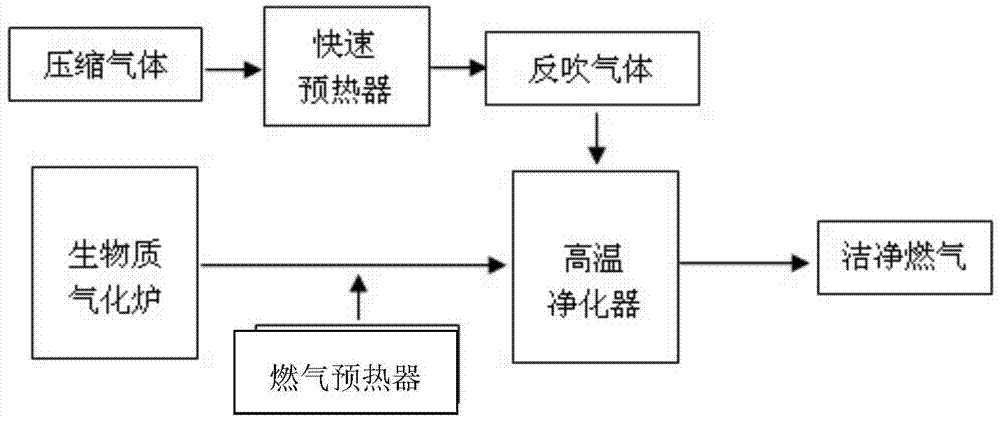

High-temperature dust-removing and coke-removing integrated purifying process of biomass crude gas

A technology for high-temperature dust removal and purification process, which is applied in gas dust removal, catalytic conversion of impurities, gas purification, etc., can solve problems such as environmental pollution, deactivation of nickel-based catalyst coke deposits, and large fluctuations in gas production, and achieves simple and convenient process flow. Flexible, broad market application prospects, and the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment is a 2.0MW circulating fluidized bed biomass gasification power station with wood chips as raw material, and adopts the high-temperature gas dedusting and decoking integrated purification process and device of the present invention, which can produce circulating fluidized bed biomass gasification Fly ash and tar are efficiently removed, and the purified clean biomass gas can be supplied to four 500KW gas-fired generator sets for power generation.

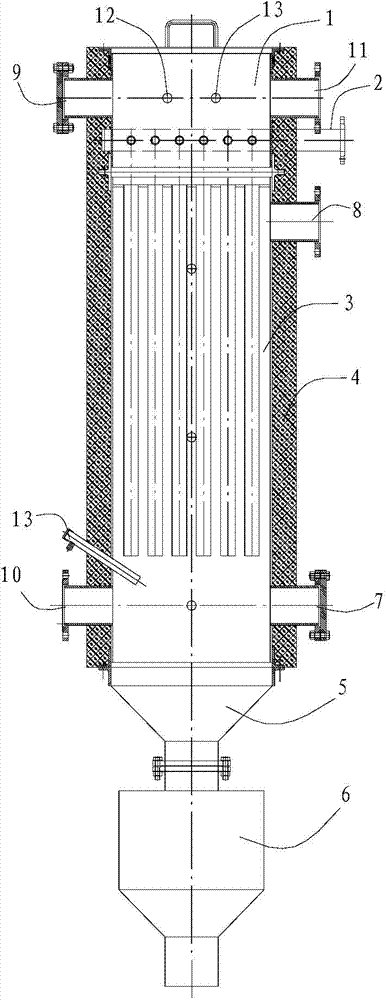

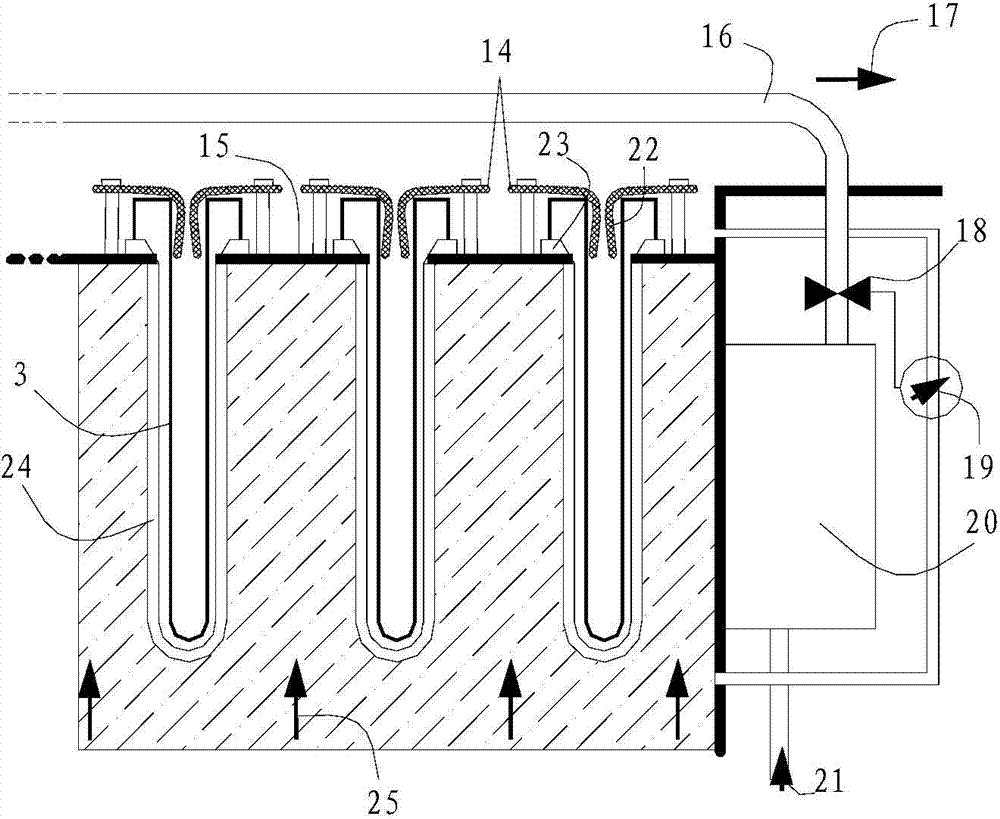

[0030] Example uses figure 2 The biomass high-temperature gas multi-stage purification device shown.

[0031] The high-temperature purification process of this set of gas is as follows: ① The high-temperature biomass gas with a temperature of about 750 °C passes through the outlet of the fluidized bed gasifier and is transported to the high-temperature gas heat exchanger, that is, the air preheater, where it exchanges heat with cold air in the high-temperature gas Fully heat exchange in the gasifier, so that...

Embodiment 2

[0033] This embodiment is a 2.0t / h mixed-suction fixed-bed biomass gasification heating system with wood chips as the raw material. By adopting the high-temperature gas integrated purification process and device of the present invention, the fly ash produced by fixed-bed biomass gasification can be processed. Efficiently removed, the purified high-temperature biomass gas (including gaseous tar) can be directly supplied to a 8.0t / h steam boiler for stable operation.

[0034] The structure of the gas purification system is the same as that of Example 1, and the specific process is as follows: ① Turn on the gas preheater and the electric heating and heat preservation system to raise the temperature of the high-temperature gas purifier and related pipelines to 350-450°C. ② The high temperature biomass gas at 450°C passes through the outlet of the fixed bed gasifier (the dust content of the crude gas is 2.5g / Nm 3 Therefore, the tar content is 0.5g / Nm 3 ), enter the high-temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com