of the aromatics system or plant, and a plurality of added heat exchanger units providing various advanced thermal coupling arrangements.

Owner:SAUDI ARABIAN OIL CO

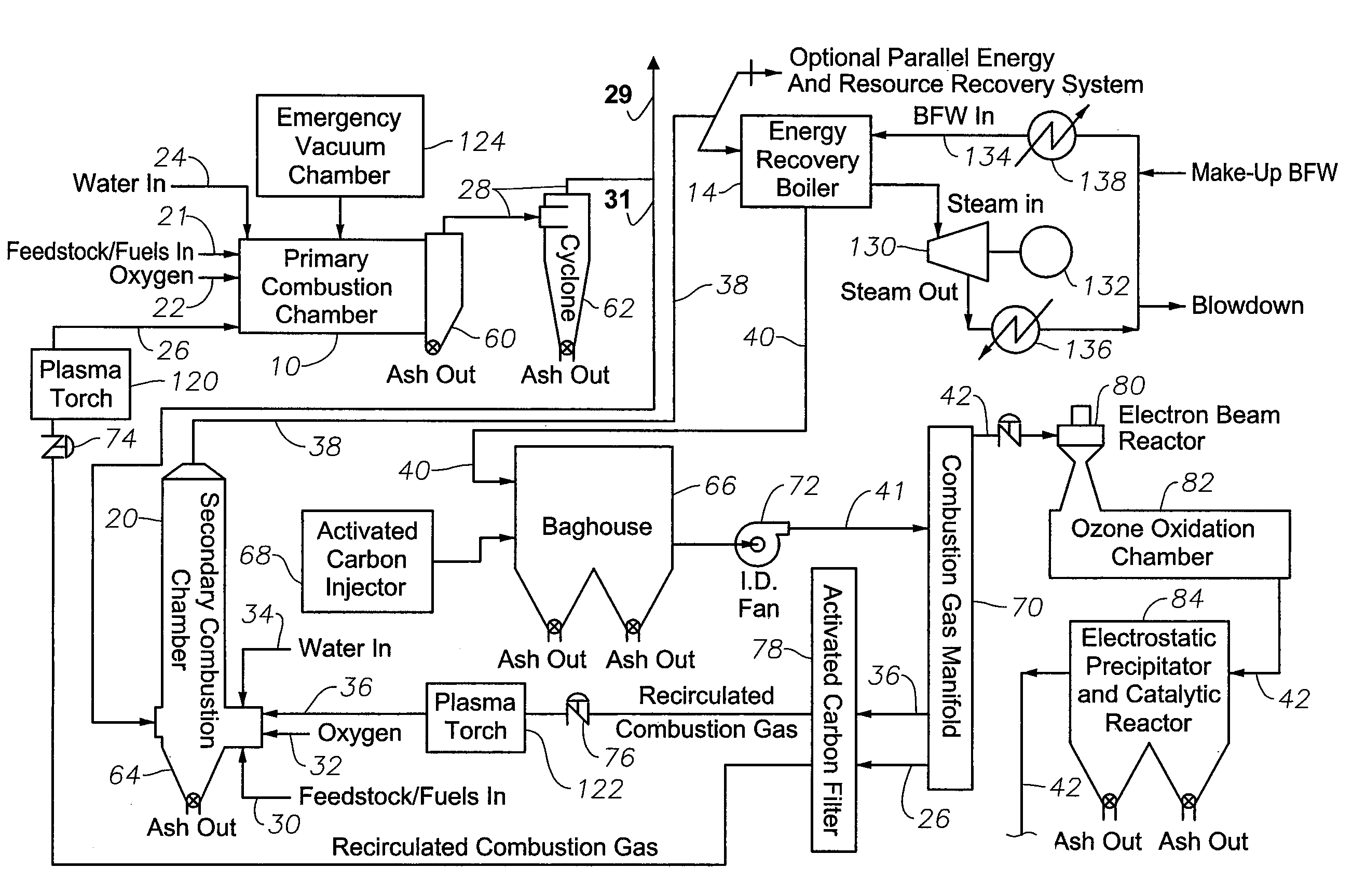

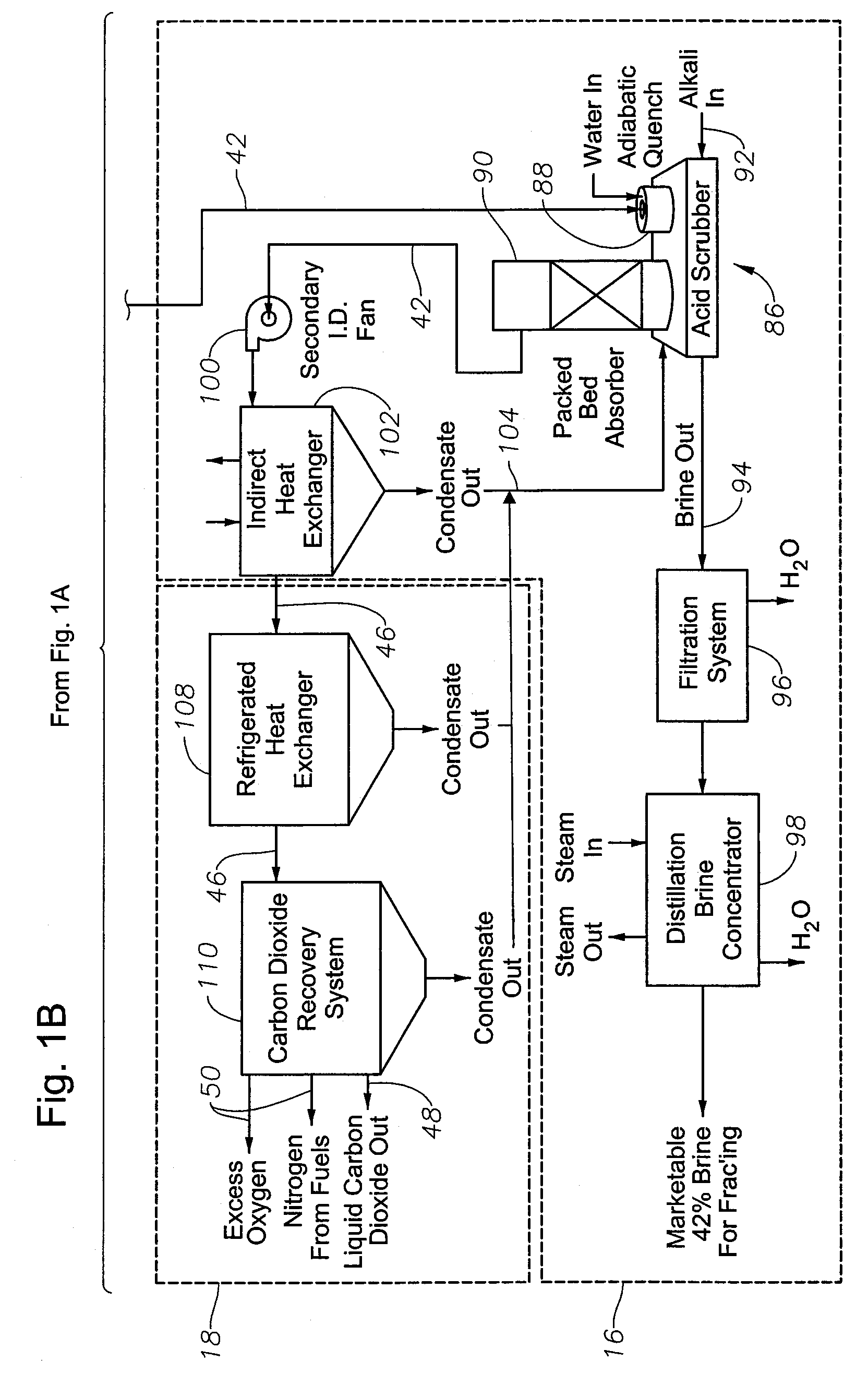

Reduced-emission gasification and oxidation of hydrocarbon materials for liquid fuel production

InactiveUS8038746B2Reduce system sizeHigh heat transfer rateHydrogenGas modification by gas mixingLiquid hydrocarbonsLiquid fuel

Owner:CLARK STEVE L

Low oxygen carrier fluid with heating value for feed to transport gasification

ActiveUS20090188165A1Reduce and eliminate partial and complete oxidationReduce and eliminate exothermic conversionMultiple metal hydridesCombustible gas catalytic treatmentCarrier fluidOxidizing agent

Systems and processes for producing synthesis gas. A carbonaceous feedstock can be combined with one or more low-oxygen carrier fluids having a high heating value. The feedstock and carrier fluid, in the presence of one or more oxidants, can be gasified to provide a synthesis gas. In one or more embodiments, at least a portion of the synthesis gas can be recycled for use as the carrier fluid.

Owner:KELLOGG BROWN & ROOT LLC

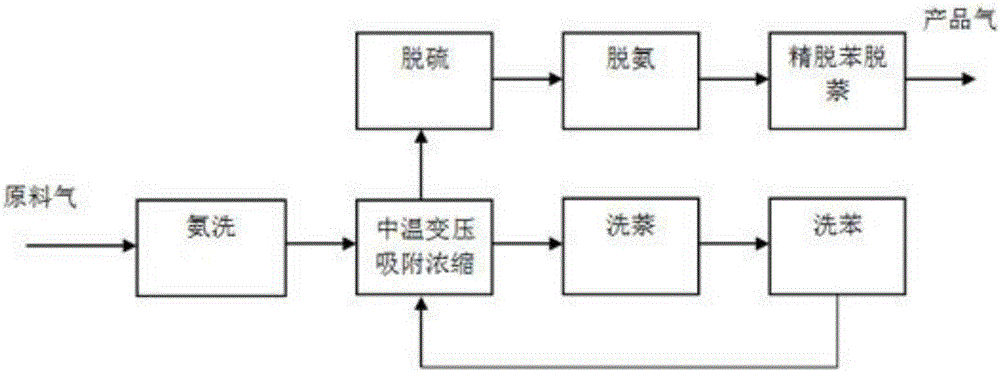

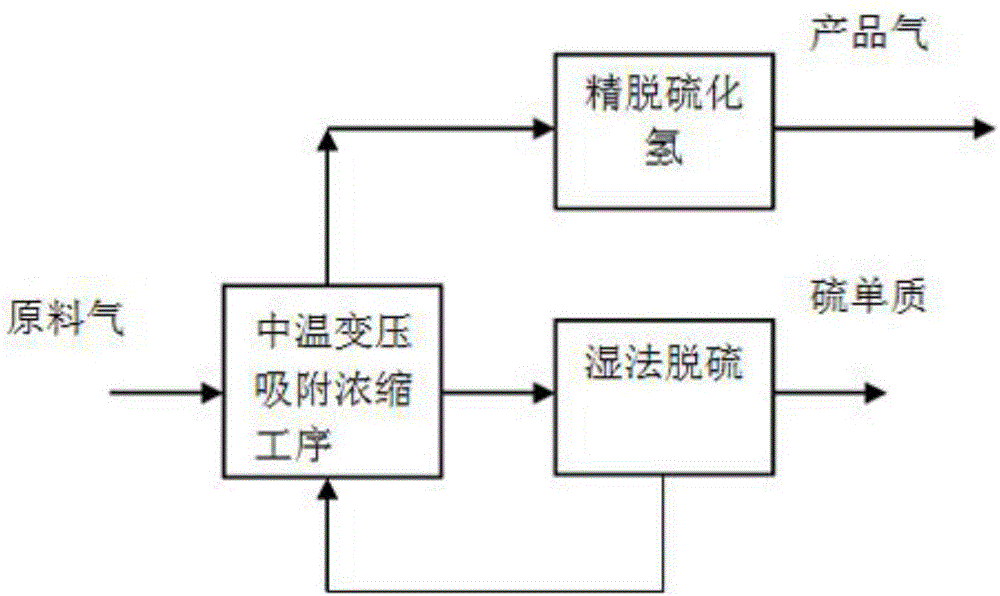

Full-temperature-range pressure swing adsorption gas separation, refinement and purification method

ActiveCN105749699AReduce energy consumptionBroaden the scope of adsorption separation applicationsSolidificationLiquefactionEnergy gradientPurification methods

The invention discloses a full-temperature-range pressure swing adsorption gas separation, refinement and purification method.By means of the difference of the temperatures and pressures of different raw material gases and the difference of the adsorption separation coefficients and physical chemistry properties of all components in the raw material gases in the temperature range of 80-200 DEG C and the pressure range of 0.03-4.0 MPa, the adsorption or desorption regeneration operation of the pressure swing adsorption circulation process is adjusted by coupling all separation methods, the adsorption theory that the pressure or temperature swing adsorption separation process is only limited to the adsorption and desorption regeneration circulation operation through pressure or temperature changes is expanded, and therefore all raw material gases are separated, refined and purified by achieving the energy gradient utilization in the gas separation, refinement and purification process and achieving the circulation operation, where adsorption, desorption and regeneration are easily matched and balanced, in the moderate to low cold and moderate to high temperature pressure swing adsorption separation process, and it is changed that a traditional adsorption method is only limited to the auxiliary effect of refinement and purification, and adsorption becomes the basic separation unit operation just as important as refinement, absorption and extraction separation.

Owner:SICHUAN TECHAIRS

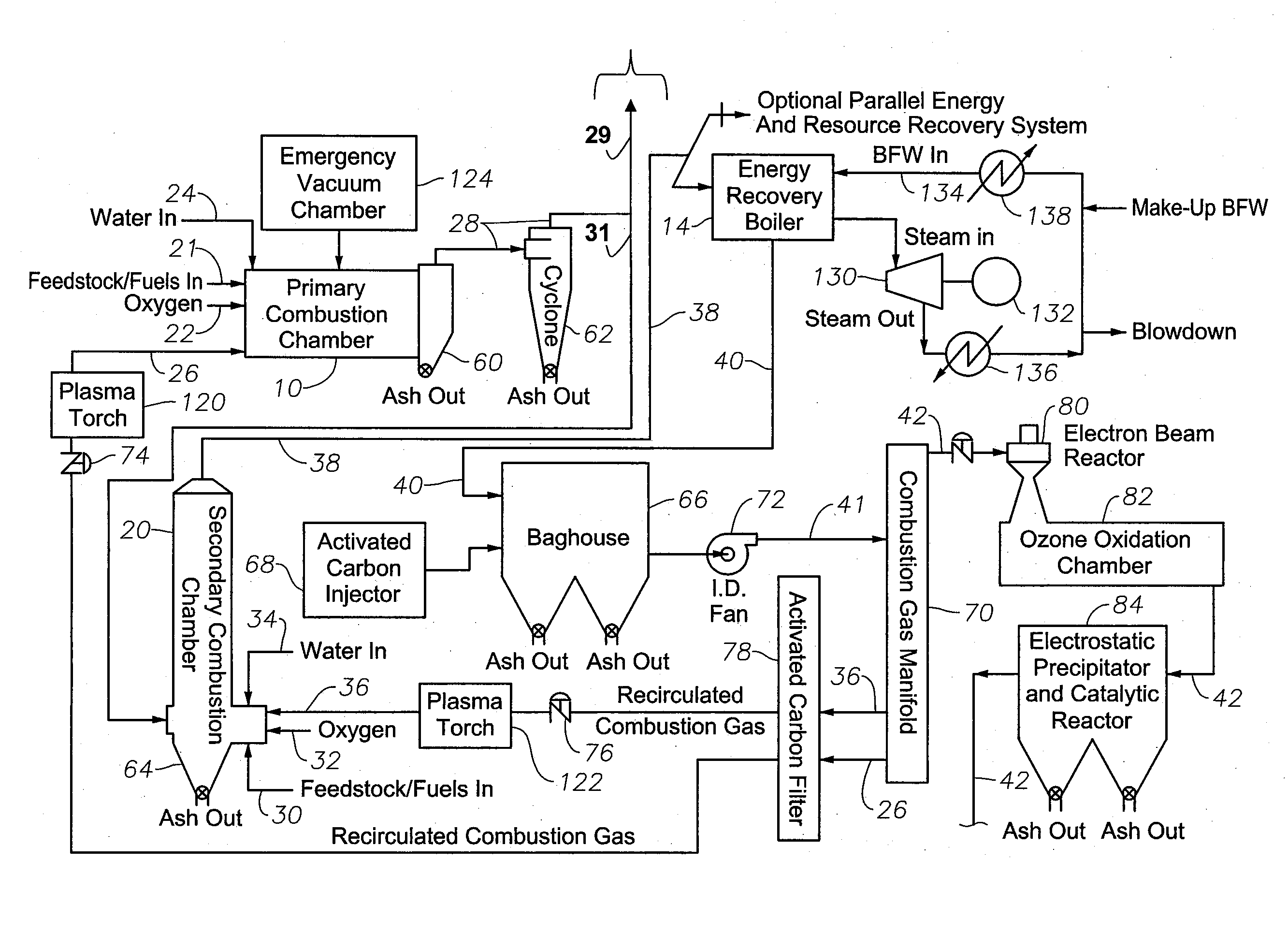

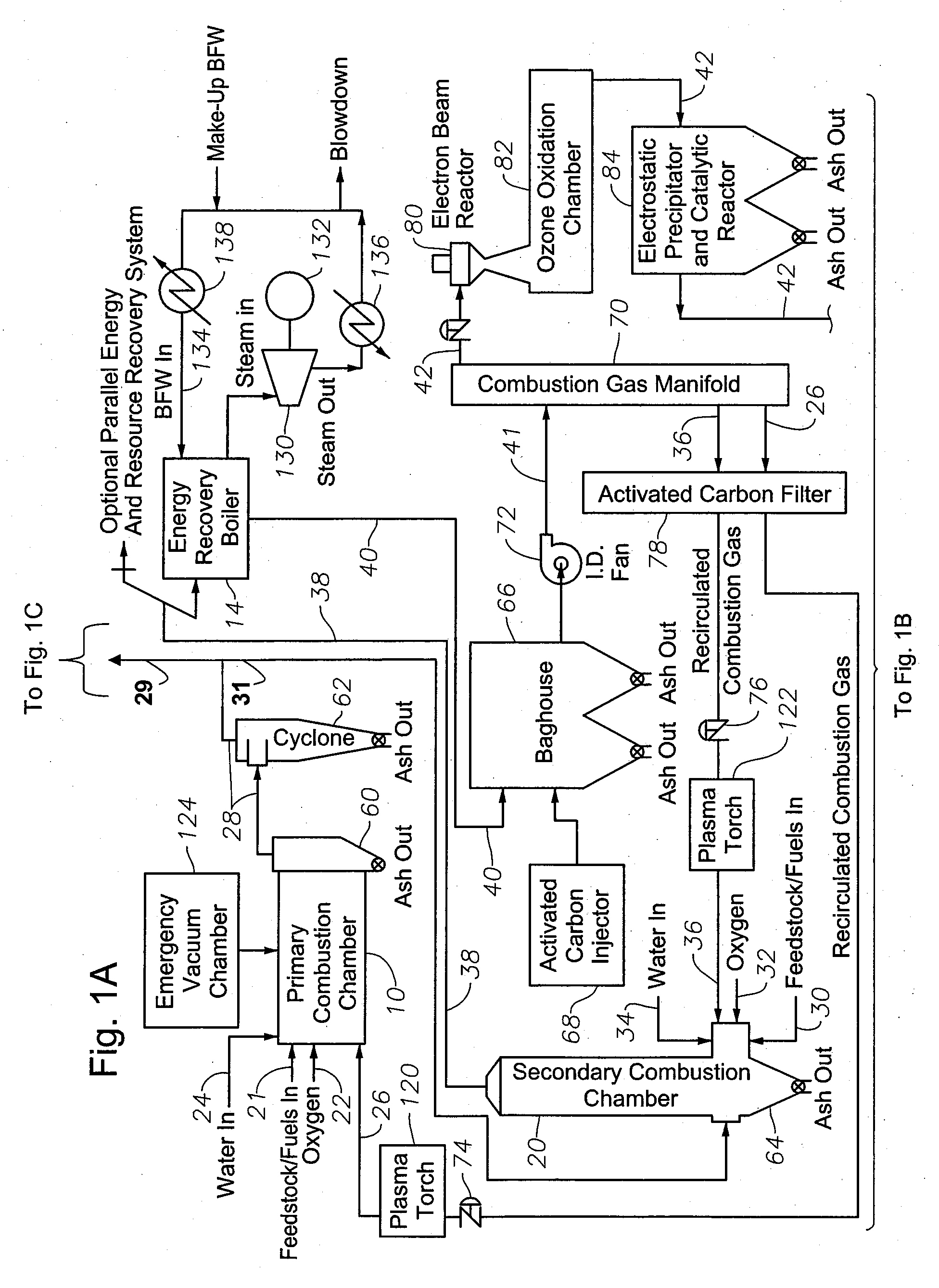

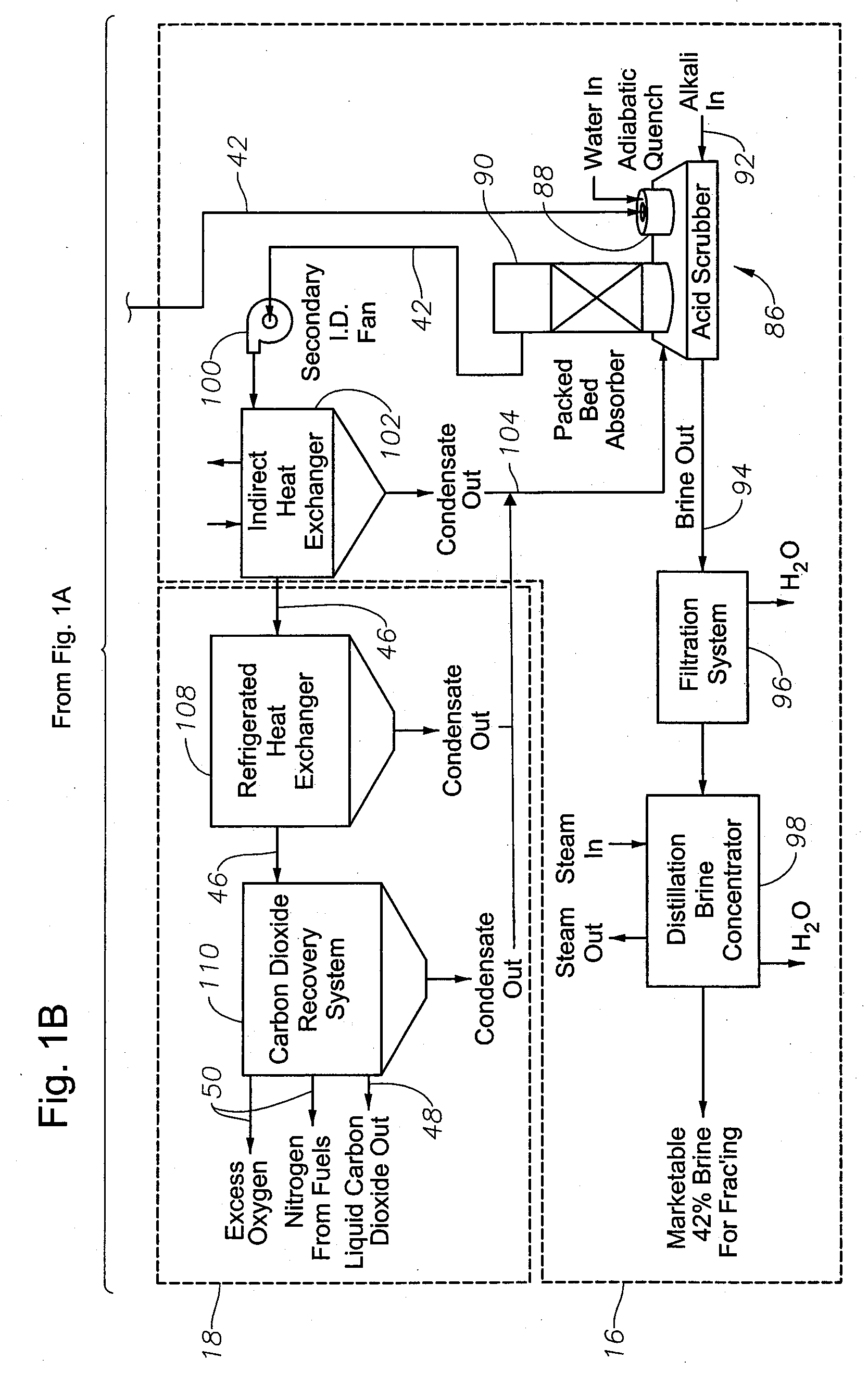

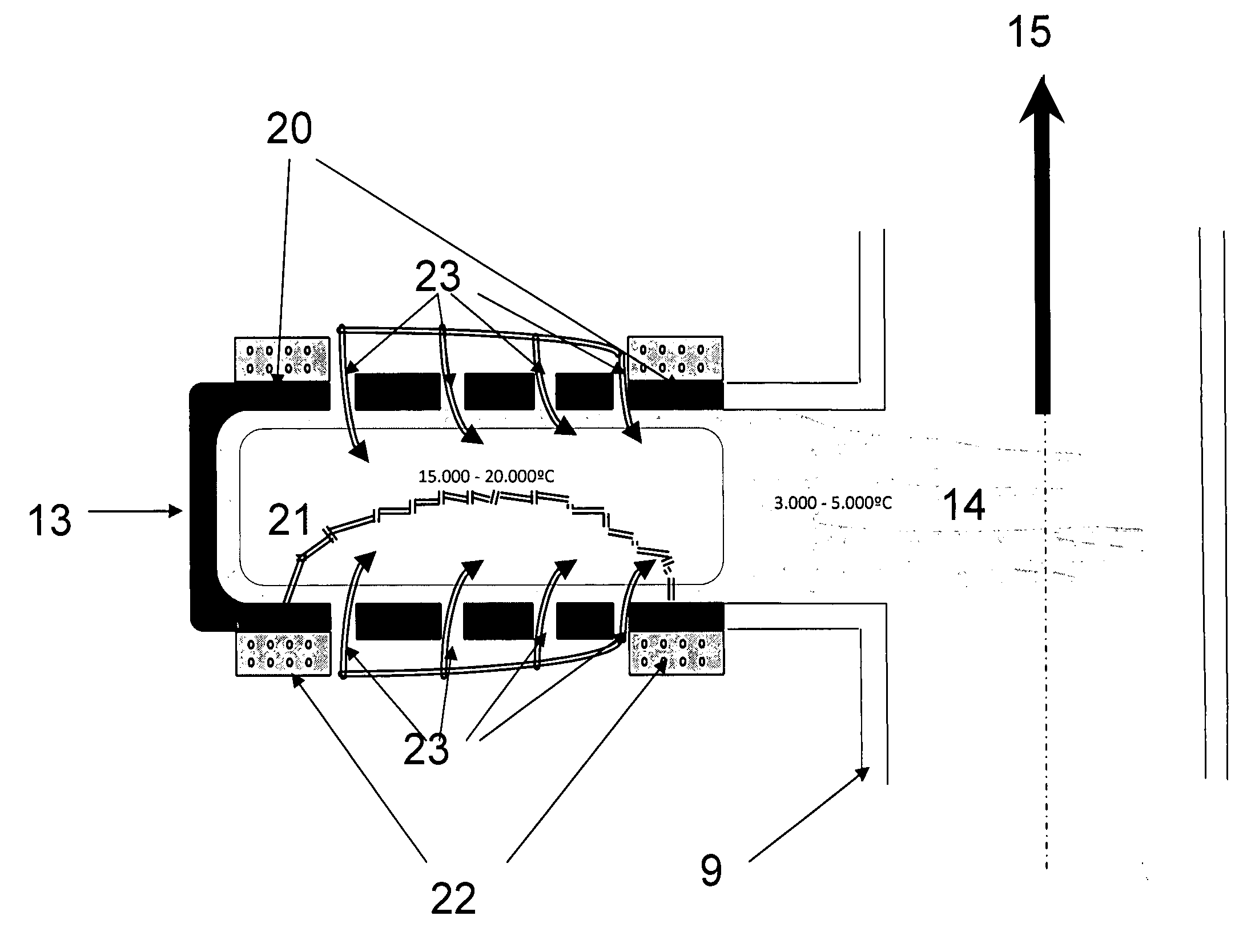

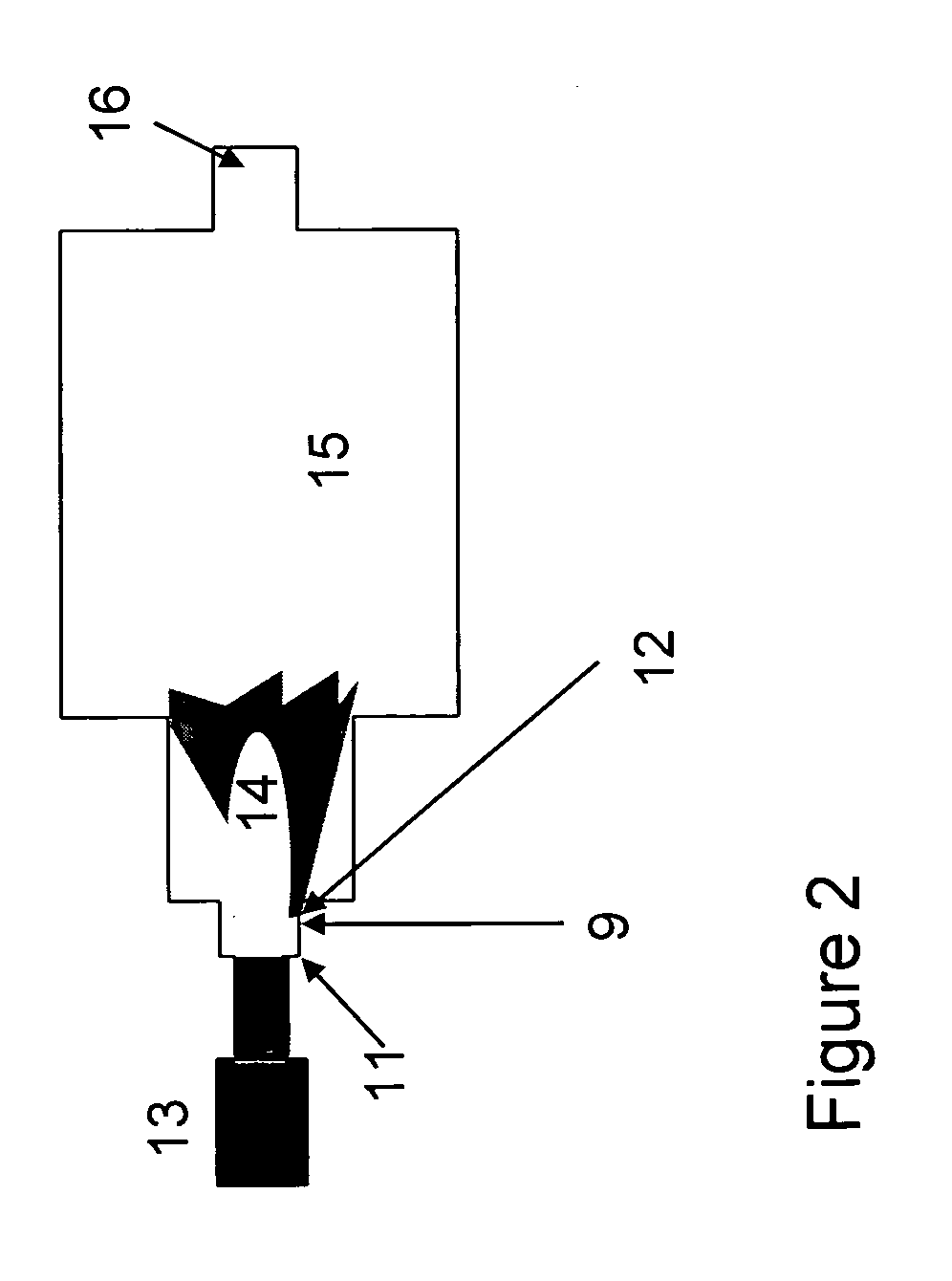

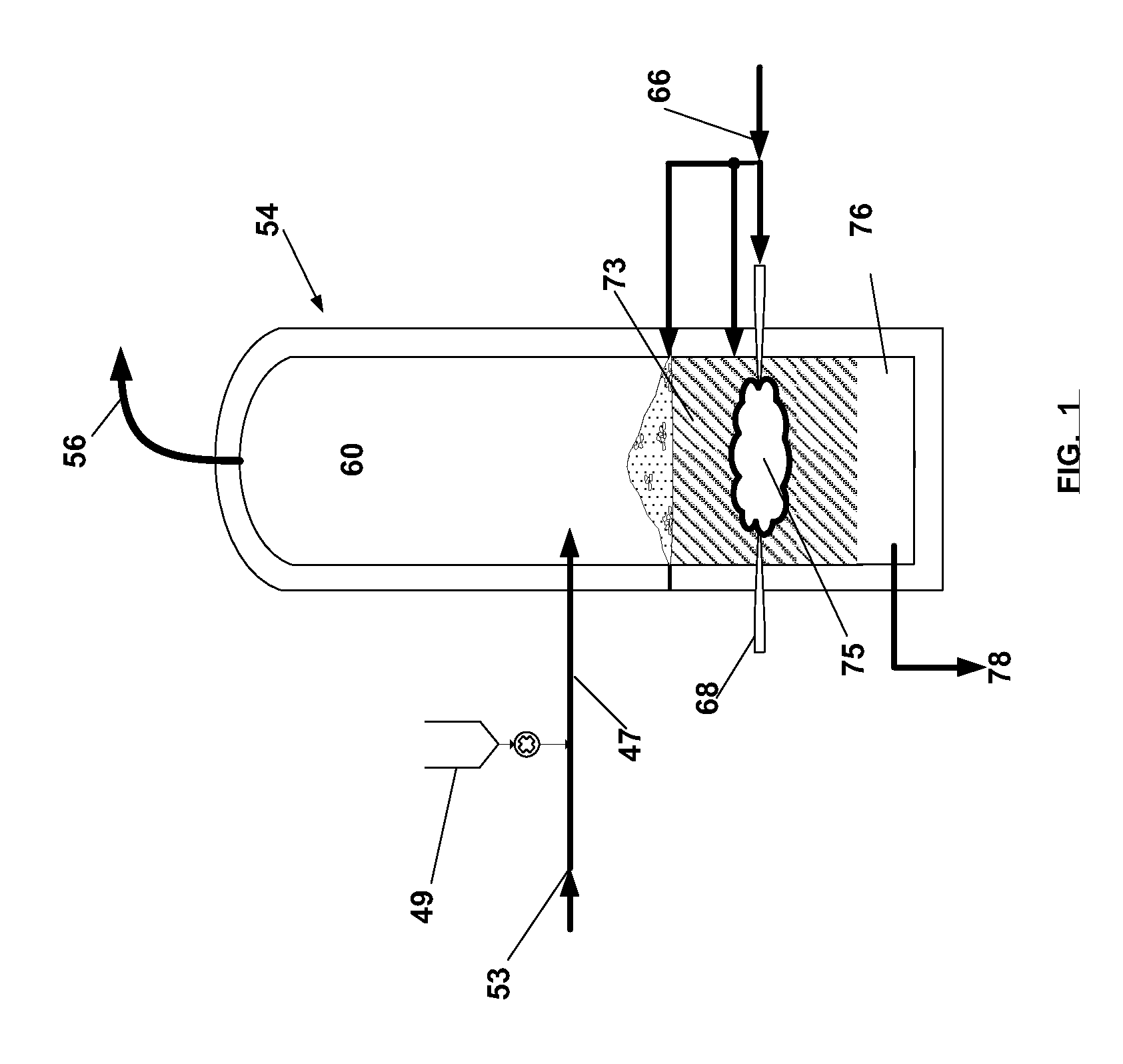

Reduced-Emission Gasification and Oxidation of Hydrocarbon Materials for Liquid Fuel Production

InactiveUS20080275278A1Reduce system sizeRaise the combustion temperatureGas modification by gas mixingLiquid hydrocarbon mixture productionThermal energyLiquid hydrocarbons

A system and process are disclosed for the controlled combustion of a wide variety of hydrocarbon feedstocks to produce thermal energy, liquid fuels, and other valuable products with little or no emissions. The hydrocarbon feeds, such as coal and biomass, are first gasified and then oxidized in a two-chamber system / process using pure oxygen rather than ambient air. A portion of the intermediate gases generated in the system / process are sent to a Fischer-Tropsch synthesis process for conversion into diesel fuel and other desired liquid hydrocarbons. The remaining intermediate gases are circulated and recycled through each of the gasification / oxidation chambers in order to maximize energy production. The energy produced through the system / process is used to generate steam and produce power through conventional steam turbine technology. In addition to the release of heat energy, the hydrocarbon fuels are oxidized to the pure product compounds of water and carbon dioxide, which are subsequently purified and marketed. The system / process minimizes environmental emissions.

Owner:CLARK STEVE L

Methods for integrated fast pyrolysis processing of biomass

ActiveUS8100990B2Minimizes water contentImprove collection efficiencyDirect heating destructive distillationBiofuelsPre treatmentSafe handling

Methods, process, apparatus, equipment, and systems are disclosed for converting biomass into bio-oil fractions for chemicals, materials, feedstocks and fuels using a low-cost, integrated fast pyrolysis system. The system improves upon prior art by creating stable, bio-oil fractions which have unique properties that make them individually superior to conventional bio-oil. The invention enables water and low-molecular weight compounds to be separated into a final value-added fraction suitable for upgrading or extracting into value-added chemicals, fuels and water. Initial bio-oil fractions from the process are chemically distinct, have low-water content and acidity which reduces processing costs normally associated with conventional bio-oil post-production upgrading since fewer separation steps, milder processing conditions and lower auxiliary inputs are required. Biochar is stabilized so that it can be handled safely. The integrated fast pyrolysis process includes biomass storage, preparation, pretreatment, and conversion, product recovery and processing to create and store stable biochar and bio-oil fractions.

Owner:AVELLO BIOENERGY

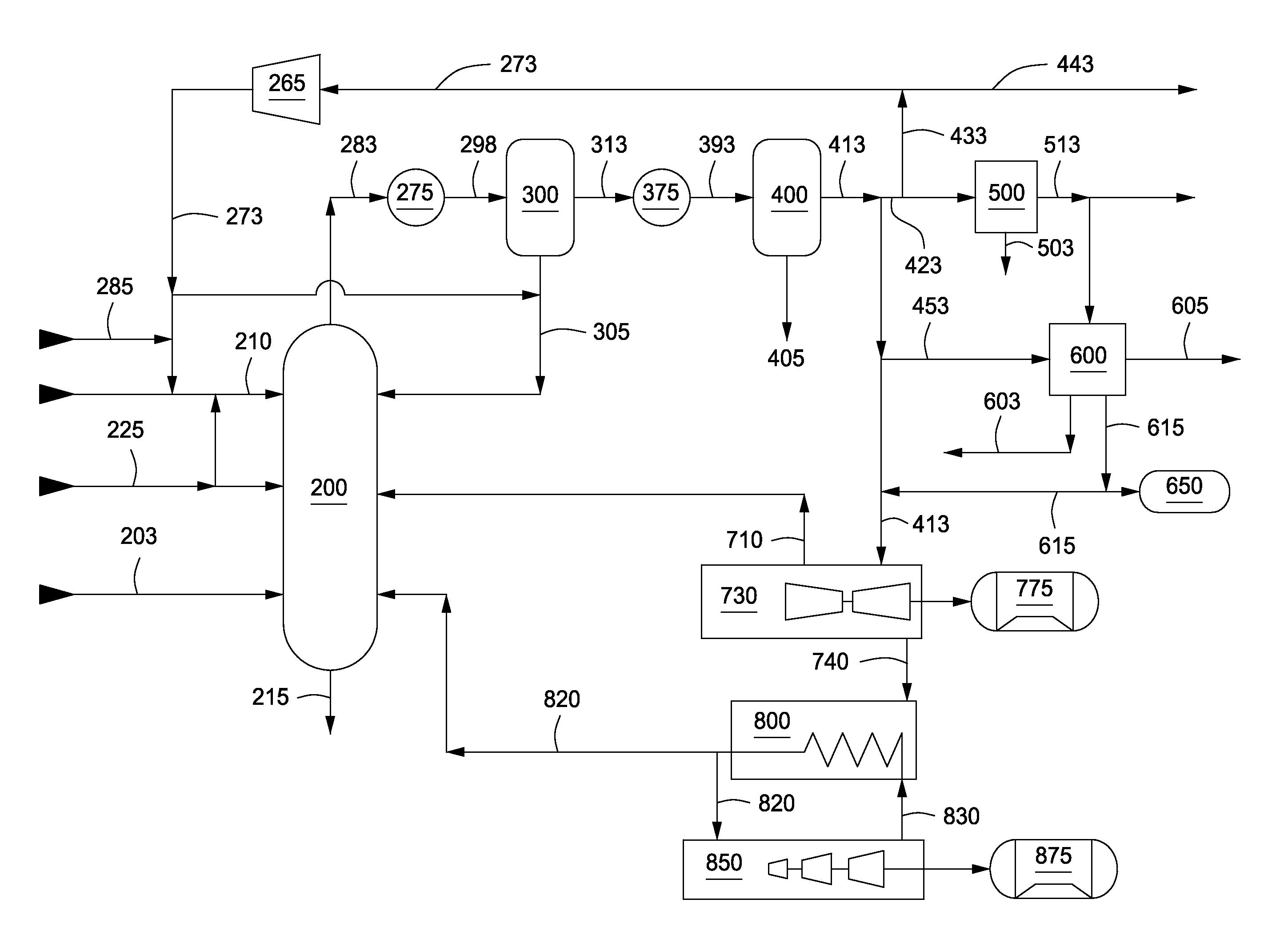

Efficiency of gasification processes

InactiveUS20090151250A1Combustible gas catalytic treatmentGas modification by gas mixingSyngasProcess systems

Systems and processes for producing syngas and power therefrom are provided. One or more feedstocks and one or more oxidants can be combined in a fluidized reaction zone operated at a temperature from 550° C. to 1,050° C. to provide a syngas. Heat can be indirectly exchanged in a first zone from the syngas to a condensate to provide steam. Heat can also be indirectly exchanged in a second zone from the syngas to the steam to provide superheated steam. Heat can then be indirectly exchanged in a third zone from the syngas to provide a cooled syngas and the condensate for the first zone. At least a portion of the superheated steam can be directly supplied to one or more steam turbines to produce power.

Owner:KELLOGG BROWN & ROOT LLC

Method of Operation of Process to Produce Syngas from Carbonaceous Material

InactiveUS20120256131A1High CO/CO molar ratioEffective coolingGasifier feeding meansInternal combustion piston enginesSyngasProcess engineering

A process is provided for producing syngas that is effective for use in downstream processes. The process for producing syngas includes operating a gasification apparatus in a start-up mode until the gasification apparatus and equipment downstream of the gasification apparatus are adequately warmed up to a first target temperature. Upon reaching a first target temperature, the process is then operated in a production mode to produce a second syngas with a higher CO / CO2 molar ratio. Operation in a start-up mode until reaching a first target temperature, provides a process that is effective for reducing fouling in downstream equipment and for providing a second syngas can be more effectively cooled and cleaned.

Owner:INEOS BIO SA

Process and plant for production of biofuels

InactiveUS20100216898A1Easy to useHigh yieldDirect heating destructive distillationCombustible gas catalytic treatmentSyngasCellulose

The invention concerns a method and a plant for producing hydrocarbon based fuels from waste and biomass including wood and / or other cellulose containing biomass, where biomass and / or waste is gasified in anaerobic conditions, heating the formed syngas in for decomposition and subsequent condensation in anaerobic conditions, subjecting the heat treated biosyngas to cleaning measures for removing elements / compounds which are poisonous towards the catalysts of the Fischer-Tropsch synthesis, and passing the cleaned heat treated biosyngas through a Fischer-Tropsch synthesis for production of biofuels.

Owner:TONSETH ERIK

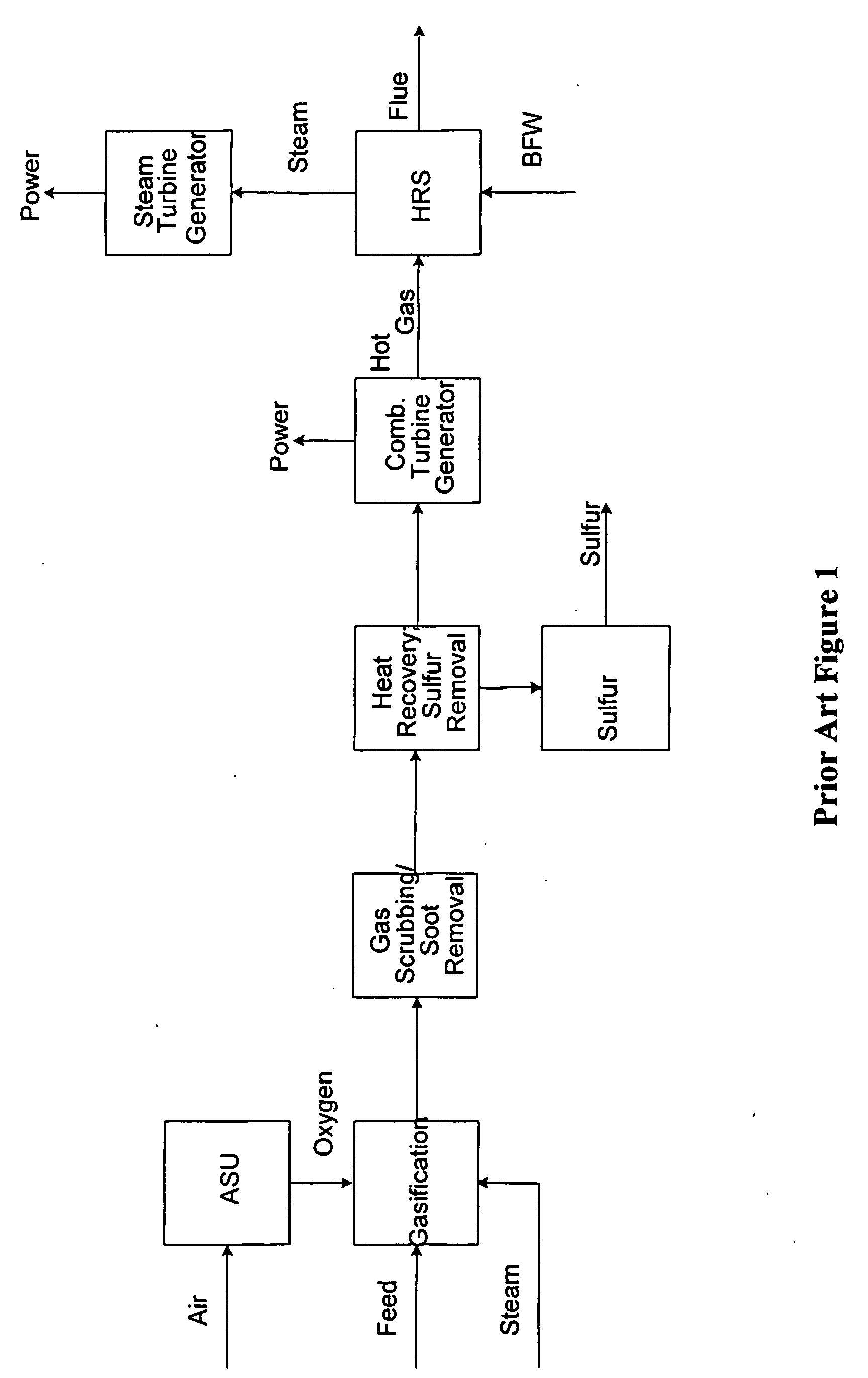

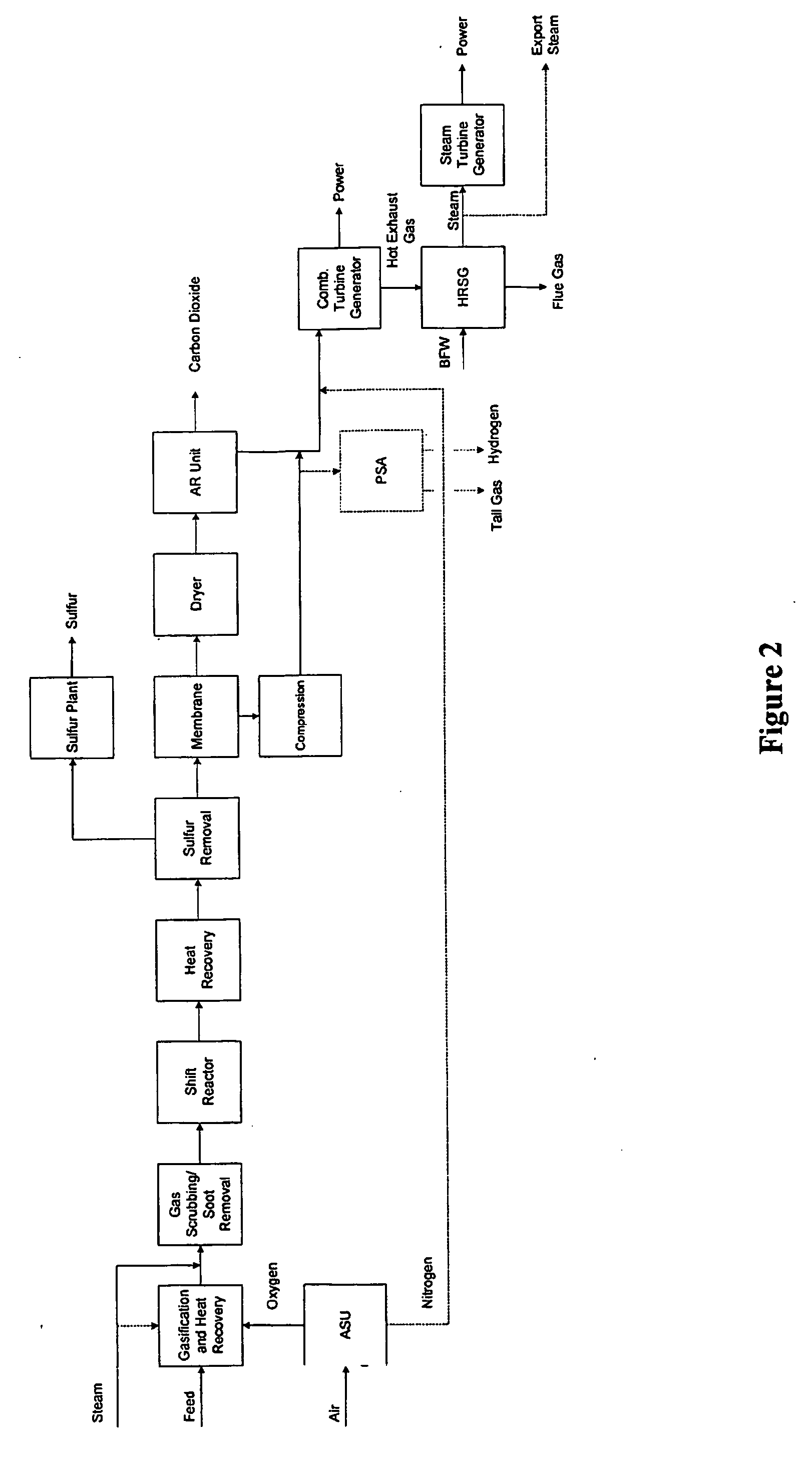

Configurations and methods of carbon capture

An IGCC plant has a precombustion decarbonization unit in which acid gas is removed from a combustion gas before the combustion gas enters a combustion turbine. In one preferred configuration, a sulfur removal unit removes hydrogen sulfide from a feed gas before the desulfurized feed gas enters an autorefrigeration unit in which carbon dioxide is removed. In another preferred configuration, hydrogen sulfide is converted to carbonyl sulfide in a dryer, and the carbonyl sulfide is absorbed in the liquid carbon dioxide that is prepared from the feed gas using autorefrigeration.

Owner:FLUOR TECHSE CORP

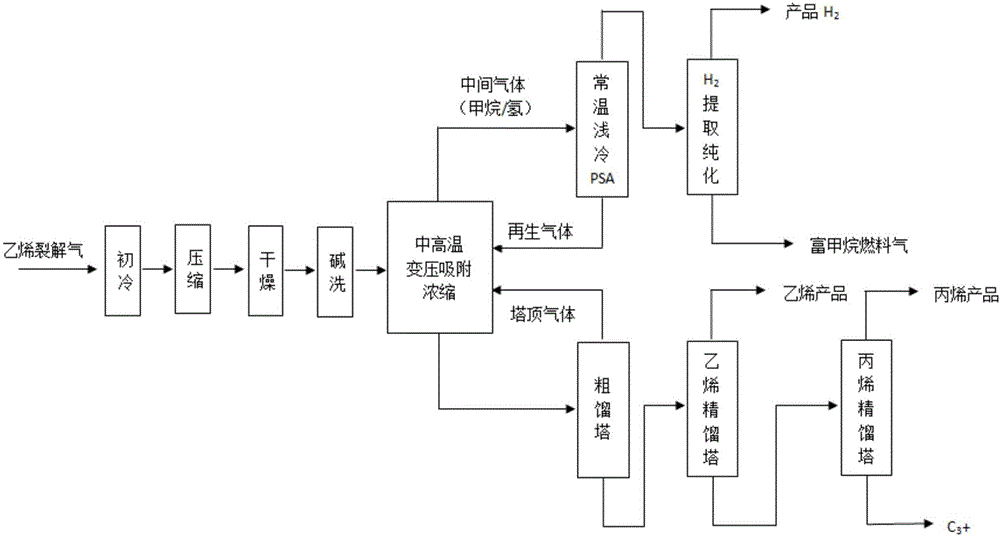

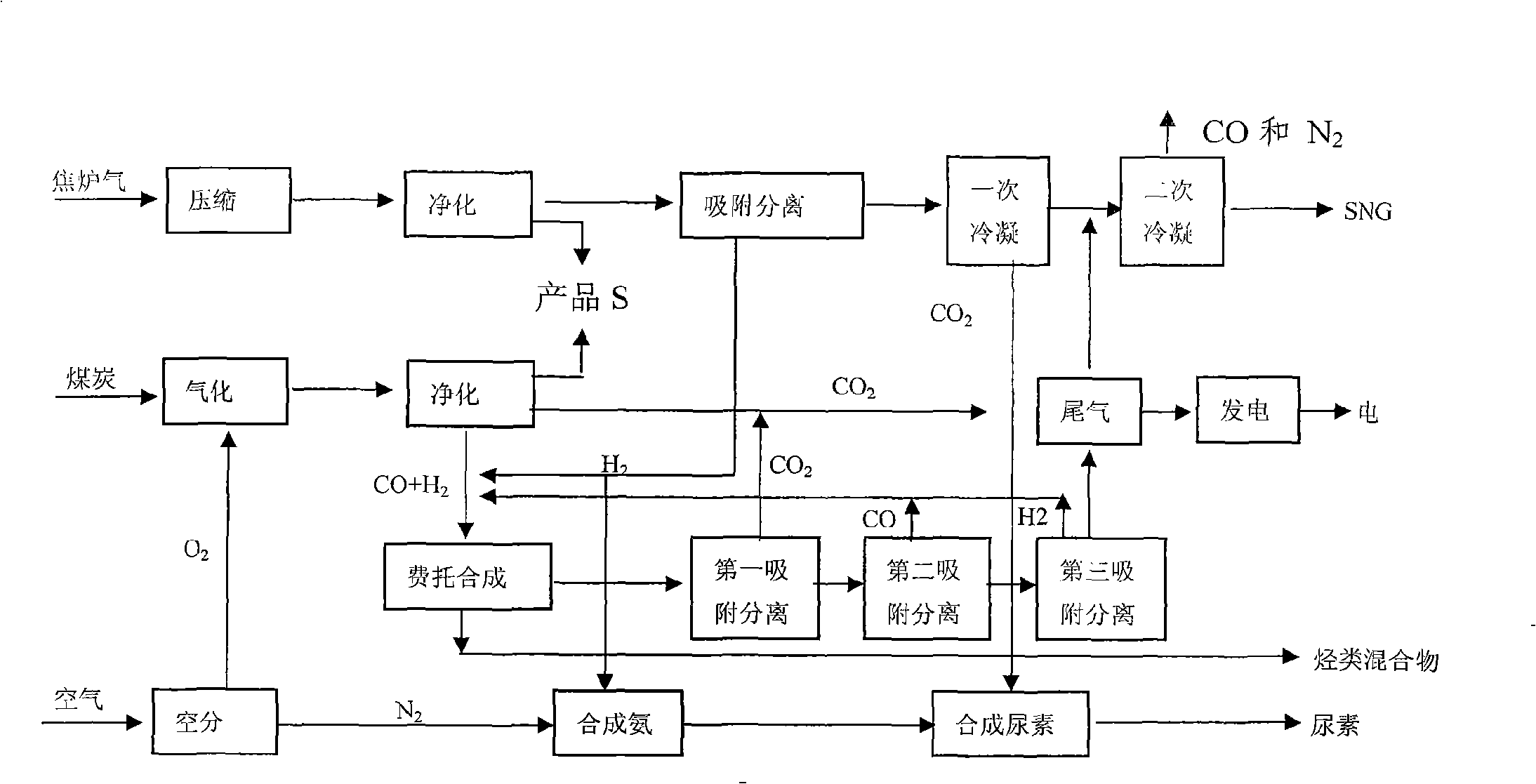

Poly-generation technique for using coal gas and coke oven gas as raw materials

ActiveCN101538483ANo conversionNo transform operationUrea derivatives preparationOrganic compound preparationHydrocarbon mixturesDesorption

The invention relates to a poly-generation technique for using coal gas and coke oven gas as raw materials. The poly-generation technique comprises the following steps of: carrying out mixing on part of H2 prepared by purified water gas and coke oven gas through pressure swing adsorption and tail gas obtained by Fischer-Tropsch synthesis, carrying out Fischer-Tropsch synthesis and obtaining hydrocarbon mixture and tail gas. The CO2 separated from tail gas separate by first pressure swing adsorption enters a urea synthesis unit for reaction, the CO and the hydrogen respectively obtained by separation of second pressure swing adsorption and third pressure swing adsorption of the residual tail gas are circulated back to a Fischer-Tropsch synthesis unit for reaction; and the residual gases can be used for generating power or obtaining SNG by secondary condensation. The coke oven gas enters pressure swing adsorption after being purified and desulphurized so as to separate H2; wherein one part of H2 is used as supplementation of H2 needed by Fischer-Tropsch synthesis and the other part of H2 is mixed with N2 for ammonia synthesis so as to obtain synthetic ammonia; and the synthetic ammonia is mixed with CO2 obtained by the first condensation and CO2 separated from the Fischer-Tropsch synthesis for urea synthesis so as to obtain urea. The CO2 separated from the first condensation of desorption gas by pressure swing adsorption of the coke oven gas is used for urea synthesis; and the residual gases is treated by the second condensation to obtain SNG and mixed gas of CO and N2. The invention has no emission of greenhouse gases, uses richness in carbon and deficiency in hydrogen of the coal gas and the richness in hydrogen and deficiency in carbon of the coke oven gas to carry out complementation, realizes modulation of product structure by Fischer-Tropsch synthesis and improves the economical efficiency of the process of Fischer-Tropsch synthesis.

Owner:中科潞安能源技术有限公司

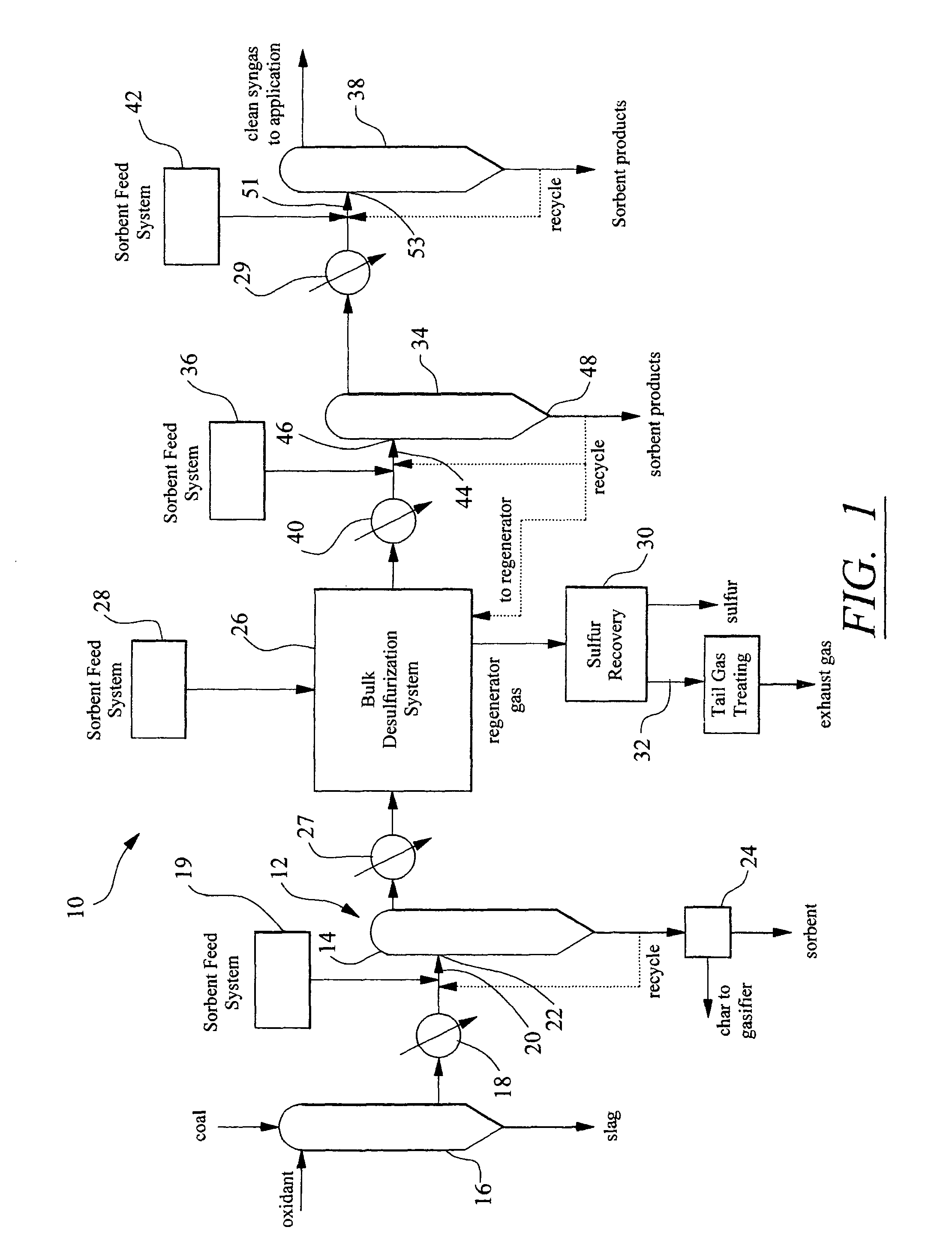

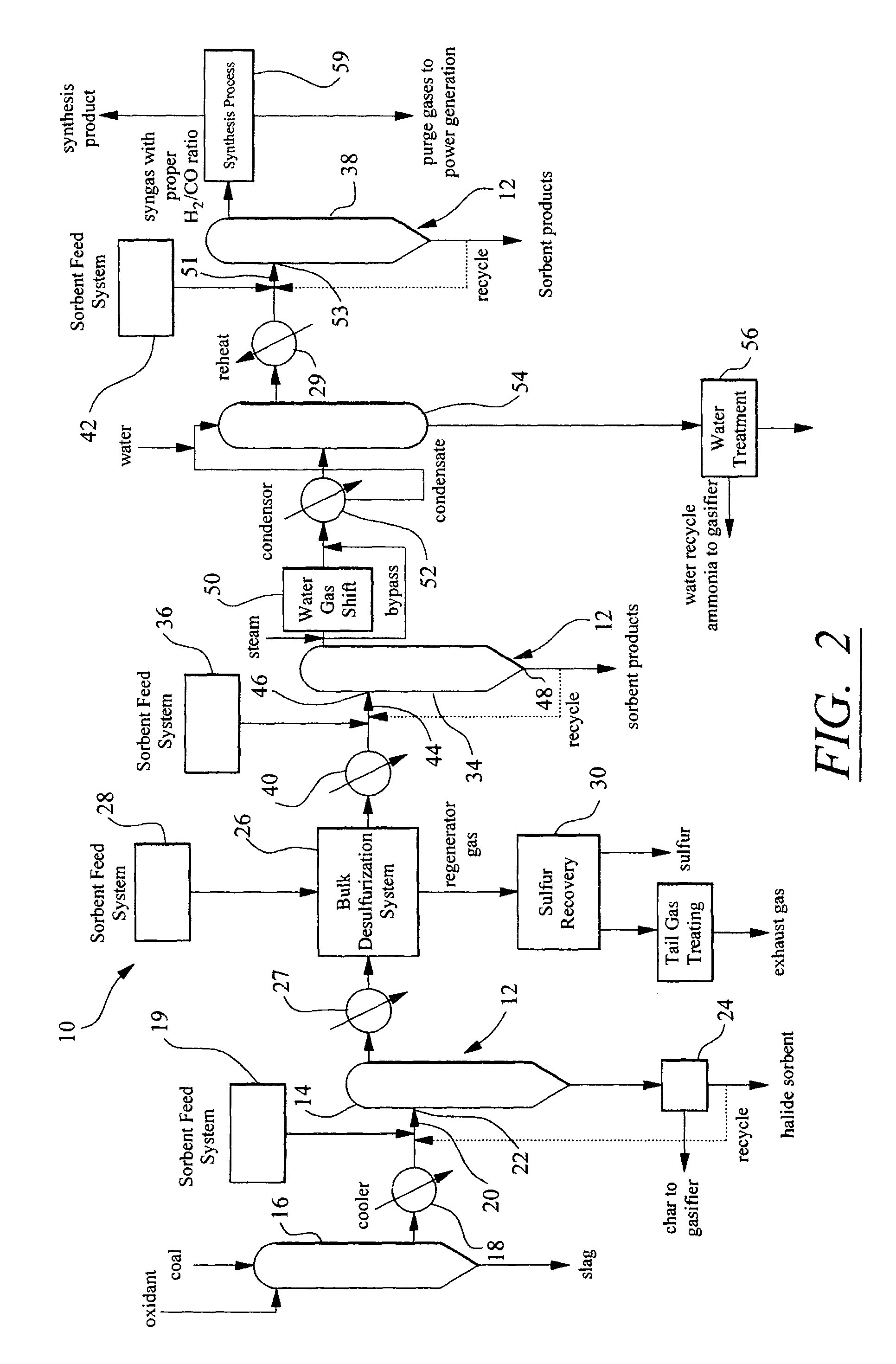

Gas cleaning system and method

A gas cleaning system for removing at least a portion of contaminants, such as halides, sulfur, particulates, mercury, and others, from a synthesis gas (syngas). The gas cleaning system may include one or more filter vessels coupled in series for removing halides, particulates, and sulfur from the syngas. The gas cleaning system may be operated by receiving gas at a first temperature and pressure and dropping the temperature of the syngas as the gas flows through the system. The gas cleaning system may be used for an application requiring clean syngas, such as, but not limited to, fuel cell power generation, IGCC power generation, and chemical synthesis.

Owner:SIEMENS ENERGY INC

Process for controlling sulfur in a fermentation syngas feed stream

Ethanol and other liquid products are produced from biomass using gasification of the biomass to produce a syngas containing CO2, CO, H2 and sulfur or sulfur compounds that passes the syngas to a fermentation step for the conversion of the CO and CO2 and H2 to ethanol. Sulfur and sulfur compounds in the syngas are used to satisfy sulfur demanded by bacteria in the fermentation step. A sulfur control additive is added to the gasification to control syngas sulfur and sulfur compounds at a desired concentration to meet bacteria sulfur demand.

Owner:SYNATA BIO INC

Silica-alumina catalyst support, catalysts made therefrom and methods of making and using same

ActiveUS20050119116A1High catalytic activityHigh activityHydrocarbon from carbon oxidesOther chemical processesCompound (substance)Catalytic metal

This invention relates to catalysts comprising a catalytic metal deposited on a composite support with well-dispersed chemical “anchor” species acting as nucleation centers for catalytic metal crystallites growth. The catalysts have the advantage that the average catalytic metal crystallite size can be controlled by the molar ratio of catalytic metal to chemical “anchor,” and is not limited by the porous structure of the support. A preferred embodiment comprises a cobalt-based catalyst on a silica-alumina support made by a co-gel method, wherein its average pore size can be controlled by the pH. The alumina species in the support most likely serve as chemical “anchors” to control the dispersion of cobalt species, such that the average cobalt crystallite size can be greater than the average pore size.

Owner:CLARIANT INT LTD

Process for dust removing, cooling and tar oil recovering of pyrolysis coal gas

The invention discloses a process for dust removing, cooling and tar oil recovering of pyrolysis coal gas. The process adopts an overheater, a high-temperature dust remover, an accident quench tower, a waste heat recovering boiler, an indirect cooling device and an electrical tar precipitator which are connected in sequence, and comprises the following steps: pyrolysis coal gas is fed into the overheater to be cooled to 400-700 DEG C, fed into the high-temperature dust remover to be subjected to dust removing, fed into the waste heat recovering boiler to be cooled to 50-100 DEG C and condensed to separate out water and tar oil, fed into the indirect cooling device to be cooled to 10-30 DEG C and further condensed to separate out water and tar oil, and finally fed into the electrical tar precipitator, so that the carried tar oil mist and water mist are recovered. According to the process, dust particles in the coal gas are removed by high-performance dust removing equipment before condensing of tar oil, so as to prevent tar oil and dust separated out through condensation in the coal gas cooling process from being mixed together, improve the quality of tar oil and avoid the problems of equipment blockage and high dust content of tar oil.

Owner:ZHEJIANG UNIV

Method for upgrading coal pyrolysis

ActiveCN101608125AAvoid enteringReduce separation loadDirect heating destructive distillationOven incrustations prevention/removalGranularityFlue gas

The invention provides a method for upgrading coal pyrolysis, comprising the following steps: (a) sending raw coal with granularity being less than and equal to 30mm into a rotary drier, so that the raw coal and hot flue gas are connected with each other by the means of parallel flow and directly change heat, and the raw coal exchanges heat indirectly with hot semicoke from a pyrolyzer in the rotary drier, to dry the raw coal; (b) mixing the dried raw coal with the high-temperature semicoke from a heating rotary kiln and sending the mixture into the pyrolyzer, wherein the coal material directly changes heat with the high-temperature semicoke and pyrolyzes to generate hot semicoke, tar steam and coal gas, wherein final pyrolyzing temperature is 500 DEG C-700 DEG C; and (c) sending a part of the hot semicoke generated into the heating rotary kiln for processing by means of heating, and sending the rest part of the hot semicoke into the rotary drier for exchanging heat directly with the raw coal. The method for upgrading coal pyrolysis has flexible operation, wide granularity range of the coal material, good quality of the generated semicoke and the generated tar, high cascade utilization of energy and high system thermal efficiency, properly solving the technical problems such as dust and tar blocking, high dust content in the tar, etc.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Device for improving quality of coal by pyrolysis

ActiveCN101608126AAvoid enteringReduce separation loadDirect heating destructive distillationOven incrustations prevention/removalGranularityFlue gas

The invention provides a device for improving the quality of the coal by pyrolysis, comprising a rotary drier, a pyrolyzer and a heating rotary kiln. The rotary drier is used for receiving and drying raw coal with granularity being less than and equal to 30mm, and is provided with a sleeve structure to directly change heat between the raw coal and the hot flue gas and indirectly change heat between the raw coal and hot semicoke; the pyrolyzer receives mixture of the dried raw coal and the high-temperature semicoke by a feed line of solid material, directly changes heat between the raw coal and the hot semicoke, pyrolyzes the mixture, and is further provided with a heat clamping sleeve accompanied with high-temperature flue gas; and the heating rotary kiln is used for receiving the hot semicoke from the pyrolyzer and processing the hot semicoke by the means of heating. The device for improving the quality of the coal by pyrolysis has flexible operation, good quality of the generated semicoke and the generated tar, high cascade utilization of energy and high system thermal efficiency, properly solving the technical problems such as dust and tar blocking, high dust content in the tar, etc.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Low temperature gasification facility with a horizontally oriented gasifier

A low-temperature gasification system comprising a horizontally oriented gasifier is provided that optimizes the extraction of gaseous molecules from carbonaceous feedstock while minimizing waste heat. The system comprises a plurality of integrated subsystems that work together to convert municipal solid waste (MSW) into electricity. The subsystems comprised by the low-temperature gasification system are: a Municipal Solid Waste Handling System; a Plastics Handling System; a Horizontally Oriented Gasifier with Lateral Transfer Units System; a Gas Reformulating System; a Heat Recycling System; a Gas Conditioning System; a Residue Conditioning System; a Gas Homogenization System and a Control System.

Owner:PLASCO CONVERSION TECH INC

Asymetric membrane FeAl intermetallic compound porosint filter element and application thereof

ActiveCN101524609AGood degree of pore structure controlWide range of regulationIncreasing energy efficiencyManufacturing convertersPorosityVulcanization

The invention belongs to the field of inorganic porosint and particularly relates to an asymetric membrane FeAl intermetallic compound porosint filter element and the application thereof. The filter element of the invention consists of a multiaperture support body and complex film; wherein, the multiaperture support body is in tubular shape or platy shape, the complex film is made in the following steps: a compound sizing agent is coated on outer surface of a single side of the multiaperture support body; and degreasing, bias diffusion, reaction synthesis and sintering are carried out to form thin-layer complex film with millipores. The millipores on the surface of the filter element is small and uniform, porosity is high, no dust is blocked inside filter material, filtering gas circuit is smooth, and resistance is small; in addition, the element has good resistance to high temperature oxidation / vulcanization and good normal temperature and high temperature mechanical properties. The element can directly carry out solid-gas separation on industrial gasses, bear top load and high-pressure and high-speed back washing, thus saving relative cooling devices, saving a large amount of water resources, avoiding cooling water treatment, lowering energy loss, shortening process flow and improving work efficiency.

Owner:CHENGDU INTERMENT TECH

Shell metal catalyst and a precursor thereof, a process for their preparation and the use of the catalyst

A process for preparing a shell metal catalyst or a precursor of a shell metal catalyst which process includes the steps of: applying a slurry having a diluent; a catalytically active metal or a precursor compound thereof; and optionally a refractory oxide; designated hereinafter as “first refractory oxide” of an element having an atomic number of at least 20 or a precursor of the first refractory oxide; onto the surface of particles of a core carrier; forming a wet coating; and removing at least a part of the diluent from the wet coating; wherein the slurry has at least 5% w of the catalytically active metal or the precursor compound thereof; calculated on the weight of the metal relative to the weight of calcinations residue which can be formed from the slurry by drying the slurry and calcining. The invention also relates to a shell metal catalyst or a precursor of a shell metal catalyst which is obtainable by the process; and the use of the shell metal catalyst in a chemical conversion process. The invention also relates to a process for producing hydrocarbons; which process involves contacting a mixture of carbon monoxide and hydrogen with a shell metal catalyst, wherein the catalytically active metal is a Group VIII metal which is present at least partly in metallic form.

Owner:SHELL OIL CO

Process to prepare a sweet crude

ActiveUS20080142408A1Hydrocarbon distillationCombustible gas catalytic treatmentOil sandsRemoval Units

A process to prepare a sweet crude from an ash containing and heavy fraction of a tar sand oil by:(a) supplying an atmospheric distillation bottoms of a tar sands originated feed to a vacuum distillation to obtain a vacuum gas oil and a vacuum bottoms,(b) contacting the vacuum gas oil with hydrogen in the presence of a suitable hydrocracking catalyst to obtain a sweet synthetic crude(c) separating the vacuum bottoms obtained in step (a) into an asphalt fraction comprising between 0.1 and 4 wt % ash and a de-asphalted oil,(d) feeding said asphalt fraction to a burner of a gasification reactor where the asphalt fraction is partially oxidized in the presence of an oxidizer gas in a burner to obtain a mixture of hydrogen and carbon monoxide,(e) performing a water gas shift reaction on the mixture of hydrogen and carbon monoxide,(f) separating hydrogen sulphide and carbon dioxide from the shifted gas in an acid removal unit thereby obtaining crude hydrogen,(g) purifying the crude hydrogen to obtain pure hydrogen and(h) using part of the pure hydrogen in step (b), wherein in step (d) the asphalt fraction is provided to the burner in a liquid state and wherein in case separation step (c) fails to provide sufficient feed for step (d), step (d) is performed by feeding the vacuum bottoms of step (a) to the burner in a liquid state.

Owner:AIR PROD & CHEM INC

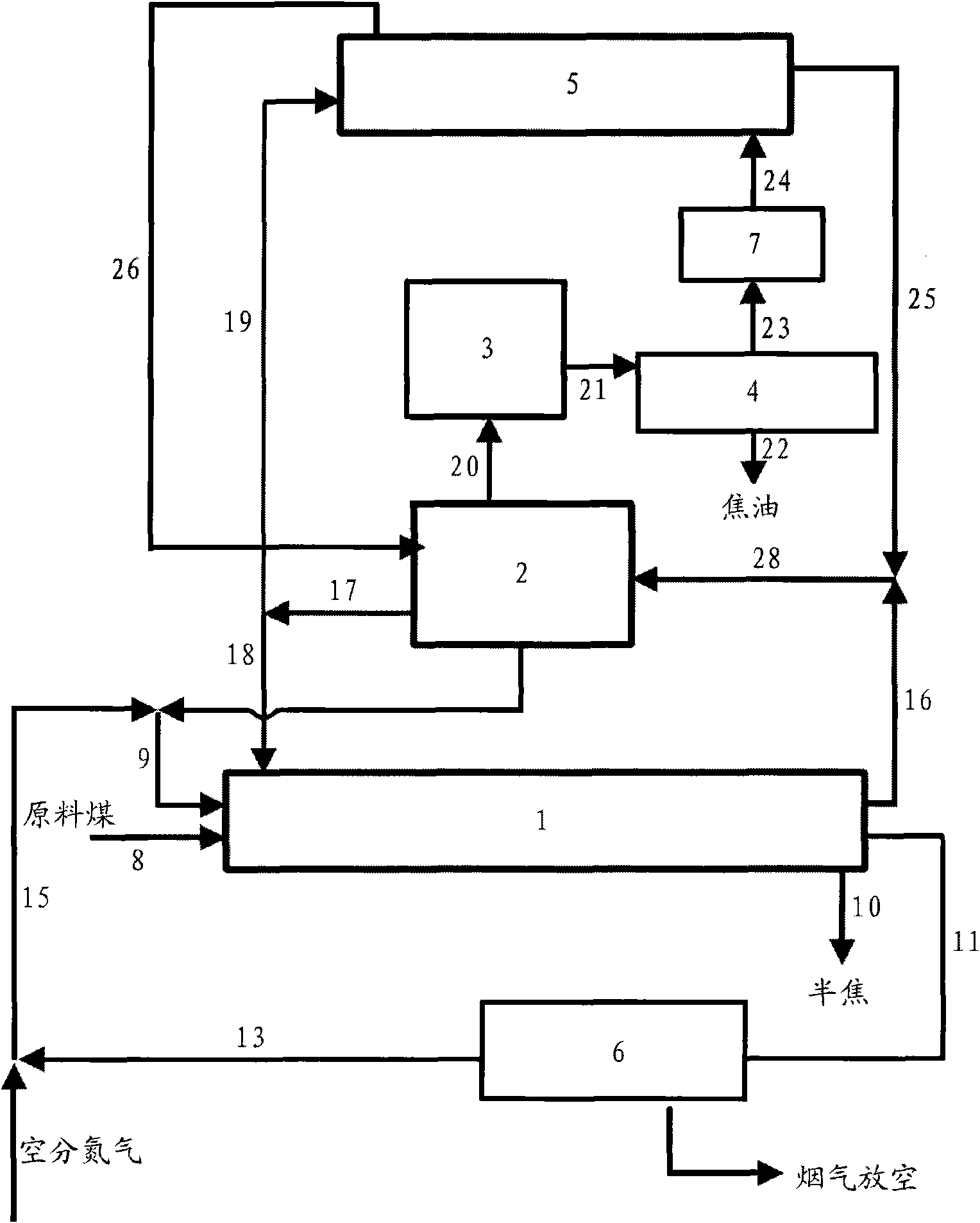

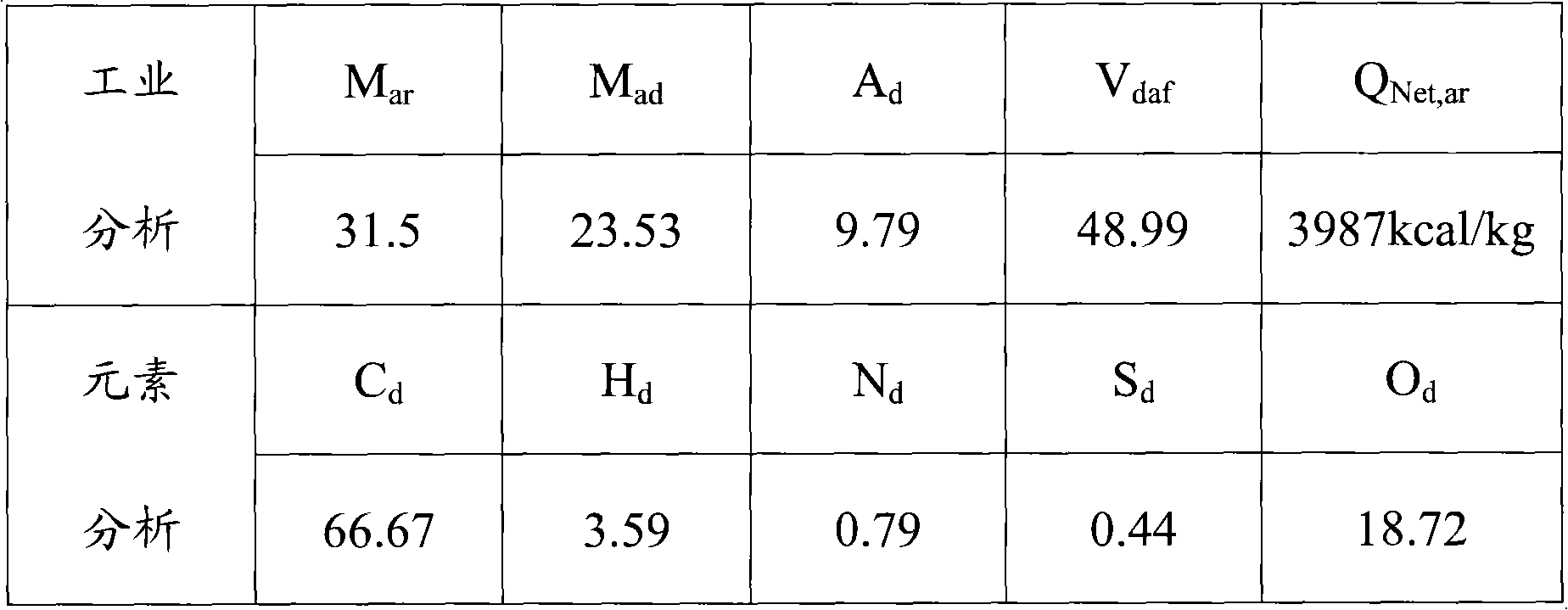

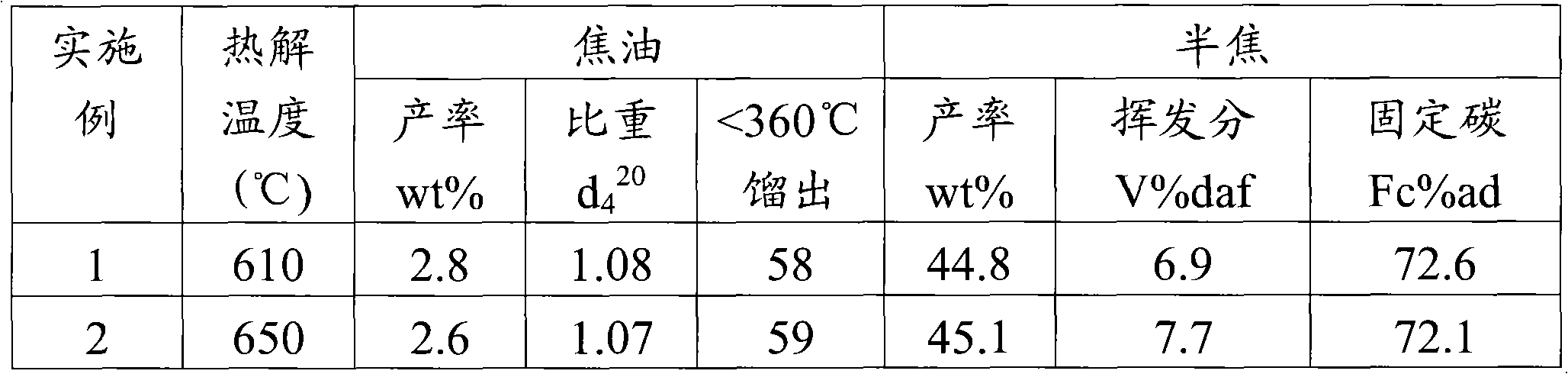

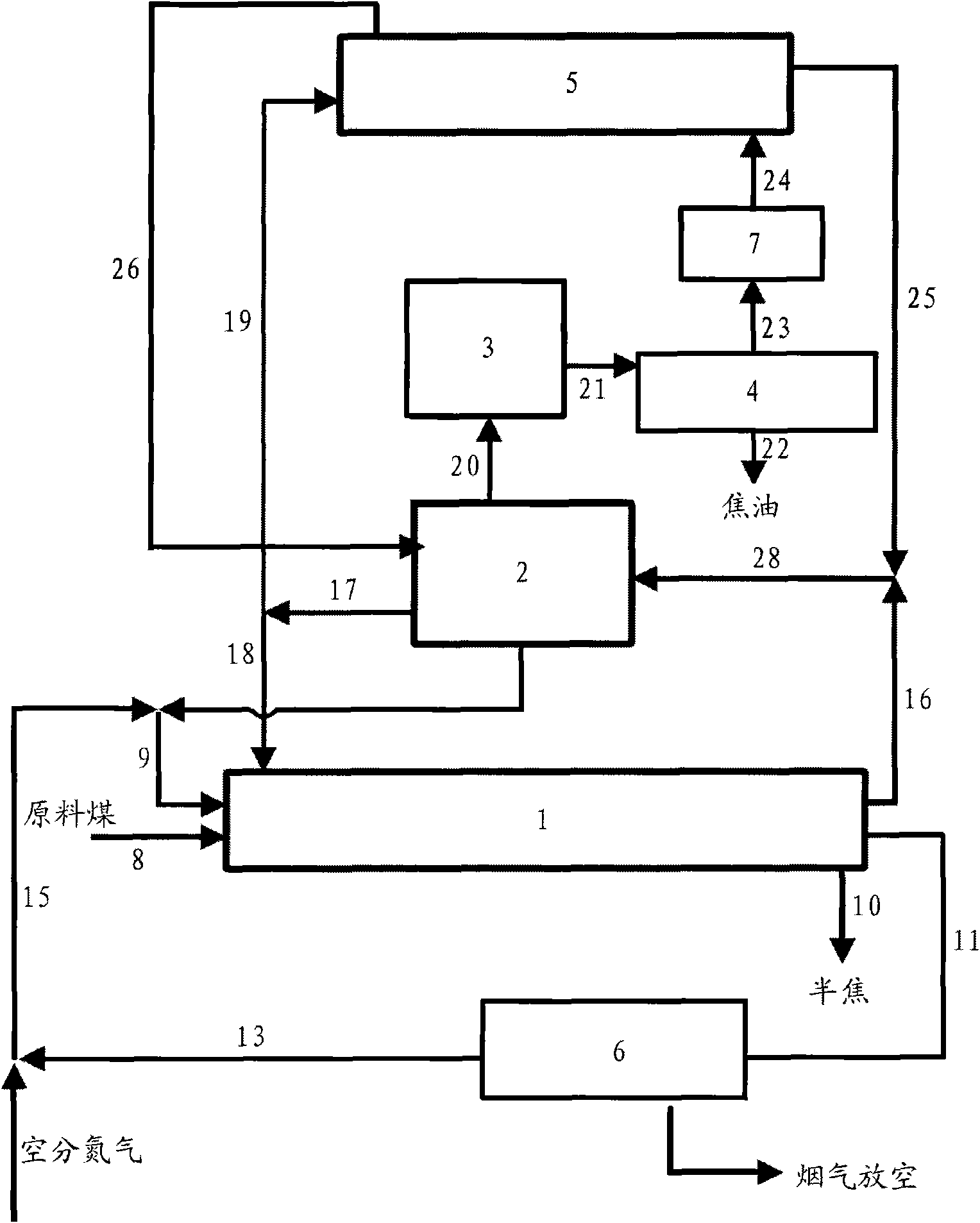

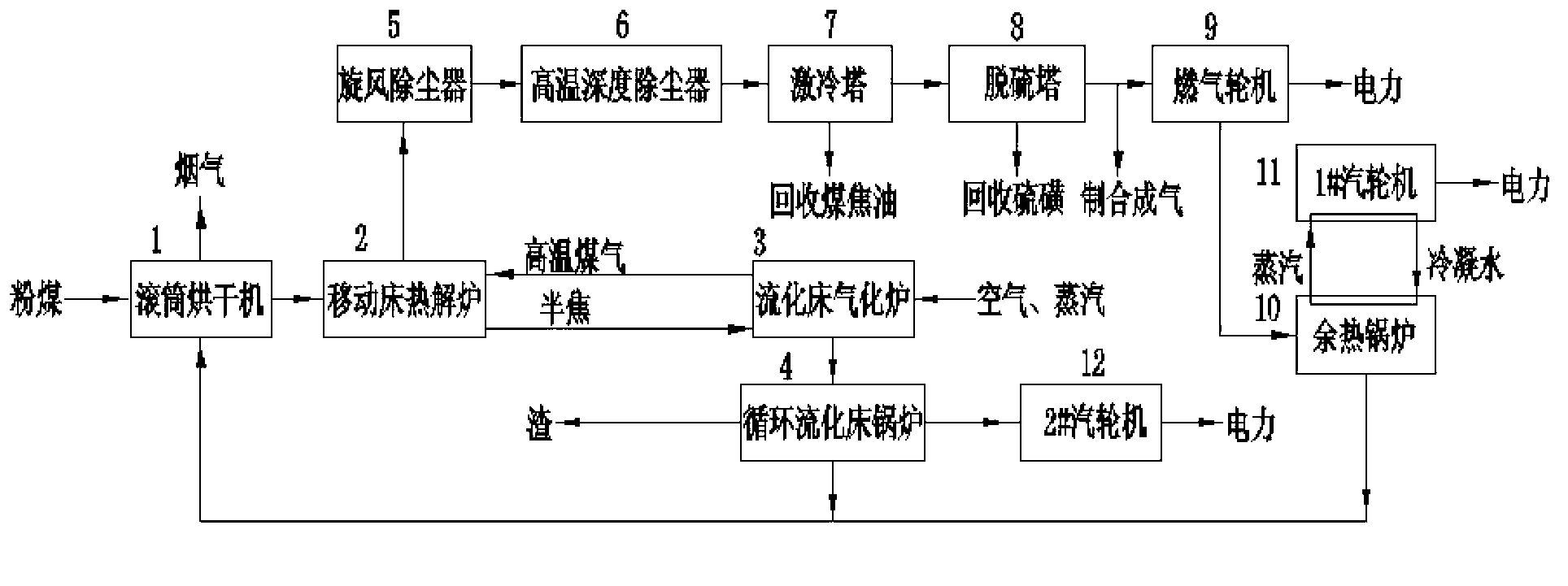

IGCC (Integrated Gasification Combined Cycle) poly-generation device and method based on pyrolysis and gasification of low metamorphic powdered coal

InactiveCN103013576ATake advantage ofAchieve integrationEnergy inputGas turbine plantsResource utilizationChemical products

The invention discloses an IGCC (Integrated Gasification Combined Cycle) poly-generation device and method based on pyrolysis and gasification of low metamorphic powdered coal. The device comprises a pyrolysis / gasification system, a coal gas purifying system, a circulating fluidized bed boiler and a gas turbine / steam turbine system. The method comprises the steps as follows: carrying out low temperature pyrolysis and partial air gasification on the low metamorphic powdered coal, grading and converting into coal gas, tar and semi-coke, and carrying out the IGCC poly-generation process by the semi-coke and the coal gas with high calorific value. According to the device and the method, the tar, sulphur and other chemical products can be produced while clean power is generated, the products obtained by grading and converting the low metamorphic powdered coal are fully utilized, the material conversion and energy conversion functions are integrated, the resource utilization rate is high, and the heat energy efficiency is high. The device and method are suitable for the low metamorphic powdered coal such as peat, brown coal, jet coal, non-sticking coal and the like, and the particle size of raw materials is 0-8 mm. The high-temperature coal gas generated in a fluidized bed gasification furnace contains a large amount of hydrogen, so that the powdered coal can be subjected to hydropyrolysis, and the tar recovery rate can reach more than 12%.

Owner:陕西华祥能源科技集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com